Inter Laminar Shear Strength of Flax-Glass Hybrid Polymer Composites for Automotive Frame: Numerical Modelling and Experimental Analysis

Highlights

- Development of hybrid polymer composites from natural and glass fiber-based fabrics.

- Finite element analysis-based prediction of interlaminar shear strength (ILSS).

- Experimental testing of the ILSS and validation of the predicted performance.

- Microscopic analysis of fracture and interfacial debonding between fiber and matrix.

- Performance of hybrid composites in real loading conditions in automotive frames.

Abstract

1. Introduction

2. Materials and Methods

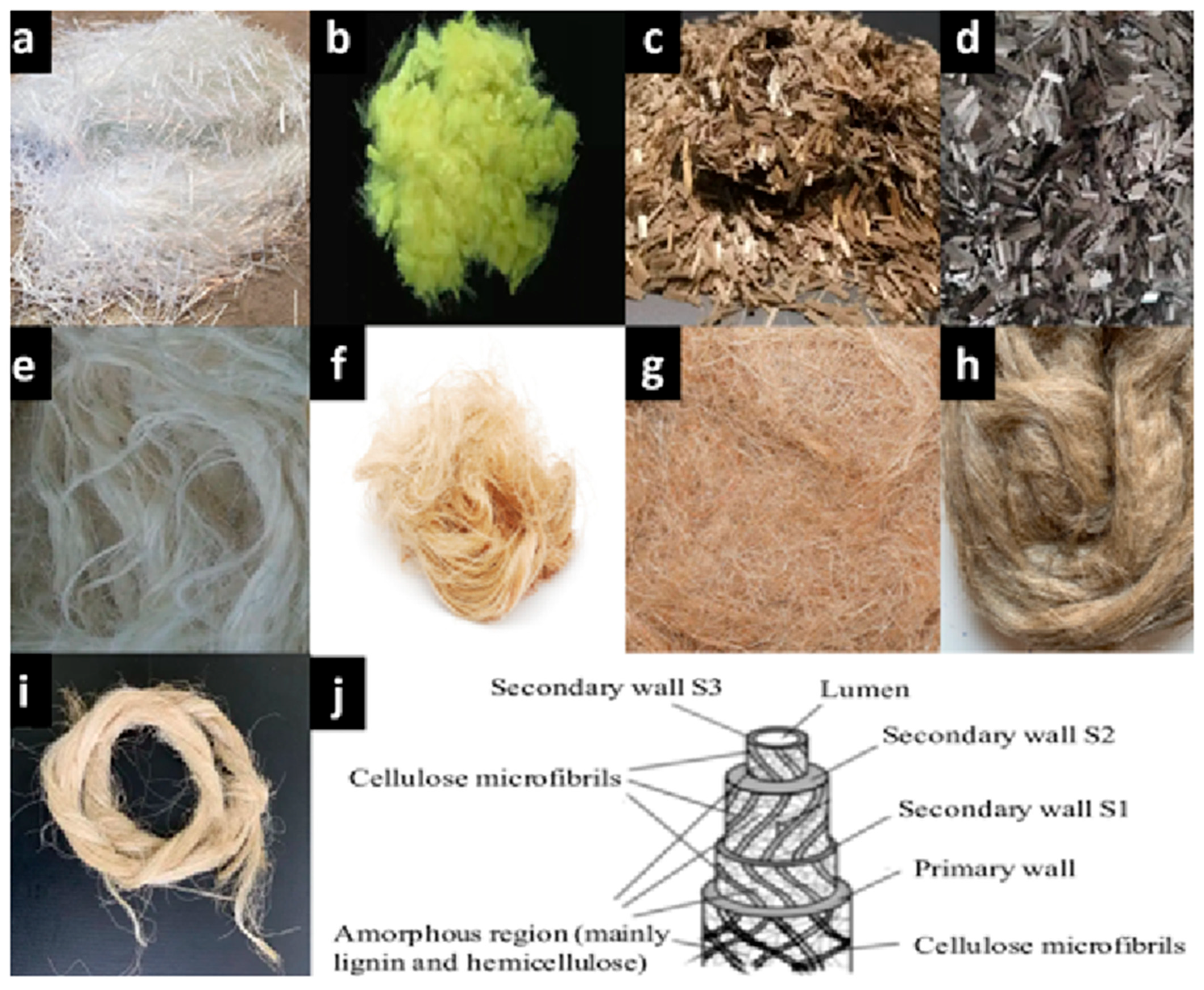

2.1. Materials

2.2. Methods

2.2.1. Modelling Software

2.2.2. Sample Preparation

- Prior to the application of the first layer of fabric, a releasing agent is to be applied onto the surface.

- The subsequent layers are added to the base fabric by coating the base fabric with epoxy resin and placing the next layer of fabric. All the samples had a fibre volume fraction of 45%.

- To separate the samples from the moulds easily, auxiliary fabric was used.

- A pressure of 1000 mbar was applied for 2 h and the samples were allowed to be cured at room temperature for 24 h and subsequently the samples were cured at 120 °C for 2 h.

2.3. Experimental Testing

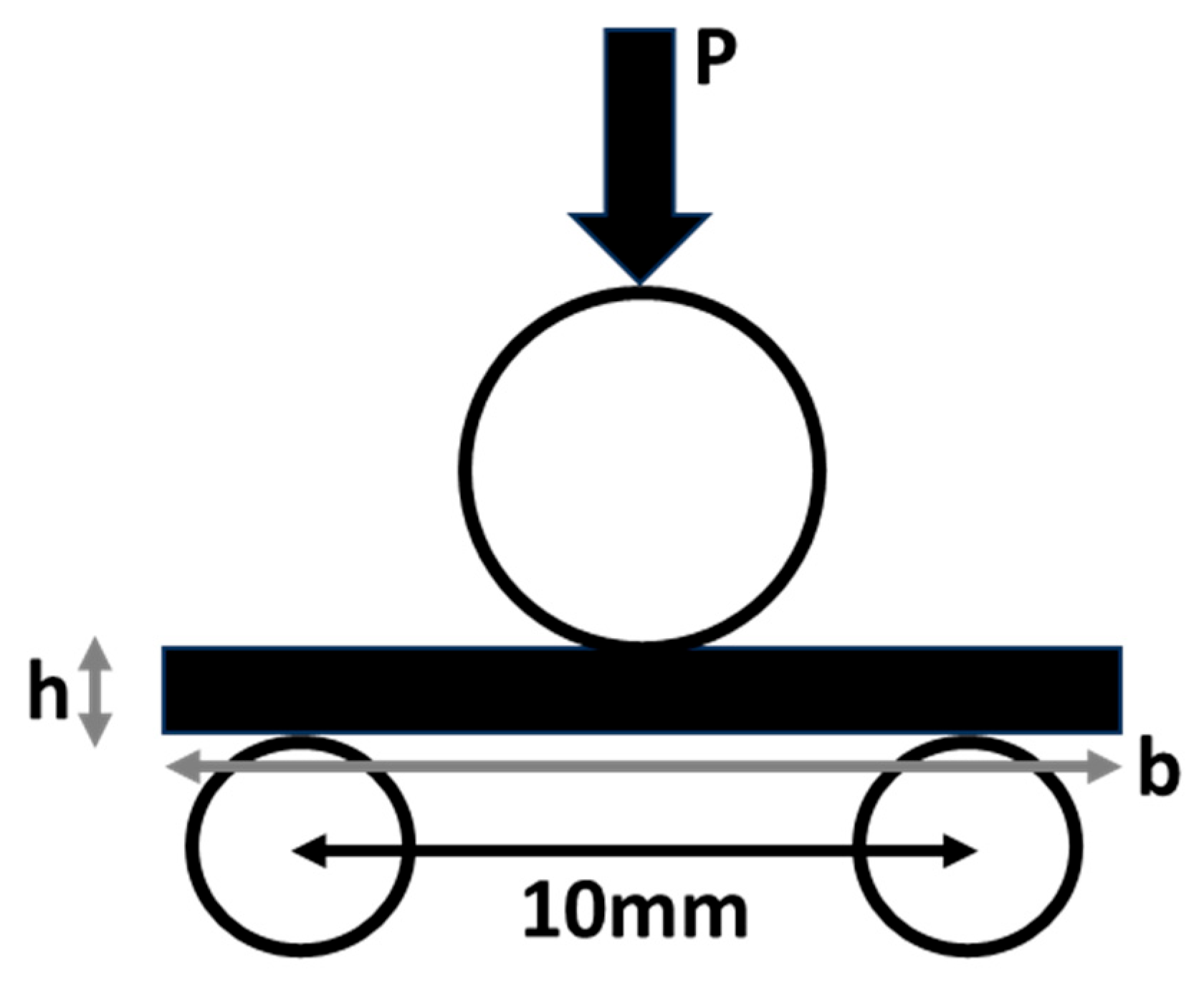

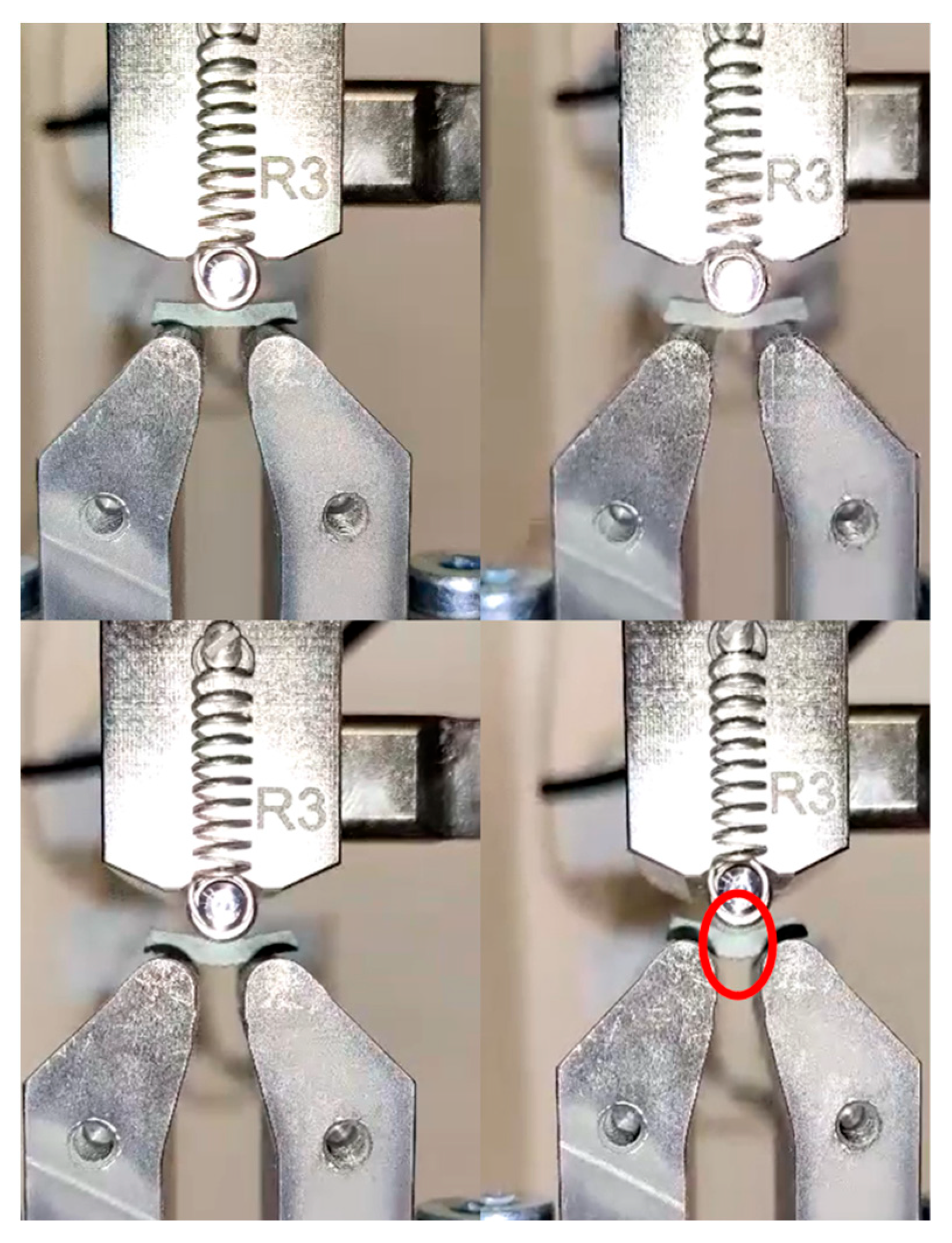

2.3.1. Interlaminar Shear Testing

2.3.2. Fractured Surface Morphology

2.4. Modelling Methodology

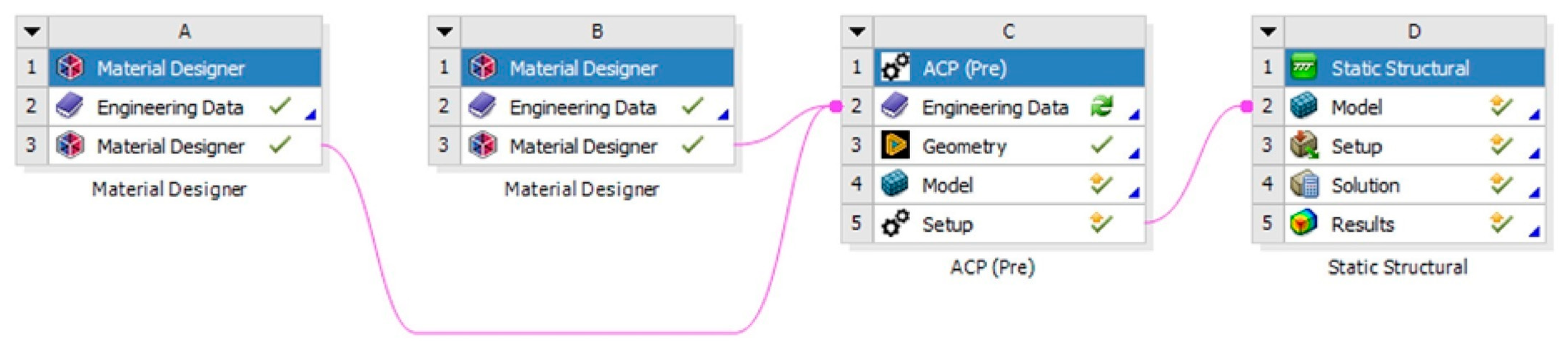

- The fabrics used to model the composite are modelled in the material designer module. In order to model the fabric, the following details are to be entered:

- Type of weave

- Spacing of the yarn

- Volume fraction of the fibre

- Thickness

- b.

- After feeding the required data, the fabric is generated, and along with the fabric, data about the fabric is also generated.

- c.

- The designer module generates data for the fabric, and this data is then transferred to the engineering data segment of the ACP (Pre) i.e., (Ansys Composite PrePost) module.

- d.

- In the ACP (Pre) module the geometry that was created in the AUTOCAD software version 2024 (LIBTEX, Liberec, Czech Republic) as shown in Figure 6, is imported. The imported model is fed into the Geometry segment of the module.

- e.

- The geometry which has been imported is now transferred to the Model segment of the ACP (Pre) module, and in this segment the imported geometry is designated as a flexible object, and the mesh for the sample is generated.

- f.

- In the setup segment of the ACP (Pre) module, the fabrics along with their properties are created and applied to the model of the sample as shown in Figure 6. The fabrics that were created were 0.25 mm each to give a total thickness of 2 mm (thickness of the sample).

- g.

- In the setup segment of the ACP (Pre), plies are generated with the appropriate properties.

- h.

- The data generated in the setup segment is now transferred to the model segment in the Static Structural module.

- i.

- In the Static Structural module, the boundary conditions are defined, the simulations are run, and the data is collected.

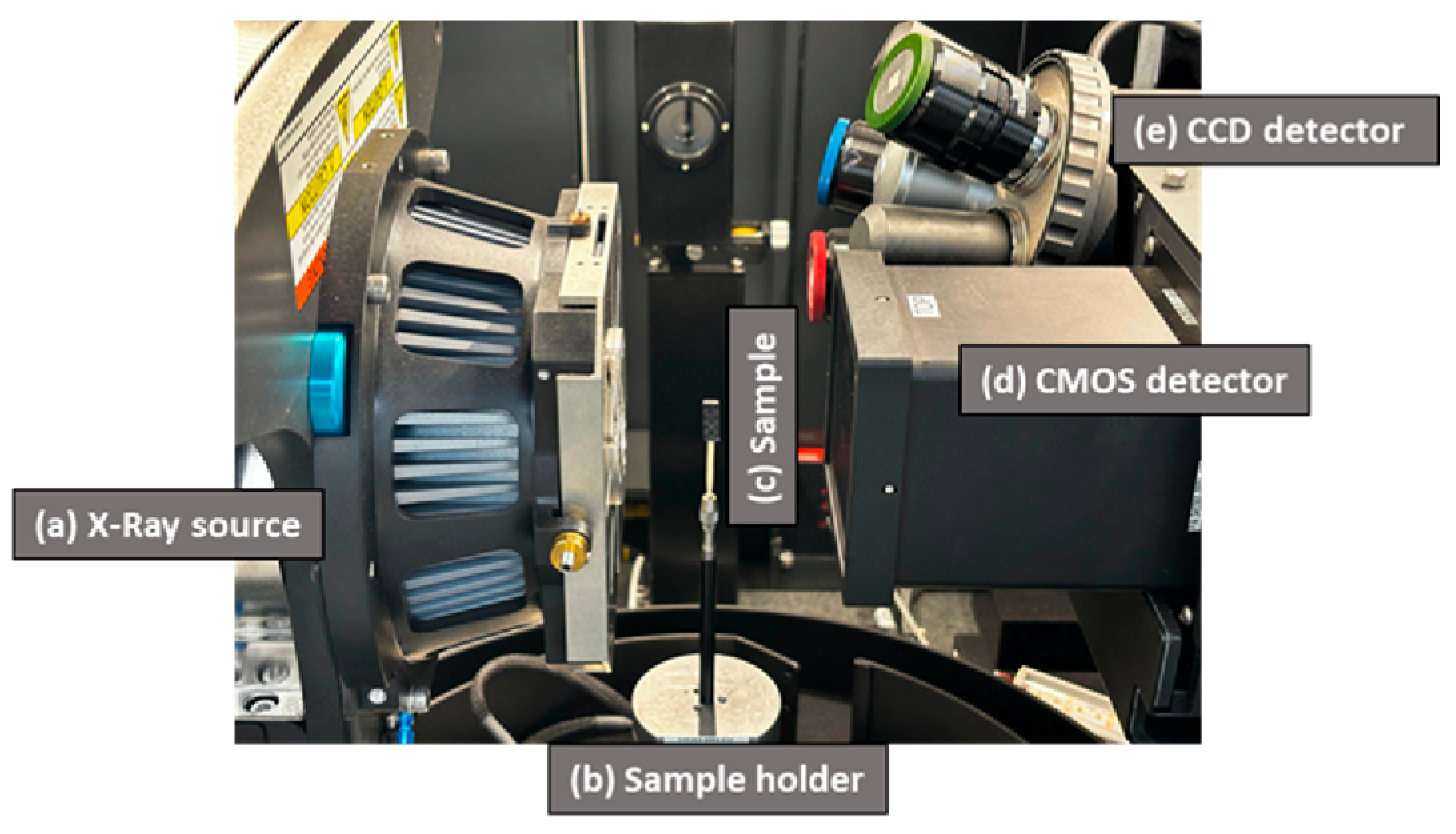

2.5. X-Ray 3-D Imaging

3. Results and Discussion

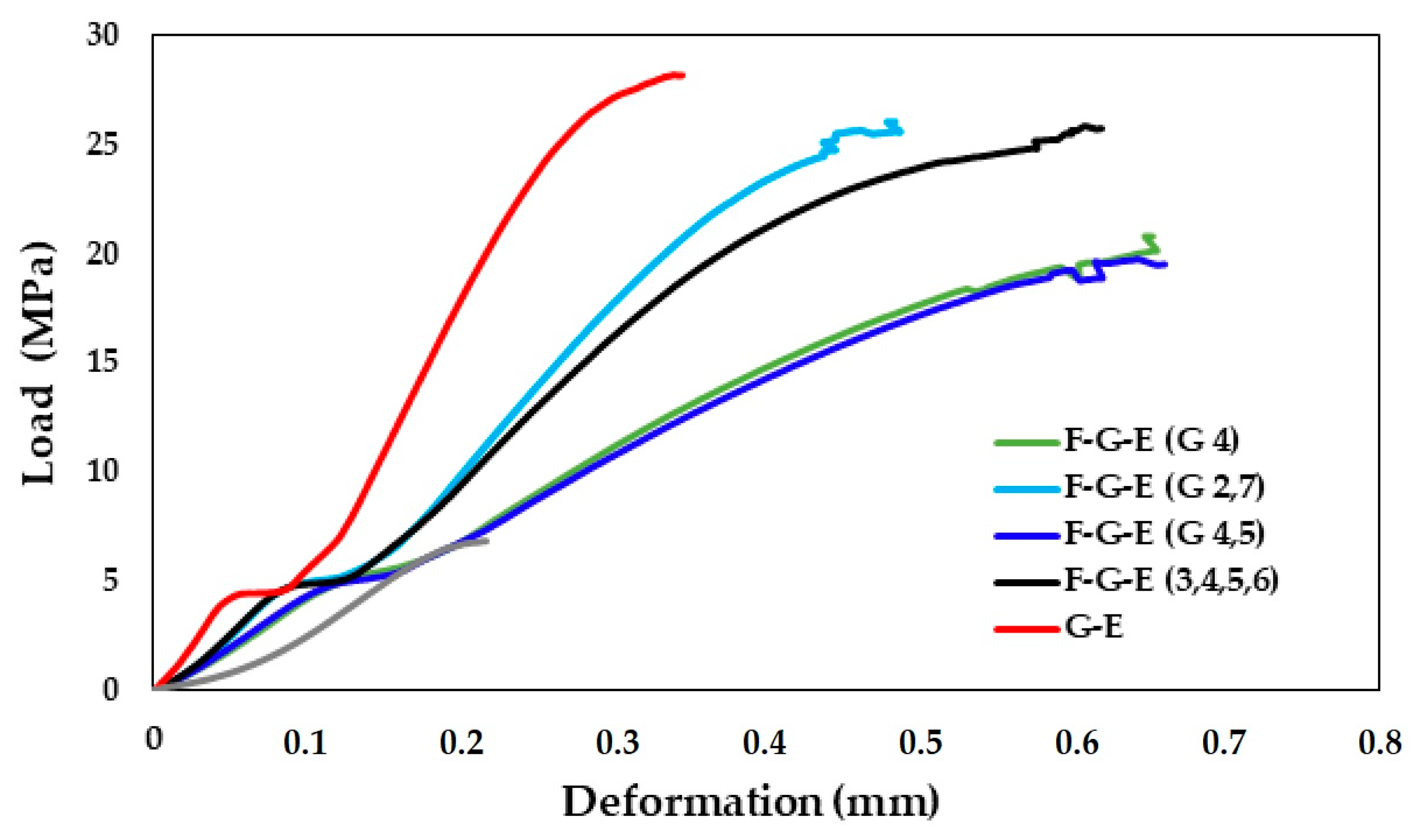

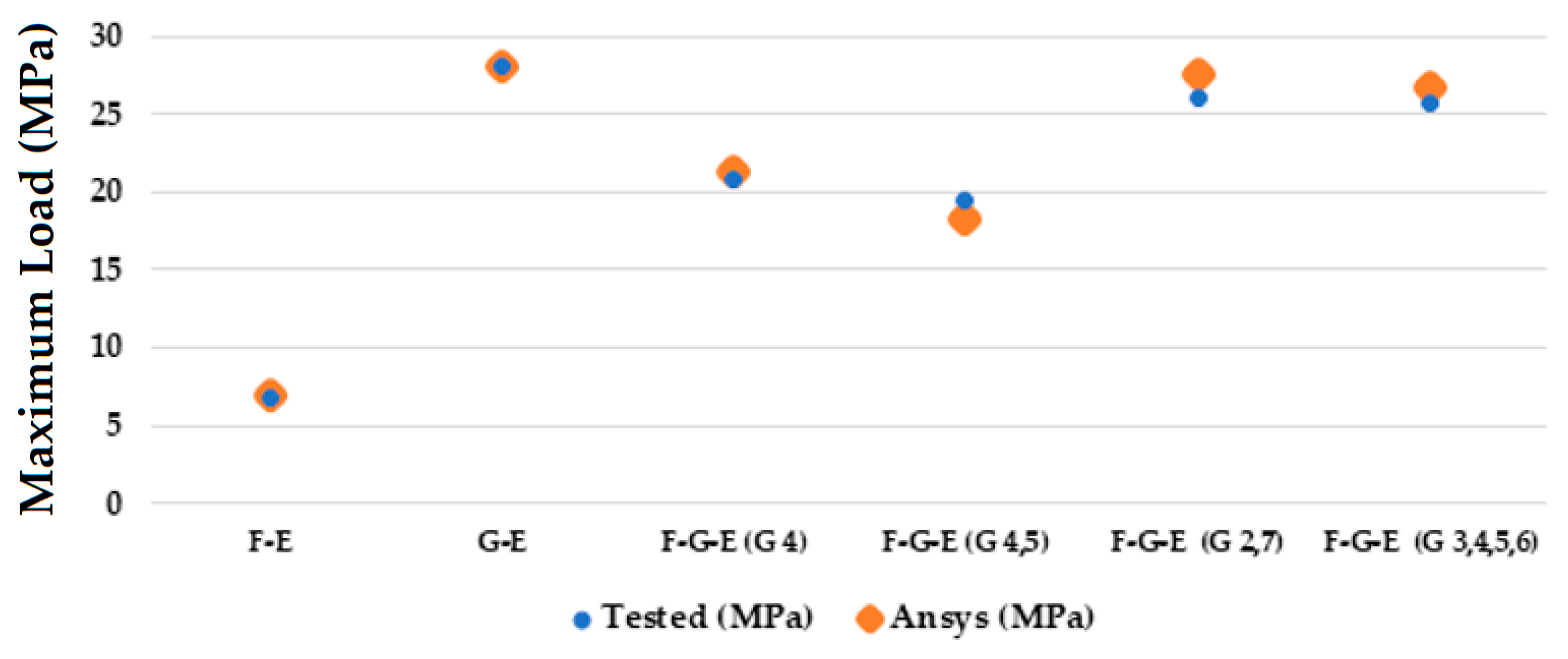

3.1. Experimental Results

3.2. Effect of Stacking Sequence on ILSS

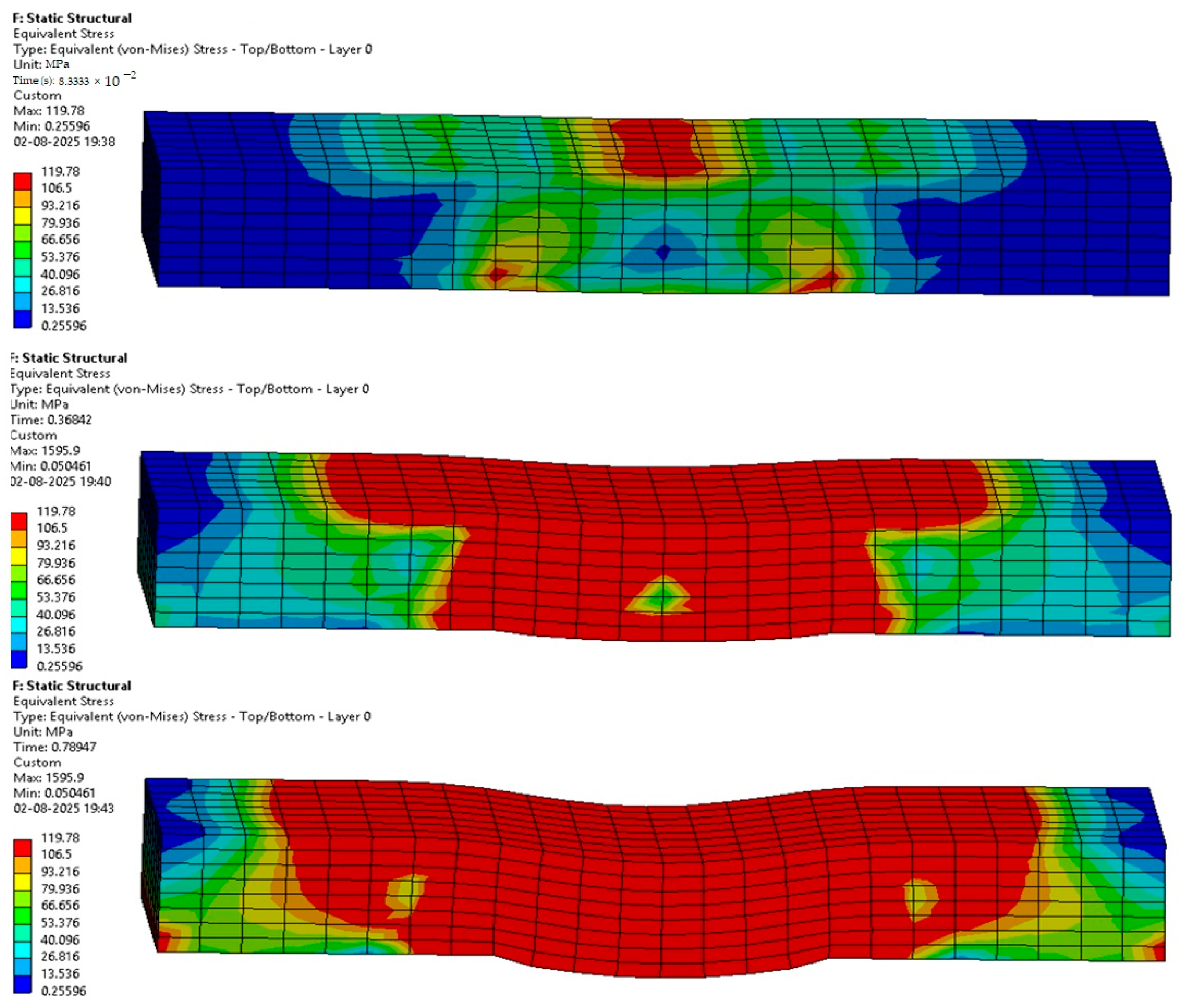

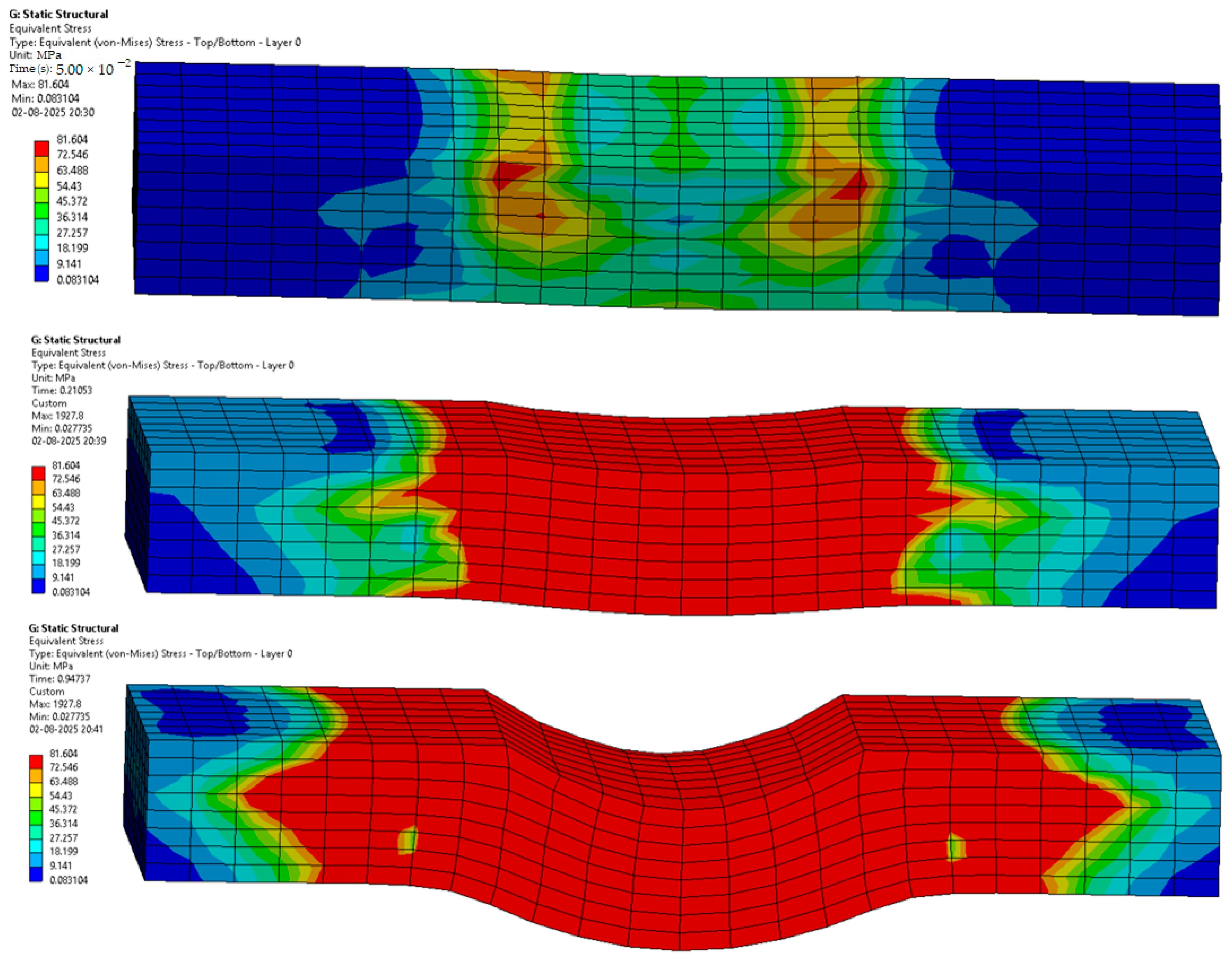

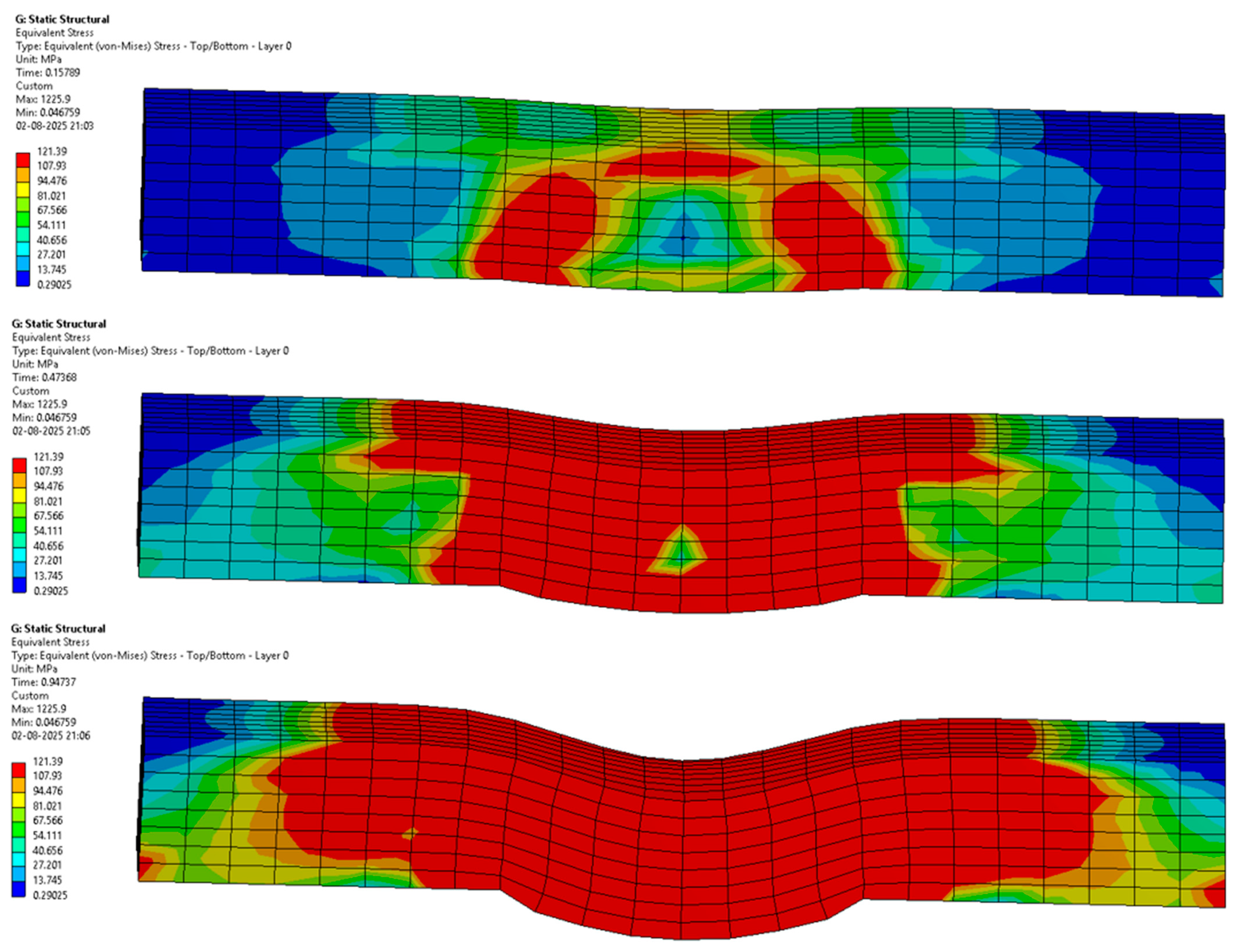

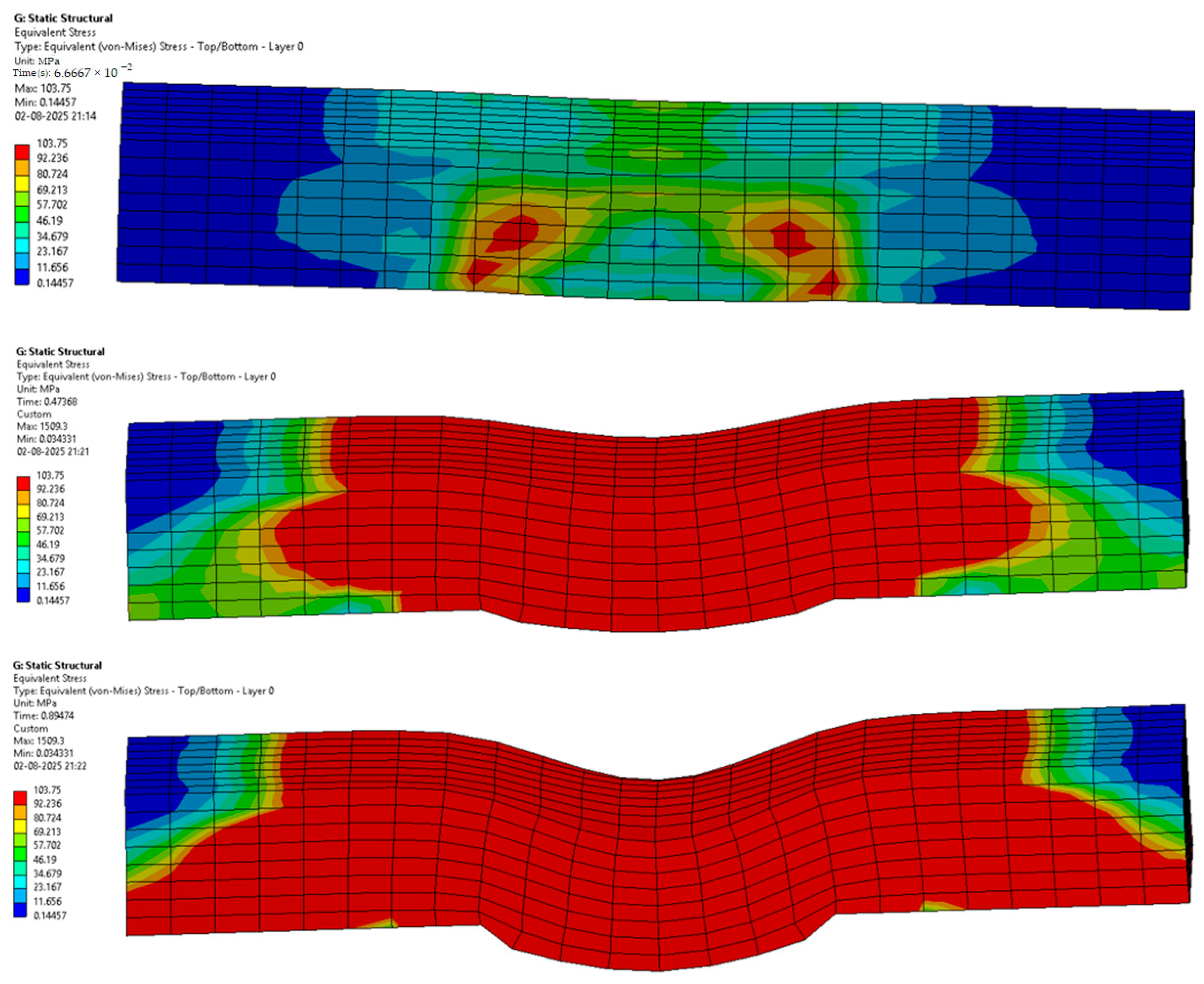

3.3. Simulation of Samples

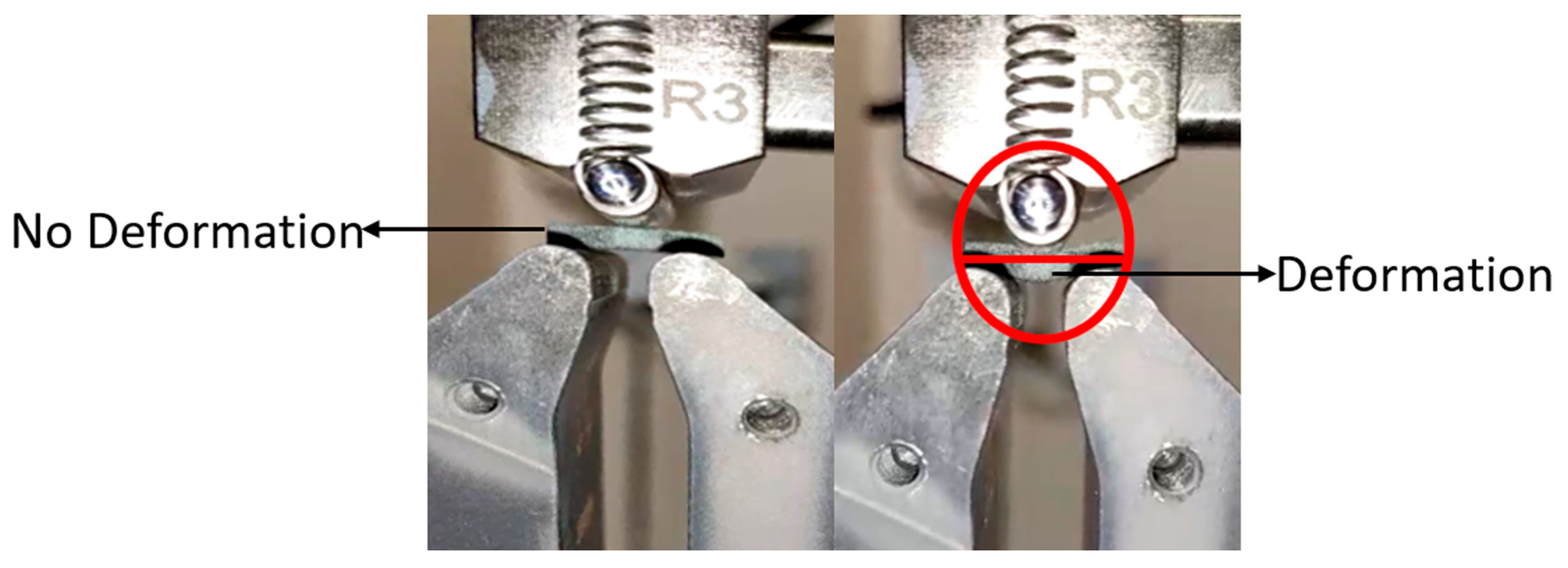

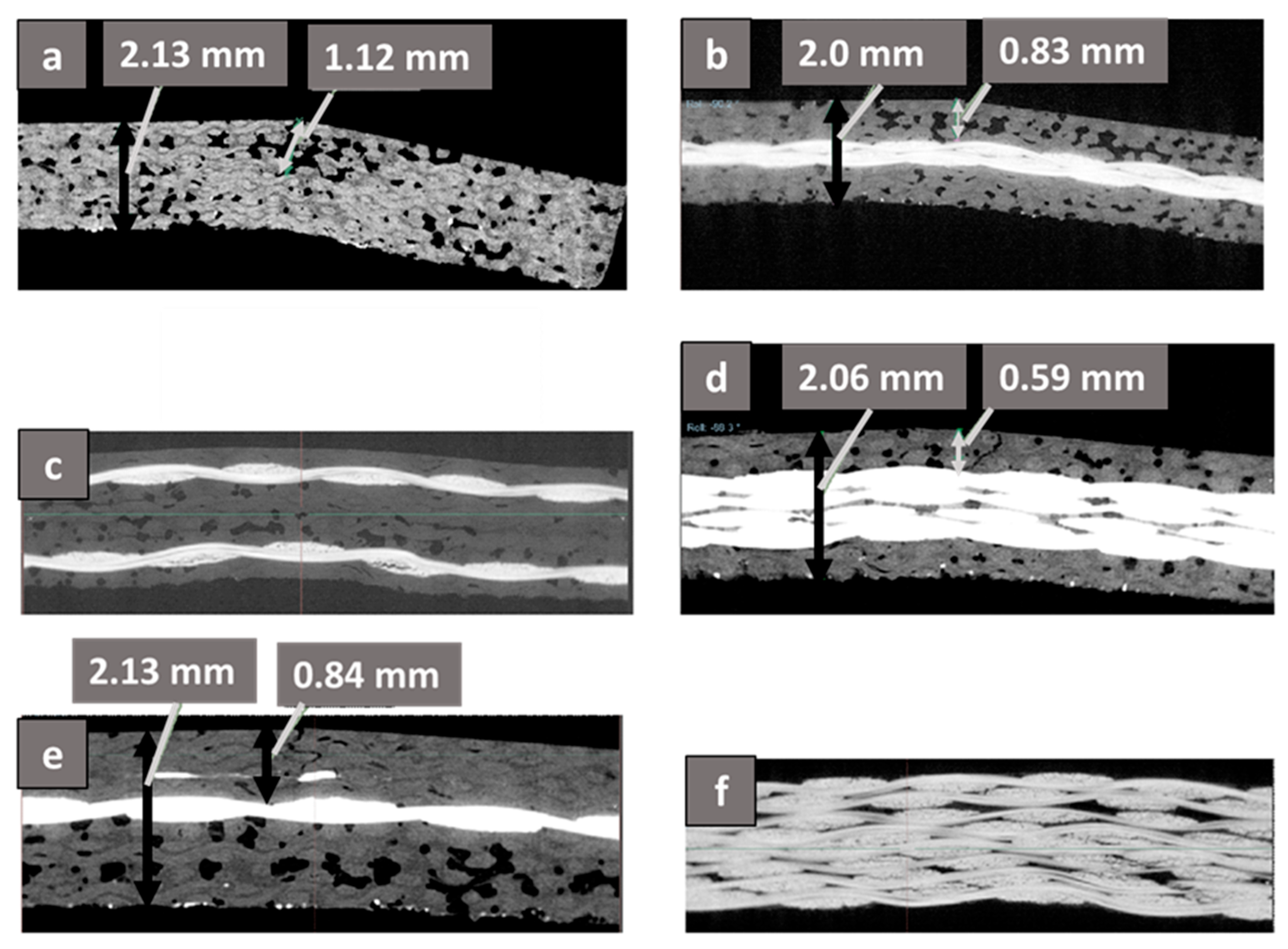

3.4. Failure Modes on ILSS Testing

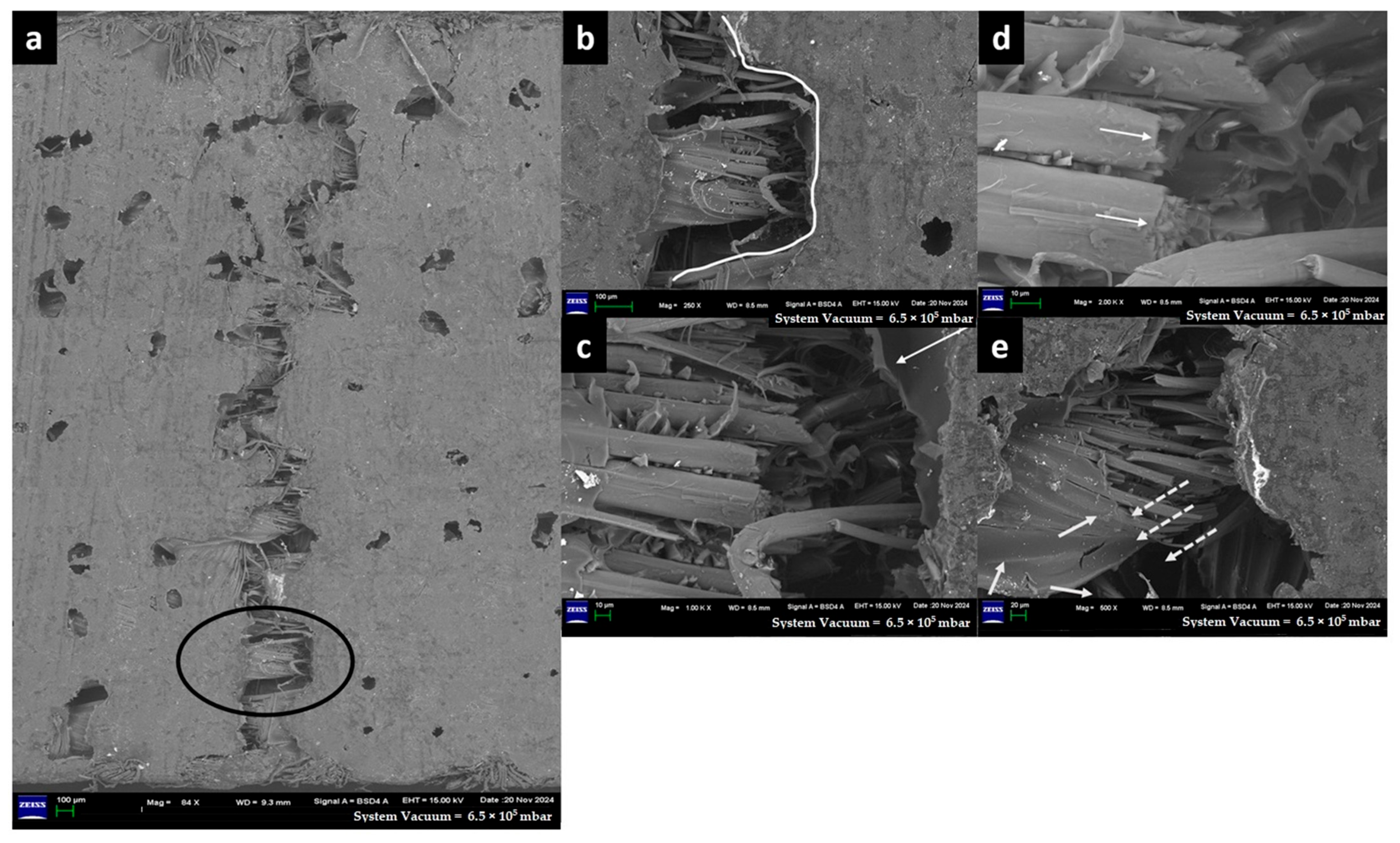

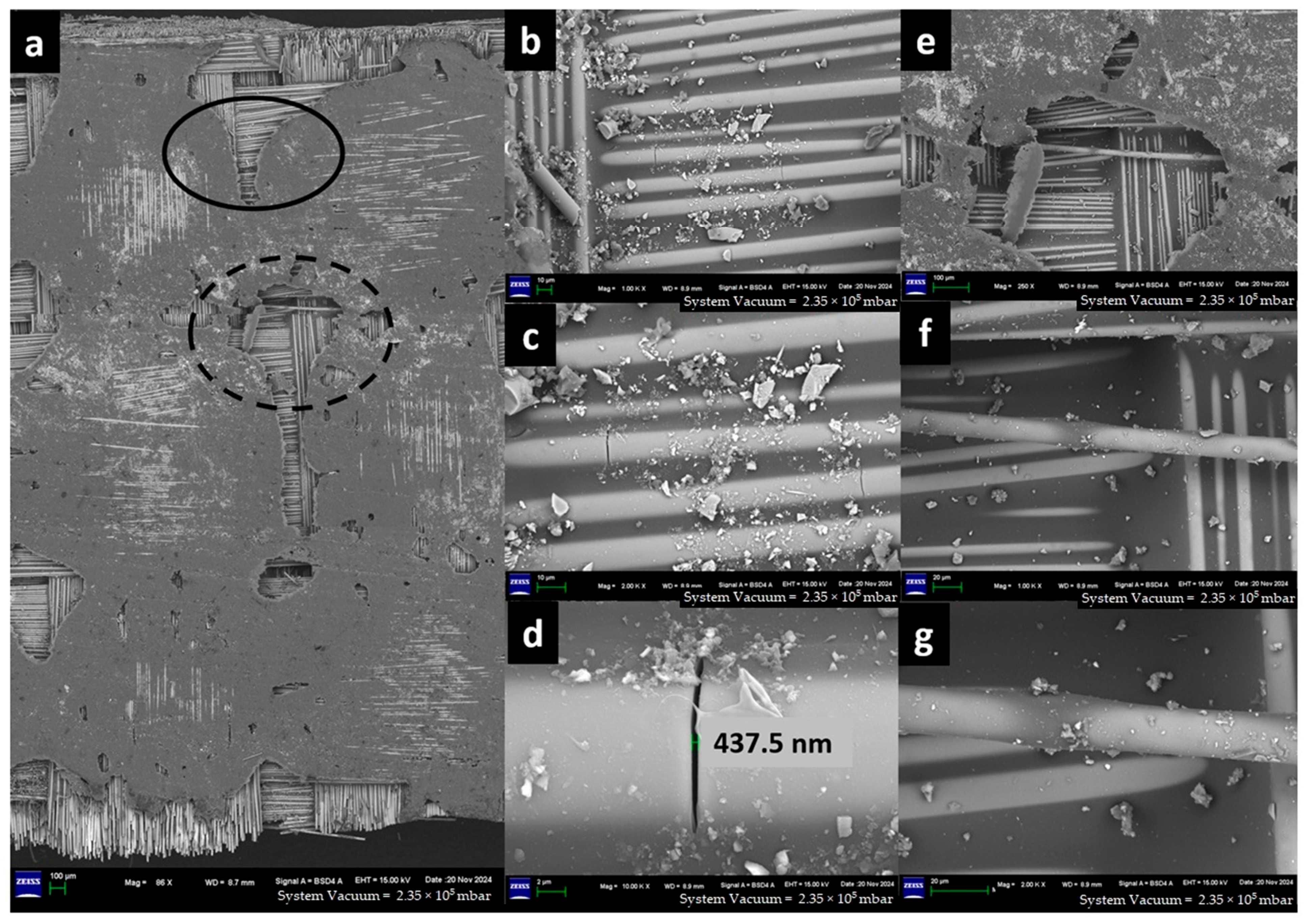

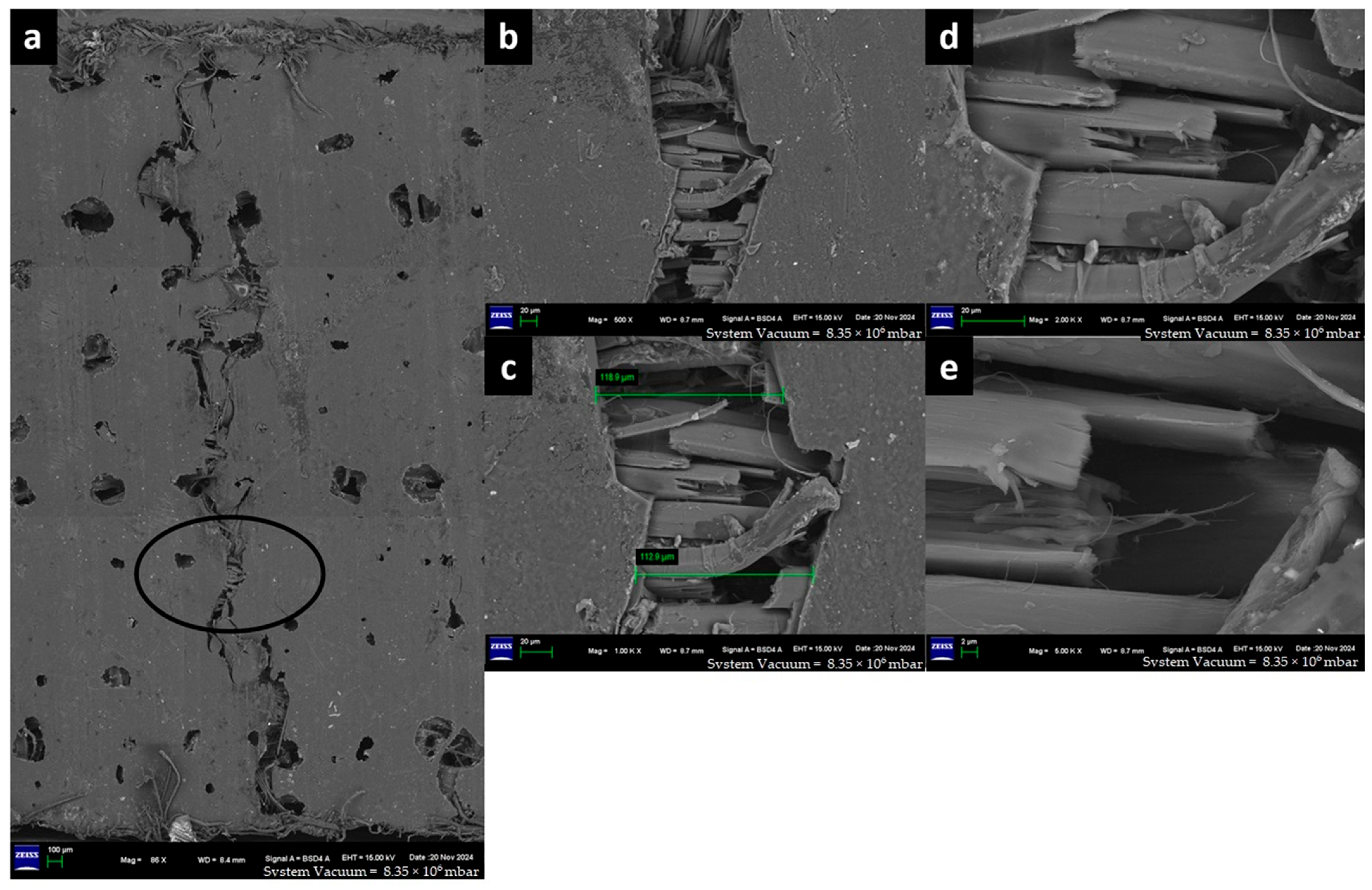

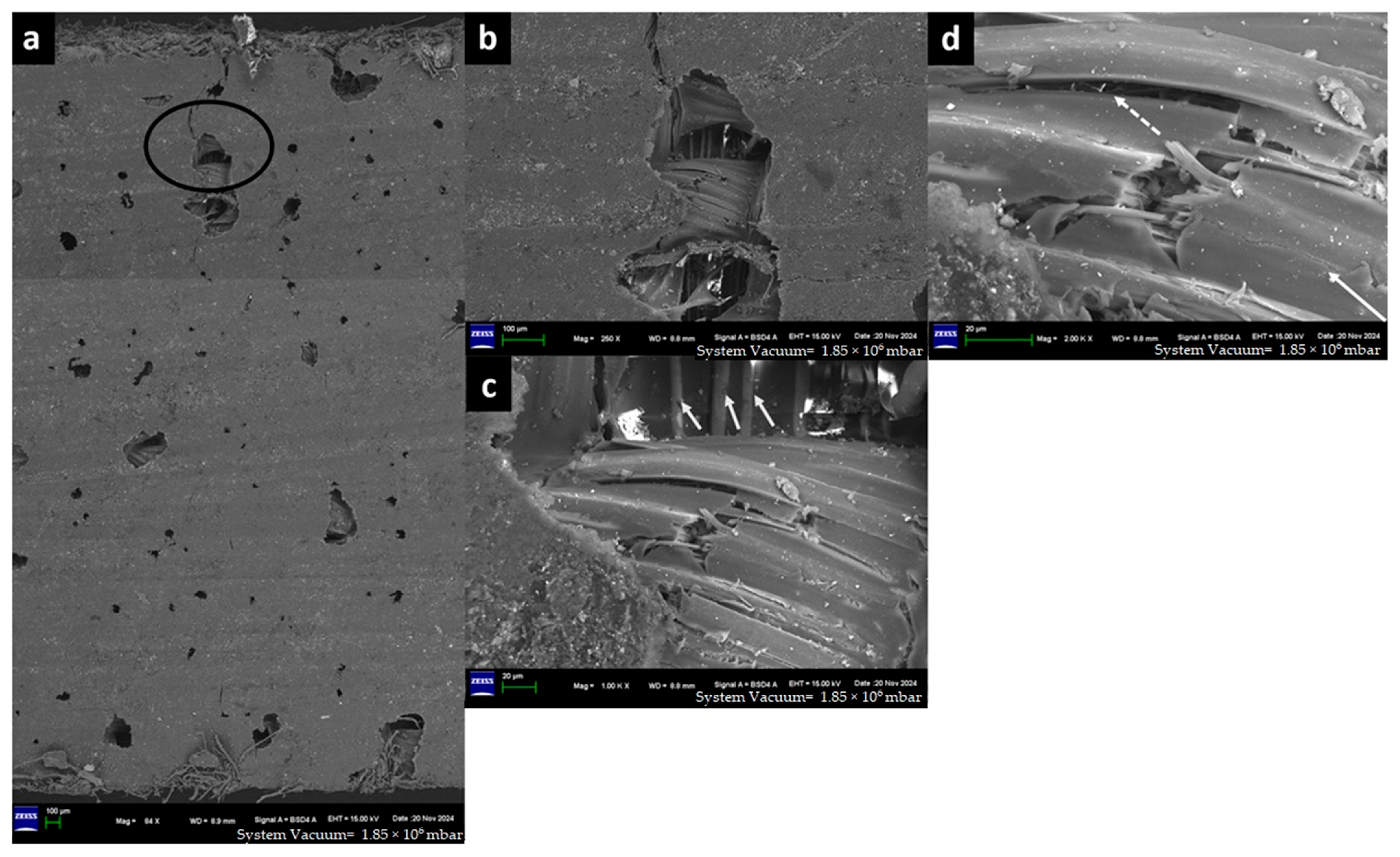

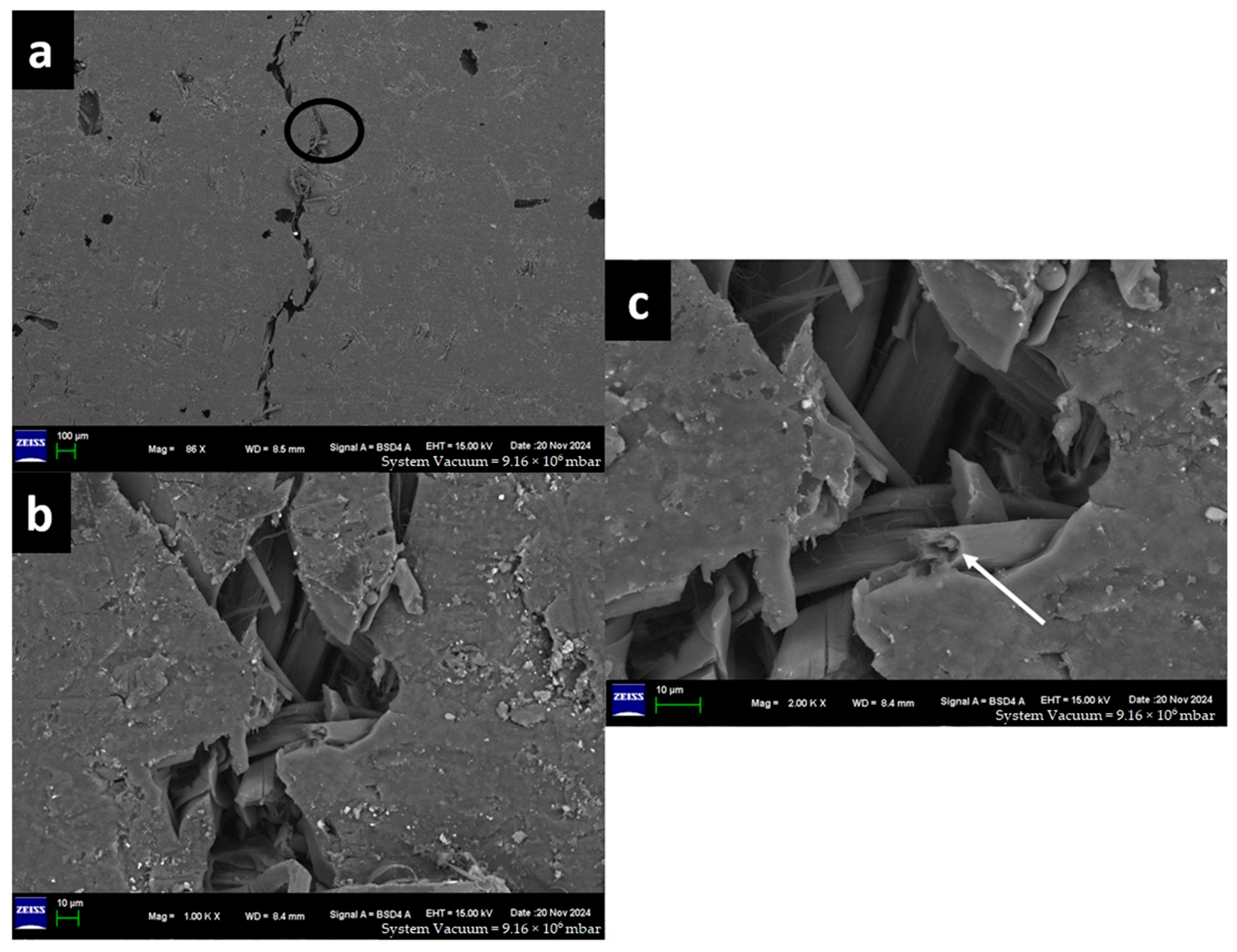

3.5. Morphology

4. Conclusions

- Hybridisation of flax with glass fibre improves the interlaminar shear strength considerably as compared to that of the flax fibre alone, and the reported values are higher than that of the pure flax and lower than that of the pure glass fibre.

- Hybrid samples of F-G-E (G 2,7) with glass as the penultimate layers and F-G-E (G 3,4,5,6) with four layers of glass in the core have almost the same strength. When we compare these hybrid samples with the sample which has 8 layers of glass G-E, it is seen that the pure glass fibre sample is stronger.

- When comparing the two hybrid samples with two layers of glass, F-G-E (2,7) and F-G-E (G 4,5), it can be seen that F-G-E (G 4,5) has a lower strength than F-G-E (G 2,7), which can be attributed to a host of reasons like good fibre-matrix interface, low void content and bridging effect.

- The stated hypothesis at the start of the present study that the interlaminar shear strength will increase with the increase in the number of layers of glass in the hybrid composites irrespective of their position in the stack stands rejected, as the number and position of the glass layers in the stack had an overriding influence.

- Using the advanced XRM imaging technique, the depth of the crack on the tensile side of the specimen has been measured for the first time, to the best of the authors’ knowledge, to study the progression of the crack. XRM proves to be an excellent technique, as it does not involve any sample/section preparation.

- All the specimens considered in the present study, except G-E and F-G-E (G 2,7), failed primarily due to the combination of interlaminar shear and tensile failure as seen by a crack over the entire width as revealed by the XRM images. G-E and F-G-E (G2,7) specimens failed due to the interlaminar shear and the micro-damages suffered on the tensile and compressive sides.

- The observed tensile failure of the flax fibre was confirmed as the morphology exhibited the transverse and brittle failure or the transverse failure coupled with longitudinal splitting.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, S.; Sharma, N.; Biswas, R.; Singh, K.K. Effect of temperature on the flexural and ILSS behaviour of symmetric and asymmetric basalt fibre-reinforced polymer composites. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Hawileh, R.A.; Abu-Obeidah, A.; JaAbdalla, J.A.; Al-Tamimi, A. Temperature effect on the mechanical properties of carbon, glass and carbon–glass FRP laminates. Constr. Build. Mater. 2015, 75, 342–348. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, K.K.; Ramkumar, J. Comparative study of the influence of graphene nanoplatelets filler on the mechanical and tribological behavior of glass fabric-reinforced epoxy composites. Polym. Compos. 2020, 41, 5403–5417. [Google Scholar] [CrossRef]

- Zhou, Y.; Fan, Z.; Du, J.; Sui, L.; Xing, F. Bond behavior of FRP-to-concrete interface under sulfate attack: An experimental study and modeling of bond degradation. Constr. Build. Mater. 2015, 85, 9–21. [Google Scholar] [CrossRef]

- Akshat, T.; Petru, M.; Mishra, R.K. Numerical Modelling of Hybrid Polymer Composite Frame for Selected Construction Parts and Experimental Validation of Mechanical Properties. Polymers 2025, 17, 168. [Google Scholar] [CrossRef] [PubMed]

- Realfonzo, R.; Martinelli, E.; Napoli, A.; Nunziata, B. Experimental investigation of the mechanical connection between FRP laminates and concrete. Compos. Part B Eng. 2013, 45, 341–355. [Google Scholar] [CrossRef]

- Wong, P.M.H.; Wang, Y.C. An experimental study of pultruded glass fibre reinforced plastics channel columns at elevated temperatures. Compos. Struct. 2007, 81, 84–95. [Google Scholar] [CrossRef]

- Huang, X. Fabrication and Properties of Carbon Fibers. Materials 2009, 2, 2369–2403. [Google Scholar] [CrossRef]

- Vandeurzen, P.; Ivens, J.; Verpoest, I. A three-dimensional micromechanical analysis of woven-fabric composites: I. Geometric analysis. Compos. Sci. Technol. 1996, 56, 1303–1315. [Google Scholar] [CrossRef]

- Thwe, M.M.; Liao, K. Durability of bamboo-glass fiber reinforced polymer matrix hybrid composites. Compos. Sci. Technol. 2003, 63, 375–387. [Google Scholar] [CrossRef]

- Jacob, M.; Joseph, S.; Pothan, L.A.; Thomas, S. A study of advances in characterization of interfaces and fiber surfaces in lignocellulosic fiber-reinforced composites. Compos. Interfaces 2005, 12, 95–124. [Google Scholar] [CrossRef]

- Arumugam, V.; Militky, J.; Davies, L.; Slater, S. Thermal and water vapor transmission through porous warp knitted 3D spacer fabrics for car upholstery applications. J. Text. Inst. 2018, 109, 345–357. [Google Scholar] [CrossRef]

- Burgani, T.; Alaie, S.; Tehrani, M. Modeling Flexural Failure in Carbon-Fiber-Reinforced Polymer Composites. J. Compos. Sci. 2022, 6, 33. [Google Scholar] [CrossRef]

- Behera, B.K.; Pattanayak, A.K.; Mishra, R. Prediction of Fabric Drape Behaviour using Finite Element Method. J. Text. Eng. 2008, 54, 103–110. [Google Scholar] [CrossRef]

- Tsai, K.-H.; Chiu, C.-H.; Wu, T.-H. Fatigue behavior of 3D multi-layer angle interlock woven composite plates. Compos. Sci. Technol. 2000, 60, 241–248. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Wan, F.N.; Zulkifli, F.; Harussani, M.M.; et al. Critical Review of Natural Fiber Reinforced Hybrid Composites: Processing, Properties, Applications and Cost. Polymers 2021, 13, 3514. [Google Scholar] [CrossRef]

- Wagh, J.P.; Malagi, R.R.; Madgule, M. Investigative studies on natural fiber reinforced composites for automotive bumper beam applications. J. Reinf. Plast. Compos. 2024. [Google Scholar] [CrossRef]

- Bidadi, J.; Arabha, M.; Googarchin, H.S. Adhesive bonding in automotive hybrid multi-cell square tubes: Experimental and numerical investigation on quasi-static axial crashworthiness performance. Int. J. Adhes. Adhes. 2024, 135, 103832. [Google Scholar] [CrossRef]

- Venkataraman, M.; Xiong, X.; Marek, J.; Yao, J.; Zhu, G. Electrospun nanofibrous membranes embedded with aerogel for advanced thermal and transport properties. Polym. Adv. Technol. 2018, 29, 2583–2592. [Google Scholar] [CrossRef]

- Chandan, V.; Mishra, R.K.; Kolar, V.; Muller, M.; Hrabe, P. Green hybrid composites partially reinforced with flax woven fabric and coconut shell waste-based micro-fillers. Ind. Crops Prod. 2024, 222, 119948. [Google Scholar] [CrossRef]

- Bachtiar, D.; Sapuan, S.M.; Hamdan, M.M. Flexural Properties of Alkaline Treated Sugar Palm Fibre Reinforced Epoxy Composites. Int. J. Automot. Mech. Eng. 2010, 1, 79–90. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Fatimah Athiyah, S.; Shazleen, S.S.; Rafiqah, S.A.; Harussani, M.M.; Kamarudin, S.H.; Razman, M.R.; Rahmah, M.; Zainudin, E.S.; et al. A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications. Polymers 2021, 13, 2170. [Google Scholar] [CrossRef]

- Lee, C.H.; Khalina, A.; Nurazzi, N.M.; Norli, A.; Harussani, M.M.; Rafiqah, S.A.; Aisyah, H.A.; Ramli, N. The Challenges and Future Perspective of Woven Kenaf Reinforcement in Thermoset Polymer Composites in Malaysia: A Review. Polymers 2021, 13, 1390. [Google Scholar] [CrossRef] [PubMed]

- Bidadi, J.; Hampaiyan, M.H.; Saeidi, G.H.; Akhavan-Safar, A.; da Silva, L.F.M. Experimental and numerical investigation on the crashworthiness performance of double hat-section Al-CFRP beam subjected to quasi-static bending test. Polym. Compos. 2024, 45, 5656–5674. [Google Scholar] [CrossRef]

- Bidadi, J.; Saeidi Googarchin, H.; Akhavan-Safar, A.; Carbas, R.J.C.; da Silva, L.F.M. Characterization of Bending Strength in Similar and Dissimilar Carbon-Fiber-Reinforced Polymer/Aluminum Single-Lap Adhesive Joints. Appl. Sci. 2023, 13, 12879. [Google Scholar] [CrossRef]

- Suriani, M.J.; Zainudin, H.A.; Ilyas, R.A.; Petrů, M.; Sapuan, S.M.; Ruzaidi, C.M.; Mustapha, R. Kenaf Fiber/Pet Yarn Reinforced Epoxy Hybrid Polymer Composites: Morphological, Tensile, and Flammability Properties. Polymers 2021, 13, 1532. [Google Scholar] [CrossRef] [PubMed]

- Kalaprasad, G.; Thomas, S.; Pavithran, C.; Neelakantan, N.R.; Balakrishnan, S. Hybrid Effect in the Mechanical Properties of Short Sisal/Glass Hybrid Fiber Reinforced Low Density Polyethylene Composites. J. Reinf. Plast. Compos. 1996, 15, 48–73. [Google Scholar] [CrossRef]

- Rudov-Clark, S.; Mouritz, A.P. Tensile fatigue properties of a 3D orthogonal woven composite. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1018–1024. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, S.; Sun, X. Experimental investigation on the elastic modulus and fracture properties of basalt fiber–reinforced fly ash geopolymer concrete. Constr. Build. Mater. 2022, 338, 127570. [Google Scholar] [CrossRef]

- Xie, H.; Yang, L.; Zhang, Q.; Huang, C.; Chen, M.; Zhao, K. Research on energy dissipation and damage evolution of dynamic splitting failure of basalt fiber reinforced concrete. Constr. Build. Mater. 2022, 330, 127292. [Google Scholar] [CrossRef]

- Hassan, T.; Jamshaid, H.; Khan, M.Q.; Tichy, M.; Muller, M. Factors Affecting Acoustic Properties of Natural-Fiber-Based Materials and Composites: A Review. Textiles 2021, 1, 55–85. [Google Scholar] [CrossRef]

- Wang, A.; Wang, X.; Xian, G. Mechanical, Low-Velocity Impact, and Hydrothermal Aging Properties of Flax/Carbon Hybrid Composite Plates. Polym. Test. 2020, 90, 106759. [Google Scholar] [CrossRef]

- Fiore, V.; Valenza, A.; Di Bella, G. Mechanical Behavior of Carbon/Flax Hybrid Composites for Structural Applications. J. Compos. Mater. 2012, 46, 2089–2096. [Google Scholar] [CrossRef]

- Fehri, M.; Ragueh, R.R.; Vivet, A.; Dammak, F.; Haddar, M. Improvement of Natural Fiber Composite Materials by Carbon Fibers. J. Renew. Mater. 2016, 5, 38–47. [Google Scholar] [CrossRef]

- Nisini, E.; Santulli, C.; Liverani, A. Mechanical and Impact Characterization of Hybrid Composite Laminates with Carbon, Basalt and Flax Fibres. Compos. Part B Eng. 2016, 127, 92–99. [Google Scholar] [CrossRef]

- Issa, H.; Robin, G.; Duigou, L.; Cadou, J.M.; Guevel, Y.; Daya, E.M. Experimental Investigation of the Effect of Stacking Sequences in Hybrid Carbon/Flax Composites. In Proceedings of the International Congress for Applied Mechanics, Marrakech, Morocco, 13–15 November 2024. [Google Scholar]

- Paturel, A.; Dhakal, H.N. Influence of Water Absorption on the Low Velocity Falling Weight Impact Damage Behaviour of Flax/Glass Reinforced Vinyl Ester Hybrid Composites. Molecules 2020, 25, 278. [Google Scholar] [CrossRef] [PubMed]

- Heckadka, S.S.; Ballambat, R.P.; Manjeshwar, V.K.; Kumar, M.; Hegde, P.; Kamath, A. Influence of Stack Sequence on the Mechanical Characteristics of Hybrid Composites Analyzed Using Cone Beam Computed Tomography and Scanning Electron Microscopy. Polym. Compos. 2020, 41, 5059–5071. [Google Scholar] [CrossRef]

- Jamshaid, H.; Ali, H.; Mishra, R.K.; Nazari, S.; Chandan, V. Durability and Accelerated Ageing of Natural Fibers in Concrete as a Sustainable Construction Material. Materials 2023, 16, 6905. [Google Scholar] [CrossRef]

- Barouni, A.K.; Dhakal, H.N. Damage Investigation and Assessment Due to Low-Velocity Impact on Flax/Glass Hybrid Composite Plates. Compos. Struct. 2019, 226, 111224. [Google Scholar] [CrossRef]

- Kim, C.-U.; Song, J.-I. Effect of Hybrid Reinforcement on the Mechanical Properties of Vinyl Ester Green Composites. Fibers Polym. 2020, 21, 428–436. [Google Scholar] [CrossRef]

- Attia, M.A.; El-Baky, M.A.A.; Abdelhaleem, M.M.; Hassan, M.A. Hybrid Composite Laminates Reinforced with Flax-Basalt-Glass Woven Fabrics for Lightweight Load Bearing Structures. J. Ind. Text. 2020, 51, 4622S–4664S. [Google Scholar] [CrossRef]

- Davies, P. Review of standard procedures for delamination resistance testing. In Delamination Behaviour of Composites; Sridharan, S., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2008; pp. 65–86. [Google Scholar]

- Arumugam, V.; Militky, J.; Tunak, M. In-plane shear behavior of 3D spacer knitted fabrics. J. Ind. Text. 2016, 46, 868–886. [Google Scholar] [CrossRef]

- Chaterjee, S.; Adams, D.; Oplinger, D.W. Test Methods for Composites, a Status Report Volume III: Shear Test Methods; DOT/FAA/CT-93/17; FAA Technical Center: Atlantic City, NJ, USA, 1993; pp. 97–102. [Google Scholar]

- Fuqua, M.; Huo, S.; Thapa, A.; Gibbon, L.; Ulven, C.A. Challenges in manufacturing oilseed versus linen flax fiber reinforced composites. In Proceedings of the International SAMPE Symposium and Exhibition, Baltimore, MD, USA, 18–21 May 2009. [Google Scholar]

- Rong, M.Z.; Zhang, M.Q.; Liu, Y.; Yang, C.C.; Zeng, H.M. The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos. Sci. Technol. 2001, 61, 1437–1447. [Google Scholar] [CrossRef]

- Monette, D.; Dumond, P.; Chikhaoui, I.; Nichols, P.; Lemaire, E.D. Preliminary Material Evaluation of Flax Fibers for Prosthetic Socket Fabrication. J. Biomech. Eng. 2020, 143, 021006. [Google Scholar] [CrossRef] [PubMed]

- Dhason, R.; Roy, S.; Datta, S. The Influence of Composite Bone Plates in Vancouver Femur B1 Fracture Fixation after Post-Operative, and Healed Bone Stages: A Finite Element Study. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2022, 236, 1288–1296. [Google Scholar] [CrossRef] [PubMed]

- Bihari, A.; Gee, A.; Bougherara, H.; Brzozowski, P.; Lawendy, A.-R.; Schemitsch, E.H.; Zdero, R. Cytotoxicity of Novel Hybrid Composite Materials for Making Bone Fracture Plates. Biomed. Mater. 2024, 19, 041001. [Google Scholar] [CrossRef]

- Daud, S.Z.M.; Mustapha, F.; Adzis, Z. Lightning Strike Evaluation on Composite and Biocomposite Vertical-Axis Wind Turbine Blade Using Structural Health Monitoring Approach. J. Intell. Mater. Syst. Struct. 2018, 29, 3444–3455. [Google Scholar] [CrossRef]

- Hinzmann, C.; Johansen, N.F.-J.; Hasager, C.B.; Holst, B. Towards Greener Wind Power: Nanodiamond-Treated Flax Fiber Composites Outperform Standard Glass Fiber Composites in Impact Fatigue Tests. Compos. Part A Appl. Sci. Manuf. 2024, 186, 108342. [Google Scholar] [CrossRef]

- Yang, T.; Xiong, X.; Venkataraman, M.; Novák, J. Investigation on sound absorption properties of aerogel/polymer nonwovens. J. Text. Inst. 2019, 110, 196–201. [Google Scholar] [CrossRef]

- Hess, K.M.; Srubar, W.V., III. Mechanical Characterization of Gelatin-Flax Natural-Fiber Composites for Construction. J. Renew. Mater. 2015, 3, 175–182. [Google Scholar] [CrossRef]

- Bąk, A.; Mikuła, J.; Oliinyk, I.; Łach, M. Basic Research on Layered Geopolymer Composites with Insulating Materials of Natural Origin. Sci. Rep. 2024, 14, 12576. [Google Scholar] [CrossRef] [PubMed]

- Mak, K.; Fam, A.; MacDougall, C. Flax fibre composite sandwich panels for structural applications. Building on our growth opportunities. In Proceedings of the Annual Conference—Canadian Society for Civil Engineering, Regina, SK, Canada, 27–30 May 2015; Curran Associates, Inc.: Red Hook, NY, USA, 2016; pp. 1585–1594. [Google Scholar]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar] [CrossRef]

- Lincoln, J.D.; Shapiro, A.A.; Earthman, J.C.; Saphores, J.-d.M.; Ogunseitan, O.A. Design and Evaluation of Bioepoxy-Flax Composites for Printed Circuit Boards. IEEE Trans. Electron. Packag. Manuf. 2008, 31, 211–220. [Google Scholar] [CrossRef]

- Amiri, A.; Burkart, V.; Yu, A.; Webster, D.; Ulven, C. The Potential of Natural Composite Materials in Structural Design. In Sustainable Composites for Aerospace Applications; Woodhead Publishing: Cambridge, UK, 2018; pp. 269–291. [Google Scholar]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Papanicolaou, G.; Chalkias, D.; Koutsomitopoulou, A. Low Energy Impact and post-impact Behaviour of Epoxy matrix-woven flax fabric composites. UPB Sci. Bull. Ser. D Mech. Eng. 2016, 78, 25–36. [Google Scholar]

- Flax Weaves Its Way into Cars and Aircraft. Available online: https://www.plasticsnews.com/article/20130328/NEWS/130329909/flax-weaves-its-way-into-cars-and-aircraft (accessed on 3 July 2025).

- Manivannan, J.M.; Sathishkumar, T.P.; Subramani, S.; Dhairiyasamy, R. Investigation on the Fracture and Creep Behavior of the Synthetic and Natural Fiber Laminate Polymer Composite. Matéria (Rio J. ) 2024, 29, e20240608. [Google Scholar] [CrossRef]

- Zouhar, J.; Slaný, M.; Sedlák, J.; Joska, Z.; Pokorný, Z.; Barényi, I.; Majerík, J.; Fiala, Z. Application of Carbon–Flax Hybrid Composite in High Performance Electric Personal Watercraft. Polymers 2022, 14, 1765. [Google Scholar] [CrossRef] [PubMed]

- An, H.; Song, Y.; Liu, L.; Meng, X. Experimental Study of the Compressive Strengths of Basalt Fiber-Reinforced Concrete after Various High-Temperature Treatments and Cooling in Open Air and Water. Appl. Sci. 2021, 11, 8729. [Google Scholar] [CrossRef]

- Deng, Z.; Liu, X.; Liang, N.; de la Fuente, A.; Peng, H. Flexural Performance of a New Hybrid Basalt-Polypropylene Fiber-Reinforced Concrete Oriented to Concrete Pipelines. Fibers 2021, 9, 43. [Google Scholar] [CrossRef]

- Mohammad Jani, N.; Shakir Nasif, M.; Shafiq, N.; Holt, I. Experimental Investigation on the Effect of Varying Fiber Mix Proportion on the Mechanical and Thermal Performances of Fiber-Reinforced Self-Compacting Concrete under Hydrocarbon Fire Condition. Appl. Sci. 2020, 10, 4586. [Google Scholar] [CrossRef]

- Xiong, X.; Yang, T.; Mishra, R.; Militky, J. Transport properties of aerogel-based nanofibrous nonwoven fabrics. Fibers Polym. 2017, 17, 1709–1714. [Google Scholar] [CrossRef]

- Dvorkin, L.; Bordiuzhenko, O.; Tekle, B.H.; Ribakov, Y. A Method for the Design of Concrete with Combined Steel and Basalt Fiber. Appl. Sci. 2021, 11, 8850. [Google Scholar] [CrossRef]

- Bakis, C.; Bank, L.C.; Brown, V.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Triantafillou, T.C. Fiber-reinforced polymer composites for construction-state-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- ASTM D2344/D2344M-22; Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. ASTM International: West Conshohocken, PA, USA, 2022.

- Fan, Z.; Santare, M.H.; Advani, S.G. Interlaminar Shear Strength of Glass Fiber Reinforced Epoxy Composites Enhanced with Multi-Walled Carbon Nanotubes. Compos. Part A Appl. Sci. Manuf. 2007, 39, 540–554. [Google Scholar] [CrossRef]

- Petrucci, R.; Santulli, C.; Puglia, D.; Sarasini, F.; Torre, L.; Kenny, J.M. Mechanical Characterisation of Hybrid Composite Laminates Based on Basalt Fibres in Combination with Flax, Hemp and Glass Fibres Manufactured by Vacuum Infusion. Mater. Des. 2013, 49, 728–735. [Google Scholar] [CrossRef]

- Barouni, A.; Lupton, C.; Jiang, C.; Saifullah, A.; Giasin, K.; Zhang, Z.; Dhakal, H.N. Investigation into the Fatigue Properties of Flax Fibre Epoxy Composites and Hybrid Composites Based on Flax and Glass Fibres. Compos. Struct. 2021, 281, 115046. [Google Scholar] [CrossRef]

- Poole, M.; Gower, M. Mechanical Characterisation of 3D Fibre-Reinforced Plastic (FRP) Composites; Good Practise Guide No. 151; The National Physical Laboratory: Teddington, UK, 2022. [Google Scholar] [CrossRef]

- Padmanabhan, K.; Kishore, J. Interlaminar shear of woven fabric Kevlar-epoxy composites in three-point loading. Mater. Sci. Eng. A 1995, 197, 113–118. [Google Scholar] [CrossRef]

- Cui, W.C.; Wisnom, M.R.; Jones, M. Failure mechanisms in three and four point short beam bending tests of unidirectional glass/epoxy. J. Strain Anal. Eng. Des. 1992, 27, 235–243. [Google Scholar] [CrossRef]

- Madsen, B.; Aslan, M.; Lilholt, H. Fractographic Observations of the Microstructural Characteristics of Flax Fibre Composites. Compos. Sci. Technol. 2015, 123, 151–162. [Google Scholar] [CrossRef]

- Aslan, M.; Chinga-Carrasco, G.; Sørensen, B.F.; Madsen, B. Strength Variability of Single Flax Fibres. J. Mater. Sci. 2011, 46, 6344–6354. [Google Scholar] [CrossRef]

- Beaugrand, J.; Guessasma, S. Scenarios of Crack Propagation in Bast Fibers: Combining Experimental and Finite Element Approaches. Compos. Struct. 2015, 133, 667–678. [Google Scholar] [CrossRef]

- Richely, E.; Beaugrand, J.; Coret, M.; Binetruy, C.; Ouagne, P.; Bourmaud, A.; Guessasma, S. In Situ Tensile Testing under High-Speed Optical Recording to Determine Hierarchical Damage Kinetics in Polymer Layers of Flax Fibre Elements. Polymers 2023, 15, 2794. [Google Scholar] [CrossRef] [PubMed]

| Properties | Flax | Glass |

|---|---|---|

| Diameter of fibre (µm) | 20 ± 1.2 | 21 ± 1.1 |

| Linear density of fibre (Tex, g/km) | 21 ± 1.2 | 20 ± 1.1 |

| Linear density of yarn (Tex, g/km) | 600 ± 11 | 600 ± 2 |

| Density (g/cm3) | 1.5 ± 0.1 | 2.48 ± 0.2 |

| Areal density of Fabric (g/m2) | 600 ± 10 | 600 ± 25 |

| Young’s modulus of yarn (GPa) | 86.5 ± 1.4 | 37.5 ± 0.8 |

| Bulk modulus for yarn (GPa) | 37.7 ± 1.5 | 15.4 ± 1.1 |

| Warp density in fabric (cm−1) | 15 | 15 |

| Weft density in fabric (cm−1) | 14 | 14 |

| Strength (GPa) | 2.47 ± 0.05 | 4.65 ± 0.15 |

| Samples | Sample Code | Orientation | Representative Sample | Layers | Fabrics | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |||||

| Flax- Epoxy | F-E | 0/90 |  | 8 | F | F | F | F | F | F | F | F |

| Glass-Epoxy | G-E | 0/90 |  | 8 | G | G | G | G | G | G | G | G |

| Flax-Glass-Epoxy (G 4) | F-G-E (G 4) | 0/90 |  | 8 | F | F | F | G | F | F | F | F |

| Flax-Glass-Epoxy (G 3,4) | F-G-E (G 4,5) | 0/90 |  | 8 | F | F | G | G | F | F | F | F |

| Flax-Glass-Epoxy (G 2,7) | F-G-E (G 2,7) | 0/90 |  | 8 | F | G | F | F | F | F | G | F |

| Flax-Glass-Epoxy (G 3,4,5,6) | F-G-E (G 3,4,5,6) | 0/90 |  | 8 | F | F | G | G | G | G | F | F |

| Machine Parameter | Setting |

|---|---|

| Accelerating Voltage (kV) | 40 |

| Power (W) | 3 |

| Exposure Time (s) | 2.5 |

| Voxel Volume (µm3) | 14 |

| X-ray Source to Sample distance (mm) | 87 |

| Sample to Detector distance (mm) | 17 |

| Filter | Air |

| Sample Codes | Load (MPa) | Deformation (mm) | Number of Samples Tested |

|---|---|---|---|

| F-E | 6.87 | 0.22 | 8 |

| G-E | 28.13 | 0.35 | 8 |

| F-G-E (G 4) | 20.75 | 0.62 | 8 |

| F-G-E (G 4,5) | 19.55 | 0.66 | 8 |

| F-G-E (G 2,7) | 26.0018 | 0.48 | 8 |

| F-G-E (G 3,4,5,6) | 25.713 | 0.62 | 8 |

| Sample Codes | Load (MPa) | Ansys (MPa) | Percentage Error (%) |

|---|---|---|---|

| F-E | 6.87 | 7.01 | 2.03 |

| G-E | 28.13 | 28.1 | 0.106 |

| F-G-E (G 4) | 20.75 | 21.33 | 1.93 |

| F-G-E (G 4,5) | 19.55 | 18.28 | 6.25 |

| F-G-E (G 2,7) | 26.0018 | 27.5 | 5.76 |

| F-G-E (G 3,4,5,6) | 25.713 | 26.8 | 4.22 |

| Composite Specimen Codes | Type of Failure Noticed in the Sample | Depth of Crack, a (mm) in Relation to the Thickness, b (mm) of the Composite Specimen | Normalised Depth of Crack, a/b |

|---|---|---|---|

| F-E | Interlaminar shear with Tensile failure exhibiting a crack over the entire width of the sample | 1.12/2.13 | 0.526 |

| F-G-E (G 4,5) | Interlaminar shear with Tensile failure exhibiting a crack over the entire width of the sample | 0.83/2.0 | 0.415 |

| F-G-E (2,7) | Interlaminar shear with micro-damage on the tensile and compressive side but without the crack | -- | -- |

| F-G-E (G 3,4,5,6) | Interlaminar shear with Tensile failure exhibiting a crack over the entire width of the sample | 0.59/2.06 | 0.286 |

| F-G-E (G 4) | Interlaminar shear with Tensile failure exhibiting a crack over the entire width of the sample | 0.84/2.13 | 0.394 |

| G-E | Interlaminar shear with micro-damage on the tensile and compressive side but without the crack | -- | -- |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akshat, T.; Petru, M.; Mishra, R.K. Inter Laminar Shear Strength of Flax-Glass Hybrid Polymer Composites for Automotive Frame: Numerical Modelling and Experimental Analysis. Materials 2025, 18, 3852. https://doi.org/10.3390/ma18163852

Akshat T, Petru M, Mishra RK. Inter Laminar Shear Strength of Flax-Glass Hybrid Polymer Composites for Automotive Frame: Numerical Modelling and Experimental Analysis. Materials. 2025; 18(16):3852. https://doi.org/10.3390/ma18163852

Chicago/Turabian StyleAkshat, Tegginamath, Michal Petru, and Rajesh Kumar Mishra. 2025. "Inter Laminar Shear Strength of Flax-Glass Hybrid Polymer Composites for Automotive Frame: Numerical Modelling and Experimental Analysis" Materials 18, no. 16: 3852. https://doi.org/10.3390/ma18163852

APA StyleAkshat, T., Petru, M., & Mishra, R. K. (2025). Inter Laminar Shear Strength of Flax-Glass Hybrid Polymer Composites for Automotive Frame: Numerical Modelling and Experimental Analysis. Materials, 18(16), 3852. https://doi.org/10.3390/ma18163852