Effects of Homogenization Heat Treatment on Microstructure of Inconel 718 Lattice Structures Manufactured by Selective Laser Melting

Abstract

1. Introduction

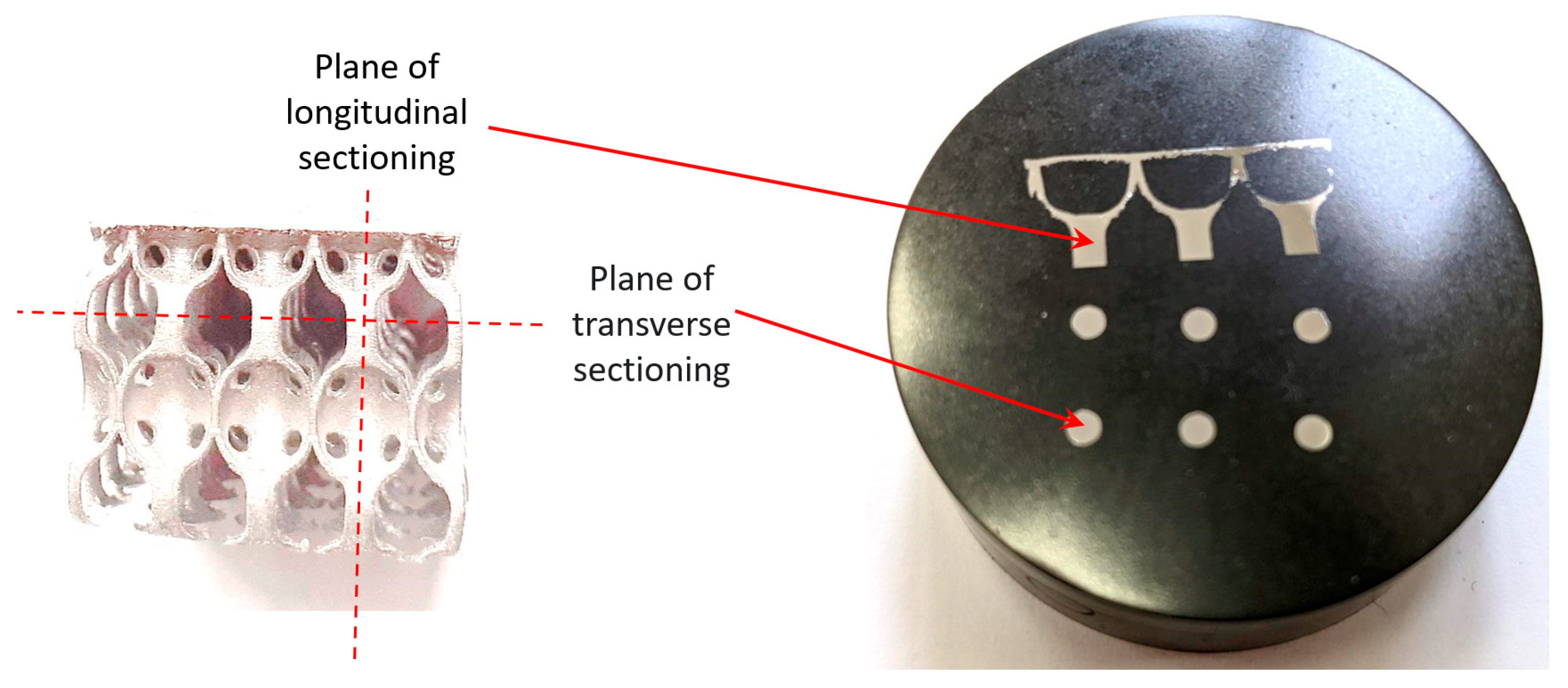

2. Materials and Methods

2.1. SLM Fabrication of Samples

2.2. The Heat Treatment of SAMPLES

3. Results and Discussion

4. Conclusions

- -

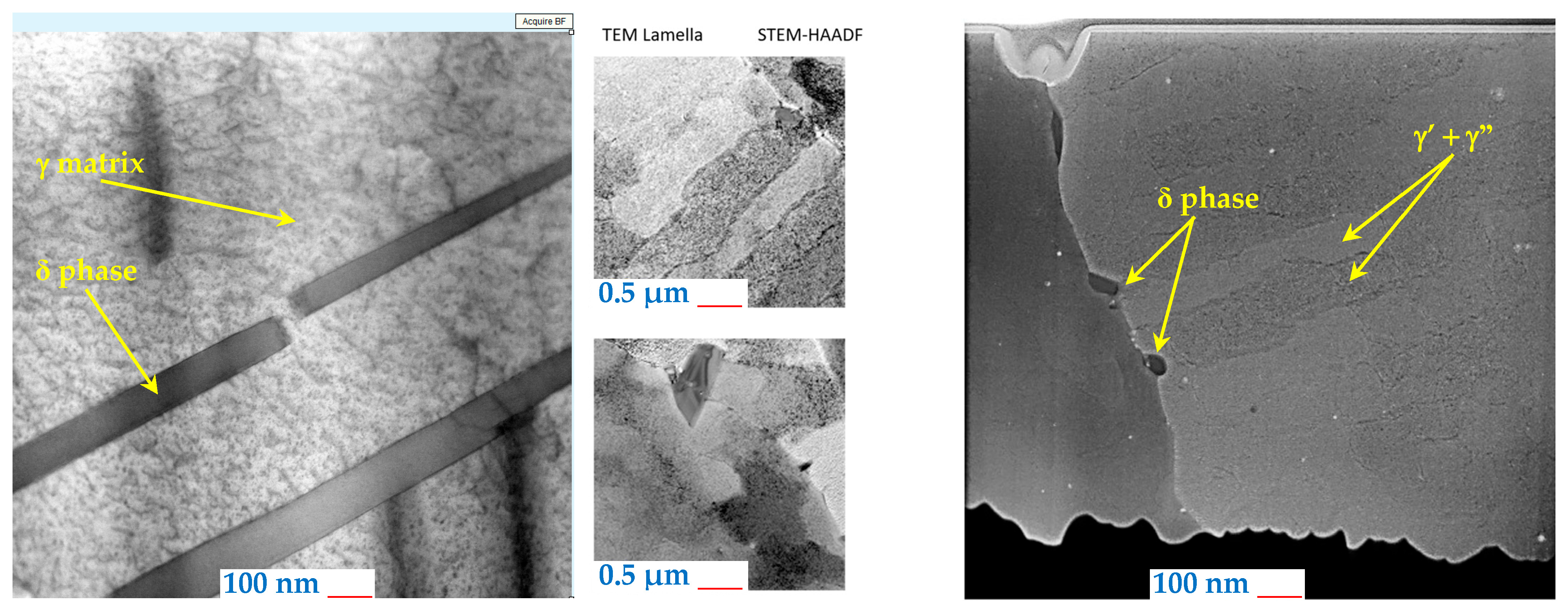

- After heat treatment, the Laves phase generates a δ phase in the vicinity due to the diffusion effect, and γ’ and γ’’ phases are also generated in the material structure. These phases contribute to the enhanced mechanical performance of the Inconel 718 superalloy due to their strengthening effect.

- -

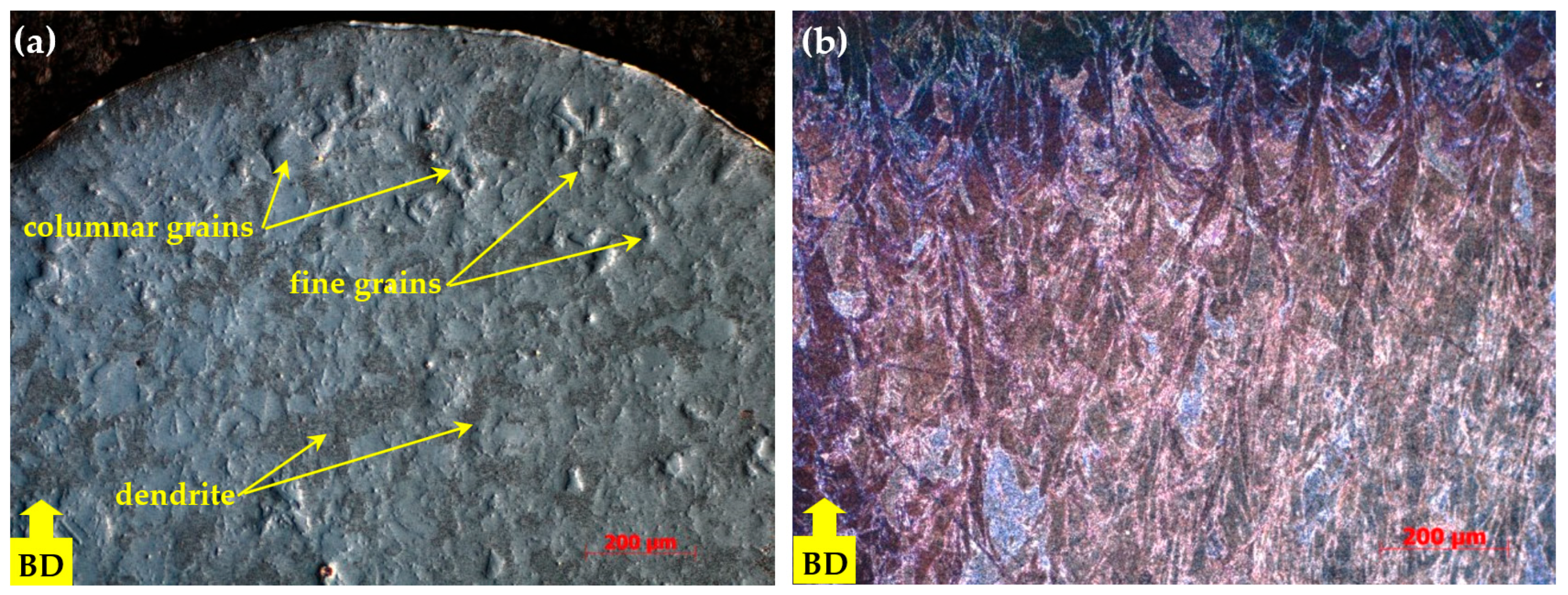

- Optical microscopy confirms the need for heat treatment by revealing a columnar dendritic structure caused by the rapid thermal cycles and radiative heat transfer in the SLM process.

- -

- The quantitative results of EDX analysis allow for a simultaneous and quantitative original position statistical distribution analysis of different elements in the Inconel 718 alloy, before and after homogenization heat treatment. This analysis shows a maximum ≈21% Cr and ≈21% Fe segregation, at the selected spots. After homogenization heat treatment, the results of EDX analysis indicate a reduction in the mass percentages of these elements, with a maximum segregation of approximately 19% Cr and 17% Fe at the selected spots. These findings confirm the formation of the δ phase.

- -

- A reduction in the mass percentages of these elements is further evidenced by the calculation of the arithmetic averages of all mass percentages before and after heat treatment. Specifically, the average mass percentages of Cr and Fe decrease from 18.57% to 13.6% and from 16.36% to 12.33%, respectively.

- -

- Ageing heat treatment significantly enhances the microstructure and mechanical properties of additively manufactured IN718 by promoting grain growth, dissolving microstructural inhomogeneities, and reducing internal stresses.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qi, H. Review of INCONEL 718 alloy: Its history, properties, processing and developing substitutes. J. Mater. Eng. 2012, 92–100. [Google Scholar]

- Adzhamsky, S.V. Implementation of SLM—Technologies for the Manufacture of Samples from Inconel 718 Heat-Resistant Alloy, Used in Aviation-Space Technology. Aerosp. Tech. Technol. 2019, 2, 69–75. [Google Scholar]

- Borisov, E.V.; Popovich, V.A.; Popovich, A.A.; Sufiiarov, V.S.; Zhu, J.-N.; Starikov, K.A. Selective laser melting of Inconel 718 under high laser power. Mater. Today Proc. 2020, 30, 784–788. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Charalampous, P.; Tsongas, K.; Kostavelis, I.; Tzovaras, D.; Tzetzis, D. Influence of Selective Laser Melting Additive Manufacturing Parameters in Inconel 718 Superalloy. Materials 2022, 15, 1362. [Google Scholar] [CrossRef]

- Material Data Sheet IN718, Nikon SLM Solutions AG. Available online: https://nikon-slm-solutions.com/wp-content/uploads/2025/02/mds5128.pdf (accessed on 13 April 2025).

- Blackwell, P.L. The mechanical and microstructural characteristics of laser-deposited IN718. J. Mech. Work. Technol. 2005, 170, 240–246. [Google Scholar] [CrossRef]

- Smith, D.H.; Bicknell, J.; Jorgensen, L.; Patterson, B.M.; Cordes, N.L.; Tsukrov, I.; Knezevic, M. Microstructure and mechanical behavior of direct metal laser sintered Inconel alloy 718. Mater. Charact. 2016, 113, 1–9. [Google Scholar] [CrossRef]

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propuls. Power. 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Sullivan, T.N.; Wang, B.; Espinosa, H.D.; Meyers, M.A. Extreme lightweight structures: Avian feathers and bones. Mater. Today 2017, 20, 377–391. [Google Scholar] [CrossRef]

- Niesłony, P.; Grzesik, W.; Jarosz, K.; Laskowski, P. FEM-based optimization of machining operations of aerospace parts made of Inconel 718 superalloy. Proc. CIRP 2018, 77, 570–573. [Google Scholar] [CrossRef]

- Iturbe, A.; Giraud, E.; Hormaetxe, E.; Garay, A.; Germain, G.; Ostolaza, K.; Arrazola, P.J. Mechanical characterization and modelling of Inconel 718 material behavior for machining process assessment. Mater. Sci. Eng. B 2017, 682, 441–453. [Google Scholar] [CrossRef]

- Muralidharan, B.G.; Shankar, V.; Gill, T.P.S. Inconel 718 Alloy—A Review; Indira Gandhi Centre for Atomic Research: Kalpakkam, India, 1996. [Google Scholar]

- Tang, Z.; Yang, C.; Duan, Y.; Ma, L.; Zheng, S.; Li, M. Corrosion and wear behaviors of Inconel 718 nickel-based alloy by boroaluminizing. Surf. Coatings Technol. 2024, 478, 130500. [Google Scholar] [CrossRef]

- Arva, E.R.U.; Abrudeanu, M.; Negrea, D.A.; Galatanu, A.; Galatanu, M.; Rizea, A.-D.; Anghel, D.-C.; Branzei, M.; Jinga, A.I.; Petrescu, M.I. Experimental Research on the Influence of Repeated Overheating on the Thermal Diffusivity of the Inconel 718 Alloy. Appl. Sci. 2024, 14, 8574. [Google Scholar] [CrossRef]

- Sonar, T.; Balasubramanian, V.; Malarvizhi, S.; Venkateswaran, T.; Sivakumar, D. An overview on welding of Inconel 718 alloy—Effect of welding processes on microstructural evolution and mechanical properties of joints. Mater. Charact. 2021, 174, 110997. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, L.; Lin, X.; Yang, H.; Huang, W. The formation and dissolution mechanisms of Laves phase in Inconel 718 fabricated by selective laser melting compared to directed energy deposition and cast. Compos. B Eng. 2022, 239, 109994. [Google Scholar] [CrossRef]

- Ajay, P.; Dabhade, V.V. Heat treatments of Inconel 718 nickel-based superalloy: A Review. Met. Mater. Int 2024, 31, 1204–1231. [Google Scholar] [CrossRef]

- Yao, X.; Moon, S.K.; Lee, B.Y.; Bi, G. Effects of heat treatment on microstructures and tensile properties of IN718/TiC nano-composite fabricated by selective laser melting. Int. J. Precis. Eng. Manuf. 2017, 18, 1693–1701. [Google Scholar] [CrossRef]

- Zaharia, S.-M.; Lancea, C.; Kruk, A.; Cempura, G.; Gruszczyński, A.; Chicos, L.-A.; Pop, M.A. Mechanical Properties and Microstructure of Inconel 718 Lattice Structures Produced by Selective Laser Melting Process. Materials 2024, 17, 622. [Google Scholar] [CrossRef]

- Chang, L.; Sun, W.; Cui, Y.; Zhang, F.; Yang, R. Effect of heat treatment on microstructure and mechanical properties of thehot-isostatic-pressed Inconel 718 powder compact. J. Alloys Compd. 2014, 590, 227–232. [Google Scholar] [CrossRef]

- SLM®280 Machine, by Nikon SLM Solutions AG. Available online: https://nikon-slm-solutions.com/slm-systems/slm280-2-0/ (accessed on 15 April 2025).

- ISO/ASTM52921-13; Standard Terminology for Additive Manufacturing-Coordinate Systems and Test Methodologies. ASTM International: West Conshohocken, PA, USA, 2013.

- Huang, W.; Yang, J.; Yang, H.; Jing, G.; Wang, Z.; Zeng, X. Heat treatment of Inconel 718 produced by selective laser melting: Microstructure and mechanical properties. Mater. Sci. Eng. A. 2019, 750, 98–107. [Google Scholar] [CrossRef]

- Hosseini, E.; Popovich, V.A. A review of mechanical properties of additively manufactured Inconel 718. Addit. Manuf. 2019, 30, 100877. [Google Scholar] [CrossRef]

- ASTM E407-07 e1; Standard Practice for Microetching Metals and Alloys. ASTM International: West Conshohocken, PA, USA, 2015.

- Kruk, A.; Cempura, G.; Lech, S.; Wusatowska-Sarnek, A.M.; Czyrska-Filemonowicz, A. Application of analytical electron microscopy and tomographic techniques for metrology and 3D imaging of microstructural elements in Allvac ® 718Plus™. In Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: Energy, Aerospace, and Industrial Applications; Ott Al, E.E., Ed.; The Minerals, Metals & Materials Series. Springer: Cham, Switzerland, 2018. [Google Scholar]

- Stadelmann, P. Simulation of Diffraction Patterns and High-Resolution Images Using JEMS. Available online: https://www.jems-swiss.ch/Home/Docs/PDF/Manual.pdf (accessed on 16 April 2025).

- Chicos, L.A.; Zaharia, S.M.; Cempura, G.; Kruk, A.; Lech, S.; Kryshtal, O.; Ziętara, M.; Michta, G.; Rodríguez, J.; Cosnita, M.; et al. Effect of concentrated solar energy on microstructure evolution of selective laser melted Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2022, 118, 3183–3207. [Google Scholar] [CrossRef]

- Li, X.; Shi, J.J.; Wang, C.H.; Cao, G.H.; Russell, A.M.; Zhou, Z.J.; Li, C.P.; Chen, G.F. Effect of heat treatment on microstructure evolution of Inconel 718 alloy fabricated by selective laser melting. J. Alloys Compd. 2018, 764, 639–649. [Google Scholar] [CrossRef]

- Cao, G.H.; Sun, T.Y.; Wang, C.H.; Li, X.; Liu, M.; Zhang, Z.X.; Hu, P.F.; Russell, A.M.; Schneider, R.; Gerthsen, D.J.M.C.; et al. Investigations of γ′, γ″ and δ precipitates in heat-treated Inconel 718 alloy fabricated by selective laser melting. Mater. Charact. 2018, 136, 398–406. [Google Scholar] [CrossRef]

- Gullipalli, C.; Burad, P.; Thawari, N.; Bhatt, J.; Gupta, T.V.K. Microstructure Evolution in Direct Energy Deposited Multilayer Inconel 718. Arab. J. Sci. Eng. 2021, 47, 7985–7994. [Google Scholar] [CrossRef]

- Santhosh, V.; Babu, N. A Study on Microstructure and Mechanical Properties of Inconel 718 Superalloy Fabricated by Novel CMT-WAAM Process. Mat. Res 2024, 27, e2023025. [Google Scholar]

- Li, Y.; Yang, S.; Peng, Z.; Wang, Z.; Gao, Z. Effects of Heat Treatment and Carbon Element Invasion on Microstructure and Mechanical Properties of Inconel 718 Alloys Fabricated by Selective Laser Melting. J. Mater. Eng. Perform. 2023, 33, 8015–8032. [Google Scholar] [CrossRef]

- Zhou, X.; Li, D.; Zhou, Q.; Jiang, F.; Song, Y.; Liang, W.; Liu, M.; Shen, X.; Wang, H. Quantitative Characterization of Elemental Segregation in Inconel 718 Superalloy by Micro-Beam X-ray Fluorescence Spectroscopy and Its Correlation Study. Materials 2023, 16, 7163. [Google Scholar] [CrossRef]

- Tajyar, A.; Brooks, N.; Holtham, N.; Rowe, R.; Newell, D.J.; Palazotto, A.N.; Davami, K. Effects of a modified heat-treatment on microstructure and mechanical properties of additively manufactured Inconel 718. Mater. Sci. Eng. A 2022, 838, 142770. [Google Scholar] [CrossRef]

| ASTM F3055/ASTM B637/AMS5664 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe | Ni | Cr | Ta+Nb | Mo | Ti | Co | Al | Si | Mn | Cu | C | P | S | B | |

| Min. | Bal. | 50.00 | 17.00 | 4.75 | 2.80 | 0.65 | 0.20 | ||||||||

| Max. | 55.00 | 21.00 | 5.50 | 3.30 | 1.15 | 1.00 | 0.80 | 0.35 | 0.35 | 0.30 | 0.08 | 0.015 | 0.015 | 0.006 | |

| Zone No. | Al-K | Cr-KA | Ni-KA | Nb-KA | Ti-KA | Co-KA | Fe-KA | Mo-KA |

|---|---|---|---|---|---|---|---|---|

| 1 | 1.35 | 22.14 | 50.08 | 3.72 | 1.23 | 0.38 | 18.38 | 2.72 |

| 2 | 1.35 | 20.18 | 52.86 | 2.84 | 1.02 | 0.37 | 18.84 | 2.55 |

| 3 | 2.47 | 20.01 | 51.83 | 3.28 | 1.14 | 0.37 | 18.36 | 2.55 |

| 4 | 1.55 | 20.18 | 52.77 | 2.72 | 0.9 | 0.37 | 18.98 | 2.54 |

| 5 | 1.54 | 20.48 | 51.96 | 2.59 | 0.81 | 0.37 | 19.72 | 2.52 |

| 6 | 1.33 | 21.24 | 50.62 | 2.15 | 0.7 | 0.35 | 21.19 | 2.42 |

| 7 | 1.5 | 20.4 | 52.28 | 2.92 | 0.97 | 0.37 | 18.94 | 2.62 |

| 8 | 1.96 | 20.15 | 52.22 | 2.95 | 1.07 | 0.38 | 18.72 | 2.56 |

| 9 | 2.55 | 20.06 | 51.67 | 3.32 | 1.18 | 0.37 | 18.25 | 2.59 |

| 10 | 1.37 | 20.53 | 52.88 | 2.3 | 0.75 | 0.36 | 19.45 | 2.36 |

| 11 | 1.2 | 16.13 | 46.82 | 16.33 | 2.18 | 0.34 | 12.74 | 4.26 |

| 12 | 1.42 | 15.96 | 47.24 | 15.59 | 2.32 | 0.35 | 12.97 | 4.16 |

| 13 | 1.27 | 15.98 | 46.02 | 17.03 | 2.35 | 0.35 | 12.76 | 4.23 |

| 14 | 1.4 | 18.88 | 51.1 | 7.21 | 1.74 | 0.3 | 16.27 | 3.09 |

| 15 | 1.05 | 15.87 | 45.05 | 18.38 | 2.11 | 0.32 | 12.75 | 4.47 |

| 16 | 1.08 | 15.53 | 45.94 | 18.13 | 2.12 | 0.37 | 12.7 | 4.03 |

| 17 | 1.34 | 15.36 | 46.39 | 17.86 | 2.17 | 0.37 | 12.52 | 4 |

| 18 | 1.22 | 15.96 | 45.36 | 17.49 | 2.61 | 0.32 | 12.8 | 4.23 |

| 19 | 1.4 | 17.83 | 49.46 | 10.68 | 1.98 | 0.36 | 14.56 | 3.73 |

| Zone No. | Al-K | Cr-KA | Ni-KA | Nb-KA | Ti-KA | Co-KA | Fe-KA | Mo-KA |

|---|---|---|---|---|---|---|---|---|

| 1 | 5.93 | 19.28 | 50.48 | 12.44 | 0.81 | 0.51 | 5.71 | 4.84 |

| 2 | 3.92 | 19.18 | 48.74 | 4.27 | 1.63 | 0.99 | 17.5 | 3.78 |

| 3 | 3.99 | 19.04 | 48.69 | 4.26 | 1.71 | 1.02 | 17.45 | 3.84 |

| 4 | 4.01 | 19.14 | 48.81 | 4.23 | 1.6 | 0.99 | 17.45 | 3.78 |

| 5 | 3.92 | 19.1 | 48.81 | 4.21 | 1.64 | 1.02 | 17.52 | 3.79 |

| 6 | 4.08 | 19.33 | 48.79 | 4.03 | 1.57 | 0.99 | 17.55 | 3.66 |

| 7 | 4.1 | 6.19 | 52.36 | 14.17 | 1.72 | 1.03 | 17.62 | 3.82 |

| 8 | 3.57 | 2.24 | 54.09 | 20.39 | 3.45 | 0.96 | 12.28 | 3.03 |

| 9 | 4.62 | 10.6 | 53.74 | 19.91 | 3.46 | 0.96 | 3.67 | 3.03 |

| 10 | 4.95 | 9.97 | 53.41 | 20.81 | 3.63 | 0.88 | 3.34 | 3.02 |

| 11 | 4.55 | 9.98 | 51.25 | 20.21 | 14,01 | 0.78 | 9.22 | 4.01 |

| 12 | 4.14 | 9.14 | 42.32 | 17.44 | 13.31 | 0.88 | 8.65 | 4.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chicos, L.-A.; Lancea, C.; Zaharia, S.-M.; Cempura, G.; Kruk, A.; Pop, M.A. Effects of Homogenization Heat Treatment on Microstructure of Inconel 718 Lattice Structures Manufactured by Selective Laser Melting. Materials 2025, 18, 4149. https://doi.org/10.3390/ma18174149

Chicos L-A, Lancea C, Zaharia S-M, Cempura G, Kruk A, Pop MA. Effects of Homogenization Heat Treatment on Microstructure of Inconel 718 Lattice Structures Manufactured by Selective Laser Melting. Materials. 2025; 18(17):4149. https://doi.org/10.3390/ma18174149

Chicago/Turabian StyleChicos, Lucia-Antoneta, Camil Lancea, Sebastian-Marian Zaharia, Grzegorz Cempura, Adam Kruk, and Mihai Alin Pop. 2025. "Effects of Homogenization Heat Treatment on Microstructure of Inconel 718 Lattice Structures Manufactured by Selective Laser Melting" Materials 18, no. 17: 4149. https://doi.org/10.3390/ma18174149

APA StyleChicos, L.-A., Lancea, C., Zaharia, S.-M., Cempura, G., Kruk, A., & Pop, M. A. (2025). Effects of Homogenization Heat Treatment on Microstructure of Inconel 718 Lattice Structures Manufactured by Selective Laser Melting. Materials, 18(17), 4149. https://doi.org/10.3390/ma18174149