3.1. Analysis of Temperature Effects on Inductance Under Tensile Load Absence

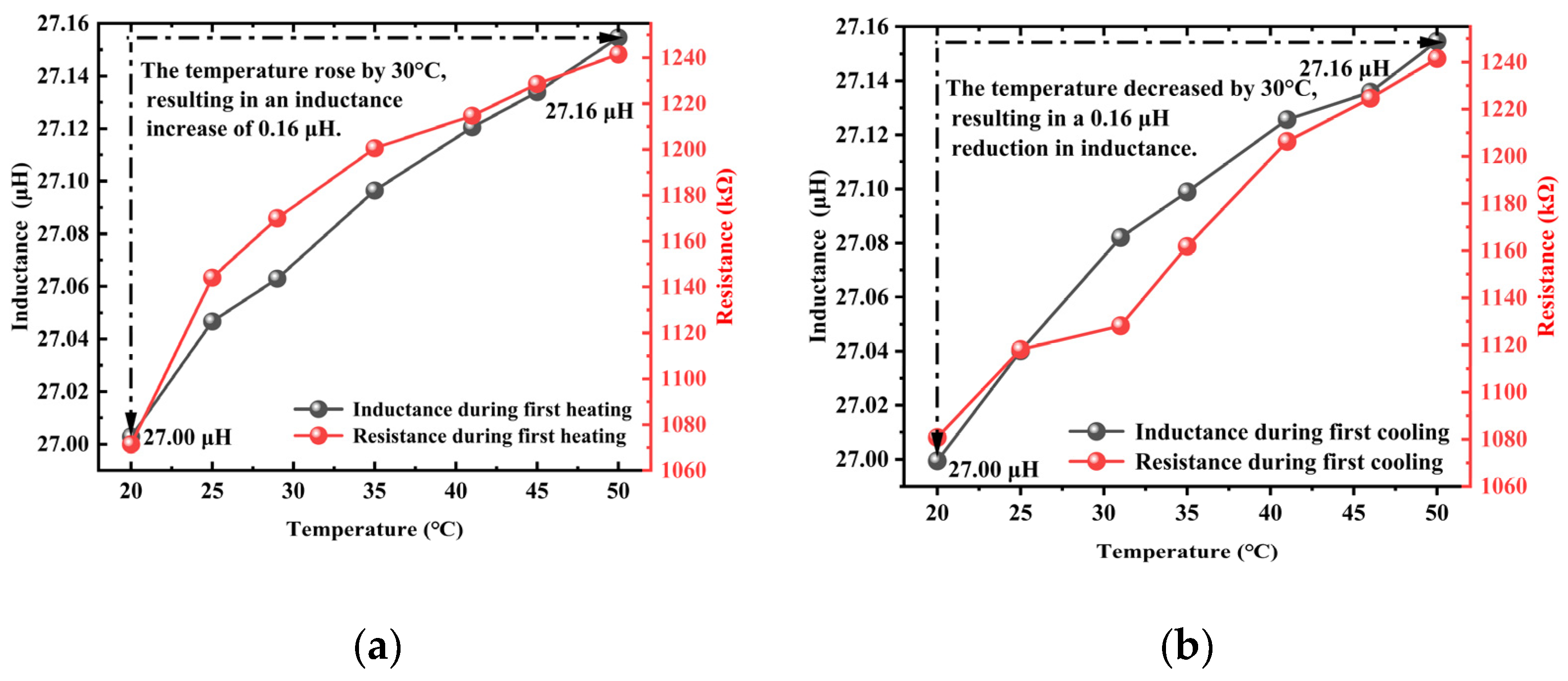

The results of three heating and cooling tests are presented in

Figure 7, where it can be observed that the inductance of the unstressed steel cable increased gradually with temperature, showing a relatively small overall variation amplitude of approximately 0.15 μH. The cooling trend essentially mirrored the heating trend, demonstrating good repeatability and reversibility without significant hysteresis. Compared to the temperature-dependent resistance curve shown in

Figure 5, the inductance curve presented in

Figure 7 was less affected by temperature under the same environmental conditions, showing a much smaller variation amplitude than the resistance curve while maintaining excellent reversibility.

Under thermal loading, the electrical resistance of the steel cable exhibits more pronounced and abrupt variations compared to the relatively stable inductance, which can be attributed to distinct underlying physical mechanisms. The resistance change is primarily influenced by four factors. First, the positive temperature coefficient of the metallic material’s resistivity, where increased lattice vibration amplitudes at elevated temperatures enhance electron scattering, leading to a near-linear rise in resistivity. Second, interfacial contact resistance changes caused by differential thermal expansion between materials such as the steel strand and sensor electrodes, resulting in microscopic gaps or contact pressure variations that induce abrupt resistance jumps. Then, surface oxidation effects accelerated by higher temperatures, particularly in copper or steel elements, where even thin oxide layers introduce additional and often nonlinear interfacial resistance. Finally, non-uniform thermal expansion altering the geometric dimensions of conductive paths, with localized stress concentrations or anisotropic behavior occasionally triggering sharper resistance changes. In contrast, inductance remains comparatively stable due to its dependence on bulk magnetic properties and the magnetoelastic effect, which responds to the average stress and magnetization state within the material. These magnetic characteristics evolve more gradually with temperature, making inductance less sensitive to acute interfacial and surface phenomena that dominate resistance behavior.

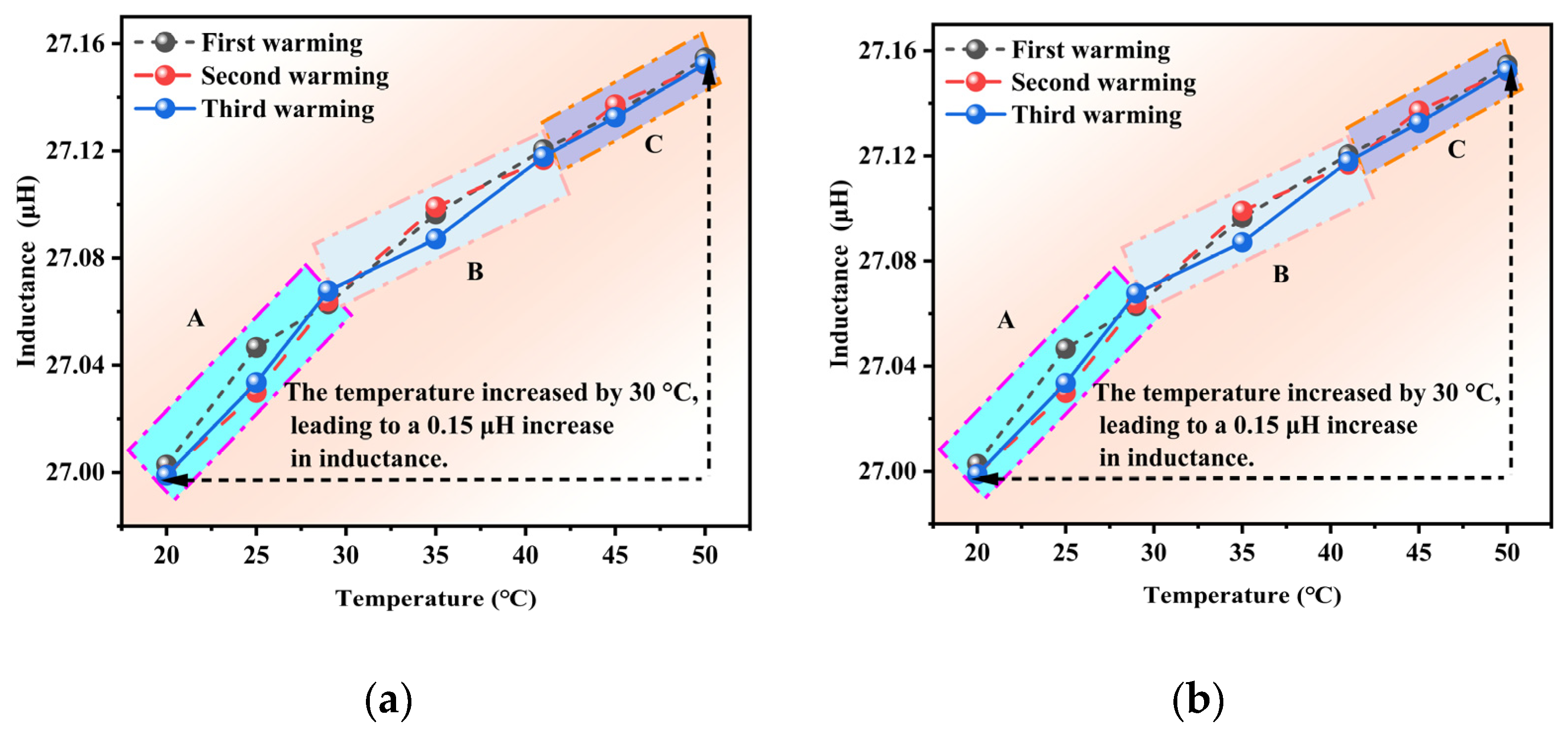

The influence of temperature on inductance is presented in

Figure 8. As shown in

Figure 8a, the inductance value increased with the temperature across all experimental trials and could be categorized into three distinct regions. Based on the difference in inductance values between the three experiments, the variation with temperature can be divided into three regions: A, B, and C. The differences in inductance value between the three tests were as follows: Region A (0.017 μH) > Region B (0.012 μH) > Region C (0.005 μH). A 30 °C temperature increase produced a 0.15 μH. The experimental results revealed distinct temperature-dependent inductance characteristics across the three defined regions. Region A exhibited the most pronounced inductance variations, which could correspond to the temperature-sensitive zone of either the magnetic core’s permeability or the conductor’s resistivity. In contrast, Region C demonstrated significantly attenuated variations, indicating stabilization of both the material properties and structural deformation in this region. In addition, increased conductor resistivity, particularly in copper windings, enhanced the skin effect, reducing effective conduction area and consequently increasing the equivalent inductance. Furthermore, thermal expansion induced micro-deformations in the coil formers and windings, thus modifying inter-turn capacitance and magnetic circuit air gaps, which jointly affected inductance parameters. The non-uniform temperature distributions generated localized stress variations that exacerbated inductance dispersion.

The coil former is made of nylon (thermal expansion coefficient ≈ 80–100 × 10−6/°C), while the copper winding has a coefficient of approximately 17 × 10−6/°C. The significant mismatch in their thermal expansion behaviors induces interfacial stresses during temperature changes, causing the former to expand more than the winding. This differential expansion alters the inter-turn spacing and distorts the magnetic circuit air gap, leading to measurable changes in inductance.

In addition, the core material has a relatively low thermal expansion coefficient (≈10 × 10−6/°C). When combined with the much higher expansion of the nylon former, non-uniform temperature distribution produces localized stress gradients, particularly near material interfaces. These stresses not only contribute to geometric changes (e.g., increased magnetic reluctance due to widening air gaps) but may also leave residual strains after thermal cycling, further dispersing inductance readings over repeated experiments.

As illustrated in

Figure 8b, the inductance value demonstrated a consistent decreasing trend with temperature reduction across all experimental trials, exhibiting three distinct characteristic regions. The inductance variations in the three tests followed a specific pattern of first decreasing, then increasing, and finally decreasing again. Notably, at 40 °C, the observed inductance variation reached 0.017 μH. The experimental data further revealed that a 30 °C temperature decrease corresponded to an inductance reduction of 0.16 μH.

The results showed that lower temperatures reduced the resistivity of copper windings, diminishing the skin effect. This yielded a more uniform current distribution and increased the effective conduction cross-sectional area, ultimately decreasing the equivalent inductance. Second, enhanced domain alignment in ferrite-based soft magnetic materials at reduced temperatures decreased the initial permeability, consequently reducing the inductance value. Third, thermal contraction of coil formers and windings induced microstructural modifications, including changes in inter-turn spacing and adjustments of magnetic circuit air gaps. All these structural alterations jointly influenced the inductance parameters. Furthermore, non-uniform material contraction might introduce mechanical stresses, causing nonlinear variations in the inductance value.

The observed inductance variation of 0.017 μH at 40 °C suggested that this temperature range might correspond to a critical transition point for either material phase change or structural response. During the overall 30 °C cooling process, the inductance decreased by 0.16 μH, demonstrating approximate symmetry with the heating cycle measurements. This near-symmetric behavior indicated that the temperature dependence of inductance exhibited partial reversibility, while the measurable difference confirmed the presence of thermal hysteresis effects. The observed hysteresis could originate from irreversible microstructural modifications or residual stresses accumulated during thermal cycling. This was consistent with the nonlinear variation patterns observed in different temperature regions.

The observed behavior suggested a non-monotonic relationship between temperature changes and inductance variations during the cooling cycles that could potentially have different underlying physical mechanisms compared to the heating process shown in

Figure 8a. The measured 0.16 μH change represents a 6.7% variation relative to the baseline inductance value, which highlights the significant temperature dependence of the system’s electromagnetic properties.

3.2. Analysis of Temperature Effect on Inductance Under Tensile Load

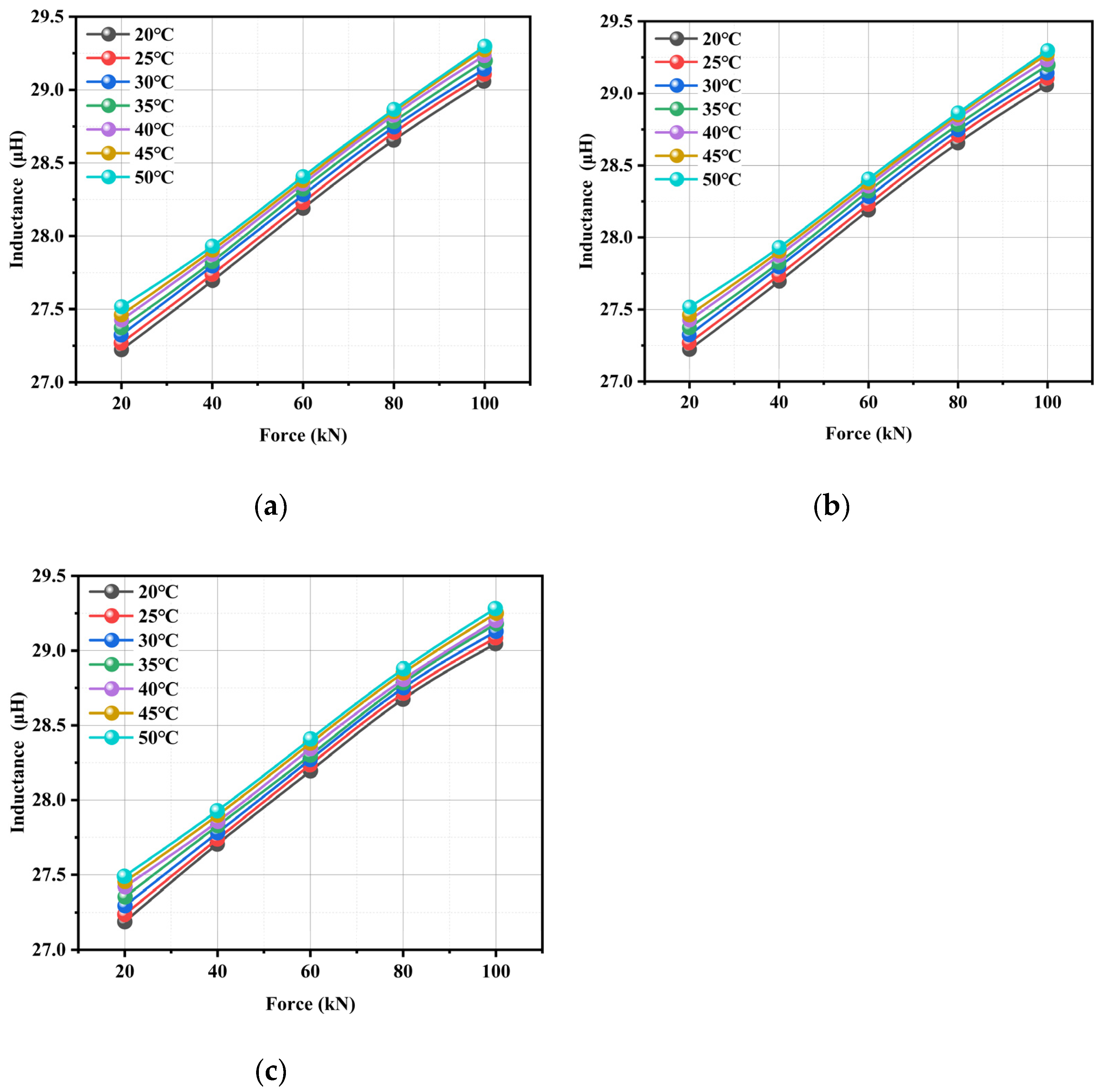

The inductance variations as a function of force are presented in

Figure 9. The results demonstrated that the inductance value increased systematically from approximately 27.25 μH to 29.25 μH with an increasing tensile force under constant temperature conditions. Microstructurally, elastic lattice deformation under tensile stress modified the material’s magnetic permeability characteristics, but geometrically, the decrease in steel cable diameter and the elongation of the helical pitch during stretching significantly altered the electromagnetic parameters. The least-squares regression analysis yielded a linear fit with exceptional correlation (R

2 > 0.99), which validated inductance as a precise indicator of tensile state. The measured force sensitivity of 0.025 μH/kN demonstrated robust performance across the specified thermal range, demonstrating the proposed method’s reliability for structural health monitoring applications.

The inductance exhibited a gradual increase with temperature, demonstrating a stable variation amplitude of (0.2–0.3) μH under a constant tensile load with a 30 °C temperature rise. This phenomenon indicated that when the steel cable inductance increased with temperature, its sensitivity to temperature variation (within the 10 °C range) remained significantly lower compared to the force dependence. Further, enhanced thermal motion in the magnetic field at elevated temperatures increased the material’s effective permeability. Finally, microscale geometric modifications occurred due to thermal expansion.

Under isothermal conditions, the steel cable’s inductance had a well-defined linear relationship with the applied tensile force, which was characterized by a systematic increase in inductance with increasing load. The experimental results revealed that limited temperature variations had a minimal influence on the inductance value; this was demonstrated by the essentially parallel nature of inductance-force curves across different temperature gradients. The observed parallel shift in inductance–force curves across temperature gradients—indicative of minimal temperature–load coupling—can be attributed to multiple underlying mechanisms. Firstly, the influence of mechanical load operates predominantly through the magnetoelastic effect, where stress alters magnetic permeability via domain rotation and deformation-induced anisotropy. In contrast, temperature impacts inductance mainly through thermal expansion and changes in intrinsic magnetic properties such as saturation magnetization. These mechanisms function largely independently, leading to additive rather than coupled effects. Secondly, within the studied range (20–50 °C), both the thermal expansion of materials and the stress-induced changes in magnetic permeability exhibit approximately linear behavior. The superposition of these linear responses results in a parallel displacement of the curves with temperature, without significant slope variation. Thirdly, the sensor structure is designed to limit nonlinear interactions at material interfaces; thermal expansion does not substantially disrupt stress distributions caused by axial loading. Finally, the operating temperatures remain well below the Curie point of the ferromagnetic material, ensuring stable and reversible magnetic responses without irreversible transitions. This decoupling facilitates straightforward temperature compensation in practical applications. This parallelism confirmed the absence of significant force–temperature coupling effects in the electromechanical response.

Physically, thermal variations predominantly alter the material’s intrinsic magnetic properties, while tensile forces concurrently modify both geometric and magnetic parameters. Multiple experiments have validated that the regular exhibited a certain degree of similarity, showing inter-experimental variations of less than 5% in sensitivity coefficients.

3.3. Analysis of Tensile Load Effect on Inductance at Different Temperatures

According to the Joule effect [

30], the relationship between stress and magnetic permeability can be expressed as follows:

where Δ

M is the variation in magnetization intensity;

ε is the axial deformation;

E is the elastic modulus;

l is the steel cable length; Δ

l is the change in the steel cable length under tension;

λs is the axial deformation constant;

Ms is the maturation magnetization intensity;

Ku is the uniaxial magnetic anisotropy constant;

θ0 is the angle between the magnetic field direction and the easy magnetization axis.

The variation in magnetization intensity (Δ

M) is directly related to the product of the change in material permeability and the excitation current [

28]. Substituting this relationship into Equation (1) yields:

where

μ is the magnetic permeability;

μ0 is the permeability of free space;

n is the number of coil turns;

I is the excitation current;

Lw is the effective magnetic path length.

The relationship between magnetic permeability and inductance can be expressed by:

where

Af is the cross-sectional area of the steel cable, and

Aair is the cross-sectional area of the air gap.

By integrating Equations (1)–(3), the relationship between the stress and inductance can be expressed by:

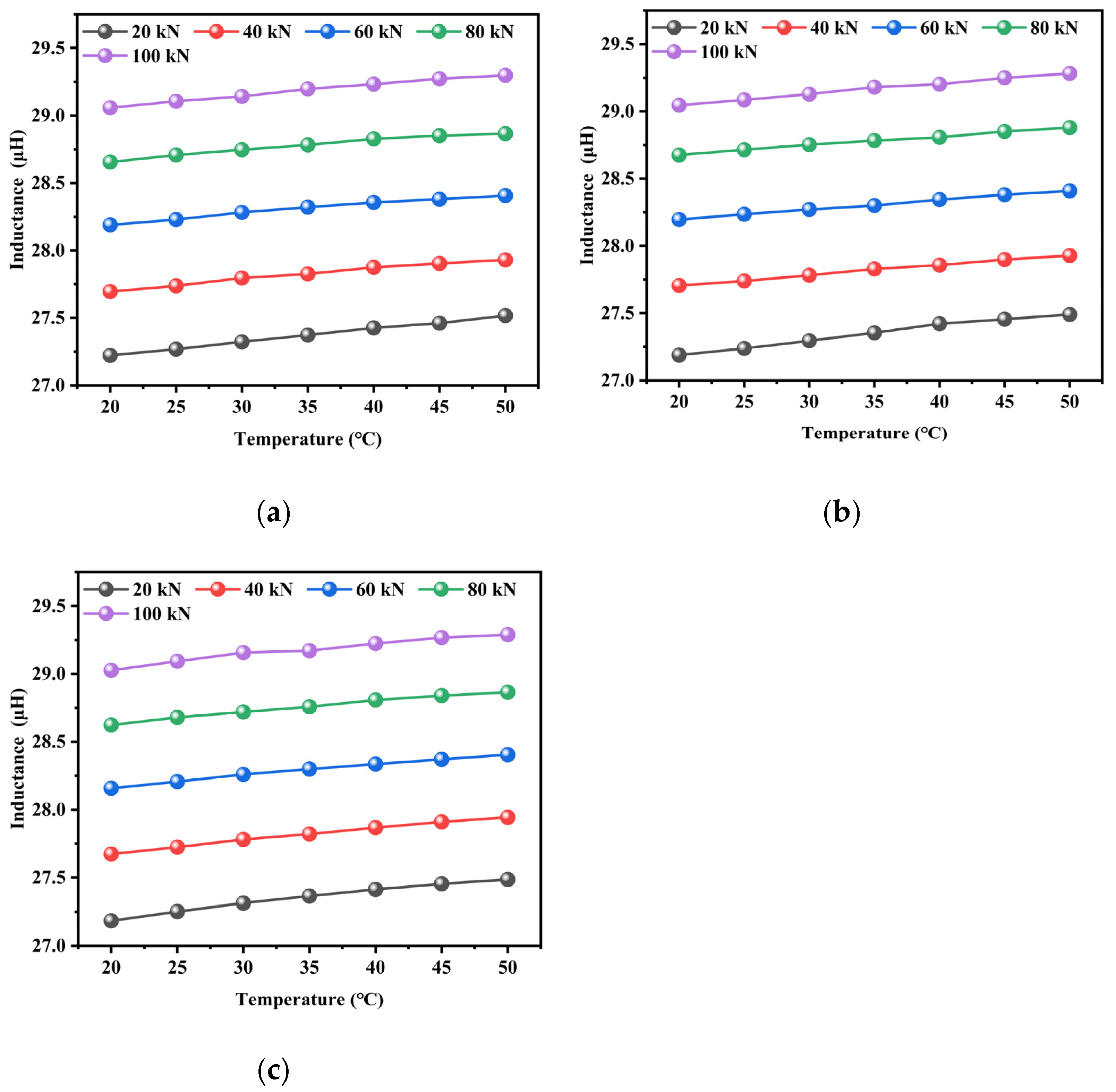

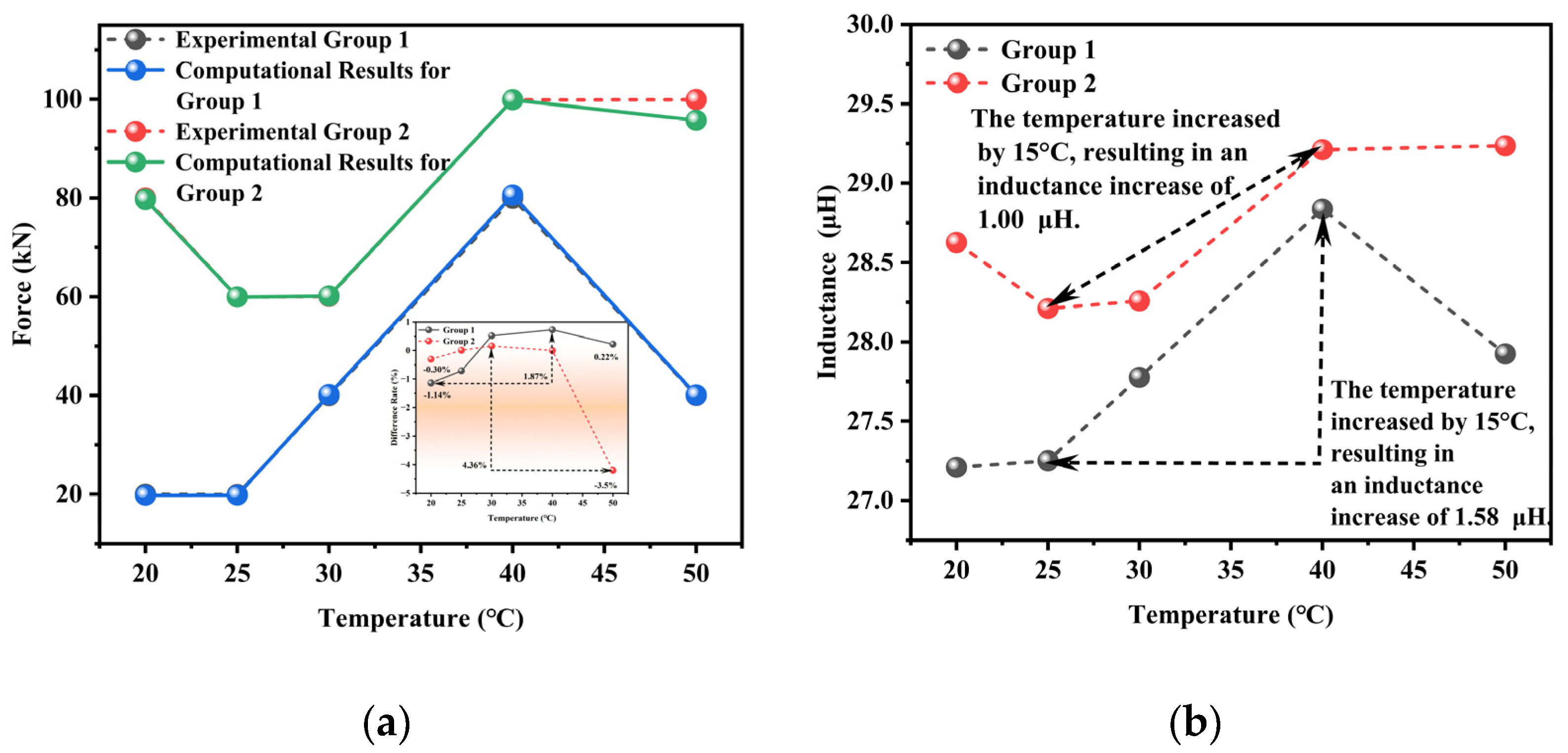

The influence of temperature on the inductance value under different tensile loads is presented in

Figure 10, where it can be seen that the inductance value showed a significant increasing trend with the temperature. Under a constant tensile load of 20 kN, a 250% temperature increase resulted in an inductance increment of 0.26 μH. Particularly, the incremental change in inductance between adjacent temperature intervals exhibited a progressive attenuation with continual temperature increase, and a consistent pattern was observed across various tensile load conditions. The enhanced domain wall mobility caused by thermal activation increased material permeability. Thermally induced geometric dimensional changes in the steel cable were observed, as well as high-temperature relaxation of internal residual stresses that modified domain alignment configurations. The observed reduction in the inductance increment at elevated temperatures indicated that the steel cable was approaching magnetic saturation. Under such conditions, the enhancement effect of the domain wall motion progressively stopped, reducing the rate of inductance variation. The experimental results exhibited excellent reproducibility, and the three tests demonstrated high consistency, with a relative deviation of up to 2.5%. This robustly validated both the reliability and repeatability of the electromagnetic response-based method for axial load detection in steel cables. These findings provide critical insights for temperature-compensated force sensing applications in structural health monitoring systems.

The experimental results clearly demonstrate that the inductance of the steel strand exhibits distinct yet consistent behaviors under the combined influence of tension and temperature. As shown in

Figure 9, under a constant excitation frequency of 10 kHz, the inductance increases strongly and linearly with tension across all tested temperature conditions—rising from approximately 27.25 μH at 20 kN to about 29.25 μH at 100 kN, with an excellent regression fit (R

2 > 0.99). This linear behavior is attributed to stress-induced alterations in magnetic domain alignment and geometric deformations, such as the reduction in strand diameter under load. The effect of temperature variation on inductance is comparatively minor: a temperature increase of 30 °C results in a change of only about 0.15 μH in the unstressed state, demonstrating high reversibility and negligible hysteresis. Furthermore, the inductance-temperature profiles during both heating and cooling show similar trends with segment-dependent sensitivity, where the greatest variability occurred in the medium-temperature region (e.g., a difference of 0.017 μH at 40 °C), suggesting a possible thermally sensitive regime for the magnetic material. The inductance-tension curves obtained at different temperatures remain parallel, indicating that the influences of tension and temperature are largely decoupled. This behavior offers a robust foundation for thermal compensation in practical tension-monitoring applications. The high repeatability observed across three experimental trials (with a relative deviation of less than 2.5%) further confirms the reliability and consistency of the magnetoelastic inductance-based method for accurate tension estimation under varying thermal conditions.

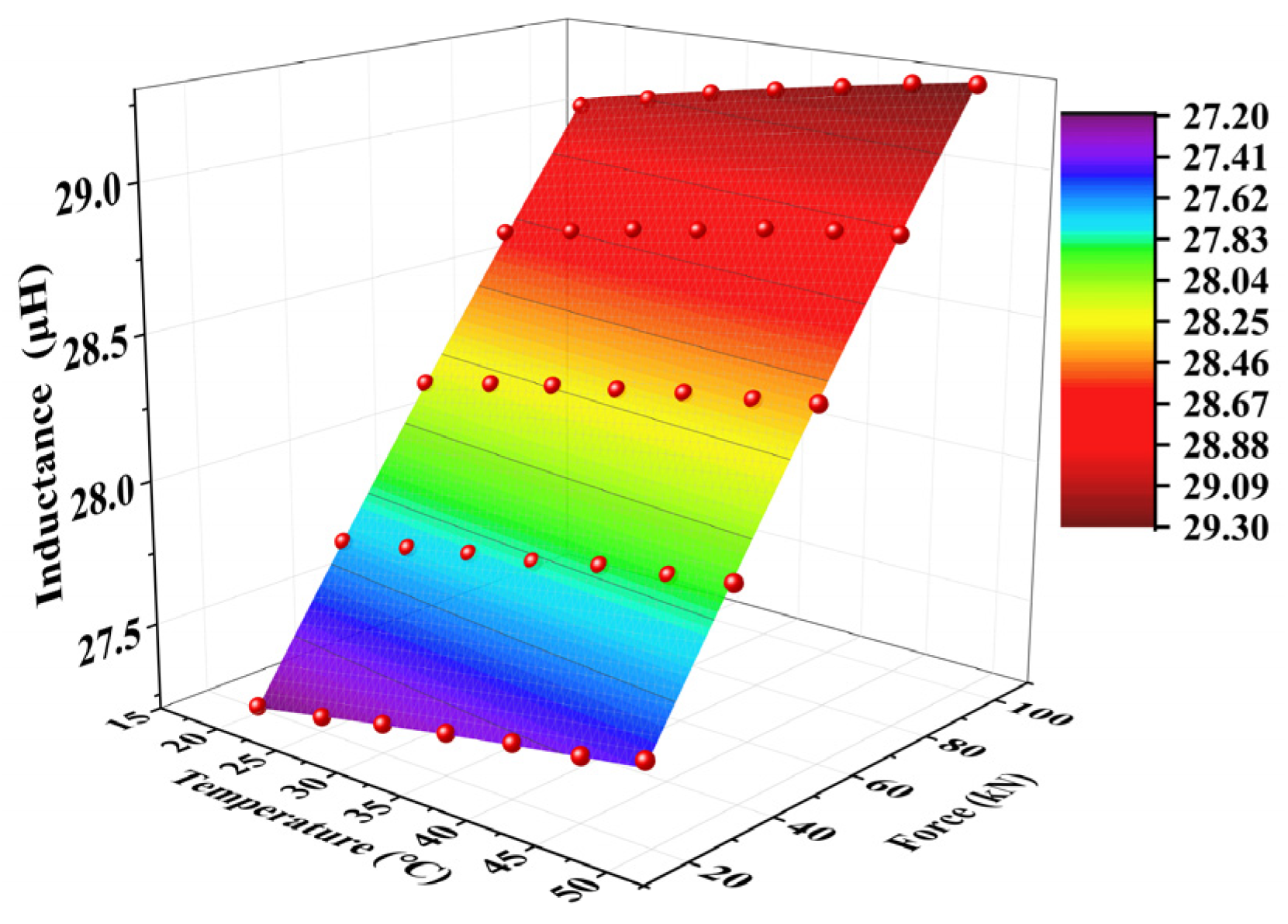

3.4. Curved Surface Fitting Model for Axial Tension Prediction

The systematic experimental investigations of steel cables under varying temperatures (20–50 °C) and tensile loads (20–100 kN) showed that the inductance parameter demonstrated significant feasibility and reproducibility for axial load characterization. Building upon these findings, the data-driven regression model was established in this study. In the proposed model, surface fitting was performed using temperature and tensile load as independent variables and inductance as a dependent variable. This approach yielded a robust fitting model across the three experimental trials, and detailed results are presented in

Figure 11. The proposed model could effectively capture the coupled thermomechanical-electromagnetic behavior, allowing for reliable load estimation through inductance measurements under varying environmental conditions.

The three experimental trials yielded fitting results with high coefficients of determination, where R

2 > 0.999. This demonstrated the proposed model’s high precision in characterizing inductance variations with respect to both tensile load and temperature. However, to ensure a robust correlation between the inductance and axial load across different temperatures, the experimental data were processed by averaging the temperature, load, and inductance values from the three trials. The averaged parameters were used to develop a final quantitative detection model. The resulting fitted model is shown in

Figure 12; this model provided an optimized representation of the temperature-compensated axial load measurement.

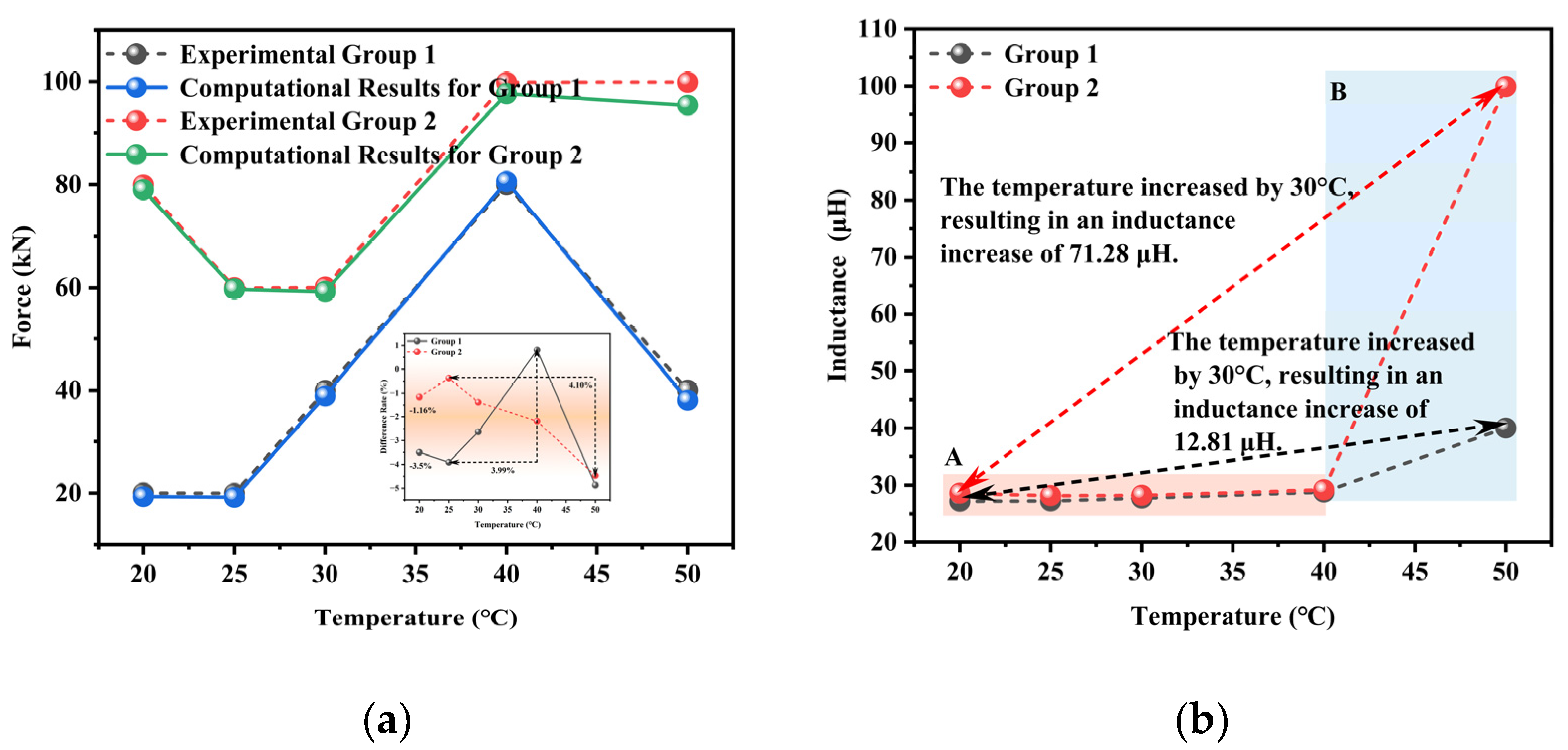

The developed surface fitting model demonstrated excellent goodness-of-fit performance, with a coefficient of determination approaching 0.9994. Next, rigorous validation was conducted using other independent measured datasets similar to the experimental results mentioned above that replicated the original environmental conditions. The tensile load values were obtained by inputting the measured temperature and inductance data into the established surface response function. Further, a physics-based solution screening protocol was used to eliminate non-physical multiple solutions. Finally, a systematic comparison between the model-predicted and experimentally applied loads was conducted.

The error analysis results of the surface fitting model obtained under combined force–temperature conditions are presented in

Figure 13. A comprehensive error analysis was conducted to compare the load values calculated by the quantitative detection model and actual measurement data, and different temperature-dependent error patterns were observed. The experimental data were obtained from laboratory measurements, whereas the theoretical values were calculated using the proposed model. In Experimental Group 1, the error rate exhibited nonlinear variation with temperature increase, namely first decreasing before reaching a peak error of 3.91% and then decreasing again, with a maximum error increment of 3.99% at 60% temperature elevation. The non-monotonic error behavior—initial decrease, peak error of 3.91%, and subsequent decline with temperature rise—stems from competing thermal mechanisms. Initially, reduced viscous damping and enhanced magnetic domain mobility improve response consistency. Around 40% heating duration, non-uniform thermal expansion among components (e.g., cable, sensor core, windings) induces transient misalignments and stress imbalances, elevating error. Beyond this point, the system approaches thermal equilibrium: stress relaxation stabilizes thermal gradients, reducing distortions, while thermal activation of domains and reduced hysteresis enhance signal stability. This behavior highlights the need for effective thermal management and system-wide calibration to ensure reliability across the temperature range. Experimental Group 2 demonstrated different characteristics than Experimental Group 1, showing an initial error increase followed by a reduction, which culminated in a 4.10% error increase at a 100% temperature rise. Fundamentally, both test conditions maintained excellent error control, with all differences falling within the range of −4.87–0.80% and absolute errors remaining below 5%. Temperature-dependent nonlinearity in material permeability increased model deviation at elevated temperatures. In addition, thermal stress gradients induced non-uniform spatial distribution of electromagnetic properties, and measurement system temperature drift introduced additional errors.

Notably, the non-monotonic error–temperature relationship correlated strongly with the material’s nonlinear response characteristics near magnetic saturation. In this study, model validation was performed by inputting multiple independent experimental datasets of

Section 3.1 (containing different temperature and inductance values) into the surface fitting model. The resulting load calculations confirmed the proposed model’s accuracy under identical experimental conditions.

3.5. BPNN-Based Axial Tension Prediction Model

Considering the characteristic trends and data features observed in the curves, a BPNN architecture was selected for training and prediction of the axial tension of a steel cable. After model development and training, a comprehensive performance evaluation was conducted to quantitatively evaluate the proposed model’s prediction accuracy. The proposed model’s predictive capability was systematically evaluated using two established statistical metrics: mean squared error and coefficient of determination. The mean squared error (MSE) was used to measure the absolute deviation between the predicted and experimental values, and the coefficient of determination (

R2) was employed to evaluate the proportion of variance explained by the model. The MSE value was calculated by:

where

n is the total number of samples in a dataset,

is the actual measured value of the

ith sample, and

is the model-predicted value of the

ith sample.

The

R2 value was calculated by:

where

is the mean of the measured values.

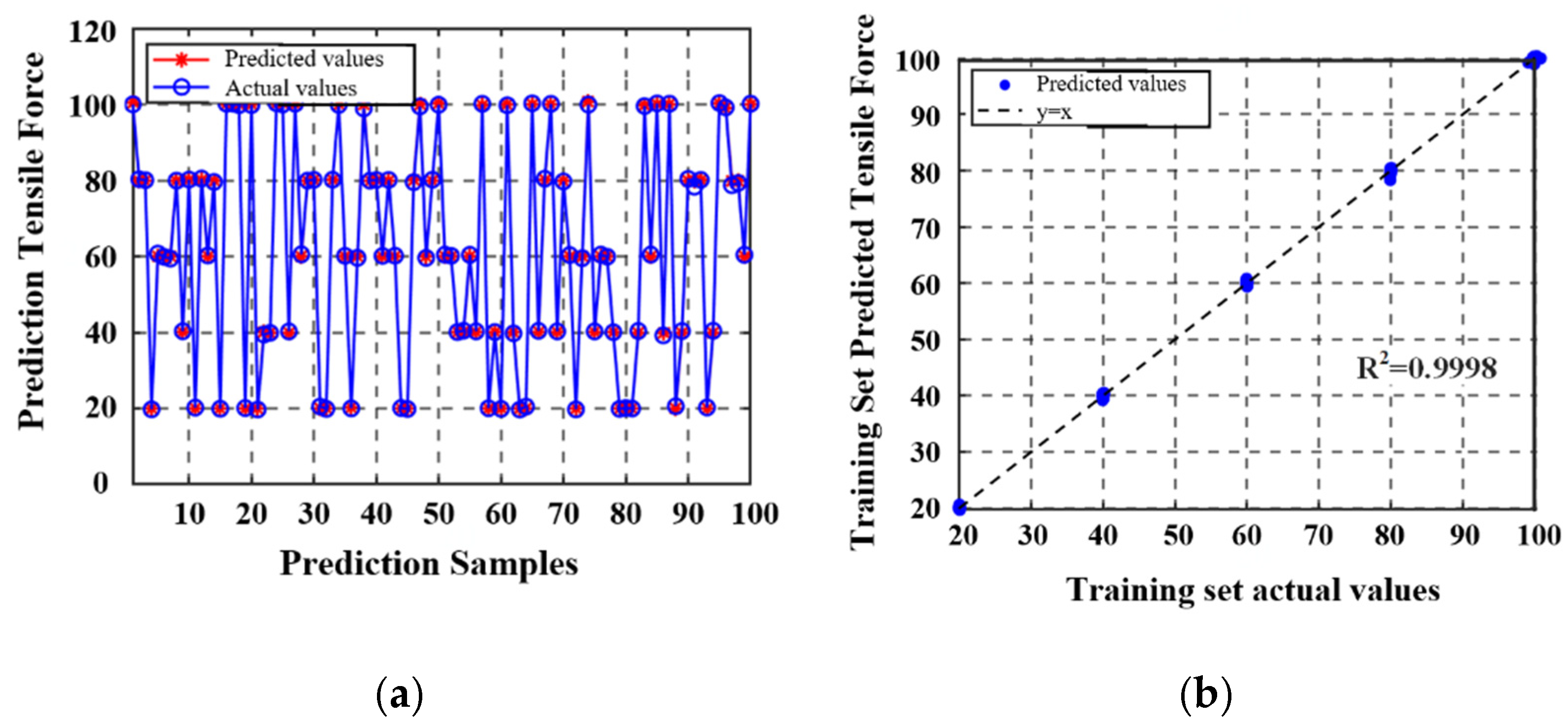

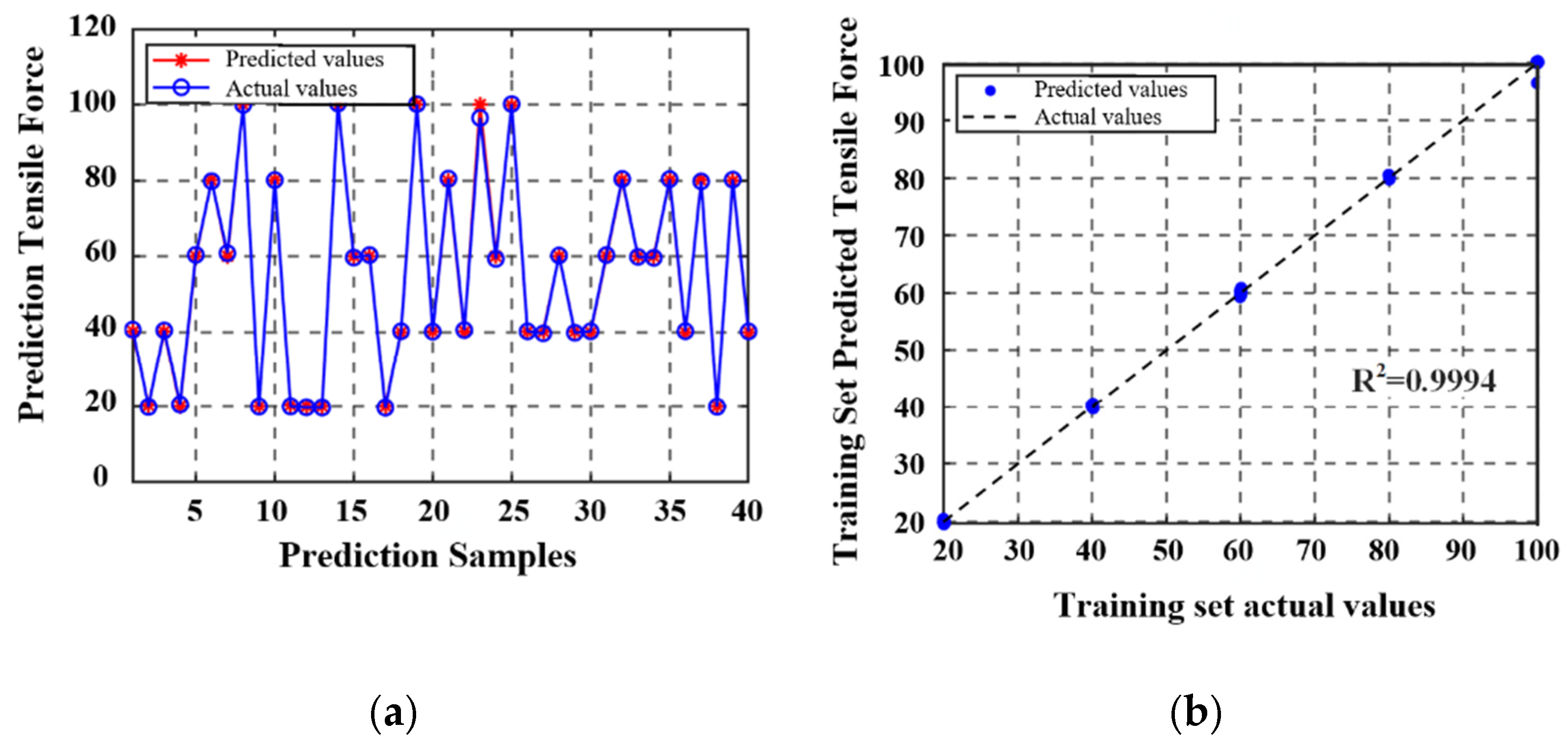

The complete dataset included 140 sets of temperature, inductance, and tensile load measurements and was partitioned into training and testing subsets. Namely, 100 samples were allocated for model training, and the remaining 40 samples were used for independent validation. After model development and evaluation, the prediction performance of the proposed model was visually assessed using comparison plots. The correlation between the predicted and actual values in the training set is presented in

Figure 14; the corresponding validation results for the test set are shown in

Figure 15.

The detection error results of the BPNN-based axial tension prediction model are illustrated in

Figure 16, where it can be seen that the first group exhibited a nonlinear variation trend in the error rate with the temperature increase, which was characterized by an initial increase followed by a decrease. The error rate reached a peak value of 1.14% before declining. When the temperature increased from 20 °C to 40 °C, the error rate increased by only 1.87%, which indicated that the system achieved favorable temperature stability in the normal temperature range. In contrast, the second group displayed a markedly different response characteristic; namely, once the temperature exceeded the 40 °C threshold, the error rate exhibited exponential growth, with an increase of 4.36% in the range of 30–50 °C. The tension calculation errors for both operating conditions were within the −3.50–0.73% range, with absolute errors remaining below 4.50%. Compared to the surface fitting model, the BPNN model achieves a reduced error rate, demonstrating higher prediction accuracy.