The Effects of Deep Cryogenic Treatment with Regard to the Mechanical Properties and Microstructural Evolution of Al-Mg Alloys with Different Grain Sizes

Abstract

1. Introduction

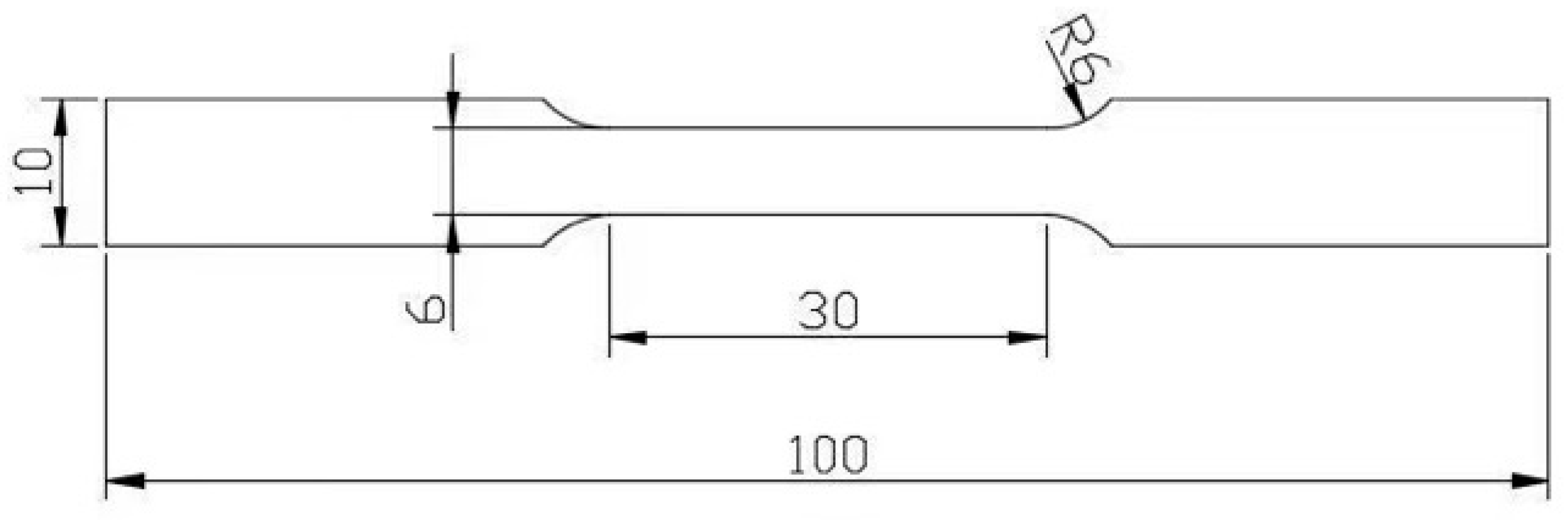

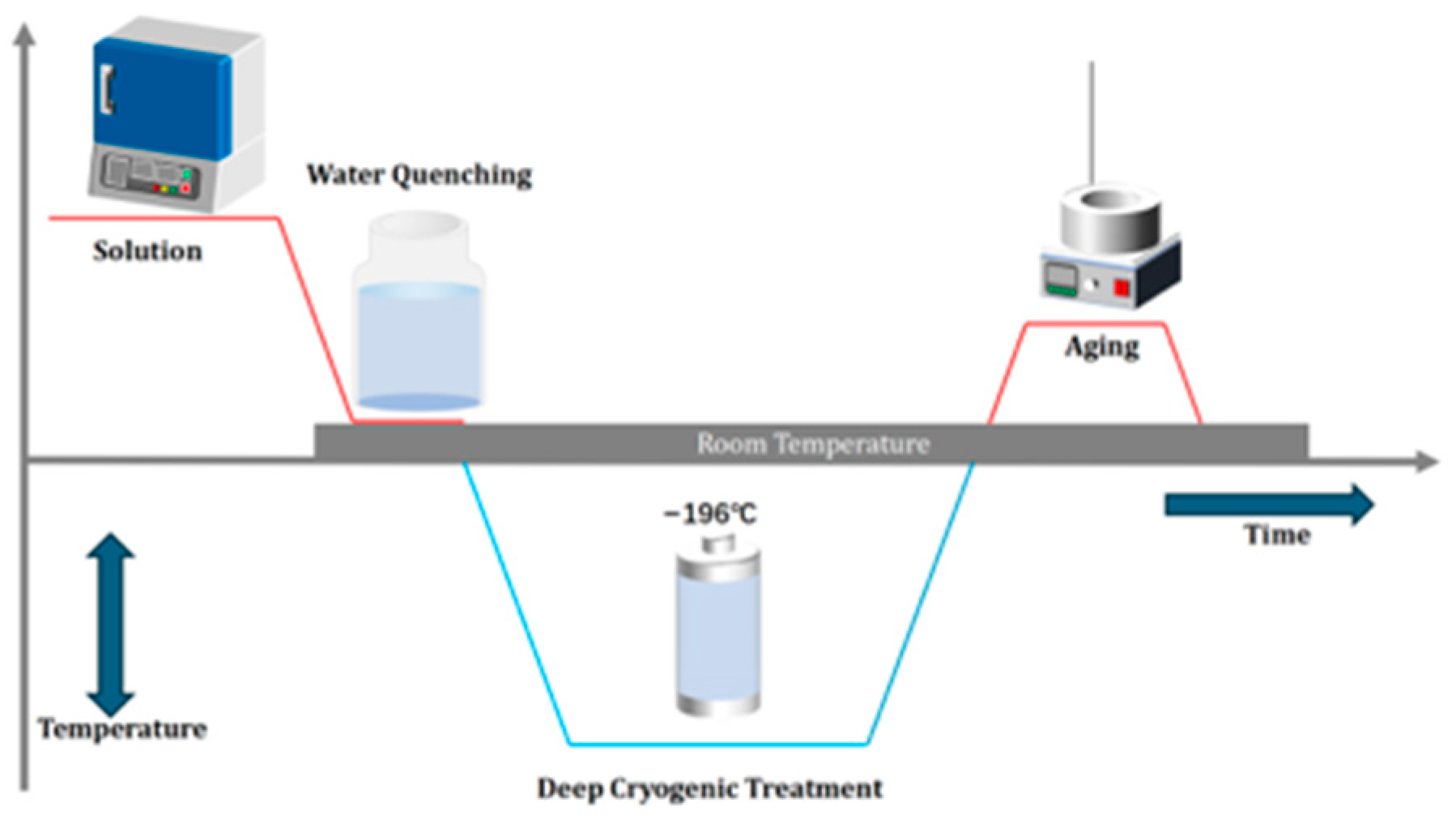

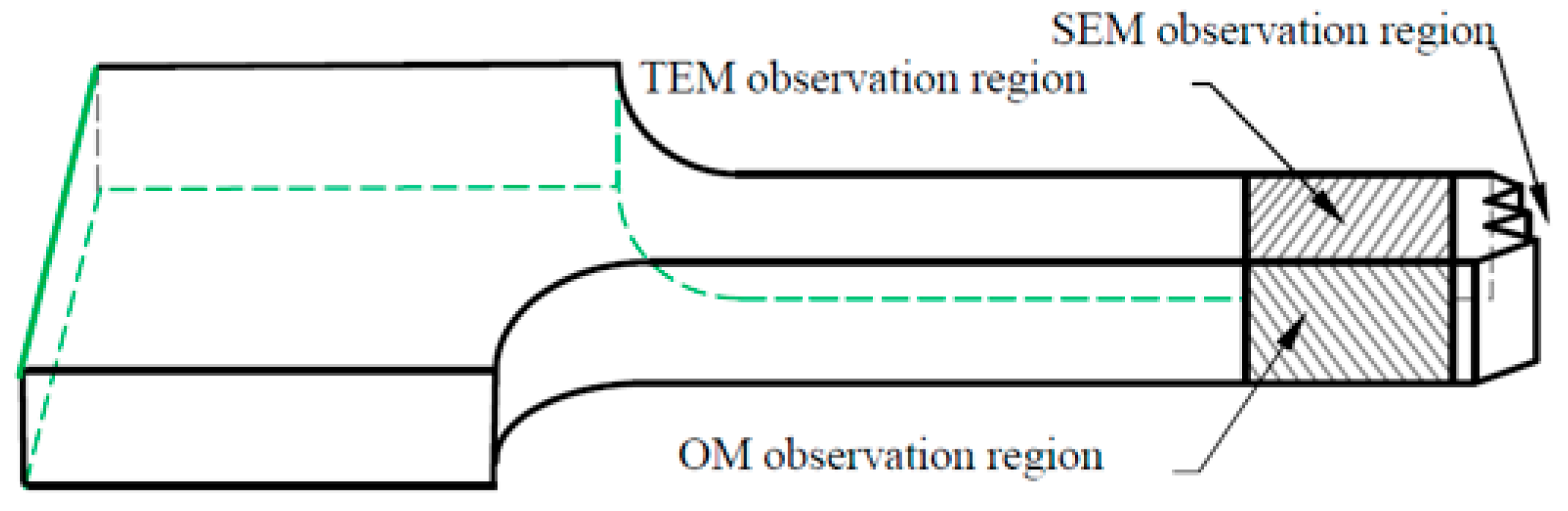

2. Materials and Experimental Methods

3. Results and Discussion

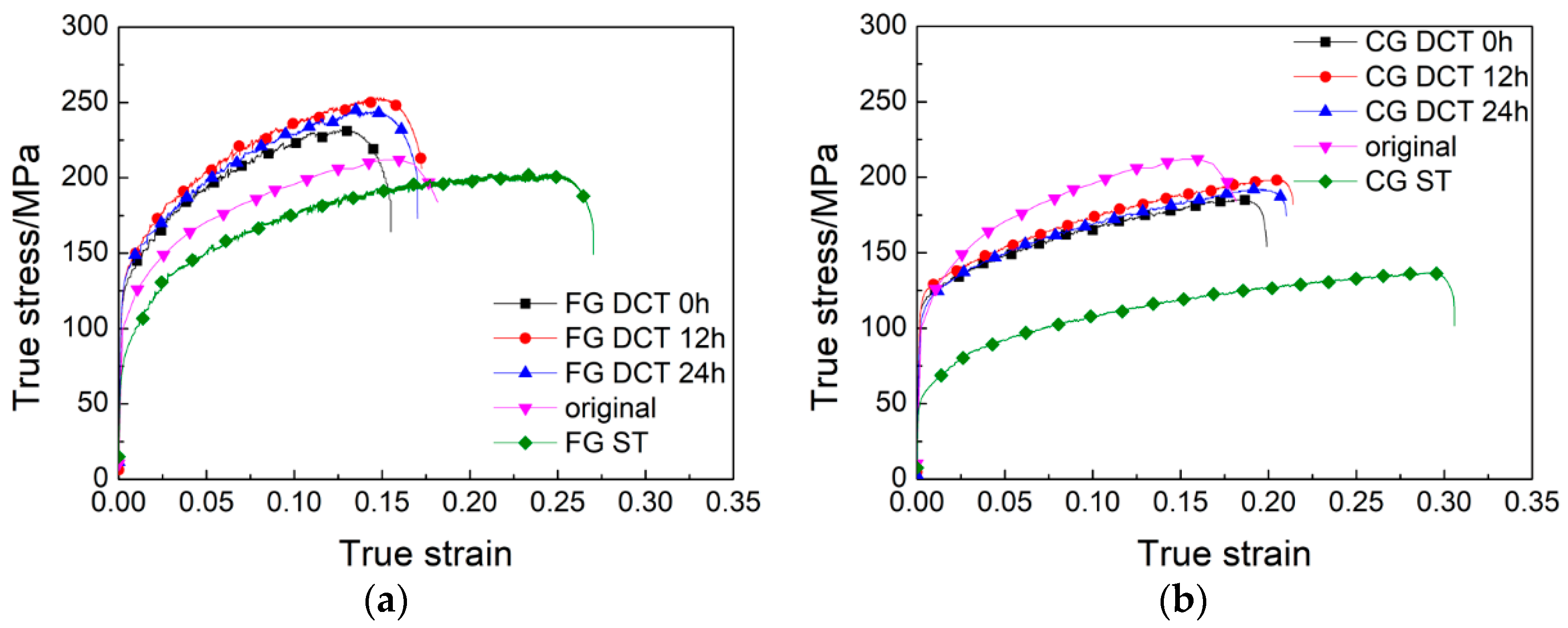

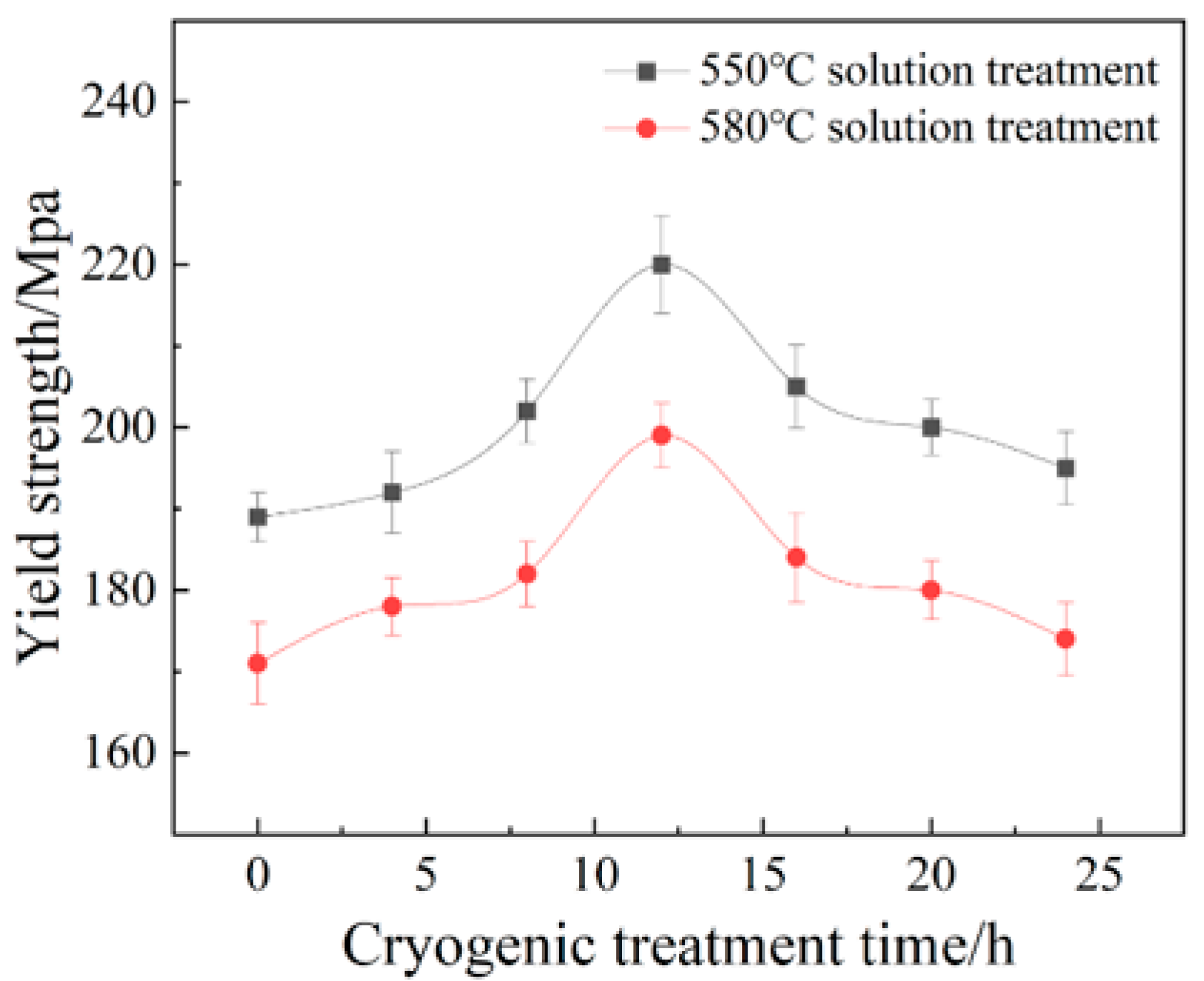

3.1. Mechanical Properties

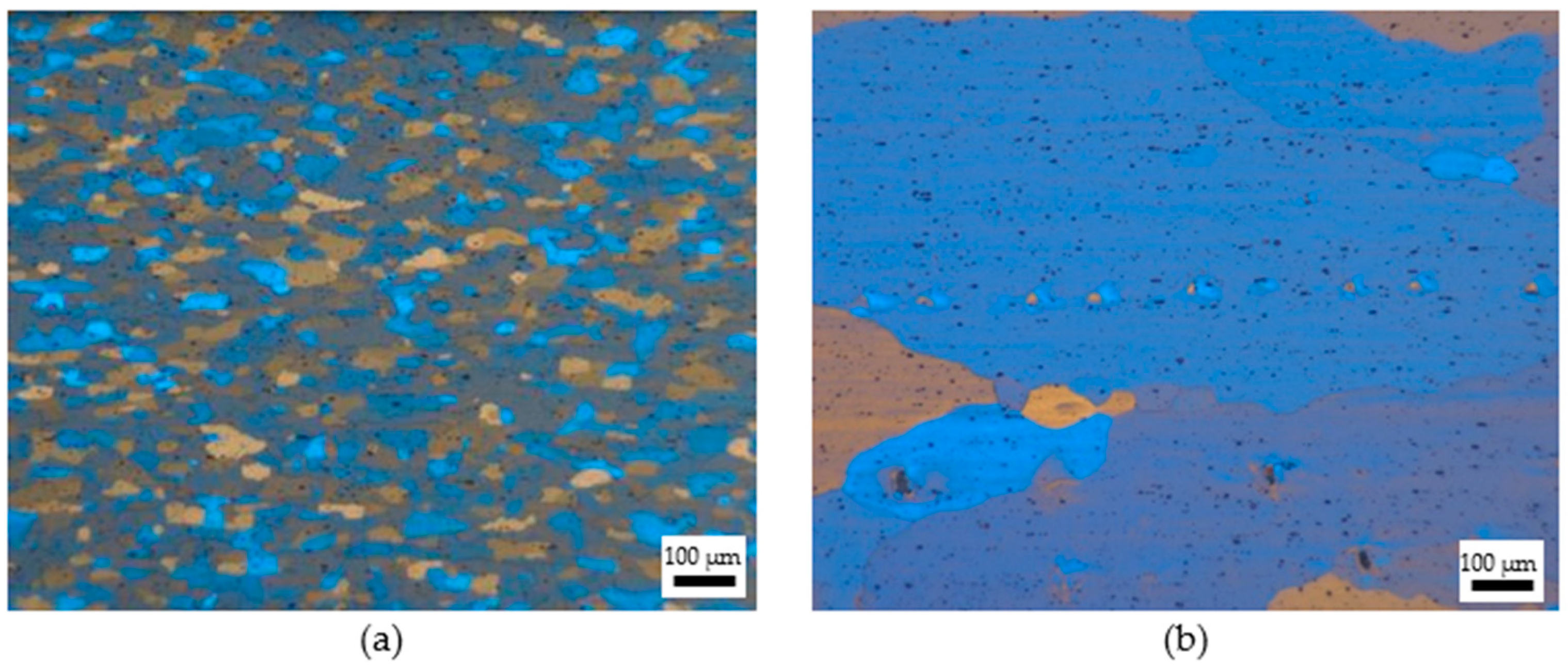

3.2. The Characterization of Microstructure

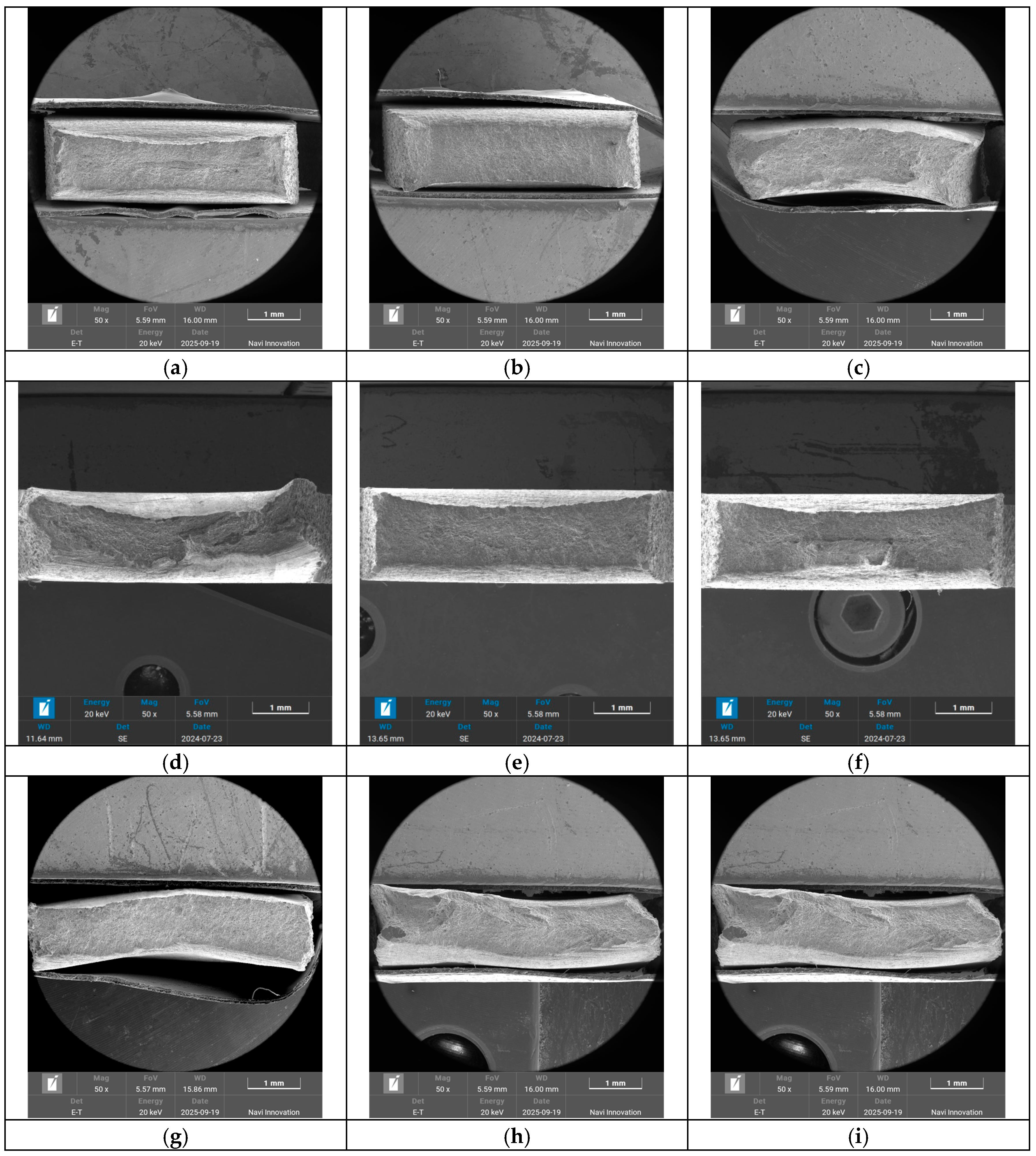

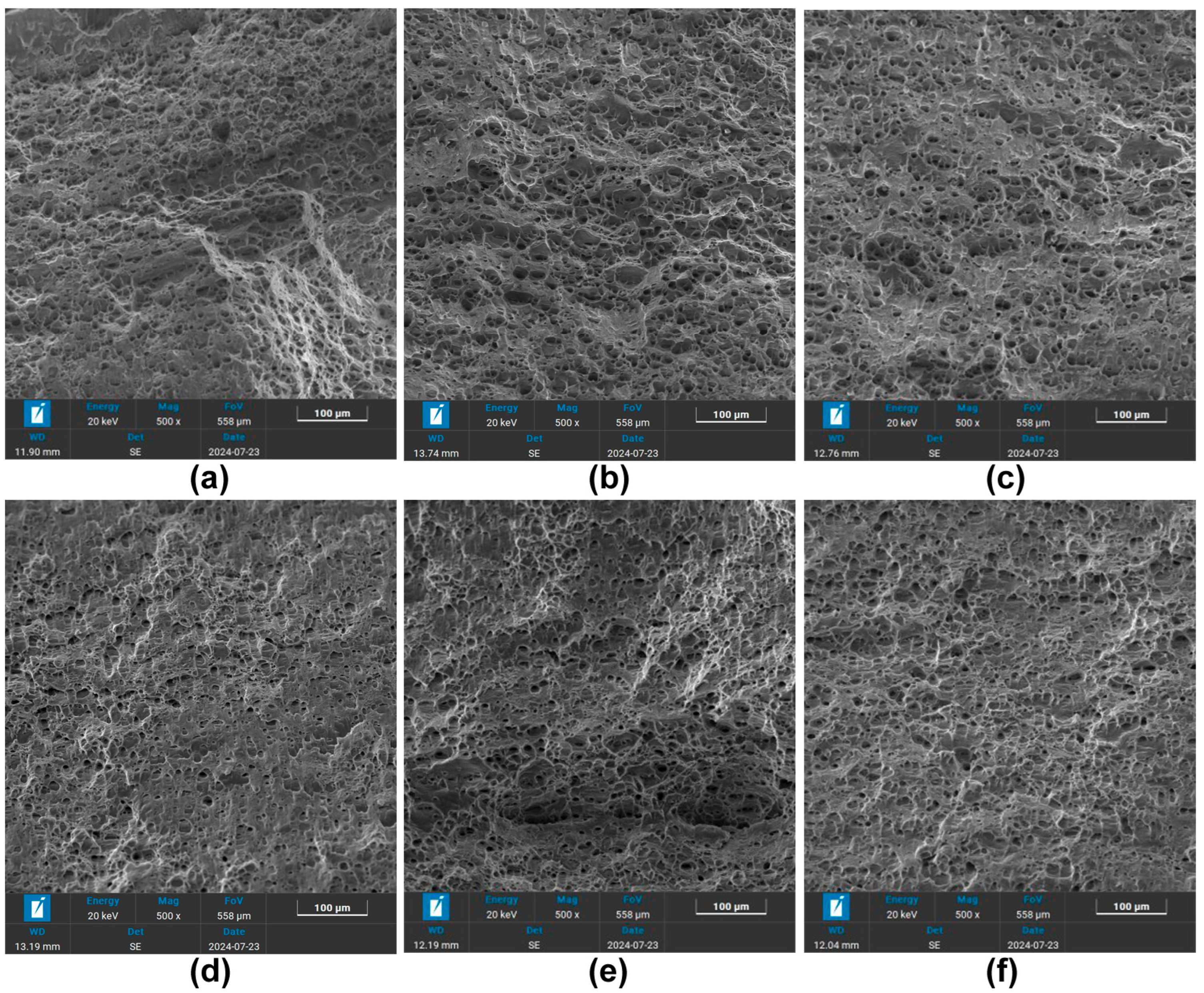

3.2.1. The Fracture Behavior

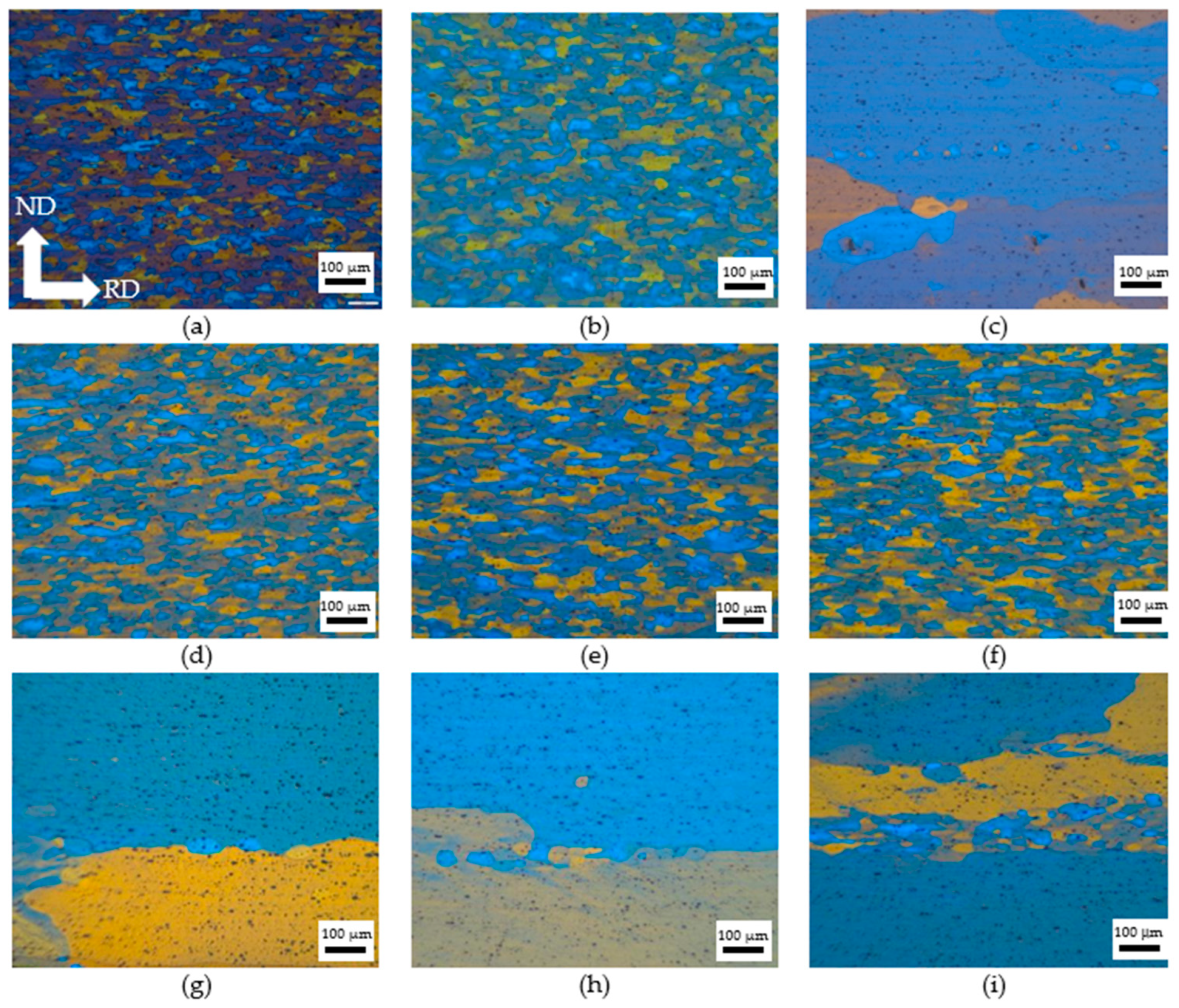

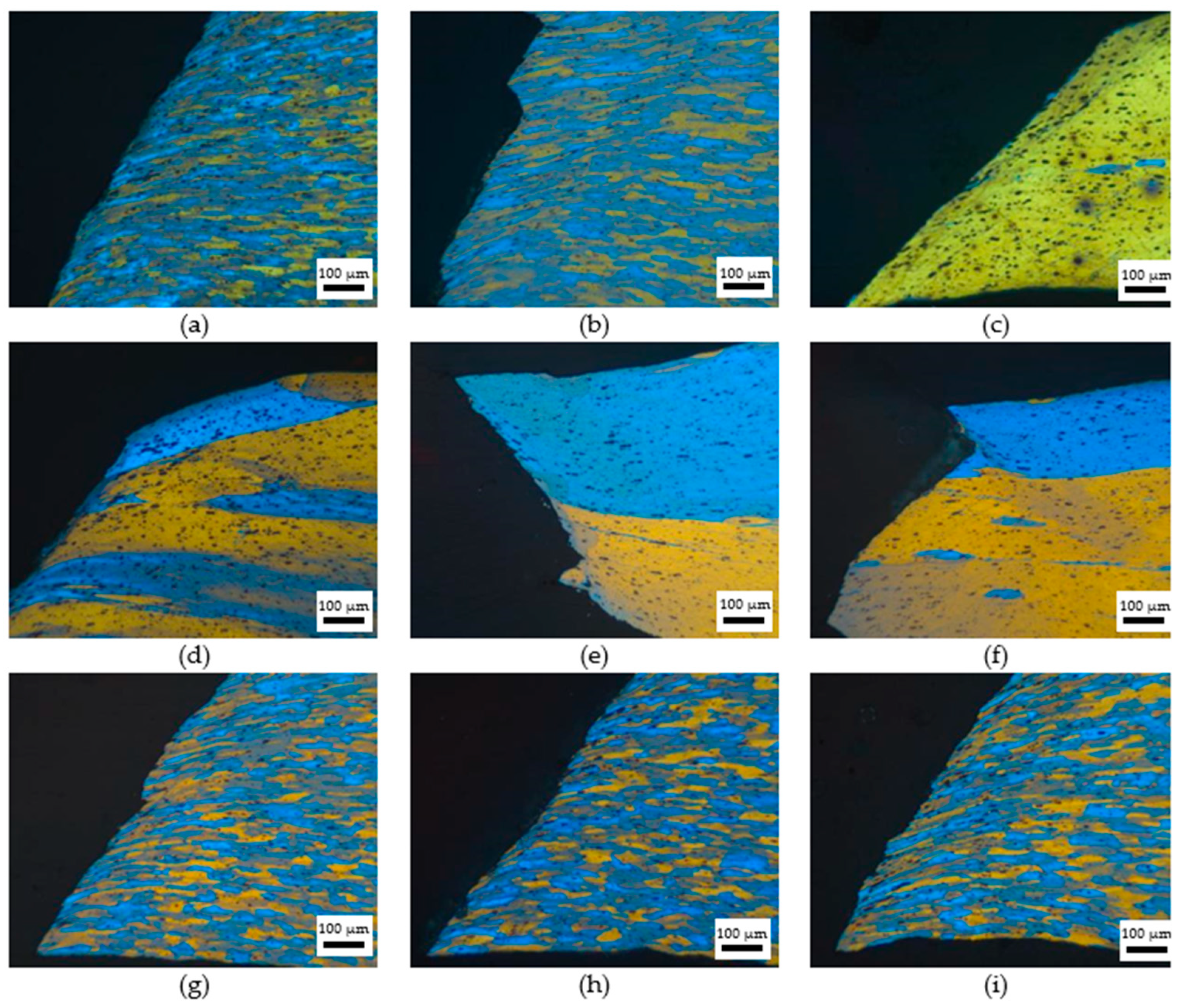

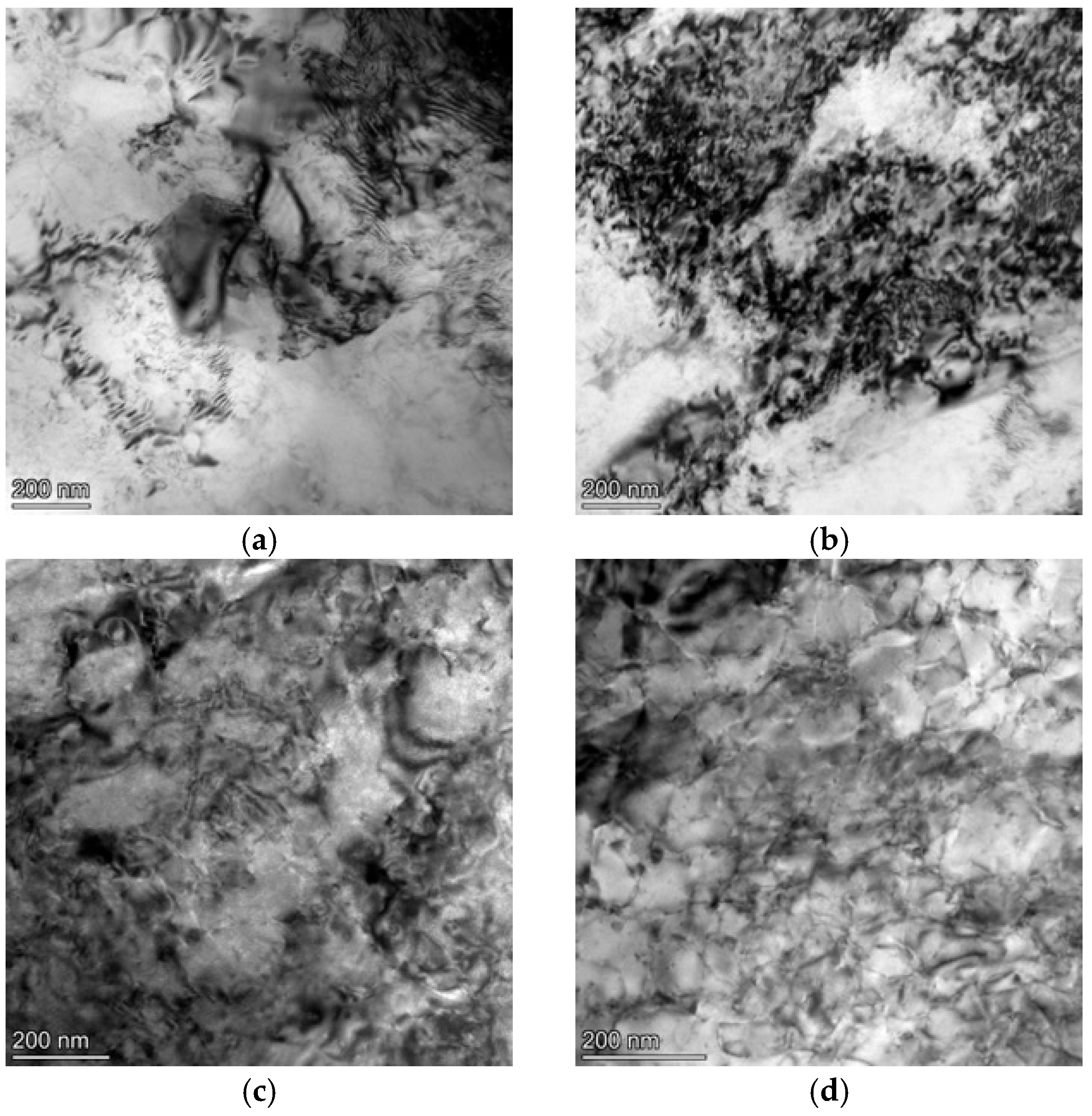

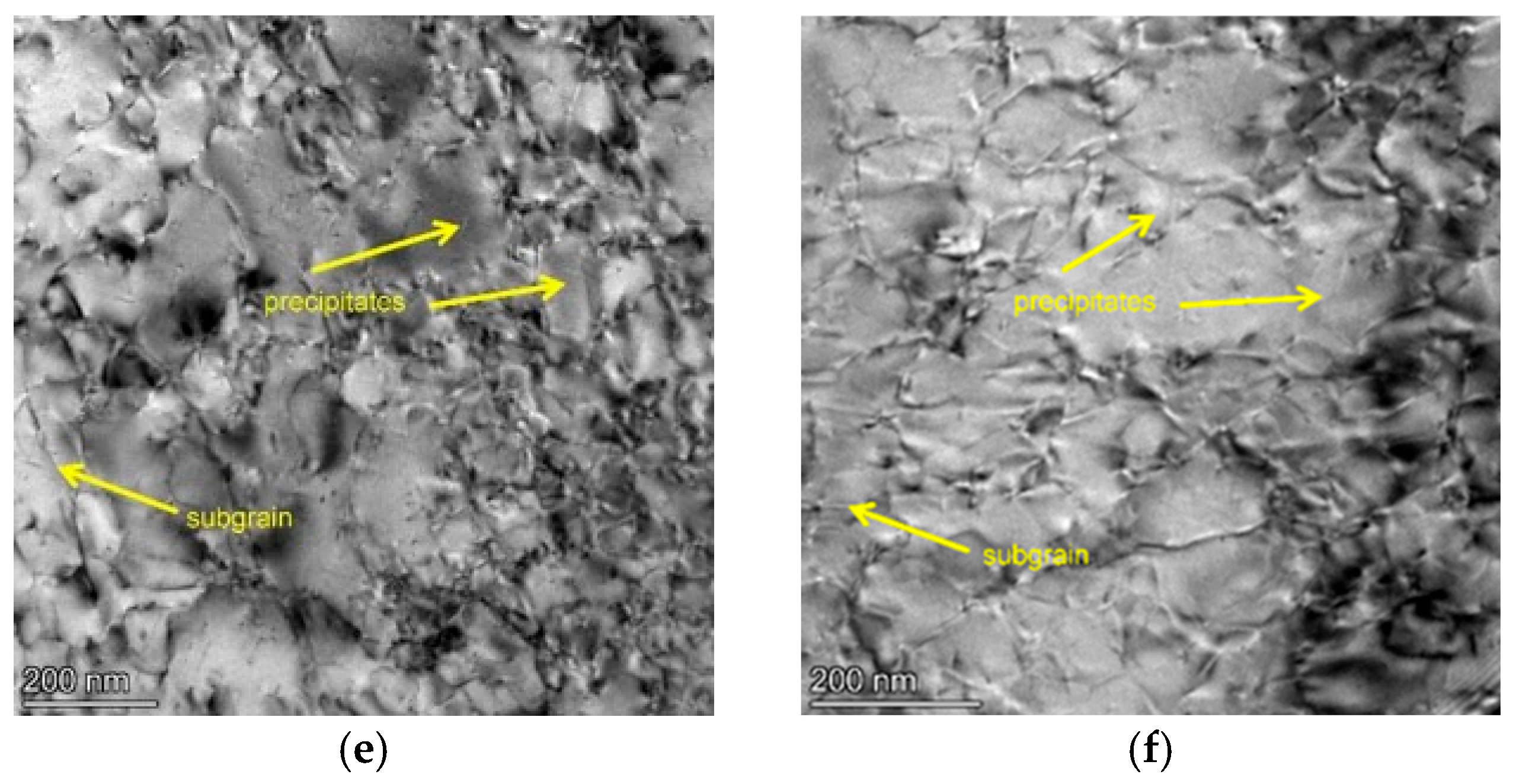

3.2.2. The Grain Structure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Song, C.R.; Dong, B.X.; Zhang, S.Y.; Yang, H.Y.; Liu, L.; Kang, J.; Jiang, Q.C. Recent progress of Al-Mg alloys: Forming and preparation process, microstructure manipulation and application. J. Mater. Res. Technol. 2024, 31, 3255–3286. [Google Scholar] [CrossRef]

- Zhu, Q.; Du, X.; Liu, Y.; Fang, X.; Chen, D.; Zhang, Z. Preparation and applications of superhydrophobic coatings on aluminum alloy surface for anti-corrosion and anti-fouling: A mini review. Coatings 2023, 13, 1881. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, D.; Li, A.; Yi, D.; Li, T. A review on traditional processes and laser powder bed fusion of aluminum alloy microstructures, mechanical properties, costs, and applications. Materials 2024, 17, 2553. [Google Scholar] [CrossRef]

- Song, C.R.; Zhang, S.Y.; Liu, L.; Yang, H.Y.; Kang, J.; Meng, J.; Jiang, Q.C. Research progress on the microstructure evolution mechanisms of al-Mg alloys by severe plastic deformation. Materials 2024, 17, 4235. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.; Srivastawa, K.; Jana, S.; Dixit, C. Advancements in lightweight materials for aerospace structures: A comprehensive review. Acceleron Aerosp. J. 2024, 2, 173–183. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Najm, S.M. Current trends in metallic materials for body panels and structural members used in the automotive industry. Materials 2024, 17, 590. [Google Scholar] [CrossRef]

- Gaurav, S.; Mishra, R.S.; Zunaid, M. A critical review on mechanical and microstructural properties of dissimilar aluminum (Al)-magnesium (Mg) alloys. J. Adhes. Sci. Technol. 2023, 37, 1117–1149. [Google Scholar] [CrossRef]

- Baek, M.S.; Shah, A.W.; Kim, Y.K.; Kim, S.K.; Kim, B.H.; Lee, K.A. Microstructures, tensile properties, and strengthening mechanisms of novel Al-Mg alloys with high Mg content. J. Alloys Compd. 2023, 950, 169866. [Google Scholar] [CrossRef]

- Nagaraja, S.; Anand, P.B.; Mariswamy, M.; Alkahtani, M.Q.; Islam, S.; Khan, M.A.; Khan, W.A.; Bhutto, J.K. Friction stir welding of dissimilar Al–Mg alloys for aerospace applications: Prospects and future potential. Rev. Adv. Mater. Sci. 2024, 63, 20240033. [Google Scholar] [CrossRef]

- Wang, L.Y.; Liu, C.Y. Effect of Ce and Zr on the microstructure and mechanical properties of high-Mg content Al-Mg alloy. Mater. Sci. Eng. A 2024, 915, 147210. [Google Scholar] [CrossRef]

- Belkin, O.; Chuvil’dEev, V.; Chegurov, M.; Nokhrin, A.; Sysoev, A. Analysis of contributions of plastic deformation and intergranular corrosion to corrosion-fatigue failure of Al-Mg alloys. Mater. Lett. 2025, 389, 138411. [Google Scholar] [CrossRef]

- Sun, P.; Huang, Y.; Sun, L.; Li, Y.; Zheng, X.; Li, B.; Li, X.; Yan, H.; Liu, Y.; Du, Y. Effect of heat treatment on microstructure evolution, strengthening mechanisms and mechanical properties of Zn modified Al–Mg alloys with Sc and Zr additions. Mater. Sci. Eng. A 2024, 896, 146206. [Google Scholar] [CrossRef]

- Wang, B.B.; Xie, G.M.; Wu, L.H.; Xue, P.; Ni, D.R.; Xiao, B.L.; Ma, Z.Y. Grain size effect on tensile deformation behaviors of pure aluminum. Mater. Sci. Eng. A 2021, 820, 141504. [Google Scholar] [CrossRef]

- Shou, W.B.; Yi, D.Q.; Liu, H.Q.; Tang, C.; Shen, F.H.; Wang, B. Effect of grain size on the fatigue crack growth behavior of 2524-T3 aluminum alloy. Arch. Civ. Mech. Eng. 2016, 16, 304–312. [Google Scholar] [CrossRef]

- He, J.; Hu, M.; Zhou, Z.; Li, C.; Sun, Y.; Zhu, X. Effect of initial grain size on hot deformation behavior and recrystallization mechanism of Al-Zn-Mg-Cu alloy. Mater. Charact. 2024, 212, 114012. [Google Scholar] [CrossRef]

- Kamikawa, N.; Hirooka, T.; Furuhara, T. Yielding behaviour and Hall–Petch relationship in ultrafine-grained Al-Mg binary alloys. Mater. Sci. Technol. 2021, 37, 210–223. [Google Scholar] [CrossRef]

- Gogoi, S.; Siddiqui, H.R.; Banerjee, S.; Kashyap, S.; Kirtania, S.; Bhadra, R. Hall–Petch and Hollomon modeling for microalloyed 2219Al alloys under different thermo-mechanical treatments. Int. J. Interact. Des. Manuf. 2024, 18, 6543–6557. [Google Scholar] [CrossRef]

- Tian, N.; Yuan, F.; Duan, C.; Liu, K.; Wang, G.; Zhao, G.; Zuo, L. Prediction of the work-hardening exponent for 3104 aluminum sheets with different grain sizes. Materials 2019, 12, 2368. [Google Scholar] [CrossRef]

- Yao, E.; Zhang, H.; Ma, K.; Ai, C.; Gao, Q.; Lin, X. Effect of deep cryogenic treatment on microstructures and performances of aluminum alloys: A review. J. Mater. Res. Technol. 2023, 26, 3661–3675. [Google Scholar] [CrossRef]

- Sonar, T.; Lomte, S.; Gogte, C. Cryogenic treatment of metal—A review. Mater. Today Proc. 2018, 5, 25219–25228. [Google Scholar] [CrossRef]

- Jovičević-Klug, P.; Podgornik, B. Review on the effect of deep cryogenic treatment of metallic materials in automotive applications. Metals 2020, 10, 434. [Google Scholar] [CrossRef]

- Li, G.; Cao, Z.; Wang, H.; Ye, Y.; Xiong, M.; Dong, K.; Guo, S.; Zhou, P. Effect of deep cryogenic treatment on microstructures and mechanical properties of automotive 6063Al alloy. J. Mater. Sci. 2024, 59, 5558–5575. [Google Scholar] [CrossRef]

- Xia, E.; Ye, T.; Qiu, S.; Liu, J.; Luo, J.; Sun, L.; Wu, Y. Mechanical Properties and Microstructural Evolution of 6082 Aluminum Alloy with Different Heat Treatment Methods. Coatings 2024, 14, 602. [Google Scholar] [CrossRef]

- Qiu, S.; Tang, J.; Tian, Y.; Wu, C.; Ye, T.; Xia, E.; Wu, Y. Effect of Deep Cryogenic Treatment on the Artificial Aging Behavior of 6082 Aluminum Alloy. Coatings 2024, 14, 755. [Google Scholar] [CrossRef]

- Gao, W.; Wang, X.; Chen, J.; Ban, C.; Cui, J.; Lu, Z. Influence of deep cryogenic treatment on microstructure and properties of 7A99 ultra-high strength aluminum alloy. Metals 2019, 9, 631. [Google Scholar] [CrossRef]

- Guo, J.; Jin, M.; Su, R.; Li, G.; Qu, Y. Microstructural morphology and mechanical properties of deep cryogenic treatment modified Al-Cu-Mg-Ag alloy. Mater. Today Commun. 2024, 38, 107670. [Google Scholar] [CrossRef]

- Madhloom, M.A.; Ataiwi, A.H.; Dawood, J.J. Influence of cryogenic treatment on hardness, tensile properties, and microstructure of aluminum alloy AA6061. Mater. Today Proc. 2022, 60, 2157–2161. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, Z.; Liu, J.; Yu, J.; Mai, Q.; Yue, X. Effect of aging plus cryogenic treatment on the machinability of 7075 aluminum alloy. Vacuum 2023, 208, 111692. [Google Scholar] [CrossRef]

- Zhou, D.; Wang, H.; Saxey, D.W.; Muránsky, O.; Geng, H.; Rickard, W.D.A.; Quadir, Z.; Yang, C.; Reddy, S.M.; Zhang, D. Hall–Petch slope in ultrafine grained Al-Mg alloys. Metall. Mater. Trans. A 2019, 50, 4047–4057. [Google Scholar] [CrossRef]

- Dangwal, S.; Edalati, K.; Valiev, R.Z.; Langdon, T.G. Breaks in the Hall–Petch relationship after severe plastic deformation of magnesium, aluminum, copper, and iron. Crystals 2023, 13, 413. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, H.; Tong, M.; Jiang, F.; Zhang, M. Effect of cryogenic environment on tensile property and microstructure evolution of an Al-Mg-Sc alloy. Mater. Charact. 2023, 195, 112550. [Google Scholar] [CrossRef]

- Liu, J.; Shi, L.; Su, R.; Liu, T.; Li, G. Effect of deep cryogenic treatment on microstructure and properties of Al-Cu-Mg-Ag alloy with RRA. J. Alloys Compd. 2025, 1020, 179574. [Google Scholar] [CrossRef]

| Element | Fe | Cu | Si | Cr | Mg | Mn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| wt% | 0.25 | 0.02 | 0.12 | 0.15 | 2.13 | 0.09 | 0.02 | Balance |

| Type | Solution Treatment | Deep Cryogenic Treatment | Artificial Aging |

|---|---|---|---|

| FG alloys | 550 °C/1 h; water quenching | 0, 4 h, 8 h, 12 h, 16 h, 20 h, 24 h | 180 °C/8 h |

| CG alloys | 580 °C/2 h; water quenching | 0, 4 h, 8 h, 12 h, 16 h, 20 h, 24 h | 180 °C/8 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Zhang, L.; Xia, E.; Luo, J.; Tian, Y.; Cai, W.; Gong, Y. The Effects of Deep Cryogenic Treatment with Regard to the Mechanical Properties and Microstructural Evolution of Al-Mg Alloys with Different Grain Sizes. Materials 2025, 18, 4518. https://doi.org/10.3390/ma18194518

Liu W, Zhang L, Xia E, Luo J, Tian Y, Cai W, Gong Y. The Effects of Deep Cryogenic Treatment with Regard to the Mechanical Properties and Microstructural Evolution of Al-Mg Alloys with Different Grain Sizes. Materials. 2025; 18(19):4518. https://doi.org/10.3390/ma18194518

Chicago/Turabian StyleLiu, Wei, Luxiang Zhang, Erli Xia, Jing Luo, Yiran Tian, Wentao Cai, and Yuqing Gong. 2025. "The Effects of Deep Cryogenic Treatment with Regard to the Mechanical Properties and Microstructural Evolution of Al-Mg Alloys with Different Grain Sizes" Materials 18, no. 19: 4518. https://doi.org/10.3390/ma18194518

APA StyleLiu, W., Zhang, L., Xia, E., Luo, J., Tian, Y., Cai, W., & Gong, Y. (2025). The Effects of Deep Cryogenic Treatment with Regard to the Mechanical Properties and Microstructural Evolution of Al-Mg Alloys with Different Grain Sizes. Materials, 18(19), 4518. https://doi.org/10.3390/ma18194518