Effect of CMT and MIG Welding on Microstructure and Mechanical Properties of Al-Zn-Mg-Cu-Er-Zr Alloy

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Weld Surface Forming and Cross-Section Appearance

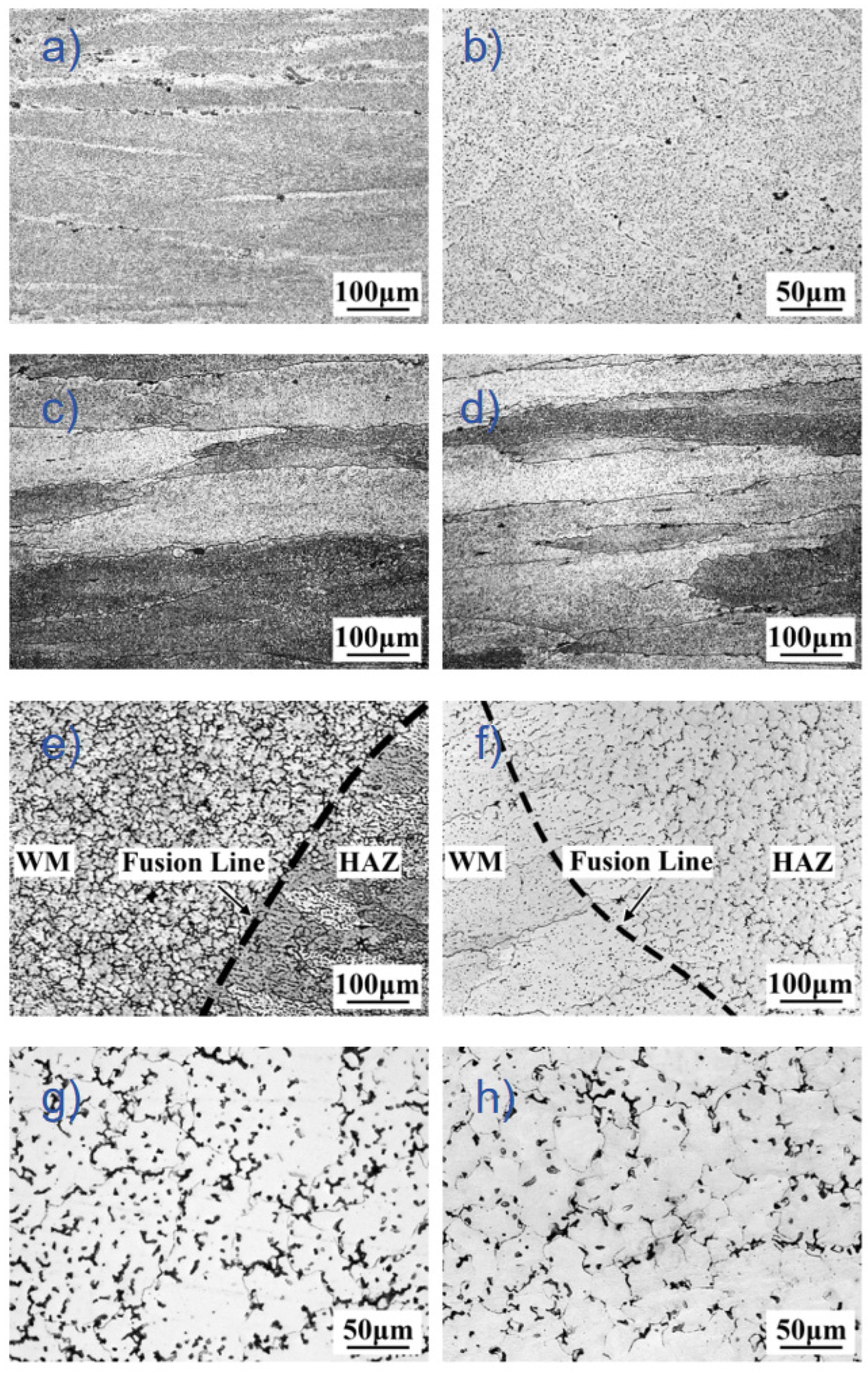

3.2. Microstructure and Phase Composition of Joint

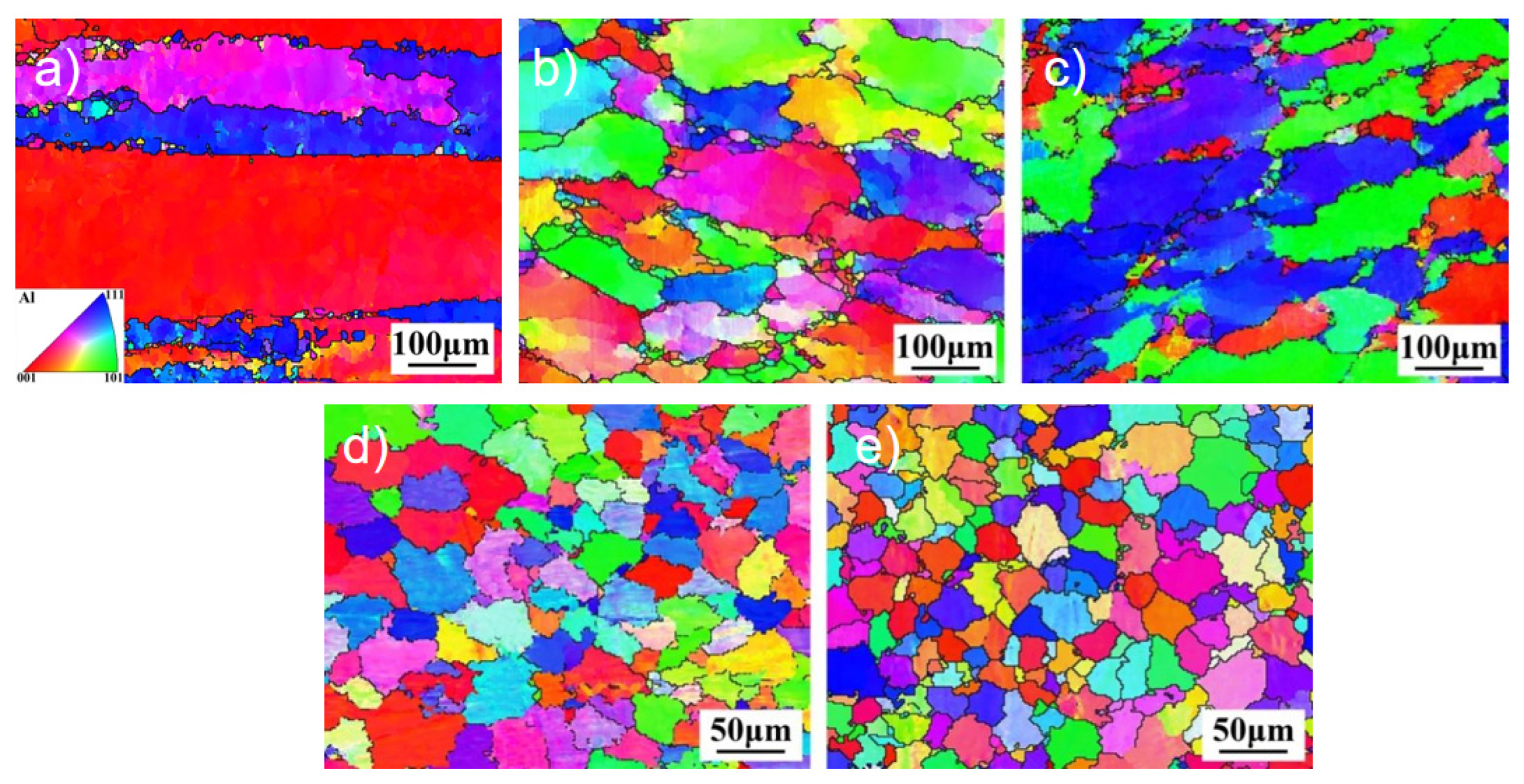

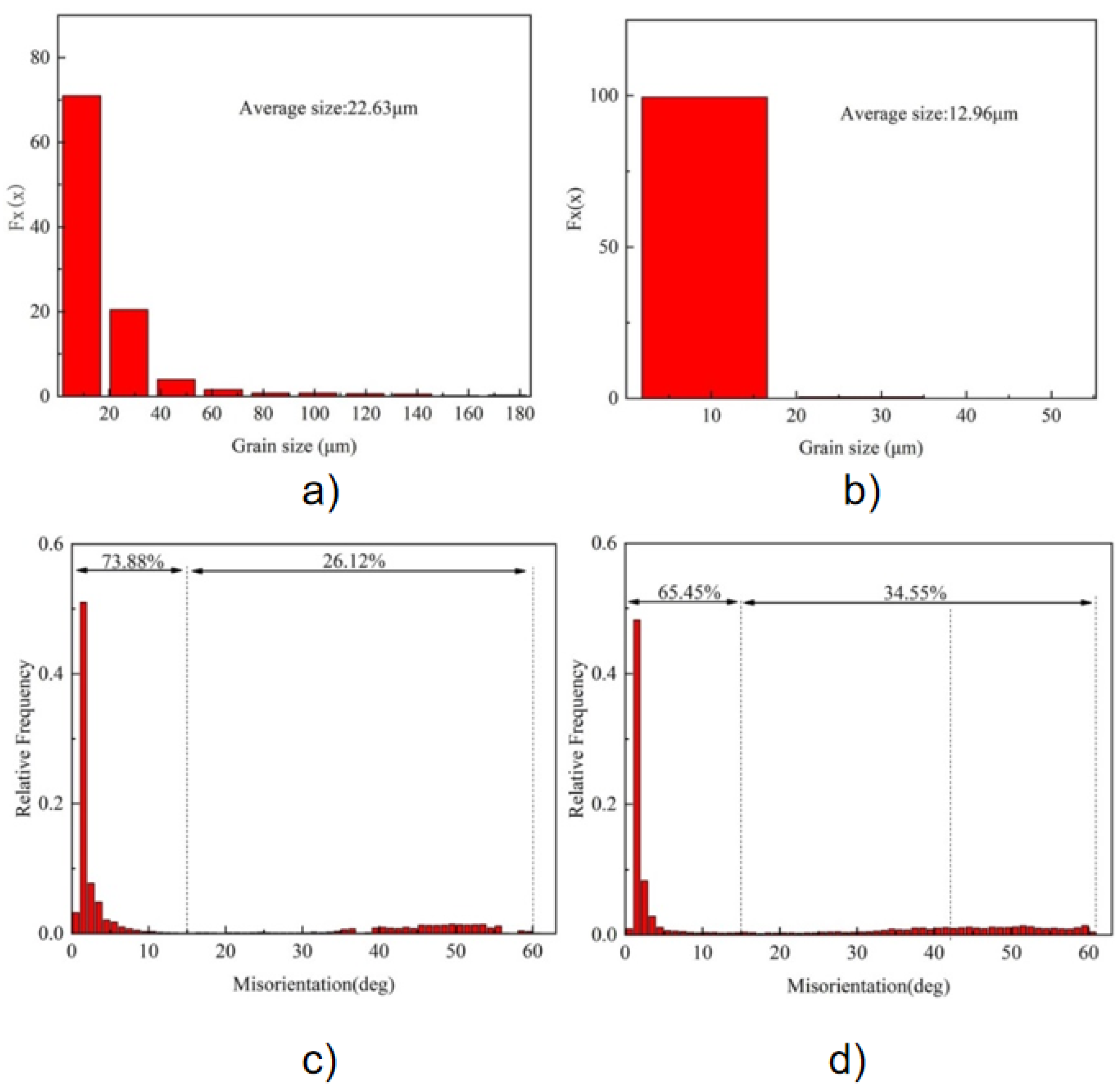

3.3. Grain Morphology and Grain Orientation Distribution of Weld Microstructure

3.4. The Secondary Phase of the Joint with Different Regional Organization

3.5. Mechanical Properties of Welded Joints

4. Conclusions

- (1)

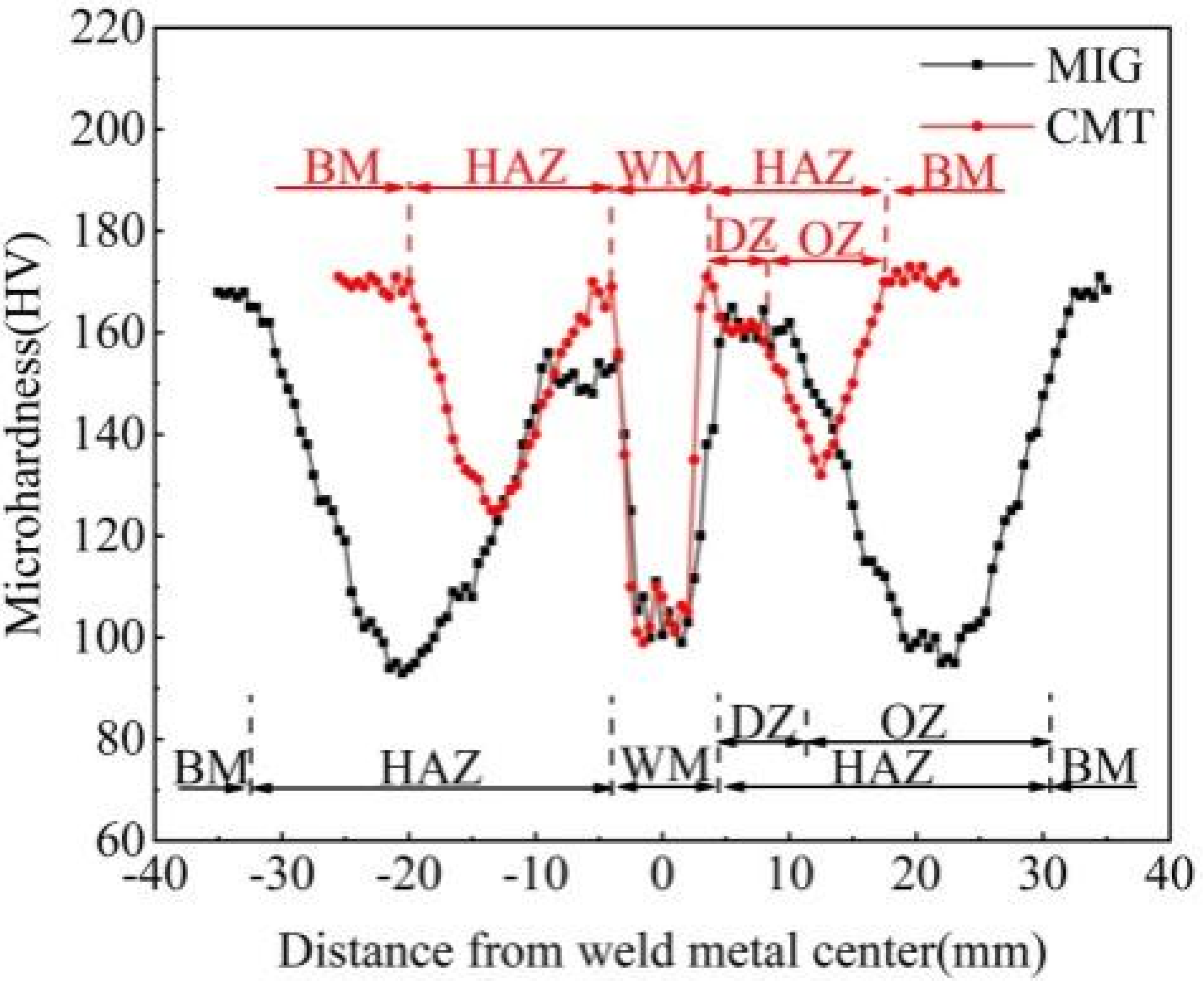

- The new Al-Zn-Mg-Cu-Er-Zr alloy welded by CMT and MIG can obtain well-formed full-penetration joints with similar weld formation coefficients, but the HAZ width of MIG welding is about two times that of CMT welding.

- (2)

- Crystallization and EQZ occur near the fusion lines of CMT and MIG joints of Al-Zn-Mg-Cu-Er-Zr alloys, respectively. CMT and MIG welds are composed of cellular crystals with grain sizes of 12.96 μm and 22.63 μm, respectively. The grains of CMT are significantly refined, and the grain boundaries of CMT welds are 24.43% higher than those of MIG. The second phase in the two kinds of weld structures comprises the η phase, primary Al3Er phase, and S phase, but their contents are different. The thick S phase consumes the main alloying element and reduces the mechanical properties of the joint.

- (3)

- The hardness of the Al-Zn-Mg-Cu-Er-Zr alloy is 168.9 HV, the hardness of CMT and MIG weld zone is 103.9 HV and 92.6 HV, respectively, and the lowest HAZ hardness is 125.2 HV and 97.0 HV, and the hardness of weld and HAZ are lower than that of base metal. However, the HAZ softening of MIG joints is more serious than that of CMT joints.

- (4)

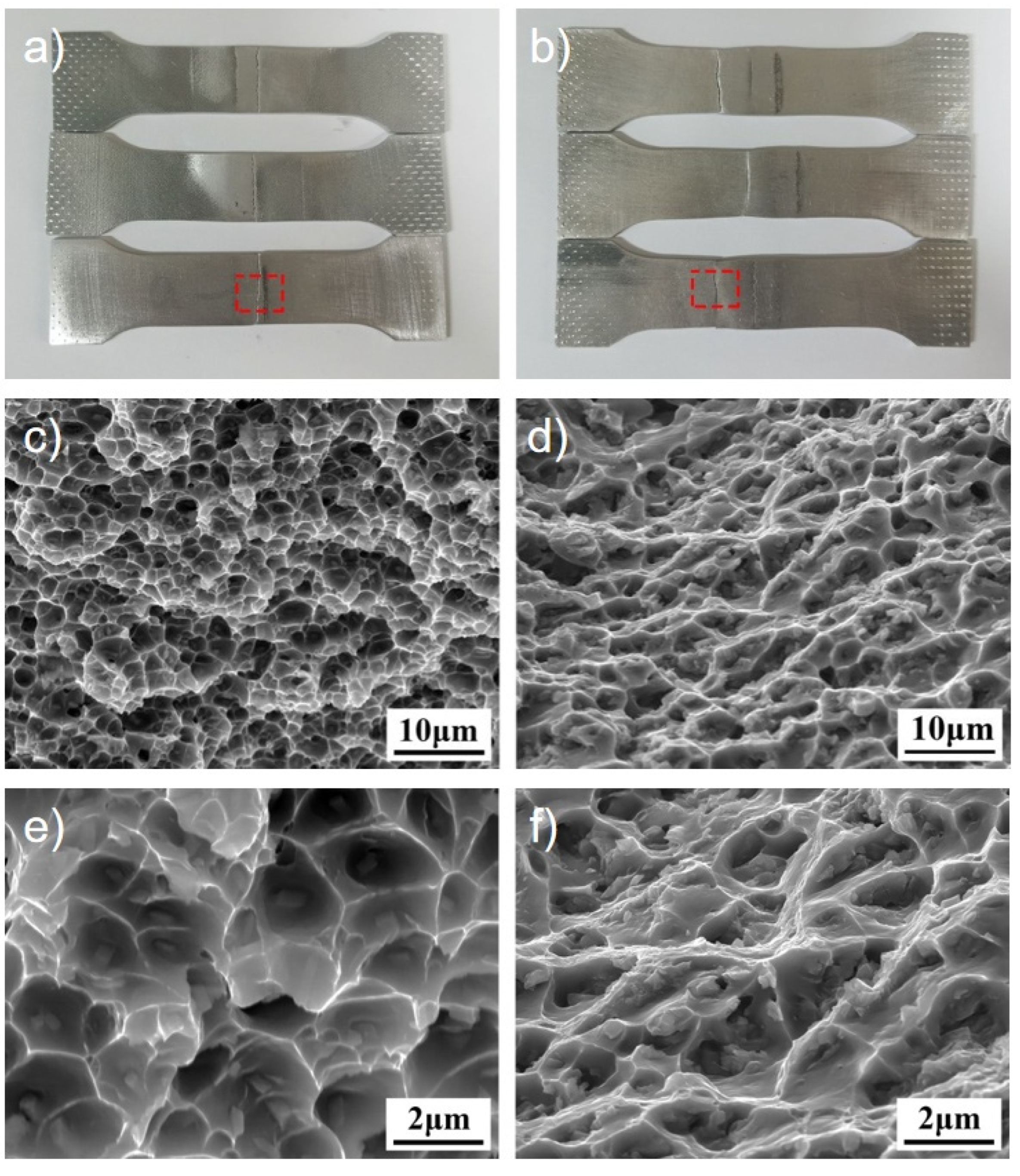

- The tensile strength of the Al-Zn-Mg-Cu-Er-Zr alloy MIG joint is 270.3 MPa, the elongation is 9.0%, and the welding strength coefficient is 0.47. The tensile strength of the CMT joint is 334.0 MPa, the elongation is 11.5%, and the welding strength coefficient is 0.60. Compared with the base material, the tensile strength of the two joints is lower than that of the base material. Still, the CMT joint of Al-Zn-Mg-Cu-Er-Zr alloy has higher tensile properties and improves the softening degree of the joint.

- (5)

- The superior mechanical properties of CMT joints over MIG joints are primarily attributed to their lower heat input and controlled solidification. This yields a finer weld grain structure, a narrower and less softened heat-affected zone, a more uniform distribution of secondary phases, and a higher proportion of strengthening high-angle grain boundaries. Collectively, these factors mitigate joint softening and enhance performance in the Al-Zn-Mg-Cu-Er-Zr alloy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pei, Y.; Wei, W.; Hu, J.; Bi, J.; Gao, K.; Wen, S.; Wu, X.; Huang, H.; Nie, Z. Microstructure and mechanical properties of Al–Zn–Mg–Cu–Er–Zr alloy processed by laser powder bed fusion. J. Mater. Res. Technol. 2025, 35, 4164–4174. [Google Scholar] [CrossRef]

- Wang, Y.-C.; Wu, X.-D.; Yue, L.; Guo, M.-X.; Cao, L.-F. Aging precipitation behavior and properties of Al–Zn–Mg–Cu–Zr–Er alloy at different quenching rates. Trans. Nonferrous Met. Soc. China 2022, 32, 1070–1082. [Google Scholar] [CrossRef]

- Wu, H.; Wen, S.P.; Huang, H.; Gao, K.Y.; Wu, X.L.; Wang, W.; Nie, Z.R. Hot deformation behavior and processing map of a new type Al-Zn-Mg-Er-Zr alloy. J. Alloys Compd. 2016, 685, 869–880. [Google Scholar] [CrossRef]

- Heinz, A.; Haszler, A.; Keidel, C.; Moldenhauer, S.; Benedictus, R.; Miller, W.S. Recent development in aluminium alloys for aerospace applications. Mater. Sci. Eng. A 2000, 280, 102–107. [Google Scholar] [CrossRef]

- Xie, W.; Huang, T.; Yang, C.; Fan, C.; Lin, S.; Xu, W. Comparison of microstructure, mechanical properties, and corrosion behavior of Gas Metal Arc (GMA) and Ultrasonic-wave-assisted GMA (U-GMA) welded joints of Al–Zn–Mg alloy. J. Mater. Process. Technol. 2020, 277, 116470. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Cao, L.; Tong, X.; Couper, M.J.; Liu, Q. Effect of trace Er on the microstructure and properties of Al–Zn–Mg–Cu–Zr alloys during heat treatments. Mater. Sci. Eng. A 2020, 792, 139807. [Google Scholar] [CrossRef]

- Yeni, Ç.; Sayer, S.; Pakdil, M. Comparison of mechanical and microstructural behaviour of TIG, MIG and friction stir welded 7075 aluminium alloy. Kovove Mater. 2009, 47, 341–347. [Google Scholar]

- Hong, L.; Wu, X.; Xiong, X.; Gao, K.; Wen, S.; Wei, W.; Rong, L.; Huang, H.; Nie, Z.; Dong, Y.; et al. Study of dynamic recrystallization behavior of Al-Zn-Mg-Cu-Er-Zr alloy during isothermal compression. J. Mater. Res. Technol. 2025, 34, 1399–1409. [Google Scholar] [CrossRef]

- Liu, C.; Northwood, D.O.; Bhole, S.D. Tensile fracture behavior in CO2 laser beam welds of 7075-T6 aluminum alloy. Mater. Des. 2004, 25, 573–577. [Google Scholar] [CrossRef]

- Elrefaey, A. Effectiveness of cold metal transfer process for welding 7075 aluminium alloys. Sci. Technol. Weld. Join. 2015, 20, 280–285. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Nie, Z.; Huang, H.; Niu, L. Comparison of microstructure and mechanical properties of TIG and laser welding joints of a new Al–Zn–Mg–Cu alloy. Mater. Des. 2016, 92, 880–887. [Google Scholar] [CrossRef]

- Ramaswamy, A.; Malarvizhi, S.; Balasubramanian, V. Effect of variants of gas metal arc welding process on tensile properties of AA6061-T6 aluminium alloy joints. Int. J. Adv. Manuf. Technol. 2020, 108, 2967–2983. [Google Scholar] [CrossRef]

- Selvi, S.; Vishvaksenan, A.; Rajasekar, E. Cold metal transfer (CMT) technology—An overview. Def. Technol. 2018, 14, 28–44. [Google Scholar] [CrossRef]

- Wu, D.; Cui, L.; Wu, X.; Guo, X.; Shao, W.; Tan, Z.; He, D. Cold metal transfer welding of AlSi7Mg alloy sheets prepared by selective laser melting. J. Manuf. Process. 2022, 84, 282–297. [Google Scholar] [CrossRef]

- GB/T 2651-2008; Tensile Test Method on Welded Joints. Standardization Administration of the People’s Republic of China (SAC): Beijing, China, 2008.

- Reddy, G.M.; Gokhale, A.A.; Prasad, K.S.; Rao, K.P.; Reddy, D.; Mr, D.G.; Prasad; Rao, P.J.S.; Welding, T.O. Chill zone formation in Al–Li alloy welds. Sci. Technol. Weld. Join. 1998, 3, 208–212. [Google Scholar] [CrossRef]

- Yang, T.Y.; Cui, L.; He, D.Y.; Huang, H. Microstructure and mechanical properties enhancement of AlSi10Mg-Er-Zr alloy fabricated by selective laser melting. Acta Metall. Sin. 2022, 58, 1108–1117. [Google Scholar] [CrossRef]

- Guo, J.; Gougeon, P.; Chen, X.G. Microstructure evolution and mechanical properties of dissimilar friction stir welded joints between AA1100-B4C MMC and AA6063 alloy. Mater. Sci. Eng. A 2012, 553, 149–156. [Google Scholar] [CrossRef]

- Kekuan, W.; Jian, L.; Ruibin, D.; Wanting, C.; Huli, N.; Liangyu, L.; Jianfeng, Y. Current waveform effects on AC-CMT arc welding of 7075 Al alloy with addition of ER7075 wire. Weld. World 2024, 69, 2885–2905. [Google Scholar] [CrossRef]

- Hu, Y.; Wu, S.; Guo, Y.; Shen, Z.; Korsunsky, A.M.; Yu, Y.; Zhang, X.; Fu, Y.; Che, Z.; Xiao, T.; et al. Inhibiting weld cracking in high-strength aluminium alloys. Nat. Commun. 2022, 13, 5816. [Google Scholar] [CrossRef] [PubMed]

| Si | Fe | Cu | Mn | Mg | Zn | Ti | Cr | Zr | Er | Al | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Alloy | 0.09 | 0.08 | 0.60 | 0.30 | 2.30 | 7.30 | - | - | 0.12 | 0.11 | Bal |

| Filler | 0.40 | 0.40 | 0.05 | 0.8–0.9 | 5.5–6.1 | 0.20 | 0.02–0.03 | 0.03 | 0.10 | - | Bal |

| Location | Mg | Mn | Zn | Cu | Er | Al | Second Phase |

|---|---|---|---|---|---|---|---|

| A | 1.82 | - | 3.91 | - | - | 94.2 | Al, MgZn2 |

| B | 0.62 | 0.16 | 3.23 | 2.2 | 0.08 | 93.7 | Al, Al3Er |

| C | 4.01 | 0.53 | 3.00 | 0.38 | - | 92.08 | Al, Al6CuMg4 |

| D | 6.46 | 0.23 | 1.28 | 0.56 | - | 92.08 | Al, Al6CuMg4 |

| Yield Stress (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | |

|---|---|---|---|

| Base material | 537.0 | 568.7 | 11.5 |

| CMT joint | 207.0 | 334.0 | 11.3 |

| MIG joint | 155.0 | 270.3 | 9.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, W.; Sun, Y.; Zhang, C.; Zhai, L.; Wang, P.; Cui, L.; Wen, S.; Shi, W.; Zhou, X. Effect of CMT and MIG Welding on Microstructure and Mechanical Properties of Al-Zn-Mg-Cu-Er-Zr Alloy. Materials 2025, 18, 4688. https://doi.org/10.3390/ma18204688

Wei W, Sun Y, Zhang C, Zhai L, Wang P, Cui L, Wen S, Shi W, Zhou X. Effect of CMT and MIG Welding on Microstructure and Mechanical Properties of Al-Zn-Mg-Cu-Er-Zr Alloy. Materials. 2025; 18(20):4688. https://doi.org/10.3390/ma18204688

Chicago/Turabian StyleWei, Wu, Yijie Sun, Chao Zhang, Limin Zhai, Peng Wang, Li Cui, Shengping Wen, Wei Shi, and Xiaorong Zhou. 2025. "Effect of CMT and MIG Welding on Microstructure and Mechanical Properties of Al-Zn-Mg-Cu-Er-Zr Alloy" Materials 18, no. 20: 4688. https://doi.org/10.3390/ma18204688

APA StyleWei, W., Sun, Y., Zhang, C., Zhai, L., Wang, P., Cui, L., Wen, S., Shi, W., & Zhou, X. (2025). Effect of CMT and MIG Welding on Microstructure and Mechanical Properties of Al-Zn-Mg-Cu-Er-Zr Alloy. Materials, 18(20), 4688. https://doi.org/10.3390/ma18204688