A Comparative Analysis of the Fatigue Strength of Aluminium and Copper Wires Used for Power Cables

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- —cross-section of the wire before the wiredrawing process;

- —cross-section of the wire after the wiredrawing process.

2.2. Equipment and Research Methodology

- —max bending stress [MPa];

- —Young’s modulus [GPa];

- —wire diameter [mm];

- —wire deflection arrow [mm];

- —wire length [mm].

3. Results and Discussion

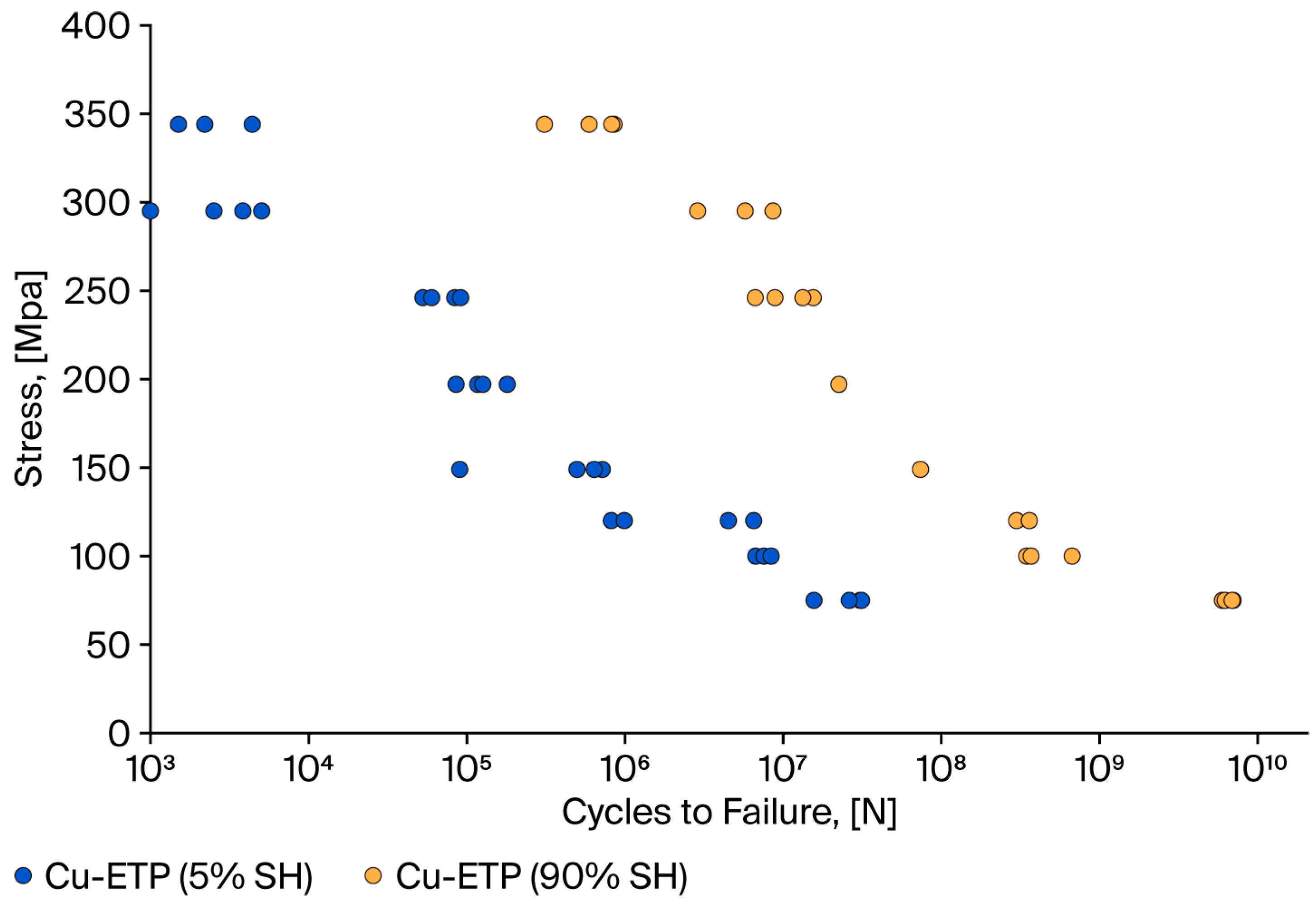

3.1. Phenomenological Analysis of Wire Fatigue Results

- —strength factor [%];

- —max stress of rotating bending fatigue test [MPa];

- —yield point of wires [MPa].

- —max stress during fatigue test;

- C—linear coefficient;

- N—number of cycles to failure;

- Z—power coefficient.

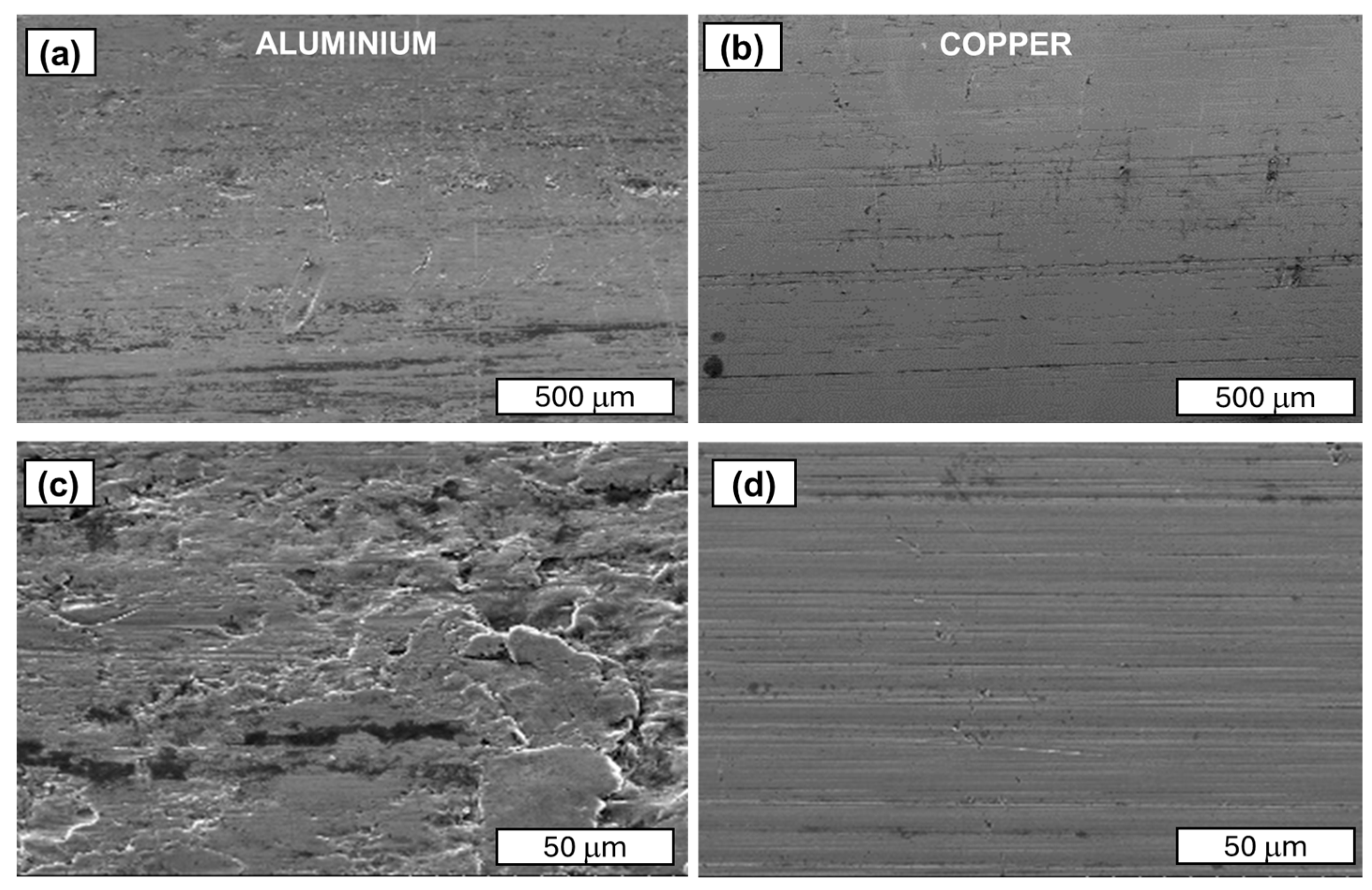

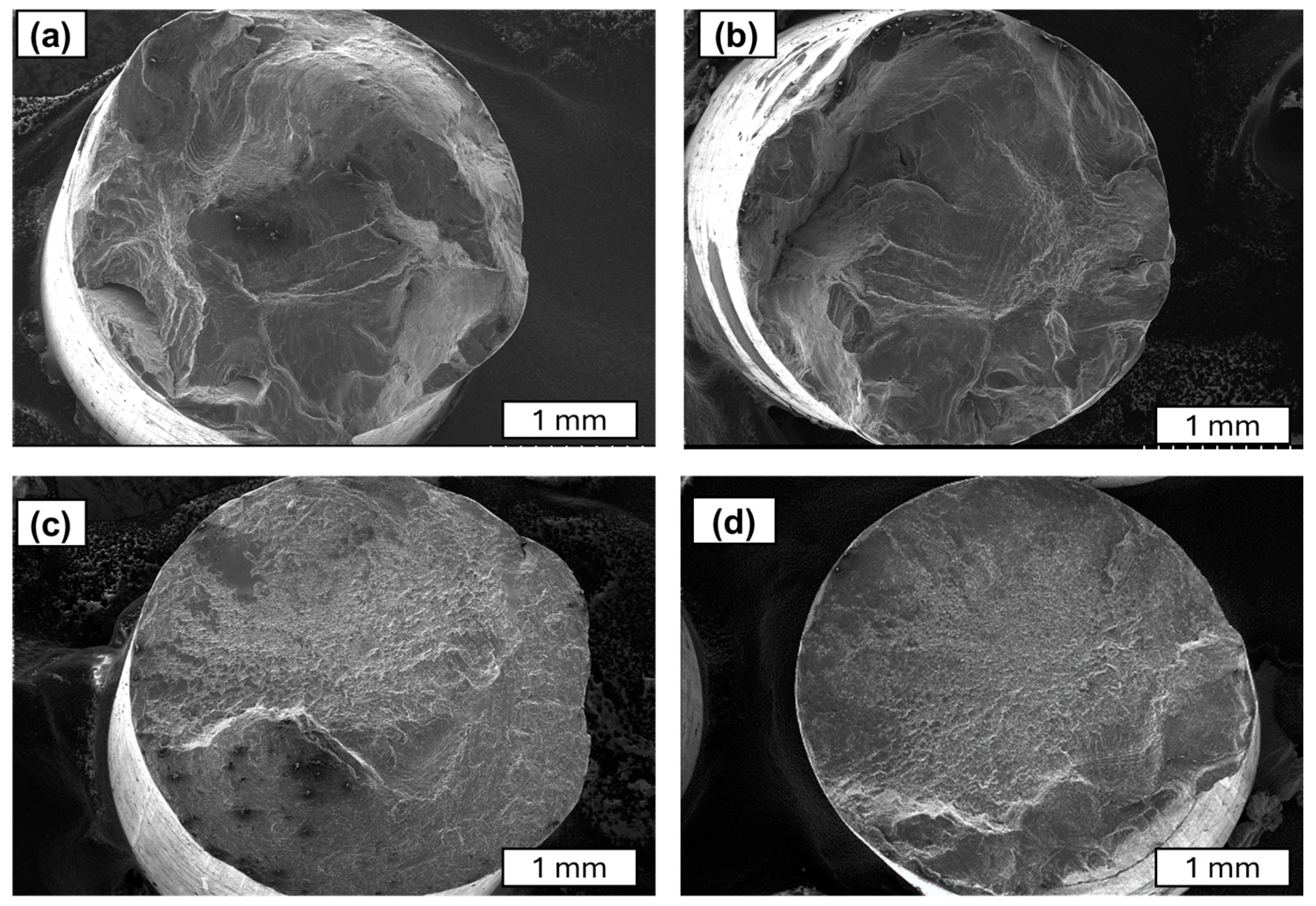

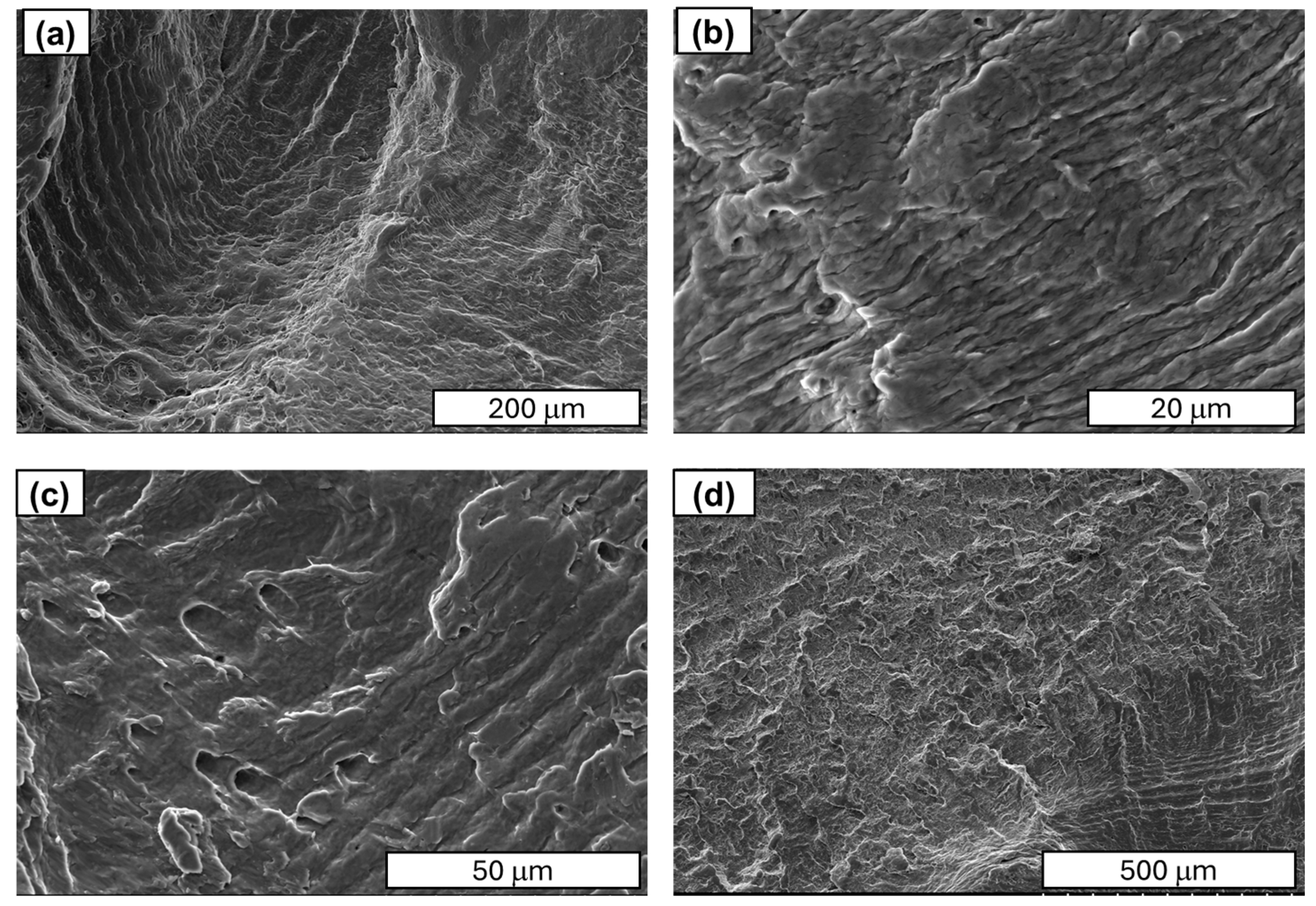

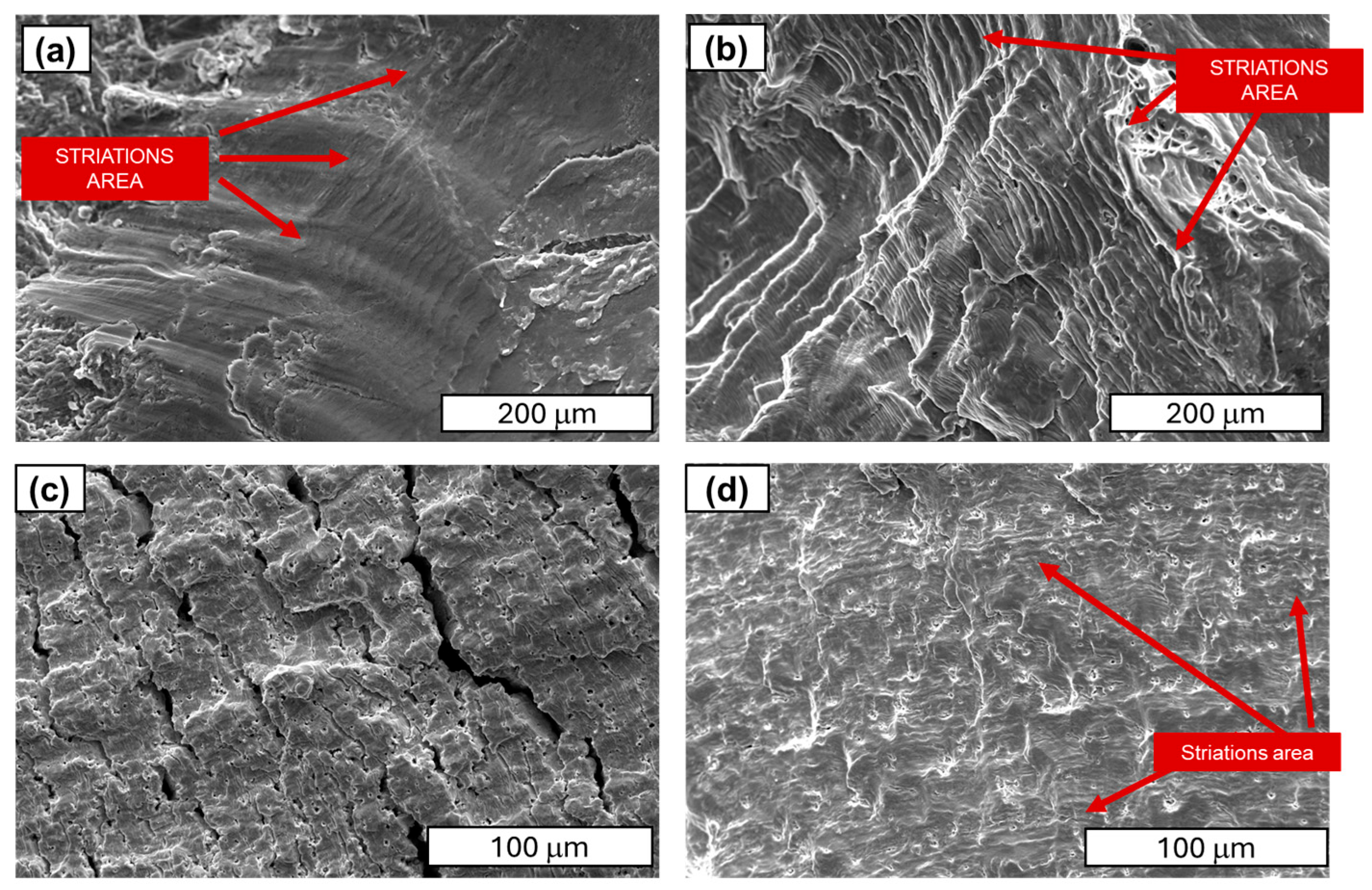

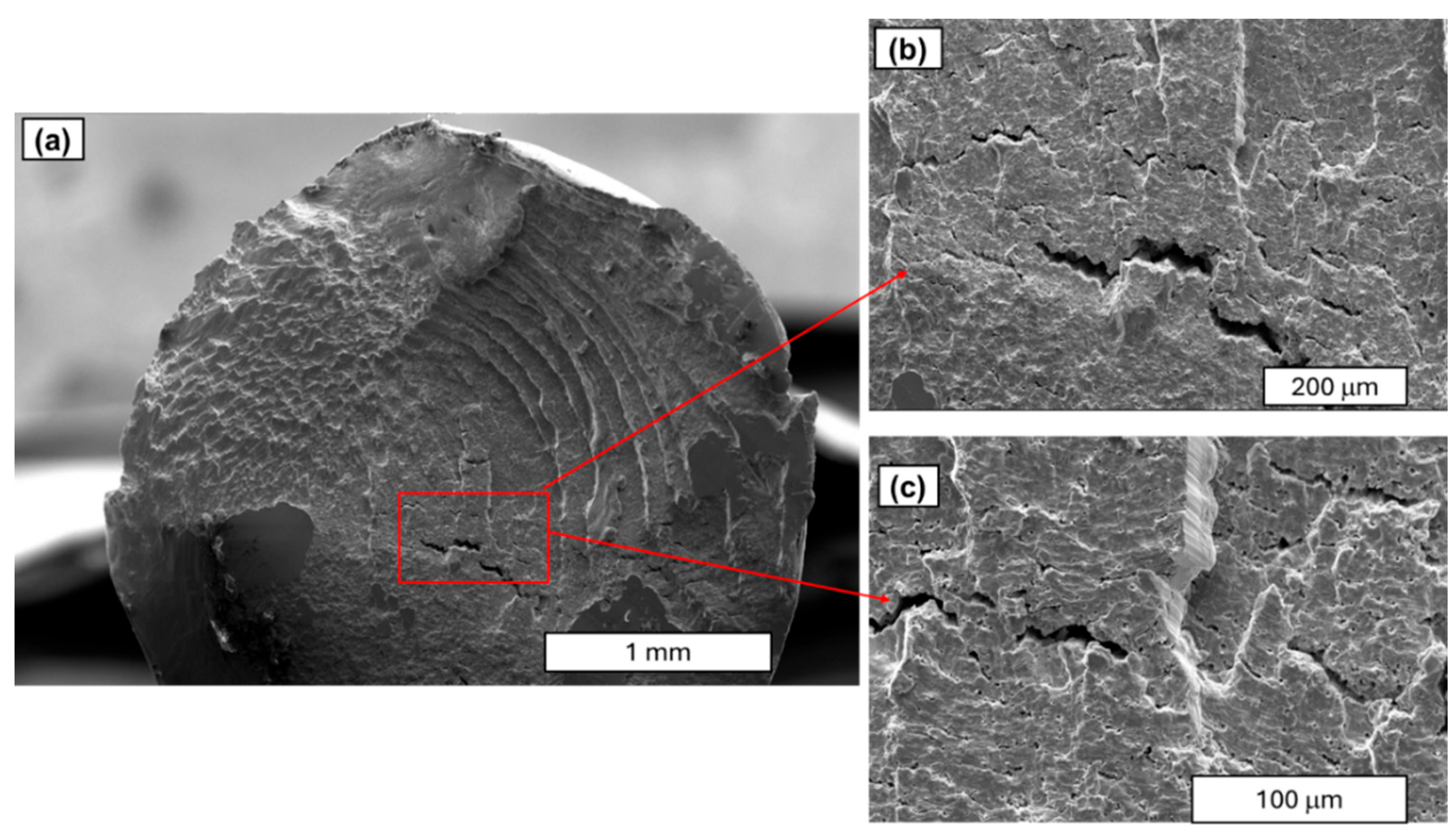

3.2. Analysis of Morphology of Fatigue Fractures

3.3. Analysis of Wire Fatigue Results for Implementation in the Design of Cable Fatigue

4. Conclusions

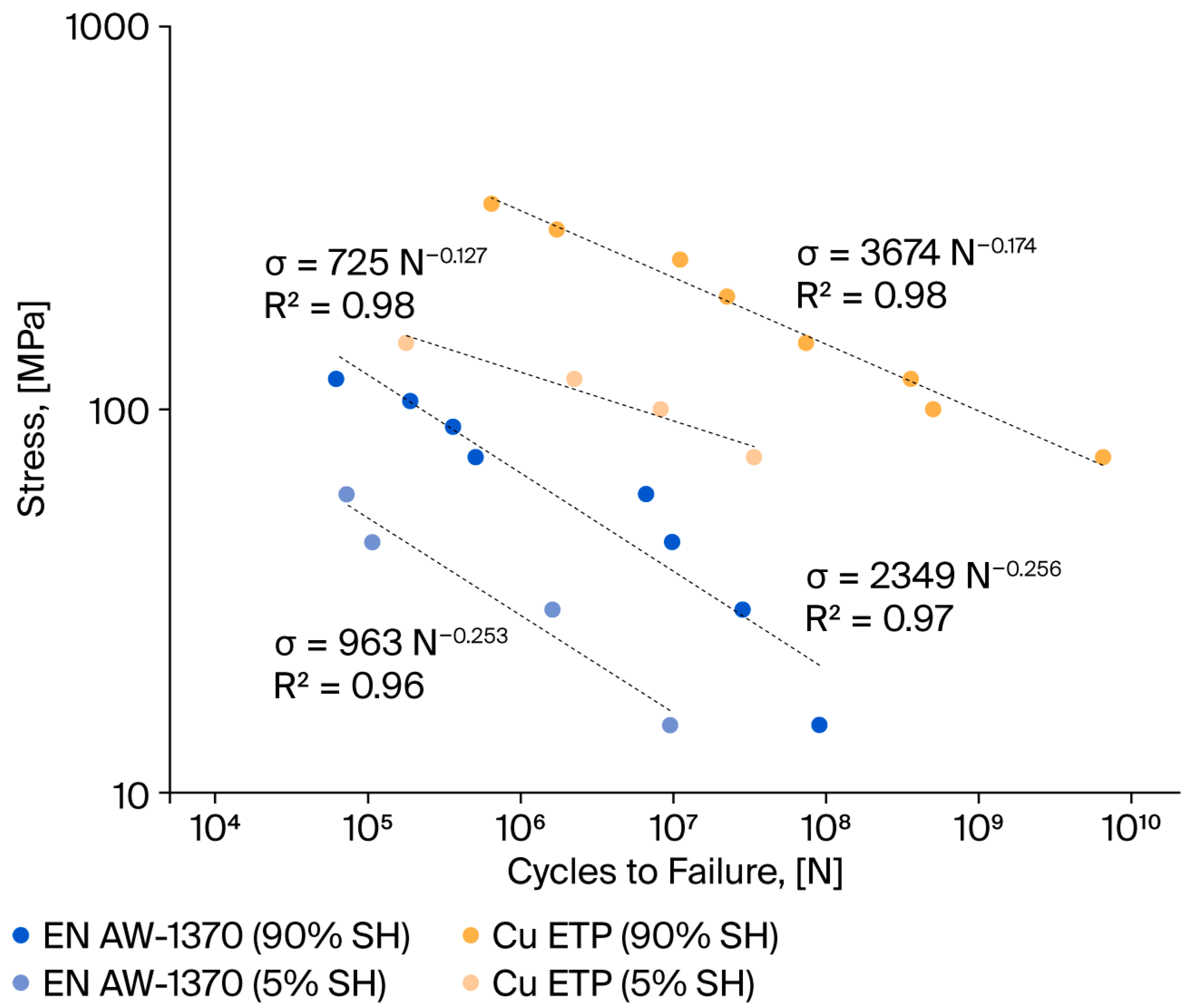

- The fatigue strength analysis encompassed the preparation of classic S-N diagrams in coordinate systems based on the bending stress amplitude and number of cycles. The Wöhler characteristics for Cu and Al intersect and differ in terms of the slope of the logσ-logN system. The curve representing aluminium wires lies slightly below the curve representing Cu-ETP wires. The fundamental distinction between these two categories is predicated on the disparity in their respective slopes, which is evidenced by the power coefficient Z, as delineated by the Wöhler equation. For aluminium wires, the Z factor is −0.253 (5% SH) and −0.256 (90% SH), while for copper wires, Z is −0.127 (5% SH) and −0.174 (90% SH). The findings of these experiments demonstrated that the absolute value of Z for aluminium wires is nearly double that of copper wires. Research has demonstrated that an elevated Z factor is indicative of accelerated degradation of the local microstructure, which, in turn, corresponds to reduced fatigue life.

- The most significant conclusion pertains to the enhanced fatigue strength exhibited by Cu-ETP wires, a phenomenon that can be attributed to their distinctive microstructural characteristics. This conclusion is applicable to copper in its mechanical state: 90% SH and 5% SH. From the perspective of microscopic fatigue fracture mechanisms, which contribute to the enhanced fatigue life of copper wires, the most salient factors are as follows: (a) the microstructure, which is characterised by homogeneity and the presence of fine grains; (b) the higher chemical purity of copper; and (c) the capacity of copper to effectively absorb and dissipate dislocations, which is the result of its higher plasticity.

- The primary factors contributing to the reduction in the fatigue strength of aluminium include lower static strength, larger grains in the aluminium structure, and poorer wire surface quality. Aluminium wires are characterised by their substantial columnar grains, with an average size of 100 micrometres. A thorough examination of the surface of aluminium and copper wires using scanning electron microscopy (SEM) reveals a substantial prevalence of surface defects in aluminium wires. These surface defects may play a pivotal role in accelerating the initiation of crack formation.

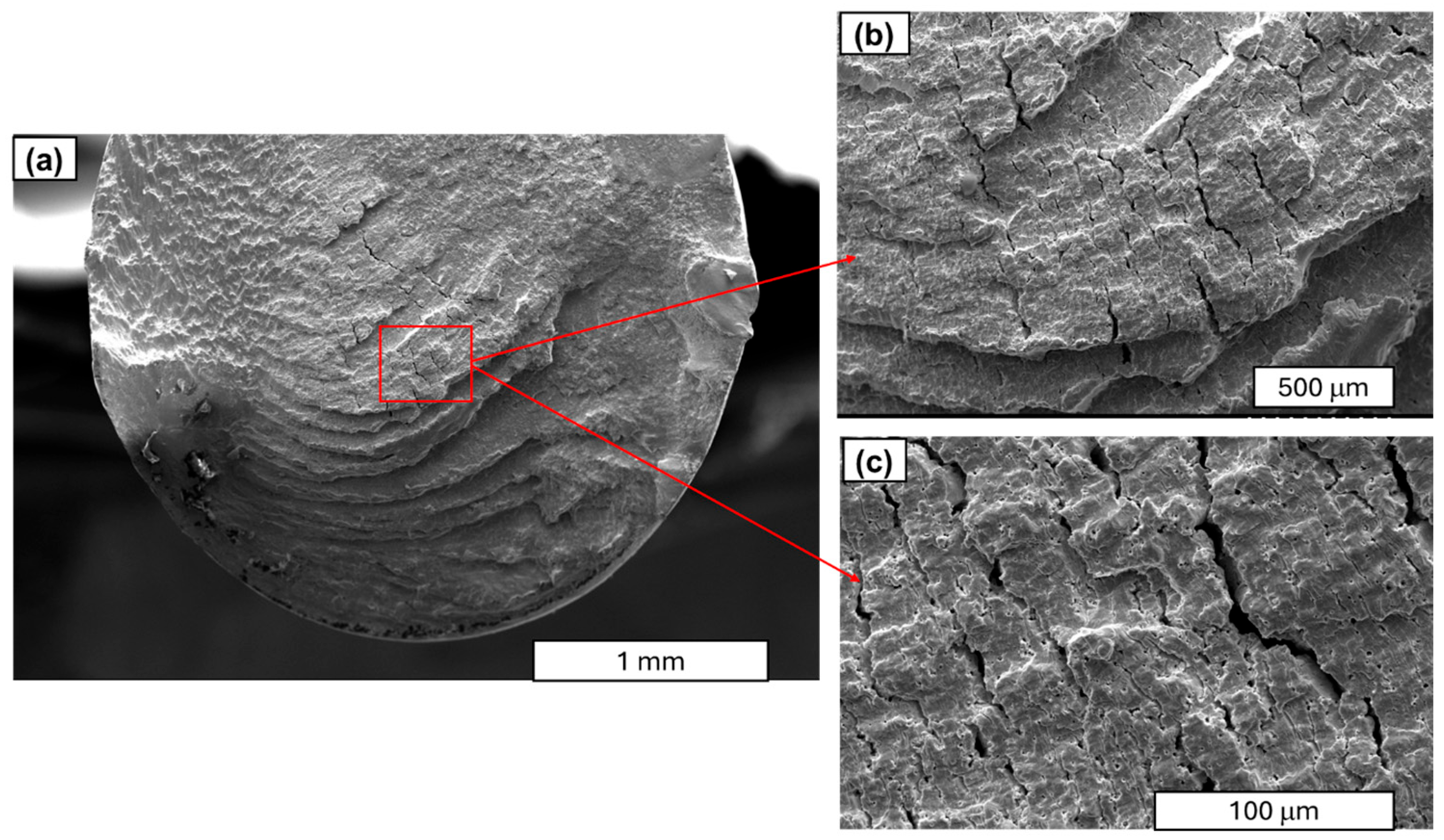

- The results of the SEM test demonstrate a clear distinction in the fatigue damage susceptibility of aluminium and copper wires. However, it should be noted that the mechanism of fatigue crack formation varies depending on the stress level at which the test is performed. In the case of cracks that are formed in the LCF range, a developed crack surface with clear plastic deformation is usually observed. In contrast, in the case of HCF, fatigue cracks in both materials manifest as smooth surfaces and exhibit characteristic striations. It is worth noting that in both cases, the observed defects are consistent with the formation of fatigue cracks. In the case of copper wires, the fatigue damage zone is characterised by a smoothed, crusty surface. A distinctive attribute of fatigue cracks in hardened copper wires is the manifestation of visible cracks along the grain boundaries, which function as indicators of the fatigue crack surface. In the case of aluminium wires, the fatigue damage zone exhibited a reduced surface area, while the temporary damage zone demonstrated a surface characteristic of elastic cracks. In contrast to the visible individual cracks that were found on the surface of the fatigue crack in copper wires, no such visible cracks were found on the surface of the fatigue crack under investigation.

- In the case of LCF, for both aluminium and copper, the fracture is characterised by an open surface, with clear signs of plastic deformation. Conversely, the HCF analysis of the fractures revealed discrepancies in the fatigue damage mechanism of aluminium and copper wires. Furthermore, the presence of material discontinuities, manifesting as isolated cracks, was detected in copper wires within the designated fatigue damage area. These cracks manifest in copper wires subsequently to HCF processes. No such cracks were observed in the aluminium wires.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guan, Y.; Shao, C.; Xiaogang, T.; Ju, M. Carbon footprint attributed to aluminum substitution for copper in the Chinese indoor air conditioner industry. J. Clean. Prod. 2013, 51, 126–132. [Google Scholar] [CrossRef]

- Czerwinski, F. Aluminum alloys for electrical engineering: A review. J. Mater. Sci. 2024, 59, 14847–14892. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Murashkin, M.; Yu, I.; Sabirov, I. A nanostructural design to produce high-strength Al alloys with enhanced electrical conductivity. Scr. Mater. 2014, 76, 13–16. [Google Scholar] [CrossRef]

- Lequien, F.; Auzoux, Q.; Moine, G.; Rousseau, M.; Pasquier-Tilliette, S.; Holande, A.; Ammi, S.; Heurtault, S.; Prieur, P. Characterization of an aluminum conductor steel reinforced (ACSR) after 60 years of operation. Eng. Fail. Anal. 2021, 120, 105039. [Google Scholar] [CrossRef]

- Smyrak, B. Analysis of the quality of aluminum overhead conductors after 30 years of operation. Eng. Fail. Anal. 2023, 154, 107600. [Google Scholar] [CrossRef]

- Azevedo, C.R.F.; Cescon, T. Failure analysis of aluminum cable steel reinforced (ACSR) conductor of the transmission line crossing the Paraná River. Eng. Fail. Anal. 2002, 9, 645–664. [Google Scholar] [CrossRef]

- Jayathilake, S.; Rajeev, P.; Gad, E. Performance Assessment of Overhead Conductors Subjected to Combined Thermal and Wind Loads. Procedia Struct. Integr. 2024, 64, 137–144. [Google Scholar] [CrossRef]

- Kopsidas, K.; Aqil, A.; Haldar, M.; Kavanagh, A. Evaluating Aeolian Vibration Performance of High-Temperature Low-Sag OHL Conductors. IEEE Trans. Power Deliv. 2021, 37, 1775–1784. [Google Scholar] [CrossRef]

- Rocha, P.; Langlois, S.; Lalonde, S.; Araújo, J.; Castro, F. A general life estimation method for overhead conductors based on fretting fatigue behaviour of wires. Theor. Appl. Fract. Mech. 2022, 121, 103443. [Google Scholar] [CrossRef]

- Tebo, G.B. Measurement and Control of Conductor Vibration. AIEE Trans. 1941, 60, 1188–1193. [Google Scholar] [CrossRef]

- Poffenberger, J.C.; Swart, R.L. Differential Displacement and Dynamic Conductor Strain. IEEE Trans. Power Appar. Syst. 1965, 84, 281–289. [Google Scholar] [CrossRef]

- Kalombo, R.B.; Martíneza, J.M.G.; Ferreiraa, J.L.A.; da Silva, C.R.M.; Araújoa, J.A. Comparative fatigue resistance of overhead conductors made of aluminium and aluminium alloy: Tests and analysis. Procedia Eng. 2015, 133, 223–232. [Google Scholar] [CrossRef]

- Fadel, A.A.; Rosa, D.; Murça, L.; Fereira, J.; Araújo, J. Effect of high mean tensile stress on the fretting fatigue life of an Ibis steel reinforced aluminium conductor. Int. J. Fatigue 2012, 42, 24–34. [Google Scholar] [CrossRef]

- Wan, D.; Brocks Hagen, A.; Viespoli, L.A.; Johanson, A.; Berto, F.; Alvaro, A. In-situ tensile and fatigue behavior of electrical grade Cu alloy for subsea cables. Mater. Sci. Eng. A 2022, 835, 142654. [Google Scholar] [CrossRef]

- Sobhaniasl, M.; Petrini, F.; Karimirad, M.; Bontempi, M. Fatigue Life Assessment for Power Cables in Floating Offshore Wind Turbines. Energies 2020, 13, 3096. [Google Scholar] [CrossRef]

- Lotsberg, I. Fatigue Design of Marine Structures; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Marta, M.; Mueller-Schuetze, S.; Ottersberg, H.; Isus Feu, D.; Johanning, L.; Thies, P.R. Development of Dynamic Submarine MV Power Cable Design Solutions for Floating Offshore Renewable Energy Applications. In Proceedings of the 9th International Conference on Insulated Power Cables Jicable’15, Versailles, France, 21–25 June 2015. [Google Scholar]

- Nasution, F.P.; Sævik, S.; Gjøsteen, J.K.Ø. Fatigue Analysis of Copper Conductor for Offshore Wind Turbines by Experimental and FE Method. Energy Procedia 2012, 24, 271–280. [Google Scholar] [CrossRef]

- Beier, D.; Schnepf, A.; Van Steel, S.; Ye, N.; Ong, M.C. Fatigue Analysis of Inter-Array Power Cables between Two Floating Offshore Wind Turbines Including a Simplified Method to Estimate Stress Factors. J. Mar. Sci. Eng. 2023, 11, 1254. [Google Scholar] [CrossRef]

- Thies, P.R.; Johanning, L.; Smith, G.H. Assessing Mechanical Loading Regimes and Fatigue Life of Marine Power Cables in Marine Energy Applications. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2012, 226, 18–32. [Google Scholar] [CrossRef]

- Yang, S.H.; Ringsberg, J.W.; Johnson, E. Parametric study of the dynamic motions and mechanical characteristics of power cables for wave energy converters. J. Mar. Sci. Technol. 2018, 23, 10–29. [Google Scholar] [CrossRef]

- Hu, H.; Yan, J.; Sævik, S.; Ye, N.; Lu, Q.; Bu, Y. Nonlinear Bending Behavior of a Multilayer Copper Conductor in a Dynamic Power Cable. Ocean Eng. 2022, 250, 110831. [Google Scholar] [CrossRef]

- Svensson, G. Fatigue Prediction Models of Dynamic Power Cables by Laboratory Testing and FE Analysis. Master’s Thesis, NTNU: Norwegian University of Science and Technology, Trondheim, Norway, 2020. [Google Scholar]

- Hou, J.P.; Wang, Q.; Yang, H.J.; Wu, X.M.; Li, C.H.; Zhang, Z.F.; Li, X.W. Fatigue and Fracture Behavior of a Cold-Drawn Commercially Pure Aluminum Wire. Materials 2016, 9, 764. [Google Scholar] [CrossRef]

- Burgsdorf, V. Recommendations for the Evaluation of Life Time of Transmission Line Conductors. Electra 1979, 63. Available online: https://www.e-cigre.org/publications/detail/elt-063-3-recommendations-for-the-evaluation-of-the-lifetime-of-transmission-line-conductors.html (accessed on 18 June 2025).

- Ramey, G.E.; Duncan, R.R.; Brunair, R.M. Experimental Evaluation of S-N Curves for Drake ACSR Conductor. J. Energy Eng. 1986, 112, 138–151. [Google Scholar] [CrossRef]

- Sonsino, C.M. Course of SN-curves especially in the high-cycle fatigue regime with regard to component design and safety. Int. J. Fatigue 2007, 29, 2246–2258. [Google Scholar] [CrossRef]

- Goto, M.; Han, S.Z.; Euh, K.; Kang, J.H.; Kim, S.S.; Kawagoishi, N. Formation of a high-cycle fatigue fracture surface and a crack growth mechanism of ultrafine-grained copper with different stages of microstructural evolution. Acta Mater. 2010, 58, 6294–6305. [Google Scholar] [CrossRef]

- Jurkiewicz, B.; Smyrak, B. Studies on the Evolution of Fatigue Strength of Aluminium Wires for Overhead Line Conductors. Materials 2024, 17, 2537. [Google Scholar] [CrossRef]

- Kaufman, J.G. Properties of Aluminium Alloys—Tensile, Creep and Fatigue Data at High and Low Temperature; The Aluminium Association: Arlington, VA, USA, 1999. [Google Scholar]

- Harlow, D.G. Statistically Modeling the Fatigue Life of Copper and Aluminum Wires Using Archival Data. Metals 2023, 13, 1419. [Google Scholar] [CrossRef]

- Abdellah, M.Y.; Karama, M.; Azam, S.A.; Alharthi, H.; Hassan, M.K. Fatigue Behavior of Copper Under Rotating Bending with Constant Reversed Amplitude. Am. J. Mech. Eng. 2024, 12, 1–9. [Google Scholar] [CrossRef]

- Tanaka, T.; Sugioka, T.; Kobayashi, T.; Shohji, I.; Shimada, Y.; Watanabe, H.; Kamakoshi, Y. Low Cycle Fatigue Characteristics of Oxygen-Free Copper for Electric Power Equipment. Materials 2021, 14, 4237. [Google Scholar] [CrossRef] [PubMed]

- Rocha, P.H.C.; Díaz, J.I.M.; Silva, C.R.M.; Araújo, J.A.; Castro, F.C. Fatigue of two contacting wires of the ACSR Ibis 397.5 MCM conductor: Experiments and life prediction. Int. J. Fatigue 2019, 127, 25–35. [Google Scholar] [CrossRef]

- Martineza, J.M.G.; Adriano, V.S.R.; Araújoa, J.A.; Ferreiraa, J.L.A.; da Silvaa, C.R.M. Geometrical size effect in the fatigue life predictions of aluminum wires with micro holes using methods of the critical distance. Eng. Fract. Mech. 2019, 209, 147–161. [Google Scholar] [CrossRef]

- Yue, F.; Jia, Y.; Zhang, M.; Song, H.; Shihong Zhang, S.; Guo, W.; Zhang, Z.; Pang, J. Research on very high cycle fatigue behavior of pure copper. Mater. Today Commun. 2025, 44, 112109. [Google Scholar] [CrossRef]

- Kuběna, I.A.; Chlupová, A.M.; Jambor, M.; Šulák, I.Z.; Chlup, Z.; Polák, J. Frequency-dependent fatigue damage in polycrystalline copper analyzed by FIB tomography. Acta Mater. 2021, 21, 116859. [Google Scholar] [CrossRef]

- Marti, N.; Favier, W.; Gregori, F.; Nicolas Sain, N. Correlation of the low and high frequency fatigue responses of pure polycrystalline copper with mechanisms of slip band formation. Mater. Sci. Eng. A 2020, 772, 138619. [Google Scholar] [CrossRef]

| Material | Chemical Composition [% by Weight]. | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Al Min. | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ga | |

| Aluminium | 97.72 | 0.03 | 0.10 | 0.04 | 0.002 | 0.001 | 0.001 | 0.03 | 0.01 |

| Material | Chemical Composition [% by Weight]. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu | O2 | Ag | Bi | Pb | Sb | As | Fe | Ni | Sn | Zn | S | Se | Te | |

| Cu-ETP | 99.99 | 0.019 | 0.0009 | 0.00001 | 0.00007 | 0.00006 | 0.00006 | 0.000017 | 0.000017 | 0.000003 | 0.00008 | 0.000025 | 0.000001 | 0.000002 |

| Material | Diameter d0 | Diameter d1 [mm] | Engineering Strain | UTS [MPa] | YP [MPa] | Elongation [%] |

|---|---|---|---|---|---|---|

| [mm] | [%] | |||||

| EN AW-1370 | 9.50 | 3.00 | 90 | 168 | 139 | 1.54 |

| EN AW-1370 | 3.08 | 3.00 | 5 | 66 | 52 | 26.0 |

| Cu-ETP | 9.50 | 3.00 | 90 | 433 | 413 | 3.50 |

| Cu-ETP | 3.08 | 3.00 | 5 | 245 | 170 | 28.4 |

| Material | Applied Max Bending Stress [MPa] | |||||||

|---|---|---|---|---|---|---|---|---|

| EN AW-1370 | 120 | 105 | 90 | 75 | 60 | 45 | 30 | 15 |

| Cu-ETP | 344 | 295 | 246 | 197 | 149 | 120 | 100 | 75 |

| Test No | Cu Wires | Al Wires | ||||

|---|---|---|---|---|---|---|

| Bending/Rotary Stress, MPa | Number of Cycles to Failure | Bending/Rotary Stress, MPa | Number of Cycles to Failure | |||

| 5% (SH) | 90% (SH) | 5% (SH) | 90% (SH) | |||

| 1 | 344 | 1.50 × 103 | 3.10 × 105 | 120 | 1.80 × 103 | 2.58 × 104 |

| 295 | 1.00 × 103 | 2.88 × 106 | 105 | 1.00 × 104 | 1.44 × 105 | |

| 246 | 5.28 × 104 | 6.66 × 106 | 90 | 7.20 × 103 | 8.88 × 104 | |

| 197 | 5.85 × 104 | 2.25 × 107 | 75 | 4.00 × 104 | 2.70 × 105 | |

| 149 | 1.60 × 106 | 7.40 × 107 | 60 | 2.30 × 104 | 5.67 × 106 | |

| 120 | 2.20 × 106 | 3.60 × 108 | 45 | 6.93 × 105 | 9.80 × 106 | |

| 100 | 5.71 × 106 | 2.24 × 108 | 30 | 1.88 × 106 | 2.58 × 107 | |

| 75 | 3.09 × 107 | 6.00 × 109 | 15 | 1.05 × 107 | 9.00 × 107 | |

| 2 | 344 | 2.20 × 103 | 5.93 × 105 | 120 | 1.40 × 103 | 3.87 × 104 |

| 295 | 2.52 × 103 | 5.76 × 106 | 105 | 2.04 × 105 | 1.87 × 105 | |

| 246 | 8.40 × 104 | 8.88 × 106 | 90 | 1.92 × 104 | 2.66 × 105 | |

| 197 | 8.55 × 104 | 2.25 × 107 | 75 | 3.43 × 104 | 3.87 × 105 | |

| 149 | 1.49 × 106 | 7.40 × 107 | 60 | 9.80 × 104 | 5.92 × 106 | |

| 120 | 2.21 × 106 | 3.60 × 108 | 45 | 5.05 × 105 | 9.80 × 106 | |

| 100 | 6.72 × 106 | 3.36 × 108 | 30 | 1.48 × 106 | 2.75 × 107 | |

| 75 | 3.14 × 107 | 6.22 × 109 | 15 | 1.05 × 107 | 9.70 × 107 | |

| 3 | 344 | 2.20 × 103 | 8.51 × 105 | 120 | 1.78 × 103 | 5.94 × 104 |

| 295 | 5.04 × 103 | 1.15 × 107 | 105 | 7.00 × 104 | 1.99 × 105 | |

| 246 | 9.12 × 104 | 1.55 × 107 | 90 | 8.60 × 103 | 3.82 × 105 | |

| 197 | 1.80 × 105 | 2.25 × 107 | 75 | 3.00 × 103 | 5.94 × 105 | |

| 149 | 1.92 × 106 | 7.40 × 107 | 60 | 2.20 × 104 | 6.44 × 106 | |

| 120 | 2.22 × 106 | 3.60 × 108 | 45 | 3.80 × 105 | 9.86 × 106 | |

| 100 | 7.56 × 106 | 6.73 × 108 | 30 | 1.60 × 106 | 2.93 × 107 | |

| 75 | 3.14 × 107 | 7.00 × 109 | 15 | 1.00 × 107 | 8.02 × 107 | |

| 4 | 344 | 4.40 × 103 | 8.26 × 105 | 120 | 2.00 × 103 | 7.74 × 104 |

| 295 | 3.84 × 103 | 1.44 × 107 | 105 | 1.28 × 105 | 2.30 × 105 | |

| 246 | 6.00 × 104 | 1.33 × 107 | 90 | 2.30 × 104 | 7.10 × 105 | |

| 197 | 1.26 × 105 | 2.25 × 107 | 75 | 9.77 × 104 | 7.83 × 105 | |

| 149 | 2.13 × 106 | 7.40 × 107 | 60 | 1.48 × 105 | 8.63 × 106 | |

| 120 | 2.30 × 106 | 3.60 × 108 | 45 | 7.00 × 105 | 9.99 × 106 | |

| 100 | 1.31 × 107 | 7.85 × 108 | 30 | 1.51 × 106 | 3.13 × 107 | |

| 75 | 4.18 × 107 | 6.90 × 109 | 15 | 1.10 × 107 | 9.62 × 107 | |

| Lp. | Material | Strain Hardening [%] | C [−] | Z [−] |

|---|---|---|---|---|

| 1 | EN AW 1370 | 5 | 963 | −0.253 |

| 2 | EN AW 1370 | 90 | 2349 | −0.256 |

| 3 | Cu-ETP | 5 | 725 | −0.127 |

| 4 | Cu-ETP | 90 | 3674 | −0.174 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Knych, T.; Smyrak, B.; Jurkiewicz, B. A Comparative Analysis of the Fatigue Strength of Aluminium and Copper Wires Used for Power Cables. Materials 2025, 18, 4426. https://doi.org/10.3390/ma18184426

Knych T, Smyrak B, Jurkiewicz B. A Comparative Analysis of the Fatigue Strength of Aluminium and Copper Wires Used for Power Cables. Materials. 2025; 18(18):4426. https://doi.org/10.3390/ma18184426

Chicago/Turabian StyleKnych, Tadeusz, Beata Smyrak, and Bartosz Jurkiewicz. 2025. "A Comparative Analysis of the Fatigue Strength of Aluminium and Copper Wires Used for Power Cables" Materials 18, no. 18: 4426. https://doi.org/10.3390/ma18184426

APA StyleKnych, T., Smyrak, B., & Jurkiewicz, B. (2025). A Comparative Analysis of the Fatigue Strength of Aluminium and Copper Wires Used for Power Cables. Materials, 18(18), 4426. https://doi.org/10.3390/ma18184426