Synergistic Effects of Lignin Fiber and Sodium Sulfate on Mechanical Properties and Micro-Structure of Cement-Stabilized Soil

Abstract

1. Introduction

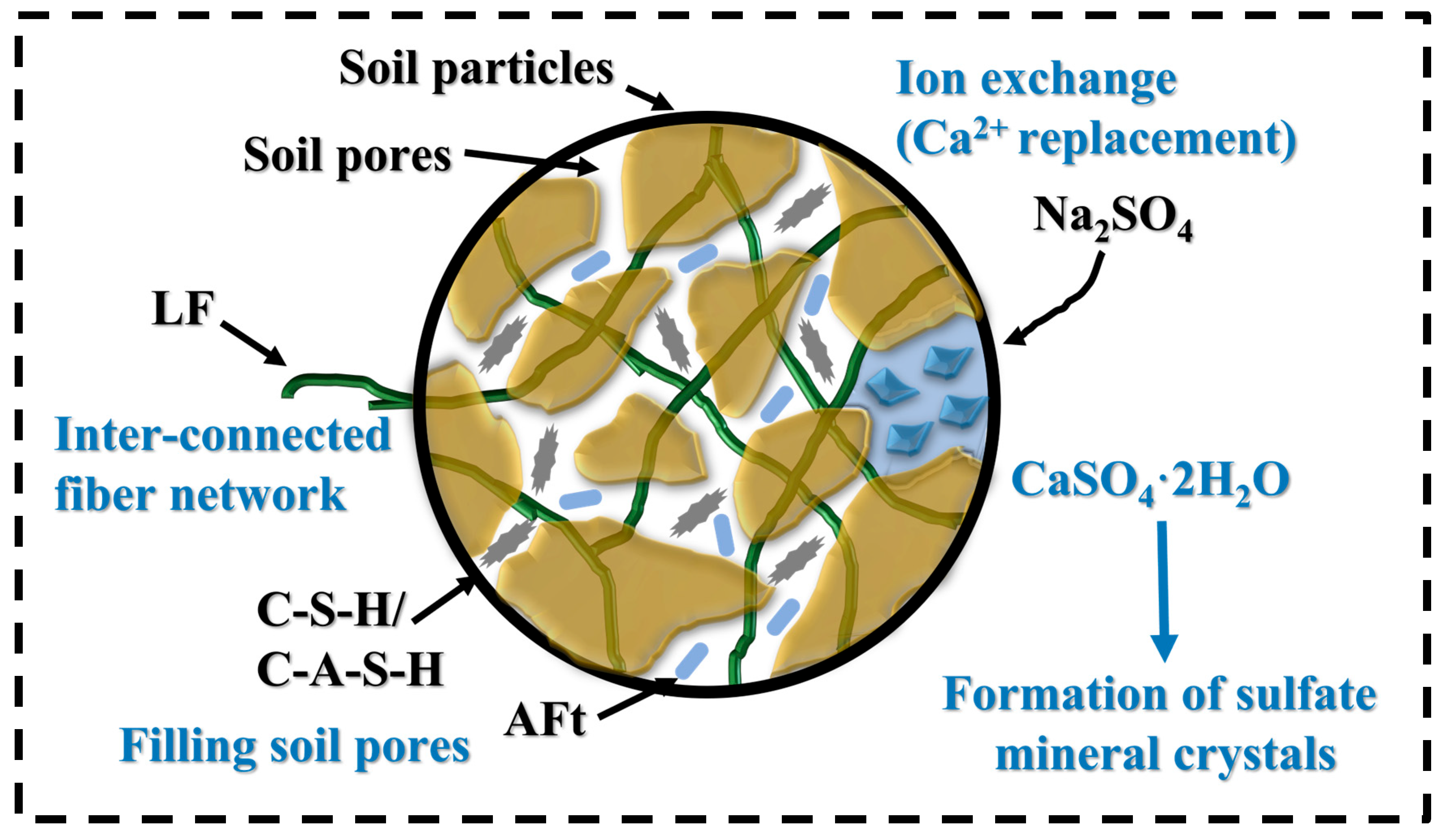

2. Experimental Program

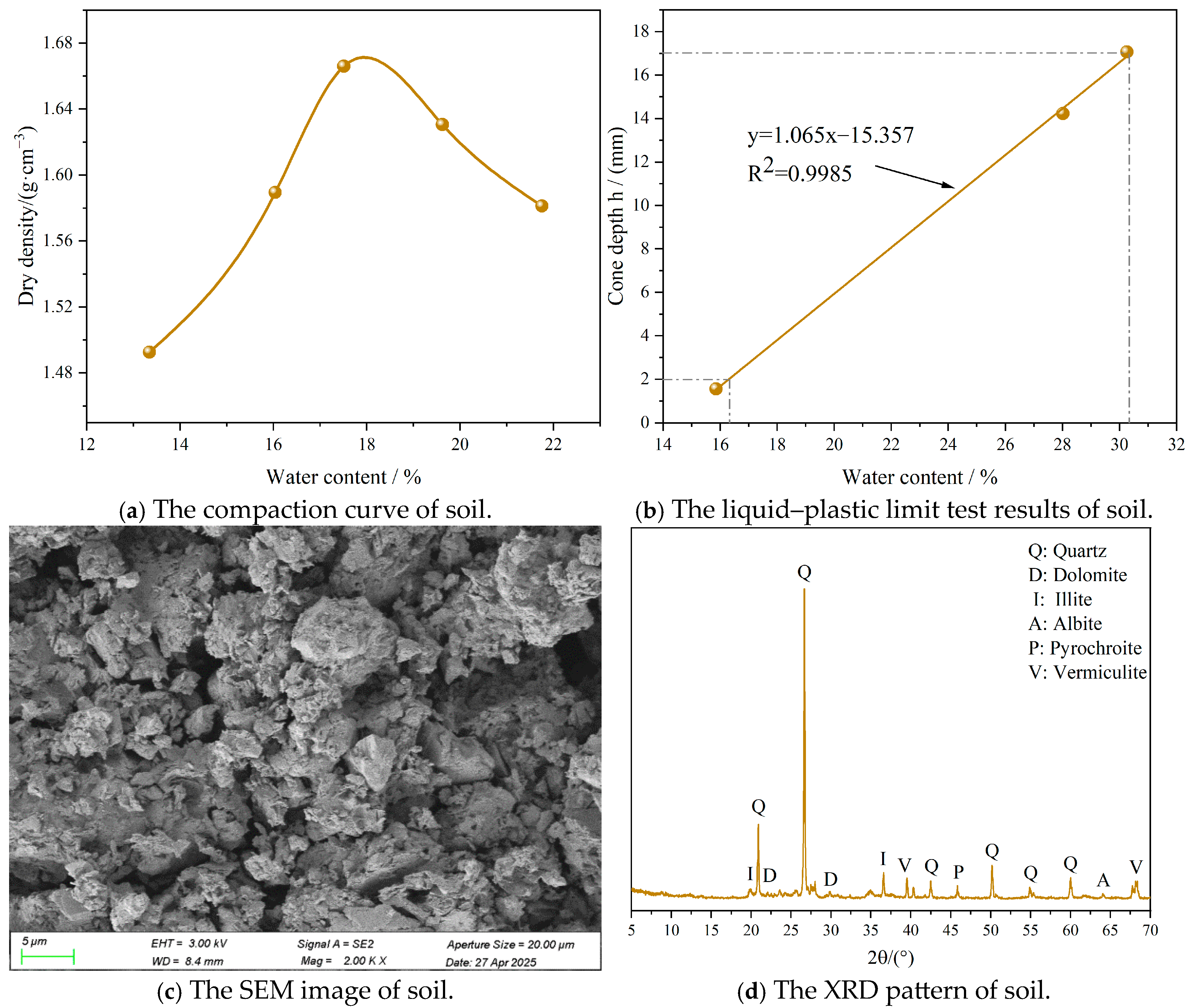

2.1. Raw Materials

2.2. Mix Design and Specimen Preparations

2.3. Test Methods

2.3.1. Unconfined Compressive Strength Tests

2.3.2. Indirect Tensile Strength Test

2.3.3. Capillary Water Absorption Test

2.3.4. X-Ray Diffraction Tests

2.3.5. Scanning Electron Microscopy Tests

3. Results

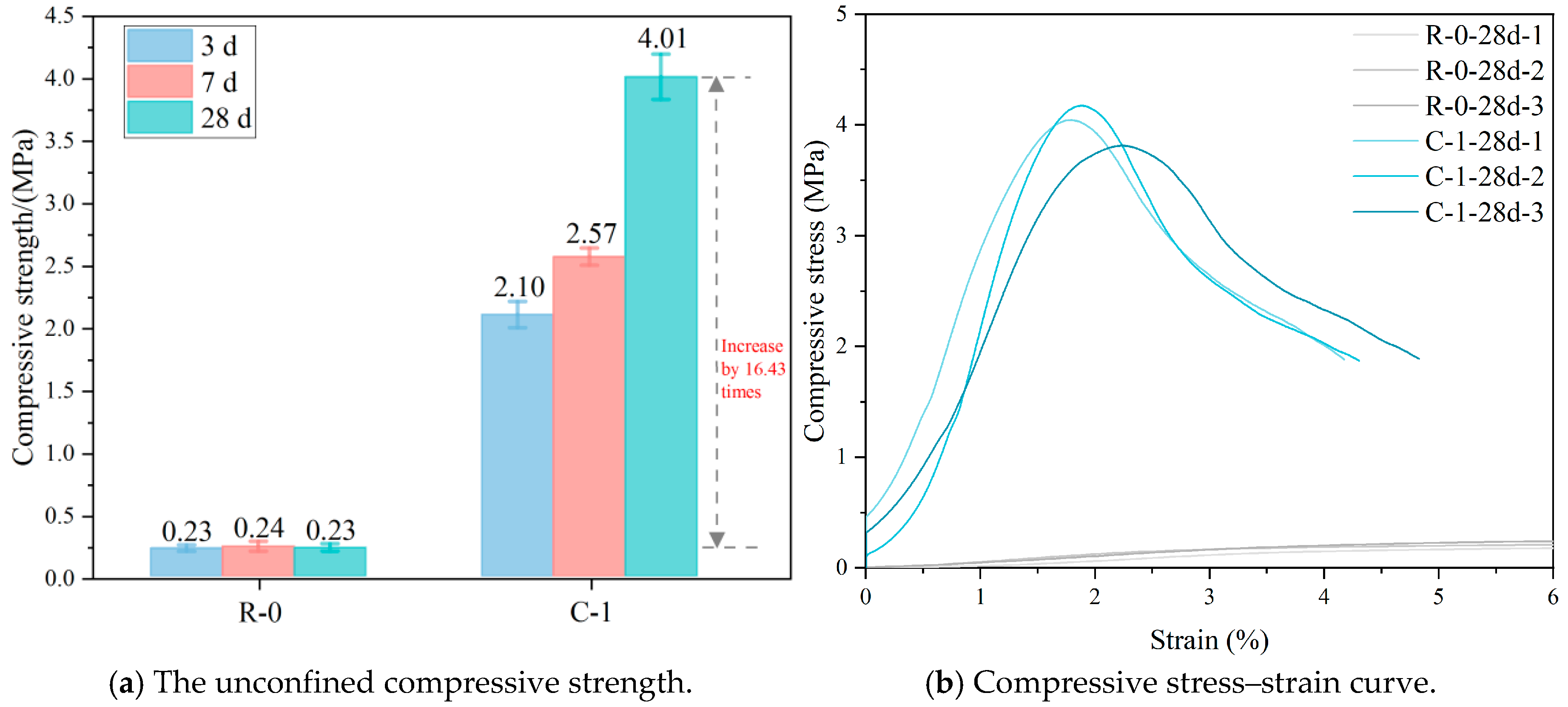

3.1. Analysis of Traditional Cement-Stabilized Soil

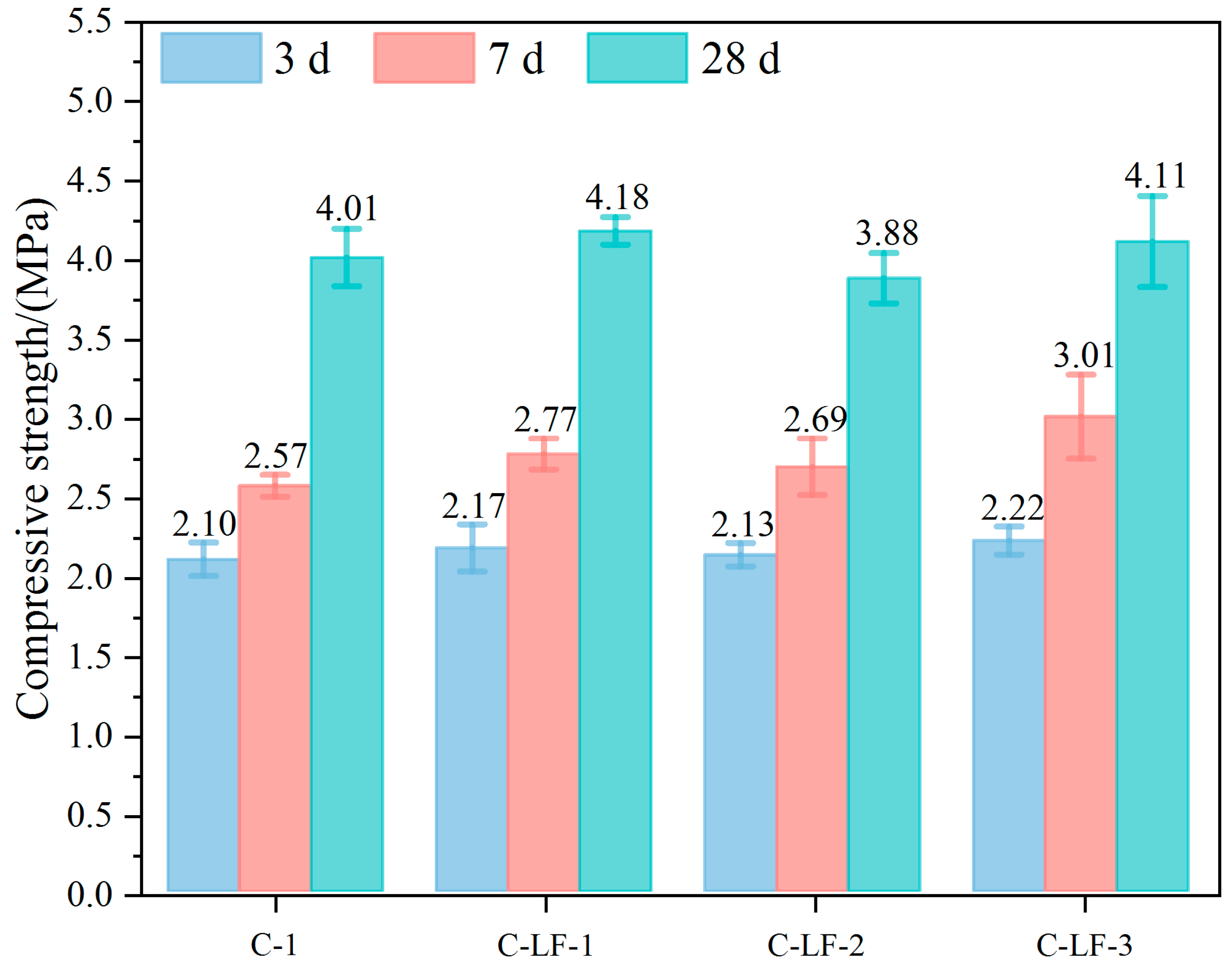

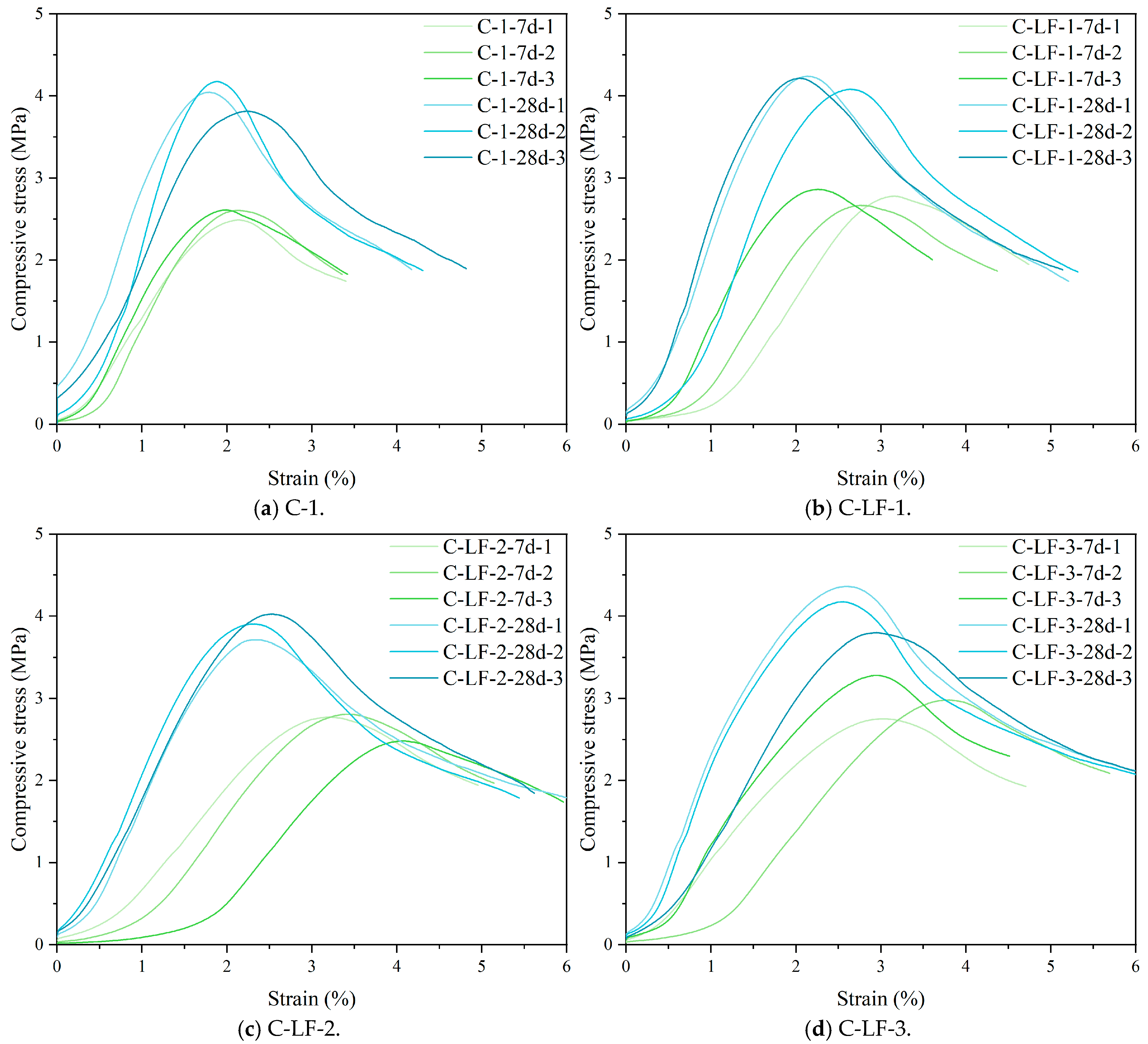

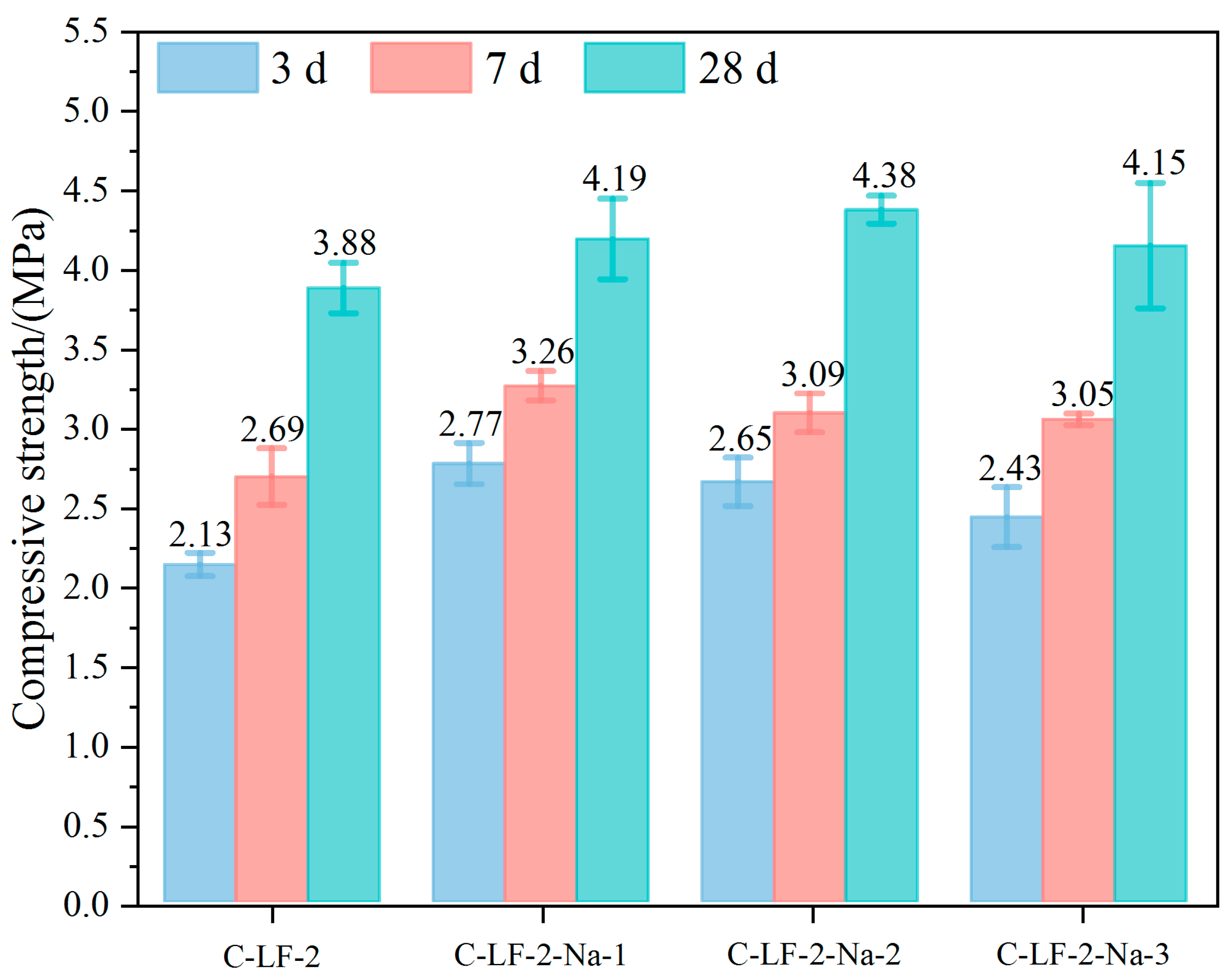

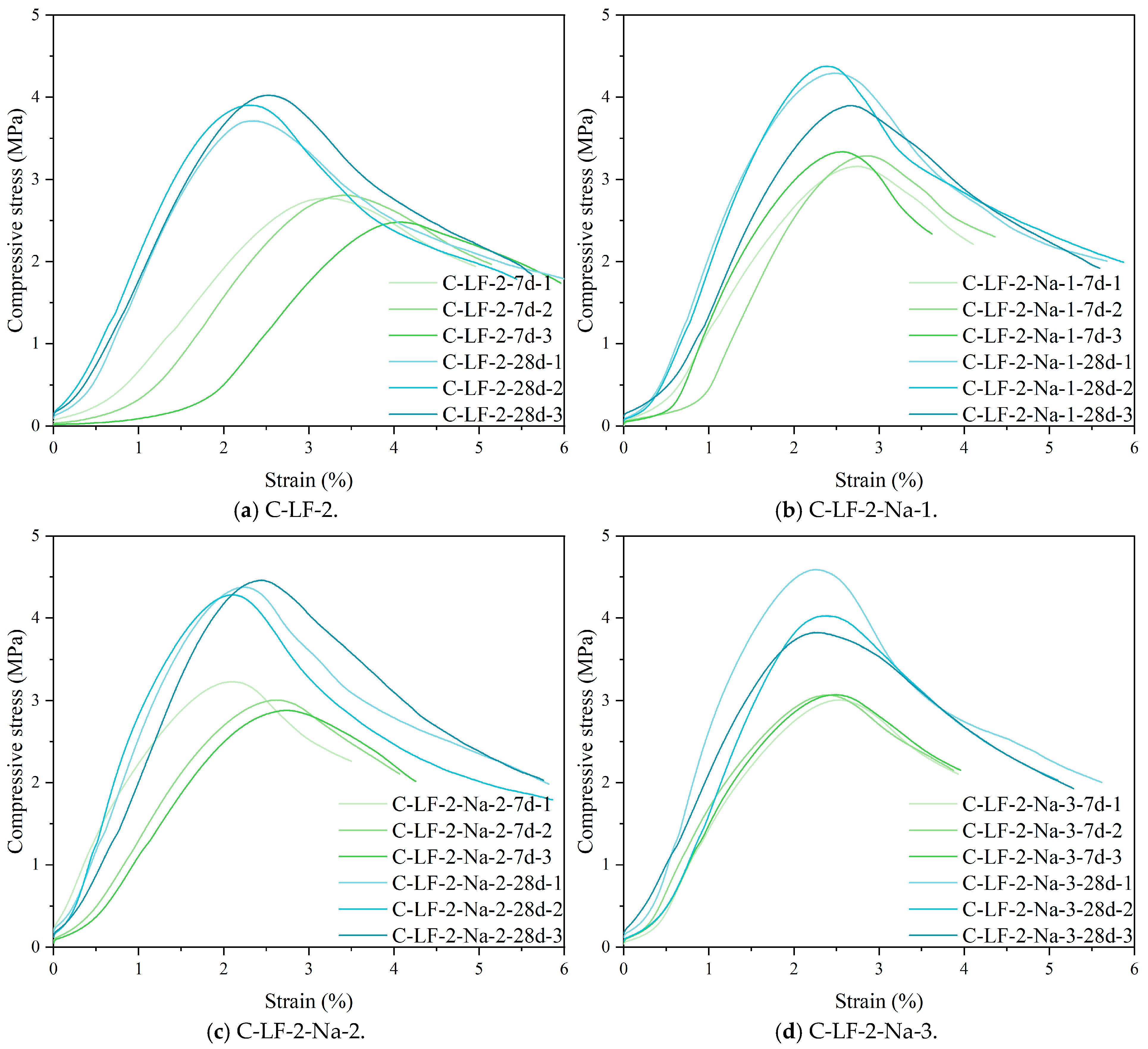

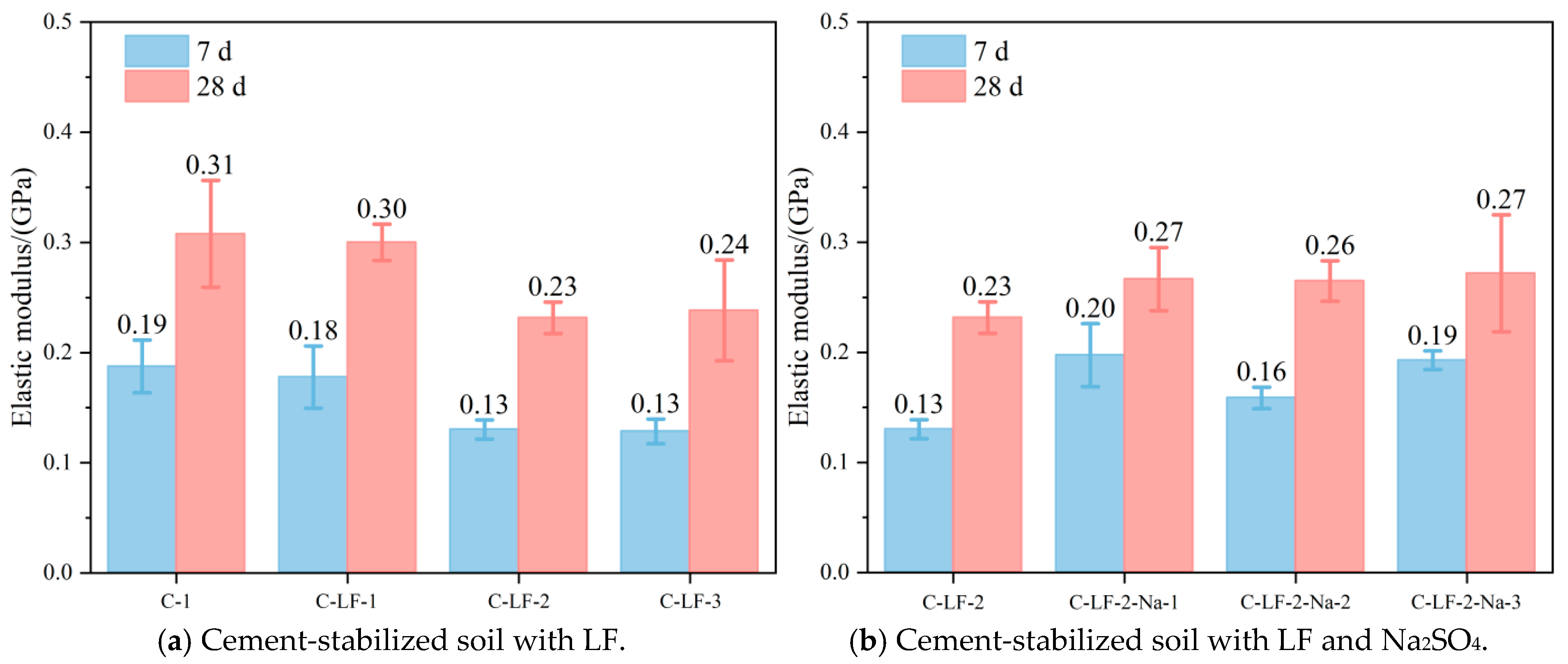

3.2. The Unconfined Compression Performance

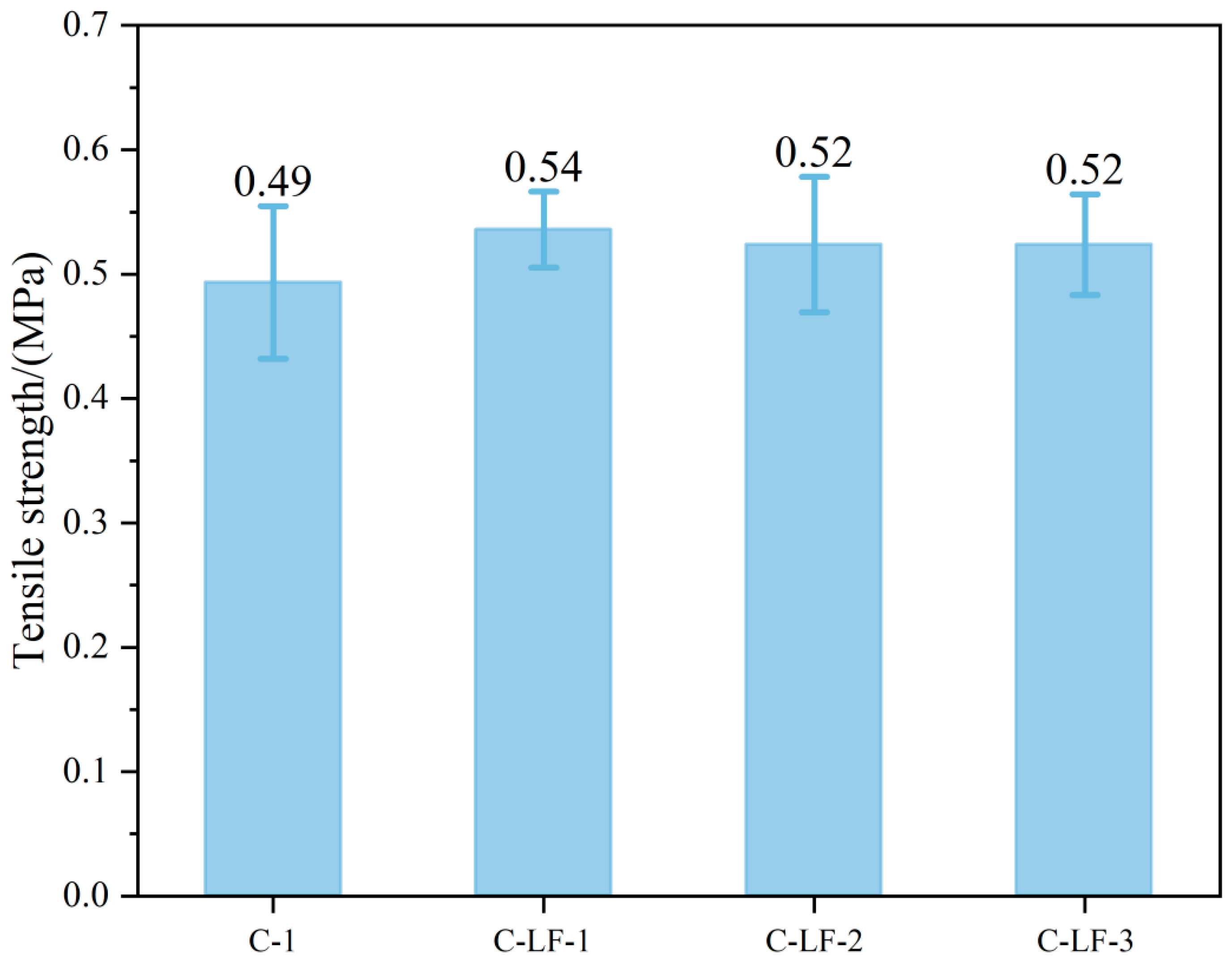

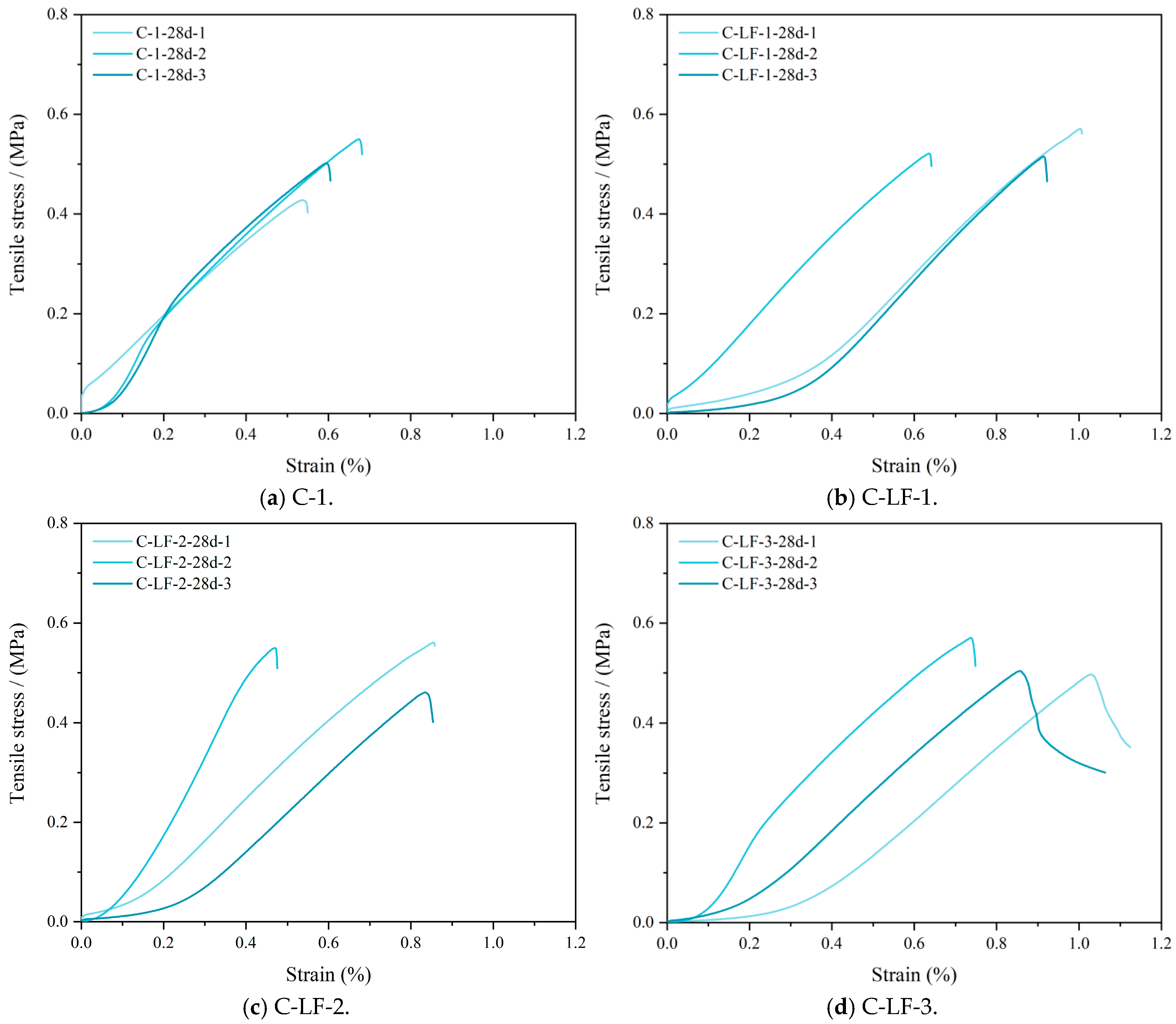

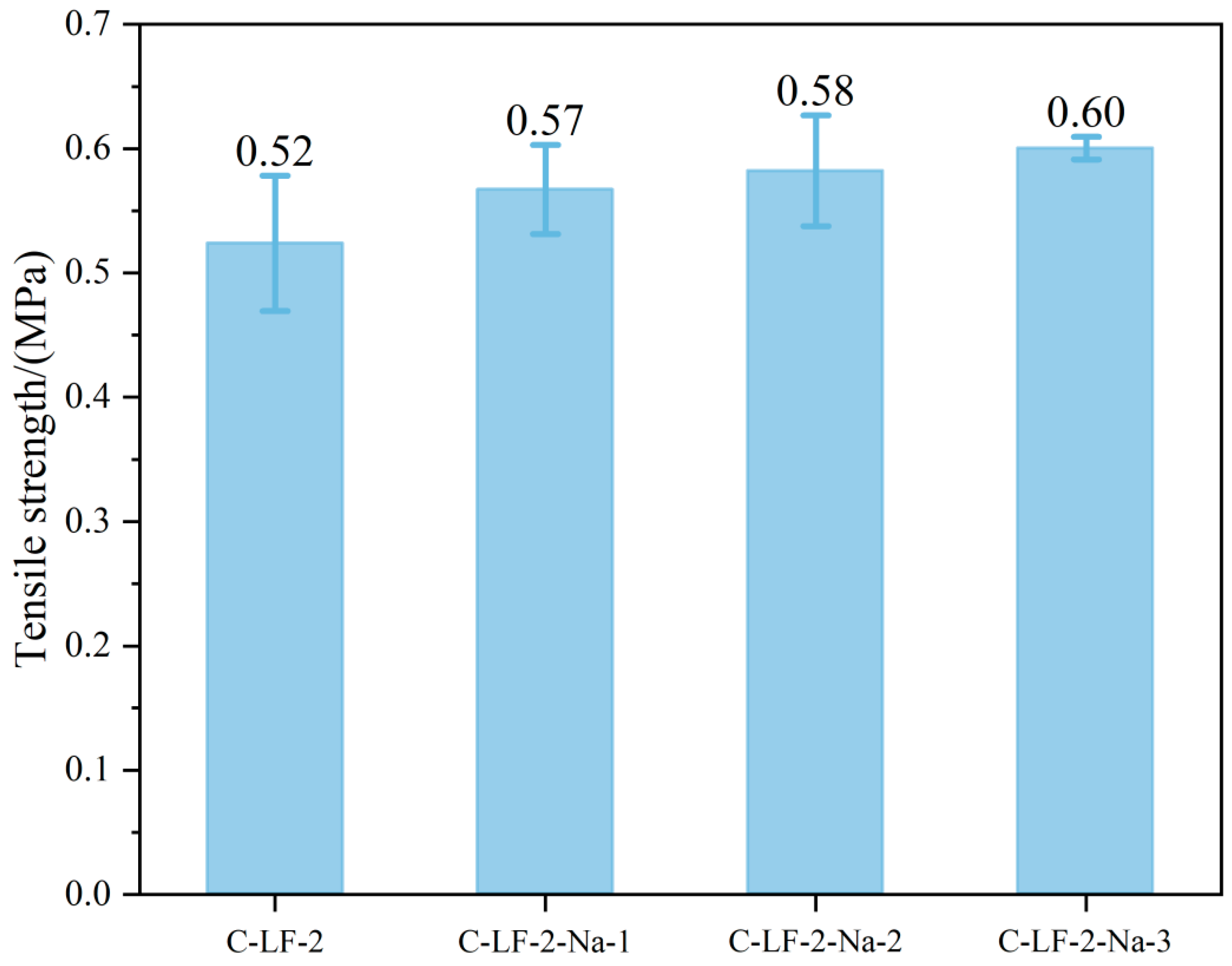

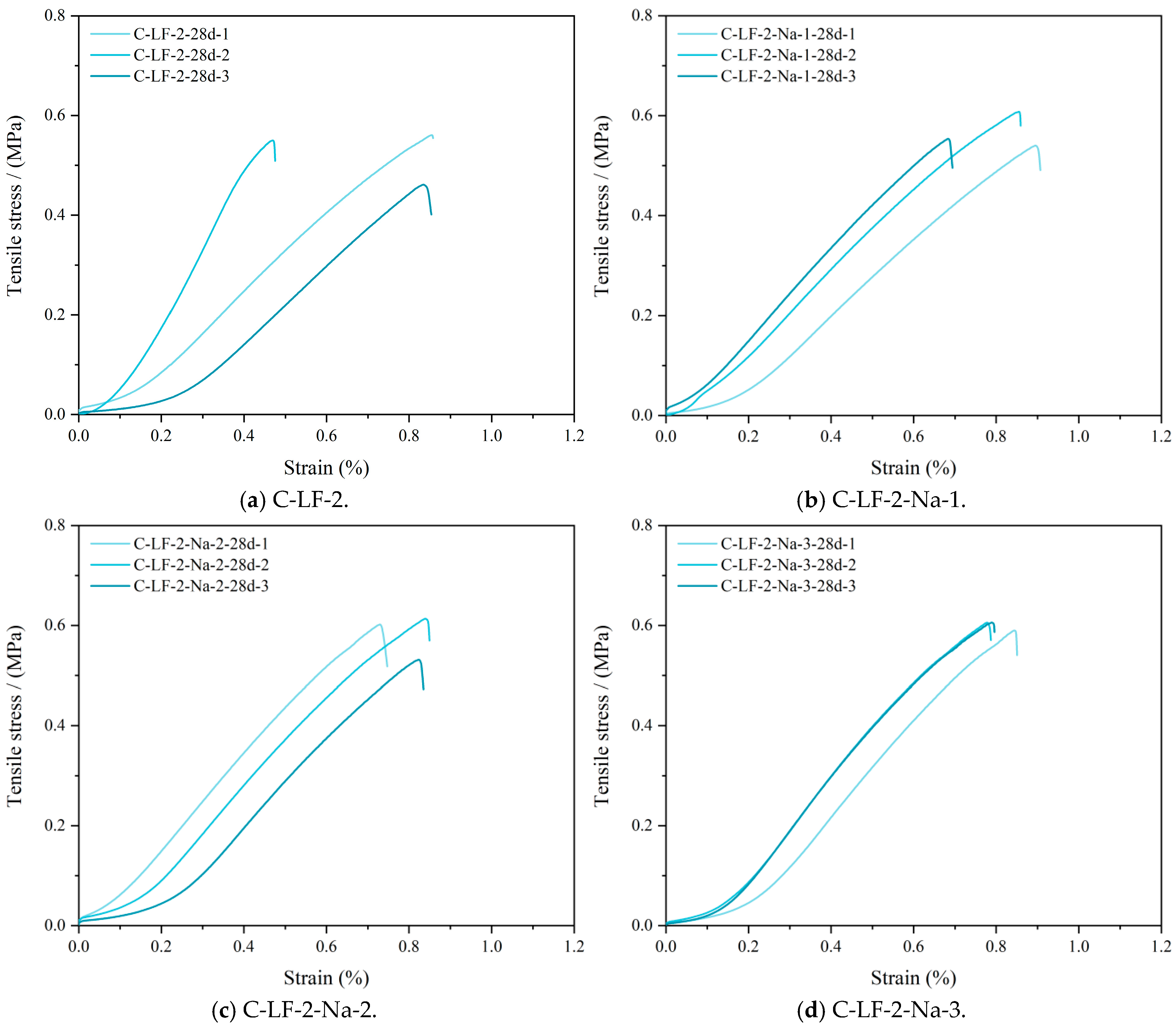

3.3. Splitting Tensile Strength

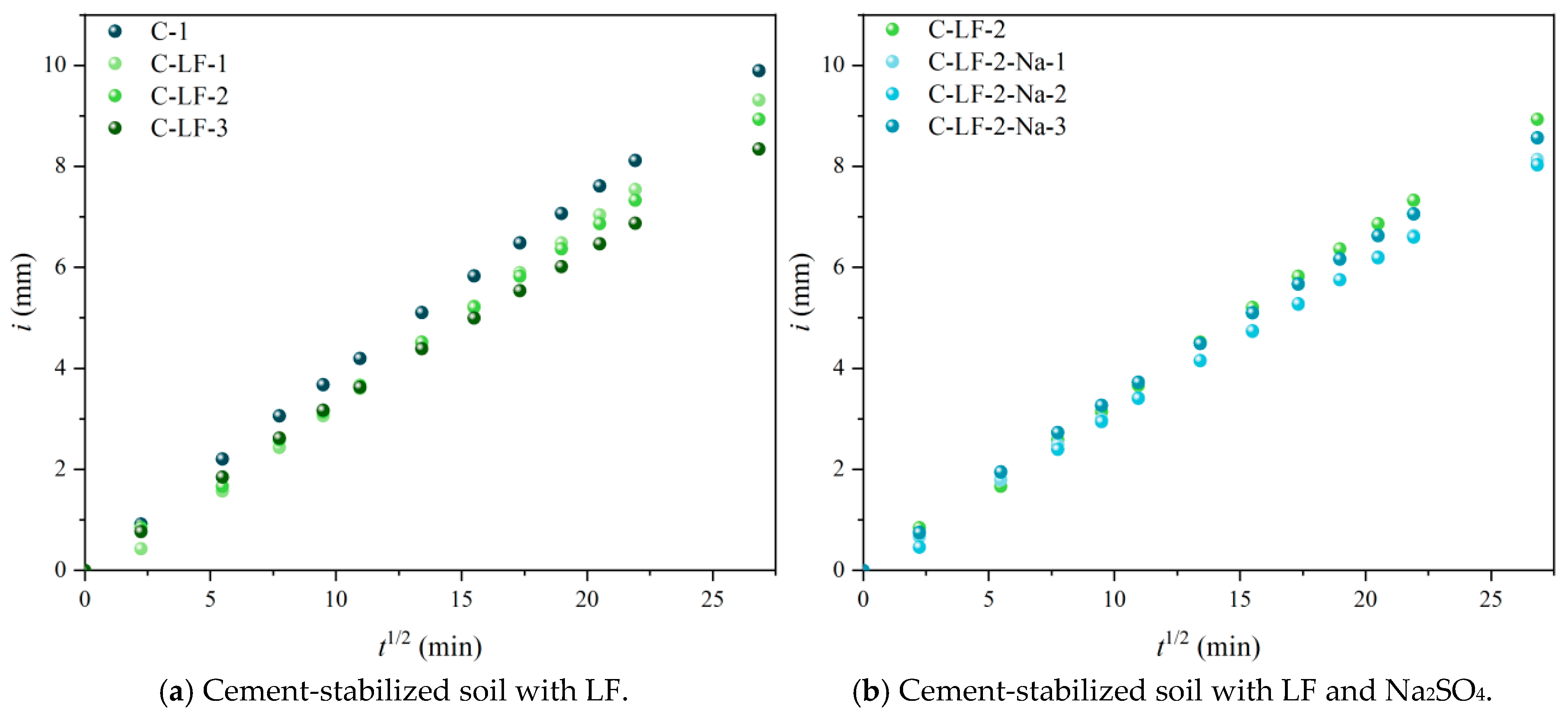

3.4. Capillary Water Absorption Characteristics

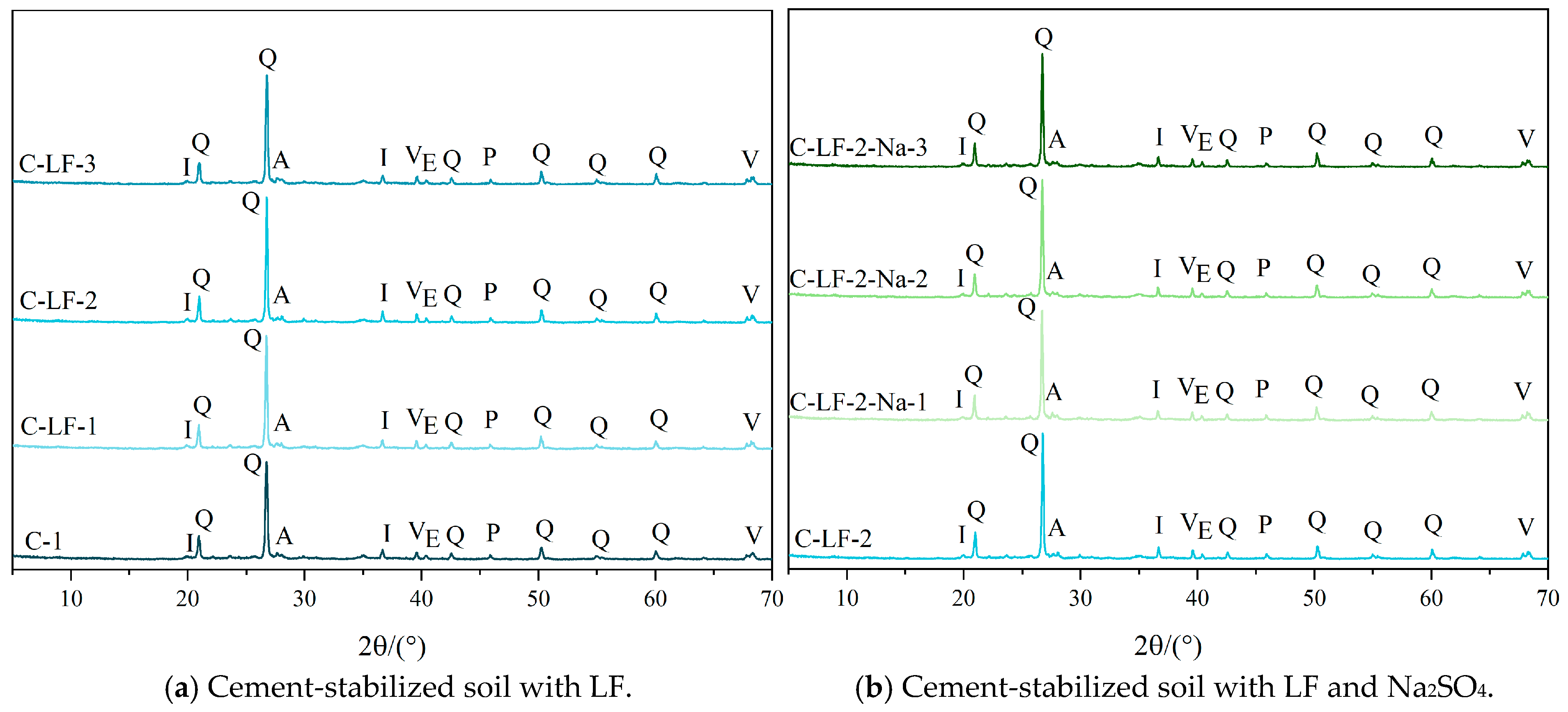

3.5. Phase Analysis

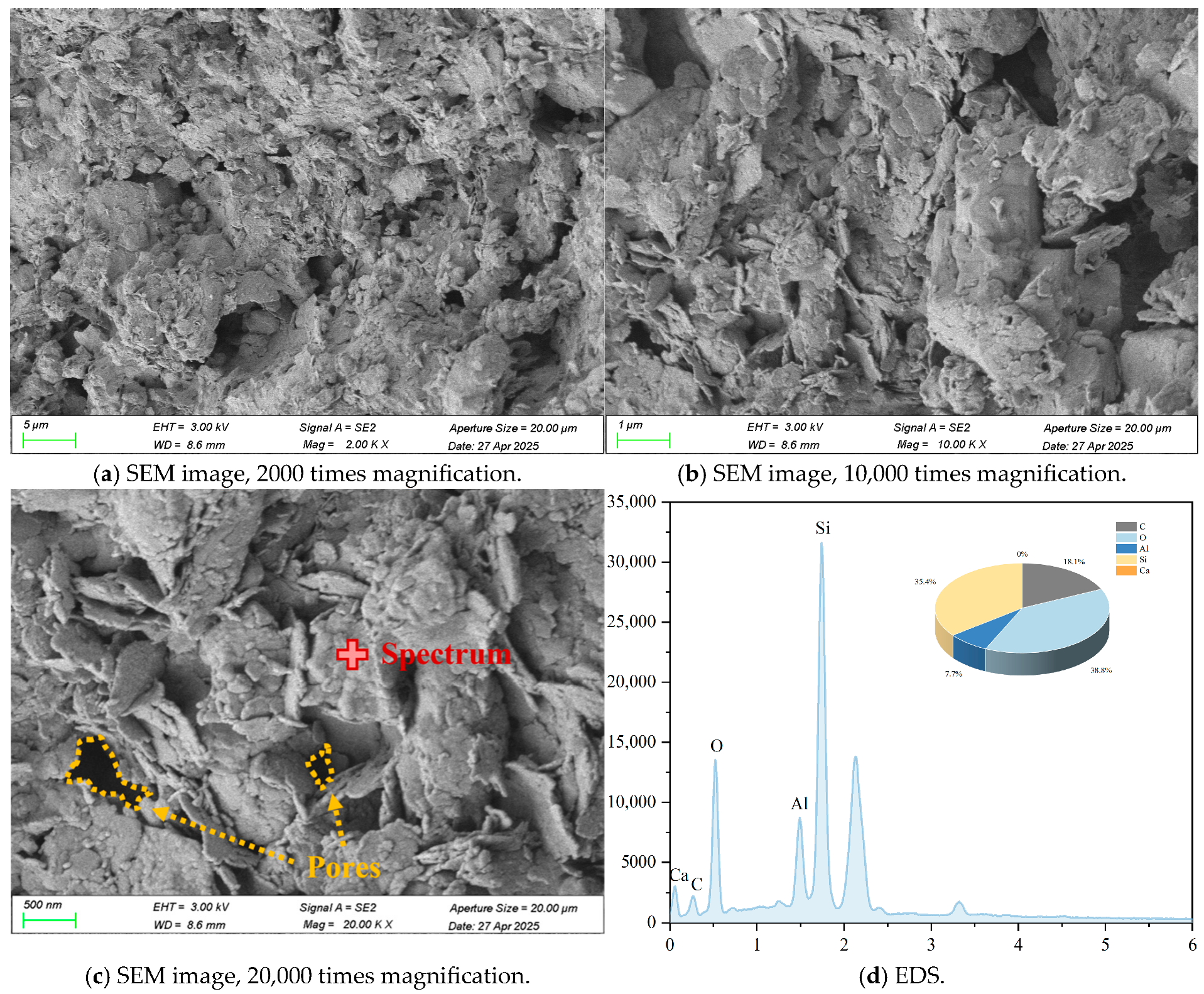

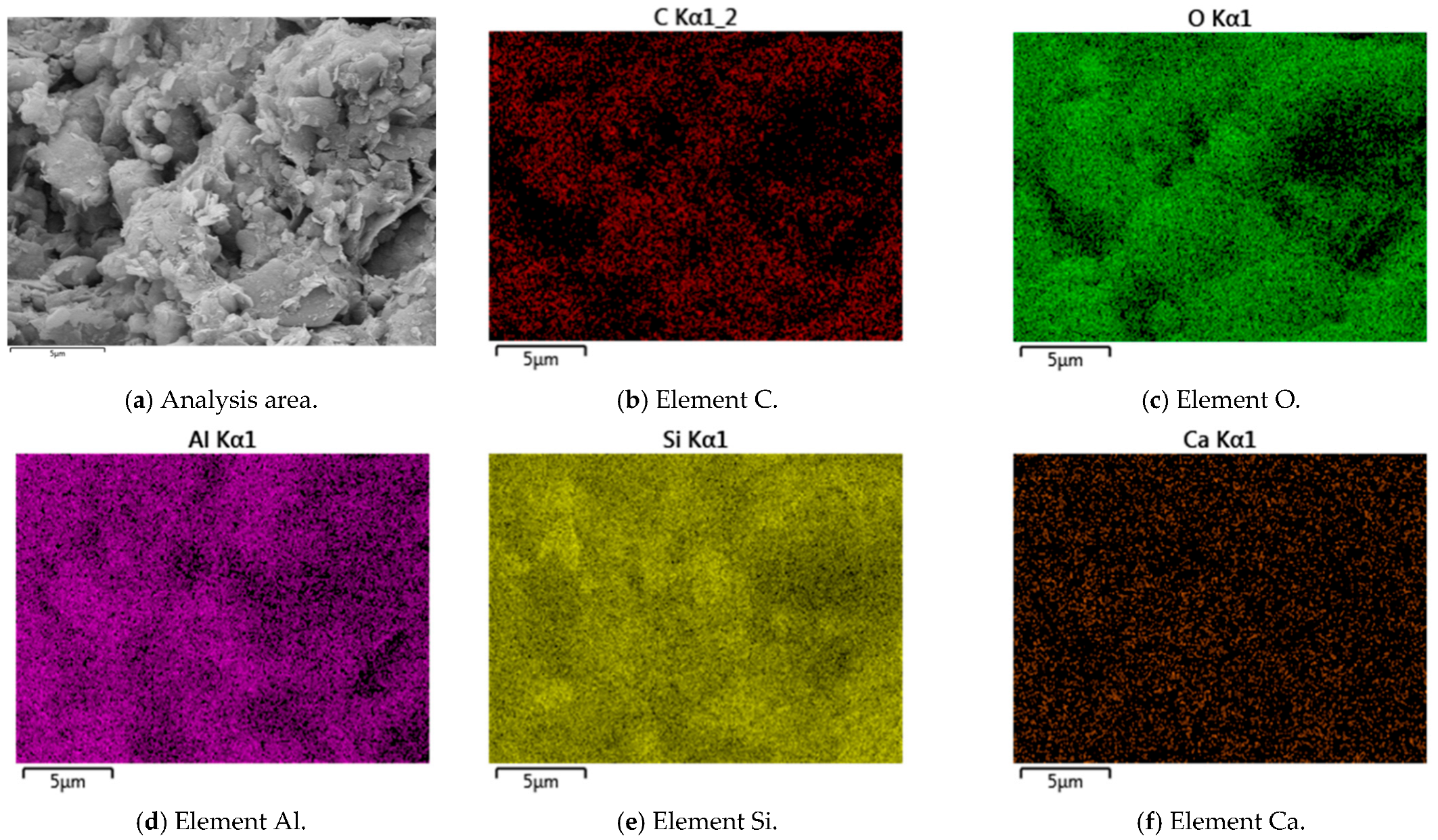

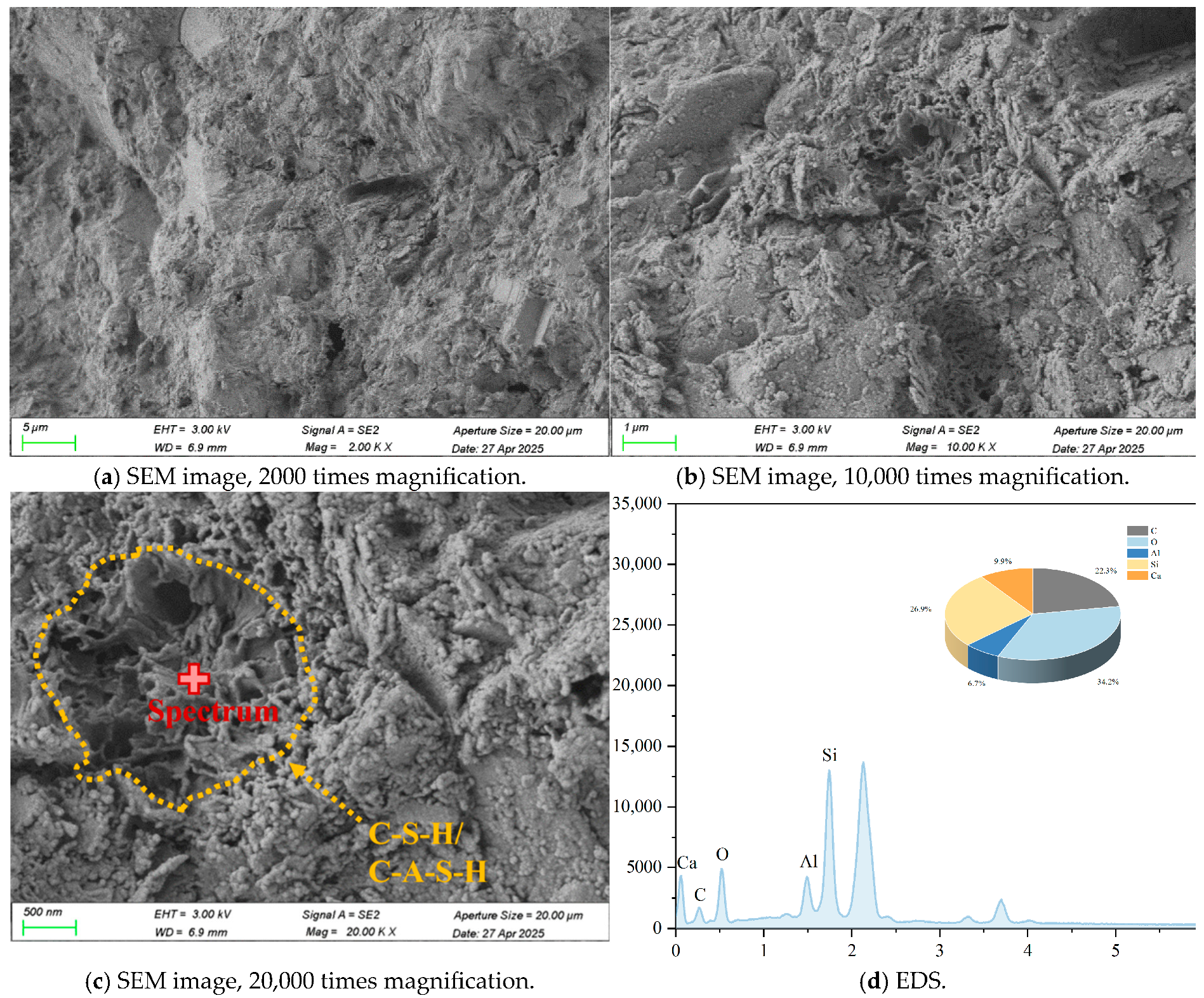

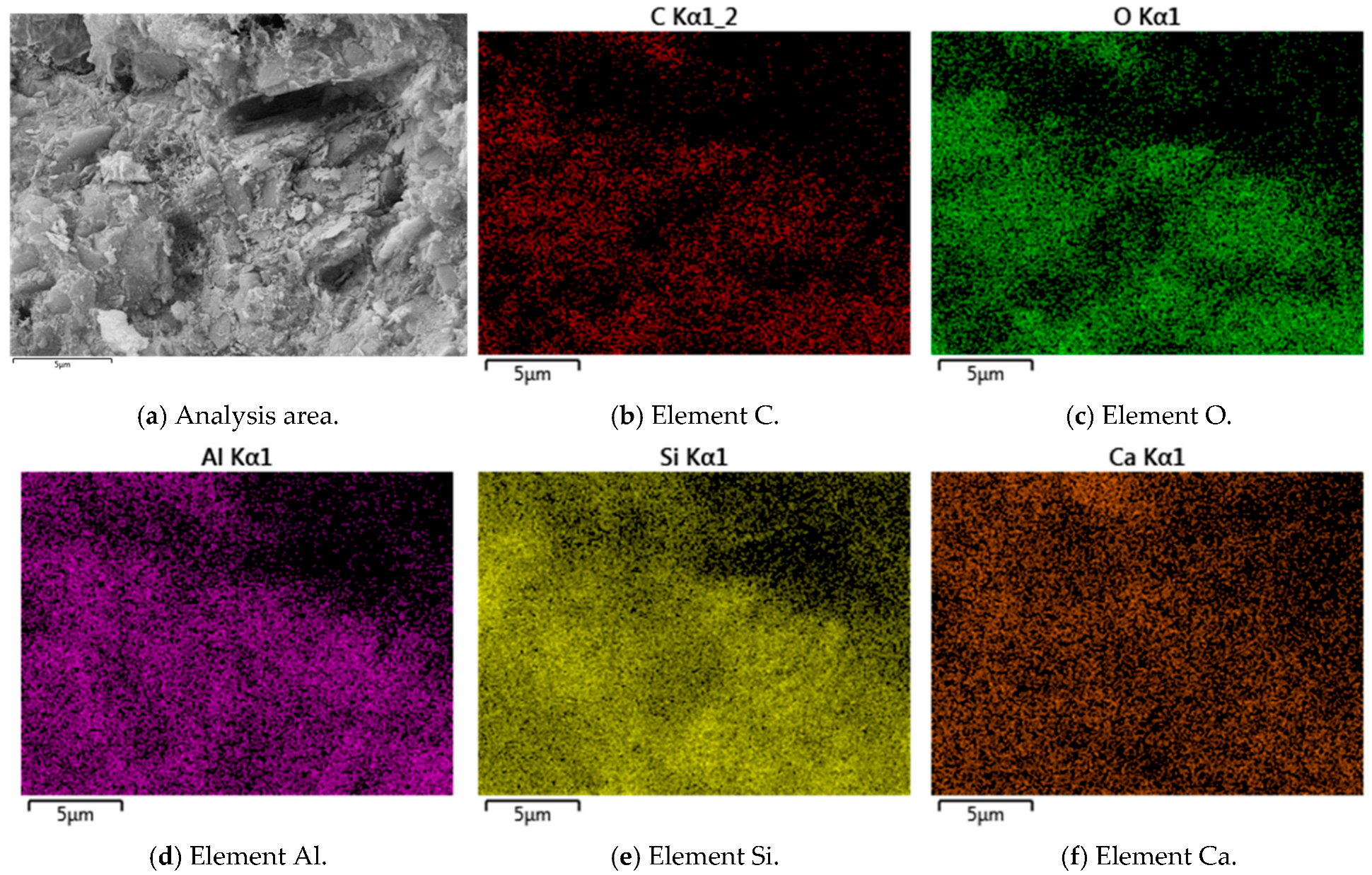

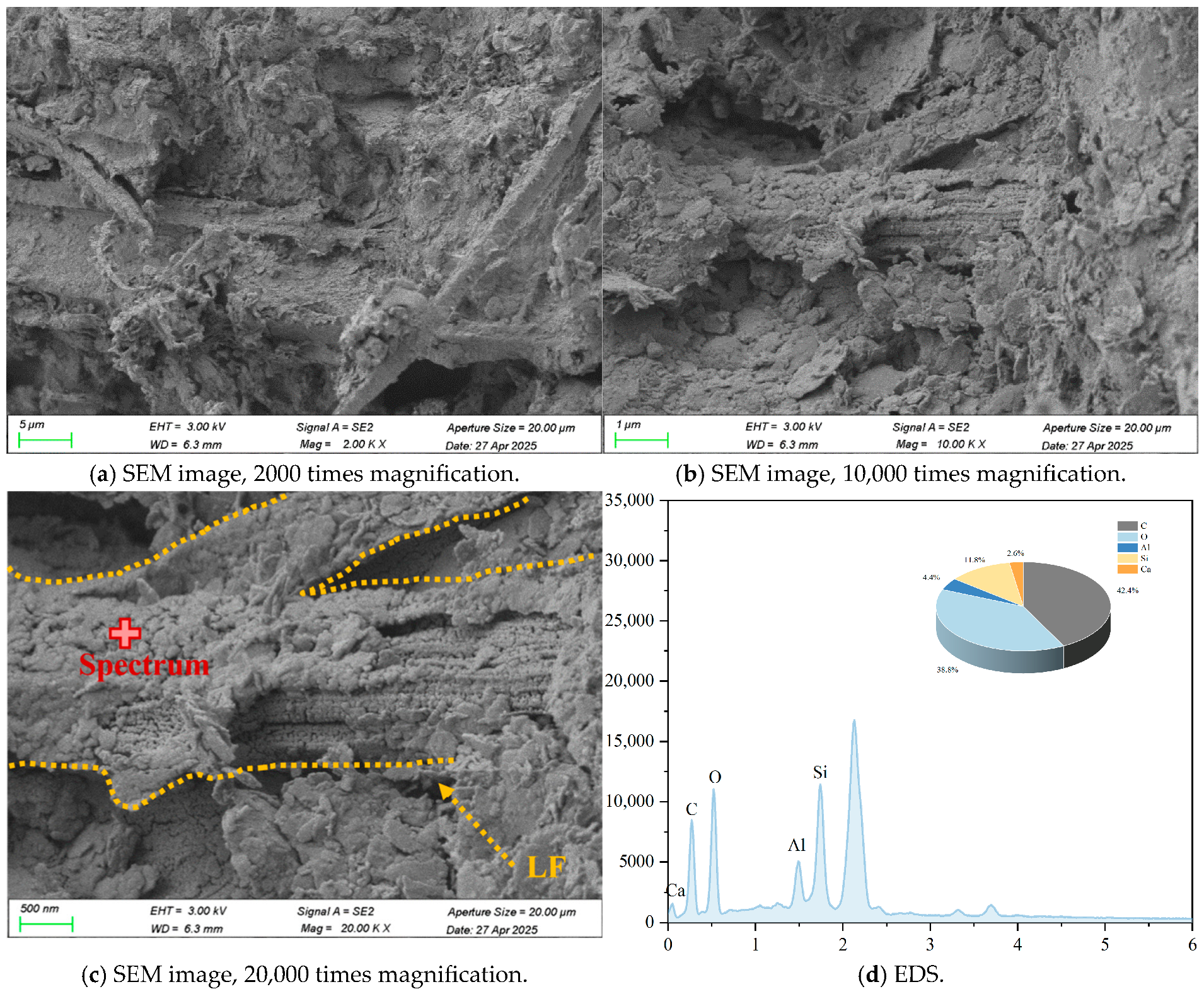

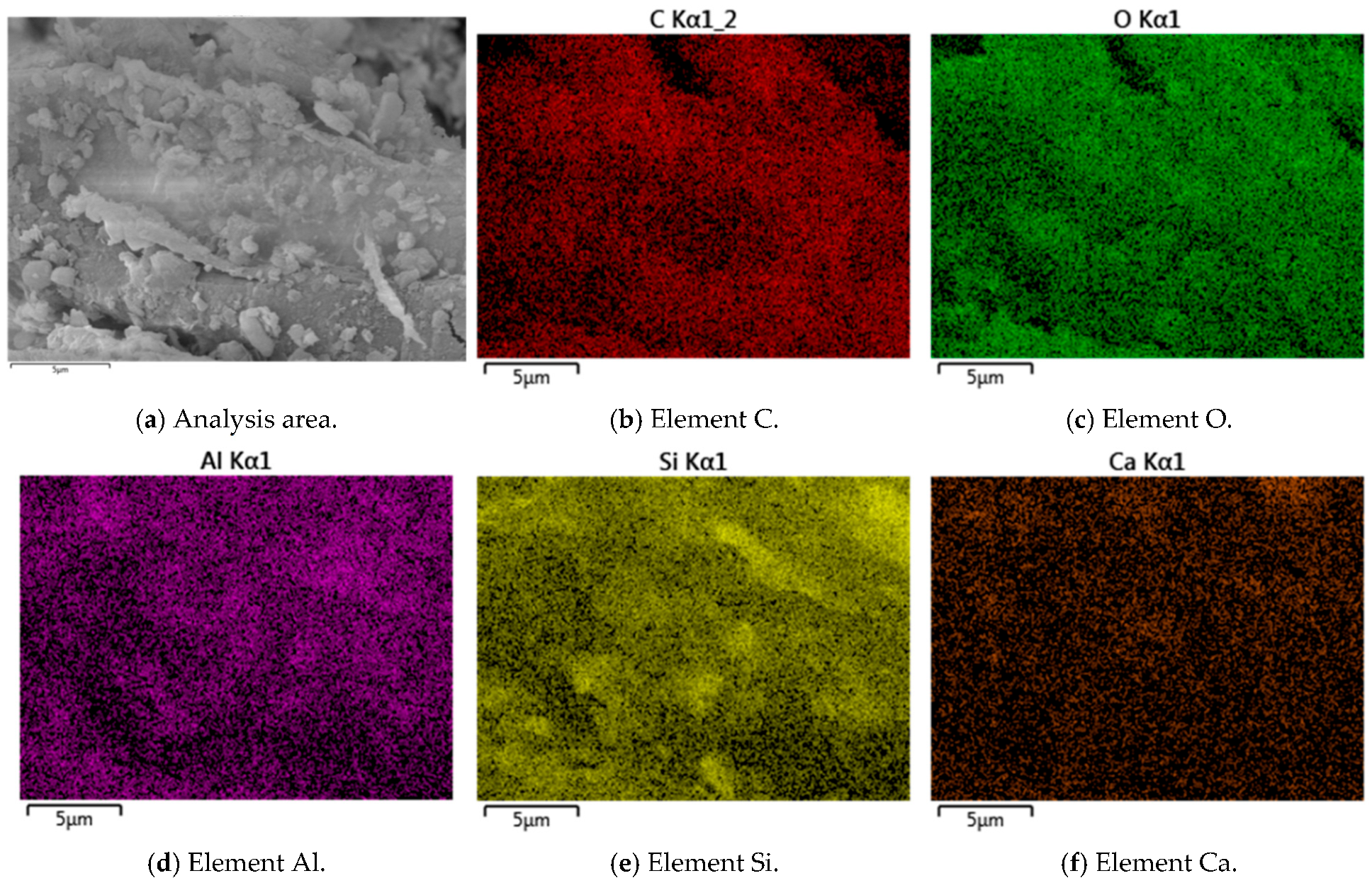

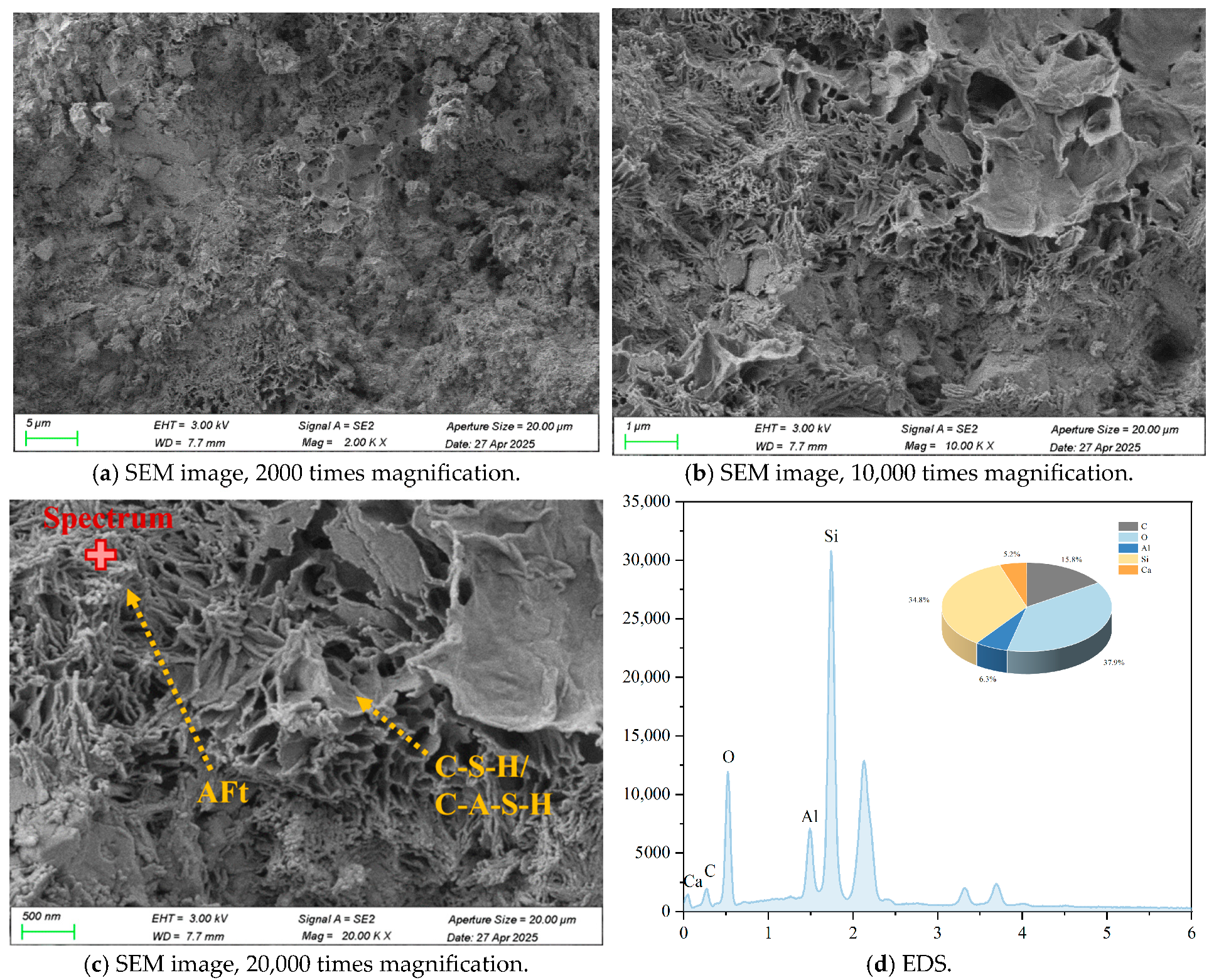

3.6. Micro-Structure Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Arabani, M.; Shalchian, M.M. A review of the use of bio-based substances in soil stabilization. Environ. Dev. Sustain. 2024, 26, 13685–13737. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.; Kanungo, D.P.; Song, Z.; Bai, Y.; Wang, Y.; Li, D.; Qian, W. Topsoil reinforcement of sandy slope for preventing erosion using water-based polyurethane soil stabilizer. Eng. Geol. 2019, 252, 125–135. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Guney Olgun, C.; Firoozi, A.A.; Baghini, M.S. Fundamentals of soil stabilization. Int. J. Geo-Eng. 2017, 8, 26. [Google Scholar] [CrossRef]

- Afrin, H. A review on different types soil stabilization techniques. Int. J. Transp. Eng. Technol. 2017, 3, 19–24. [Google Scholar] [CrossRef]

- Archibong, G.; Sunday, E.; Akudike, J.; Okeke, O.; Amadi, C. A review of the principles and methods of soil stabilization. Int. J. Adv. Acad. Res. Sci. 2020, 6, 2488–9849. [Google Scholar]

- Anburuvel, A. The engineering behind soil stabilization with additives: A state-of-the-art review. Geotech. Geol. Eng. 2024, 42, 1–42. [Google Scholar] [CrossRef]

- Solihat, N.N.; Santoso, E.B.; Karimah, A.; Madyaratri, E.W.; Sari, F.P.; Falah, F.; Iswanto, A.H.; Ismayati, M.; Lubis, M.A.R.; Fatriasari, W. Physical and chemical properties of Acacia mangium lignin isolated from pulp mill byproduct for potential application in wood composites. Polymers 2022, 14, 491. [Google Scholar] [CrossRef]

- Sharma, P. Biochar application for sustainable soil erosion control: A review of current research and future perspectives. Front. Environ. Sci. 2024, 12, 1373287. [Google Scholar] [CrossRef]

- Shalchian, M.M.; Arabani, M. A review of soil reinforcement with planetary fibers. J. Soil Sci. Plant Nutr. 2022, 22, 4496–4532. [Google Scholar] [CrossRef]

- Zhou, R.; Wang, B.-T.; Han, S.-Y.; Wang, D.-Y.; Zhang, F.-H. Mechanisms of crack development and strength deterioration in compacted expansive soils under controlled wetting-drying conditions. Eng. Fail. Anal. 2024, 159, 108133. [Google Scholar] [CrossRef]

- Xu, J.-J.; Tang, C.-S.; Cheng, Q.; Xu, Q.-L.; Inyang, H.I.; Lin, Z.-Y.; Shi, B. Investigation on desiccation cracking behavior of clayey soils with a perspective of fracture mechanics: A review. J. Soils Sediments 2022, 22, 859–888. [Google Scholar] [CrossRef]

- Xu, G.; Liu, Y.; Ni, J.; Wang, Y. Hydro-mechanical behaviour of straw fiber-reinforced cemented dredged sediment at high water content. J. Soils Sediments 2024, 24, 3530–3540. [Google Scholar] [CrossRef]

- Liu, B.; Zhou, H.; Wang, X.; Lian, G.; Yang, B. Effect of modifiers on the disintegration characteristics of red clay. Sustainability 2024, 16, 4551. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, X.; Xie, S.; Yin, P. Experimental study on improving the engineering properties of coarse grain sulphate saline soils with inorganic materials. Cold Reg. Sci. Technol. 2020, 170, 102909. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Z.; Han, Y. Progress towards the identification and improvement of dispersive soils: A review. Eur. J. Soil Sci. 2024, 75, e70002. [Google Scholar] [CrossRef]

- Abdolvand, Y.; Sadeghiamirshahidi, M. Soil stabilization with gypsum: A review. J. Rock Mech. Geotech. Eng. 2024, 16, 5278–5296. [Google Scholar] [CrossRef]

- Shruthi; Prakash, N.B.; Dhumgond, P.; Goiba, P.K.; Laxmanarayanan, M. The benefits of gypsum for sustainable management and utilization of acid soils. Plant Soil 2024, 504, 5–28. [Google Scholar] [CrossRef]

- Reigl, S.; Van Driessche, A.E.; Wagner, E.; Montes-Hernandez, G.; Mehringer, J.; Koltzenburg, S.; Kunz, W.; Kellermeier, M. Toward more sustainable hydraulic binders: Controlling calcium sulfate phase selection via specific additives. ACS Sustain. Chem. Eng. 2023, 11, 8450–8461. [Google Scholar] [CrossRef]

- Yang, R.; He, T.; Guan, M.; Guo, X.; Xu, Y.; Xu, R.; Da, Y. Preparation and accelerating mechanism of aluminum sulfate-based alkali-free accelerating additive for sprayed concrete. Constr. Build. Mater. 2020, 234, 117334. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, Y.; Zhang, D. A literature review on delayed ettringite formation: Mechanism, affect factors and suppressing methods. Mag. Concr. Res. 2021, 73, 325–342. [Google Scholar] [CrossRef]

- Ehwailat, K.I.A.; Ismail, M.A.M.; Ezreig, A.M.A. Ettringite formation and stabilization methods of sulfate-bearing soil: A state-of-the-art review. Indian Geotech. J. 2022, 52, 927–941. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Mahalakshmi, S.; Kannan, G. Potential of fibre reinforced and cement stabilized fibre reinforced soil blocks as sustainable building units. J. Build. Eng. 2023, 78, 107733. [Google Scholar] [CrossRef]

- Roshan, K.; Choobbasti, A.J.; Kutanaei, S.S. Evaluation of the impact of fiber reinforcement on the durability of lignosulfonate stabilized clayey sand under wet-dry condition. Transp. Geotech. 2020, 23, 100359. [Google Scholar] [CrossRef]

- Graça, C.J.; Ferreira-Gomes, L.M.; Pais, L.A.; Albuquerque, A.; Morais, M.V.; Studart, A.; Marchiori, L. Assessment of the potential for using PET waste as geomaterials in soil micro-reinforcement. Geosyst. Geoenviron. 2025, 4, 100438. [Google Scholar] [CrossRef]

- Ren, X.-C.; Lai, Y.-M.; Zhang, F.-Y.; Hu, K. Test method for determination of optimum moisture content of soil and maximum dry density. KSCE J. Civ. Eng. 2015, 19, 2061–2066. [Google Scholar] [CrossRef]

- Lakshmi, S.M.; Geetha, S.; Selvakumar, M. Predicting soaked CBR of SC subgrade from dry density for light and heavy compaction. Mater. Today Proc. 2021, 45, 1664–1670. [Google Scholar] [CrossRef]

- Jianqiao, L.; Xiaodong, Z.; Meng, Z.; Hao, L. Soil liquid limit and plastic limit treating system based on analytic method. Procedia Earth Planet. Sci. 2012, 5, 175–179. [Google Scholar] [CrossRef]

- Wang, F.; Li, K.; Liu, Y. Optimal water-cement ratio of cement-stabilized soil. Constr. Build. Mater. 2022, 320, 126211. [Google Scholar] [CrossRef]

- Mahedi, M.; Cetin, B.; White, D.J. Cement, lime, and fly ashes in stabilizing expansive soils: Performance evaluation and comparison. J. Mater. Civ. Eng. 2020, 32, 04020177. [Google Scholar] [CrossRef]

- Pongsivasathit, S.; Horpibulsuk, S.; Piyaphipat, S. Assessment of mechanical properties of cement stabilized soils. Case Stud. Constr. Mater. 2019, 11, e00301. [Google Scholar] [CrossRef]

- Buritatum, A.; Suddeepong, A.; Horpibulsuk, S.; Udomchai, A.; Arulrajah, A.; Mohammadinia, A.; Horpibulsuk, J.; Hoy, M. Improvement of tensile properties of cement-stabilized soil using natural rubber latex. J. Mater. Civ. Eng. 2022, 34, 04022028. [Google Scholar] [CrossRef]

- He, J.; Luo, S.-R.; Li, W.-J.; Kang, D.-Y.; Zuo, Z.-W. Capillary water absorption and strength of solidified marine soft soil. Constr. Build. Mater. 2024, 423, 135729. [Google Scholar] [CrossRef]

- de Jesús Arrieta Baldovino, J.; dos Santos Izzo, R.L.; Rose, J.L. Effects of freeze–thaw cycles and porosity/cement index on durability, strength and capillary rise of a stabilized silty soil under optimal compaction conditions. Geotech. Geol. Eng. 2021, 39, 481–498. [Google Scholar] [CrossRef]

- Choobbasti, A.J.; Kutanaei, S.S. Microstructure characteristics of cement-stabilized sandy soil using nanosilica. J. Rock Mech. Geotech. Eng. 2017, 9, 981–988. [Google Scholar] [CrossRef]

- Vázquez-Rodríguez, F.J.; López-Yépez, L.G.; Elizondo-Villarreal, N.; Guzmán-Hernández, A.M.; Gómez-Zamorano, L.Y.; Rodríguez-Castellanos, E.A. The effect of μ-limestone additions on the mechano-chemical and microstructural properties of slag and binary slag/ground fly ash alkaline-activated binders. Materials 2024, 17, 5940. [Google Scholar] [CrossRef]

- Vitale, E.; Deneele, D.; Paris, M.; Russo, G. Multi-scale analysis and time evolution of pozzolanic activity of lime treated clays. Appl. Clay Sci. 2017, 141, 36–45. [Google Scholar] [CrossRef]

- Zhou, Y.; Huo, M.; Zhang, L.; Guan, Q. Strength development and solidification mechanism of soils with different properties stabilized by cement-slag-based materials. Case Stud. Constr. Mater. 2024, 21, e04034. [Google Scholar] [CrossRef]

- Akbulut, Z.F.; Tawfik, T.A.; Smarzewski, P.; Guler, S. Advancing Hybrid Fiber-Reinforced Concrete: Performance, Crack Resistance Mechanism, and Future Innovations. Buildings 2025, 15, 1247. [Google Scholar] [CrossRef]

- Sharma, S.; Sudhakara, P.; Singh, J.; Mr, S.; Siengchin, S. Fabrication of novel polymer composites from leather waste fibers and recycled poly (ethylene-vinyl-acetate) for value-added products. Sustainability 2023, 15, 4333. [Google Scholar] [CrossRef]

- Fu, J.; Bligh, M.W.; Shikhov, I.; Jones, A.M.; Holt, C.; Keyte, L.M.; Moghaddam, F.; Arns, C.H.; Foster, S.J.; Waite, T.D. A microstructural investigation of a Na2SO4 activated cement-slag blend. Cem. Concr. Res. 2021, 150, 106609. [Google Scholar] [CrossRef]

- Wu, P.; Liu, X.; Liu, X.; Zhang, Z.; Wei, C. Effect of industrial byproduct gypsum on the mechanical properties and stabilization of hazardous elements of cementitious materials: A review. Materials 2024, 17, 4183. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, D. Durability of industrial by-products combined with cement-solidified sludge subjected to immersion and cyclic wetting–drying in various fluids. Acta Geotech. 2023, 18, 6849–6874. [Google Scholar] [CrossRef]

- Lv, T.; Zhang, J.; Hou, D.; Long, W.-J.; Dong, B. Mechanical properties and microstructural characteristics of seawater-mixed sintered sludge cement paste. Constr. Build. Mater. 2024, 414, 134996. [Google Scholar] [CrossRef]

- Mota, B.; Matschei, T.; Scrivener, K. Impact of NaOH and Na2SO4 on the kinetics and microstructural development of white cement hydration. Cem. Concr. Res. 2018, 108, 172–185. [Google Scholar] [CrossRef]

- Wei, Z.; Falzone, G.; Wang, B.; Thiele, A.; Puerta-Falla, G.; Pilon, L.; Neithalath, N.; Sant, G. The durability of cementitious composites containing microencapsulated phase change materials. Cem. Concr. Compos. 2017, 81, 66–76. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D. Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Liang, L.; Xu, Y.; Hu, S. Bending and crack evolution behaviors of cemented soil reinforced with surface modified PVA fiber. Materials 2022, 15, 4799. [Google Scholar] [CrossRef]

- Chhetri, S.; Bougherara, H. A comprehensive review on surface modification of UHMWPE fiber and interfacial properties. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106146. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Wang, Y.-S.; Dai, J.-G.; Xu, Q.-F. Effect of superplasticizers on properties of one-part Ca (OH) 2/Na2SO4 activated geopolymer pastes. Constr. Build. Mater. 2020, 241, 117990. [Google Scholar] [CrossRef]

- Cuesta, A.; Santacruz, I.; Angeles, G.; Dapiaggi, M.; Zea-Garcia, J.D.; Aranda, M.A. Local structure and Ca/Si ratio in CSH gels from hydration of blends of tricalcium silicate and silica fume. Cem. Concr. Res. 2021, 143, 106405. [Google Scholar] [CrossRef]

- Feng, L.; Yi, S.; Zhao, S.; Zhong, Q.; Ren, F.; Liu, C.; Zhang, Y.; Wang, W.; Xie, N.; Li, Z. Recycling of aluminosilicate-based solid wastes through alkali-activation: Preparation, characterization, and challenges. Buildings 2024, 14, 226. [Google Scholar] [CrossRef]

- Zhang, C.; Li, J.; Yu, M.; Lu, Y.; Liu, S. Mechanism and performance control methods of sulfate attack on concrete: A review. Materials 2024, 17, 4836. [Google Scholar] [CrossRef] [PubMed]

- Bi, R.; Cheng, W.; Chen, X. Effect of calcium sulfate variety and content on hydration mechanism of grout sealants for coal-bed methane drainage boreholes. Constr. Build. Mater. 2019, 203, 443–455. [Google Scholar] [CrossRef]

| Maximum Dry Density (g/cm3) | Optimal Moisture Content (%) | Liquid Limit (%) | Plastic Limit (%) | Plasticity Index | Properties of Soil |

|---|---|---|---|---|---|

| 1.67 | 17.94 | 30.4 | 16.3 | 14.1 | silty clay |

| Mix ID | Matrix | Curing Agent | Reinforcing Agent | |||

|---|---|---|---|---|---|---|

| Soil | Water | Cement | Lime | LF | Na2SO4 | |

| R-0 | 1 | 0.1794 | 0 | 0 | 0 | 0 |

| C-1 | 0.93 | 0.1794 | 0.525 | 0.175 | 0 | 0 |

| C-LF-1 | 0.93 | 0.1794 | 0.525 | 0.175 | 0.005 | 0 |

| C-LF-2 | 0.93 | 0.1794 | 0.525 | 0.175 | 0.01 | 0 |

| C-LF-3 | 0.93 | 0.1794 | 0.525 | 0.175 | 0.015 | 0 |

| C-LF-2-Na-1 | 0.93 | 0.1794 | 0.525 | 0.175 | 0.01 | 0.0005 |

| C-LF-2-Na-2 | 0.93 | 0.1794 | 0.525 | 0.175 | 0.01 | 0.001 |

| C-LF-2-Na-3 | 0.93 | 0.1794 | 0.525 | 0.175 | 0.01 | 0.0015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Na, B.; Chen, W. Synergistic Effects of Lignin Fiber and Sodium Sulfate on Mechanical Properties and Micro-Structure of Cement-Stabilized Soil. Materials 2025, 18, 3929. https://doi.org/10.3390/ma18173929

Wang L, Na B, Chen W. Synergistic Effects of Lignin Fiber and Sodium Sulfate on Mechanical Properties and Micro-Structure of Cement-Stabilized Soil. Materials. 2025; 18(17):3929. https://doi.org/10.3390/ma18173929

Chicago/Turabian StyleWang, Liang, Binbin Na, and Wenhua Chen. 2025. "Synergistic Effects of Lignin Fiber and Sodium Sulfate on Mechanical Properties and Micro-Structure of Cement-Stabilized Soil" Materials 18, no. 17: 3929. https://doi.org/10.3390/ma18173929

APA StyleWang, L., Na, B., & Chen, W. (2025). Synergistic Effects of Lignin Fiber and Sodium Sulfate on Mechanical Properties and Micro-Structure of Cement-Stabilized Soil. Materials, 18(17), 3929. https://doi.org/10.3390/ma18173929