4.1. Ultimate Bearing Capacity Calculation of the PCSPCs

Several methods have been developed for predicting the load-carrying capacity of steel-tube concrete members, but most of them are only applicable when the design variables, such as the yield strength of steel and the compressive strength of concrete, are within a specific range. In this paper, on the basis of the Technical Specification for Steel Pipe Concrete Structures published by the Ministry of Housing and Urban-Rural Development of the People’s Republic of China, the corresponding formulas are derived, as shown in Equation (9):

where

Nu is the ultimate bearing capacity of the PCSPCs,

N0 is the design value of the strength-bearing capacity of the PCSPCs axial compression,

θ is the hoop coefficient of the PCSPCs members,

α is the coefficient related to the strength grade of the concrete,

Ac is the cross-sectional area of the core concrete in the steel pipe (mm

2),

fc is the design value of the compressive strength of the core concrete in the steel pipe (MPa), and

As is the cross-sectional area of the steel pipe (mm

2).

f is the design value of the tensile and compressive strengths of steel pipes (MPa),

φl is the bearing capacity reduction factor considering the influence of the length and slenderness ratio,

D is the outer diameter of the PCSPCs (mm),

t is the wall thickness of the PCSPCs,

Le is the equivalent calculated length of the PCSPCs (mm),

L is the actual length of the PCSPCs (mm),

μ is the coefficient of the calculated length considering the constraint condition of the column end, which should be executed according to the current national standard “Code for the Design of Steel Structures” GB-50017 [

35], and

k is the equivalent length coefficient considering the effect of the gradient of the bending moment distribution of the column body.

4.2. Iterative Algorithm Optimization of the PCSPCs

To further evaluate the optimal combination of PCSPCs’ ultimate bearing capacity, carbon emissions, and costs, we employed a hierarchical grid search algorithm based on deterministic parameter space scanning and iterative refinement. The primary objective is to minimize both carbon emissions and costs while satisfying the ultimate bearing capacity constraint. Specifically, the algorithm first constructs an initial parameter space by discretizing the steel pipe column diameter, wall thickness, and concrete strength grade within a reasonable engineering range, forming an initial three-dimensional parameter grid matrix. For each parameter combination, the corresponding ultimate bearing capacity, carbon emissions, and construction costs are calculated, and feasible solutions meeting the minimum bearing capacity requirements are selected. Within this feasible set, the algorithm identifies the parameter combination that minimizes carbon emissions or construction costs as the optimal solution for the current iteration. The variable step size is subsequently gradually reduced to create a higher-resolution grid around the optimal solution, and the process is subsequently repeated. When the difference between the optimal target values of two consecutive iterations falls below a predefined threshold, the process is considered converged, and the optimization terminates.

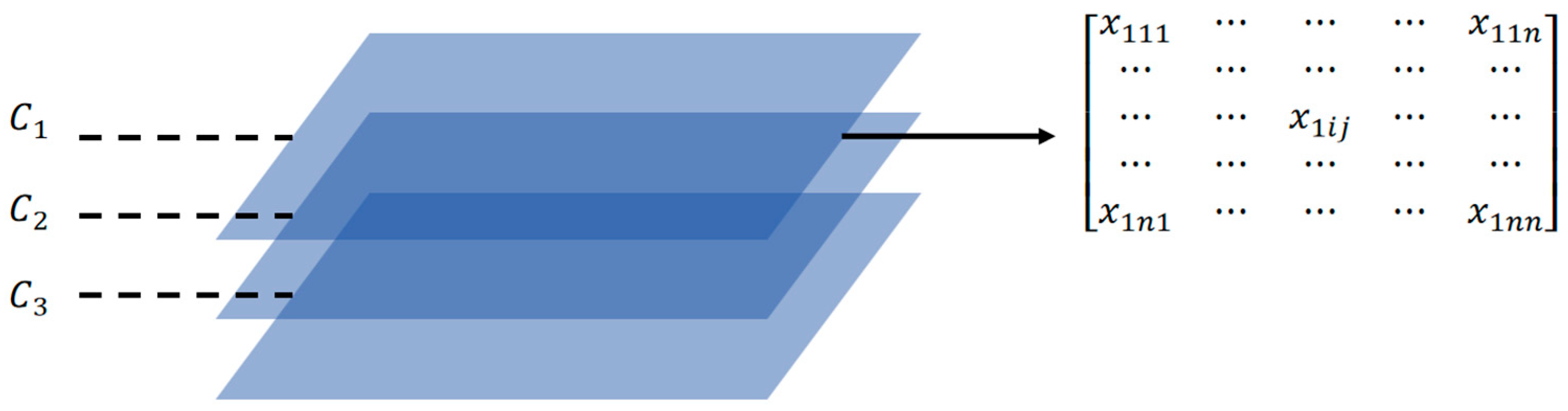

Based on the bearing capacity equation, carbon emissions were constrained and optimized under different bearing capacity conditions. In data processing and statistical analysis, parameter selection is a crucial factor in determining the frequency and quantity of samples extracted from the overall dataset. The initial selection is essentially a ratio chosen according to the research objectives, dataset size, and required accuracy. Once the initial selection is set, the parameter combination matrix can be constructed. This matrix records information about different parameter combinations, with each element representing the value of a variable. In cases with multiple variables, each item corresponds to the coordinate values sampled for each variable. The process of generating the sampling matrix can be summarized as follows: first, the required number of samples is determined on the basis of the initial sampling rate, which defines the dimensions of the sampling matrix. Next, samples are randomly or systematically drawn from the raw data according to the sampling rate, typically using a random number generator or a specific sampling algorithm to ensure representativeness. The specific values for each variable are then recorded for each extracted sample, forming the elemental coordinates of the sampling matrix. Finally, these coordinate values are populated into the sampling matrix, completing its structure. This matrix not only reflects the spatial distribution of sample points but also reveals potential relationships between variables and data distribution characteristics.

The initial parameter discrete step size

n is set, and a 3 ×

n ×

n parameter combination matrix is generated in the design variable space for multiobjective optimization calculations. The sampling matrix

X = [

xkij] is generated on the basis of parameter combinations, where the three coordinates of the matrix elements refer to the three variables

x1,

x2, and

x3, as shown in

Figure 9. In the figure,

C1 represents the diameter parameter group of the steel pipe columns,

C2 represents the wall thickness parameter group of the steel pipe columns, and

C3 represents the concrete strength grade parameter group. These three parameter groups together constitute the three-dimensional design variable space used for traversal in multiobjective optimization.

The carbon emission

Y1q = [

y1qkij] corresponds to all the sampling points, and the ultimate bearing capacity of the steel pipe column

Y2q = [

y2qkij] can be obtained via matrix operation, where q represents the number of cycles. According to the load-bearing conditions in Equation (10), the

y1qkij that meets the requirements is screened out, and its minimum value min

y1q is found.

To achieve a controlled parameter search, a grid discretization method was employed to traverse combinations of the steel pipe column diameter, wall thickness, and concrete strength grade. Owing to the discrete nature of these parameters, the optimal solution is subject to certain accuracy limitations. Therefore, the optimization process is iteratively repeated by gradually increasing the resolution of the parameter grid (i.e., refining the step size). When the difference between the optimal carbon emissions (or cost) obtained in two consecutive iterations falls below a predefined threshold, the algorithm is considered to have converged and met the accuracy requirements. The sampling rate

n is then increased, and the process repeats until the difference between the results of two successive cycles is less than the specified error, as shown in Equation (11).

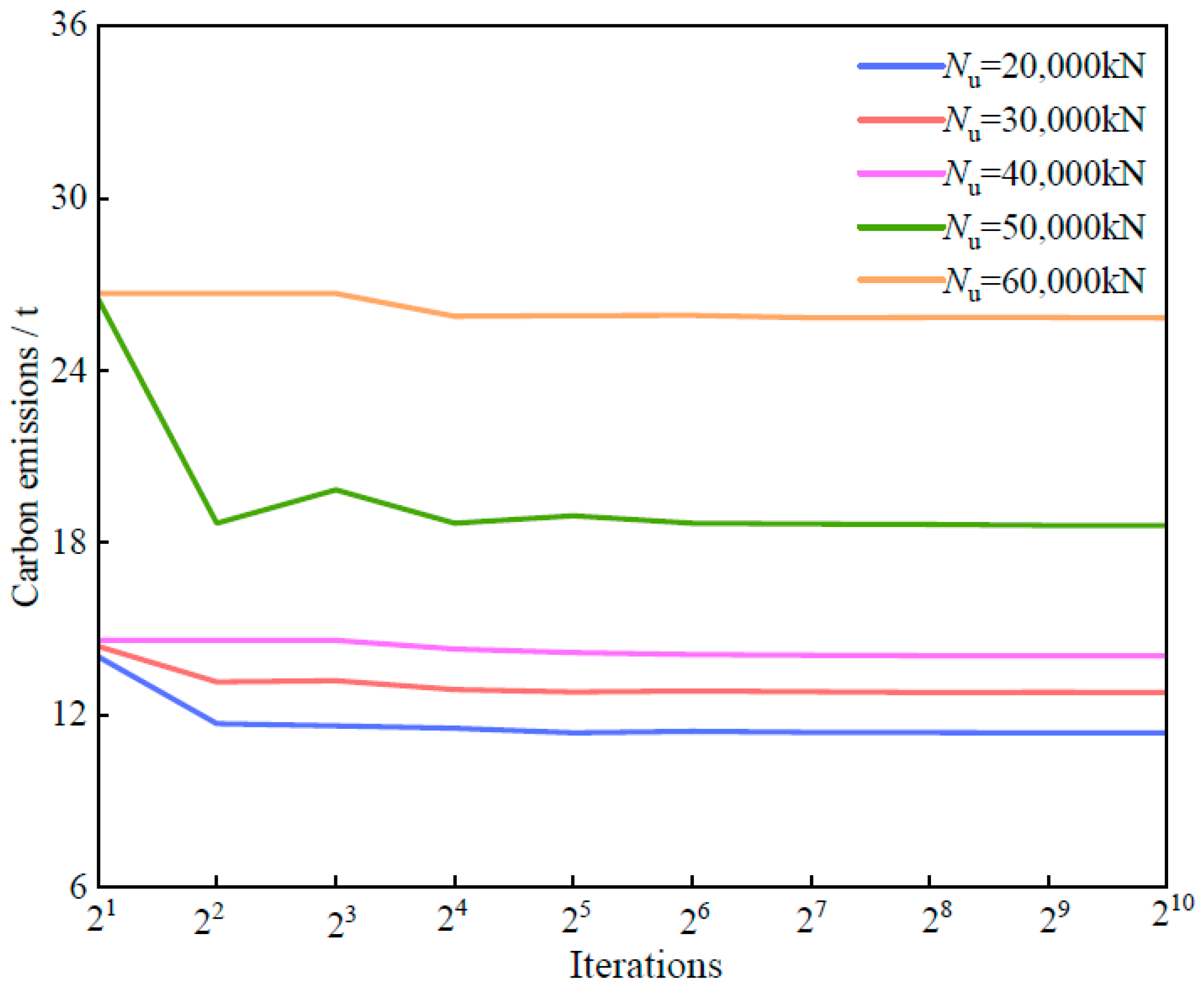

The end loop outputs the results and outputs the corresponding coordinates, thus obtaining the lowest carbon emission and cost. The optimal carbon emissions for different carrying capacities were calculated through 210 iterations and are shown in

Figure 10.

According to the optimization results shown in

Figure 10, when the ultimate load capacity is 50,000 kN, with a component diameter of 1000 mm and a wall thickness of 16.53 mm, the optimal carbon emission is 18.59 t. Compared with the design with a maximum load capacity of 40,000 kN, the load capacity increases by 25%, whereas the carbon emission increases by approximately 30%. Although the increase in carbon emissions slightly exceeds the gain in load-bearing capacity, it remains within a manageable range overall, indicating that the optimization scheme effectively controls carbon emissions while enhancing structural performance.

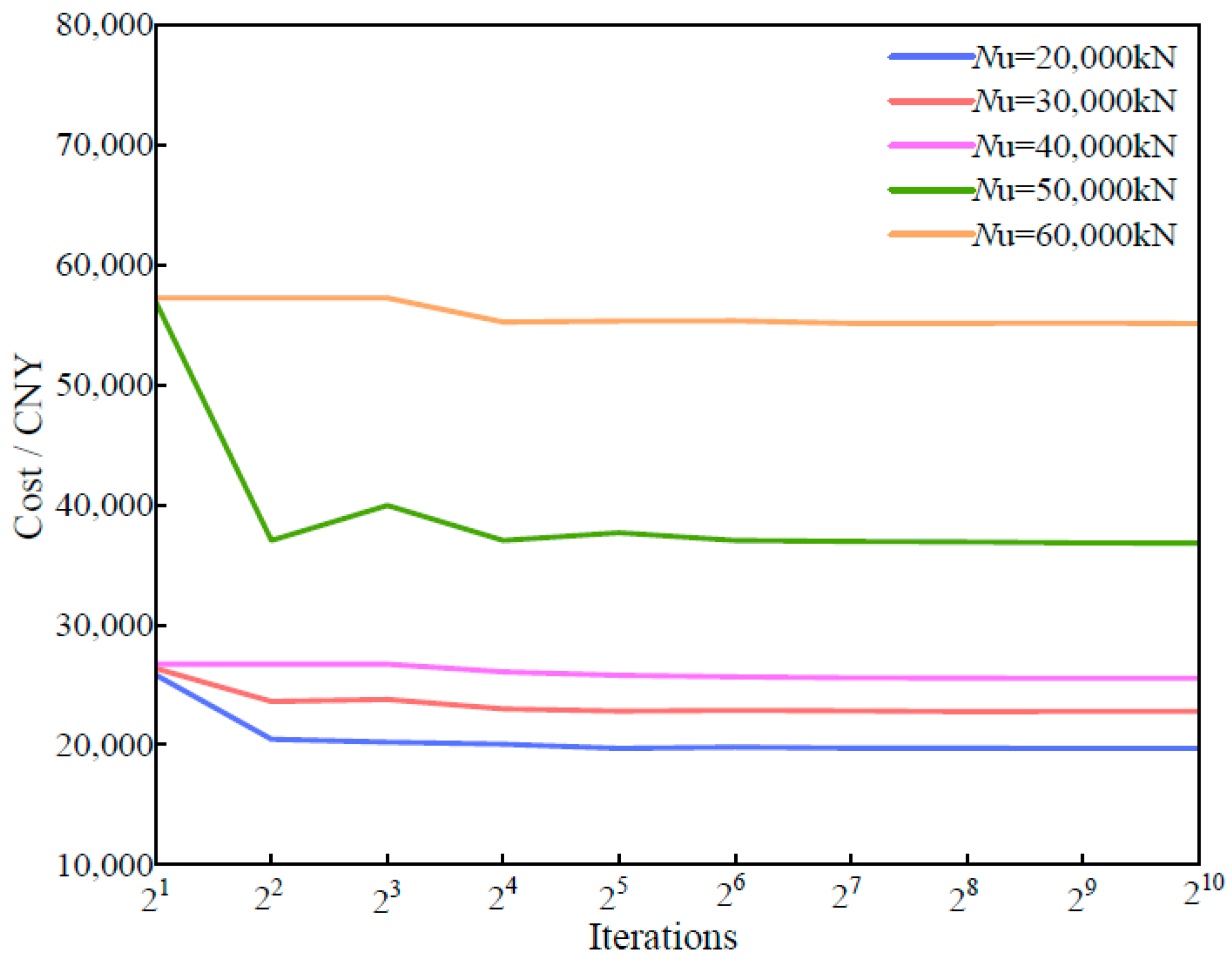

In terms of cost optimization, the same multiobjective optimization algorithm was applied, with concrete grades limited to the C30–C60 range and load-bearing capacities set between 20,000 and 60,000 kN. The optimal results are shown in

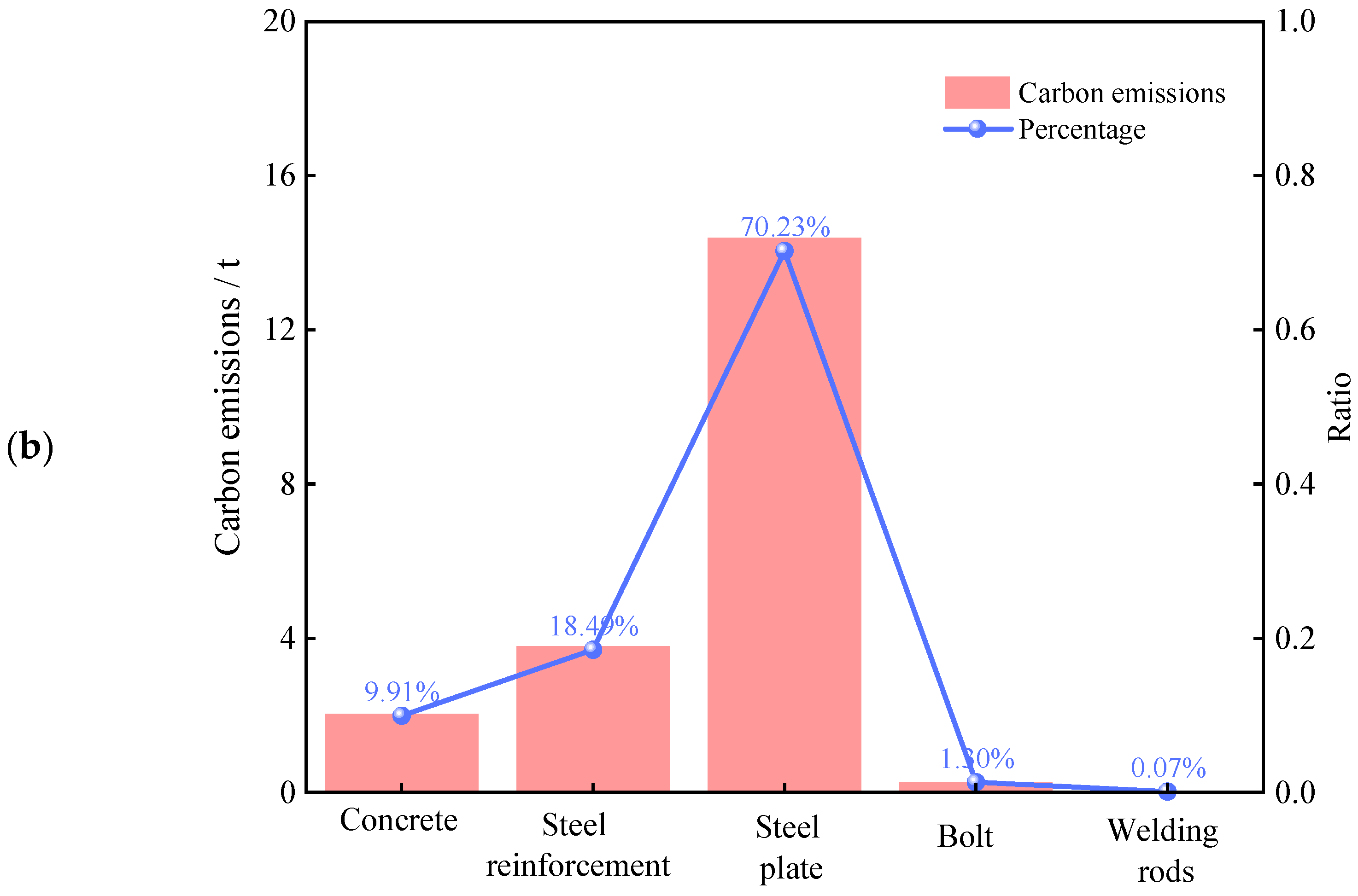

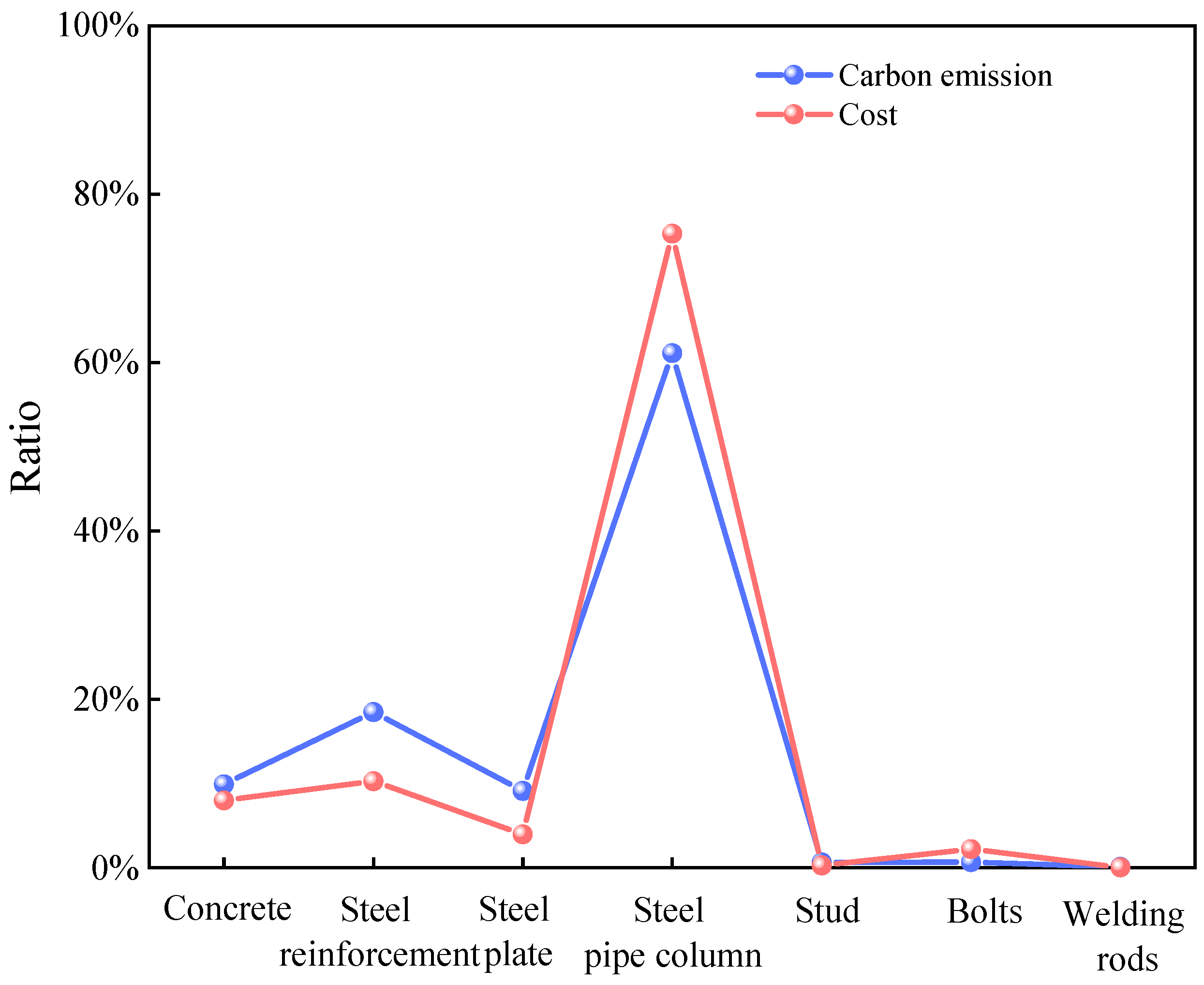

Figure 11. On the basis of the case analysis, when the ultimate load-bearing capacity reaches 50,000 kN, the lowest total cost is CNY 36,825.322. Compared with the solution with a 40,000 kN load-bearing capacity, the capacity increases by 25%, whereas the cost increases by approximately 44%. Although the cost increase is significant, this solution still offers high engineering value for structural designs requiring elevated load-bearing capacity and stringent safety standards. Moreover, when both costs and carbon emissions are optimized, the results across different load-bearing conditions display a consistent trend. This can be attributed to the dominant influence of material properties within the PCSPCs structure. Specifically, the carbon emission coefficient and unit cost of steel plates are roughly ten times greater than those of concrete. Consequently, under various load-bearing capacities, steel plates consistently have the greatest impact on total carbon emissions and overall cost. This dominance results in similar optimization trends regardless of the objective function.

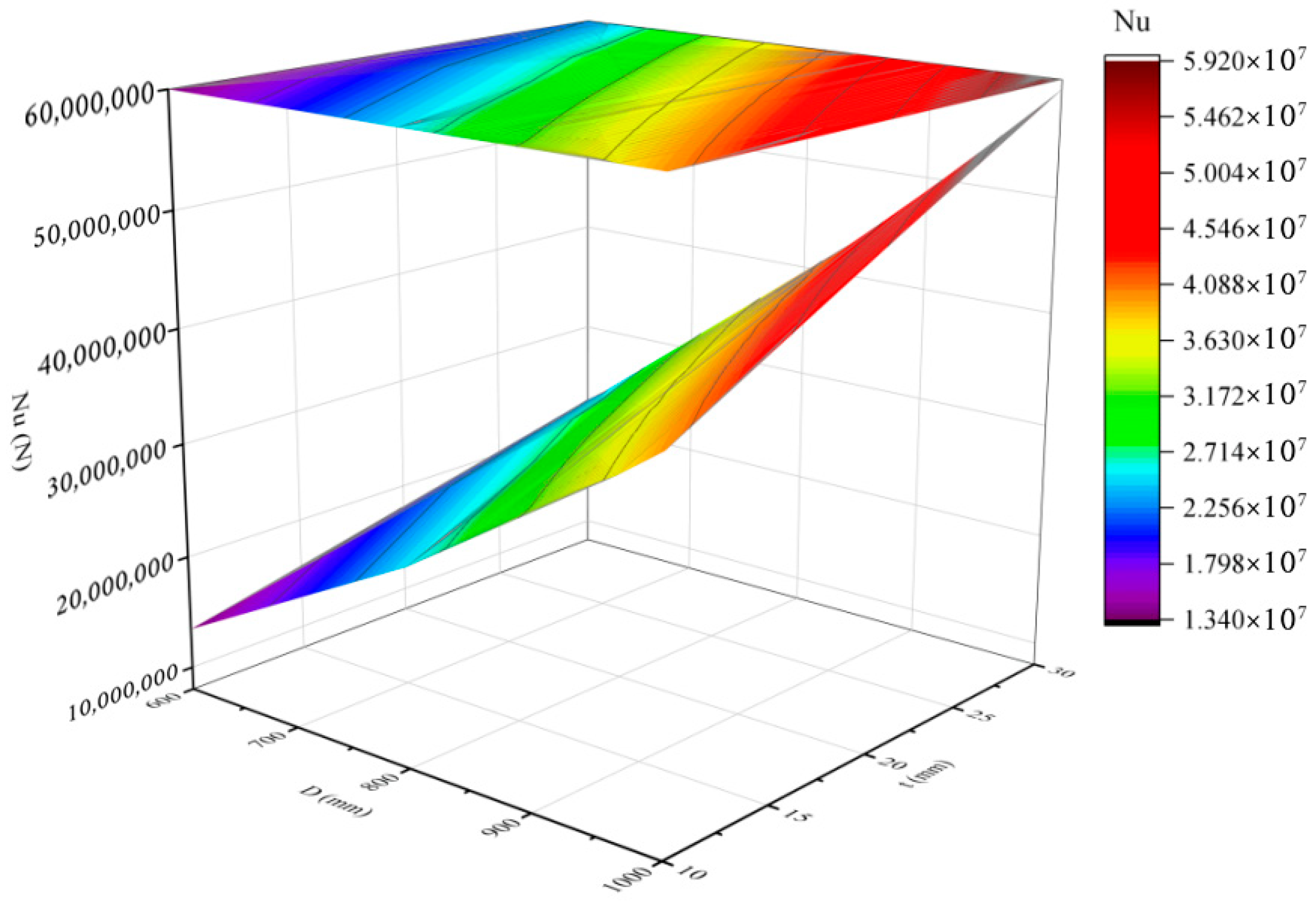

Figure 12 illustrates the trend of load-bearing capacity as a function of cross-sectional dimensions—particularly steel plate thickness—further confirming the central role of steel plates in the optimization process.

4.3. Verification of the Optimization Results

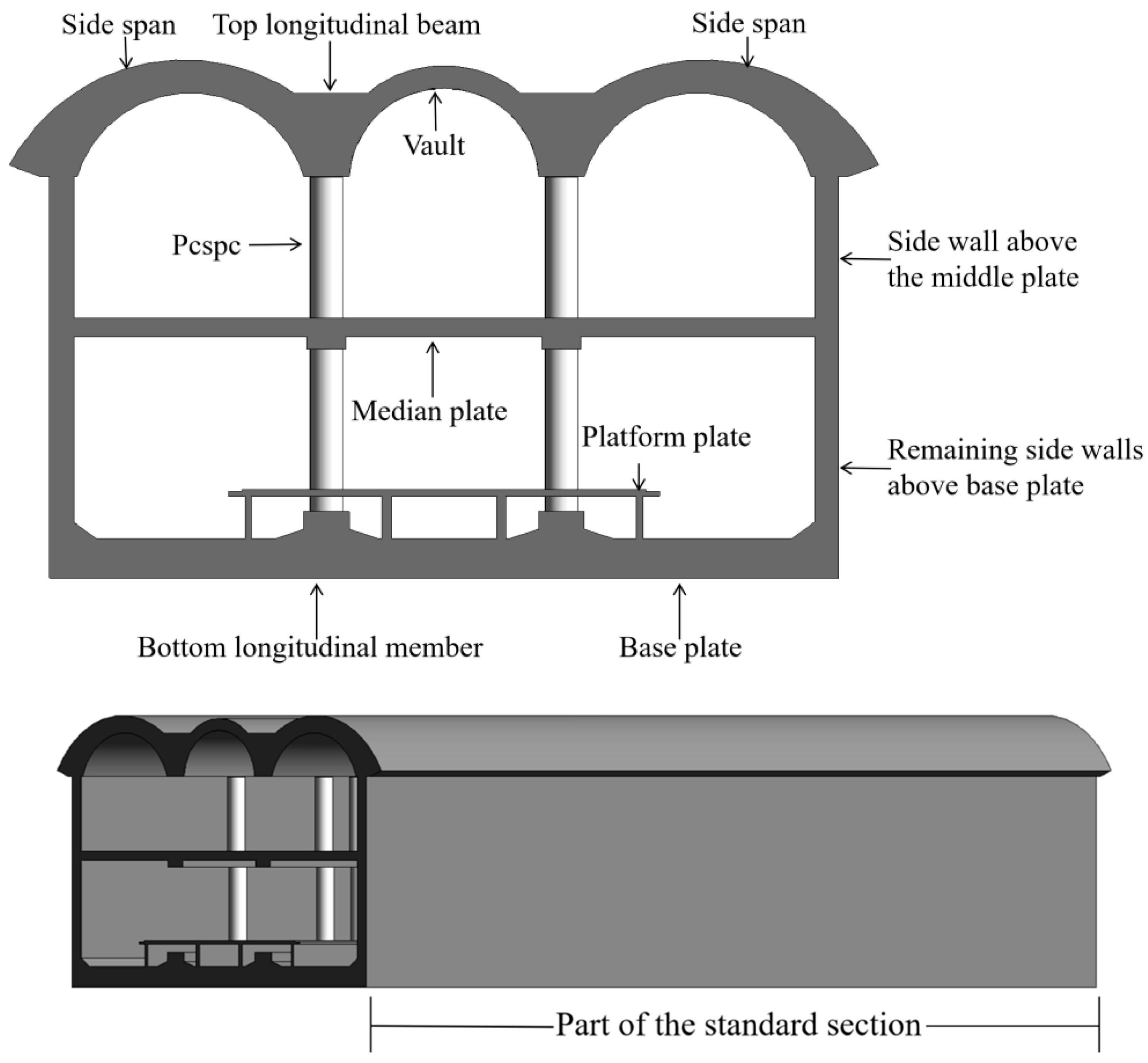

To verify the influence of the optimal solution obtained through the iterative algorithm on the structural safety of PCSPCs at the overall station, simplified modeling of several standard sections of the subway station—constructed via the PBA method—was performed via finite element analysis software ABAQUS 6.1. The design parameters of the PCSPCs were adjusted within the model to conduct a comparative analysis before and after optimization. The validity and reliability of the optimization scheme were further confirmed by comparing the structural load-bearing capacity of the metro station under the PBA method before and after PCSPCs optimization. Numerical software was employed to model and analyze the structural performance of steel-tube–concrete columns, with a focus on the interaction between the steel tube and concrete, load application, and boundary condition settings.

First, a three-dimensional model of the steel pipe and concrete was created, where the steel pipe was formed by extruding a two-dimensional circular cross-section into a cylindrical shape, and the concrete was modeled as a solid cylinder on the basis of the internal cross-sectional dimensions of the steel pipe. For material properties, the density, elastic modulus, and strength of the concrete were assigned according to the Concrete Design Code, with an appropriate dilation angle selected in the plastic damage model to ensure convergence of the calculation. The steel pipe material properties, including density and Poisson’s ratio, were assigned to uniform solid cross-sections. In terms of assembly and interaction, the contact between the steel pipe and concrete was defined via a hard contact model in the normal direction to simulate the physical interaction accurately between the inner wall of the steel pipe and the concrete. The contact surface remains constrained under normal pressure but allows separation under tensile stress, reflecting actual cracking or detachment phenomena. A penalty friction model based on Coulomb friction theory with a friction coefficient of 0.3 was subsequently applied to represent shear force transfer caused by finite slip, accurately capturing the slip mechanism at the steel–concrete interface. A fully fixed constraint was applied to the bottom surface of the column to simulate a rigid connection with the foundation. Axial displacement-controlled loads were applied to the top of the column via a coupled reference point, effectively preventing numerical instability caused by load concentration. This reference point was fully coupled to all nodes at the top surface through multipoint constraints, ensuring even load distribution. Both the steel pipe and the concrete were meshed via eight-node linear hexahedral reduced integration elements (C3D8R) to increase the convergence and computational efficiency. The steel pipe wall thickness was modeled with at least two layers to better capture the local yielding and bending behavior. The overall mesh size was determined through convergence analysis, with moderate mesh refinement applied in the concrete core area.

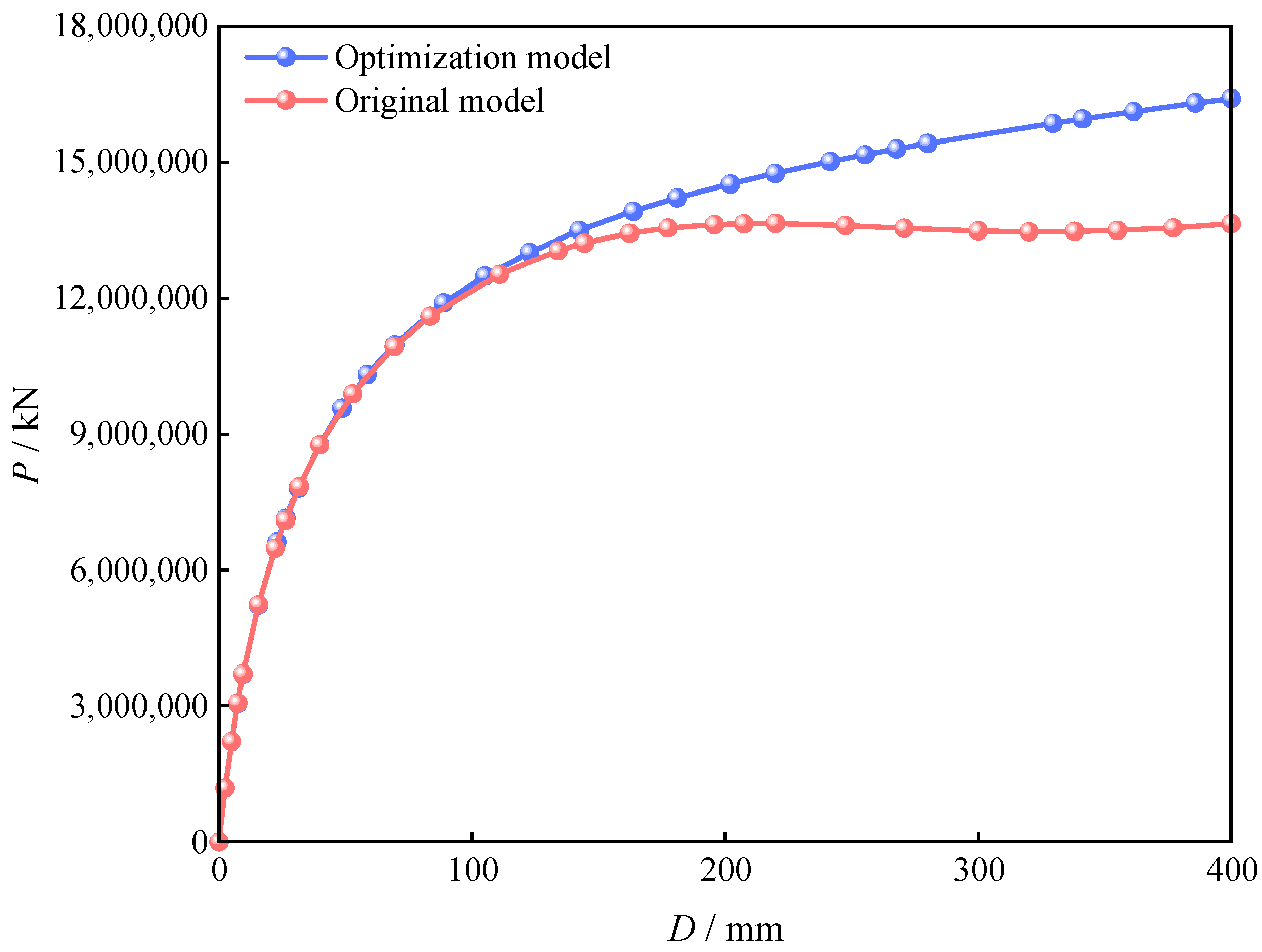

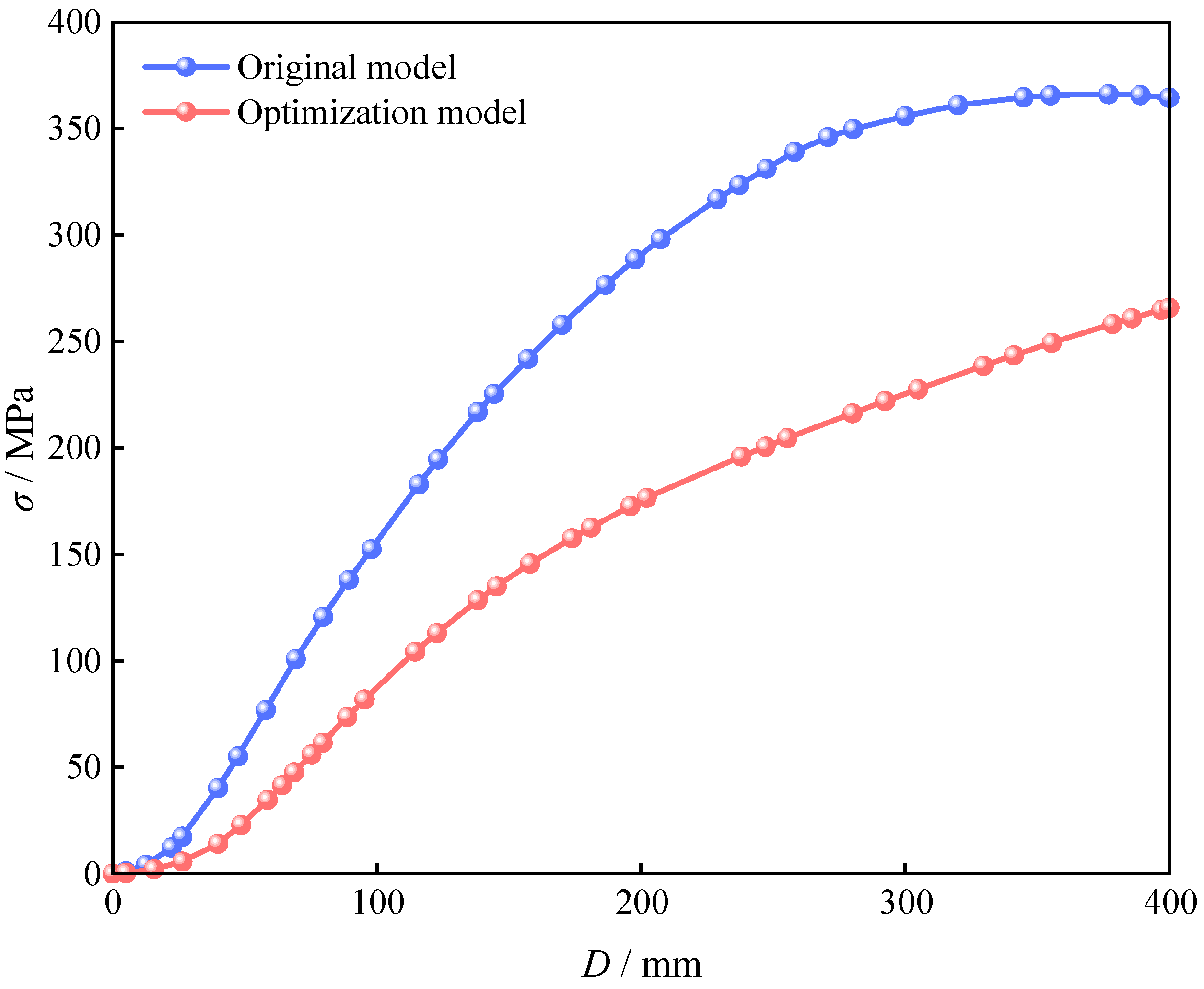

To assess the ultimate bearing capacity of the metro station structure more accurately, displacement loads were applied at the top during numerical simulation, with the resulting load–displacement curves shown in

Figure 13. The results indicate that the overall load-bearing capacity of metro stations constructed via the PBA method combined with the optimized PCSPCs strategy is significantly greater than that of stations built via the preoptimization model. Under the same displacement conditions, the optimized structure remains within the elastic stage, whereas the unoptimized model has already entered the yielding phase, clearly demonstrating the advantage of the optimized design in delaying structural failure. Furthermore, the results show that the optimization scheme not only improves load-bearing performance but also effectively reduces material consumption and carbon emissions while controlling construction costs, further validating the practical applicability and engineering feasibility of the PBA optimization strategy in metro construction.

To further evaluate the effectiveness of the PBA-optimized steel column structure in enhancing the load-bearing capacity of metro stations, models before and after optimization were compared with actual stress conditions observed in engineering cases, as shown in

Figure 14. The results indicate that, under identical displacement conditions, stress development in the bottom wall reinforcement of the optimized model progresses more gradually, resulting in delayed yielding, whereas the reinforcement in the unoptimized model reaches its yield limit earlier, highlighting a significant difference in structural load-bearing performance.

As shown in

Figure 15, the stress–displacement curve of the reinforcing bars indicates that, under the same displacement conditions, the reinforcing bars in the bottom wall of the original metro station model have reached the yield state, whereas those in the optimized PCSPCS model remain in the elastic stage. These results demonstrate that the optimized design not only delays the yielding of the reinforcing bars and enhances the load-bearing capacity of the wall but also improves the overall structural performance and reduces carbon emissions by optimizing the material distribution and stress paths.

To verify the reliability of the numerical calculations, the simulation results are compared with the calculation results in this paper, as shown in

Table 6,

Table 7 and

Table 8.

As shown in

Table 6,

Table 7 and

Table 8, when the diameter of the steel pipe column is 1000 mm, the calculated and simulated values are highly consistent, with significantly reduced errors. However, as the concrete strength grade increases, the gap between the calculated and simulated values gradually widens, particularly at the C60 grade, where the error is noticeably greater than those at C30 and C50. Further analysis of the simulation and calculation results for different diameters reveals that larger diameters correspond to smaller errors. Specifically, when the diameter is 1000 mm, a relatively high proportion of the errors are controlled within 1000 kN, indicating that the diameter significantly affects the accuracy of the results. Under fixed concrete strength conditions, the ultimate bearing capacity of steel pipe columns increases with increasing diameter or wall thickness, with the diameter having a particularly significant effect. In contrast, for components with a diameter of 600 mm, increasing the wall thickness leads to only slight improvements in the load-bearing capacity, indicating that simply increasing the wall thickness is not the optimal approach for enhancing the capacity. These results indicate that the ultimate bearing capacity generally increases with increasing component diameter, wall thickness, and concrete strength grade. Under the same concrete grade and wall thickness, increasing the diameter from 600 mm to 800 mm and 1000 mm significantly enhances the load-bearing capacity, demonstrating the dominant role of cross-sectional dimensions in component performance. At a fixed diameter, increasing the wall thickness also substantially improves the load-bearing capacity, especially with high-strength concrete such as C50 and C60. Overall, higher concrete strength corresponds to greater ultimate load-bearing capacity, with C60 components exhibiting significantly higher capacity than C30 and C50 under identical geometric parameters.

4.4. Discussions

In the carbon emission modeling process of this study, to ensure clarity in the analytical framework and operability of the calculations, some parameters were based on typical engineering assumptions or empirical settings. These assumptions primarily include averaging transportation distances, using actual onsite consumption data for building materials, selecting carbon emission factors from publicly available databases, and excluding carbon emissions from nonprimary processes such as construction waste removal and earthworks. Although sensitivity analysis was not conducted for each data point, these assumptions are reasonable within the scope of the current study. First, transportation distances were determined through communication with the project unit and onsite surveys, reflecting typical routing arrangements for most materials from local procurement to the construction site. While this assumption does not account for extreme cases, it is common in most urban subway projects and is therefore representative. Second, material usage data were obtained from actual construction records, which better reflect real carbon emissions than theoretical quantities from design drawings. This approach also naturally accounts for construction losses, providing a robust basis for carbon emission assessment. Furthermore, carbon emission factors were selected on the basis of standardized databases and local statistical data. Although differences in material sources and processing methods cannot be fully covered, this practice is widely accepted in engineering carbon assessments. Given that this study aims to evaluate the relative carbon efficiency of different design schemes rather than absolute precise values, this approach is methodologically sound. Finally, certain carbon emissions—such as those from construction waste, nonstructural materials, and temporary facilities—were excluded on the basis of their relatively small proportion of total construction emissions and their limited direct impact on the optimization of the main structural design. This simplification allows a focus on key factors with significant impact. However, these assumptions may have limitations in different project contexts. Future research could adopt more refined carbon emission process modeling methods, gradually incorporating additional influencing factors to improve assessment comprehensiveness and model generality. In summary, the following points are discussed:

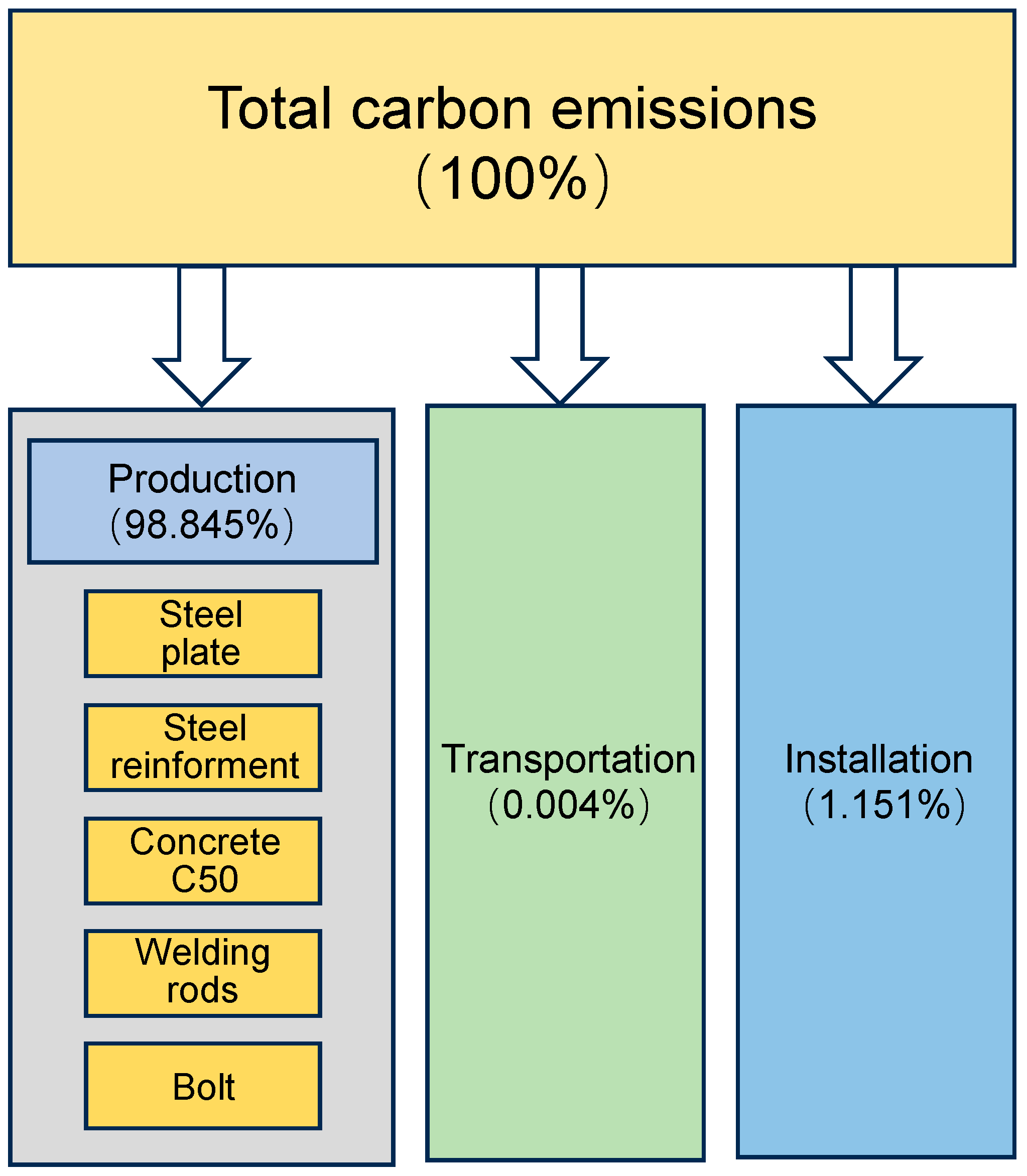

- (1)

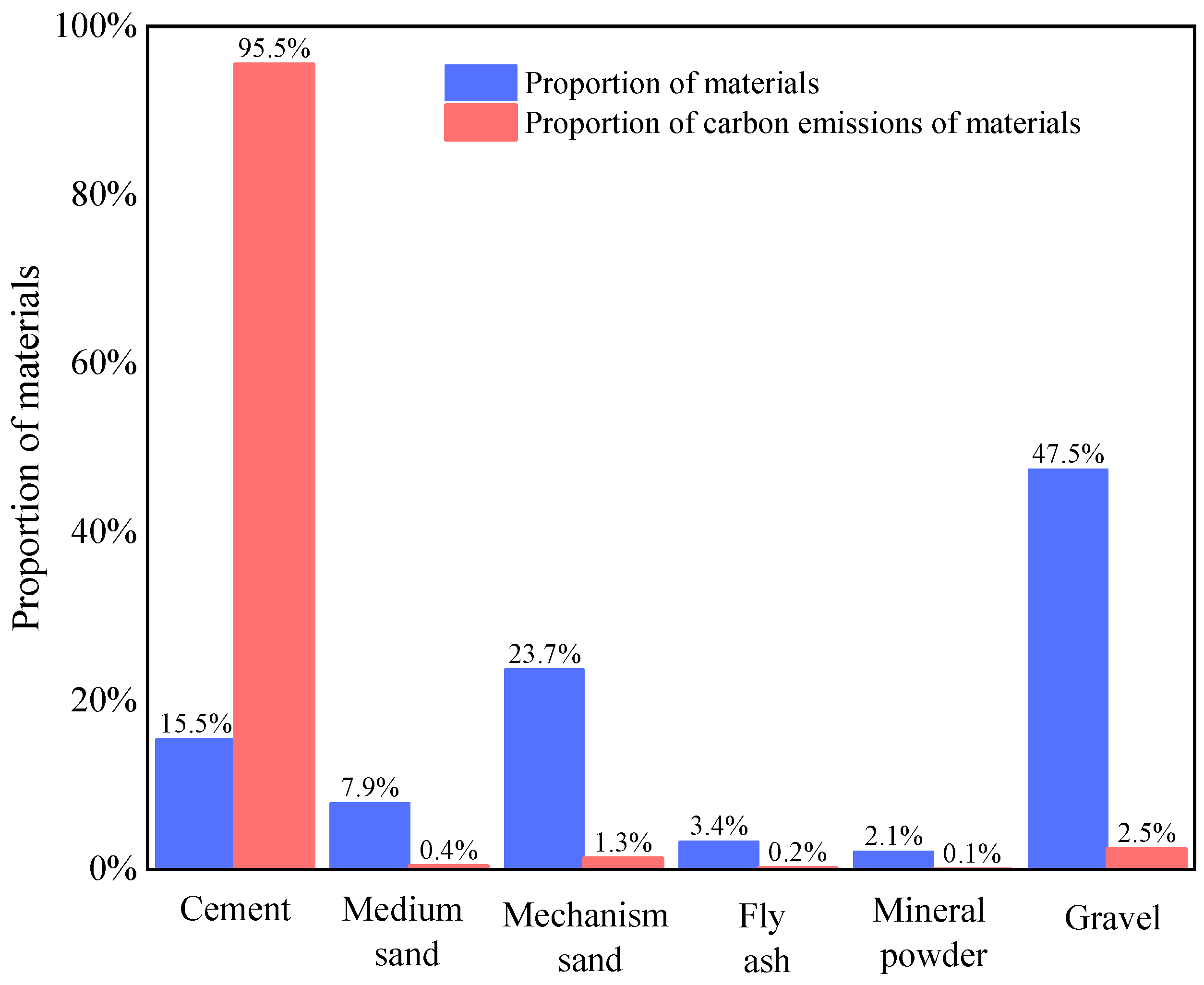

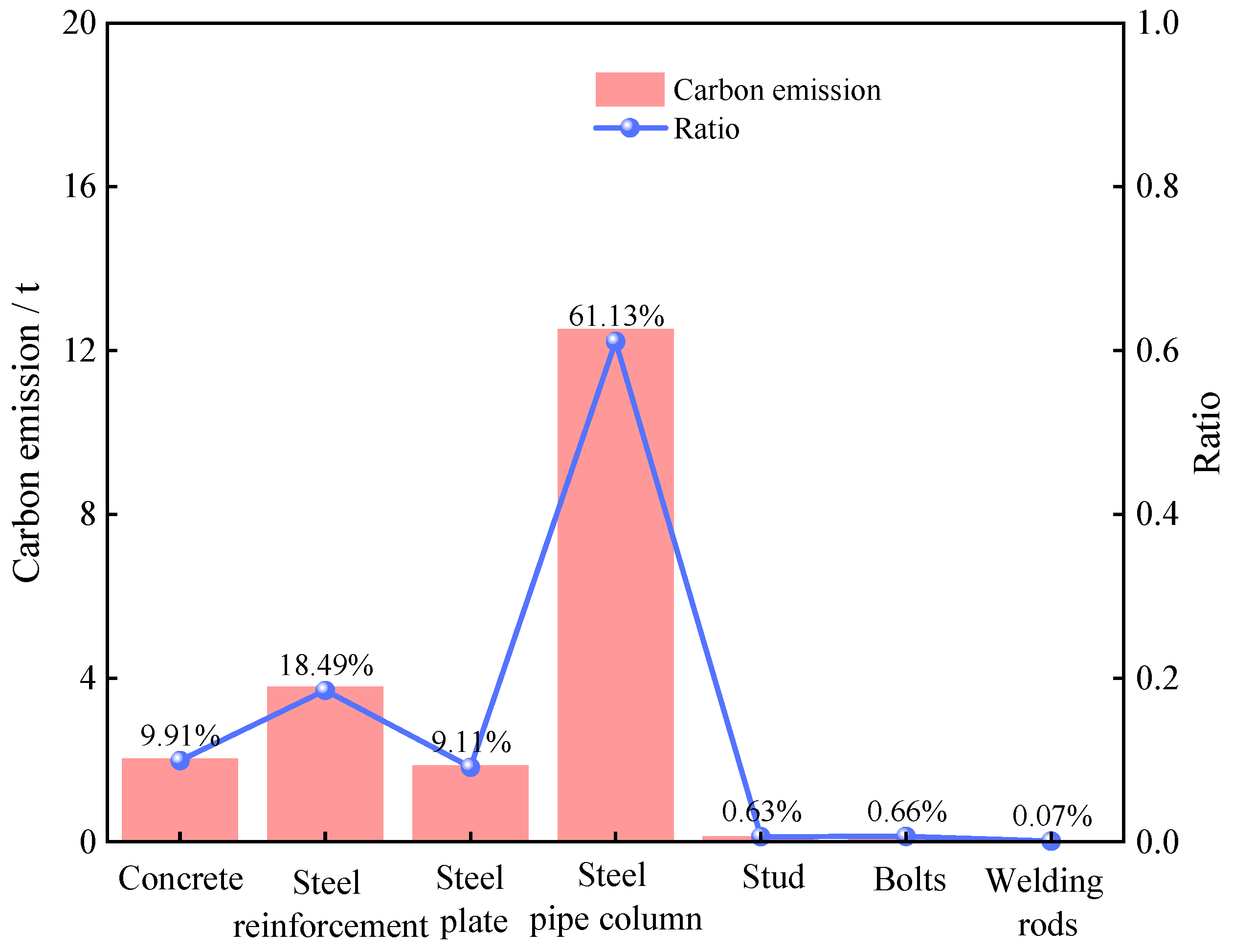

A high proportion of carbon emissions in the production stage and research significance: This study shows that, in the full life cycle of PCSPCs for metro stations, the production stage accounts for more than 90% of total carbon emissions, with the material production process alone contributing as much as 98.9%. In contrast, the transportation and construction stages contribute only 0.3% and 0.8%, respectively. Compared with aboveground buildings, the use of the PBA method in metro station construction results in a greater proportion of emissions from the production stage. Therefore, an in-depth investigation of the production stage—particularly material manufacturing—is crucial for reducing future carbon emissions in underground structures, optimizing design, and mitigating environmental impacts.

- (2)

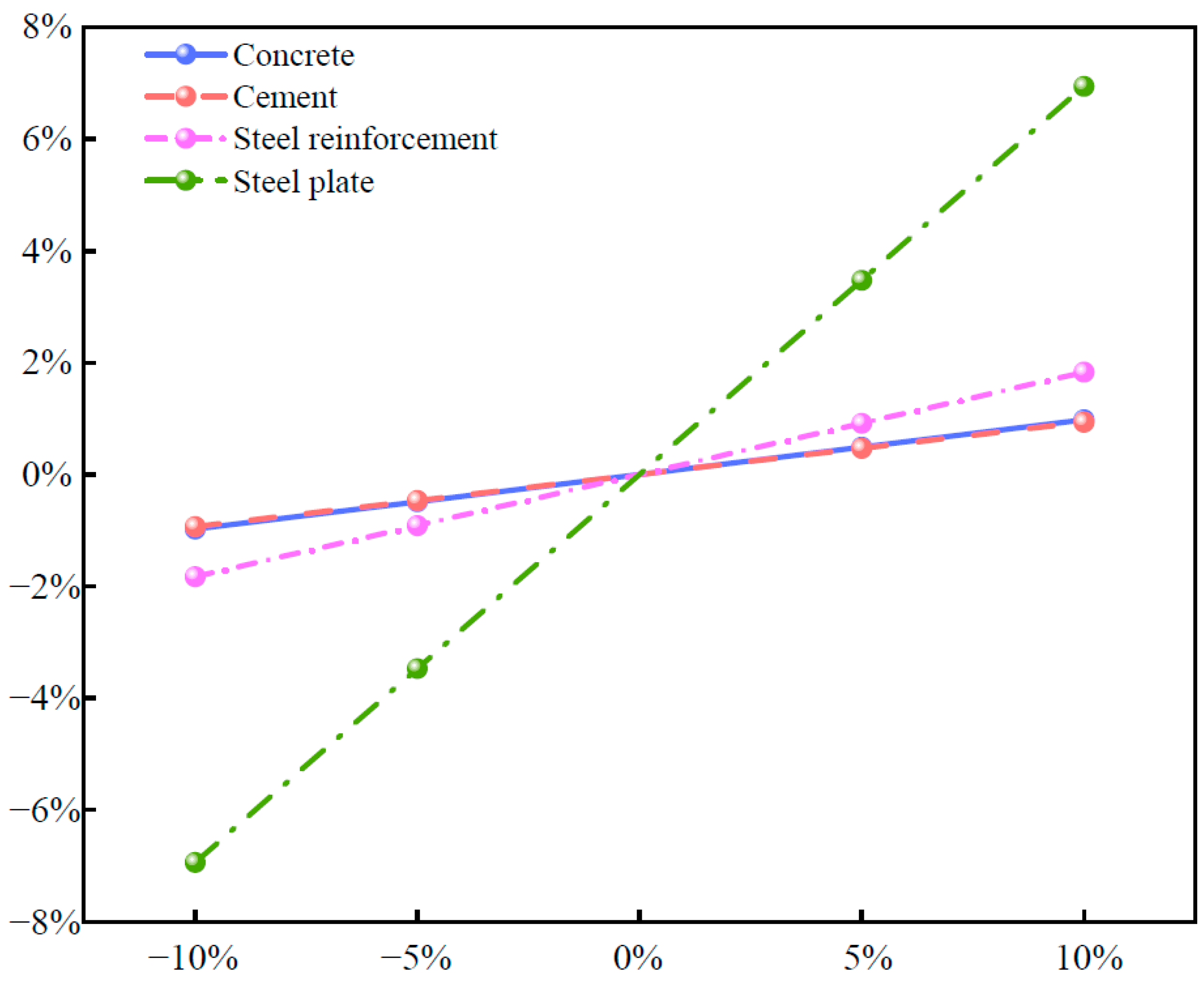

Sensitivity of high-carbon materials and emission reduction priorities: A sensitivity analysis of four major construction materials with high carbon emissions during production revealed that steel plates have the highest sensitivity (>6%), followed by steel reinforcement (<2%), whereas cement and concrete have similar sensitivities (both <1%). This indicates that emission reduction strategies should prioritize greenhouse gas-intensive materials, especially steel plates and steel reinforcements. The recommended measures include selecting environmentally friendly alternatives, increasing the recycling rates of steel structures, and adopting processes that reduce the carbon footprint associated with material use.

- (3)

Strategies for material substitution and design optimization: For high-carbon materials such as steel plates and steel reinforcements, promising alternatives such as fiber-reinforced composites (e.g., CFRPs) can significantly reduce carbon emissions due to their excellent strength–weight ratio, which lowers transportation energy use and structural dead weight. Furthermore, advanced topology optimization can refine the layout and cross-section of steel elements on the basis of the actual stress distribution, avoiding material overuse. Coupled with efficient recycling and reuse systems—where recovered materials are applied to noncritical components—these measures can extend material life cycles and substantially reduce emissions from new material production.