Recyclable Wind Turbine Blades: A Life Cycle Analysis

Abstract

1. Introduction

- Modeling the cradle-to-grave environmental performance of six full-scale 45 m wind turbine blades using detailed, open-source bills of materials that include auxiliary and consumable materials;

- Using consistent environmental indicators (embodied energy and carbon footprint) and up-to-date, industry-relevant data sources for all material and process modeling;

- Offering a systematic, side-by-side environmental comparison of full-scale wind turbine blades produced with both conventional thermoset and emerging thermoplastic (Elium-based) technologies, thereby filling a key gap in the literature and establishing a benchmark for future comparative studies;

- Providing evidence-based recommendations for material selection in line with circular economy principles.

2. Methodology and Blade Configuration Scenarios

- The manufacturing facility and materials processing;

- Blade assembly and finishing steps;

- Transportation to the wind farm;

- Use-phase energy impacts (if modeled or assumed).

2.1. Blade Design Models and Adjustments

- TS-GF: thermoset with full glass fiber reinforcement;

- TS-CF: thermoset with full carbon fiber reinforcement;

- TP-GF: thermoplastic (Elium) with full glass fiber;

- TP-CF: thermoplastic with full carbon fiber;

- TP-Hybrid: thermoplastic with hybrid GF/CF reinforcement.

2.2. Case Study Site: Rimouski Wind Farm Region

- Consistent wind resources: the regional wind atlas identifies the Rimouski area as having favorable average wind speeds at 50 m elevation, making it suitable for utility-scale wind energy generation (see Figure 1).

- Accessibility to transport logistics: proximity to waterways facilitates the delivery of large components, such as wind turbine blades, while road infrastructure allows inland transportation.

- Existing infrastructure: the presence of nearby operational wind farms confirms the feasibility of wind energy development in this location.

3. Environmental Performance Indicators and Material Impact Data

3.1. Embodied Energy

3.2. Carbon Footprint

4. Results and Discussion

4.1. Material

4.2. Manufacture

4.3. Transportation

4.4. Operation and Maintenance

4.5. Disposal and End-of-Life Potential

- Disposal encompasses all activities required to manage a blade at the end of its functional life. This includes the collection and transportation of the blade, separation, and sorting of materials, and, when applicable, final disposal in landfills or incineration.

- EoL potential refers to the environmental credits or offsets that can be attributed to the recovery and reuse of materials in subsequent product life cycles. These credits are conditional on both the recycling method employed and the material composition. While EoL potential does not reduce the immediate environmental burden of the current product, it contributes to a broader reduction in lifecycle impacts by displacing the need for virgin materials in future production cycles.

4.6. Lifetime Impact

5. Discussion

5.1. Quantitative Evaluation of the Environmental Advantages of Thermoplastic Blades

- TP-GF blades exhibit 22.4% lower embodied energy and 22.2% lower carbon footprint than TS-GF blades.

- TP-Hybrid and TP-CF configurations also exhibit improvements, albeit less pronounced, with embodied energy reductions of 7.9% and 4.3%, respectively, and carbon footprint reductions of 6.3% and 3.3%.

5.2. Trade-Off Between Mechanical Performance and Environmental Impact in Material Selection

- TP-CF compared to TP-Hybrid has 72% and 77.5% higher embodied energy and carbon footprint, respectively.

- TP-CF compared to TP-GF has 518% and 692% higher embodied energy and carbon footprint, respectively.

- TS-CF compared to TS-Hybrid has 65.6% and 74.3% higher embodied energy and carbon footprint, respectively.

- TS-CF compared to TS-GF has 401% and 573% higher embodied energy and carbon footprint, respectively.

5.3. Practicalities and Challenges of End-of-Life (EoL) Recycling

5.4. Future Prospects for Economic and Industrial Applicability

- Carbon fiber justification: reserve exclusively for performance-critical applications (e.g., offshore blades > 80 m) where mechanical benefits demonstrably outweigh sustainability costs.

- Glass fiber prioritization: optimize eco-performance for most onshore installations through thermoplastic GF systems.

- Hybrid implementation: employ partial carbon reinforcement only when operational benefits exceed environmental premiums by quantifiable margins.

6. Conclusions

- It is one of the first studies to directly compare multiple thermoset and thermoplastic composite blade configurations using a complete cradle-to-grave life cycle assessment (LCA) framework, incorporating realistic assumptions for transportation, manufacturing, maintenance, and end-of-life treatment.

- It quantifies the EoL potential of thermoplastics in blade recycling, a frequently discussed but rarely measured advantage, by applying realistic downcycling and recovery rates to embodied energy and emissions.

- It provides a detailed benchmark for embodied energy and carbon emissions across six blade types, addressing a significant research gap in comparative life cycle assessment (LCA) data for emerging thermoplastic technologies in large-scale structural applications.

- It contributes practical insights into the trade-offs between mechanical performance and sustainability, helping guide future material choices in turbine blade design.

7. Perspectives and Directions for Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Heng, H.; Meng, F.; McKechnie, J. Wind turbine blade wastes and the environmental impacts in Canada. Waste Manag. 2021, 133, 59–70. [Google Scholar] [CrossRef]

- Uddin, M.S.; Kumar, S. Energy, emissions and environmental impact analysis of wind turbine using life cycle assessment technique. J. Clean. Prod. 2014, 69, 153–164. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, S.; Dong, W.; Kaneko, T.; Chen, M.; Shi, D. High-strength, degradable and recyclable epoxy resin based on imine bonds for its carbon-fiber-reinforced composites. Materials 2023, 16, 1604. [Google Scholar] [CrossRef] [PubMed]

- Tejada-Casado, M.; Ghinea, R.; Pérez, M.M.; Ruiz-López, J.; Lübbe, H.; Herrera, L.J. Development of thickness-dependent predictive methods for the estimation of the CIEL * a * b * color coordinates of monolithic and layered dental resin composites. Materials 2023, 16, 761. [Google Scholar] [CrossRef]

- Casucci, A.; Verniani, G.; Barbieri, A.L.; Ricci, N.M.; Cagidiaco, E.F.; Ferrari, M. Flexural strength analysis of different complete denture resin-based materials obtained by conventional and digital manufacturing. Materials 2023, 16, 6559. [Google Scholar] [CrossRef]

- Tschentscher, C.; Gebhardt, M.; Chakraborty, S.; Meiners, D. Recycling of Elium CFRPs for high temperature dissolution: A study with different solvents. In Proceedings of the Symposium Materialtechnik, Clausthal-Zellerfeld, Germany, 25–26 February 2021. [Google Scholar]

- Cousins, D.S. Advanced Thermoplastic Composites for Wind Turbine Blade Manufacturing; Colorado School of Mines: Golden, CO, USA, 2018. [Google Scholar]

- Rathore, N.; Panwar, N. Environmental impact and waste recycling technologies for modern wind turbines: An overview. Waste Manag. Res. 2023, 41, 744–759. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.-J.; Kuiper, P.; de Wit, H. Recycling of composite materials. Chem. Eng. Process. Process Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Bensadoun, F.; Vanderfeesten, B.; Verpoest, I.; Van Vuure, A.W.; Van Acker, K. Environmental impact assessment of end of life options for flax-MAPP composites. Ind. Crops Prod. 2016, 94, 327–341. [Google Scholar] [CrossRef]

- Montagna, L.S.; Morgado, G.F.d.M.; Lemes, A.P.; Passador, F.R.; Rezende, M.C. Recycling of carbon fiber-reinforced thermoplastic and thermoset composites: A review. J. Thermoplast. Compos. Mater. 2023, 36, 3455–3480. [Google Scholar] [CrossRef]

- Alshammari, B.A.; Alsuhybani, M.S.; Almushaikeh, A.M.; Alotaibi, B.M.; Alenad, A.M.; Alqahtani, N.B.; Alharbi, A.G. Comprehensive review of the properties and modifications of carbon fiber-reinforced thermoplastic composites. Polymers 2021, 13, 2474. [Google Scholar] [CrossRef]

- Morini, A.A.; Ribeiro, M.J.; Hotza, D. Carbon footprint and embodied energy of a wind turbine blade—A case study. Int. J. Life Cycle Assess. 2021, 26, 1177–1187. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr. How to repair the next generation of wind turbine blades. Energies 2023, 16, 7694. [Google Scholar] [CrossRef]

- Kazemi, M.; Shanmugam, L.; Lu, D.; Wang, X.; Wang, B.; Yang, J. Mechanical properties and failure modes of hybrid fiber reinforced polymer composites with a novel liquid thermoplastic resin, Elium®. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105523. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Kantipudi, J.; Leong, K.F.; Gerard, P. Mechanical performance and damage mechanisms of thin rectangular carbon/Elium® tubular thermoplastic composites under flexure and low-velocity impact. Thin Walled Struct. 2021, 165, 107971. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Leong, K.F.; Joshi, S.C. Damping, impact and flexural performance of novel carbon/Elium® thermoplastic tubular composites. Compos. Part B Eng. 2020, 203, 108480. [Google Scholar] [CrossRef]

- Liu, P.; Meng, F.; Barlow, C.Y. Wind turbine blade end-of-life options: An eco-audit comparison. J. Clean. Prod. 2019, 212, 1268–1281. [Google Scholar] [CrossRef]

- Merugula, L.; Khanna, V.; Bakshi, B.R. Reinforced wind turbine blades-an environmental life cycle evaluation. Environ. Sci. Technol. 2012, 46, 9785–9792. [Google Scholar] [CrossRef] [PubMed]

- Ashby, M.F. Materials and the Environment: Eco-Informed Material Choice; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Li, Y.-Q.; Du, S.-S.; Liu, L.-Y.; Li, F.; Liu, D.-B.; Zhao, Z.-K.; Xiao, H.-M.; Hu, N.; Fu, S.-Y. Synergistic effects of short glass fiber/short carbon fiber hybrids on the mechanical properties of polyethersulfone composites. Polym. Compos. 2019, 40, E1725–E1731. [Google Scholar] [CrossRef]

- Ashby, M.; Coulter, P.; Ball, N.; Bream, C. The CES EduPack Eco Audit Tool—A White Paper. Available online: https://proyectaryproducir.com.ar/public_html/Seminarios_Posgrado/Material_de_referencia/Ashby%20-%20ecoaudit.pdf (accessed on 1 June 2025).

- Ansys. Granta Selector 2025 R1. 2025. Available online: https://www.ansys.com/products/materials/granta-selector (accessed on 30 July 2025).

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Ashby, M.F.; Shercliff, H.; Cebon, D. Materials: Engineering, Science, Processing and Design; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Campbell, F.C. Structural Composite Materials; ASM International: Almere, The Netherlands, 2010. [Google Scholar]

- Fantuzzi, N.; Dib, A.; Babamohammadi, S.; Campigli, S.; Benedetti, D.; Agnelli, J. Mechanical analysis of a carbon fibre composite woven composite laminate for ultra-light applications in aeronautics. Compos. Part C Open Access 2024, V, 14. [Google Scholar] [CrossRef]

- Teng, H.; Li, S.; Cao, Z.; Li, S.; Li, C.; Ko, T.J. Carbon fiber composites for large-scale wind turbine blades: Applicability study and comprehensive evaluation in China. J. Mar. Sci. Eng. 2023, 11, 624. [Google Scholar] [CrossRef]

- Obande, W.; Mamalis, D.; Ray, D.; Yang, L.; Brádaigh, C.M.Ó. Mechanical and thermomechanical characterisation of vacuum-infused thermoplastic-and thermoset-based composites. Mater. Des. 2019, 175, 107828. [Google Scholar] [CrossRef]

- The Environmental Abatement Council of Canada. Canada’ Wind Atlas. 2016. Available online: http://www.windatlas.ca/ (accessed on 20 June 2025).

- Lunetto, V.; Galati, M.; Settineri, L.; Iuliano, L. Sustainability in the manufacturing of composite materials: A literature review and directions for future research. J. Manuf. Process. 2023, 85, 858–874. [Google Scholar] [CrossRef]

- Katsiropoulos, C.V.; Loukopoulos, A.; Pantelakis, S.G. Comparative environmental and cost analysis of alternative production scenarios associated with a helicopter’s canopy. Aerospace 2019, 6, 3. [Google Scholar] [CrossRef]

- Advanced Manufacturing Office. Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Carbon Fiber Reinforced Polymer Manufacturing; USA Department of Energy: Washington, DC, USA, 2017.

- Suzuki, T.; Takahashi, J. Prediction of energy intensity of carbon fiber reinforced plastics for mass-produced passenger cars. In Proceedings of the 9th Japan International SAMPE Symposium, Tokyo, Japan, 29 November–2 December 2005; Department of Environmental and Ocean Engineering, The University of Tokyo Japan: Tokyo, Japan, 2005. [Google Scholar]

- Ramachandran, K.; Gnanasagaran, C.L.; Vekariya, A. Life cycle assessment of carbon fiber and bio-fiber composites prepared via vacuum bagging technique. J. Manuf. Process. 2023, 89, 124–131. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Song, Y.S.; Youn, J.R.; Gutowski, T.G. Life cycle energy analysis of fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1257–1265. [Google Scholar] [CrossRef]

- Incorporated, E. Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in the Manufacturing of Lightweight Materials: Carbon Fiber Reinforced Polymer Composites; National Renewable Energy Laboratory and U.S. Department of Energy, Advanced Manufacturing Office: Washington, DC, USA, 2016.

- Mishnaevsky, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for wind turbine blades: An overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr. Root causes and mechanisms of failure of wind turbine blades: Overview. Materials 2022, 15, 2959. [Google Scholar] [CrossRef]

- Liu, P.; Barlow, C.Y. Wind turbine blade waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef]

- Morici, E.; Dintcheva, N.T. Recycling of thermoset materials and thermoset-based composites: Challenge and opportunity. Polymers 2022, 14, 4153. [Google Scholar] [CrossRef] [PubMed]

- Pickering, S.J. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Palmer, J.A.T. Mechanical Recycling of Automotive Composites for Use as Reinforcement in Thermoset Composites; University of Exeter: Exeter, UK, 2009. [Google Scholar]

- Almushaikeh, A.M.; Alaswad, S.O.; Alsuhybani, M.S.; AlOtaibi, B.M.; Alarifi, I.M.; Alqahtani, N.B.; Aldosari, S.M.; Alsaleh, S.S.; Haidyrah, A.S.; Alolyan, A.A.; et al. Manufacturing of carbon fiber reinforced thermoplastics and its recovery of carbon fiber: A review. Polym. Test. 2023, 122, 108029. [Google Scholar] [CrossRef]

| Name | Materials | Country of Origin | TS-GF | TS-Hybrid | TS-CF | TP-GF | TP-Hybrid | TP-CF | |

|---|---|---|---|---|---|---|---|---|---|

| Materials Used on Blade (kg) | Glass Fiber Unidirectional | S-glass | China | 2414 | 1207 | 2414 | 1207 | ||

| Glass Fiber Biaxial/Triaxial | E-glass | China | 3084 | 1542 | 3084 | 1542 | |||

| Carbon Fiber | Canada | 1924 | 3848 | 1924 | 3848 | ||||

| Thermoset Resin | Epoxy | USA | 2940 | 2940 | 2940 | ||||

| Thermoplastic Resin | Elium 188 XO | France | 2940 | 2940 | 2940 | ||||

| Steel (nuts, washer) | 42CrMoA | 103.7 | 103.7 | 103.7 | 103.7 | 103.7 | 103.7 | ||

| Copper (thunder protection system) | Copper, C10200, wrought | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | ||

| Aluminum | Aluminum 6010, wrought | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | ||

| Balsa | End-grain balsa (0.15) | 208.9 | 208.9 | 208.9 | 208.9 | 208.9 | 208.9 | ||

| PVC | PVC crosslinked foam, DH 0.060 | 156.6 | 156.6 | 156.6 | 156.6 | 156.6 | 156.6 | ||

| Paint | Acrylic or alkyd paint | 85.4 | 85.4 | 85.4 | 85.4 | 85.4 | 85.4 | ||

| Putty | Acrylic wall putty | 62 | 62 | 62 | 62 | 62 | 62 | ||

| Spray Adhesives | Synthetic elastomer-based adhesive | 4.4 | 4.4 | 4.4 | 4.4 | 4.4 | 4.4 | ||

| VARTM Consumable Materials (kg) | Continuous Filament Mat | E-glass with acid corrosion resistance | 21 | 21 | 21 | 21 | 21 | 21 | |

| Release Film | PA66 | 28.9 | 28.9 | 28.9 | 28.9 | 28.9 | 28.9 | ||

| Vacuum Bag Film | PA 60% PE 40% | 111.3 | 111.3 | 111.3 | 111.3 | 111.3 | 111.3 | ||

| Porous Membrane | PTFE | 9.9 | 9.9 | 9.9 | 9.9 | 9.9 | 9.9 | ||

| Flow Mesh Layer | Polyethylene | 60 | 60 | 60 | 60 | 60 | 60 | ||

| Breather Bleeder | Polyester | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 | ||

| Vacuum Bagging Sealant Tape | 65.4 | 65.4 | 65.4 | 65.4 | 65.4 | 65.4 | |||

| Resin Flow Runner Pipes (Spiral) | PE | 28.6 | 28.6 | 28.6 | 28.6 | 28.6 | 28.6 | ||

| Resin Flow Runner Pipes (Omega) | PVC | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | ||

| Steel Spiral Pipes | Steel | 14.8 | 14.8 | 14.8 | 14.8 | 14.8 | 14.8 | ||

| PVC Holder | PVC | 40.9 | 40.9 | 40.9 | 40.9 | 40.9 | 40.9 | ||

| T Fitting + Infusion Valve | PPR (random copolymer) | 5 | 5 | 5 | 5 | 5 | 5 | ||

| Total weight of BOM (kg) | 9493 | 8668 | 7843 | 9493 | 8668 | 7843 |

| Material | Type | Density (kg/m3) | Source/Notes |

|---|---|---|---|

| Glass Fiber (Unidirectional) | S-glass | 2490 | Typical value for high-strength S-glass [24,25] |

| Glass Fiber (Biaxial/Triaxial) | E-glass | 2550 | Commonly used in structural composites [24,25] |

| Carbon Fiber | PAN-based (high-modulus) | 1750 | Average value for aerospace-grade CF [26,27] |

| Property | Elium 188 | Epoxy SR 1710/SD 7820 |

|---|---|---|

| Tensile strength (MPa) | 66 | 78 |

| Tensile modulus (GPa) | 3.2 | 2.8 |

| Elongation at break (%) | 2.8 | 6.2 |

| Flexural strength (MPa) | 111 | 117 |

| Flexural modulus (GPa) | 2.9 | 2.8 |

| Density (g/cm3) | 1.01 | 1.15 |

| Viscosity@25 °C (m.Pa.s) | 100 | 350 |

| Glass transition temperature (°C) | 102 | 127 |

| Fibers | Embodied Energy (MJ/kg) | Reference |

|---|---|---|

| Carbon fiber | 532–558 | [32,33] |

| 286–478 | [34] | |

| 913–1013 | [23] | |

| 1100 | [35] | |

| E-glass fiber | 13–32 | [36] |

| 30.9–34 | [23] | |

| S-glass fiber | 51.1–56.3 | [23] |

| China reed fiber | 3.6 | [37] |

| Flax fiber | 6.5 | [36,37] |

| Material | Embodied Energy (MJ/kg) | CO2 Emission (kg/kg) | Water Consumption (L/kg) |

|---|---|---|---|

| Carbon fiber | 959 | 68.1 | 7.4 |

| S-glass fiber | 52.7 | 3.36 | 296 |

| E-glass fiber | 32.5 | 2.54 | 94.5 |

| Aramid fiber | 257 | 13.1 | 940 |

| Epoxy resin | 132 | 6.5 | 28.0 |

| Polyester resin | 79.2 | 2.6 | 238 |

| Steel | 32.3 | 2.4 | 52.1 |

| Aluminum | 201 | 13.7 | 1210 |

| Balsa | 12.3 | 0.6 | 687 |

| PVC | 80.6 | 5.2 | 455 |

| Paint and adhesives | 89.4 | 5.2 | 295 |

| Production Method | Embodied Energy (MJ/kg) | Carbon Footprint (kg/kg) | Reference |

|---|---|---|---|

| Wet hand layup | 13.5 | [38] | |

| Prepreg | 123 | [38] | |

| Resin transfer molding (RTM) | 34.4–37.9 | 2.26–2.5 | [23] |

| Vacuum-assisted resin transfer molding (VARTM) | 28.8–31.7 | 1.89–2.09 | [23] |

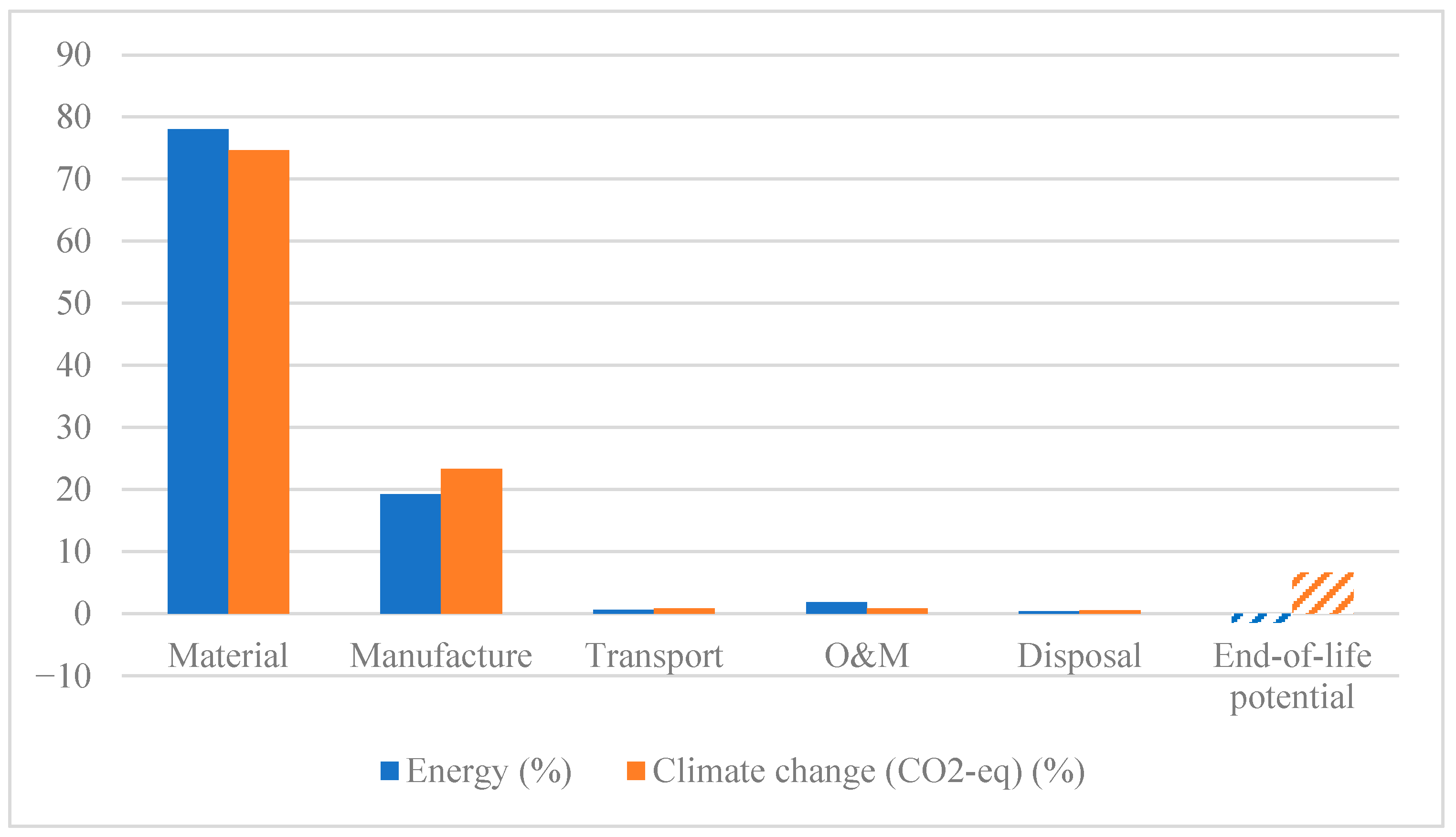

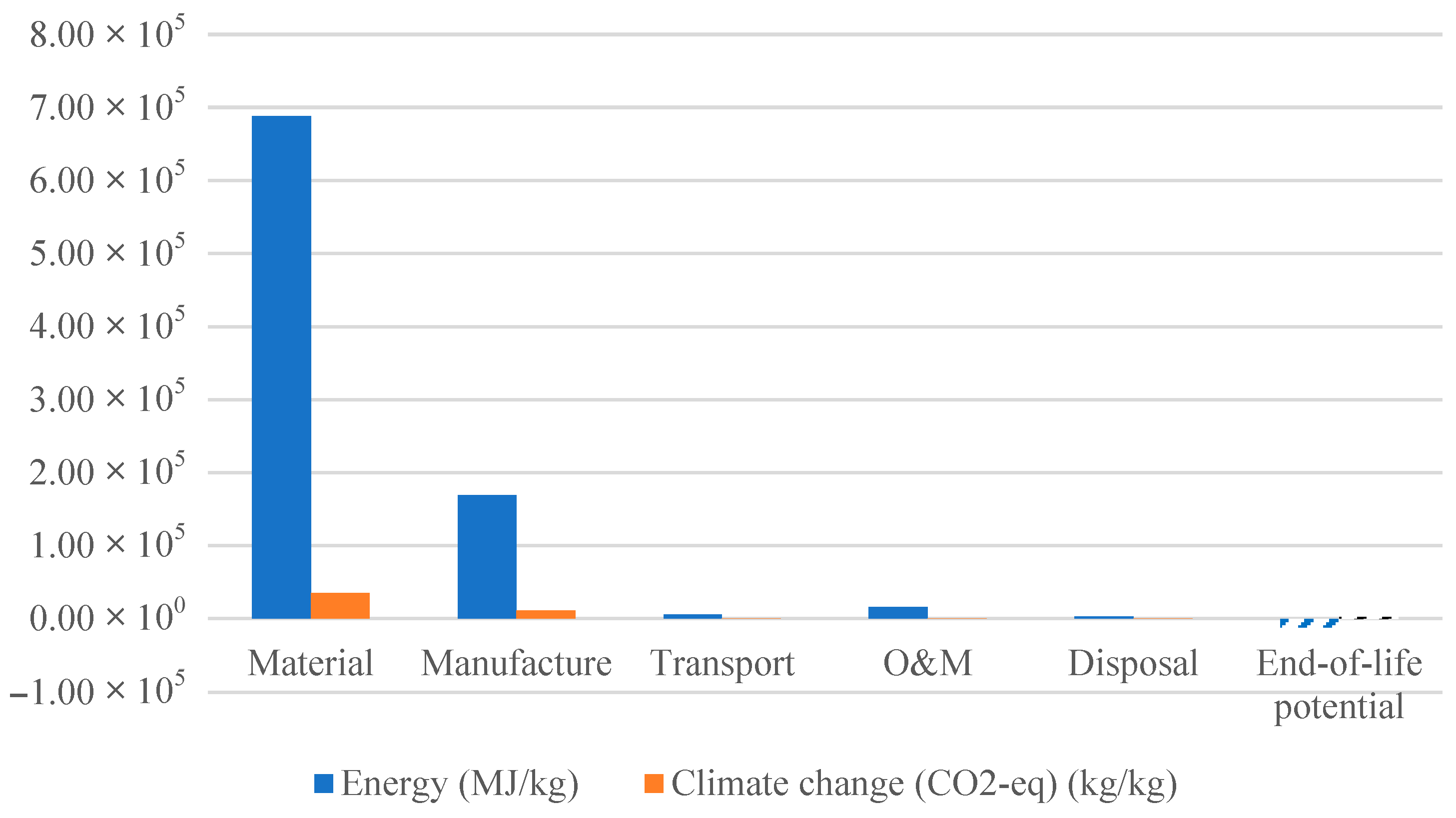

| Phase | Energy (MJ) | Energy (%) | Climate Change (CO2-eq) (kg) | Climate Change (CO2-eq) (%) |

|---|---|---|---|---|

| Material | 6.88 × 105 | 78 | 3.52 × 104 | 74.6 |

| Manufacture | 1.69 × 105 | 19.2 | 1.1 × 104 | 23.3 |

| Transport | 5.81 × 103 | 0.6 | 370 | 0.8 |

| O&M | 1.61 × 104 | 1.8 | 404 | 0.8 |

| Disposal | 3.25 × 103 | 0.4 | 227 | 0.5 |

| Total (for first life) | 8.82 × 105 | 100 | 4.72 × 104 | 100 |

| End-of-life potential | −1.16 × 104 | 2.83 × 103 |

| Phase | Environmental Indicators | TS-GF | TS Hybrid | TS CF | TP GF | TP Hybrid | TP CF |

|---|---|---|---|---|---|---|---|

| Material | Energy (MJ) | 6.88 × 105 | 2.42 × 106 | 4.16 × 106 | 5.72 × 105 | 2.31 × 106 | 4.04 × 106 |

| Carbon footprint (kg) | 3.52 × 104 | 1.6 × 105 | 2.84 × 105 | 2.82 × 104 | 1.53 × 105 | 2.77 × 105 | |

| Manufacture | Energy (MJ) | 1.69 × 105 | 1.52 × 105 | 1.36 × 105 | 8.61 × 104 | 7.77 × 104 | 6.92 × 104 |

| Carbon footprint (kg) | 1.1 × 104 | 9.9 × 103 | 8.82 × 103 | 6.92 × 103 | 6.24 × 103 | 5.57 × 103 | |

| Transport | Energy (MJ) | 5.81 × 103 | 5.3 × 103 | 4.8 × 103 | 5.81 × 103 | 5.3 × 103 | 4.8 × 103 |

| Carbon footprint (kg) | 370 | 338 | 306 | 370 | 338 | 306 | |

| O&M | Energy (MJ) | 1.61 × 104 | 8.84 × 104 | 1.12 × 105 | 1.56 × 104 | 6.24 × 104 | 1.12 × 105 |

| Carbon footprint (kg) | 404 | 4.59 × 103 | 8.16 × 103 | 907 | 4.19 × 103 | 8.17 × 103 | |

| Disposal | Energy (MJ) | 3.25 × 103 | 3.09 × 103 | 2.93 × 103 | 4.88 × 103 | 4.73 × 103 | 4.58 × 103 |

| Carbon footprint (kg) | 227 | 216 | 205 | 342 | 331 | 320 | |

| Total | Energy (MJ) | 8.82 × 105 | 2.67 × 106 | 4.42 × 106 | 6.84 × 105 | 2.46 × 106 | 4.23 × 106 |

| Carbon footprint (kg) | 4.32 × 104 | 1.67 × 105 | 2.91 × 105 | 3.63 × 104 | 1.6 × 105 | 2.84 × 105 | |

| EoL potential | Energy (MJ) | −1.16 × 104 | −1.16 × 104 | −1.16 × 104 | −2.82 × 105 | −6.19 × 105 | −9.56 × 105 |

| Carbon footprint (kg) | 2.83 × 103 | 2.83 × 103 | 2.83 × 103 | −8.98 × 103 | −3.3 × 104 | −5.69 × 104 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farazmandnia, N.; Ilinca, A. Recyclable Wind Turbine Blades: A Life Cycle Analysis. Materials 2025, 18, 3762. https://doi.org/10.3390/ma18163762

Farazmandnia N, Ilinca A. Recyclable Wind Turbine Blades: A Life Cycle Analysis. Materials. 2025; 18(16):3762. https://doi.org/10.3390/ma18163762

Chicago/Turabian StyleFarazmandnia, Navid, and Adrian Ilinca. 2025. "Recyclable Wind Turbine Blades: A Life Cycle Analysis" Materials 18, no. 16: 3762. https://doi.org/10.3390/ma18163762

APA StyleFarazmandnia, N., & Ilinca, A. (2025). Recyclable Wind Turbine Blades: A Life Cycle Analysis. Materials, 18(16), 3762. https://doi.org/10.3390/ma18163762