Life Cycle Assessment of the Construction and Demolition Waste Recovery Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Goal and Scope, System Boundaries of Processes

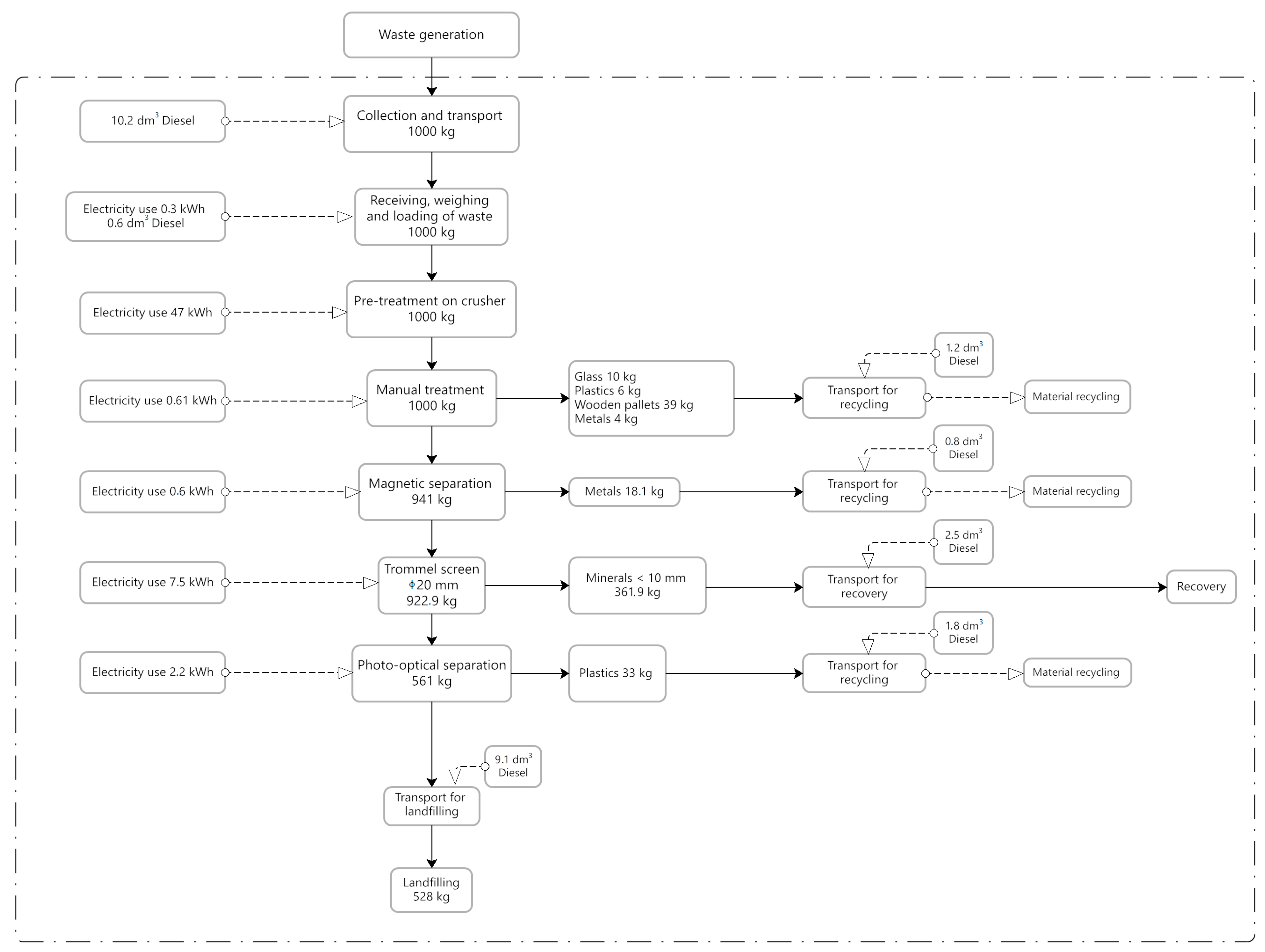

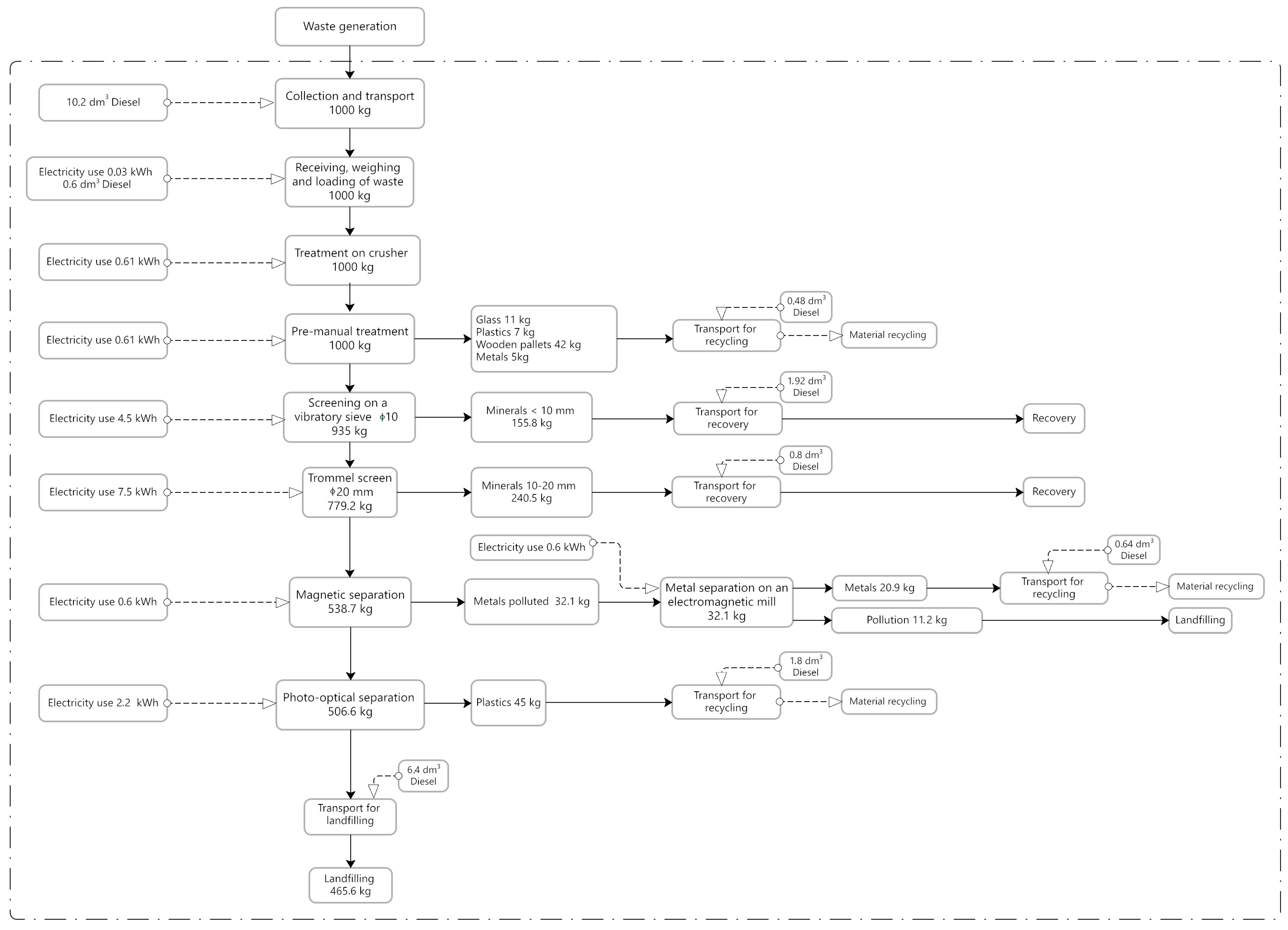

2.2. Description of Experiment

2.3. Life Cycle Impact Assessment and Interpretation

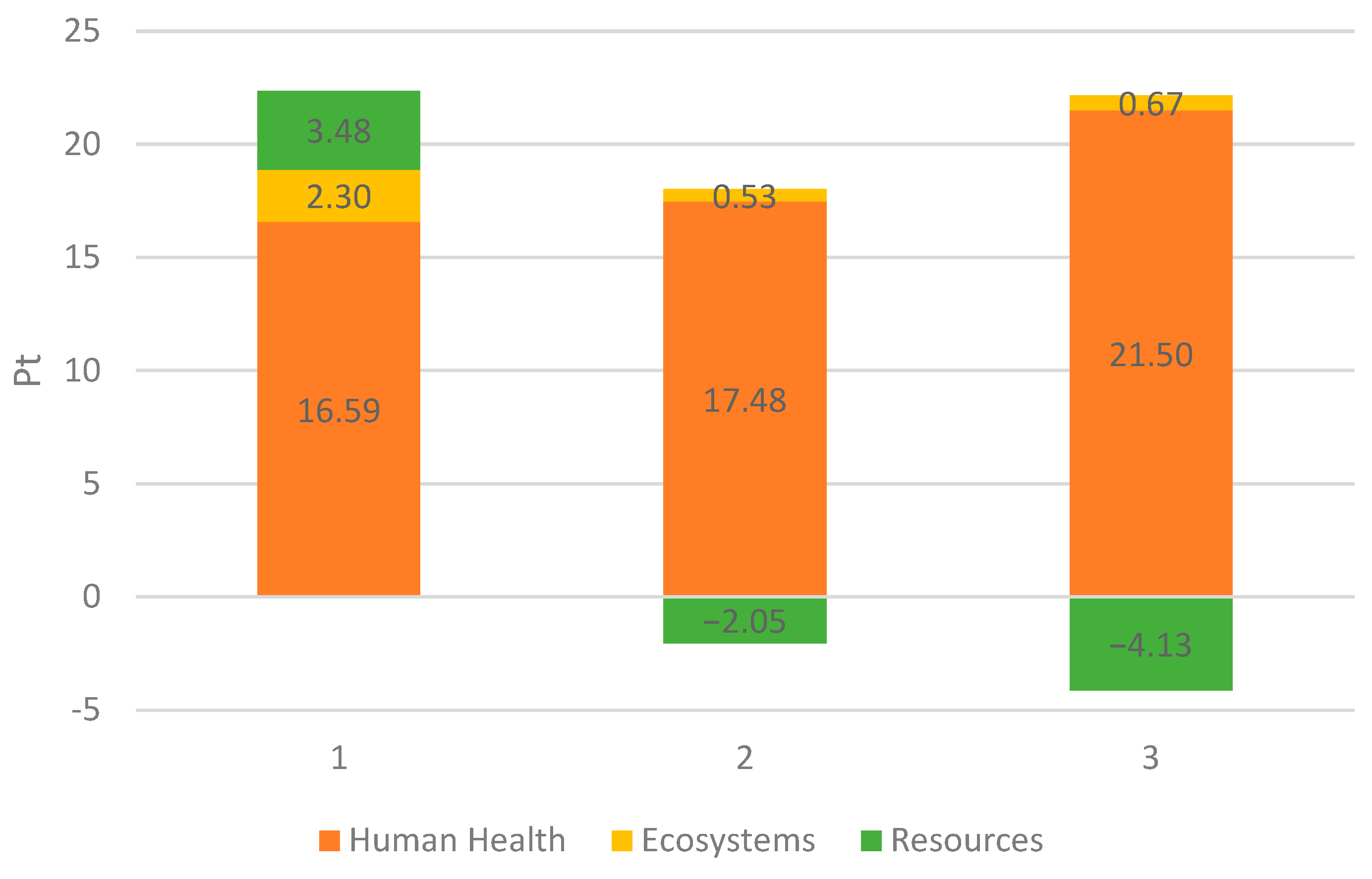

- Human health is expressed as the number of years of life lost and the number of years lived with disability. They are combined as disability-adjusted life years (DALY), an indicator also used by the World Bank and the WHO.

- Ecosystems are expressed as the loss of species in a given area over a given time.

- Resource scarcity is expressed as the excess cost of future resource production over an infinite timeframe (assuming constant annual production), taking into account a 3% discount rate. It should be remembered that fossil resource scarcity does not have a constant mid-to-endpoint ratio, but rather individual ratios for each substance.

3. Results

3.1. Material Composition of Waste

3.2. Material Recovery Results

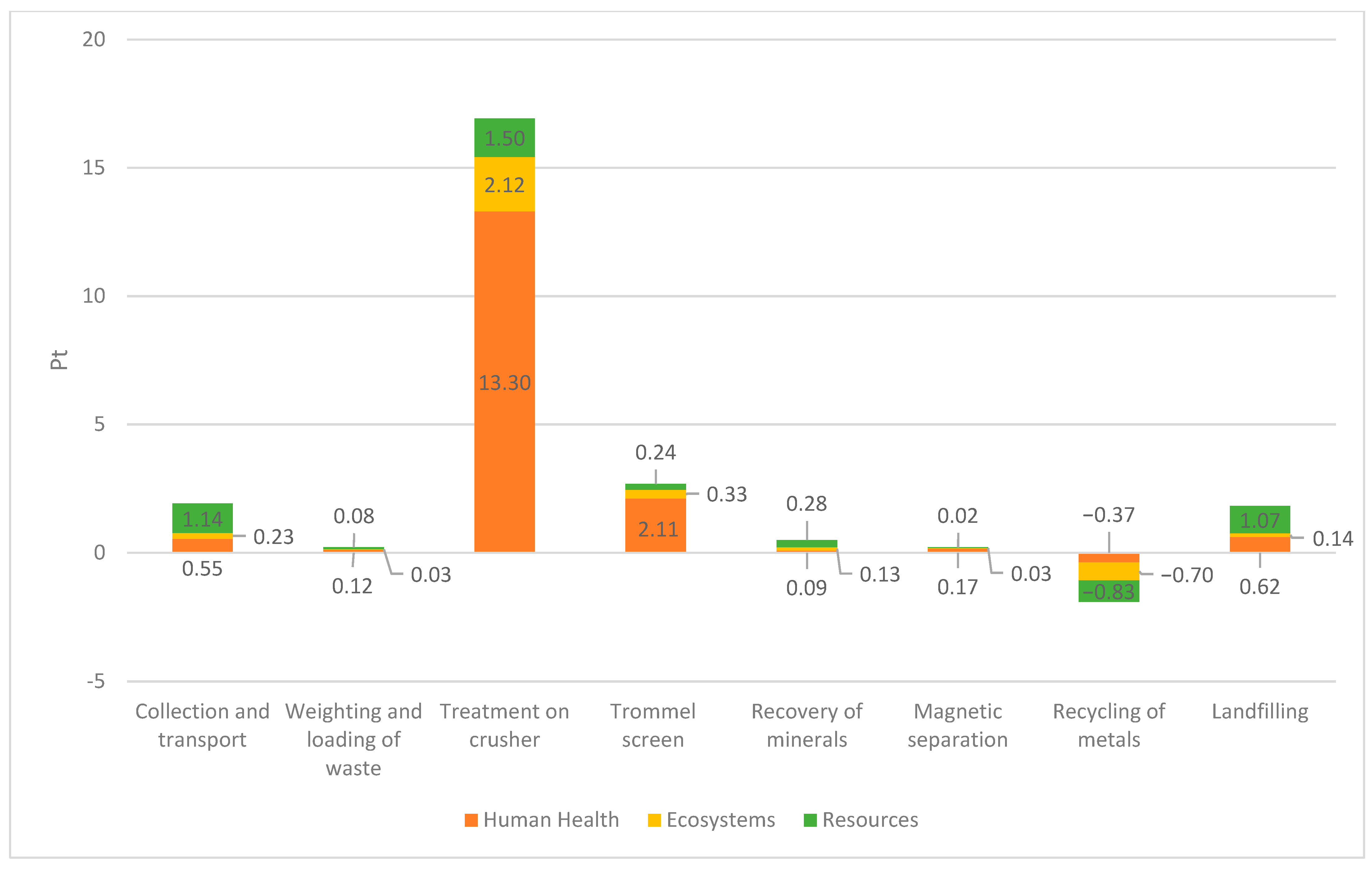

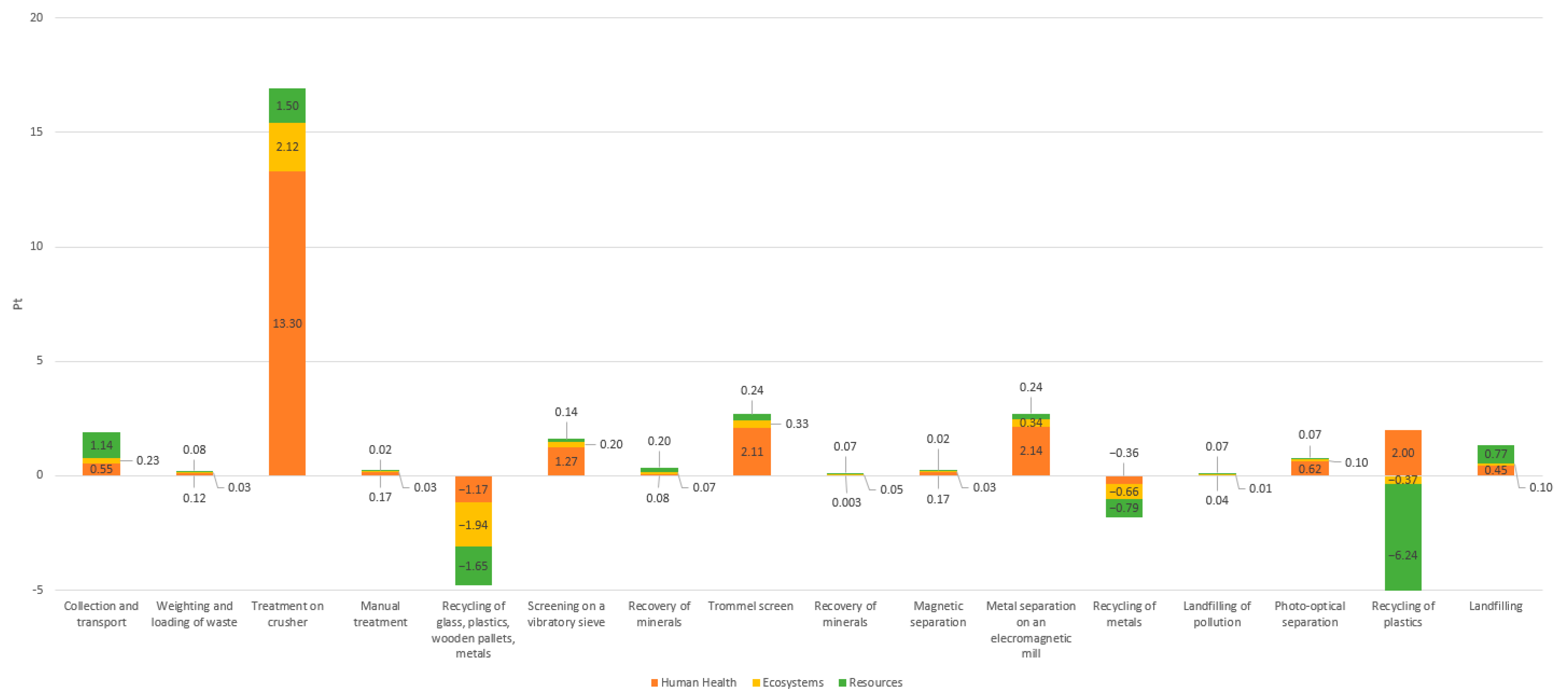

3.3. Environmental Assessment

3.4. Sensitivity Analysis

4. Discussion

5. Conclusions

- The CDW recovery process has a negative impact on the environment, mainly due to fuel and electricity consumption, which is consistent with the LCA results, particularly in terms of climate change, human health, and fossil resource depletion.

- The most burdensome stage is waste crushing (treatment involving a crusher), which is consistent with the results for all three analyzed installations. This stage is a critical link in terms of the environment. In subsequent analyses, the possibility of discontinuing this device usage within certain limits should be considered.

- Materials sorted during manual, photo-optical, and magnetic sorting have an overall positive impact on the environment, mainly due to resource savings.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CDW | Construction and demolition waste |

| LCA | Life cycle assessment |

| WHO | World Health Organization |

| PE | Personal equivalent |

References

- La Rosa, A.D.; Grammatikos, S.A.; Ursan, G.A.; Aradoaei, S.; Summerscales, J.; Ciobanu, R.C.; Schreiner, C.M. Recovery of electronic wastes as fillers for electromagnetic shielding in building components: An LCA study. J. Clean. Prod. 2021, 280, 124593. [Google Scholar] [CrossRef]

- Famielec, S.; Malinowski, M.; Tomaszek, K.; Wolny-Koładka, K.; Krilek, J. The effect of biological methods for MSW treatment on the physicochemical, microbiological and phytotoxic properties of used biofilter bed media. Waste Manag. 2024, 175, 276–285. [Google Scholar] [CrossRef] [PubMed]

- Smol, M.; Avdiushchenko, A.; Kulczycka, J.; Nowaczek, A. Public awareness of circular economy in southern Poland: Case of the Malopolska region. J. Clean. Prod. 2018, 197, 1035–1045. [Google Scholar] [CrossRef]

- Smol, M.; Kulczycka, J.; Avdiushchenko, A. Circular economy indicators in relation to eco-innovation in European regions. Clean Technol. Environ. Policy 2017, 19, 669–678. [Google Scholar] [CrossRef]

- Kulczycka, J.; Lewandowska, A.; Joachimiak–Lechman, K.; Kurczewski, P. The Circularity of Materials from the Perspective of a Product Life Cycle: A Life Cycle Assessment Case Study of Secondary Fence Boards—Part 1 (Baseline Scenario). Resources 2024, 13, 50. [Google Scholar] [CrossRef]

- Tatara, T.; Fedorczak-Cisak, M.; Furtak, M.; Surówka, M.; Steidl, T.; Knap-Miśnakiewicz, K.; Kozak, E.; Kawalec, W. Przegląd Przepisów Określających Minimalne Wymagania Dotyczące Charakterystyki Energetycznej Budynków; Politechnika Krakowska i Małopolskie Centrum Busownictwa Energooszczędnego: Kraków, Poland, 2017. [Google Scholar]

- Kania, G.; Kwiecień, K.; Malinowski, M.; Gliniak, M. Analyses of the Life Cycles and Social Costs of CO2 Emissions of Single-Family Residential Buildings: A Case Study in Poland. Sustainability 2021, 13, 6164. [Google Scholar] [CrossRef]

- Kowalczyk, Z.; Twardowski, S.; Malinowski, M.; Kuboń, M. Life cycle assessment (LCA) and energy assessment of the production and use of windows in residential buildings. Sci. Rep. 2023, 13, 19752. [Google Scholar] [CrossRef]

- Khasreen, M.; Banfill, P.; Menzies, G. Life-Cycle Assessment and the Environmental Impact of Buildings: A Review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- Rodrigues, V.; Martins, A.A.; Nunes, M.I.; Quintas, A.; Mata, T.M.; Caetano, N.S. LCA of constructing an industrial building: Focus on embodied carbon and energy. Energy Procedia 2018, 153, 420–425. [Google Scholar] [CrossRef]

- Pereira, P.M.; Vieira, C.S. A Literature Review on the Use of Recycled Construction and Demolition Materials in Unbound Pavement Applications. Sustainability 2022, 14, 13918. [Google Scholar] [CrossRef]

- Contreras-Llanes, M.; Gázquez, M.J.; Romero, M. Eco-Friendly Pavements Manufactured from Mixed Recycled Aggregates Obtained from Construction and Demolition Waste: An Industrial-Scale Validation. Materials 2023, 16, 7544. [Google Scholar] [CrossRef] [PubMed]

- Robayo–Salazar, R.; Valencia–Saavedra, W.; Mejía de Gutiérrez, R. Reuse of Powders and Recycled Aggregates from Mixed Construction and Demolition Waste in Alkali-Activated Materials and Precast Concrete Units. Sustainability 2022, 14, 9685. [Google Scholar] [CrossRef]

- Jelić, I.; Šljivić-Ivanović, M.; Dimović, S.; Antonijević, D.; Jović, M.; Mirković, M.; Smičiklas, I. The applicability of construction and demolition waste components for radionuclide sorption. J. Clean. Prod. 2018, 171, 322–332. [Google Scholar] [CrossRef]

- Dudek, K.; Bodziacki, S.; Bieszczad, A.; Malinowski, M. Characteristics of illegal dumping sites on the example of the Trzebinia municipality. Infrastrukt. I Ekol. Teren. Wiej. 2023, 18, 278–293. [Google Scholar] [CrossRef]

- Braga, A.M.; Silvestre, J.D.; de Brito, J. Compared environmental and economic impact from cradle to gate of concrete with natural and recycled coarse aggregates. J. Clean. Prod. 2017, 162, 529–543. [Google Scholar] [CrossRef]

- Nolepa, A.; Kiprian, K.; Siemiątkowski, G. Analiza wybranych problemów związanych z gospodarką odpadami budowlanymi i rozbiórkowymi. Pr. ICiMB 2018, 32, 52–62. [Google Scholar]

- Simić, V.; Abramović, F.; Andrić, N.; Delić, I.; Miladinović, Z.; Životić, D. Need to Improve the Natural Aggregate Resources Supply in the City of Belgrade (Serbia). Acta Montan. Slovaca 2016, 21, 191–199. [Google Scholar]

- Chalangaran, N.; Farzampour, A.; Paslar, N.; Fatemi, H. Experimental investigation of sound transmission loss in concrete containing recycled rubber crumbs. Adv. Concr. Constr. 2021, 11, 447–454. [Google Scholar]

- Kim, J.; Grabiec, A.M.; Ubysz, A. An Experimental Study on Structural Concrete Containing Recycled Aggregates and Powder from Construction and Demolition Waste. Materials 2022, 15, 2458. [Google Scholar] [CrossRef]

- Abramović, F.; Popović, M.P.; Simić, V.; Matović, V.; Šerović, R. Characterization and Environmental Evaluation of Recycled Aggregates from Construction and Demolition Waste in Belgrade City Area (Serbia). Materials 2024, 17, 820. [Google Scholar] [CrossRef]

- Mesa, J.A.; Fúquene-Retamoso, C.; Maury-Ramírez, A. Life Cycle Assessment on Construction and Demolition Waste: A Systematic Literature Review. Sustainability 2021, 13, 7676. [Google Scholar] [CrossRef]

- El-Shaboury, N.; Al-Sakkaf, A.; Mohammed Abdelkader, E.; Alfalah, G. Construction and Demolition Waste Management Research: A Science Mapping Analysis. Int. J. Environ. Res. Public Health 2022, 19, 4496. [Google Scholar] [CrossRef]

- Grzesik, K.; Malinowski, M. Life cycle assessment of refuse-derived fuel production from mixed municipal waste. Energy Sources Part A 2016, 38, 3150–3157. [Google Scholar] [CrossRef]

- Kossakowska, K.; Grzesik, K. Life cycle assessment of the mixed municipal waste management system based on mechanical-biological treatment. J. Ecol. Eng. 2019, 20, 175–183. [Google Scholar] [CrossRef] [PubMed]

- Bovea, M.D.; Powell, J.C. Developments in life cycle assessment applied to evaluate the environmental performance of construction and demolition wastes. Waste Manag. 2016, 50, 151–172. [Google Scholar] [CrossRef] [PubMed]

- Pranjić, A.M.; Ranogajec, J.; Škrlep, L.; Škapin, A.S.; Vučetić, S.; Rebec, K.M.; Turk, J. Life cycle assessment of novel consolidants and a photocatalytic suspension for the conservation of the immovable cultural heritage. J. Clean. Prod. 2018, 181, 293–308. [Google Scholar] [CrossRef]

- Han, B.; Wang, R.; Yao, L.; Liu, H.; Wang, Z. Life cycle assessment of ceramic façade material and its comparative analysis with three other common façade materials. J. Clean. Prod. 2015, 99, 86–93. [Google Scholar] [CrossRef]

- Kvočka, D.; Lešek, A.; Knez, F.; Ducman, V.; Panizza, M.; Tsoutis, C.; Bernardi, A. Life Cycle Assessment of Prefabricated Geopolymeric Façade Cladding Panels Made from Large Fractions of Recycled Construction and Demolition Waste. Materials 2020, 13, 3931. [Google Scholar] [CrossRef]

- Bjorklund, A.; Finnveden, G.; Roth, L. Introduction. In Application of LCA in Waste Management; Christensen, T., Ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2010; Volume 1–2, p. 137. [Google Scholar]

- PN-EN ISO 14040:2009; Zarządzanie Środowiskowe. Ocena Cyklu Życia. Zasady I Struktura. PKN: Warszawa, Poland, 2009.

- Moutik, B.; Summerscales, J.; Graham-Jones, J.; Pemberton, R. Life Cycle Assessment Research Trends and Implications: A Bibliometric Analysis. Sustainability 2023, 15, 13408. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D.; Bednárová, L.; Petrovský, J. Improving the Process of Product Design in a Phase of Life Cycle Assessment (LCA). Processes 2023, 11, 2579. [Google Scholar] [CrossRef]

- ISO 14044; Environmental Management-Life Cycle Assessment-Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Schneider, P.; Ahmed, N.; Mihai, F.C.-C.; Belousova, A.; Kucera, R.; Oswald, K.-D.; Lange, T.; Le Hung, A. Life Cycle Assessment for Substitutive Building Materials Using the Example of the Vietnamese Road Sector. Appl. Sci. 2023, 13, 6264. [Google Scholar] [CrossRef]

- Database & Support Team; PRé Sustainability. SimaPro Database Manual—Methods Library; SimaPro: Amersfoort, The Netherlands, 2021; pp. 1–56. Available online: https://simapro.com/wp-content/uploads/2021/07/DatabaseManualMethods920.pdf (accessed on 8 June 2025).

- Koinig, G.; Grath, E.; Barretta, C.; Friedrich, K.; Vollprecht, D.; Oreski, G. Lifecycle Assessment for Recycling Processes of Monolayer and Multilayer Films: A Comparison. Polymers 2022, 14, 3620. [Google Scholar] [CrossRef] [PubMed]

- Pešta, J.; Pavlů, T.; Kočí, V. Life Cycle Assessment of Recycling Processes for Demolition Waste. IOP Conf. Ser. Earth Environ. Sci. 2019, 290, 012026. [Google Scholar] [CrossRef]

- Mazzi, A.; Barbiero, C.; Miserocchi, F.; Nisato, F.; Tassinato, G.; Cerchier, P. Life cycle assessment of Al-Cu-Ag-Si recycling process from photovoltaic waste. Resour. Conserv. Recycl. 2024, 211, 107885. [Google Scholar] [CrossRef]

- Ram, V.G.; Kishore, K.C.; Kalidindi, S.N. Environmental benefits of construction and demolition debris recycling: Evidence from an Indian case study using life cycle assessment. J. Clean. Prod. 2020, 255, 120258. [Google Scholar] [CrossRef]

- Rosado, L.P.; Vitale, P.; Penteado, C.S.G.; Arena, U. Life cycle assessment of construction and demolition waste management in a large area of São Paulo State, Brazil. Waste Manag. 2019, 85, 477–489. [Google Scholar] [CrossRef]

- Chen, Y.; Ou, Y.; Mohamed, M.S.; Bao, Z. Life cycle assessment of construction and demolition waste upcycling: A critical review of studies from 2010 to 2025. Dev. Built Environ. 2025, 22, 100685. [Google Scholar] [CrossRef]

- Bilgili, L.; Çetinkaya, A.Y. Environmental impact assessment of earthquake-generated construction and demolition waste management: A life cycle perspective in Turkey. Environ. Syst. Decis. 2024, 44, 424–432. [Google Scholar] [CrossRef]

- Banias, G.F.; Karkanias, C.; Batsioula, M.; Melas, L.D.; Malamakis, A.E.; Geroliolios, D.; Skoutida, S.; Spiliotis, X. Environmental Assessment of Alternative Strategies for the Management of Construction and Demolition Waste: A Life Cycle Approach. Sustainability 2022, 14, 9674. [Google Scholar] [CrossRef]

- Iodice, S.; Garbarino, E.; Cerreta, M.; Tonini, D. Sustainability assessment of Construction and Demolition Waste management applied to an Italian case. Waste Manag. 2021, 128, 83–98. [Google Scholar] [CrossRef] [PubMed]

- Gálvez-Martos, J.-L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef]

- Dierks, C.; Hagedorn, T.; Mack, T.; Zeller, V. Consequential Life Cycle Assessment of Demolition Waste Management in Germany. Front. Sustain. 2024, 5, 1417637. [Google Scholar] [CrossRef]

- Atta, I.; Bakhoum, E.S. Environmental feasibility of recycling construction and demolition waste. Int. J. Environ. Sci. Technol. 2024, 21, 2675–2694. [Google Scholar] [CrossRef]

- Zhao, Y.; Goulias, D.; Tefa, L.; Bassani, M. Life Cycle Economic and Environmental Impacts of CDW Recycled Aggregates in Roadway Construction and Rehabilitation. Sustainability 2021, 13, 8611. [Google Scholar] [CrossRef]

- Jiang, B.; Huang, H.; Ge, F.; Huang, B.; Ullah, H. Carbon Emission Assessment During the Recycling Phase of Building Meltable Materials from Construction and Demolition Waste: A Case Study in China. Buildings 2025, 15, 456. [Google Scholar] [CrossRef]

| No. | Type of Waste | Mass Fraction of Contaminants [%] |

|---|---|---|

| 1 | Brick rubble | 11.4 ± 6.8 |

| 2 | Concrete rubble | 30.8 ± 6.3 |

| 3 | Other rubble waste (hollow bricks, crushed stone, ceramics, etc.) | 18.7 ± 5.9 |

| 4 | Gypsum plasterboards | 8.1 ± 4.8 |

| 6 | Wood (construction and packaging) | 4.9 ± 4.0 |

| 7 | Metals | 3.2 ± 2.2 |

| 8 | Plastics—mainly plastic film, construction polystyrene, and mineral wool | 5.9 ± 3.1 |

| 9 | Paper and cardboard packaging (including bags for adhesives, cement, and mortar) | 2.6 ± 1.1 |

| 10 | Construction and packaging glass | 5.2 ± 2.1 |

| 11 | Soil | 1.6 ± 0.8 |

| 12 | Hazardous waste (packaging from paints and varnishes) | 0.1 ± 0.1 |

| 13 | Other (including textiles, organic materials, electronics, roofing felt, etc.) | 7.5 ± 2.4 |

| No. | Process | Unit | Share of Materials Sent for Recycling | Share of Materials Sent for Further Recovery | Share of Waste Sent to Landfill |

|---|---|---|---|---|---|

| 1 | Installation 1 (n = 10) | % | 2.2 ± 0.9 | 39.9 ± 3.1 | 57.9 ± 3.9 |

| 2 | Installation 2 (n = 10) | % | 11.0 ± 1.3 | 36.2 ± 4.4 | 52.8 ± 4.6 |

| 3 | Installation 3 (n = 10) | % | 13.1 ± 1.4 | 39.6 ± 4.2 | 47.3 ± 4.8 |

| No. | Impact Category | Unit * | Process 1 | Process 2 | Process 3 |

|---|---|---|---|---|---|

| 1 | Climate change | kg CO2 eq | 71.52966 | 18.7309 | 17.6384 |

| 2 | Ozone depletion | kg CFC-11 eq | 1.36 × 10−5 | 1.56 × 10−5 | 1.49 × 10−5 |

| 3 | Terrestrial acidification | kg SO2 eq | 0.402112 | 0.259968 | 0.29452 |

| 4 | Freshwater eutrophication | kg P eq | 0.066238 | 0.078773 | 0.096067 |

| 5 | Marine eutrophication | kg N eq | 0.019783 | 0.032948 | 2.80 × 10−5 |

| 6 | Human toxicity | kg 1,4-DB eq | 44.18279 | 51.55441 | 64.80092 |

| 7 | Photochemical oxidant formation | kg NMVOC | 0.195164 | −0.12266 | −0.1898 |

| 8 | Particulate matter formation | kg PM10 eq | 0.060619 | 0.028752 | 0.019776 |

| 9 | Terrestrial ecotoxicity | kg 1,4-DB eq | 0.002491 | 0.000443 | 0.002971 |

| 10 | Freshwater ecotoxicity | kg 1,4-DB eq | 1.133928 | 1.378836 | 1.766191 |

| 11 | Marine ecotoxicity | kg 1,4-DB eq | 1.080263 | 1.298984 | 1.663928 |

| 12 | Ionizing radiation | kBq U235 eq | 6.684065 | 13.53276 | 17.19614 |

| 13 | Agricultural land occupation | m2a | 2.320457 | −45.7499 | −24.8917 |

| 14 | Urban land occupation | m2a | 0.509066 | −0.03988 | 0.457044 |

| 15 | Natural land transformation | m2 | 0.017242 | 0.020657 | 0.023887 |

| 16 | Water depletion | m3 | 0.210985 | 1.416365 | 1.902959 |

| 17 | Metal depletion | kg Fe eq | −17.9626 | −16.4212 | −22.9917 |

| 18 | Fossil resource depletion | kg oil eq | 40.26342 | −12.0228 | −28.6057 |

| No. | Impact Category | Unit | Process 1 | Process 2 | Process 3 |

|---|---|---|---|---|---|

| 1 | Climate change | kg CO2 eq | 68.00209 | 14.02327 | 9.910011 |

| 2 | Ozone depletion | kg CFC-11 eq | 1.36 × 10−5 | 1.56 × 10−5 | 1.49 × 10−5 |

| 3 | Terrestrial acidification | kg SO2 eq | 0.384152 | 0.236 | 0.255511 |

| 4 | Freshwater eutrophication | kg P eq | 0.062421 | 0.073678 | 0.088407 |

| 5 | Marine eutrophication | kg N eq | 0.018783 | 0.031615 | −0.00202 |

| 6 | Human toxicity | kg 1,4-DB eq | 41.87031 | 48.46835 | 60.25352 |

| 7 | Photochemical oxidant formation | kg NMVOC | 0.187939 | −0.1323 | −0.20584 |

| 8 | Particulate matter formation | kg PM10 eq | 0.055455 | 0.02186 | 0.007485 |

| 9 | Terrestrial ecotoxicity | kg 1,4-DB eq | 0.002748 | 0.000786 | 0.003683 |

| 10 | Freshwater ecotoxicity | kg 1,4-DB eq | 1.108084 | 1.344347 | 1.739121 |

| 11 | Marine ecotoxicity | kg 1,4-DB eq | 1.053006 | 1.262609 | 1.632064 |

| 12 | Ionizing radiation | kBq U235 eq | 6.609716 | 13.43354 | 17.04824 |

| 13 | Agricultural land occupation | m2a | 2.201047 | −45.9092 | −25.1855 |

| 14 | Urban land occupation | m2a | 0.494737 | −0.059 | 0.4279 |

| 15 | Natural land transformation | m2 | 0.017145 | 0.020527 | 0.023563 |

| 16 | Water depletion | m3 | 0.210539 | 1.41577 | 1.861837 |

| 17 | Metal depletion | kg Fe eq | −17.8968 | −16.3335 | −22.8058 |

| 18 | Fossil resource depletion | kg oil eq | 39.32948 | −13.2692 | −30.7083 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malinowski, M.; Basak, Z.; Famielec, S.; Bieszczad, A.; Angrecka, S.; Bodziacki, S. Life Cycle Assessment of the Construction and Demolition Waste Recovery Process. Materials 2025, 18, 4685. https://doi.org/10.3390/ma18204685

Malinowski M, Basak Z, Famielec S, Bieszczad A, Angrecka S, Bodziacki S. Life Cycle Assessment of the Construction and Demolition Waste Recovery Process. Materials. 2025; 18(20):4685. https://doi.org/10.3390/ma18204685

Chicago/Turabian StyleMalinowski, Mateusz, Zuzanna Basak, Stanisław Famielec, Arkadiusz Bieszczad, Sabina Angrecka, and Stanisław Bodziacki. 2025. "Life Cycle Assessment of the Construction and Demolition Waste Recovery Process" Materials 18, no. 20: 4685. https://doi.org/10.3390/ma18204685

APA StyleMalinowski, M., Basak, Z., Famielec, S., Bieszczad, A., Angrecka, S., & Bodziacki, S. (2025). Life Cycle Assessment of the Construction and Demolition Waste Recovery Process. Materials, 18(20), 4685. https://doi.org/10.3390/ma18204685