Rheological Optimization of 3D-Printed Cementitious Materials Using Response Surface Methodology

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Test Methods

2.2.1. Rheological Test

2.2.2. Flowability Test

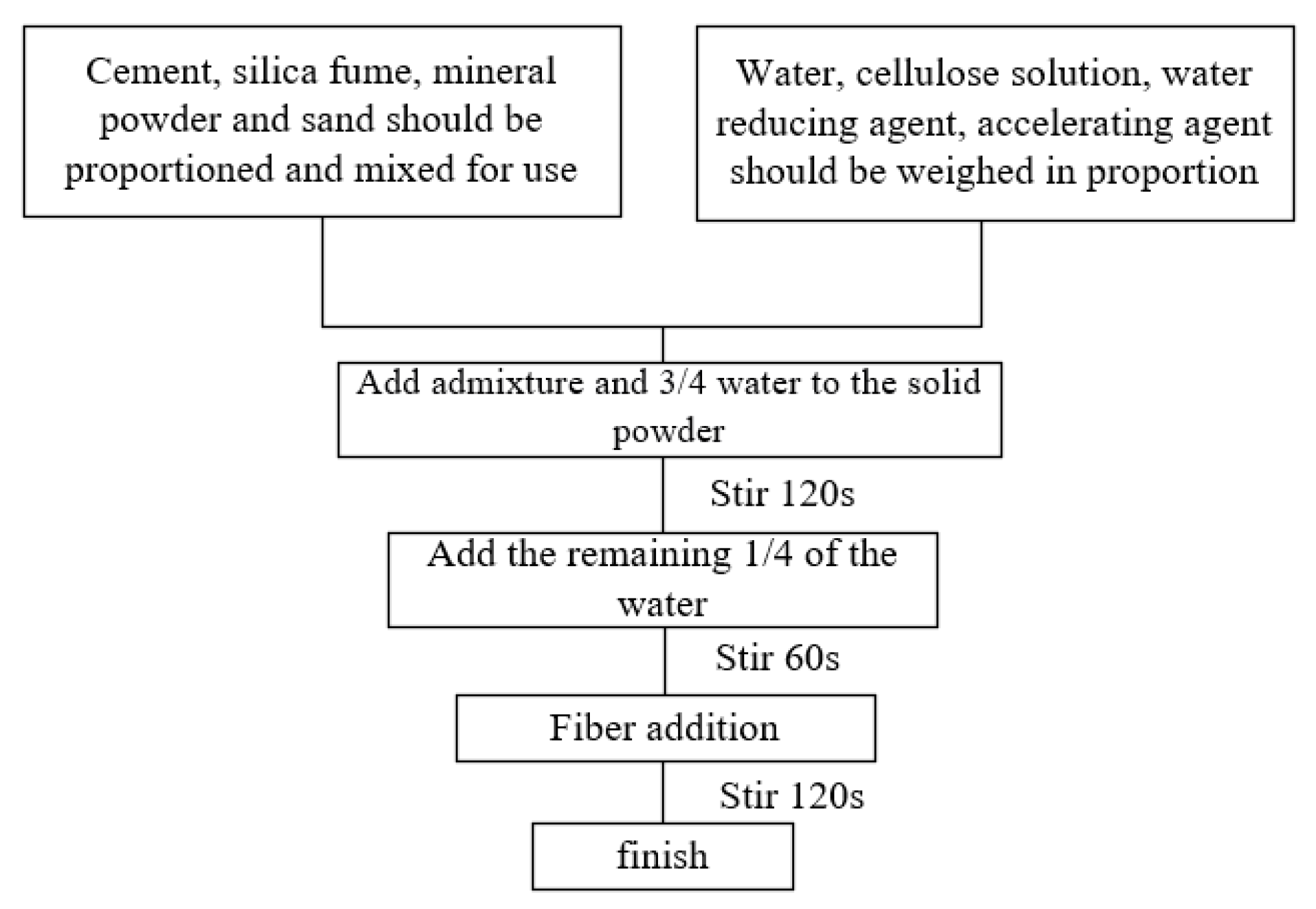

2.2.3. Preparation Procedures

- (1)

- Dry mixing was achieved by mixing the pre-weighed cement, silica fume, slag powder, and sand in a planetary mixer for 180 s to homogenize the binder components.

- (2)

- The chemical admixtures and 75% of the total water were then slowly introduced into the dry mixture and wet-mixed for 120 s, to ensure even dispersion.

- (3)

- Water adjustment was then performed, where the remaining 25% of water was incrementally added during a 60 s mixing cycle to optimize the rheology and batch consistency.

- (4)

- Fibers were then integrated by manually feeding the fibers into the matrix and blending for 120 s to ensure uniform distribution, after which mixing was stopped to minimize fiber breakage.

2.3. Test Program

2.3.1. Response Surface Method Test Design

Single-Factor Experiment

- (1)

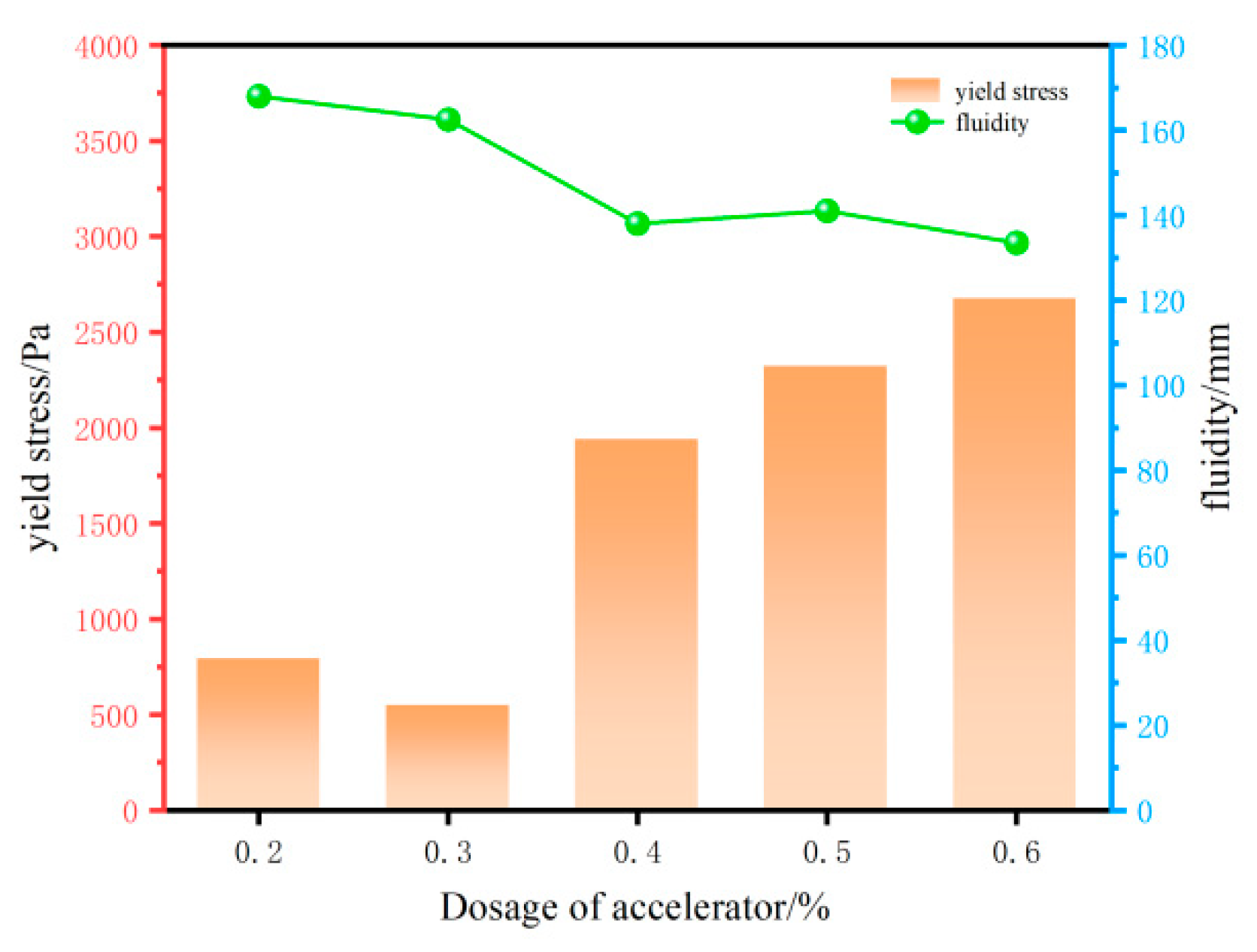

- Effect of the accelerator on rheological properties

- (2)

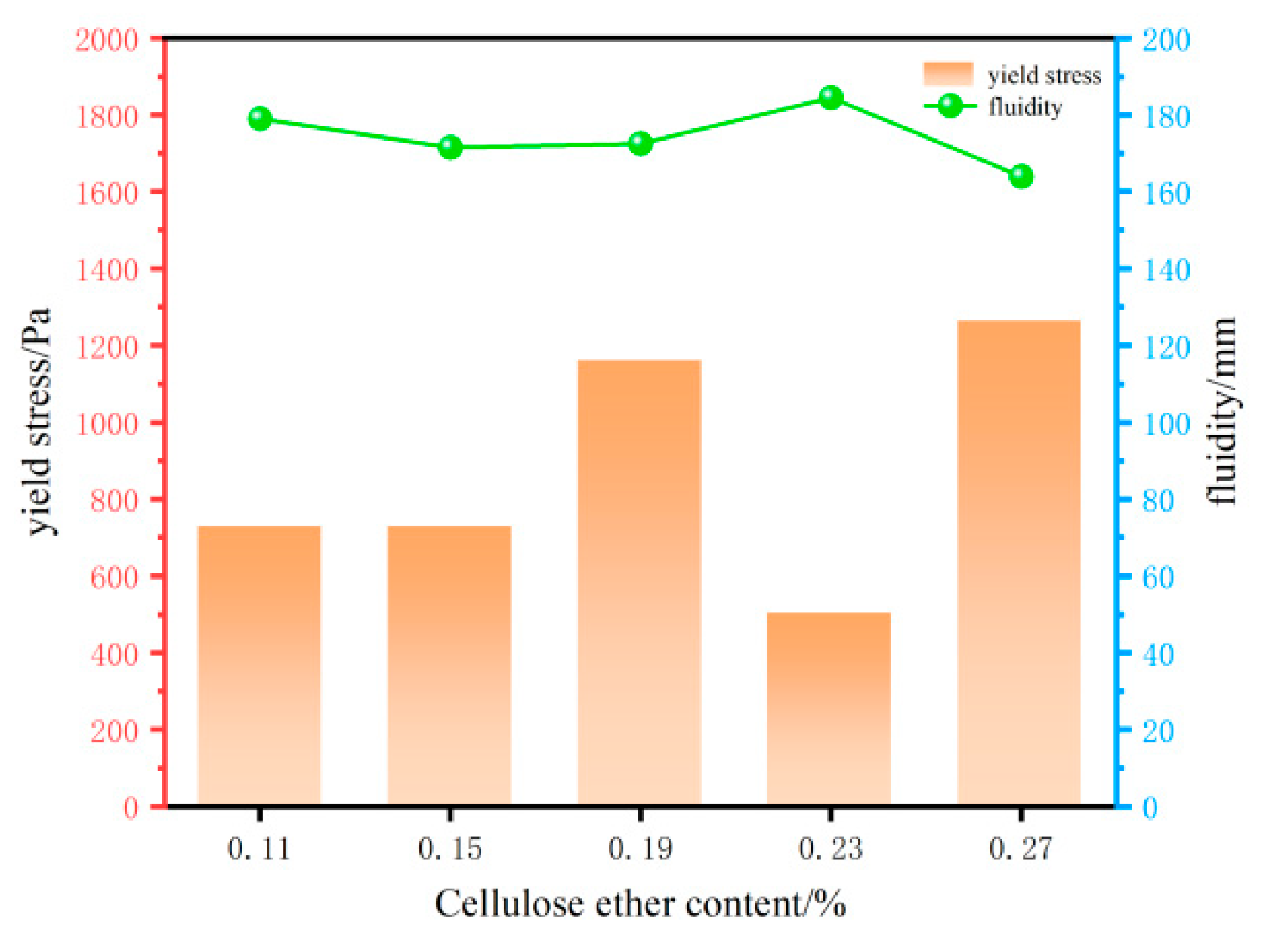

- Effect of HPMC on the rheological properties

- (3)

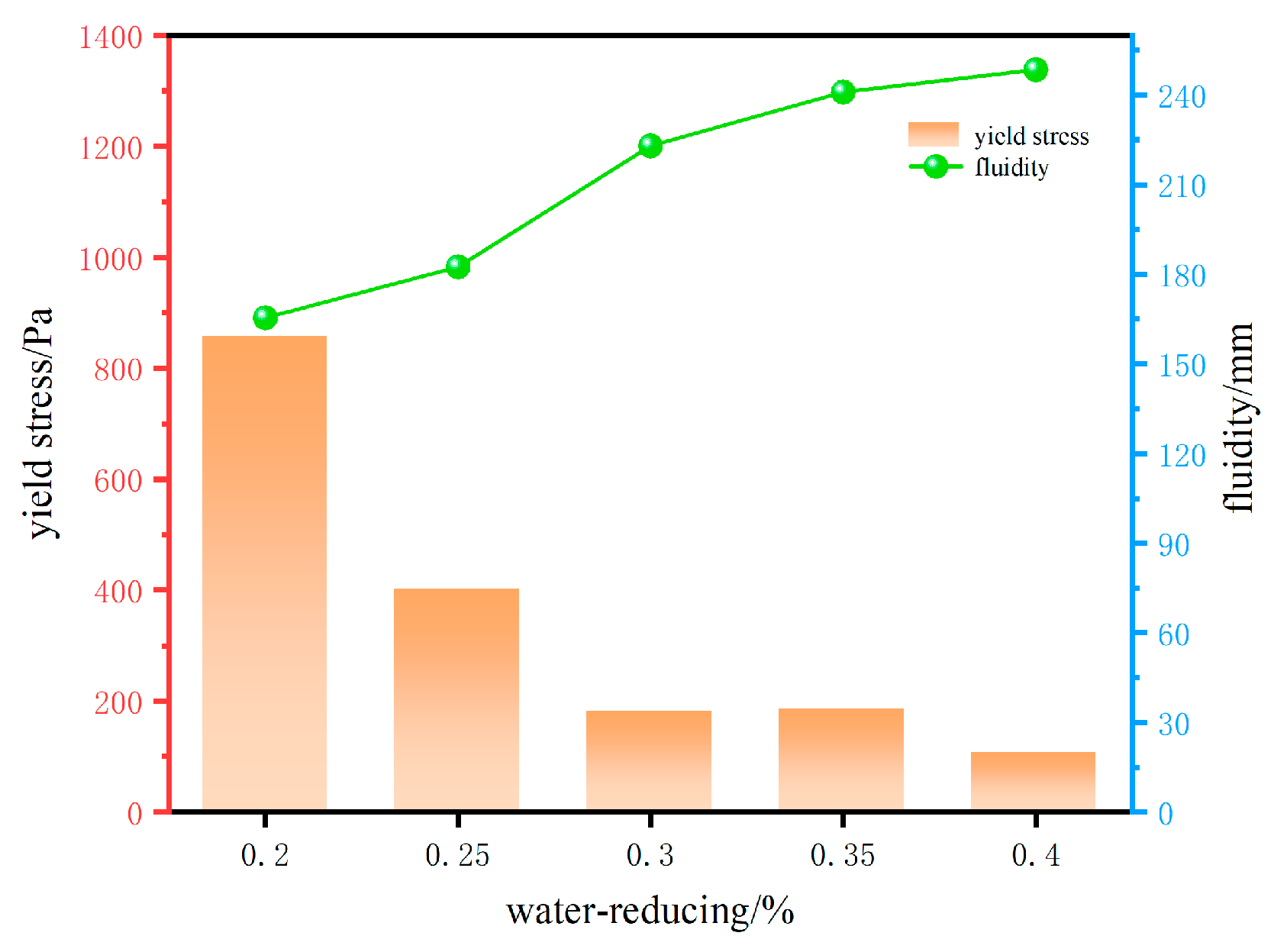

- Effect of PCE on the rheological properties

The Experimental Design of Response Surface Optimization

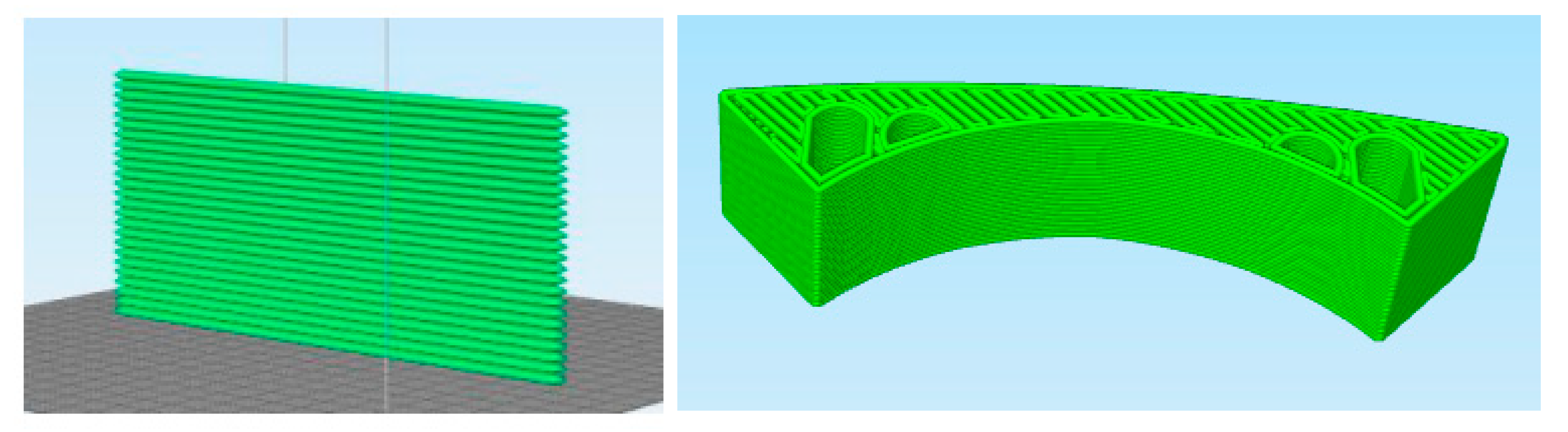

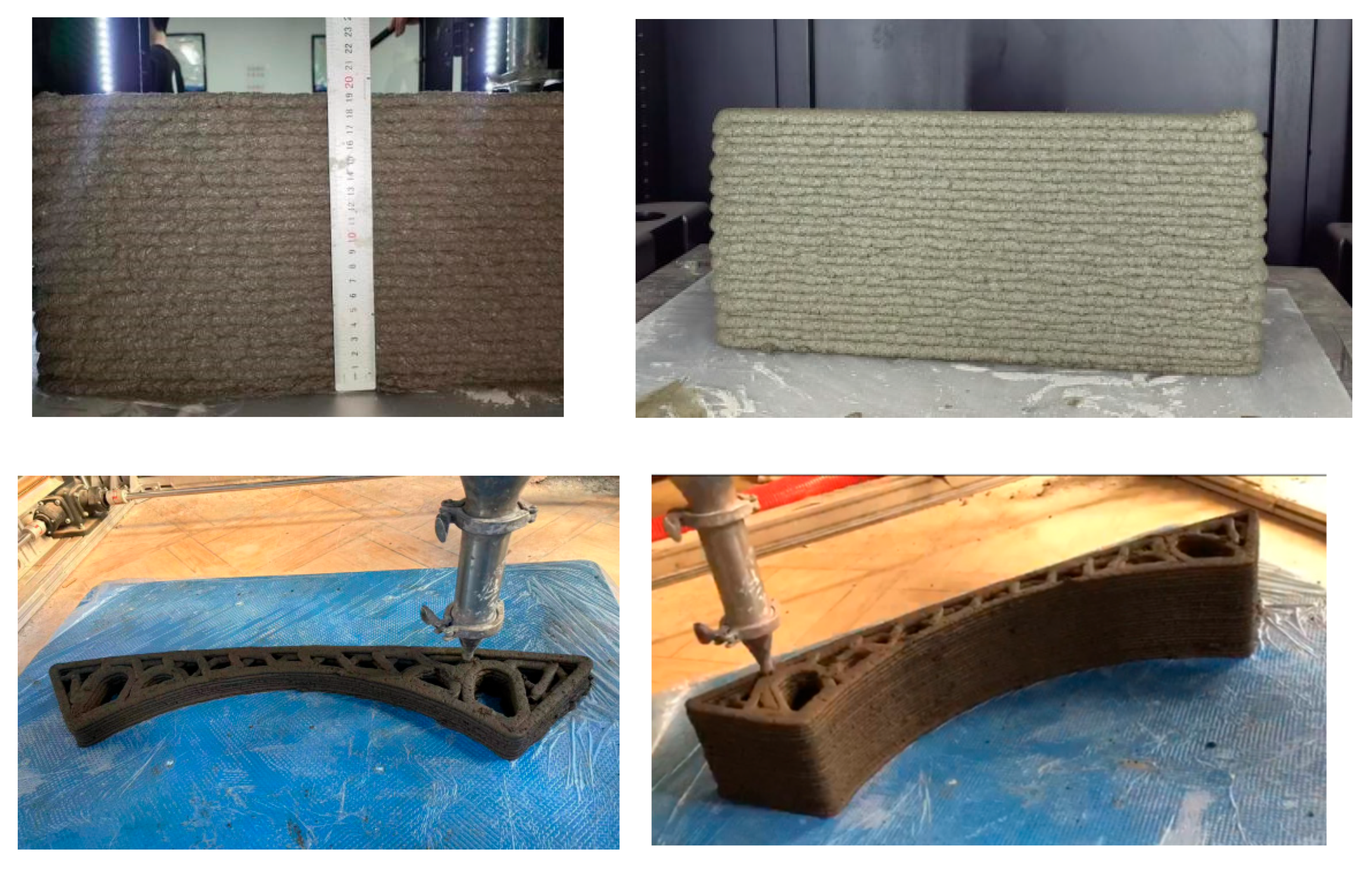

2.3.2. Three-Dimensional Printing Experiment Design

3D Printer Parameter Settings

Print Path Diagram

3. Results and Discussion

3.1. Single-Factor Test Results

- (1)

- Effect of accelerator on the rheological properties

- (2)

- Effect of HPMC solution on the rheological properties

- Effect of PCE on rheological properties

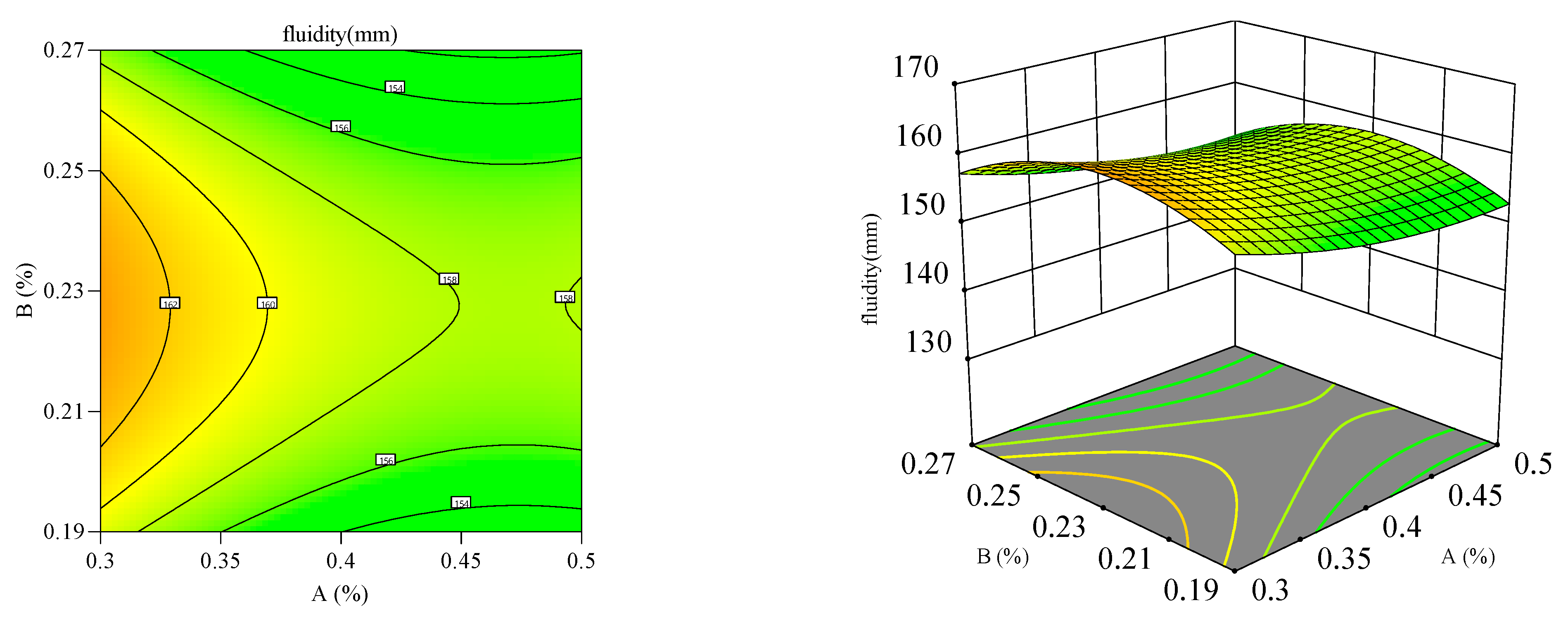

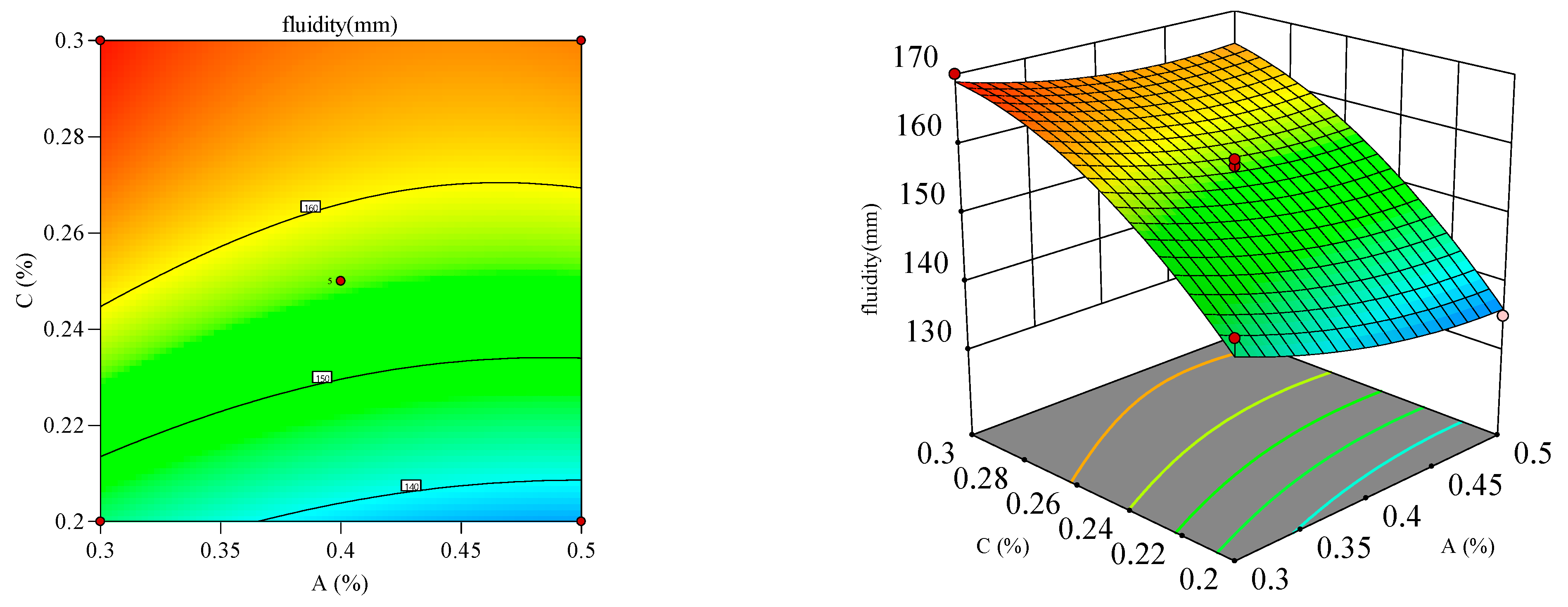

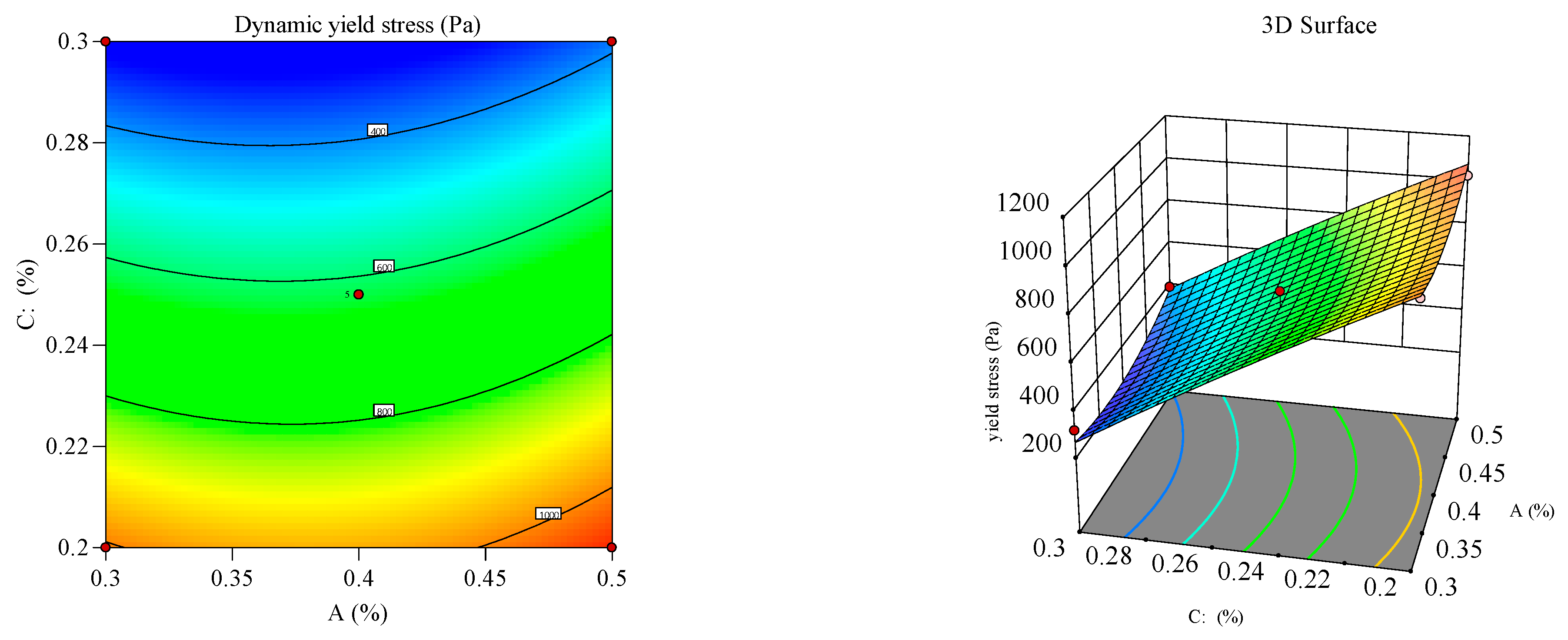

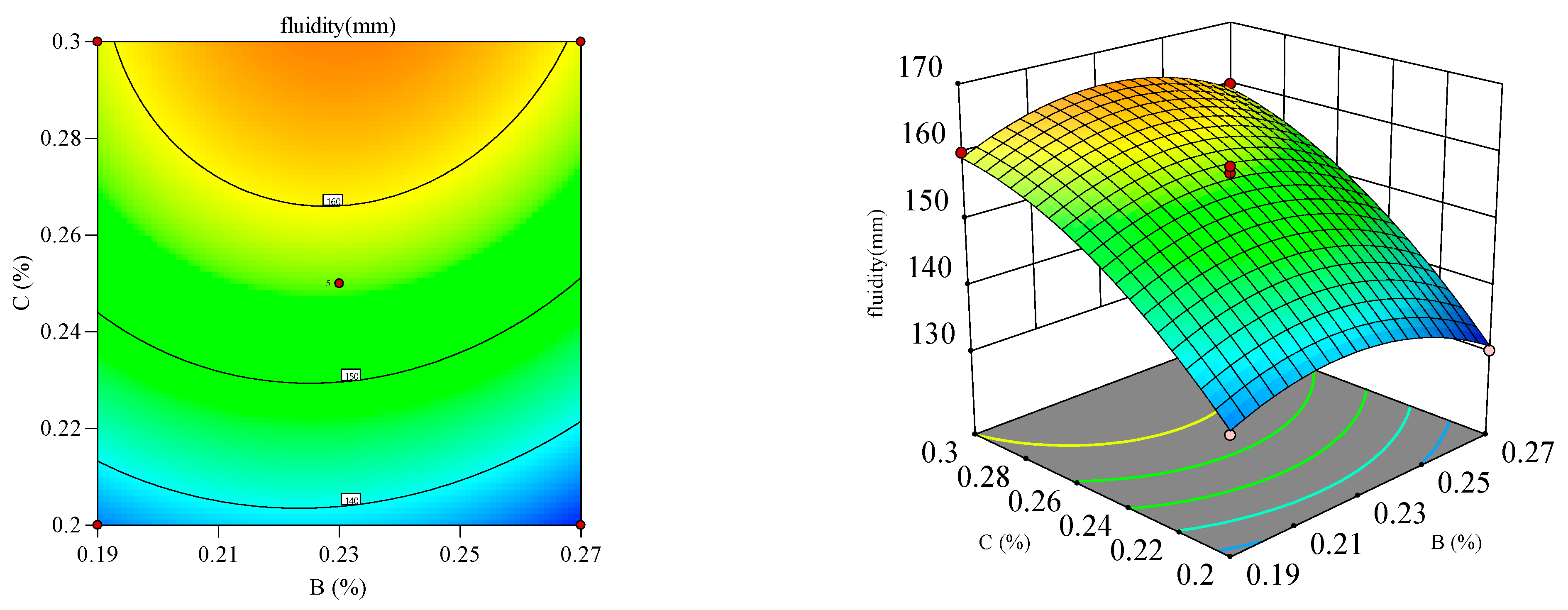

3.2. Response Surface Results

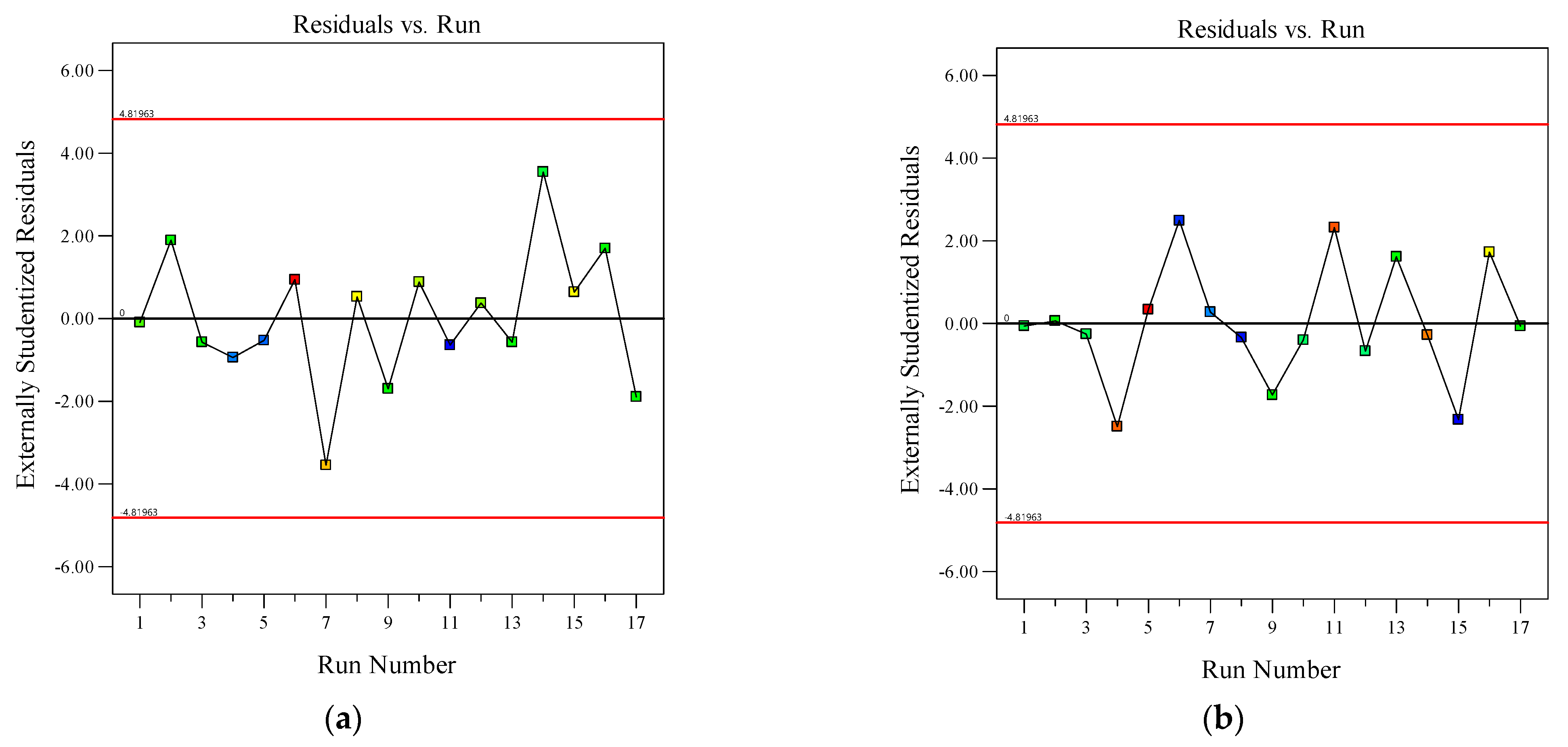

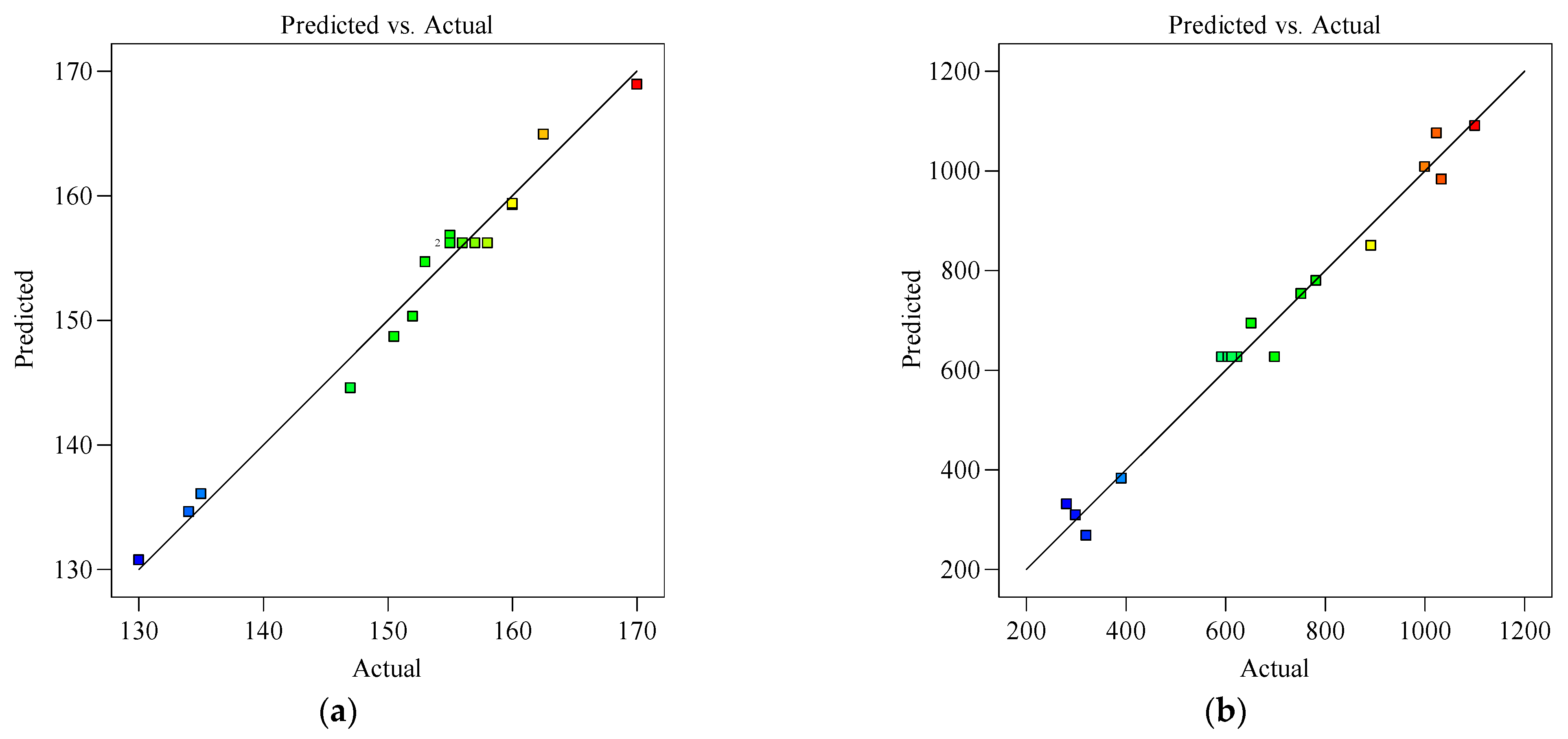

3.2.1. Response Surface Regression Model Analysis

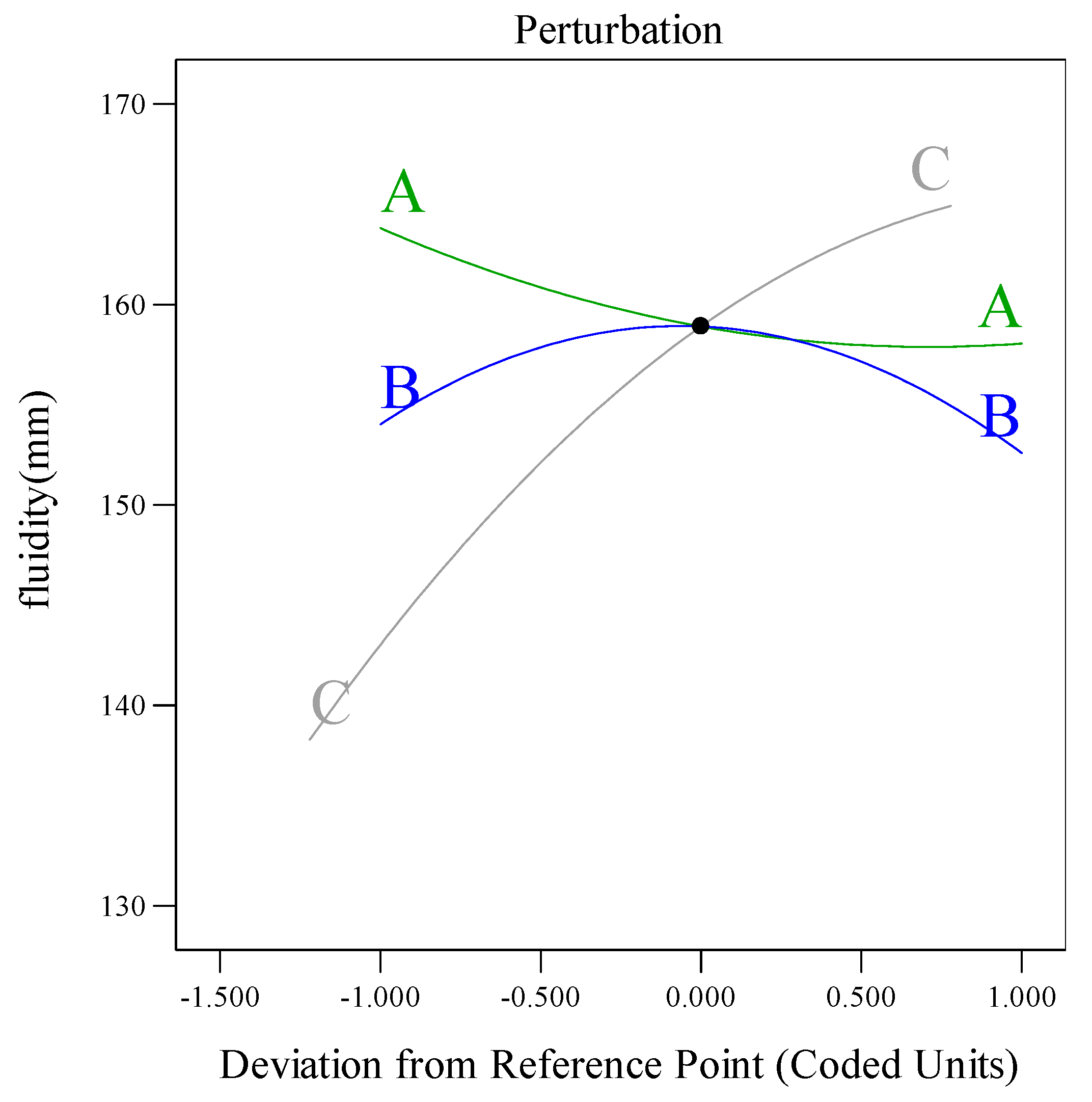

3.2.2. Response Surface Analysis

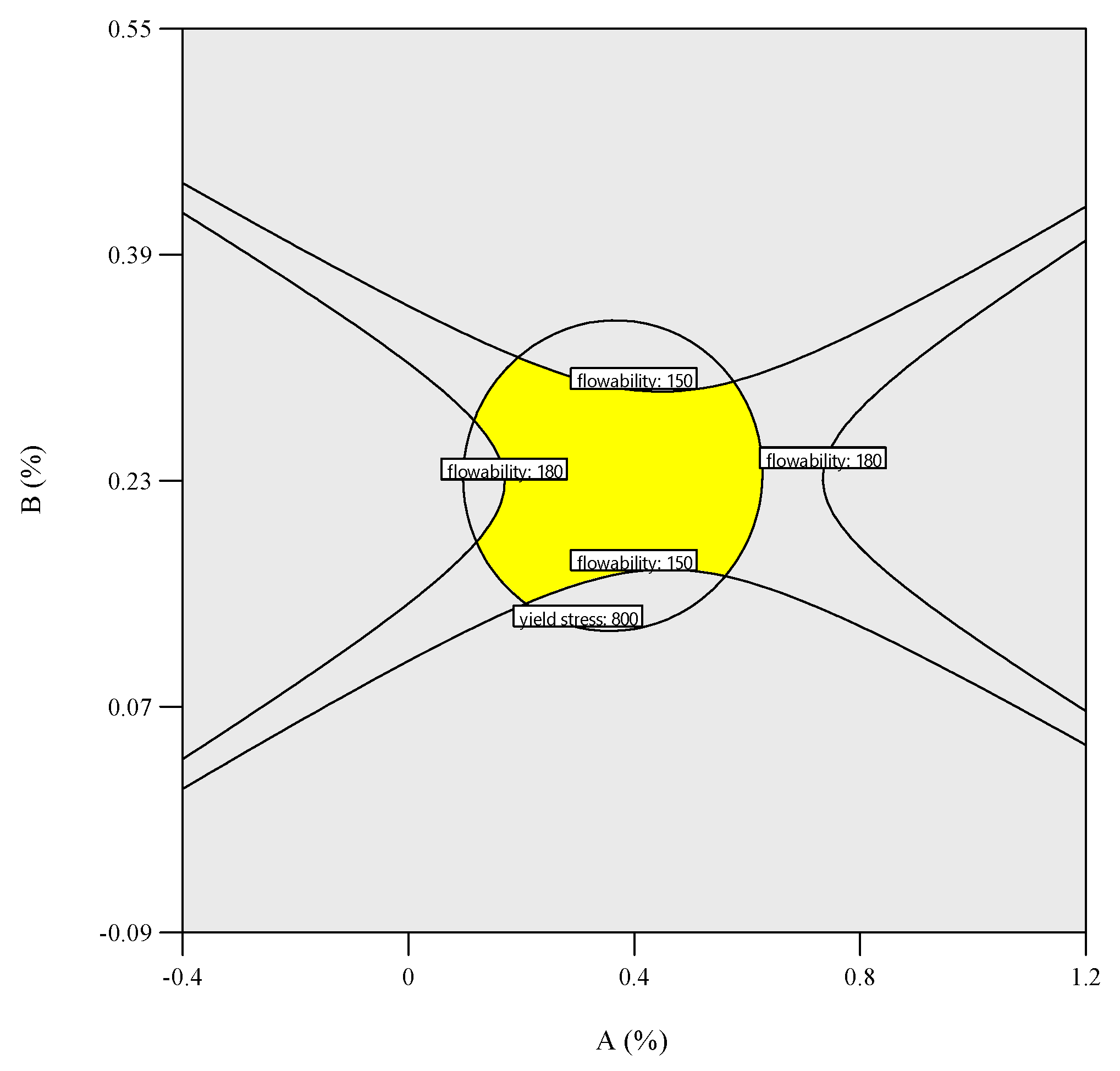

3.3. Response Surface Results Optimization and Verification

4. Conclusions

4.1. Main Conclusions

- (1)

- Model validity was established, where a statistical analysis of the quadratic polynomials for flowability and dynamic yield stress confirmed a high goodness-of-fit (R2 > 0.95) and robust predictive accuracy across responses.

- (2)

- Factor significance

- (3)

- Flowability followed the order of polycarboxylate superplasticizer (PCE) > accelerator > hydroxypropyl methylcellulose (HPMC) solution, with significant interaction between HPMC and PCE. Dynamic yield stress followed the order of PCE > accelerator > HPMC solution.

- (4)

- The optimal mix consisted of accelerator dosage = 0.32%, HPMC solution = 0.24%, and PCE dosage = 0.23%. The experimental results showed 147.5 mm flowability (4.1% deviation) and 711 Pa dynamic yield stress (7.6% deviation), aligning closely with the predictions.

4.2. Suggestions and Prospects

- (1)

- This study only uses flowability and dynamic yield stress to judge printability, but it does not consider other important factors like thixotropy, how well layers stick together, or how long the material stays workable (open time). Focusing on just two factors may miss the other key points needed for successful 3D printing.

- (2)

- The printing tests used only one optimized mix and did not try different shapes or printing conditions. Testing more types of prints would make the results stronger and more widely useful.

- (3)

- All tests were performed in a laboratory environment using limited material quantities, and the RSM model was based on some simplifying assumptions. Therefore, the applicability of the findings in actual 3D printing or construction projects requires further validation through field-based continuous printing and long-term structural performance monitoring.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khan, M. Mix suitable for concrete 3D printing: A review. Mater. Today Proc. 2020, 32, 831–837. [Google Scholar] [CrossRef]

- Buswell, R.A.; De Silva, W.R.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Nan, B.; Qiao, Y.; Leng, J.; Bai, Y. Advancing Structural Reinforcement in 3D-Printed Concrete: Current Methods, Challenges, and Innovations. Materials 2025, 18, 252. [Google Scholar] [CrossRef]

- Wahlström, M.; Laineyliijoki, J.; Helena, J.; Kaartinen, T.; Erlandsson, M.; Anna, P.C.; Wik, O.; Suer, P.; Oberender, A.; Hjelmar, O. Environmentally Sustainable Construction Products and Mate-Rials—Assessment of Release; Nordic Innovation: Oslo, Norway, 2014. [Google Scholar]

- Panda, B.; Paul, S.C.; Tan, M.J. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar] [CrossRef]

- Chen, M.; Li, L.; Zheng, Y.; Zhao, P.; Lu, L.; Cheng, X. Rheological and mechanical properties of admixtures modified 3D printing sulphoaluminate cementitious materials. Constr. Build. Mater. 2018, 189, 601–611. (In Chinese) [Google Scholar] [CrossRef]

- Liu, Z.; Li, M.; Weng, Y.; Wong, T.N.; Tan, M.J. Mixture Design Approach to optimize the rheological properties of the material used in 3D cementitious material printing. Constr. Build. Mater. 2019, 198, 245–255. [Google Scholar] [CrossRef]

- Chen, M.; Liu, B.; Li, L.; Cao, L.; Huang, Y.; Wang, S.; Zhao, P.; Lu, L.; Cheng, X. Rheological parameters, thixotropy and creep of 3D-printed calcium sulfoaluminate cement composites modified by bentonite. Compos. Part B Eng. 2020, 186, 107821. [Google Scholar] [CrossRef]

- Chen, M.; Li, L.; Wang, J.; Huang, Y.; Wang, S.; Zhao, P.; Lu, L.; Cheng, X. Rheological parameters and building time of 3D printing sulphoaluminate cement paste modified by retarder and diatomite. Constr. Build. Mater. 2020, 234, 117391.1–117391.13. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; van Zijl, G. 3D concrete printing: A lower bound analytical model for buildability performance quantification. Autom. Constr. 2019, 106, 102904.1–102904.14. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; van Zijl, G. An ab initio approach for thixotropy characterisation of (nanoparticle-infused) 3D printable concrete. Constr. Build. Mater. 2019, 224, 372–386. [Google Scholar] [CrossRef]

- Zhu, Y.M.; Zhang, Y.; Jiang, Z.W. Effect of hydroxypropyl methylcellulose on performance of 3D-printed mortar. J. Build. Mater. 2021, 24, 1123–1130. [Google Scholar]

- Zhang, C.; Hou, Z.; Chen, C.; Zhang, Y.; Mechtcherine, V.; Sun, Z. Design of 3D printable concrete based on the relationship between flowability of cement paste and optimum aggregate content. Cem. Concr. Compos. 2019, 104, 103406. [Google Scholar] [CrossRef]

- Box, G.; Wilson, K. On the experimental attainment of optimum conditions. J. R. Stat. Soc. 1951, 13, 1–45. [Google Scholar] [CrossRef]

- Mason, R.L.; Gunst, R.F.; Hess, J.L. Statistical Design and Analysis of Experiments (with Applications to Engineering and Science); Wiley: New York, NY, USA, 1989. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, J.; Su, L.; Gao, Z.; Yin, C.; Ye, Z. Optimization of Ultra-High Performance Concrete Based on Response Surface Methodology and NSGA-II. Materials 2024, 17, 4885. [Google Scholar] [CrossRef]

- Zhang, Q. Mix design and performance prediction of EPS lightweight structural concrete based on orthogonal experimentation. Sci. Rep. 2025, 15, 21420. [Google Scholar] [CrossRef]

- Mohamed, O.; Zuaiter, H. Fresh Properties, Strength, and Durability of Fiber-Reinforced Geopolymer and Conventional Concrete: A Review. Polymers 2024, 16, 141. [Google Scholar] [CrossRef]

- Li, N.; Xue, C.; Chen, S.; Aiyiti, W.; Khan, S.B.; Liang, J.; Zhou, J.; Lu, B. 3D Printing of Flexible Mechanical Metamaterials: Synergistic Design of Process and Geometric Parameters. Polymers 2023, 15, 4523. [Google Scholar] [CrossRef] [PubMed]

- GB/T 2419-2005; Test Method for Fluidity of Cement Mortar. China Standards Press: Beijing, China, 2005.

- Lim, S.; Buswell, R.; Le, T.; Austin, S.; Gibb, A.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Marchon, D.; Kawashima, S.; Bessaies-Bey, H.; Mantellato, S.; Ng, S. Hydration and rheology control of concrete for digital fabrication: Potential admixtures and cement chemistry. Cem. Concr. Res. 2018, 112, 96–110. [Google Scholar] [CrossRef]

- Iwundu, M.P.; Cosmos, J. The Efficiency of Seven-Variable Box-Behnken Experimental Design with Varying Center Runs on Full and Reduced Model Types. J. Math. Stat. 2022, 18, 196–207. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Deng, S.; Liu, L.; Yang, P.; Zhang, C.; Lv, Y.; Xie, L. Experimental Study on Early Strength and Hydration Heat of Spodumene Tailings Cemented Backfill Materials. Materials 2022, 15, 8846. [Google Scholar] [CrossRef]

- Ke, J.; Shui, Z.; Gao, X.; Qi, X.; Zheng, Z.; Zhang, S. Effect of Vibration Procedure on Particle Distribution of Cement Paste. Materials 2023, 16, 2600. [Google Scholar] [CrossRef]

- Abedi-Firoozjah, R.; Yousefi, S.; Heydari, M.; Seyedfatehi, F.; Jafarzadeh, S.; Mohammadi, R.; Rouhi, M.; Garavand, F. Application of Red Cabbage Anthocyanins as pH-Sensitive Pigments in Smart Food Packaging and Sensors. Polymers 2022, 14, 1629. [Google Scholar] [CrossRef]

- Feng, K.; Xu, Z.; Zhang, W.; Ma, K.; Shen, J.; Hu, M. Rheological Properties and Early-Age Microstructure of Cement Pastes with Limestone Powder, Redispersible Polymer Powder and Cellulose Ether. Materials 2022, 15, 3159. [Google Scholar] [CrossRef]

- Dressler, I.; Freund, N.; Lowke, D. The Effect of Accelerator Dosage on Fresh Concrete Properties and on Interlayer Strength in Shotcrete 3D Printing. Materials 2020, 13, 374. [Google Scholar] [CrossRef]

- Xia, Y.; Shi, W.; Xiang, S.; Yang, X.; Yuan, M.; Zhou, H.; Yu, H.; Zheng, T.; Zhang, J.; Jiang, Z.; et al. Synthesis and Modification of Polycarboxylate Superplasticizers—A Review. Materials 2024, 17, 1092. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Chen, Z.; Yan, D.; Ke, Y.; Ma, X.; Lai, J.; Liu, Y.; Li, G.; Zhang, X.; Lin, Z.; et al. Study on the Effect of Main Chain Molecular Structure on Adsorption, Dispersion, and Hydration of Polycarboxylate Superplasticizers. Materials 2023, 16, 4823. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Ma, Y.; Liu, J.; Chen, X.; Ren, F.; Chen, W.; Cui, H. Improvement of shrinkage resistance and mechanical property of cement-fly ash-slag ternary blends by shrinkage-reducing polycarboxylate superplasticizer. J. Clean. Prod. 2024, 447, 141493.1–141493.14. [Google Scholar] [CrossRef]

- Gong, Y.; Bai, J.; Wang, Y.; Liu, R.; Tian, J. Rheological properties of seawater-mixed seashell powder calcined slag cement slurries: Effect of polycarboxylate superplasticizer and temperature. Mater. Lett. 2024, 367, 1.1–1.4. [Google Scholar] [CrossRef]

- Aydın, Ö.K.; Koca, N.; Koç, M.; Kaymak-Ertekin, F. Process Optimization and Storage Evaluation of Explosion Puffing Dried Reduced-Fat White Cheese Snacks. J. Food Sci. 2025, 90, e70353. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Q.; Wang, J.; Tao, K.; Huang, H.; Zhao, Y.; Jia, J.; Tan, H.; Chang, H. Optimization of Phenolic-Enriched Extracts from Olive Leaves via Ball Milling-Assisted Extraction Using Response Surface Methodology. Molecules 2024, 29, 3658. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Z.; Gong, W.; Liang, Z. Quantifying the effects of fuel compositions on GDI-derived particle emissions using the optimal mixture design of experiments. Fuel 2015, 154, 252–260. [Google Scholar] [CrossRef]

- Parhi, S.K.; Patro, S.K. Application of R-curve, ANCOVA, and RSM techniques on fracture toughness enhancement in PET fiber-reinforced concrete. Constr. Build. Mater. 2023, 411, 134644.1–134644.14. [Google Scholar] [CrossRef]

- Zerig, T.; Belachia, M.; Aidoud, A.; Meftah, N.; Djedid, T.; Abbas, M. Statistical analysis using the RSM approach of the physical behavior of green polymerized eco-mortar. J. Clean. Prod. 2024, 450, 141858.1–141858.22. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, T.; Zhang, Y.; Cai, Z.; Yuan, Y. Preparation of spent fluid catalytic cracking catalyst-metakaolin based geopolymer and its process optimization through response surface method. Constr. Build. Mater. 2020, 264, 120727. [Google Scholar] [CrossRef]

- Omranian, S.R.; Hamzah, M.O.; Yee, T.S.; Hasan, M.R.M. Effects of short-term ageing scenarios on asphalt mixtures’ fracture properties using imaging technique and response surface method. Int. J. Pavement Eng. 2018, 21, 1374–1392. [Google Scholar] [CrossRef]

- Sun, G.; Yang, X.; Zheng, H.; Wang, J.; Yang, H.; Zhang, F. Preparation and accelerating mechanism of aluminum sulfate-based alkali-free liquid flash setting admixture for shotcrete. Constr. Build. Mater. 2024, 422, 135799. [Google Scholar] [CrossRef]

- Sun, G.; Yang, X.; Wang, F.; Wang, J.; Liu, Z. Development of a High Early Strength Non-fluorine and Non-alkaline Flash Setting Admixture and Flash Mechanism. J. Wuhan Univ. Technol. Sci. Ed. 2024, 39, 1518–1527. [Google Scholar] [CrossRef]

- Chen, C.; Yan, D.; Li, X.; Liu, M.; Cui, C.; Li, L. Field-tested innovation: Sustainable utilization of secondary alumina dross for flash setting admixtures production. J. Environ. Manag. 2024, 358, 120857. [Google Scholar] [CrossRef] [PubMed]

- Patural, L.; Marchal, P.; Govin, A.; Grosseau, P.; Ruot, B.; Devès, O. Cellulose ethers influence on water retention and consistency in cement-based mortars. Cem. Concr. Res. 2011, 41, 46–55. [Google Scholar] [CrossRef]

- Pourchez, J.; Peschard, A.; Grosseau, P.; Guyonnet, R.; Guilhot, B.; Vallée, F. HPMC and HEMC influence on cement hydration. Cem. Concr. Res. 2006, 36, 288–294. [Google Scholar] [CrossRef]

- Teng, L.; Wei, J.; Khayat, K.H.; Assaad, J.J. Effect of competitive adsorption between specialty admixtures and superplasticizer on structural build-up and hardened property of mortar phase of ultra-high-performance concrete. Cem. Concr. Compos. 2023, 141, 105130. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q.; An, X.; Liu, Y.; Li, H. Effect of constituents on rheological properties of fresh concrete-A review. Cem. Concr. Compos. 2017, 83, 146–159. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, Z.; Zhu, Y.; Zhang, J.; Ren, Q.; Huang, T. Effects of redispersible polymer powders on the structural build-up of 3D printing cement paste with and without hydroxypropyl methylcellulose. Constr. Build. Mater. 2021, 267, 120551.1–120551.17. [Google Scholar] [CrossRef]

- Zou, R.; Xia, Y.; Liu, S.; Hu, P.; Hou, W.; Hu, Q.; Shan, C. Isotropic and anisotropic elasticity and yielding of 3D printed material. Compos. Part B Eng. 2016, 99, 506–513. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | K2O | Na2O | Loss | |

|---|---|---|---|---|---|---|---|---|---|

| C | 64.00 | 20.10 | 5.55 | 2.55 | 2.37 | 3.86 | 0.66 | 0.25 | 3.50 |

| SF | 1.05 | 94.91 | 0.78 | 0.45 | 0.56 | 0.57 | 0.66 | 0.50 | 0.52 |

| GS | 37.92 | 31.38 | 13.77 | 9.82 | 1.09 | 0.07 | 1.52 | 0.33 | 0.23 |

| Length (mm) | Diameter (mm) | Young’s Modulus (GPa) | Elastic Modulus (GPa) | Tensile Strength (MPa) | |

|---|---|---|---|---|---|

| PPF | 6 | 0.02 | 13.2 | 3-5 | >480 |

| Factor | Level | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| A | 0.3 | 0.4 | 0.5 |

| B | 0.19 | 0.23 | 0.27 |

| C | 0.2 | 0.25 | 0.3 |

| No. | A Accelerator (%) | B HPMC (%) | C PCE (%) | Flowability (mm) | Dynamic Yield Stress (Pa) |

|---|---|---|---|---|---|

| 1 | 0.3 | 0.19 | 0.25 | 155 | 751.6 |

| 2 | 0.5 | 0.19 | 0.25 | 152 | 765.7 |

| 3 | 0.3 | 0.27 | 0.25 | 153 | 651.6 |

| 4 | 0.5 | 0.27 | 0.25 | 150.5 | 662.2 |

| 5 | 0.3 | 0.23 | 0.2 | 147 | 999.9 |

| 6 | 0.5 | 0.23 | 0.2 | 135 | 950.6 |

| 7 | 0.3 | 0.23 | 0.3 | 170 | 320.2 |

| 8 | 0.5 | 0.23 | 0.3 | 162.5 | 355 |

| 9 | 0.4 | 0.19 | 0.2 | 134 | 1183.3 |

| 10 | 0.4 | 0.27 | 0.2 | 130 | 1111.6 |

| 11 | 0.4 | 0.19 | 0.3 | 160 | 233.9 |

| 12 | 0.4 | 0.27 | 0.3 | 160 | 200 |

| 13 | 0.4 | 0.23 | 0.25 | 157 | 592.1 |

| 14 | 0.4 | 0.23 | 0.25 | 155 | 698.5 |

| 15 | 0.4 | 0.23 | 0.25 | 156 | 623.2 |

| 16 | 0.4 | 0.23 | 0.25 | 158 | 605.4 |

| 17 | 0.4 | 0.23 | 0.25 | 155 | 612.8 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 1754.27 | 9 | 194.92 | 38.86 | <0.0001 | significant |

| A | 78.12 | 1 | 78.12 | 15.57 | 0.0056 | |

| B | 7.03 | 1 | 7.03 | 1.40 | 0.2751 | |

| C | 1417.78 | 1 | 1417.78 | 282.65 | <0.0001 | |

| AB | 0.0625 | 1 | 0.0625 | 0.0125 | 0.9143 | |

| AC | 5.06 | 1 | 5.06 | 1.01 | 0.3485 | |

| BC | 4.00 | 1 | 4.00 | 0.7974 | 0.0415 | |

| A2 | 17.27 | 1 | 17.27 | 3.44 | 0.1059 | |

| B2 | 132.04 | 1 | 132.04 | 26.32 | 0.0014 | |

| C2 | 89.09 | 1 | 89.09 | 17.76 | 0.0040 | |

| Residual | 35.11 | 7 | 5.02 | |||

| Lack of Fit | 28.31 | 3 | 9.44 | 5.55 | 0.0656 | not significant |

| Pure Error | 6.80 | 4 | 1.70 | |||

| Cor Total | 1789.38 | 16 | ||||

| R2 | 0.9804 | |||||

| R2Adj | 0.9551 | |||||

| R2pred | 0.7409 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 1.100 × 106 | 9 | 1.222 × 105 | 39.90 | <0.0001 | Significant |

| A | 16,616.65 | 1 | 16,616.65 | 5.42 | 0.0527 | |

| B | 8437.00 | 1 | 8437.00 | 2.75 | 0.1410 | |

| C | 1.027 × 106 | 1 | 1.027 × 106 | 335.25 | <0.0001 | |

| AB | 28.09 | 1 | 28.09 | 0.0092 | 0.9264 | |

| AC | 552.25 | 1 | 552.25 | 0.1803 | 0.6839 | |

| BC | 1823.29 | 1 | 1823.29 | 0.5952 | 0.4657 | |

| A2 | 23,041.27 | 1 | 23,041.27 | 7.52 | 0.0288 | |

| B2 | 19,944.76 | 1 | 19,944.76 | 6.51 | 0.0380 | |

| C2 | 1184.84 | 1 | 1184.84 | 0.3868 | 0.5537 | |

| Residual | 21,444.47 | 7 | 3063.50 | |||

| Lack of Fit | 14,433.37 | 3 | 4811.12 | 2.74 | 0.1770 | Not significant |

| Pure Error | 7011.10 | 4 | 1752.77 | |||

| Cor Total | 1.122 × 106 | 16 | ||||

| R2 | 0.9596 | |||||

| R2Adj | 0.9076 | |||||

| R2pred | 0.8522 |

| Accelerator | HPMC | PCE | Flowability (mm) | Dynamic Yield Stress (Pa) | Desirability |

|---|---|---|---|---|---|

| 0.321% | 0.241% | 0.231% | 153.763 | 768.031 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Lian, J.; Fang, Y.; Fan, G.; Yang, Y.; Huang, W.; Shi, S. Rheological Optimization of 3D-Printed Cementitious Materials Using Response Surface Methodology. Materials 2025, 18, 3933. https://doi.org/10.3390/ma18173933

Wang C, Lian J, Fang Y, Fan G, Yang Y, Huang W, Shi S. Rheological Optimization of 3D-Printed Cementitious Materials Using Response Surface Methodology. Materials. 2025; 18(17):3933. https://doi.org/10.3390/ma18173933

Chicago/Turabian StyleWang, Chenfei, Junyin Lian, Yunhui Fang, Guangming Fan, Yixin Yang, Wenkai Huang, and Shuqin Shi. 2025. "Rheological Optimization of 3D-Printed Cementitious Materials Using Response Surface Methodology" Materials 18, no. 17: 3933. https://doi.org/10.3390/ma18173933

APA StyleWang, C., Lian, J., Fang, Y., Fan, G., Yang, Y., Huang, W., & Shi, S. (2025). Rheological Optimization of 3D-Printed Cementitious Materials Using Response Surface Methodology. Materials, 18(17), 3933. https://doi.org/10.3390/ma18173933