Geometric Accuracy and Mechanical Property Enhancement of Fe-Based Alloy Layers in Wide-Beam Laser Direct Energy Deposition

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

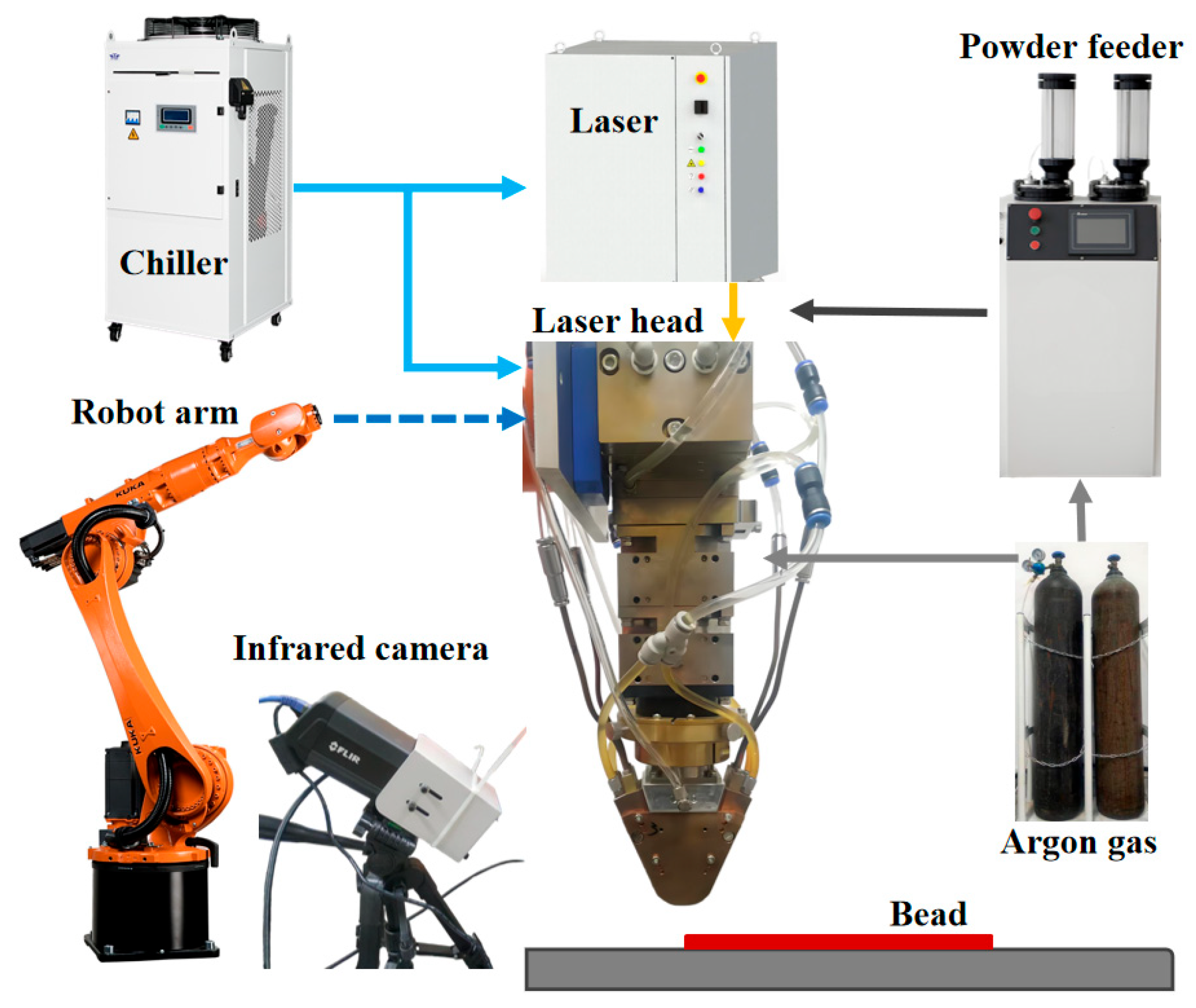

2.2. Experimental Setup

2.3. Methods

2.3.1. Experimental Approach

2.3.2. Mechanical Property Analysis

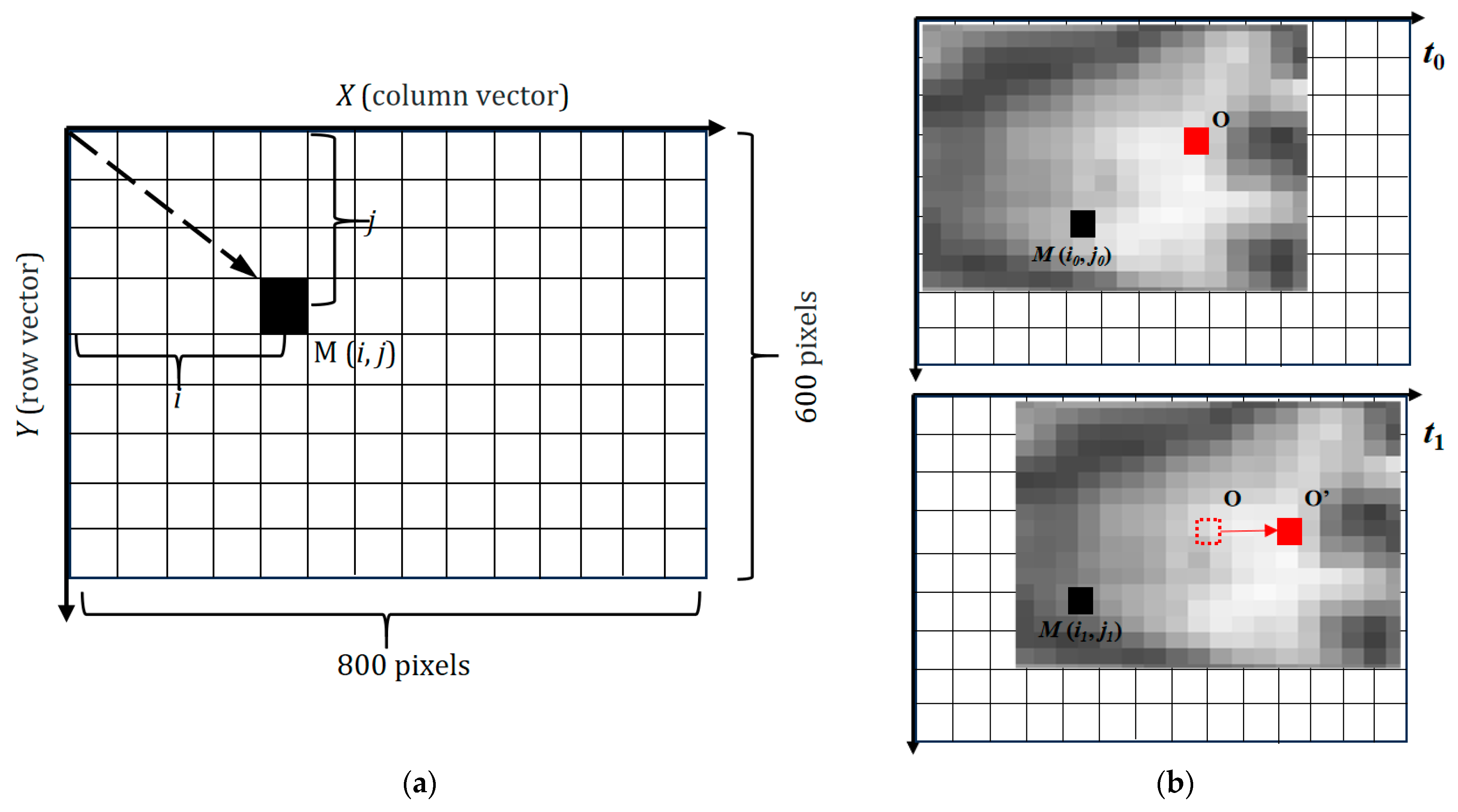

2.3.3. Cooling Rate Monitoring

3. Results and Discussion

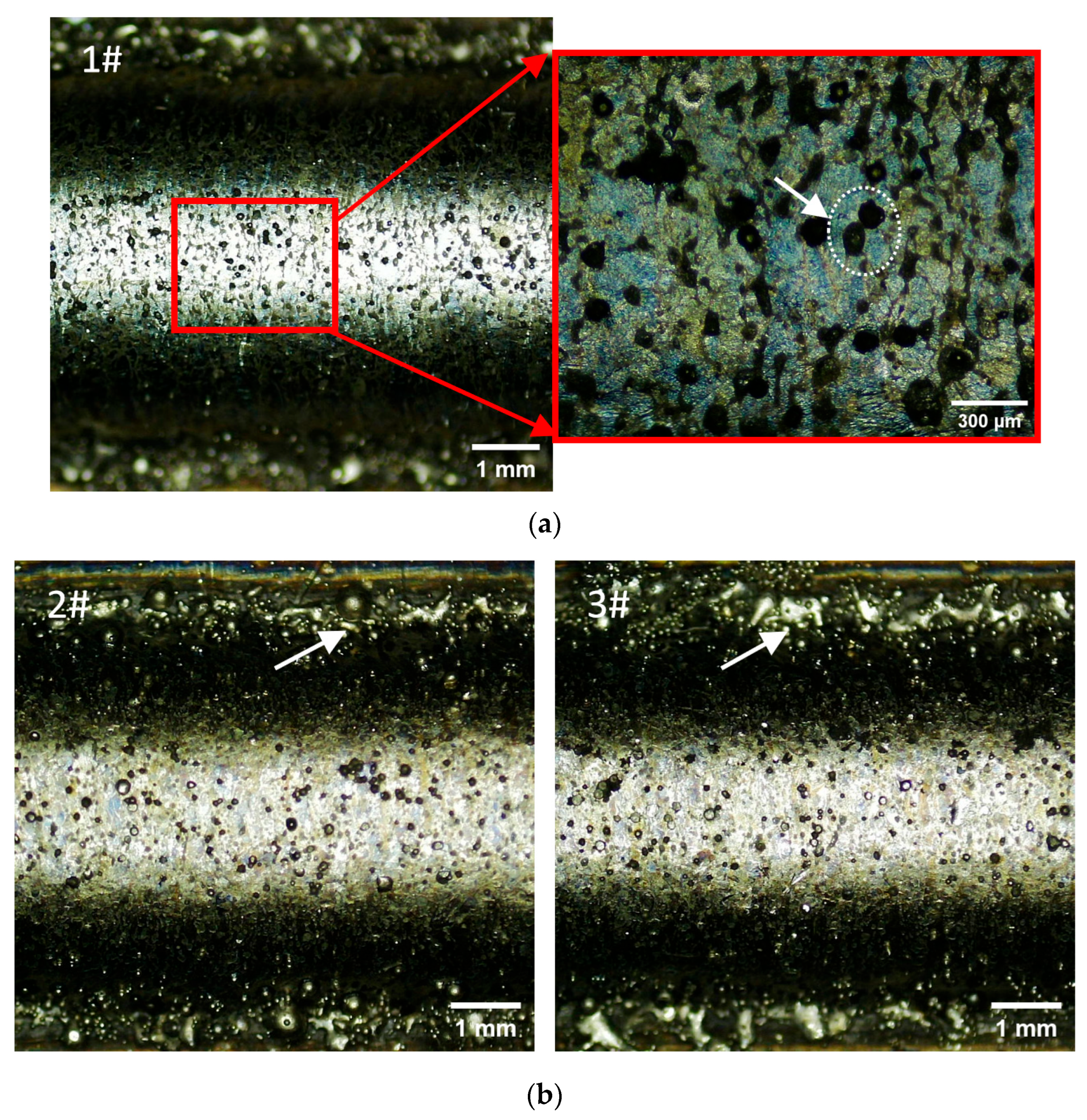

3.1. Analysis of Morphological Characteristics

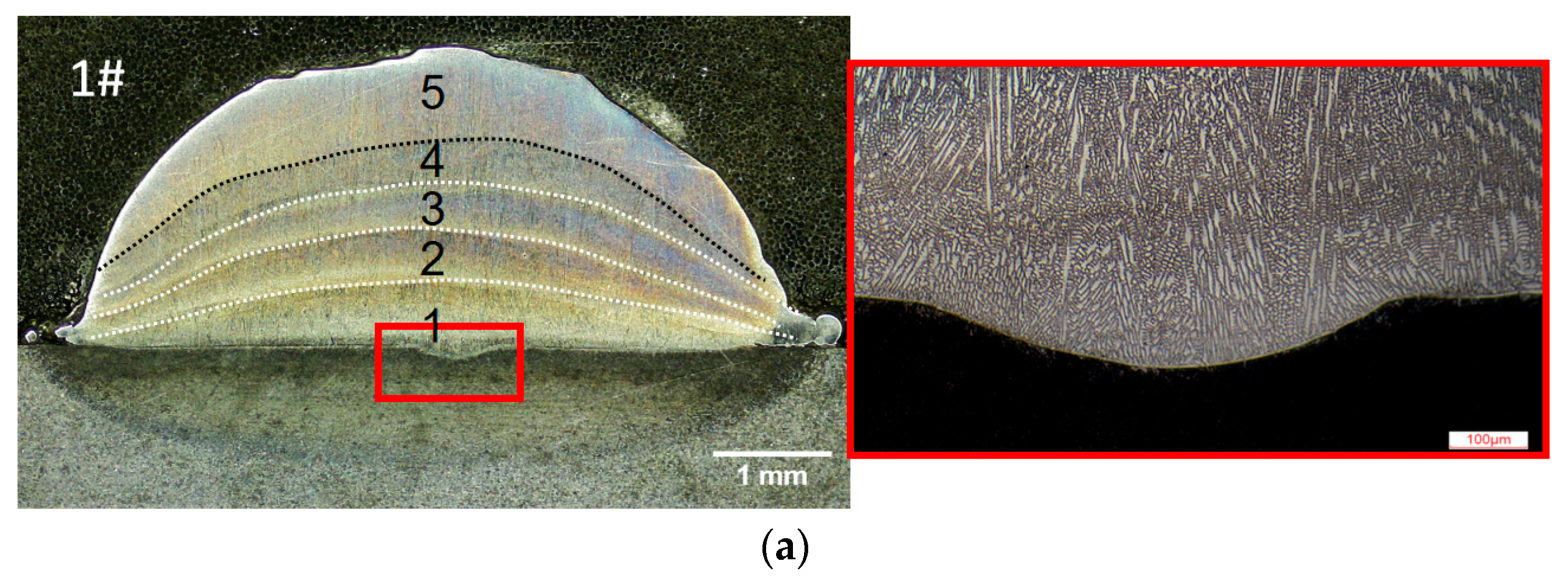

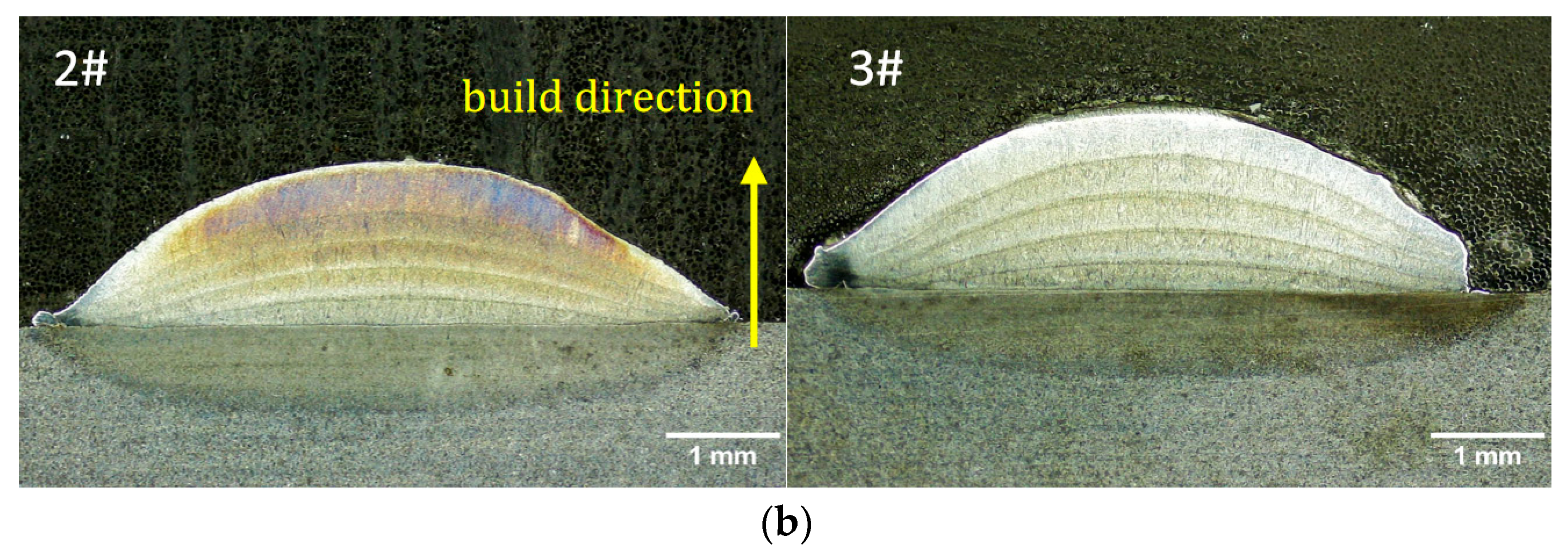

3.2. Cross-Sectional Analysis of the Cladding Layer

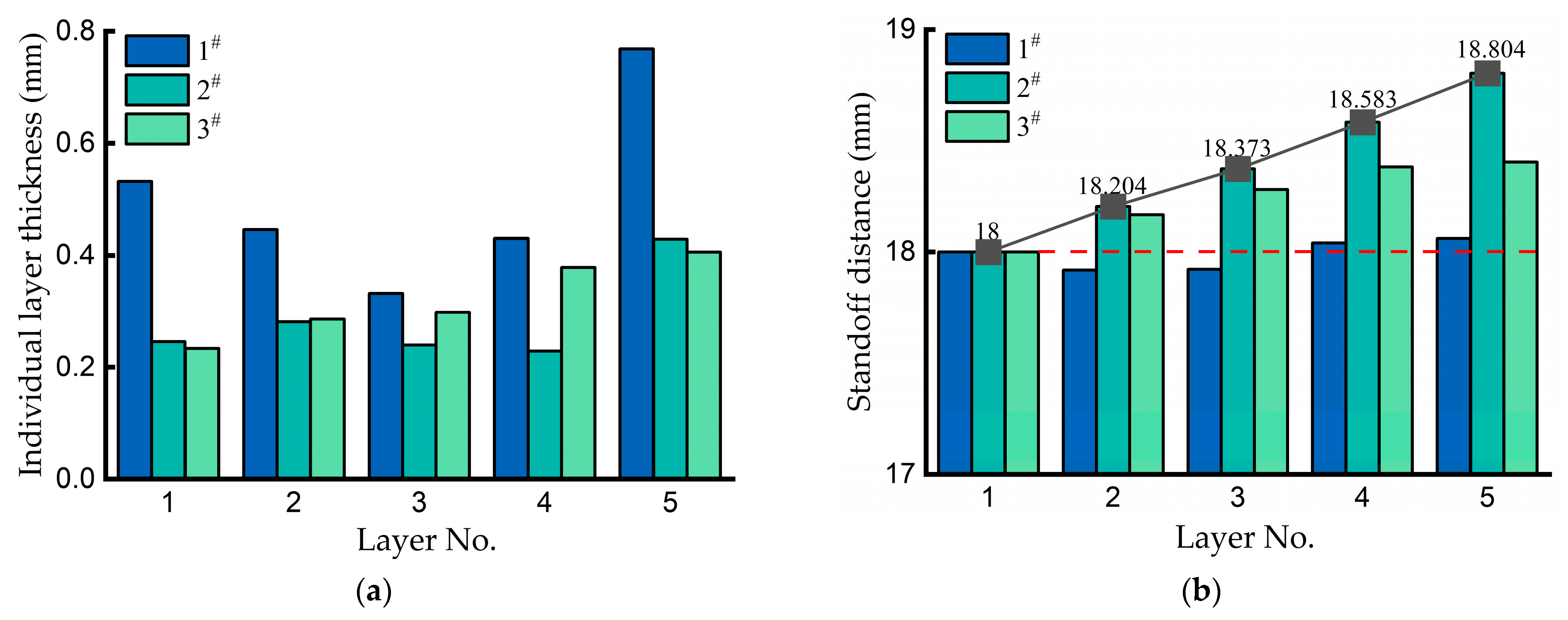

3.2.1. Layer-Wise Thickness and Axial Lifting Amount

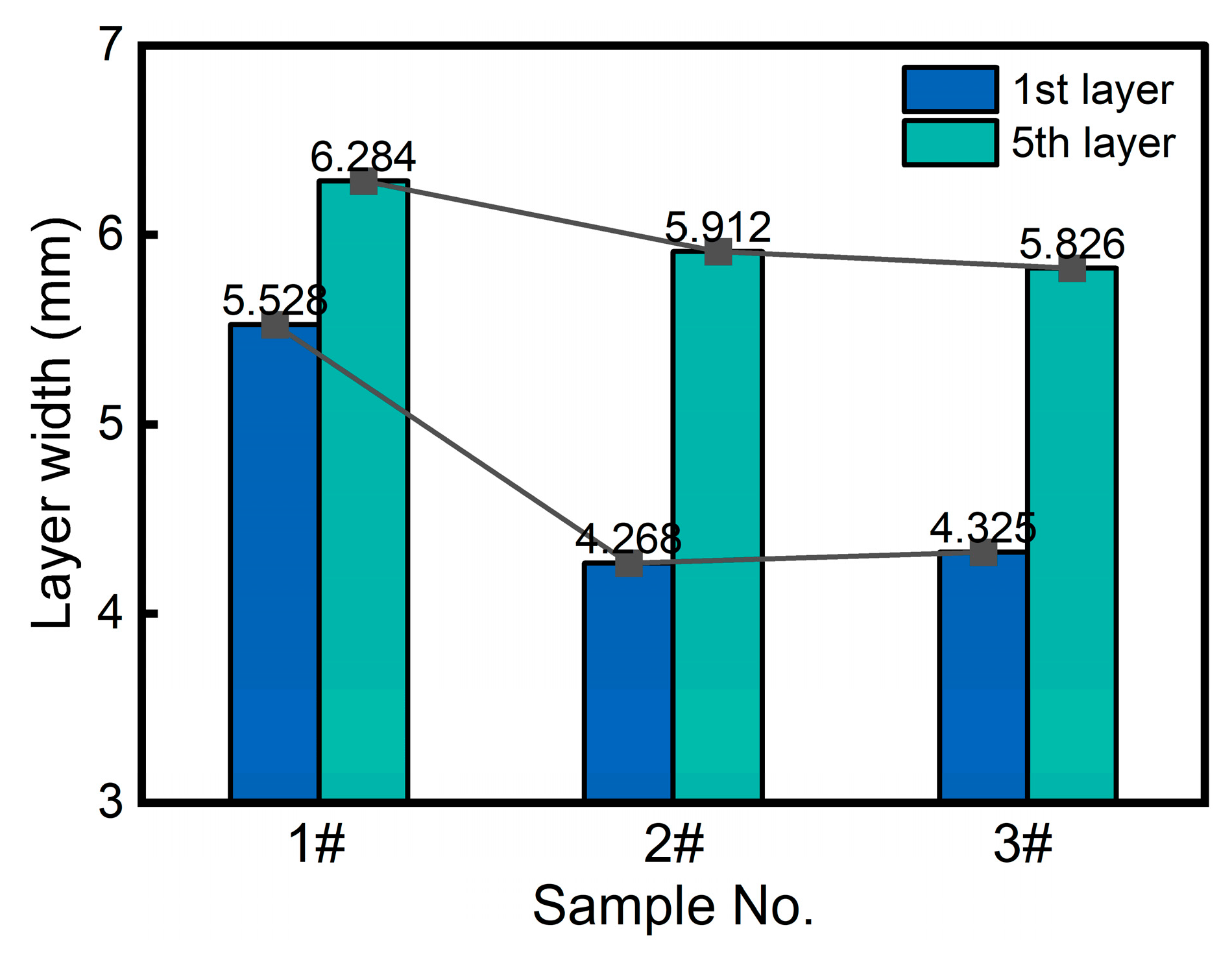

3.2.2. Layer-Wise Width

3.3. Microstructure and Mechanical Properties

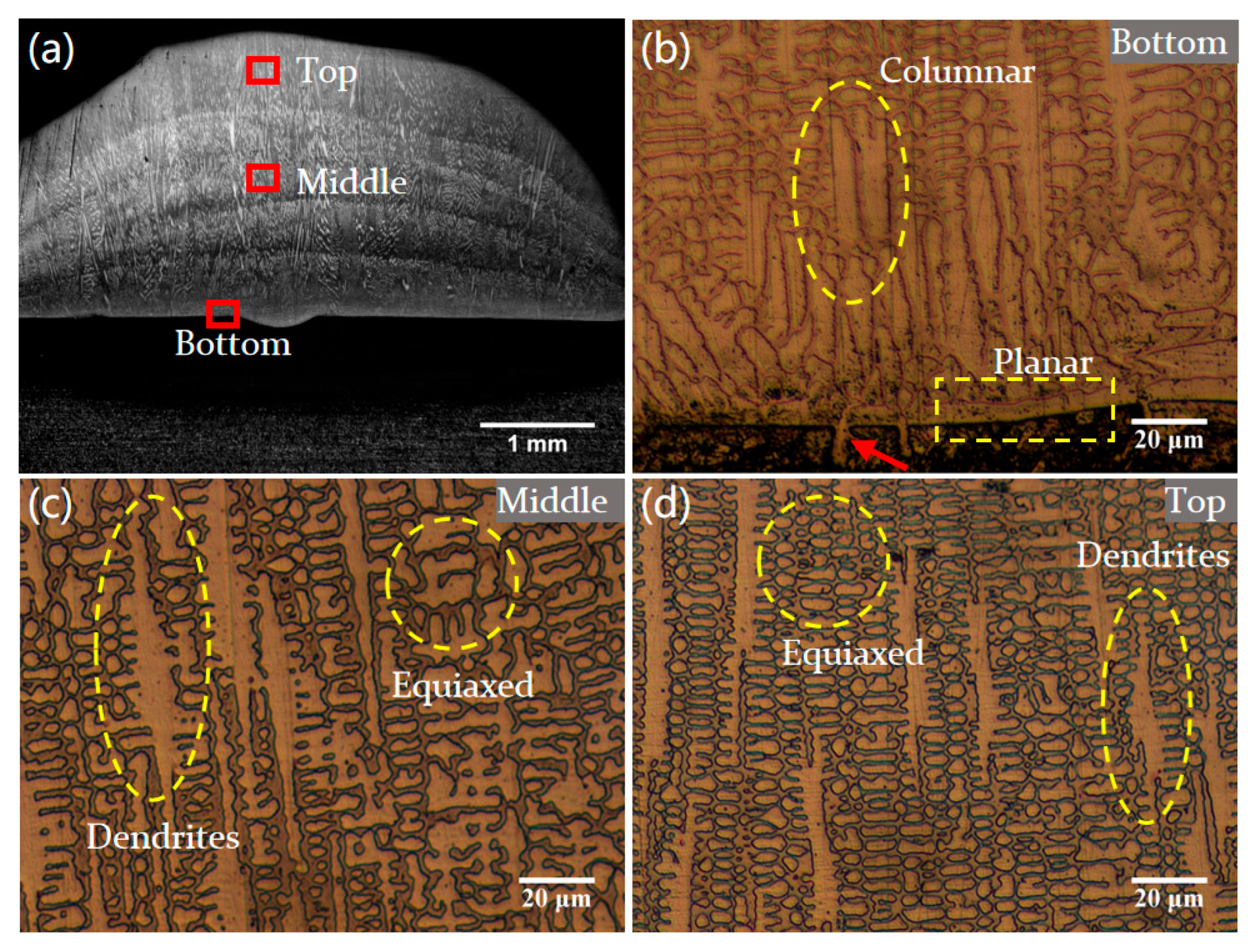

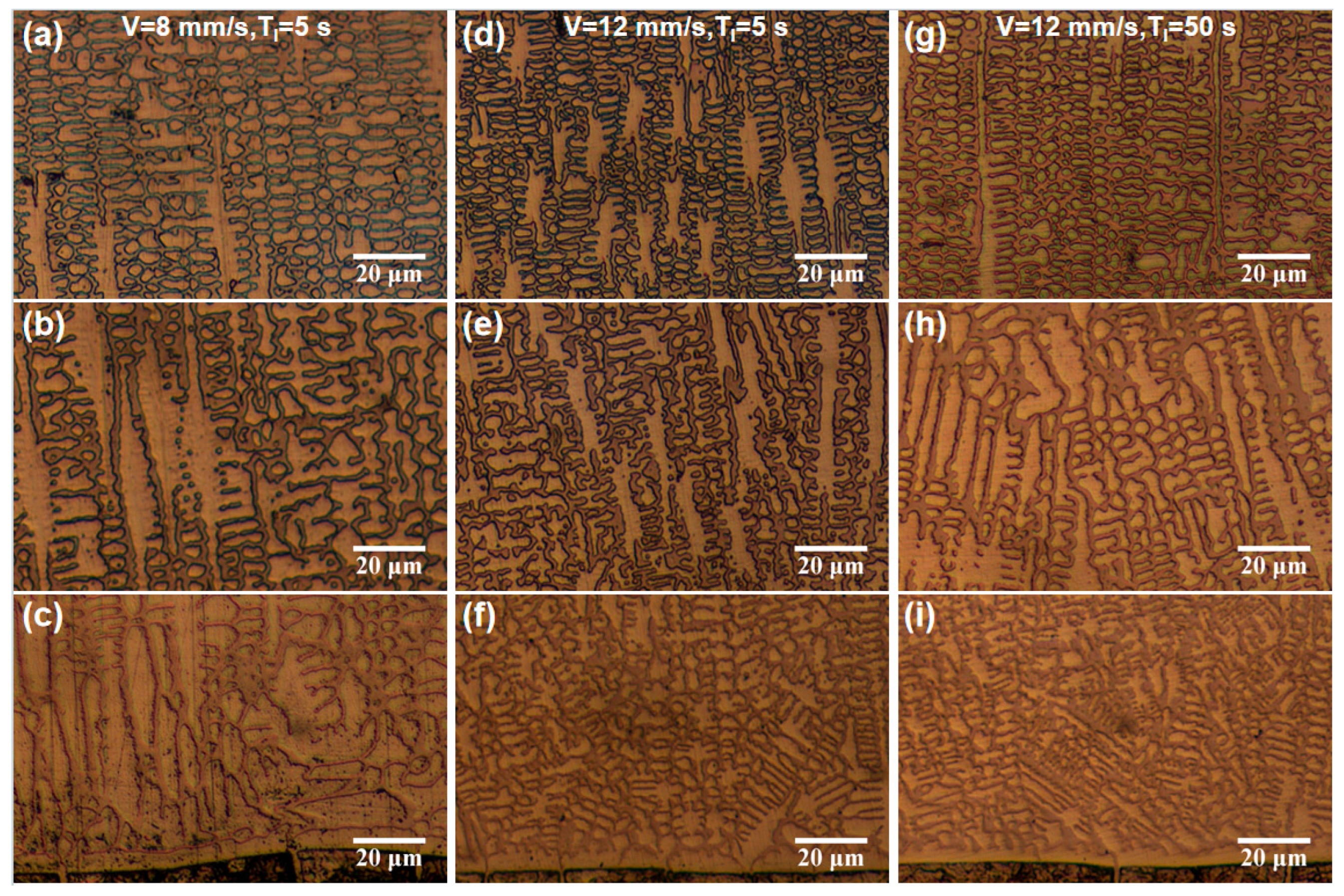

3.3.1. Microstructure Analysis

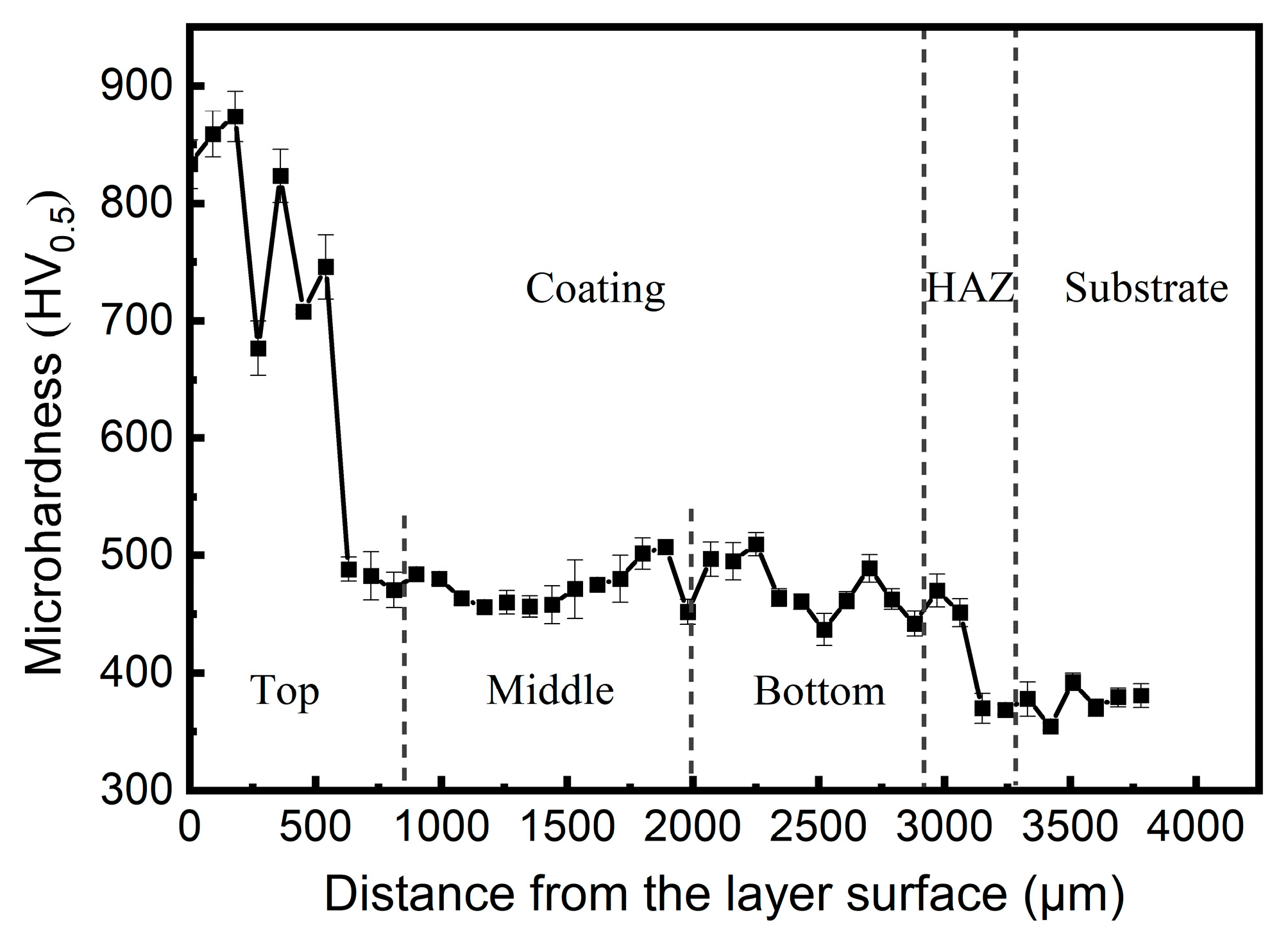

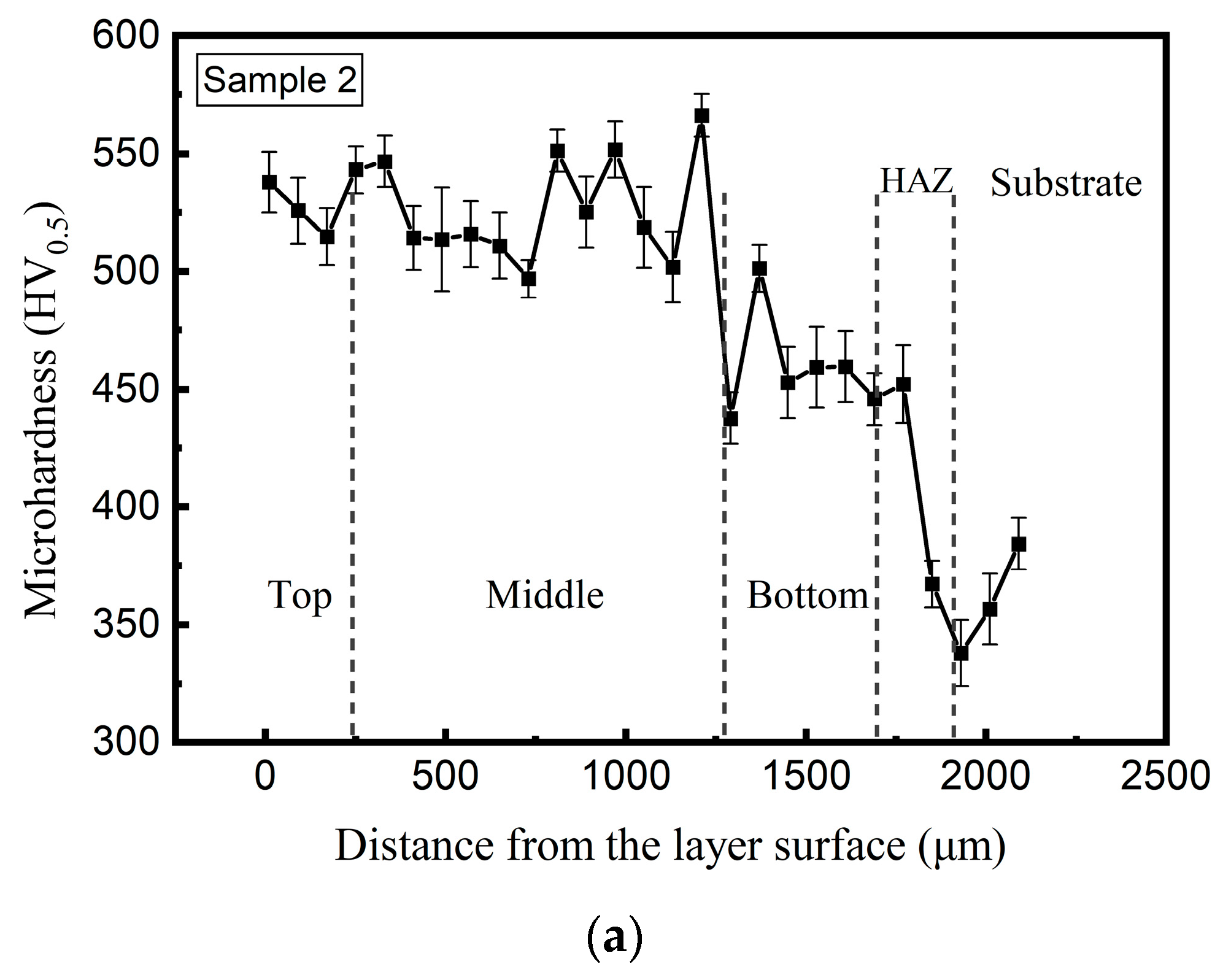

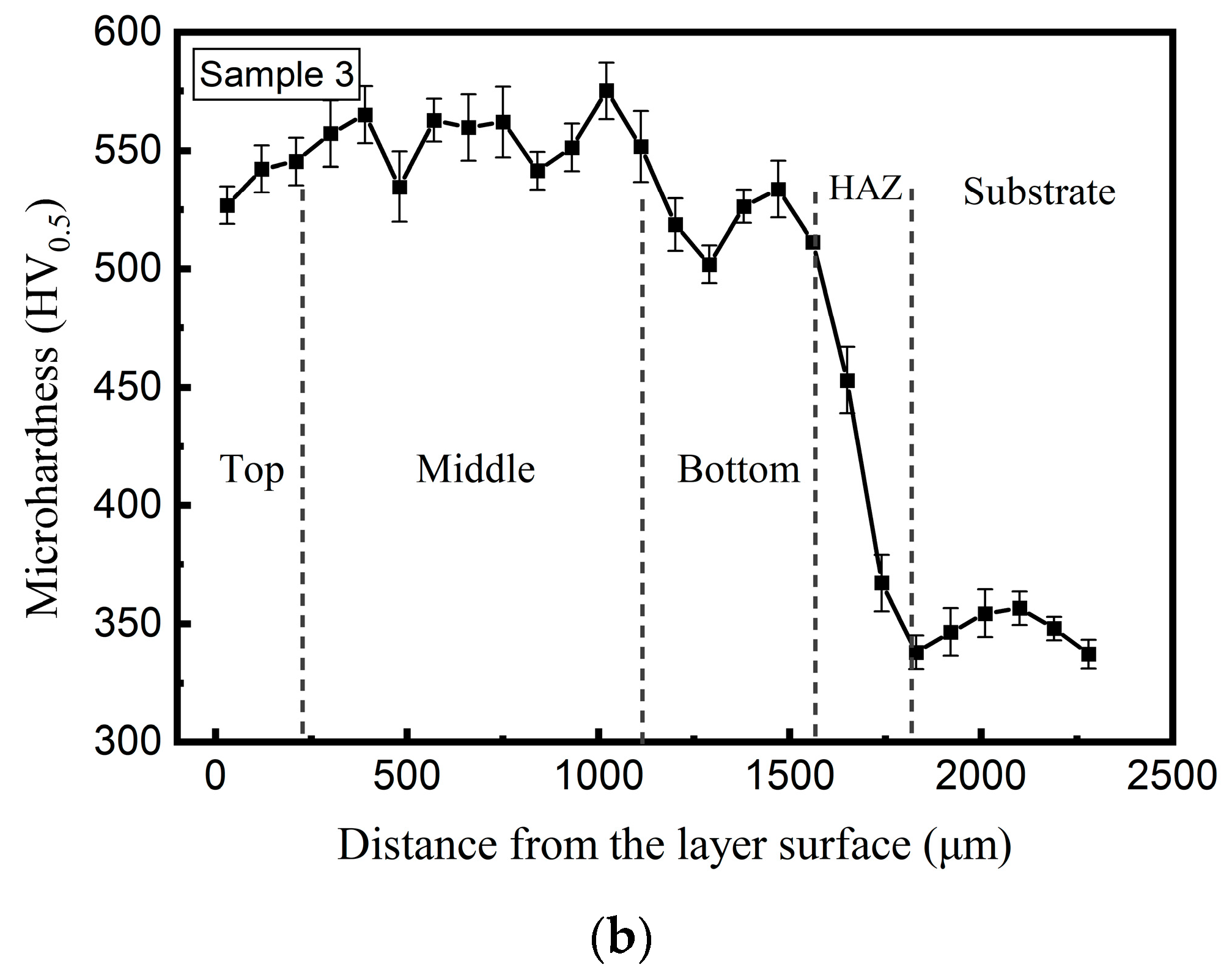

3.3.2. Microhardness Analysis

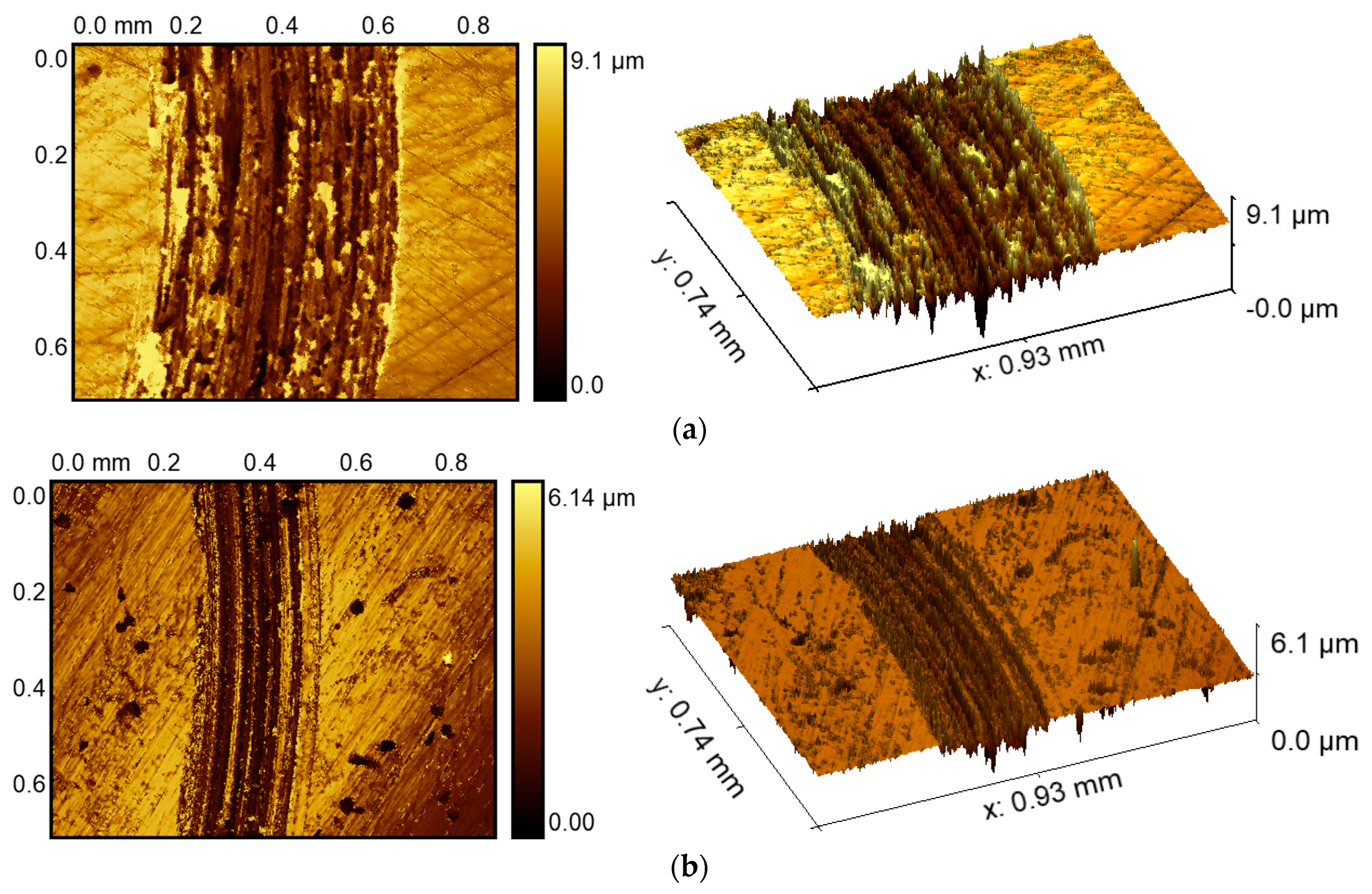

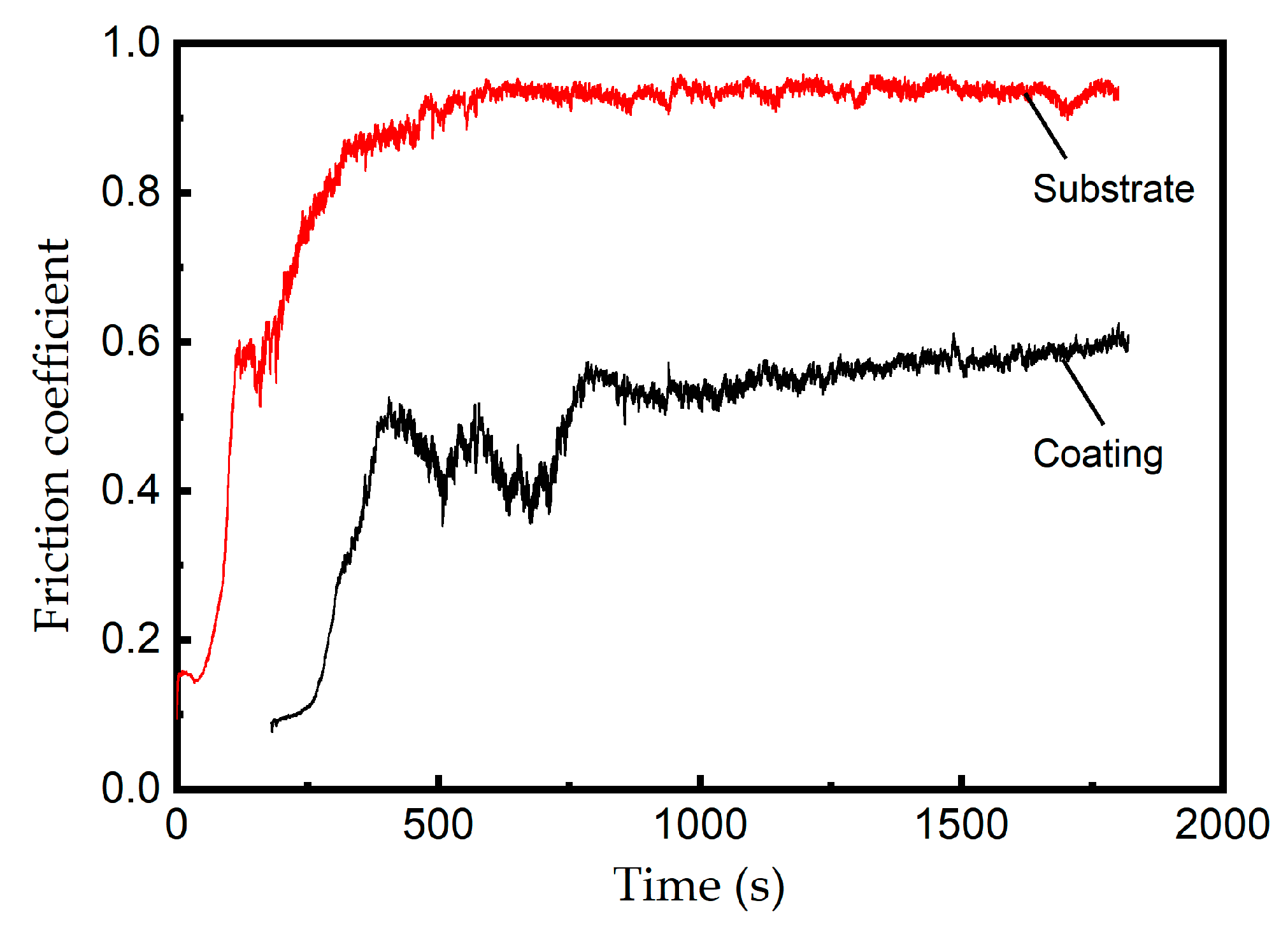

3.3.3. Wear and Friction Analysis

3.4. Cooling Rate Regulation and Microhardness Improvement

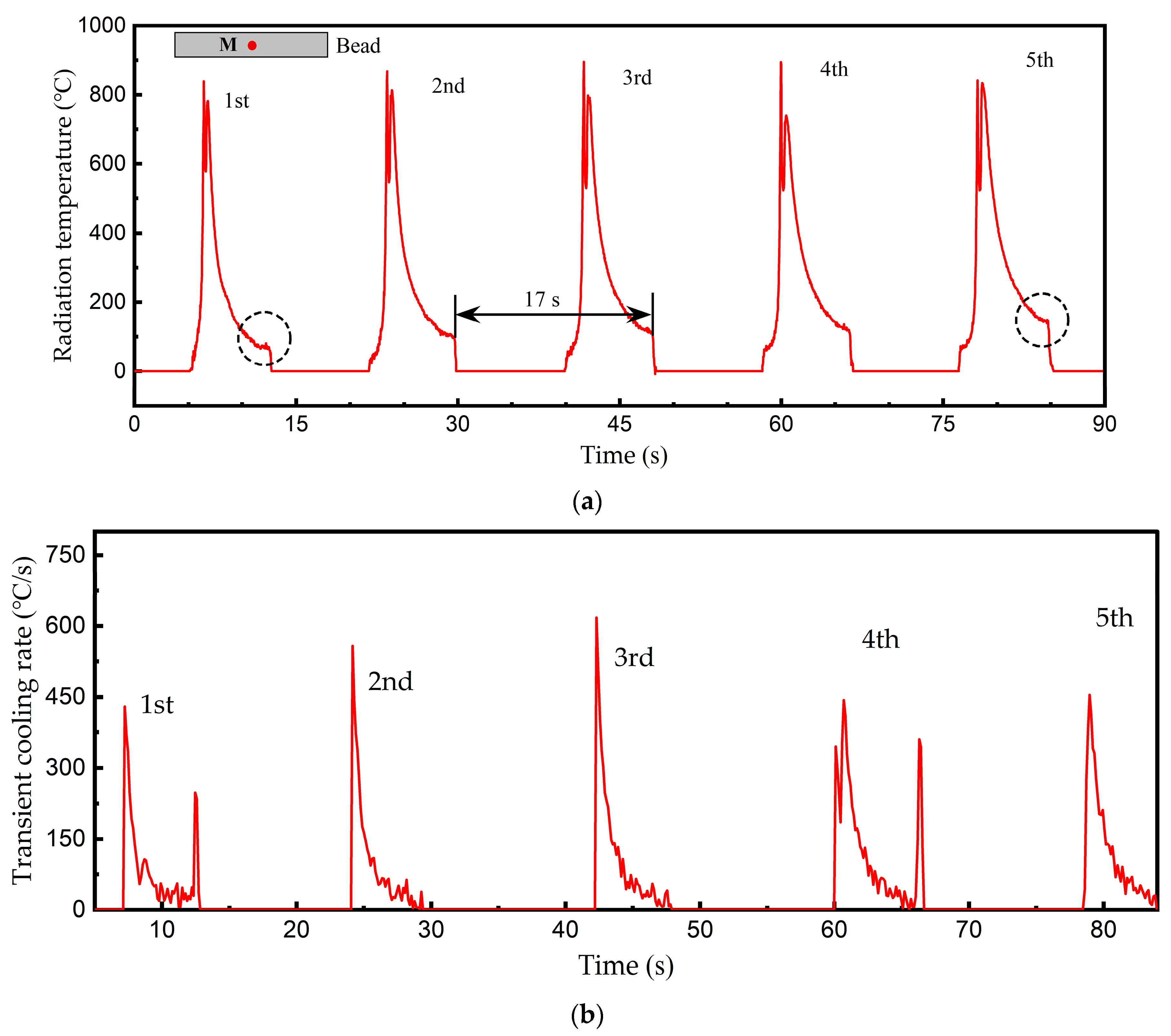

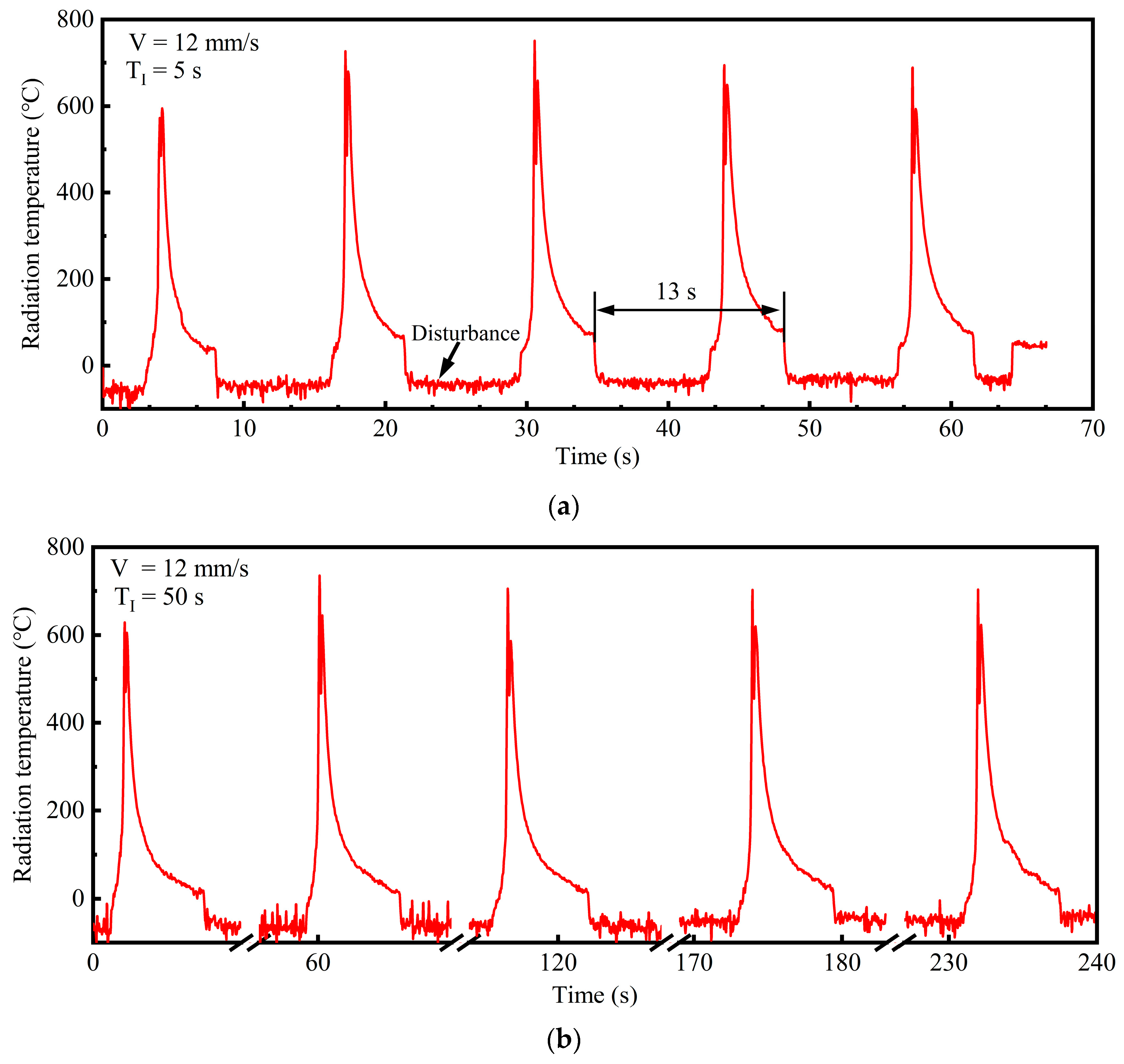

3.4.1. Cooling Rate Analysis

3.4.2. Cooling Rate Regulation

4. Conclusions

- (1)

- Interlayer fusion lines appear distinctly due to coarsened grains formed by remelting of the pre-built layer. The geometric accuracy can be significantly improved by virtue of a predicted axis lifting amount (Zd), which ensures a constant standoff distance during each layer’s deposition.

- (2)

- The Fe-based cladding layer exhibits different grain morphologies and sizes throughout the cross section. Planar grains form at the interface between the substrate and the cladding layer, and coarse columnar grains can be observed perpendicular to the bonding interface. Both dendritic and equiaxial grains coexist in the middle and top regions of the cladding layer, with finer grains on the top.

- (3)

- Increasing the laser scanning speed or extending the interlayer dwell time can effectively enhance the cooling rate, resulting in appreciable improvements in coating hardness and wear resistance. The former approach demonstrates greater efficiency and effectiveness in enhancing the cooling rate. For large-part fabrication or large-area cladding, the deposition path should be rationally planned to increase the interlayer dwell time without compromising production efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- John, M.; Kuruveri, U.B.; Menezes, P.L. Laser Cladding-Based Surface Modification of Carbon Steel and High-Alloy Steel for Extreme Condition Applications. Coatings 2022, 12, 1444. [Google Scholar] [CrossRef]

- Liu, G.; Su, Y.; Pi, X.; Xin, S.; Li, K.; Liu, D.; Lin, Y.C. Achieving high strength 316L stainless steel by laser directed energy deposition-ultrasonic rolling hybrid process. Mater. Sci. Eng. A 2024, 903, 146665. [Google Scholar] [CrossRef]

- Ahn, D. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Yao, M.; Kong, F. A review on laser cladding with wire feeding: Process fundamentals, theoretical analyses, online monitoring, and quality controls. Int. J. Adv. Manuf. Technol. 2025, 137, 4209–4242. [Google Scholar] [CrossRef]

- Li, S.; Kumar, P.; Chandra, S.; Ramamurty, U. Directed energy deposition of metals: Processing, microstructures, and mechanical properties. Int. Mater. Rev. 2023, 68, 605–647. [Google Scholar] [CrossRef]

- Li, Z.; Sui, S.; Ma, X.; Tan, H.; Zhong, C.; Bi, G.; Clare, A.T.; Gasser, A.; Chen, J. High deposition rate powder- and wire-based laser directed energy deposition of metallic materials: A review. Int. J. Mach. Tools Manuf. 2022, 181, 103942. [Google Scholar] [CrossRef]

- Svetlizky, D.; Zheng, B.; Vyatskikh, A.; Das, M.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Laser-based directed energy deposition (DED-LB) of advanced materials. Mater. Sci. Eng. A 2022, 840, 142967. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, Y.; Yang, L.; Sun, R.; Zhang, T.; Yang, X. Research and progress of laser cladding on engineering alloys: A review. J. Manuf. Process. 2021, 66, 341–363. [Google Scholar] [CrossRef]

- Liu, L.; Lin, Y.; Peng, L.; Kang, X.; Wang, X. Progress in Microstructure Design and Control of High-Hardness Fe-Based Alloy Coatings via Laser Cladding. Coatings 2024, 14, 1351. [Google Scholar] [CrossRef]

- Wu, F.; Chen, T.; Wang, H.; Liu, D. Effect of Mo on Microstructures and Wear Properties of In Situ Synthesized Ti(C,N)/Ni-Based Composite Coatings by Laser Cladding. Materials 2017, 10, 1047. [Google Scholar] [CrossRef]

- Shang, F.; Xu, Z.; Chen, J.; Chen, L.; Lu, S.; Wang, S.; Jing, X.; Dubovyi, O. Effect of Cr on wear resistance and mechanism of preset-powder laser cladding T15 alloy steel coating. J. Mater. Res. Technol. 2024, 29, 4991–4999. [Google Scholar] [CrossRef]

- Kong, L.; Shi, C.; Hao, X.; Wang, S.; Huo, Y.; Zhu, Z.; Sun, J. Effect of Ti and Mo content changes on microstructure and properties of laser cladding FeCoCrNiMn high entropy alloy coatings. Intermetallics 2024, 175, 108509. [Google Scholar] [CrossRef]

- Shang, F.; Chen, S.; Zhang, C.; Liang, J.; Liu, C.; Wang, M. The effect of Si and B on formability and wear resistance of preset-powder laser cladding W10V5Co4 alloy steel coating. Opt. Laser Technol. 2021, 134, 106590. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, Y.; Geng, R.; Wang, B.; Chen, Y.; Liang, X. Comparative study on microstructure and properties of Fe-based amorphous coatings prepared by conventional and high-speed laser cladding. J. Alloys Compd. 2023, 952, 169842. [Google Scholar] [CrossRef]

- Ribeiro, K.S.B.; Mariani, F.E.; Coelho, R.T. A Study of Different Deposition Strategies in Direct Energy Deposition (DED) Processes. Procedia Manuf. 2020, 48, 663–670. [Google Scholar] [CrossRef]

- Shin, S.; Jeon, I.; Sohn, H. Enhanced geometric accuracy in directed energy deposition via closed-loop melt pool height control using real-time thermal imaging. Addit. Manuf. 2025, 109, 104846. [Google Scholar] [CrossRef]

- Wang, K.; Liu, W.; Hong, Y.; Sohan, H.; Tong, Y.; Hu, Y.; Zhang, M.; Zhang, J.; Xiang, D.; Fu, H.; et al. An Overview of Technological Parameter Optimization in the Case of Laser Cladding. Coatings 2023, 13, 496. [Google Scholar] [CrossRef]

- Pinkerton, A.J.; Li, L. The significance of deposition point standoff variations in multiple-layer coaxial laser cladding (coaxial cladding standoff effects). Int. J. Mach. Tools Manuf. 2004, 44, 573–584. [Google Scholar] [CrossRef]

- Wang, X.; Deng, D.; Hu, Y.; Ning, F.; Wang, H.; Cong, W.; Zhang, H. Overhang structure and accuracy in laser engineered net shaping of Fe-Cr steel. Opt. Laser Technol. 2018, 106, 357–365. [Google Scholar] [CrossRef]

- Mazzarisi, M.; Errico, V.; Angelastro, A.; Campanelli, S.L. Influence of standoff distance and laser defocusing distance on direct laser metal deposition of a nickel-based superalloy. Int. J. Adv. Manuf. Technol. 2022, 120, 2407–2428. [Google Scholar] [CrossRef]

- Zhu, G.; Li, D.; Zhang, A.; Pi, G.; Tang, Y. The influence of standoff variations on the forming accuracy in laser direct metal deposition. Rapid Prototyp. J. 2011, 17, 98–106. [Google Scholar] [CrossRef]

- Yu, T.; Sun, J.; Qu, W.; Zhao, Y.; Yang, L. Influences of z-axis increment and analyses of defects of AISI 316L stainless steel hollow thin-walled cylinder. Int. J. Adv. Manuf. Technol. 2018, 97, 2203–2220. [Google Scholar] [CrossRef]

- Li, P.; Ji, S.; Zeng, X.; Hu, Q.; Xiong, W. Direct laser fabrication of thin-walled metal parts under open-loop control. Int. J. Mach. Tools Manuf. 2007, 47, 996–1002. [Google Scholar]

- Hu, B.; Han, J.; Wang, J.; Li, X. Prediction of the bead profile for wide-band laser cladding via hybrid model of mathematics and thermal simulation. Opt. Laser Technol. 2024, 170, 110206. [Google Scholar] [CrossRef]

- Shan, B.; Chen, J.; Chen, S.; Ma, M.; Ni, L.; Shang, F.; Zhou, L. Laser cladding of Fe-based corrosion and wear-resistant alloy: Genetic design, microstructure, and properties. Surf. Coat. Technol. 2022, 433, 128117. [Google Scholar] [CrossRef]

- Liu, W.; Li, L.; Mi, G.; Wang, J.; Pan, Y. Effect of Fe Content on Microstructure and Properties of Laser Cladding Inconel 625 Alloy. Materials 2022, 15, 8200. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Farshidianfar, M.H.; Gerlich, A.P.; Khajepour, A.; Mohammadi, M.; Withers, P.J. Engineering of textured gradient microstructures using directed energy deposition: The impact of adaptive cooling rate. Mater. Design 2024, 245, 113266. [Google Scholar] [CrossRef]

- Reindl, T.; Hempel, N.; Mayr, P. Effect of substrate preheating and in situ cooling on dimensional accuracy, microstructure, and hardness of wire-arc directed energy deposition components. Weld World 2025. [Google Scholar] [CrossRef]

- Zhang, H.; Mei, K.; Guo, W.; Li, Z.; Lai, Y.; Zhao, W.; Xiao, G.; Zhang, Y.; Cha, X. Comparative study on microstructures and properties of air-cooled and water-cooled Fe-based plasma arc cladding layers. J. Mater. Res. Technol. 2023, 23, 1599–1608. [Google Scholar] [CrossRef]

- Mithal, A.; Maharjan, N.; Idapalapati, S. Enhanced cooling rates in laser directed energy deposition with interlayer peening. Rapid Prototyp. J. 2023, 29, 1289–1298. [Google Scholar] [CrossRef]

- Foster, B.K.; Beese, A.M.; Keist, J.S.; McHale, E.T.; Palmer, T.A. Impact of Interlayer Dwell Time on Microstructure and Mechanical Properties of Nickel and Titanium Alloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2017, 48, 4411–4422. [Google Scholar] [CrossRef]

- Guévenoux, C.; Hallais, S.; Charles, A.; Charkaluk, E.; Constantinescu, A. Influence of interlayer dwell time on the microstructure of Inconel 718 Laser Cladded components. Opt. Laser Technol. 2020, 128, 106218. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Z.; Yang, Y.; Xiao, G.; Yi, M.; Zhou, T.; Xu, C. Influence of interlayer dwell time on microstructure and mechanical properties additively manufactured 316L stainless steel by laser directed energy deposition. J. Mater. Res. Technol. 2025, 34, 1304–1312. [Google Scholar] [CrossRef]

- Farshidianfar, M.H.; Khajepour, A.; Gerlich, A.P. Effect of real-time cooling rate on microstructure in Laser Additive Manufacturing. J. Mater. Process. Technol. 2016, 231, 468–478. [Google Scholar] [CrossRef]

- Nair, A.M.; Mahata, A.; Choudhury, A.R.; Nath, A.K. Effect of adaptive control of cooling rate on microstructure and mechanical properties of laser additively manufactured Inconel 718 thin walls. Mater. Charact. 2024, 213, 114032. [Google Scholar] [CrossRef]

- Hu, B.; Han, J.; Wang, J. Parameter Study and Economic Efficiency Optimization for Laser Cladding with Wide-Band Fiber Laser. Int. J. Opt. 2022, 2022, 6373772. [Google Scholar] [CrossRef]

- Farshidianfar, M.H.; Khajepour, A.; Gerlich, A. Real-time control of microstructure in laser additive manufacturing. Int. J. Adv. Manuf. Technol. 2016, 82, 1173–1186. [Google Scholar] [CrossRef]

- Derekar, K.; Lawrence, J.; Melton, G.; Addison, A.; Zhang, X.; Xu, L. Influence of Interpass Temperature on Wire Arc Additive Manufacturing (WAAM) of Aluminium Alloy Components. MATEC Web Conf. 2019, 269, 5001. [Google Scholar] [CrossRef]

- Liu, C.M.; Tian, X.J.; Tang, H.B.; Wang, H.M. Microstructural characterization of laser melting deposited Ti–5Al-5Mo–5V–1Cr–1Fe near β titanium alloy. J. Alloys Compd. 2013, 572, 17–24. [Google Scholar] [CrossRef]

- Farshidianfar, M.H.; Khodabakhshi, F.; Khajepour, A.; Gerlich, A.P. Closed-loop control of microstructure and mechanical properties in additive manufacturing by directed energy deposition. Mater. Sci. Eng. A 2021, 803, 140483. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, D.; Wang, P.; Yan, M.; Yang, C.; Chen, Z.; Lu, J.; Lu, Z. Additive manufacturing of metals: Microstructure evolution and multistage control. J. Mater. Sci. Technol. 2022, 100, 224–236. [Google Scholar] [CrossRef]

- Xie, Y.; Chen, W.; Liang, L.; Huang, B.; Zhuang, J. Influence of laser power on the microstructure and properties of Fe314 alloy cladding layer on EA4T steel. Weld World 2022, 66, 1551–1563. [Google Scholar] [CrossRef]

- Gao, W.; Wang, S.; Hu, K.; Jiang, X.; Yu, H.; Sun, D. Effect of laser cladding speed on microstructure and properties of titanium alloy coating on low carbon steel. Surf. Coat. Technol. 2022, 451, 129029. [Google Scholar] [CrossRef]

- Hu, B.; Han, J.; Li, X.; Wang, J. Modeling of melt pool and thermal field simulation for wide-band laser cladding. Opt. Eng. 2023, 62, 116103. [Google Scholar] [CrossRef]

- Costa, J.N.; de Assis Faria, G.; Porcaro, R.R.; Pereira, I.C. Evaluation of near immersion active cooling on the microstructure and mechanical properties of AISI 316L stainless steel obtained with additive manufacturing by DED-Arc. Int. J. Adv. Manuf. Technol. 2024, 134, 1419–1432. [Google Scholar] [CrossRef]

| C | Cr | Ni | Fe | P | Mo | B | S |

|---|---|---|---|---|---|---|---|

| 0.173 | 17.78 | 2.68 | Bal. | 0.013 | 0.90 | 0.86 | 0.004 |

| Size Distribution (μm) | Flow Rate (s/50 g) | Degree of Sphericity | |||

|---|---|---|---|---|---|

| D10 | D50 | D90 | D97 | ||

| 67.30 | 109.1 | 177.8 | 219.8 | 17.69 | 0.859 |

| C | Cr | Ni | Fe | Mn | Si |

|---|---|---|---|---|---|

| 0.42 | 0.2 | 0.255 | Bal. | 0.65 | 0.3 |

| Sample | P (W) | V (mm/s) | F (g/min) | Zd (mm) | TI (s) | Qp (L/min) | QS (L/min) | DS (mm) |

|---|---|---|---|---|---|---|---|---|

| 1# | 2000 | 7 | 22.5 | 0.45 | 5 | 10 | 12 | 18 |

| 2# | 2000 | 12 | 22.5 | 0.45 | 5 | 10 | 12 | 18 |

| 3# | 2000 | 12 | 22.5 | 0.4 | 50 | 10 | 12 | 18 |

| Layer No. | 1st | 2nd | 3rd | 4th | 5th |

|---|---|---|---|---|---|

| Mean cooling rate (°C/s) | 139 | 131 | 116 | 100 | 113 |

| Layer No. | 1st | 2nd | 3rd | 4th | 5th |

|---|---|---|---|---|---|

| Mean cooling rate of Sample 2 (°C/s) | 151 | 155 | 148 | 145 | 129 |

| Mean cooling rate of Sample 3 (°C/s) | 130 | 129 | 117 | 129 | 128 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, B.; Wang, J.; Xu, J.; Wang, Q.; Zhang, L. Geometric Accuracy and Mechanical Property Enhancement of Fe-Based Alloy Layers in Wide-Beam Laser Direct Energy Deposition. Materials 2025, 18, 4350. https://doi.org/10.3390/ma18184350

Hu B, Wang J, Xu J, Wang Q, Zhang L. Geometric Accuracy and Mechanical Property Enhancement of Fe-Based Alloy Layers in Wide-Beam Laser Direct Energy Deposition. Materials. 2025; 18(18):4350. https://doi.org/10.3390/ma18184350

Chicago/Turabian StyleHu, Bin, Junhua Wang, Junfei Xu, Qingyang Wang, and Li Zhang. 2025. "Geometric Accuracy and Mechanical Property Enhancement of Fe-Based Alloy Layers in Wide-Beam Laser Direct Energy Deposition" Materials 18, no. 18: 4350. https://doi.org/10.3390/ma18184350

APA StyleHu, B., Wang, J., Xu, J., Wang, Q., & Zhang, L. (2025). Geometric Accuracy and Mechanical Property Enhancement of Fe-Based Alloy Layers in Wide-Beam Laser Direct Energy Deposition. Materials, 18(18), 4350. https://doi.org/10.3390/ma18184350