Effect of the Degree of Crystallinity of Base Material and Welded Material on the Mechanical Property of Ultrasonically Welded CF/PA6 Joints

Abstract

1. Introduction

2. Materials and Methods

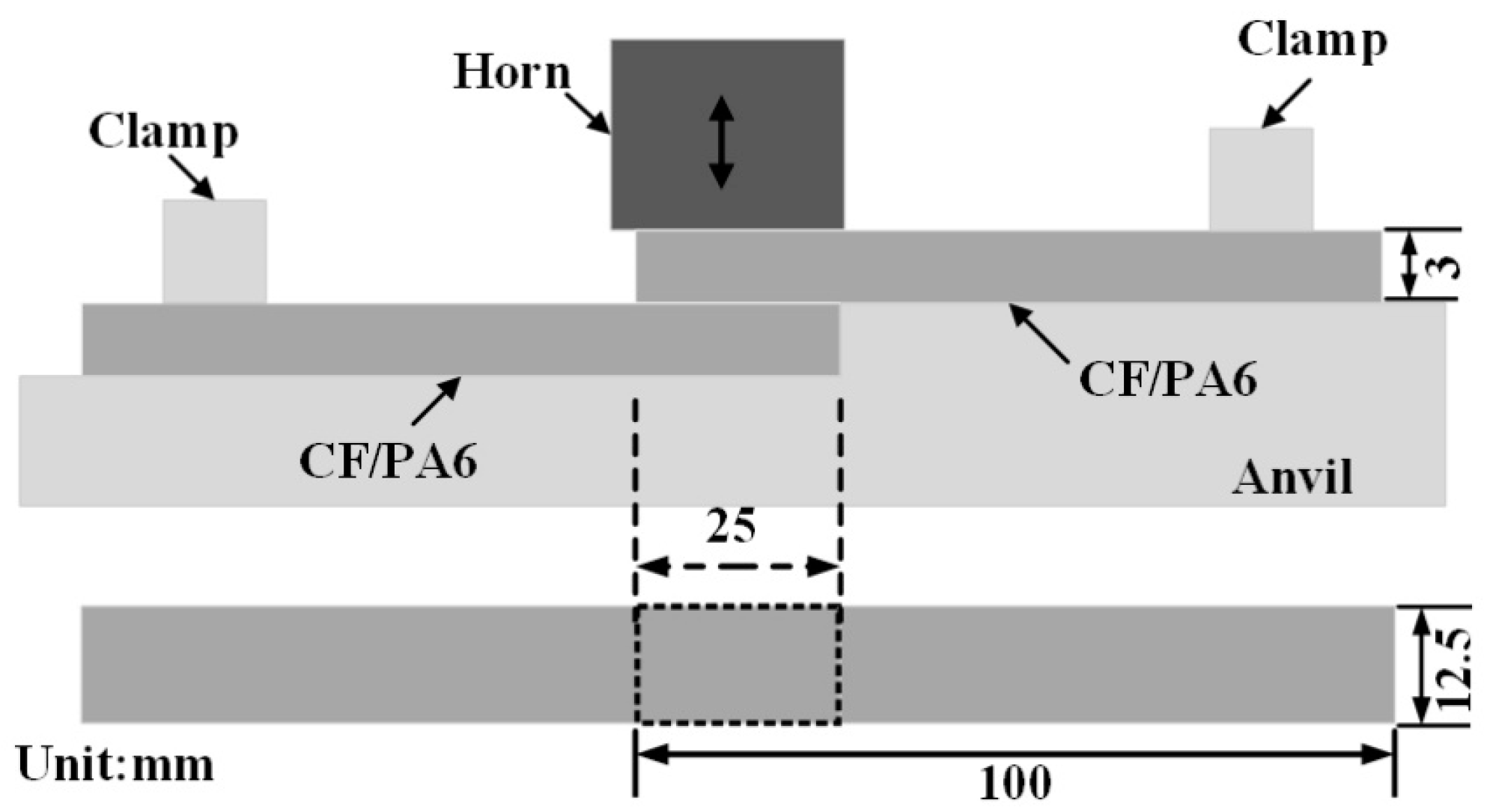

2.1. Material and Experimental Set-Up

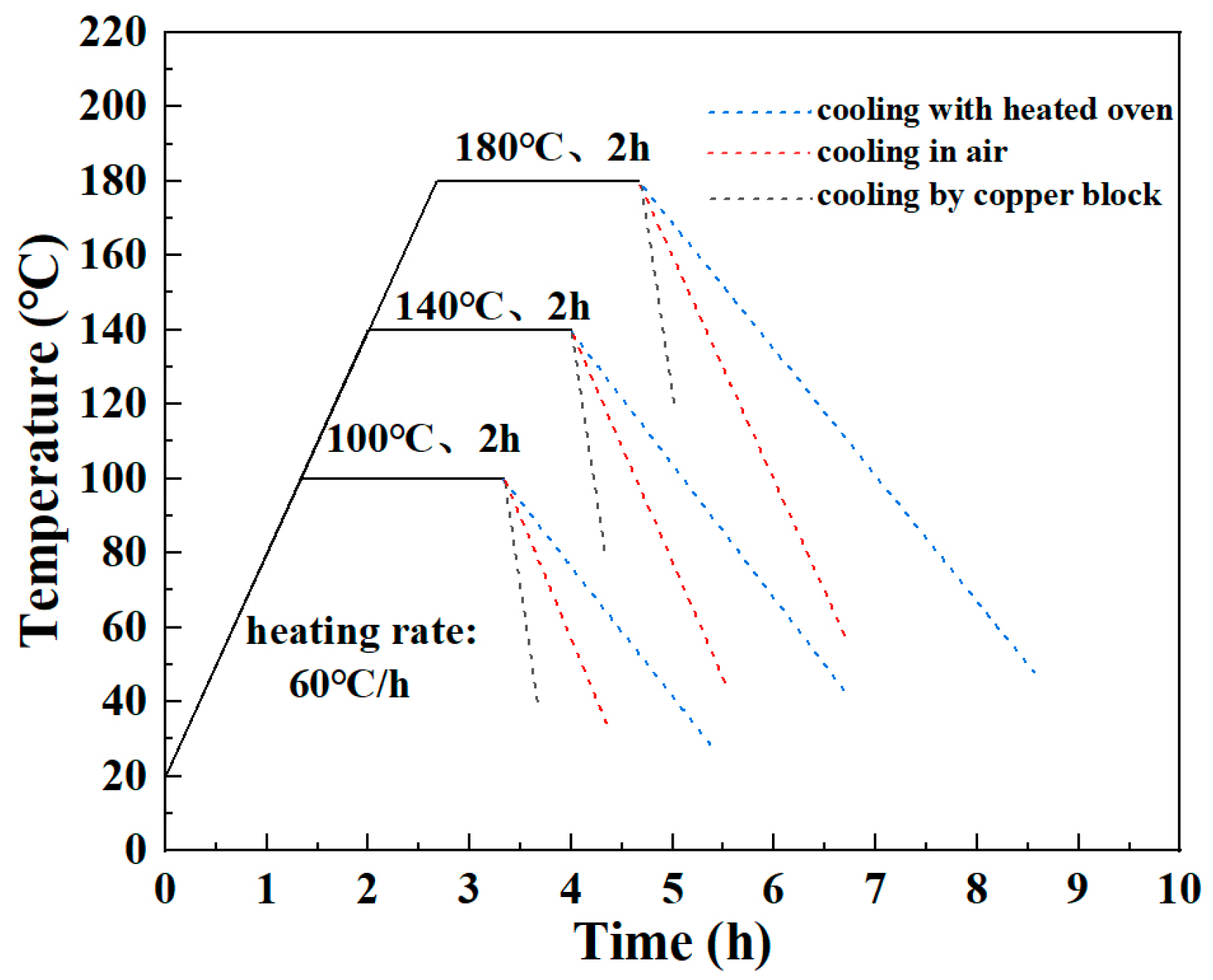

2.2. Heat-Treatment Process

2.3. DSC Analysis

2.4. XRD Analysis

2.5. Temperature Measurement

3. Results

3.1. Effect of the DoC of CF/PA6 Base Material on the USW Process and Joint Strength

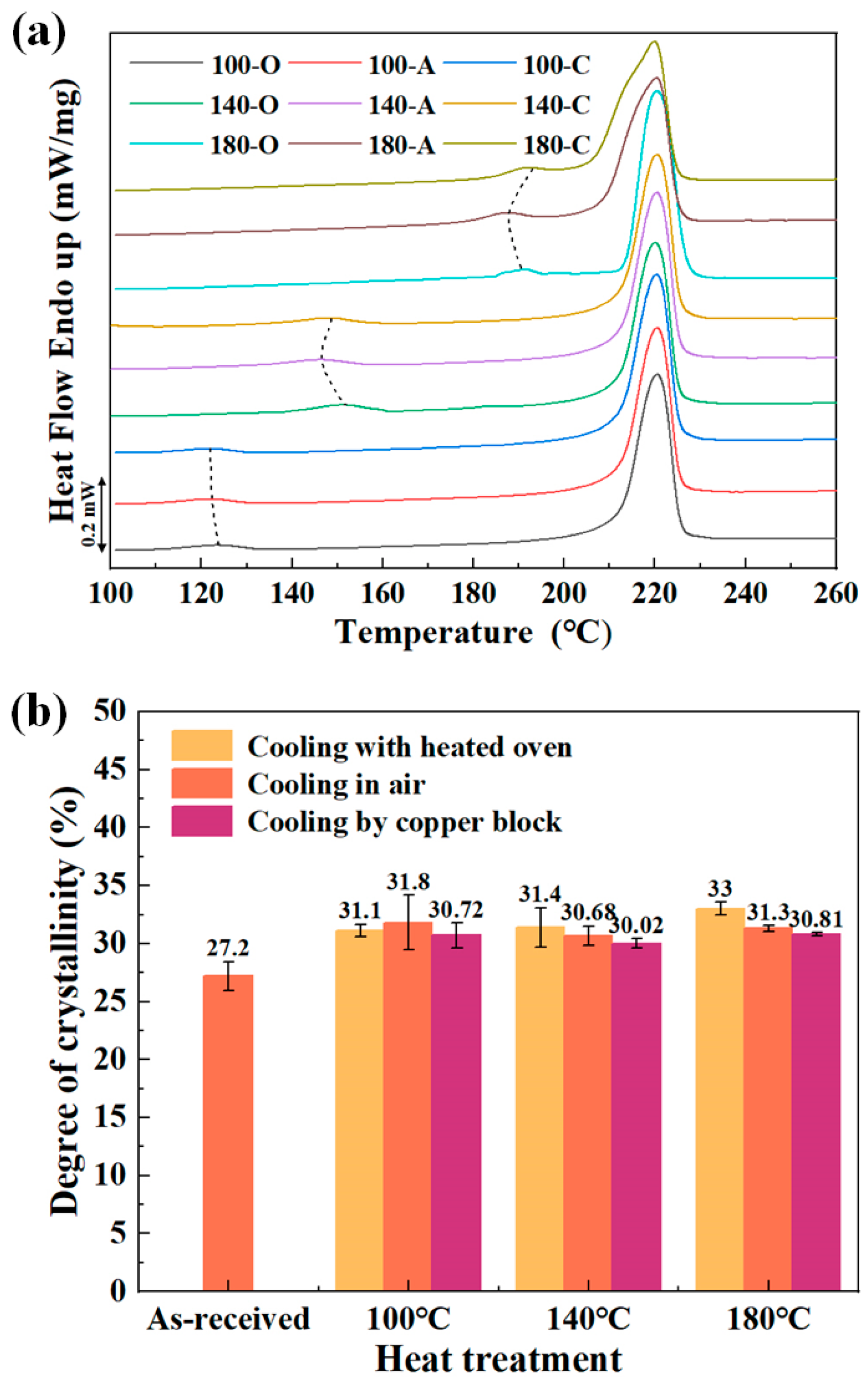

3.1.1. Effect of Heat Treatment on the DoC of CF/PA6

3.1.2. Effect of Heat Treatment on the α/γ Ratio and Crystalline Size

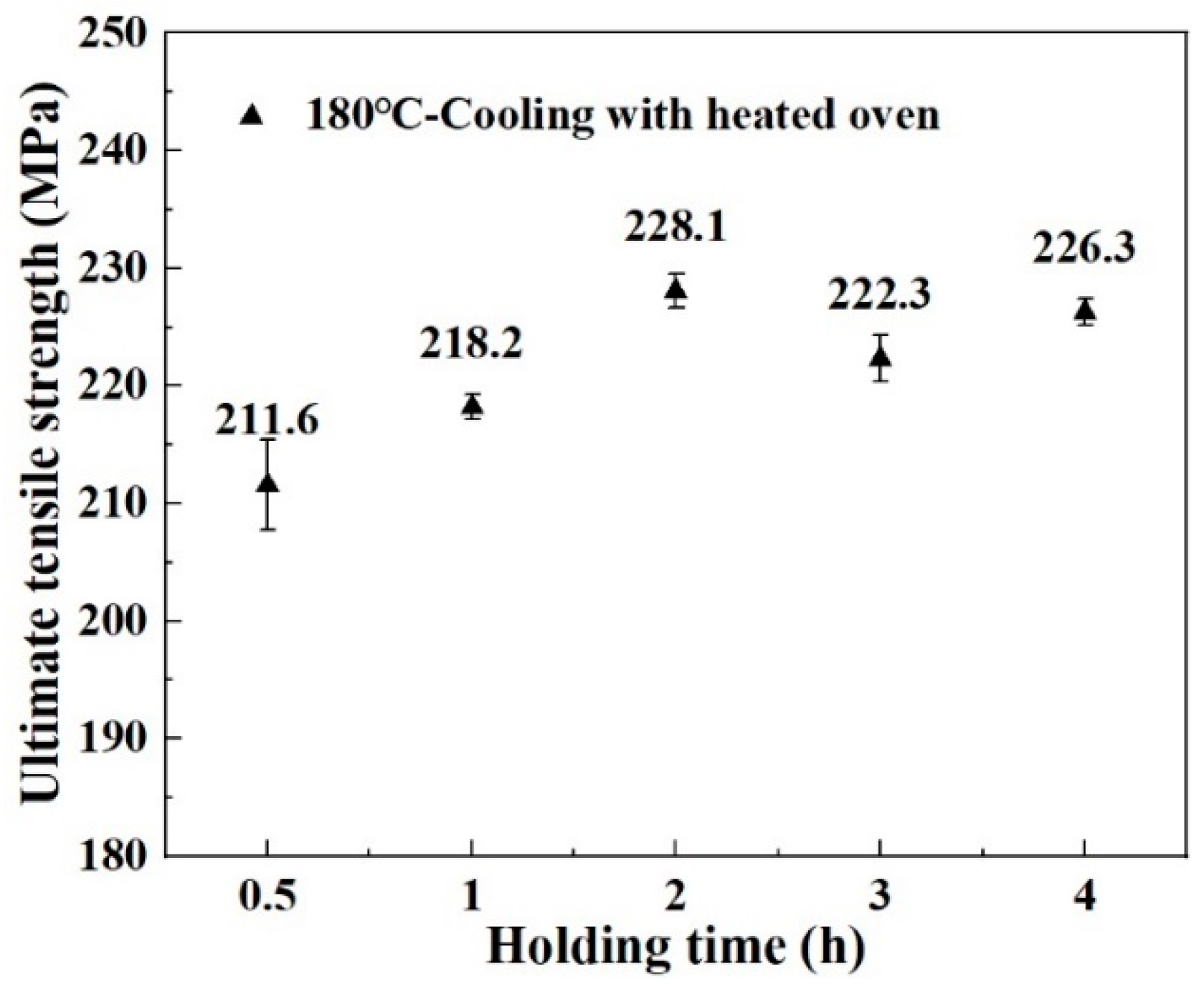

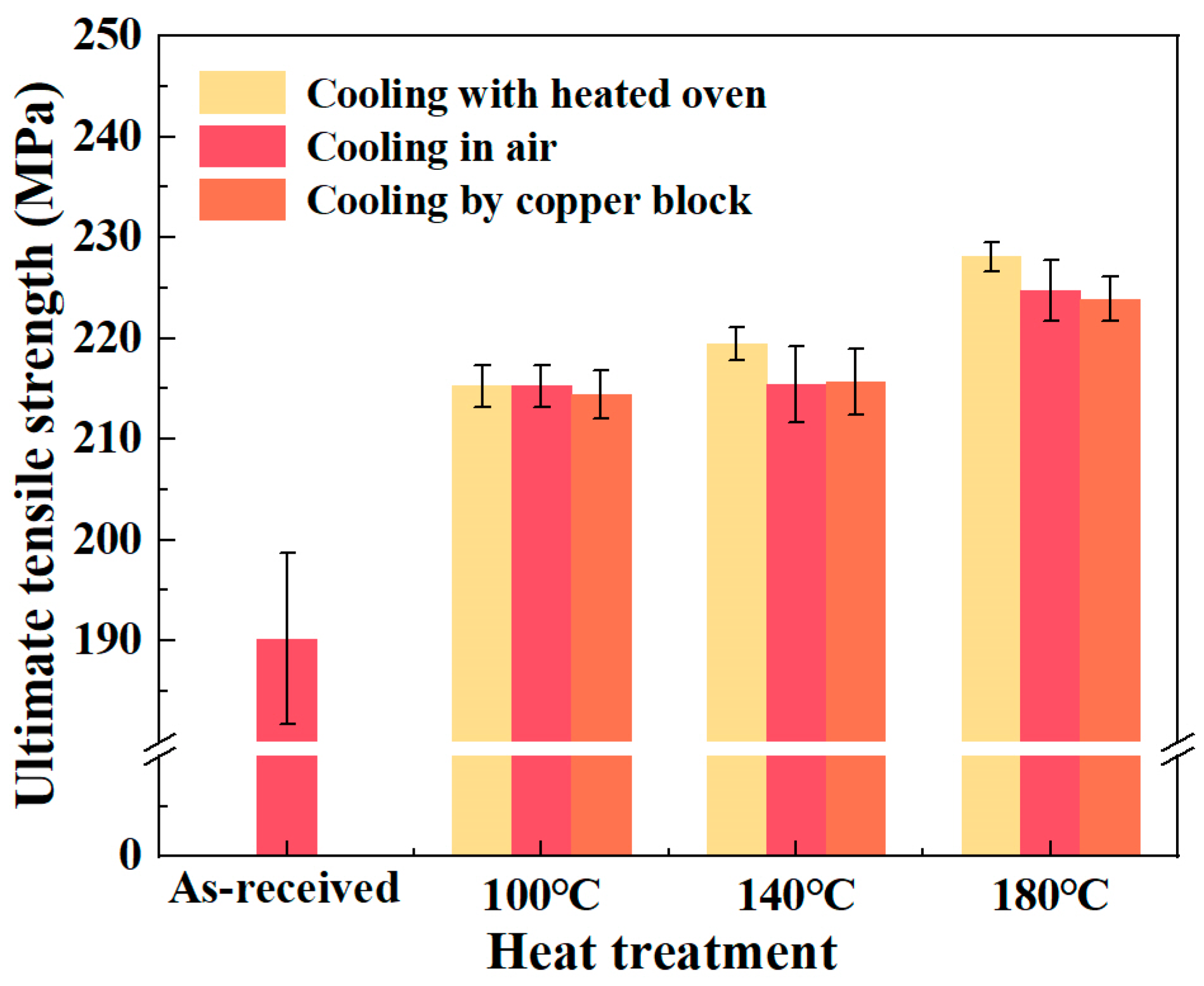

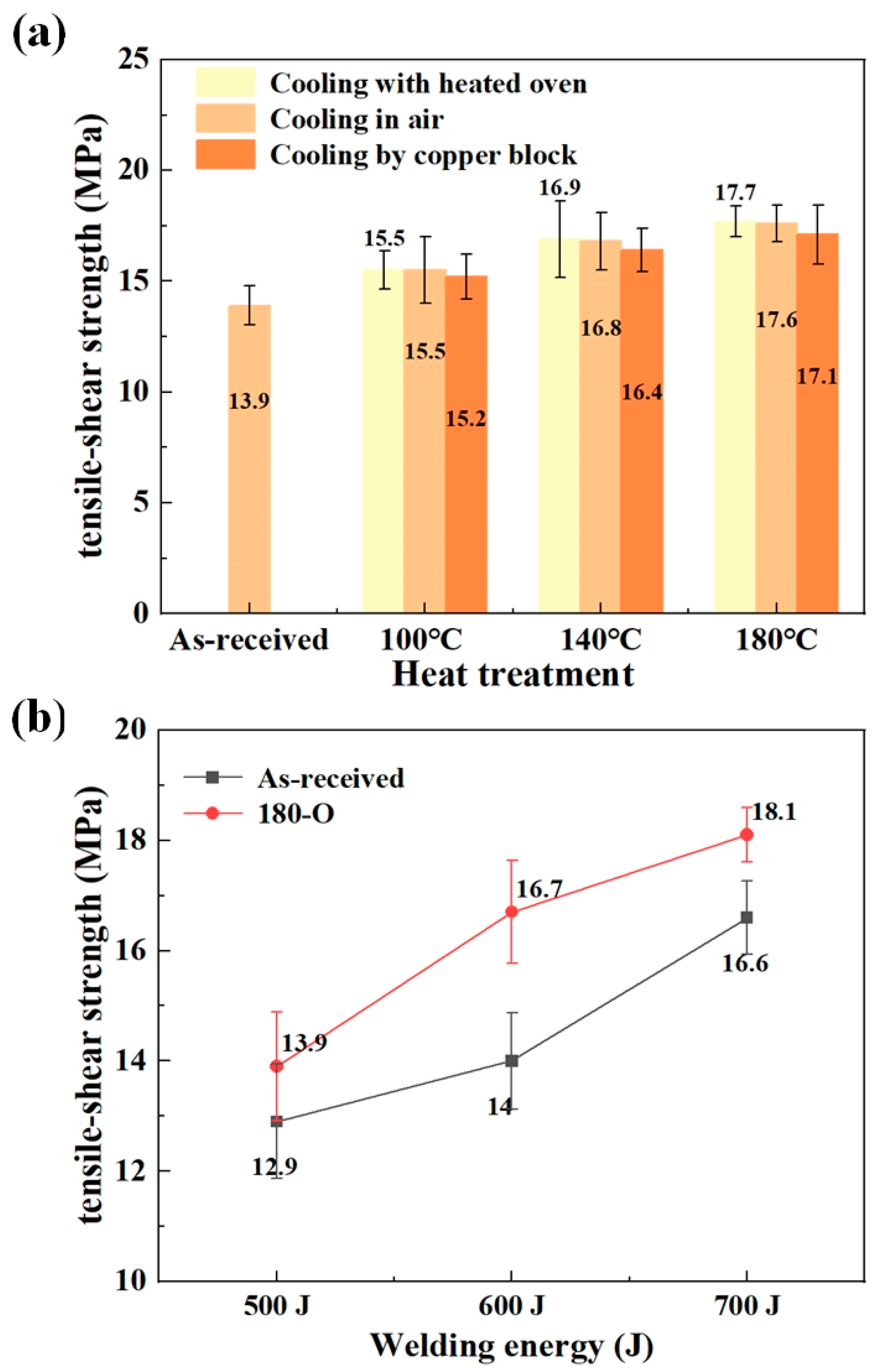

3.1.3. Effect of Heat Treatment on the Joint Strength

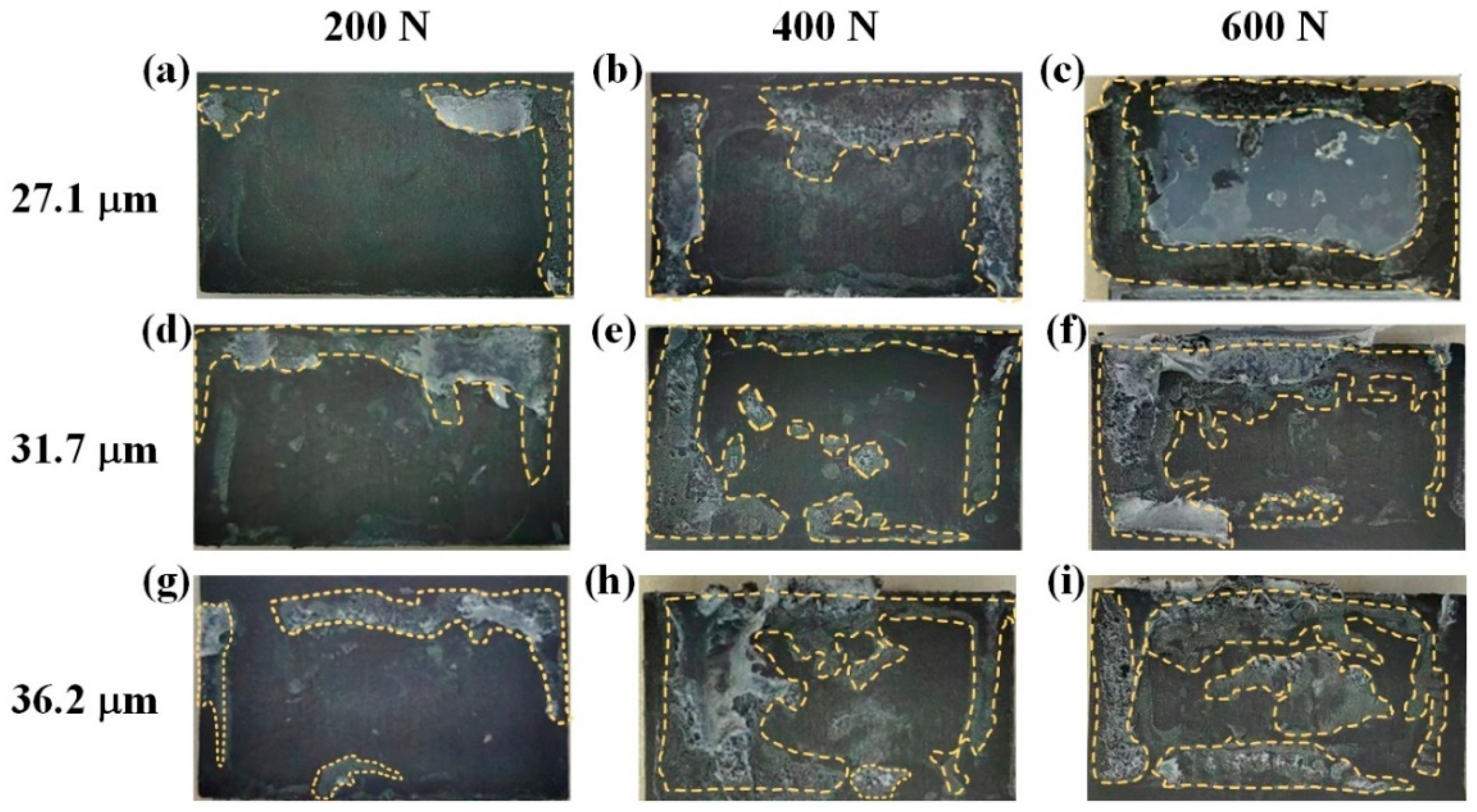

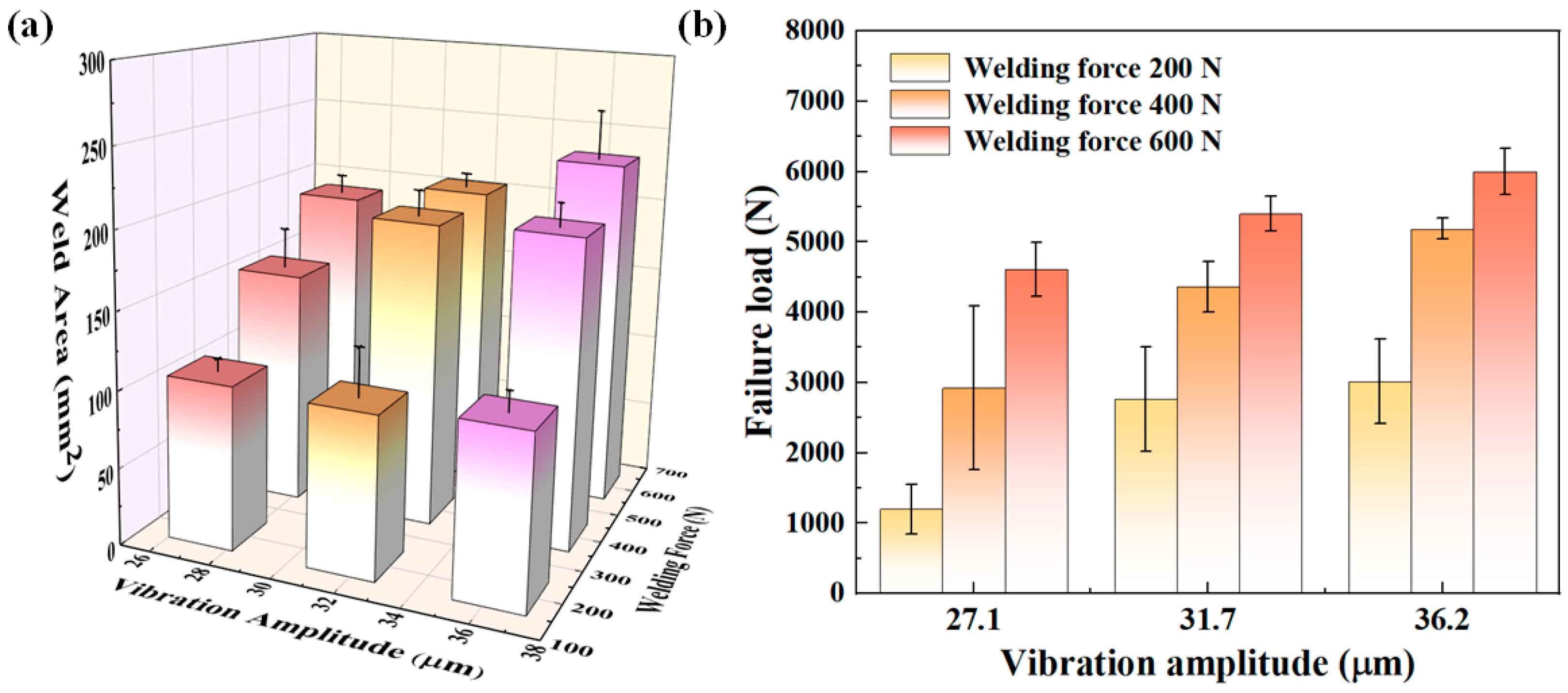

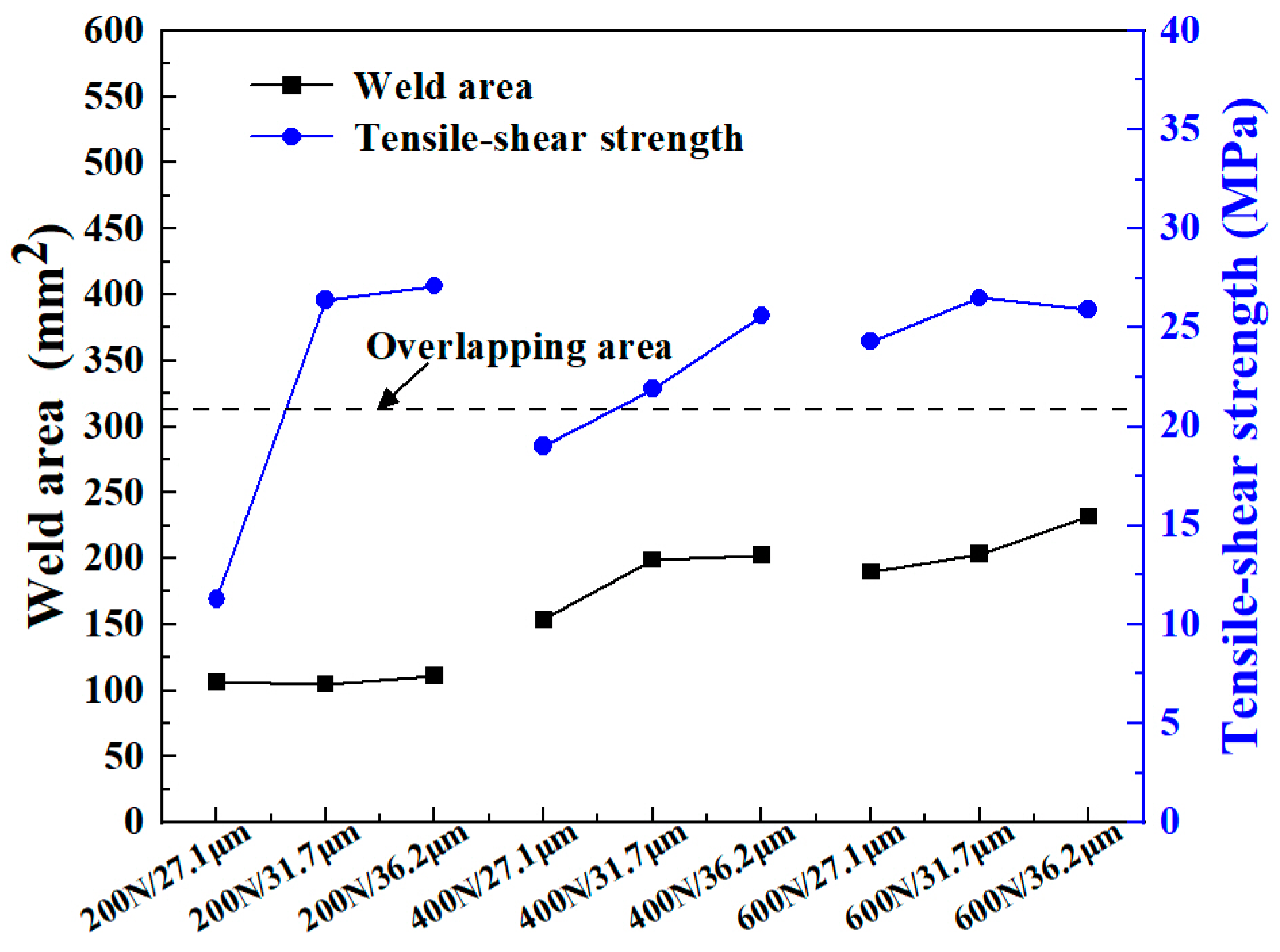

3.2. Effect of Welding Parameters on the DoC at the Welding Interface and Joint Strentgth

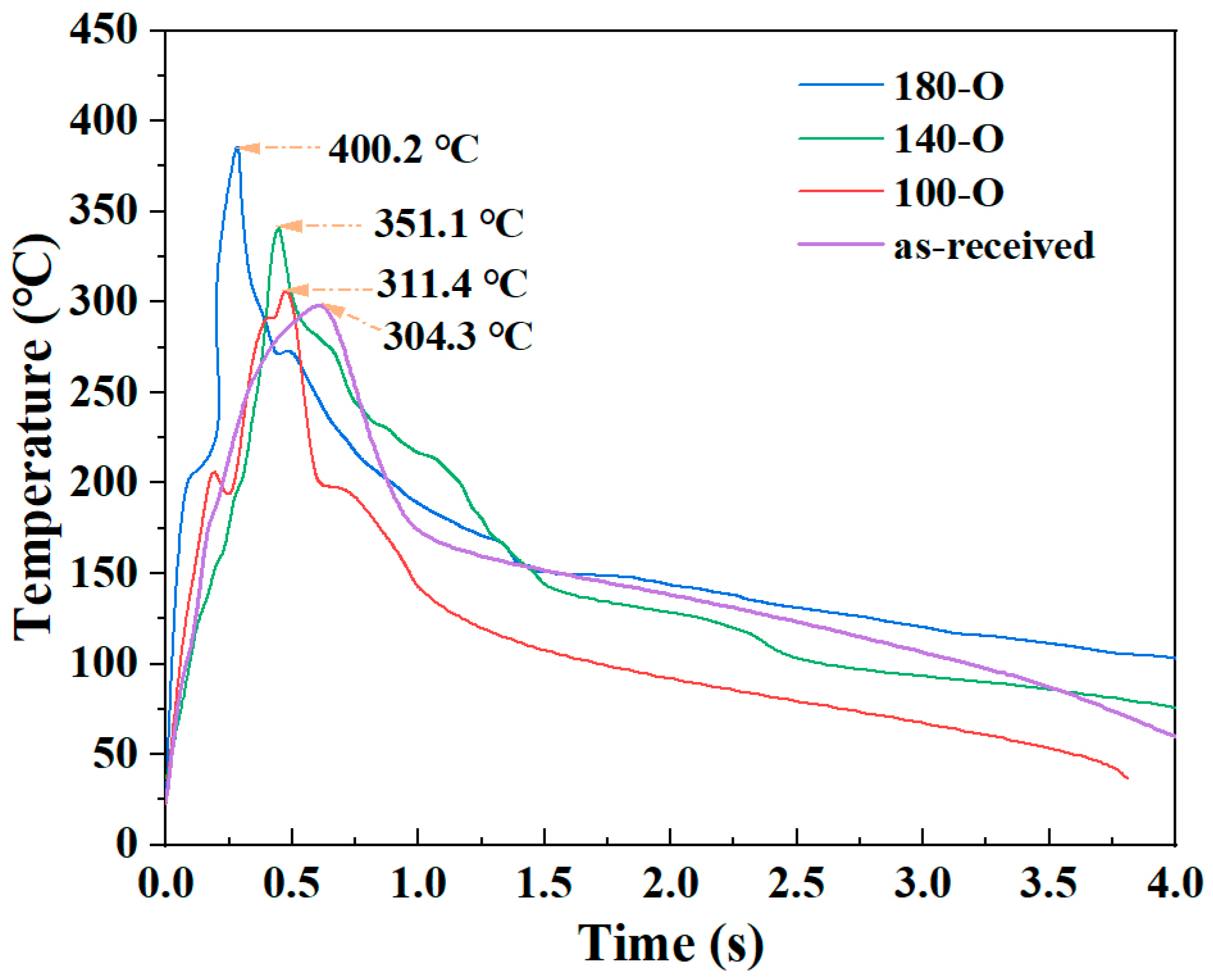

3.2.1. Effect of Welding Parameters on the Cooling Rate at the Welding Interface

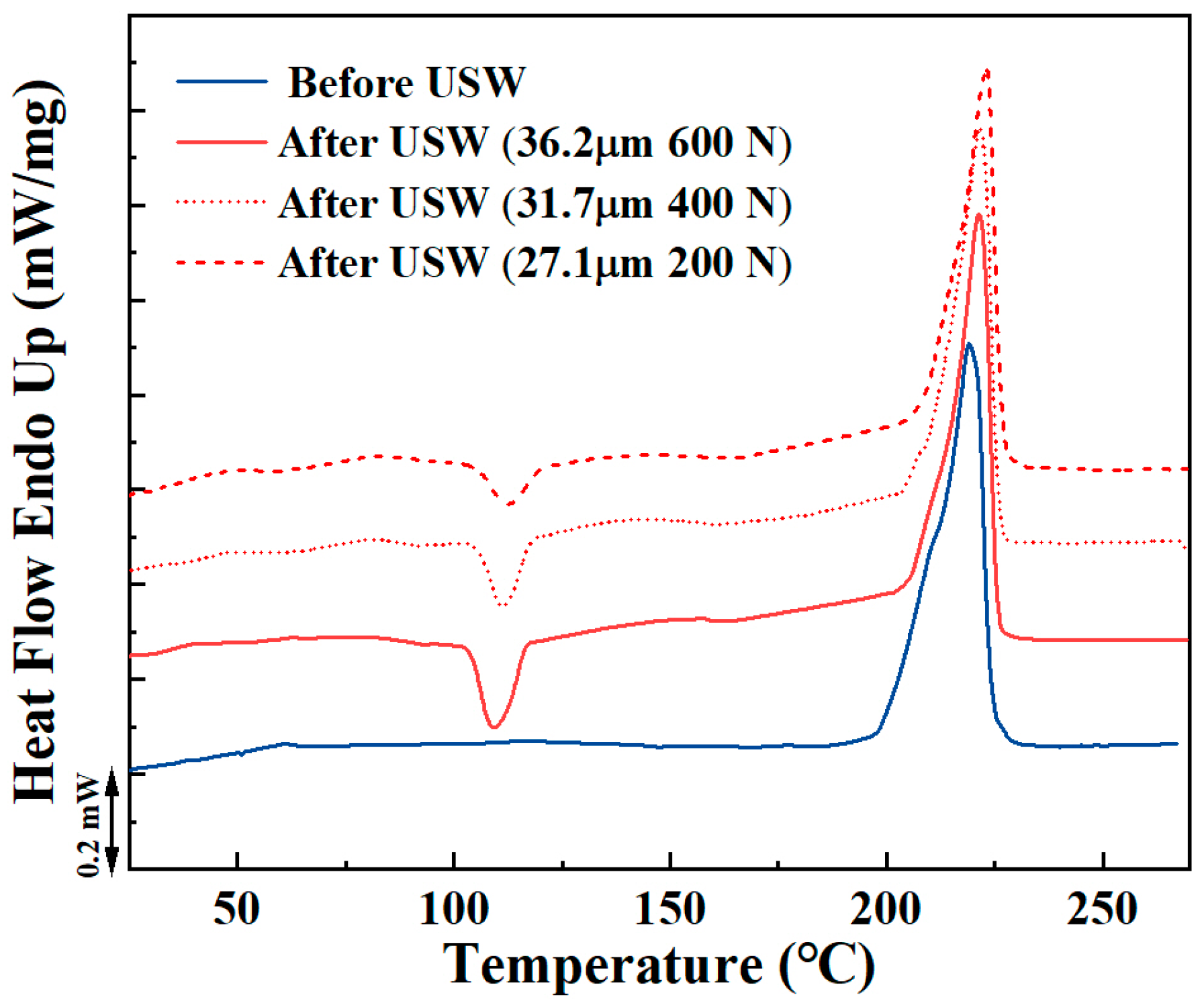

3.2.2. Effect of Welding Parameters on the DoC at the Welding Interface

3.2.3. Effect of Welding Parameters on Joint Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yu, M.; Xiao, R.; Xie, W.; Liu, W.; Ge, L. The effects of temperature and hygrothermal aging on the properties of CF/PA6 composite and its compression failure mechanisms. Polym. Compos. 2024, 45, 10775–10787. [Google Scholar] [CrossRef]

- Zhang, X.; Gohn, A.; Mendis, G.; Buzinkai, J.F.; Weigand, S.J.; Rhoades, A.M. Probing Three Distinct Crystal Polymorphs of Melt-Crystallized Polyamide 6 by an Integrated Fast Scanning Calorimetry Chip System. Macromolecules 2021, 54, 7512–7528. [Google Scholar] [CrossRef]

- Almushaikeh, A.M.; Alaswad, S.O.; Alsuhybani, M.S.; AlOtaibi, B.M.; Alarifi, I.M.; Alqahtani, N.B. Manufacturing of carbon fiber reinforced thermoplastics and its recovery of carbon fiber: A review. Polym. Test. 2023, 122, 108029. [Google Scholar] [CrossRef]

- Vannini, M.; Marchese, P.; Celli, A.; Marega, C.; Lorenzetti, C. Strategy to improve PA6 performances by melt compounding. Polym. Test. 2018, 67, 84–91. [Google Scholar] [CrossRef]

- Zhang, X.; Buzinkai, J.; Quinn, E.; Rhoades, A. Key insights into the differences between bimodal crystallization kinetics of polyamide 66 and polyamide 6. Macromolecules 2022, 55, 9220–9231. [Google Scholar] [CrossRef]

- Li, Y.; Yu, B.; Wang, B.; Lee, T.H.; Banu, M. Online quality inspection of ultrasonic composite welding by combining artificial intelligence technologies with welding process signatures. Mater. Des. 2020, 194, 108912. [Google Scholar] [CrossRef]

- Biswal, A.K.; Nandi, A.; Wang, H.; Vashisth, A. Ultrasonic welding of fiber reinforced vitrimer composites. Compos. Sci. Technol. 2023, 242, 110202. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Leong, K.F.; Islam, A. Advances in Ultrasonic Welding of Thermoplastic Composites, A Review. Materials 2020, 13, 1284. [Google Scholar] [CrossRef]

- Wang, K.; Shriver, D.; Li, Y.; Banu, M.; Hu, S.J.; Xiao, G.; Arinez, J.; Fan, H.T. Characterization of weld attributes in ultrasonic welding of short carbon fiber reinforced thermoplastic composites. J. Manuf. Process. 2017, 29, 124–132. [Google Scholar] [CrossRef]

- Zhao, Q.; Gao, Z.; Wang, H.; Wu, H.; Chen, X.; Qu, Z.; Zhao, T.; Fang, D. On accurate characterization of interfacial morphology and damage evolution of thermoplastic composite welded joints: A microscale study via in-situ micro-CT. Compos. Sci. Technol. 2023, 236, 110004. [Google Scholar] [CrossRef]

- Tian, Z.; Zhi, Q.; Feng, X.; Zhang, G.; Li, Y.; Liu, Z. Effect of Preload on the Weld Quality of Ultrasonic Welded Carbon-Fiber-Reinforced Nylon 6 Composite. Polymers 2022, 14, 2650. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Arinez, J.; Liu, Z.; Lee, T.H.; Fan, H.T.; Xiao, G.; Banu, M.; Hu, S.J. Ultrasonic Welding of Carbon Fiber Reinforced Composite with Variable Blank Holding Force. J. Manuf. Sci. Eng. 2018, 140, 091011. [Google Scholar] [CrossRef]

- Tian, Z.; Zhi, Q.; Zhang, G.; Tan, X.; Lu, L.; Wang, P.; Liu, Z. Influence of Pre-Pressing Ring on the Weld Quality of Ultrasonically Welded Short Carbon Fiber Reinforced Nylon 6 Composite. Polymers 2022, 14, 3115. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Yu, M.; Li, Z.; Ji, C.; Li, J.; Zhang, C.; Shen, J.; Zhou, J.; Zhu, S. Exploring the self-nucleation effect: Transforming crystalline morphology for improved mechanical performance of carbon fiber reinforced polyphenylene sulfide composites. Compos. Part B Eng. 2024, 272, 111231. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, G.; An, P.; Yu, K.; Huang, J.; Gu, Y.; Yao, J.; Cao, R.; Liu, H.; Chen, C.; et al. The effect of cooling rates on crystallization and low-velocity impact behaviour of carbon fibre reinforced poly (aryl ether ketone) composites. Compos. Part B Eng. 2023, 254, 110569. [Google Scholar] [CrossRef]

- Sakai, T.; Shamsudim, N.S.B.; Fukushima, R.; Kageyama, K. Effect of matrix crystallinity of carbon fiber reinforced polyamide 6 on static bending properties. Adv. Compos. Mater. 2020, 30, 71–84. [Google Scholar] [CrossRef]

- Wang, X.; Rao, Z.; Liao, S.; Wang, F. Ultrasonic welding of fiber reinforced thermoplastic composites, Current understanding and challenges. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106578. [Google Scholar] [CrossRef]

- Lee, T.H.; Fan, H.T.; Li, Y.; Shriver, D.; Arinez, J.; Xiao, G.; Banu, M. Enhanced Performance of ultrasonic welding of short carbon fiber polymer composites through control of morphological parameters. J. Manuf. Sci. Eng. 2020, 142, 011009. [Google Scholar] [CrossRef]

- Koutras, N.; Amirdine, J.; Boyard, N.; Villegas, I.F.; Benedictus, R. Characterisation of crystallinity at the interface of ultrasonically welded carbon fibre PPS joints. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105574. [Google Scholar] [CrossRef]

- Uchida, M.; Yoshida, T.; Okada, E.; Touji, M.; Kaneko, Y. Mechanical modeling of polyamide 6 obtained from different thermal histories. Polymer 2024, 296, 126770. [Google Scholar] [CrossRef]

- Kortaberria, G.; Arruti, P.; Jimeno, A.; Serrano, E.; Mondragon, I. Molecular dynamics of poly(glycolide) and poly(glycolide-co-L-lactide) during isothermal cold crystallization. J. Non-Cryst. Solids 2006, 352, 5087–5092. [Google Scholar] [CrossRef]

- Pérez-Martín, H.; Mackenzie, P.; Baidak, A.; Brádaigh, C.M.Ó.; Ray, D. Crystallisation behaviour and morphological studies of PEKK and carbon fibre/PEKK composites. Compos. Part A Appl. Sci. Manuf. 2022, 159, 106992. [Google Scholar] [CrossRef]

- Hu, X.; Zhao, X. Effects of annealing (solid and melt) on the time evolution of polymorphic structure of PA6/silicate nanocomposites. Polymer 2004, 45, 3819–3825. [Google Scholar] [CrossRef]

- Yan, X.; Imai, Y.; Shimamoto, D.; Hotta, Y. Relationship Study Between Crystal Structure and Thermal/Mechanical Properties of Polyamide 6 Reinforced and Unreinforced by Carbon Fiber from Macro and Local View. Polymer 2014, 55, 6186–6194. [Google Scholar] [CrossRef]

- Elahi, M.A.; Koch, M.; Bardon, J.; Addiego, F.; Plapper, P. Failure mechanism analysis based on laser-based surface treatments for aluminum-polyamide laser joining. J. Mater. Process. Technol. 2021, 298, 117318. [Google Scholar] [CrossRef]

- Fornes, T.D.; Paul, D.R. Crystallization behavior of nylon 6 nanocomposites. Polymer 2003, 44, 3945–3961. [Google Scholar] [CrossRef]

- Lee, T.H.; Boey, F.Y.C.; Khor, K.A. On the determination of polymer crystallinity for a thermoplastic PPS composite by thermal analysis. Compos. Sci. Technol. 1995, 53, 259–274. [Google Scholar] [CrossRef]

- Ostberg, C.M.K.; Seferis, J.C. Annealing effects on the crystallinity of polyetheretherketone (PEEK) and its carbon fiber composite. J. Appl. Polym. Sci. 2003, 33, 29–39. [Google Scholar] [CrossRef]

- Lauritzen, J.I.; Hoffman, J.D.J. Crystallization of bulk polymers with chain folding theory of growth of lamellar spherulites. J. Res. Natl. Bur. Stand. A Phys. Chem. 1961, 65, 297–335. [Google Scholar]

- Najeeb, M.A.S.M.; Mahdi, S.H.; Fadil, N.Q. The effect of heat treatment on the degree of crystallinity and grain size for (N6, PS) polymers. J. Xi’an Univ. Archit. Technol. 2020, 12, 4319–4325. [Google Scholar]

- Villegas, I.F. Strength development versus process data in ultrasonic welding of thermoplastic composites with flat energy directors and its application to the definition of optimum processing parameters. Compos. Part A Appl. Sci. Manuf. 2014, 65, 27–37. [Google Scholar] [CrossRef]

- Chien, M.C.; Weiss, R.A. Strain-induced crystallization behavior of poly(ether ether ketone) (PEEK). Polym. Eng. Sci. 2004, 28, 6–12. [Google Scholar] [CrossRef]

- Yaghini, N.; Peters, G.W.M. Modeling Crystallization Kinetics and Resulting Properties of Polyamide 6. Macromolecules 2021, 54, 1894–1904. [Google Scholar] [CrossRef]

- Ullah, M.A.; Palardy, G. Effect of Ultrasonic Welding Process Parameters on the Crystallinity of Gf/Mwcnt/Pp Composites. In Proceedings of the American Society for Composites, Woburn, MA, USA, 18–20 September 2023. [Google Scholar]

| Welding Parameters | Value |

|---|---|

| Welding energy (J) | 500/600/700 |

| Vibration amplitude (μm) | 27.1/31.7/36.2 |

| Welding force (N) | 200/400/600 |

| Trigger force (N) | 600 |

| Specimens | Welding Force (N) | Vibration Amplitude (μm) | Welding Energy (J) |

|---|---|---|---|

| Low Force and Low Amplitude (LF-LA) | 200 | 27.1 | 600 |

| Medium Force and Medium Amplitude (MF-MA) | 400 | 31.7 | 600 |

| High Force and High Amplitude (HF-HA) | 600 | 36.2 | 600 |

| Heat Treatment | Heat-Treatment Temperature (°C) | Cooling Method |

|---|---|---|

| 100-O | 100 | cooling with heated oven |

| 100-A | 100 | cooling in air |

| 100-C | 100 | cooling by copper block |

| 140-O | 140 | cooling with heated oven |

| 140-A | 140 | cooling in air |

| 140-C | 140 | cooling by copper block |

| 180-O | 180 | cooling with heated oven |

| 180-A | 180 | cooling in air |

| 180-C | 180 | cooling by copper block |

| Property | α Form | γ Form |

|---|---|---|

| Crystal structure | Monoclinic | Hexagonal/pseudohexagonal |

| Lattice constants | a = 9.587 Ả | a = 4.931 Ả |

| b = 17.602 Ả | b = 17.267 Ả | |

| c = 7.760 Ả | c = 8.810 Ả | |

| β = 69° | β = 126.8° | |

| Melting point (°C) | 215 | 272 |

| Density (g/cm3) | 1.232 | 1.16 |

| (J/g) | 241 | 239 |

| Young’s modulus (GPa) | 235.29 | 131.97 |

| Heat Treatment | 100-O | 100-A | 100-C | 140-O | 140-A | 140-C | 180-O | 180-A | 180-C |

|---|---|---|---|---|---|---|---|---|---|

| Tm1 (°C) | 123.9 | 121.9 | 120.9 | 152.9 | 146 | 149.9 | 191 | 188.1 | 192.4 |

| Tm2 (°C) | 220.9 | 219.9 | 219.8 | 221.1 | 220 | 221 | 220 | 221.1 | 220.3 |

| Welding Force and Vibration Amplitude | Maximum Power (W) (Cov %) | Vibration Time (ms) (Cov %) |

|---|---|---|

| 200 N/27.1 μm | 473 ± 61 (12.9) | 1667 ± 187 (11.2) |

| 400 N/27.1 μm | 848 ± 58 (6.9) | 1147 ± 73 (6.4) |

| 600 N/27.1 μm | 1248 ± 35 (2.8) | 794 ± 124 (15.7) |

| 200 N/31.7 μm | 567 ± 23 (4.0) | 1279 ± 53 (4.1) |

| 400 N/31.7 μm | 1001 ± 80 (8.0) | 790 ± 20 (2.5) |

| 600 N/31.7 μm | 1577 ± 148 (9.4) | 626 ± 82 (13.1) |

| 200 N/36.2 μm | 726 ± 34 (4.7) | 1069 ± 88 (8.3) |

| 400 N/36.2 μm | 1355 ± 54 (4.0) | 683 ± 15 (2.1) |

| 600 N/36.2 μm | 2061 ± 137 (6.6) | 440 ± 24 (5.5) |

| Temperature Region | 220~150 °C | 150~100 °C |

|---|---|---|

| HF-HA | 232 °C/s | 58.4 °C/s |

| MF-MA | 136.4 °C/s | 49.1 °C/s |

| LF-LA | 96.4 °C/s | 18.4 °C/s |

| Specimen | ΔHm (J/g) | DoC (%) (CoV %) | Tm (°C) | Tc (°C) | ΔHcc (J/g) |

|---|---|---|---|---|---|

| ED_ref | 74.48 ± 6.29 | 31.1 ± 2.62 (8.4) | 221.65 ± 1.39 | -- | -- |

| ED_HF-HA | 62.14 ± 5.09 | 22.9 ± 2.12 (10) | 222.87 ± 0.79 | 108.01 ± 0.57 | 6.99 ± 1.39 |

| ED_MF-MA | 53.96 ± 10.32 | 19.8 ± 4.34 (21.9) | 222.00 ± 0.36 | 111.32 ± 2.18 | 4.87 ± 1.49 |

| ED_LF-LA | 51.07 ± 7.92 | 18.3 ± 3.37 (18.4) | 223.14 ± 0.93 | 112.07 ± 2.93 | 3.89 ± 1.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, R.; Li, M.; Ao, S.; Li, Y. Effect of the Degree of Crystallinity of Base Material and Welded Material on the Mechanical Property of Ultrasonically Welded CF/PA6 Joints. Materials 2025, 18, 420. https://doi.org/10.3390/ma18020420

Shi R, Li M, Ao S, Li Y. Effect of the Degree of Crystallinity of Base Material and Welded Material on the Mechanical Property of Ultrasonically Welded CF/PA6 Joints. Materials. 2025; 18(2):420. https://doi.org/10.3390/ma18020420

Chicago/Turabian StyleShi, Ruoya, Mingyang Li, Sansan Ao, and Yang Li. 2025. "Effect of the Degree of Crystallinity of Base Material and Welded Material on the Mechanical Property of Ultrasonically Welded CF/PA6 Joints" Materials 18, no. 2: 420. https://doi.org/10.3390/ma18020420

APA StyleShi, R., Li, M., Ao, S., & Li, Y. (2025). Effect of the Degree of Crystallinity of Base Material and Welded Material on the Mechanical Property of Ultrasonically Welded CF/PA6 Joints. Materials, 18(2), 420. https://doi.org/10.3390/ma18020420