The Effect of Different Particle Sizes of Fly Ash on the Properties of Mortar

Abstract

1. Introduction

2. Materials and Testing Methods

2.1. Materials

2.2. Mix Proportion

2.3. Testing Methods

2.3.1. Preparation of Fly Ash with Different Particle Size

2.3.2. Preparation of Mortar

2.4. Characterization Method

2.4.1. Mechanical Properties

2.4.2. Setting Time Test

2.4.3. Granularity Distribution

2.4.4. Rheological Property

2.4.5. XRD

2.4.6. FT-IR

2.4.7. SEM

2.4.8. Hydration Heat

2.4.9. MIP

2.4.10. TG/DSC

3. Results and Discussion

3.1. Characteristics of Fly Ash with Different Particle Sizes

3.1.1. Particle Size Distribution of Fly Ash

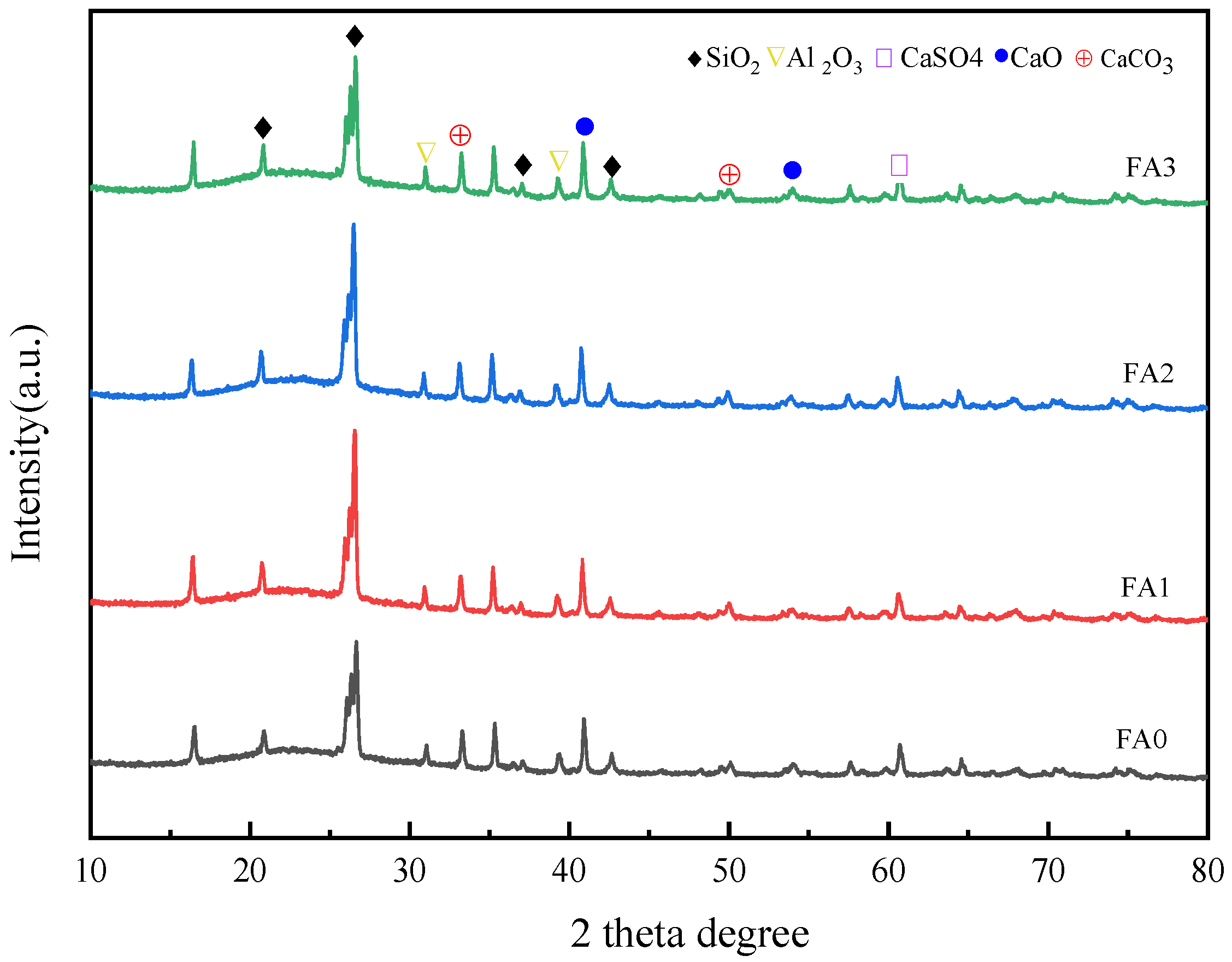

3.1.2. XRD Analysis of Fly Ash with Different Particle Size

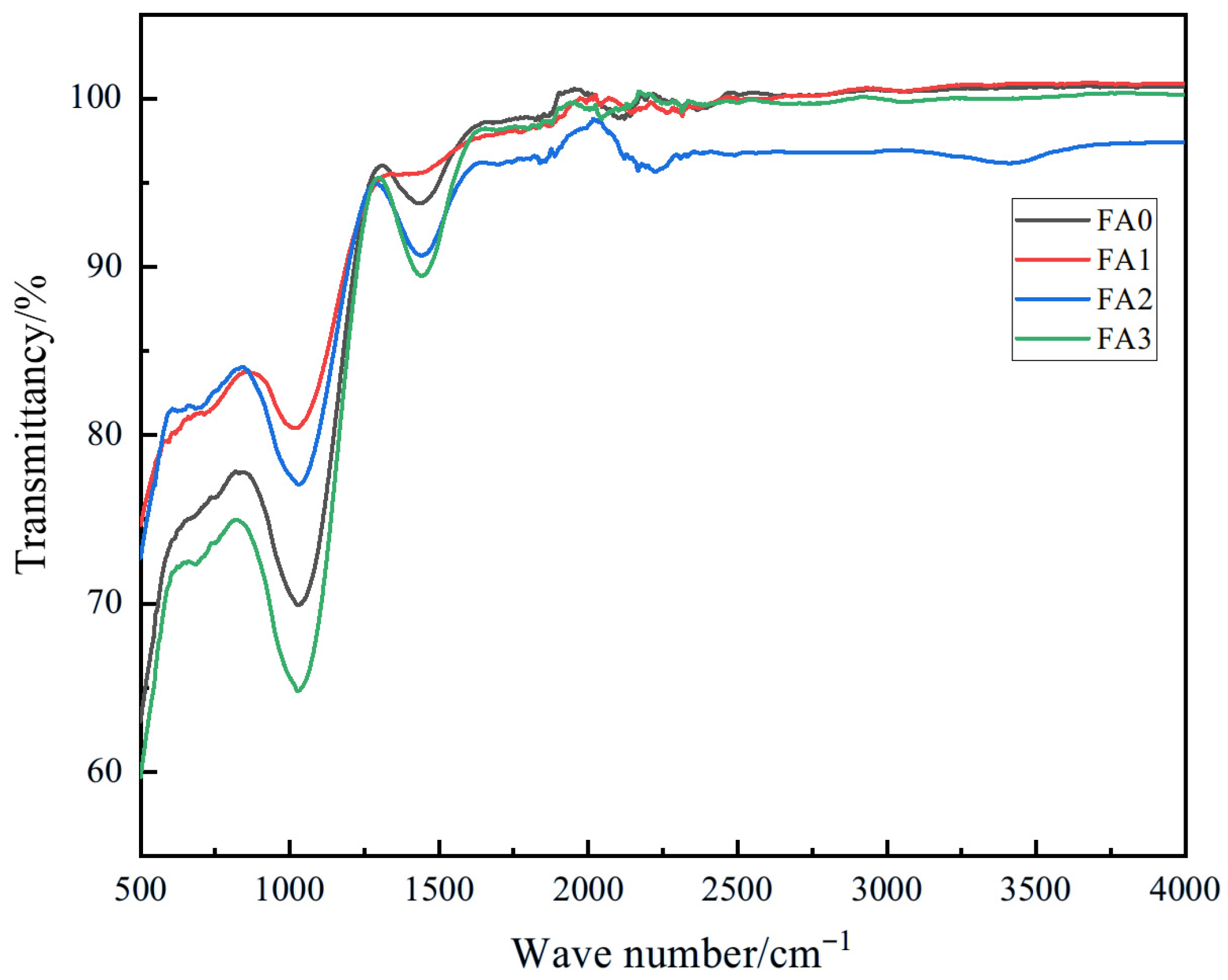

3.1.3. FT-IR Analysis of Fly Ash with Different Particle Size

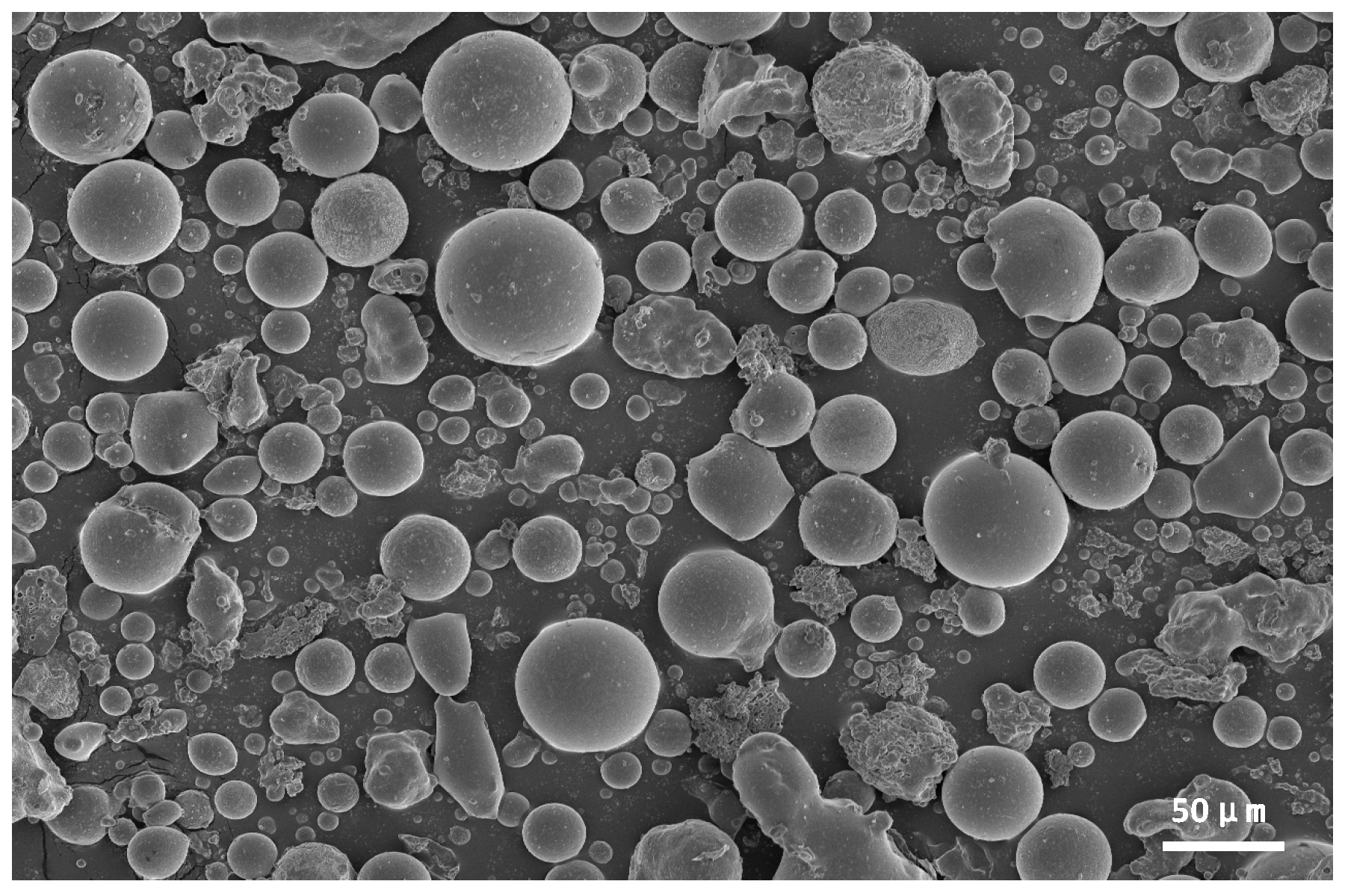

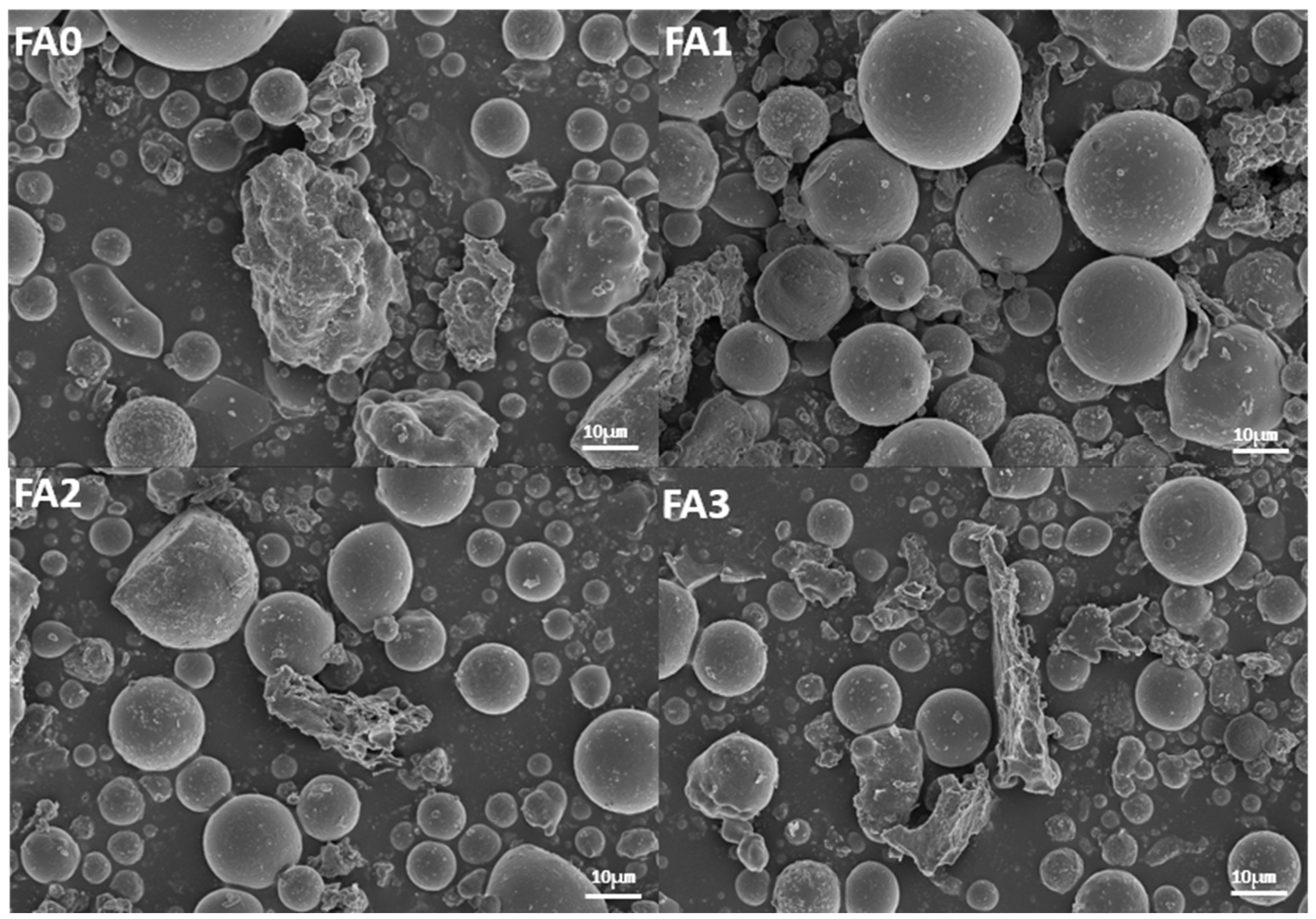

3.1.4. SEM Analysis of Fly Ash with Different Particle Size

3.2. The Effect of Fly Ash Particle Size on the Properties of Cement Mortar

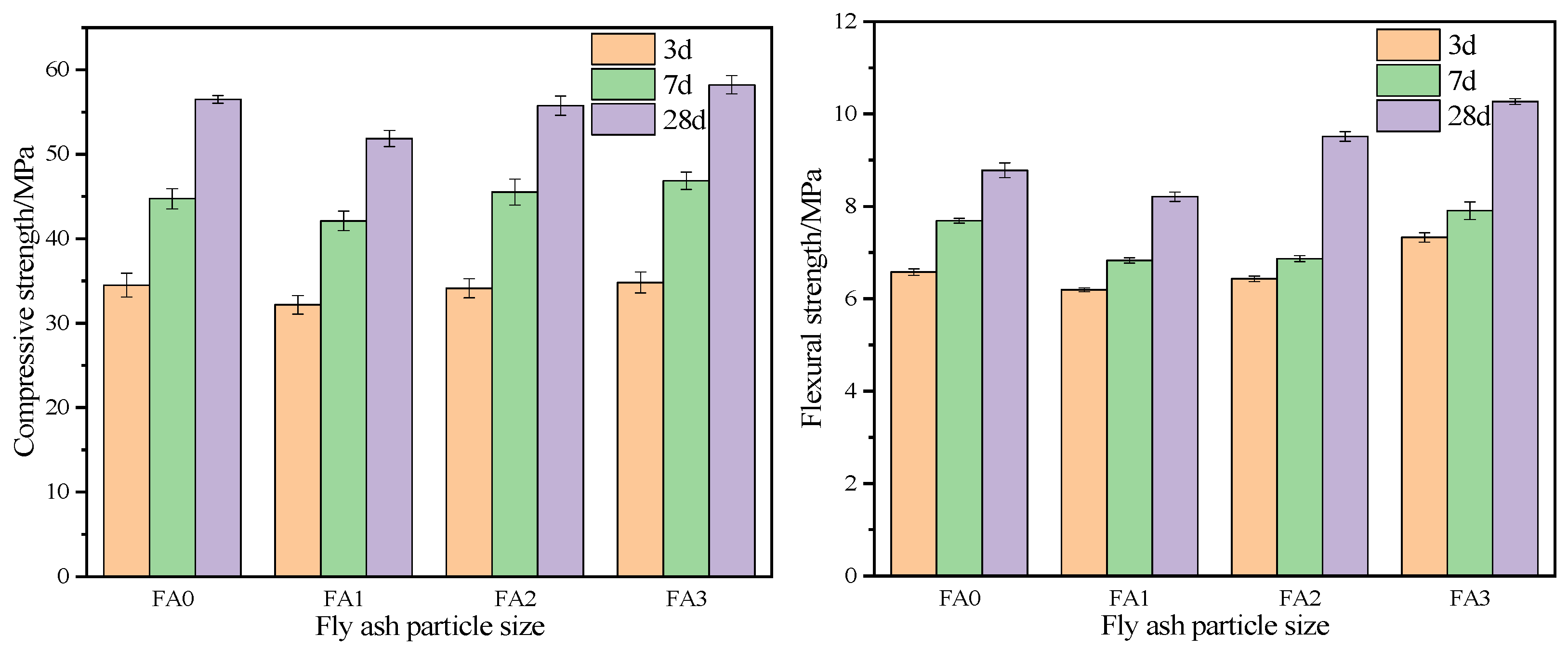

3.2.1. Effect of Different Particle Size Fly Ash on the Mechanical Properties of Mortar

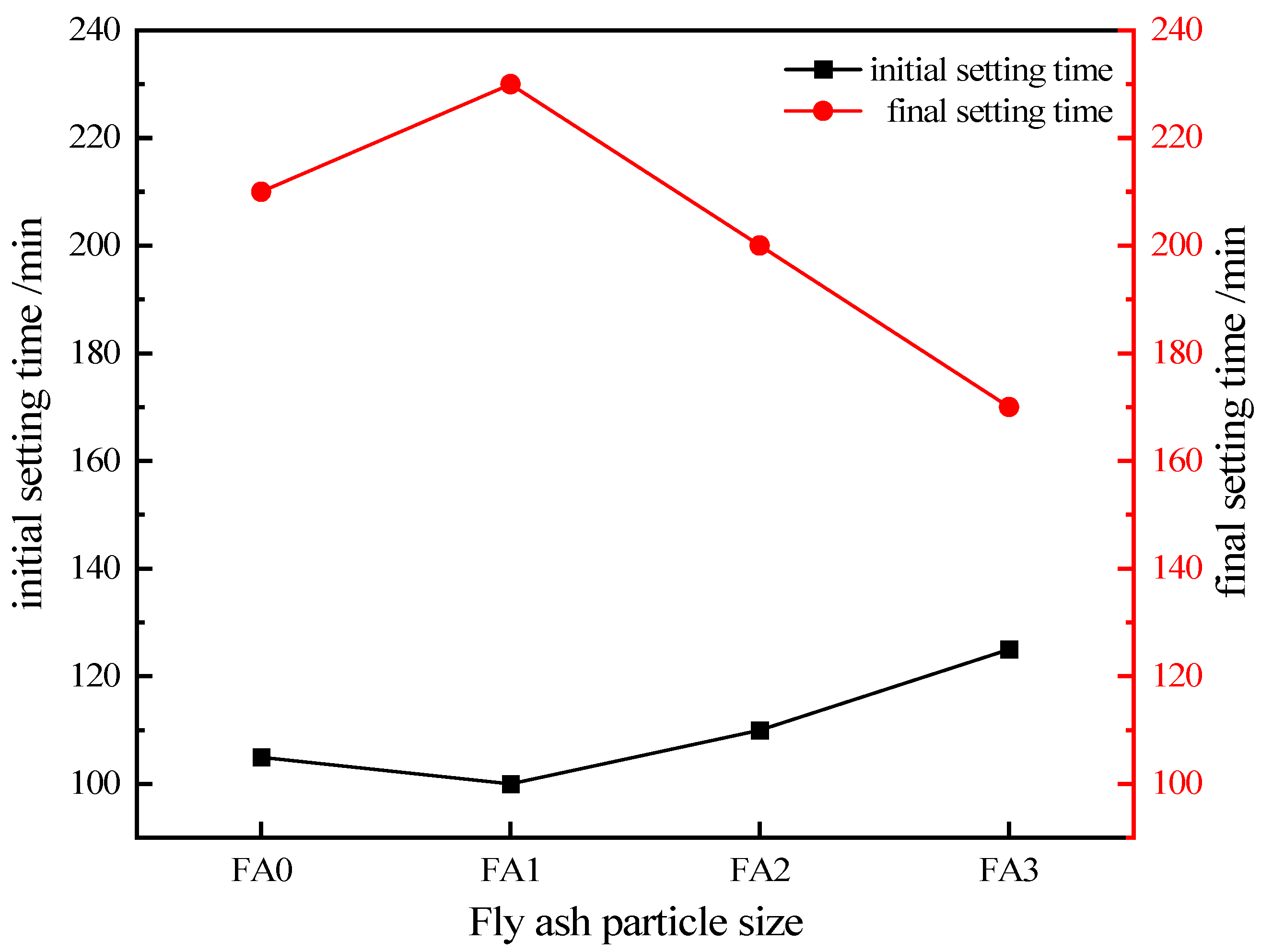

3.2.2. The Effect of Fly Ash Particle Size on the Setting Time of Cement Mortar

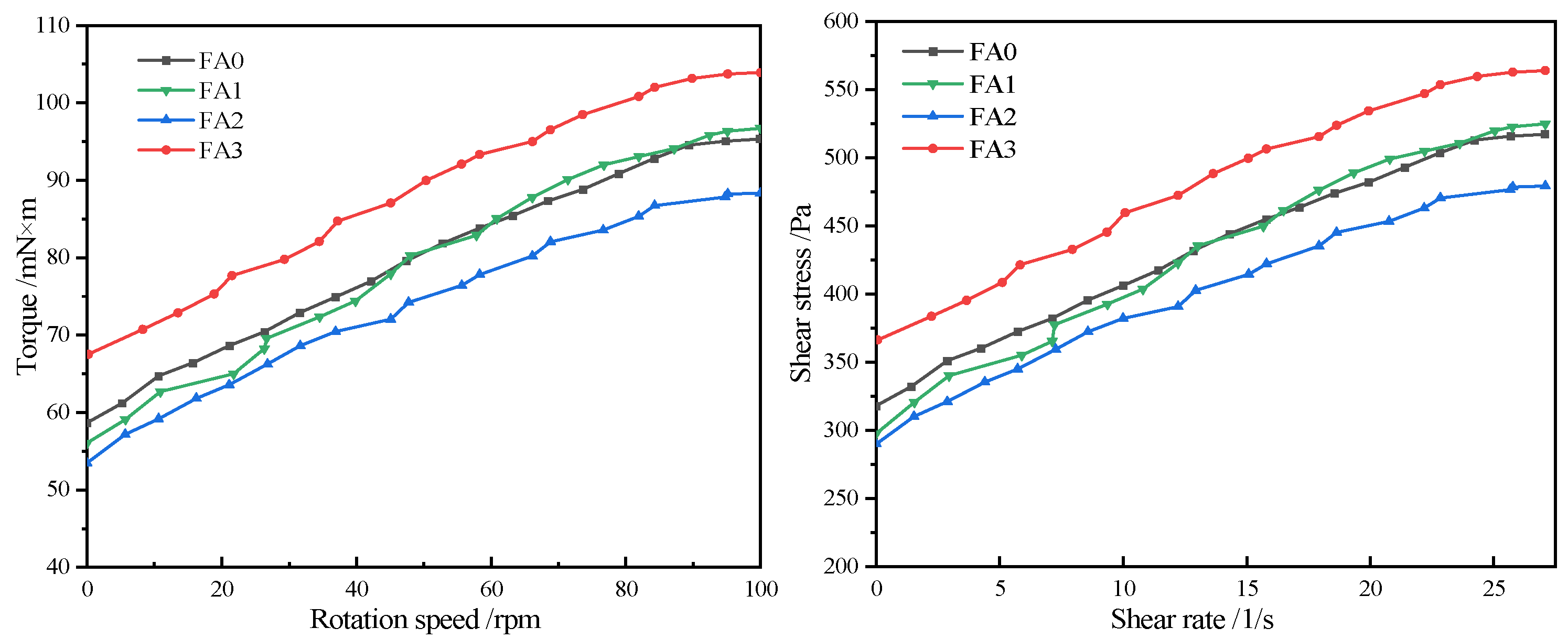

3.2.3. Effect of Fly Ash with Different Particle Sizes on the Rheological Properties of Cement

3.2.4. Effect of Fly Ash with Different Particle Size on Hydration Heat of Cement

3.3. Effect of Different Particle Size Fly Ash on Pore Structure of Mortar

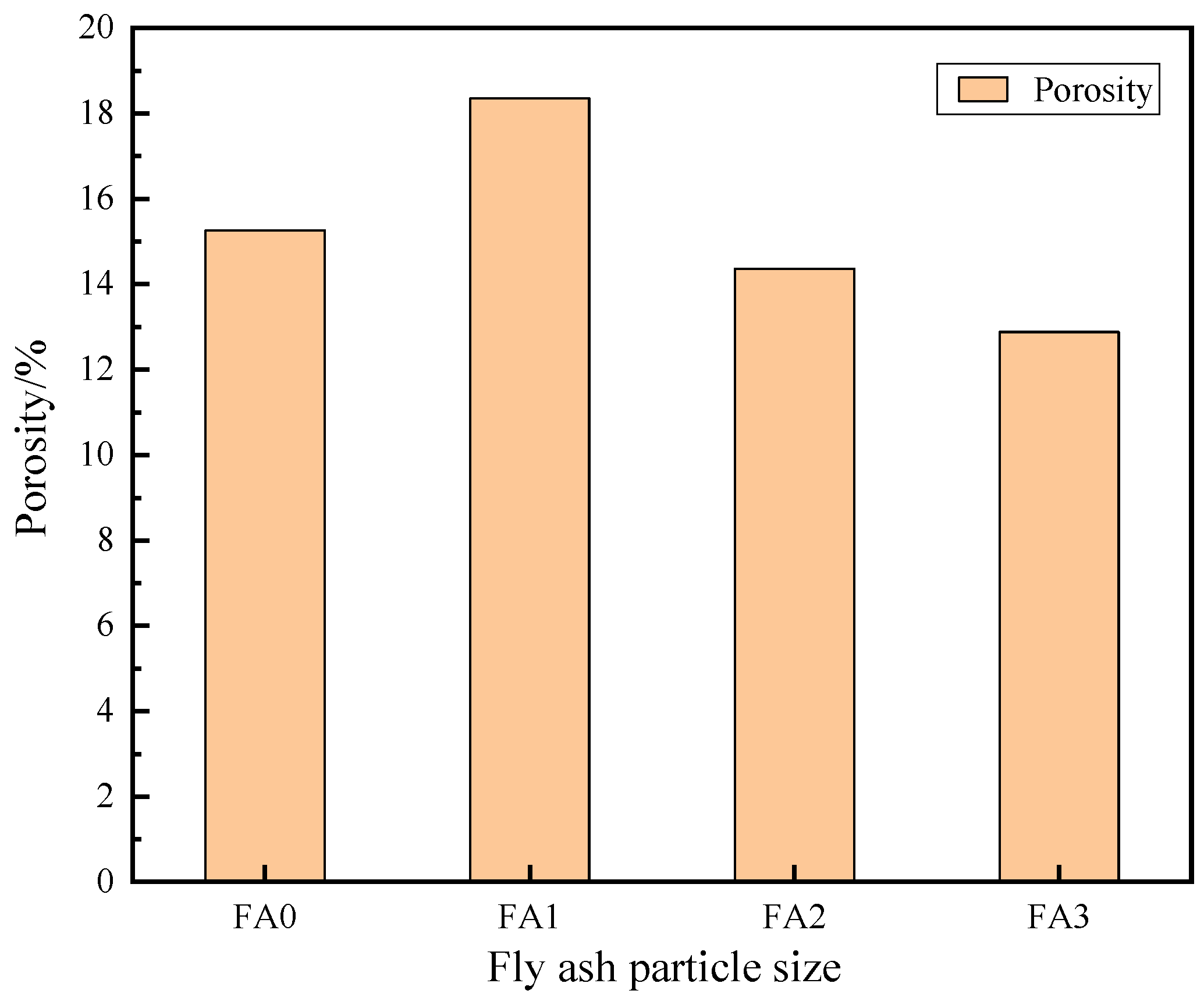

3.3.1. Effect of Fly Ash Particle Size on the Porosity of Mortar

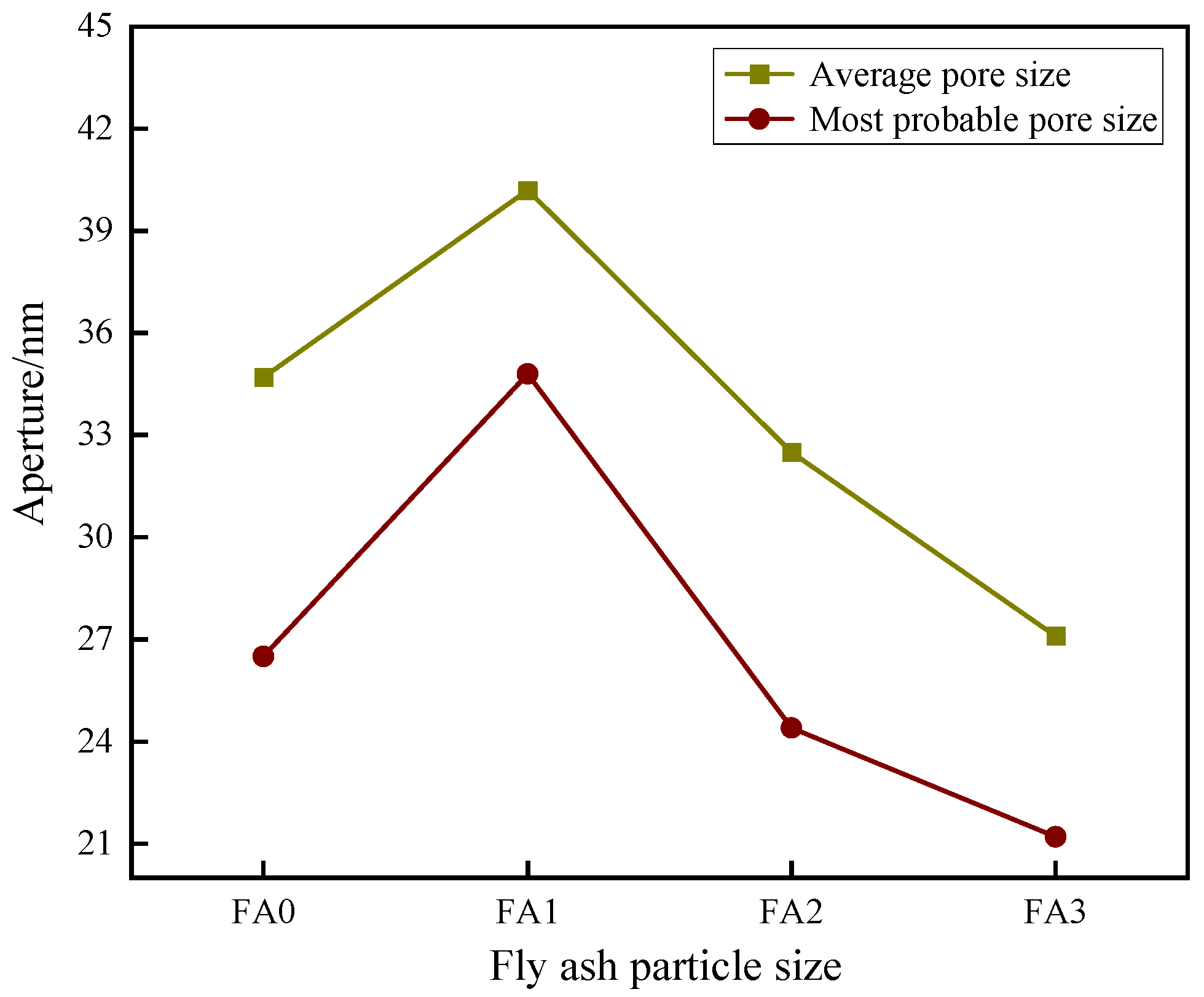

3.3.2. Effect of Fly Ash Particle Size on the Average Pore Size and the Most Probable Pore Size of Mortar

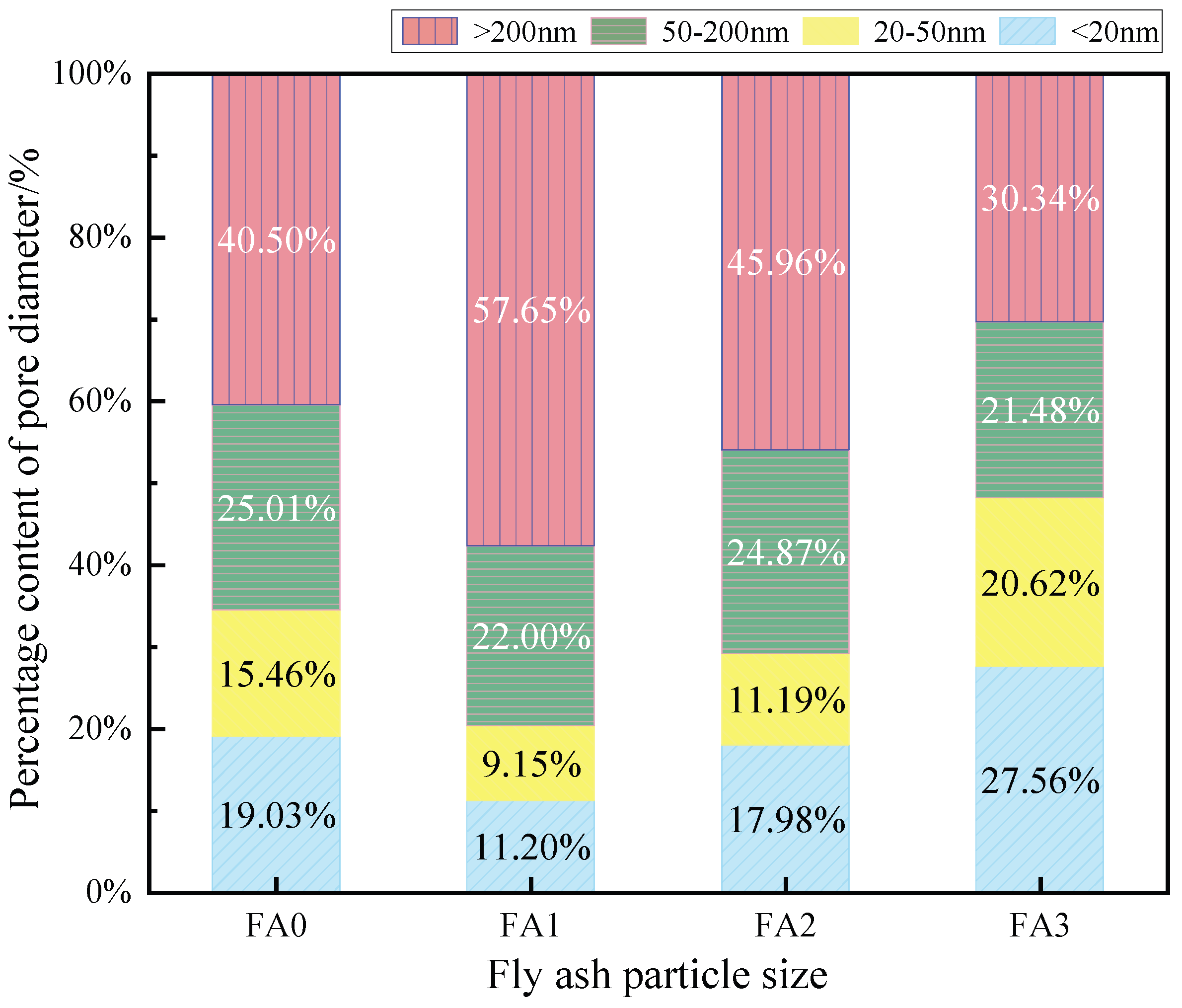

3.3.3. Effect of Fly Ash Particle Size on Pore Size Distribution of Mortar

3.4. Effect of Fly Ash Particle Size on the Phase of Mortar

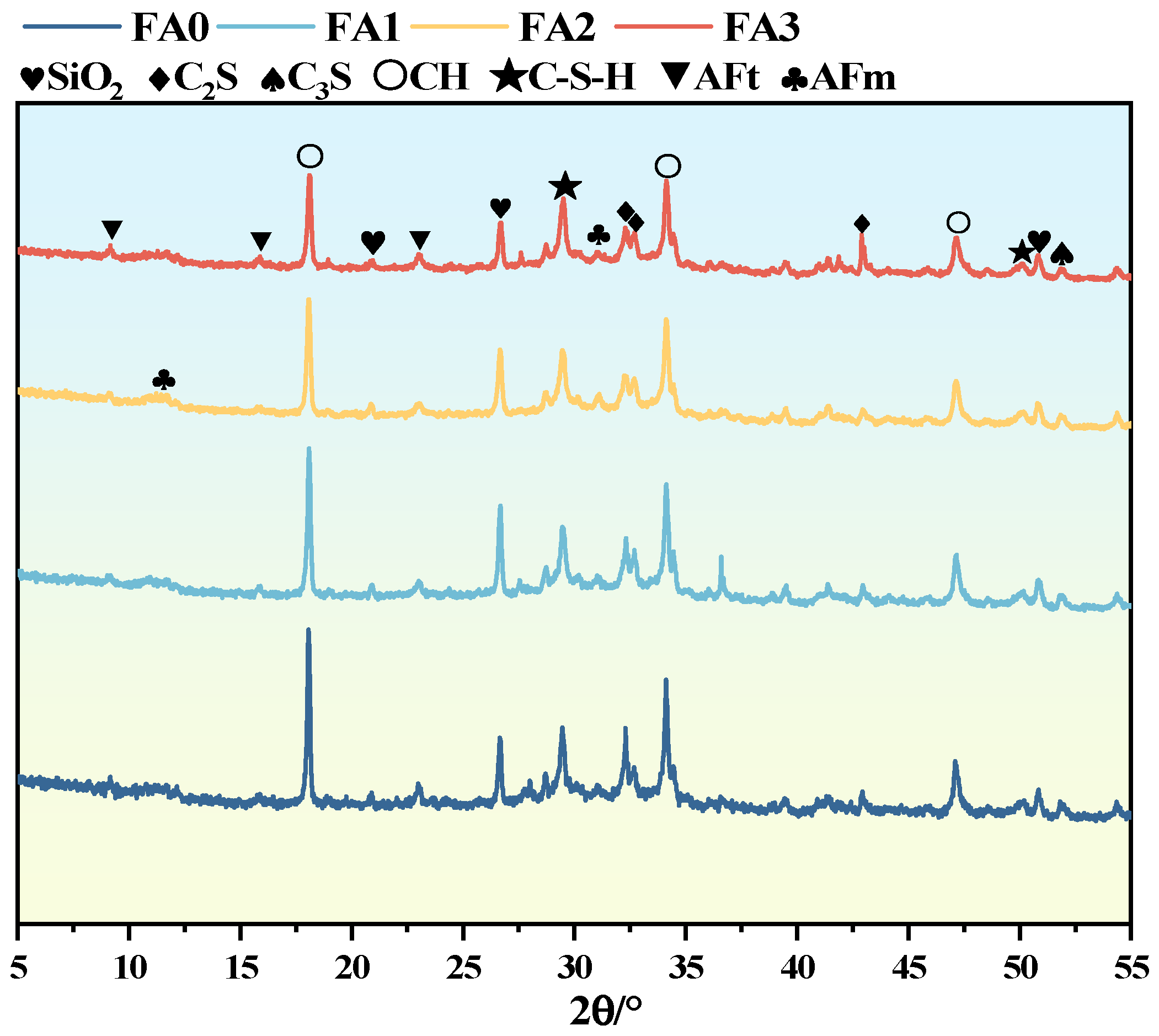

3.4.1. XRD Analysis

3.4.2. TG/DSC Analysis

3.5. Analysis of Microstructure of Cement Mortar

3.6. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, S.H.; Kim, H.J.; Sakai, E.; Daimon, M. Effect of particle size distribution of fly ash–cement system on the fluidity of cement Pastes. Cem. Concr. Res. 2003, 33, 763–768. [Google Scholar] [CrossRef]

- Tangpagasit, J.; Cheerarot, R.; Jaturapitakkul, C.; Kiattikomol, K. Packing effect and pozzolanic reaction of fly ash in Mortar. Cem. Concr. Res. 2005, 35, 1145–1151. [Google Scholar] [CrossRef]

- Sevim, Ö.; Demir, I. Optimization of fly ash particle size distribution for cementitious systems with high compactness. Constr. Build. Mater. 2019, 195, 104–114. [Google Scholar] [CrossRef]

- Wibawa, H.S.; Hardjito, D. Influence of particle size distribution of high calcium fly ash on HVFA mortar properties. Civ. Eng. Dimens. 2018, 20, 51–56. [Google Scholar] [CrossRef]

- Yang, J.; Zeng, L.; He, X.; Su, Y.; Li, Y.; Tan, H.; Jiang, B.; Zhu, H.; Oh, S.-K. Improving durability of Heat-cured high volume fly ash cement mortar by wet-grinding Activation. Constr. Build. Mater. 2021, 289, 123157. [Google Scholar] [CrossRef]

- Hsu, S.; Chi, M.; Huang, R. Effect of fineness and replacement ratio of ground fly ash on properties of blended cement Mortar. Constr. Build. Mater. 2018, 176, 250–258. [Google Scholar] [CrossRef]

- Danish, A.; Torres, A.S.; Moro, C.; Salim, M.U. Hope or hype? Evaluating the environmental footprint of reclaimed fly ash in geopolymer Production. Resour. Conserv. Recy 2024, 205, 107564. [Google Scholar] [CrossRef]

- Seifan, M.; Mendoza, S.; Berenjian, A. Effect of nano and micro iron oxide particles on the workability, strength and absorption rate of cement mortar containing fly Ash. Eur. J. Environ. Civ. Eng. 2020, 26, 3898–3912. [Google Scholar] [CrossRef]

- Sevim, O.; Sengul, C.G. Comparison of the Influence of Silica-rich Supplementary Cementitious Materials on Cement Mortar Composites: Mechanical and Microstructural Assessment. Silicon 2021, 13, 1675–1690. [Google Scholar] [CrossRef]

- Cho, Y.K.; Jung, S.H.; Choi, Y.C. Effects of chemical composition of fly ash on compressive strength of fly ash cement Mortar. Constr. Build. Mater. 2019, 204, 255–264. [Google Scholar] [CrossRef]

- Zhang, J.; Jin, C.; Wang, B.; Han, J.; Guo, L.; Tang, N. Study on the micro-rheological properties of fly ash-based cement mortar. Constr. Build. Mater. 2024, 442, 137664. [Google Scholar] [CrossRef]

- Sevim, Ö.; Demir, I. Physical and permeability properties of cementitious mortars having fly ash with optimized particle size Distribution. Cem. Concr. Comp. 2019, 96, 266–273. [Google Scholar] [CrossRef]

- Siddique, S.; Kim, H.; Jang, J.G. Properties of High-volume slag cement mortar incorporating circulating fluidized bed combustion fly ash and bottom Ash. Constr. Build. Mater. 2021, 289, 123150. [Google Scholar] [CrossRef]

- Kim, K.W.; Park, K.T.; Ates, F.; Kim, H.G.; Woo, B.-H. Effect of pretreated biomass fly ash on the mechanical properties and durability of cement Mortar. Case Stud. Constr. Mater. 2023, 18, e01754. [Google Scholar] [CrossRef]

- Krishnaraj, L.; Ravichandran, P. Investigation on grinding impact of fly ash particles and its characterization analysis in cement mortar Composites. Ain Shams Eng. J. 2019, 10, 267–274. [Google Scholar] [CrossRef]

- Delihowski, J.; Izak, P.; Wojcik, Ł.; Stempkowska, A.; Jarosz, M. The influence of selected grain size fractions of coal fly ash on properties of clay-cement mortars used for the flood levees construction. Sci. Rep. 2024, 14, 21485. [Google Scholar] [CrossRef]

- Jie, W.; Yuehua, L. Application of concrete produced from reused Ready-mixed concrete wastewater filtration residue. J. Mater. Res. Technol. 2023, 25, 2826–2840. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, B.; Yuan, Q.; Huang, D.; Peng, H. Characterization, factors, and fractal dimension of pore structure of fly ash-based Geopolymers. J. Mater. Res. Technol. 2023, 26, 3395–3407. [Google Scholar] [CrossRef]

- Mahmood, W.; Mohammed, A.; Ghafor, K.; Sarwar, W. Model Technics to Predict the Impact of the Particle Size Distribution (PSD) of the sand on the mechanical properties of the cement mortar modified with fly ash. Iran. J. Sci. Technol.-Trans. Civ. Eng. 2020, 45, 1657–1684. [Google Scholar] [CrossRef]

- Liu, K.; Wang, H.; Wang, Y.; Tang, J.; Wang, A.; Liu, T. Sulfate resistance of mortars under semi-immersion condition: Impact of environmental humidity and fly ash content. J. Build. Eng. 2024, 97, 110819. [Google Scholar] [CrossRef]

- Wang, K.; Guo, S.; Yuan, H.; Ren, J.; Chen, P.; Zhang, Q. Influence of cement particle size, ultra-fine fly ash, and ultra-fine silica fume on the physical and microscopic properties of slurry. AIP Conf. Proc. 2025, 22, e04337. [Google Scholar] [CrossRef]

- Medepalli, S.; Bishnoi, S. Modeling the Variation in Hydration and Strength of Blended Cement–Fly Ash Systems. J. Mater. Civ. Eng. 2021, 33, 04021213. [Google Scholar] [CrossRef]

- Balakrishnan, B.; Maghfouri, M.; Alimohammadi, V.; Asadi, I.; Roychand, R. The acid and chloride permeability resistance of masonry cement plaster mortar incorporating high-volume fly ash content. J. Build. Eng. 2024, 86, 108783. [Google Scholar] [CrossRef]

- Krishnaraj, L.; Ravichandran, P.T.; Sagadevan, S. Synthesis and characterization of grinding aid fly ash blended mortar effect on bond strength of masonry prisms. Mater. Res. Express 2018, 5, 045052. [Google Scholar] [CrossRef]

- Capela, M.N.; Tobaldi, D.M.; Tarelho, L.A.C.; Seabra, M.P.; Labrincha, J.A. Development of a Commercial Screed Mortar with Low OPC Content by Incorporation of Biomass Fly Ash. Appl. Sci. 2021, 11, 9630. [Google Scholar] [CrossRef]

- Ma, J.; Wang, D.; Zhao, S.; Duan, P.; Yang, S. Influence of Particle Morphology of Ground Fly Ash on the Fluidity and Strength of Cement Paste. Materials 2021, 14, 283. [Google Scholar] [CrossRef]

- Gismera, S.; Alonso, M.d.M.; Palacios, M.; Puertas, F. Rheology of Alkali-Activated Mortars: Influence of Particle Size and Nature of Aggregates. Minerals 2020, 10, 726. [Google Scholar] [CrossRef]

- Haustein, E.; Kuryłowicz-Cudowska, A.; Łuczkiewicz, A.; Fudala-Książek, S.; Cieślik, B.M. Influence of Cement Replacement with Sewage Sludge Ash (SSA) on the Heat of Hydration of Cement Mortar. Materials 2022, 15, 1547. [Google Scholar] [CrossRef]

- Li, G.; Wu, X. Influence of fly ash and its mean particle size on certain engineering properties of cement composite Mortars. Cem. Concr. Res. 2005, 35, 1128–1134. [Google Scholar] [CrossRef]

- Lin, K.L.; Chang, W.C.; Lin, D.F.; Tsai, M.C. Effects of Nano-SiO2 and different ash particle sizes on sludge ash–cement Mortar. J. Environ. Manag. 2008, 88, 708–714. [Google Scholar] [CrossRef] [PubMed]

- Erdoğdu, K.; Türker, P. Effects of fly ash particle size on strength of portland cement fly ash Mortars. Cem. Concr. Res. 1998, 28, 1217–1222. [Google Scholar] [CrossRef]

- Li, H.; Gao, P.; Xu, F.; Sun, T.; Zhou, Y.; Zhu, J.; Peng, C.; Lin, J. Effect of Fine Aggregate Particle Characteristics on Mechanical Properties of Fly Ash-Based Geopolymer Mortar. Minerals 2021, 11, 897. [Google Scholar] [CrossRef]

- Zhu, C.; Wan, Y.; Wang, L.; Ye, Y.; Yu, H.; Yang, J. Strength Characteristics and Microstructure Analysis of Alkali-Activated Slag–Fly Ash Cementitious Material. Materials 2022, 15, 6169. [Google Scholar] [CrossRef] [PubMed]

- JGJ /T70-2009; Standard for Test Methods of Basic Properties of Construction Mortar. China Architecture and Building Publishing House: Beijing, China, 2009.

- GB/T 1346; Methods for Testing the Water Requirement of Standard Consistency, Setting Time, and Stability of Cement. China Standards Publishing House: Beijing, China, 2024.

| Chemical Composition | CaO | Fe2O3 | Al2O3 | MgO | SiO2 | SO3 | Loss on Ignition |

|---|---|---|---|---|---|---|---|

| Content | 61.17 | 4.52 | 7.22 | 4.63 | 22.35 | 2.34 | 5.31 |

| Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|

| Initial Setting Time | Final Setting Time | 3 Days | 28 Days | 3 Days | 28 Days |

| 125 | 175 | 25.4 | 55.3 | 4.6 | 7.5 |

| Chemical Composition | CaO | SiO2 | Fe2O3 | Al2O3 | MgO | SO3 | Miscellaneous |

|---|---|---|---|---|---|---|---|

| Content | 4.73 | 52.68 | 7.58 | 27.77 | 1.71 | 1.23 | 1.84 |

| Density (g/cm3) | Specific Surface Area (m2/kg) | Water Demand (%) | Loss on Ignition (%) | Active Index (%) |

|---|---|---|---|---|

| 2.76 | 438 | 90 | 3.0 | 82.6 |

| Numbering | Fly Ash Particle Size | W/C | Cement | Water | Fly Ash | River Sand |

|---|---|---|---|---|---|---|

| FA0 | Control group | 0.4 | 850 | 380 | 94 | 1416 |

| FA1 | 60–80 μm | |||||

| FA2 | 30–50 μm | |||||

| FA3 | 10–20 μm |

| Mesh Number | Aperture/μm |

|---|---|

| 180 | 80 |

| 250 | 60 |

| 300 | 50 |

| 500 | 30 |

| 800 | 20 |

| 1400 | 10 |

| Fly Ash Particle Size | Yield Stress/Pa | Plastic Viscosity/Pa·s |

|---|---|---|

| FA0 | 336.31 | 8.98 |

| FA1 | 313.91 | 8.29 |

| FA2 | 316.16 | 8.95 |

| FA3 | 385.26 | 9.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.; Yang, Y.; Pang, B.; Cui, Y. The Effect of Different Particle Sizes of Fly Ash on the Properties of Mortar. Materials 2025, 18, 4693. https://doi.org/10.3390/ma18204693

Wu C, Yang Y, Pang B, Cui Y. The Effect of Different Particle Sizes of Fly Ash on the Properties of Mortar. Materials. 2025; 18(20):4693. https://doi.org/10.3390/ma18204693

Chicago/Turabian StyleWu, Changqing, Yuanquan Yang, Bo Pang, and Yunpeng Cui. 2025. "The Effect of Different Particle Sizes of Fly Ash on the Properties of Mortar" Materials 18, no. 20: 4693. https://doi.org/10.3390/ma18204693

APA StyleWu, C., Yang, Y., Pang, B., & Cui, Y. (2025). The Effect of Different Particle Sizes of Fly Ash on the Properties of Mortar. Materials, 18(20), 4693. https://doi.org/10.3390/ma18204693