Crack-Mitigating Strategy in Directed Energy Deposition of Refractory Complex Concentrated CrNbTiZr Alloy

Abstract

1. Introduction

2. Materials and Methods

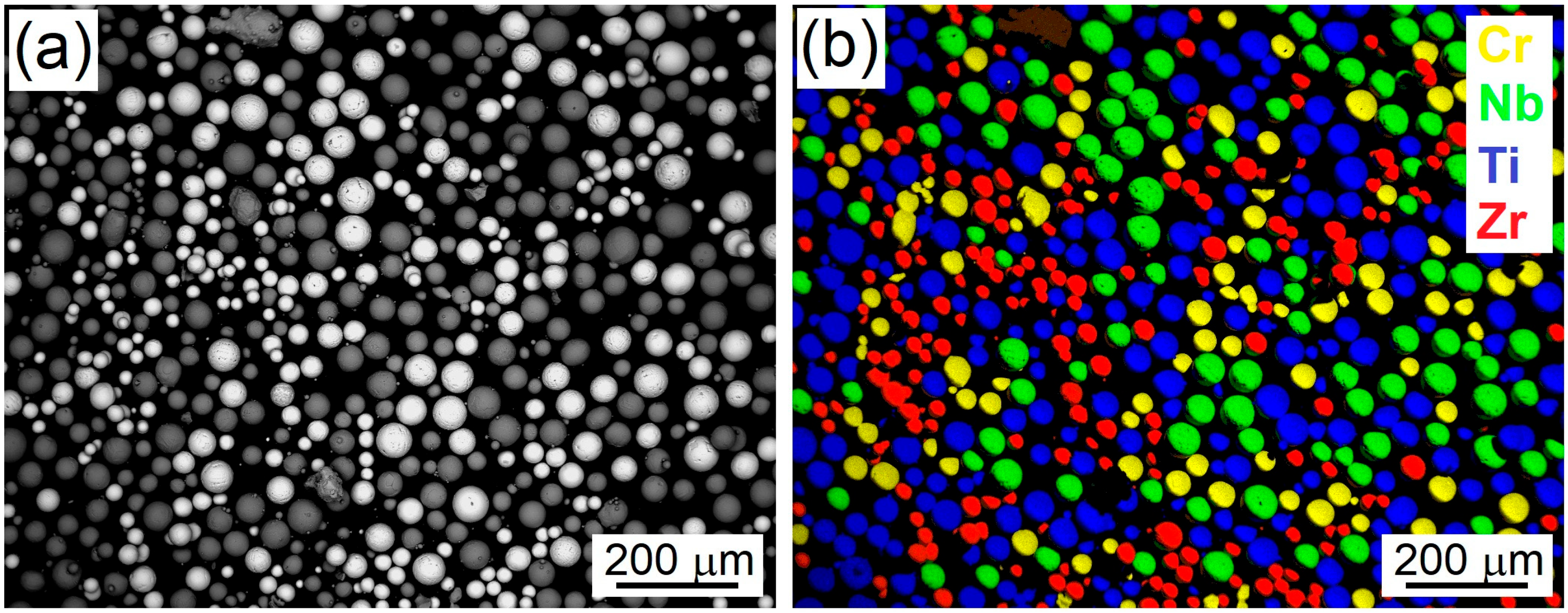

2.1. Powder Mixture Characteristics and Preparation

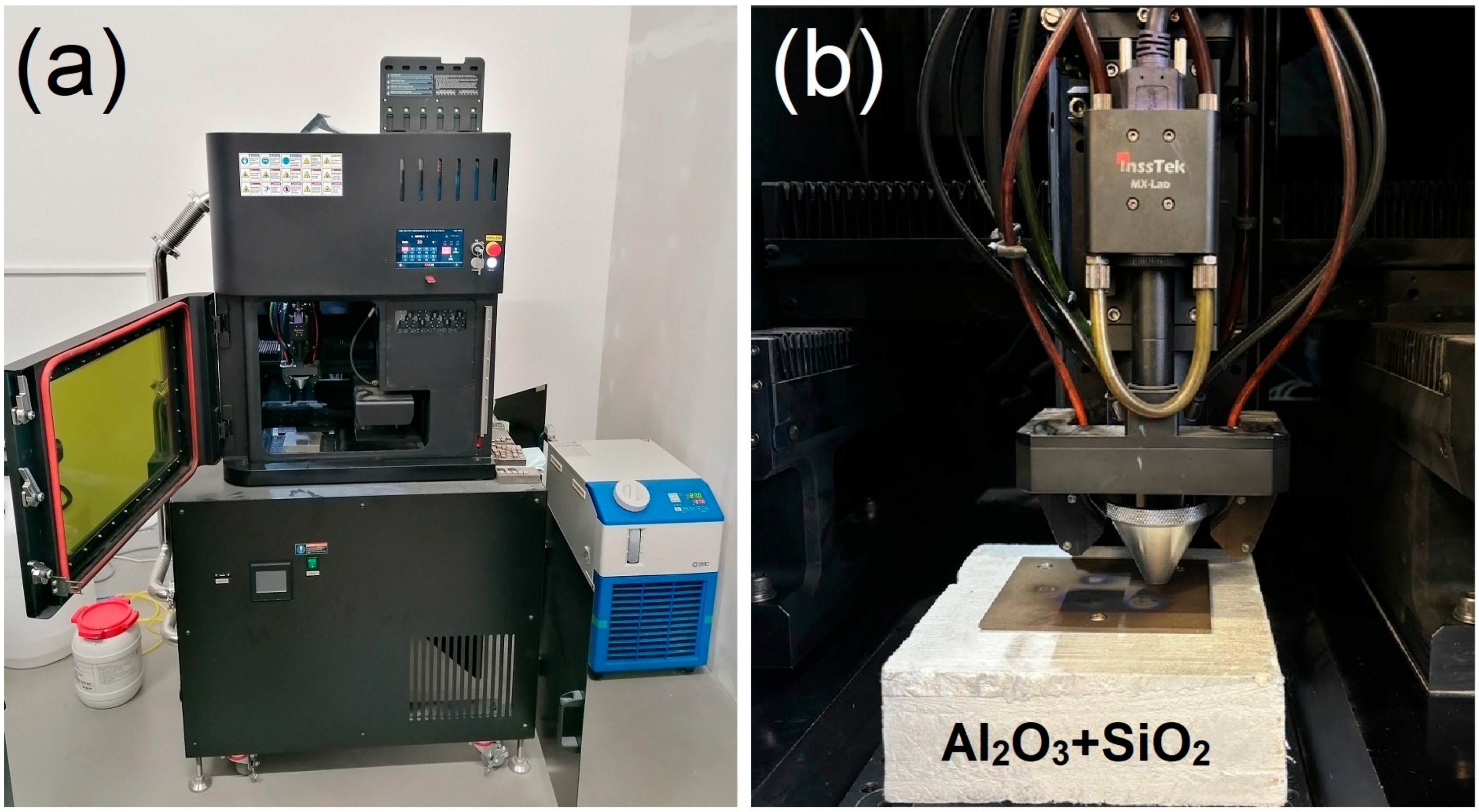

2.2. Directed Energy Deposition of the Experimental Material

2.3. Material Characterization

3. Results

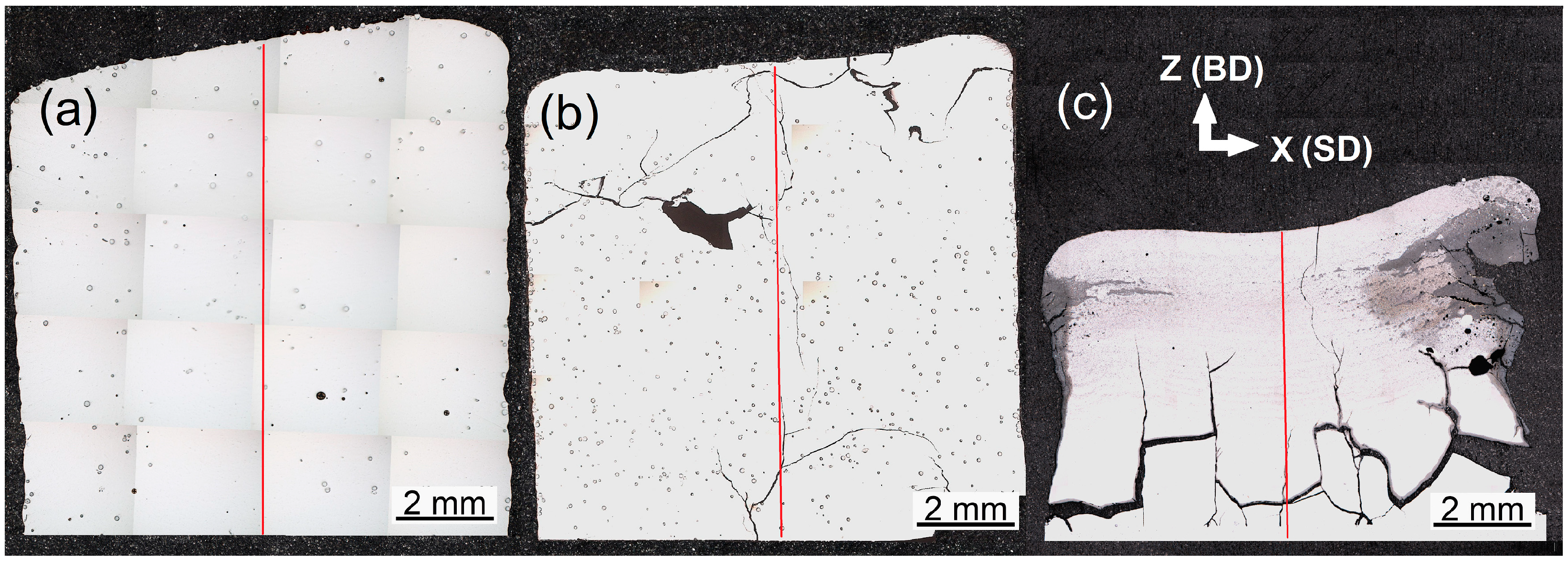

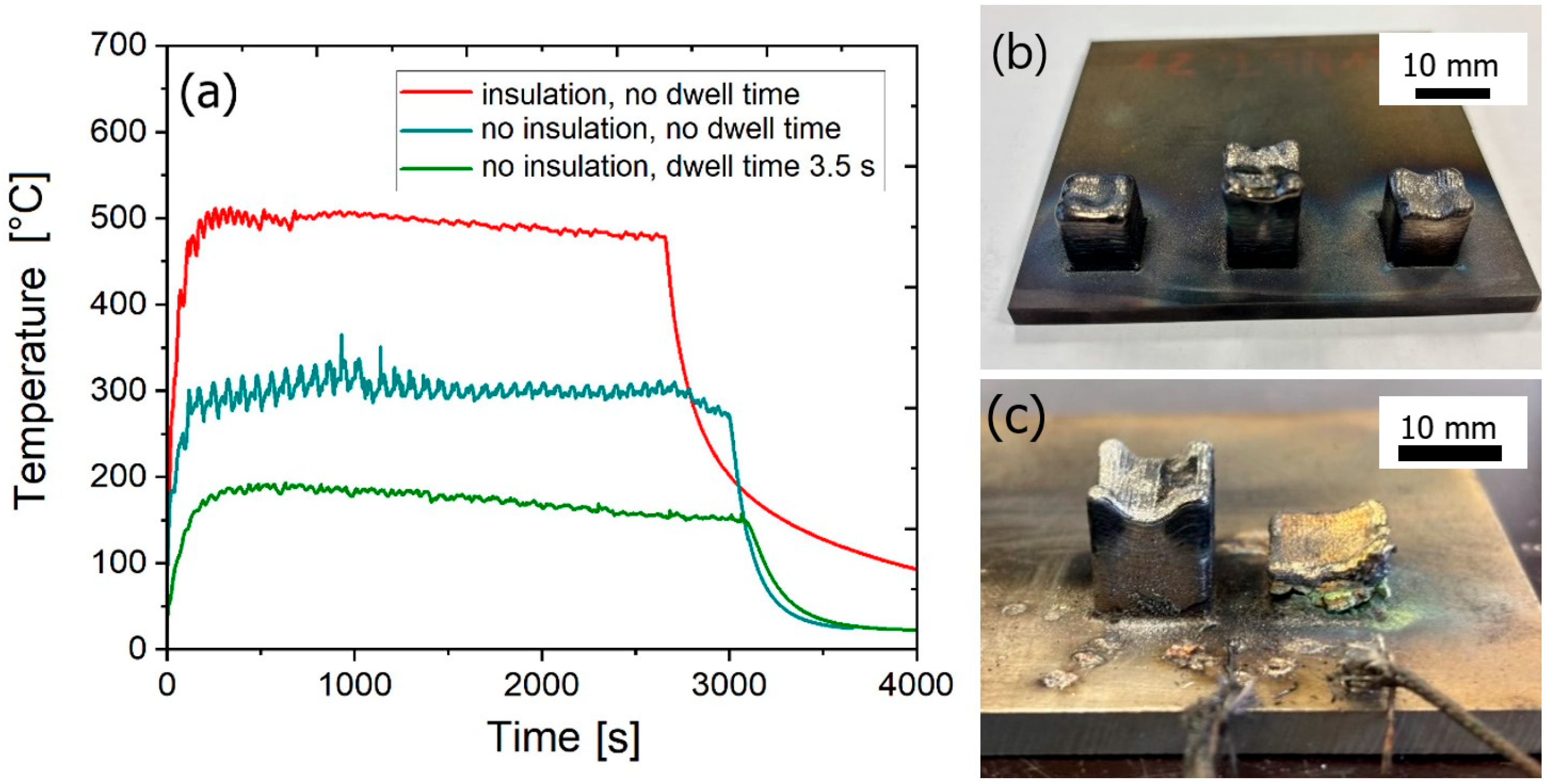

3.1. Microstructure Comparison of Samples Deposited on Conductive and Thermally Insulated Platform

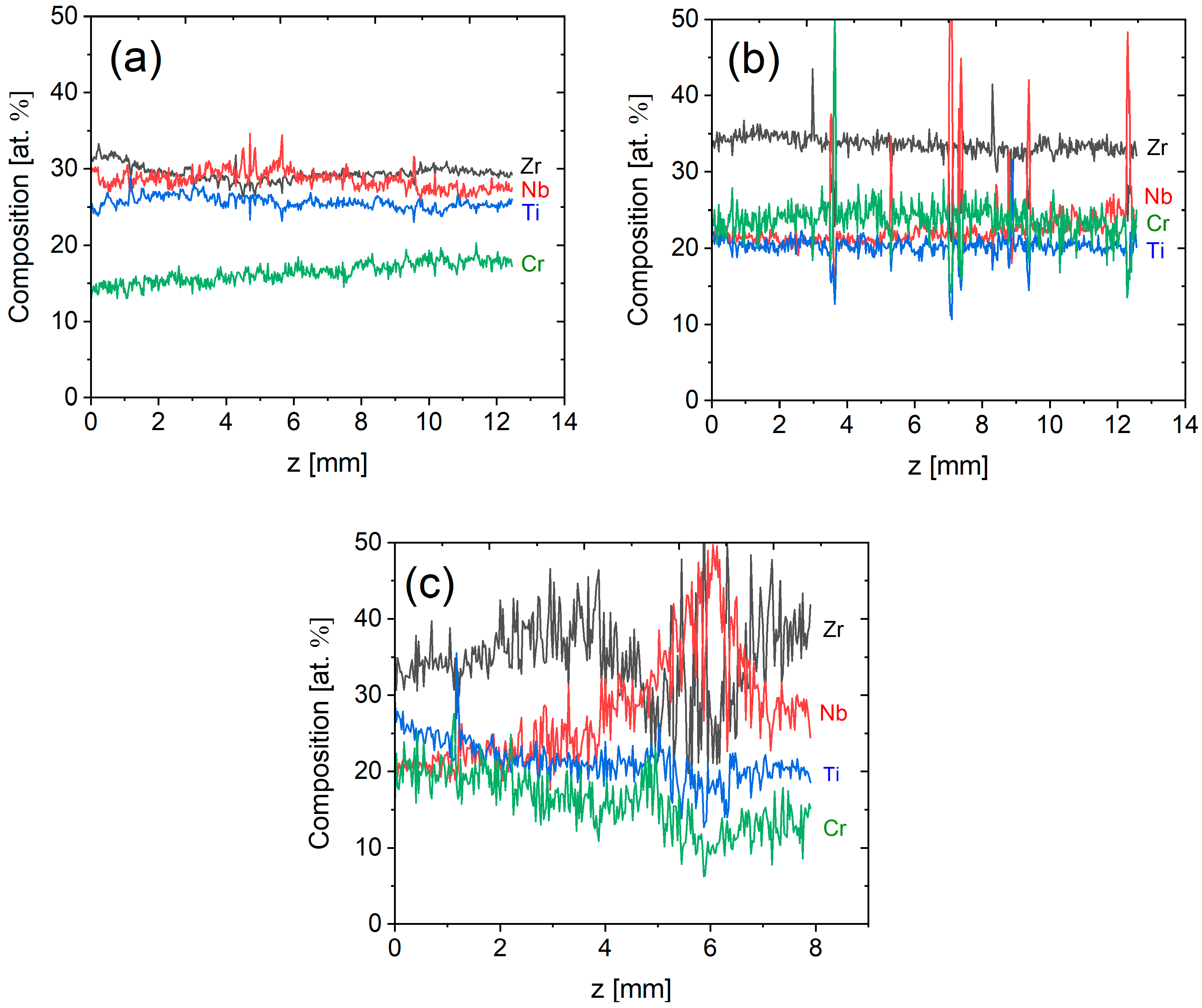

3.2. Chemical Composition of the Samples Along Z-Axis

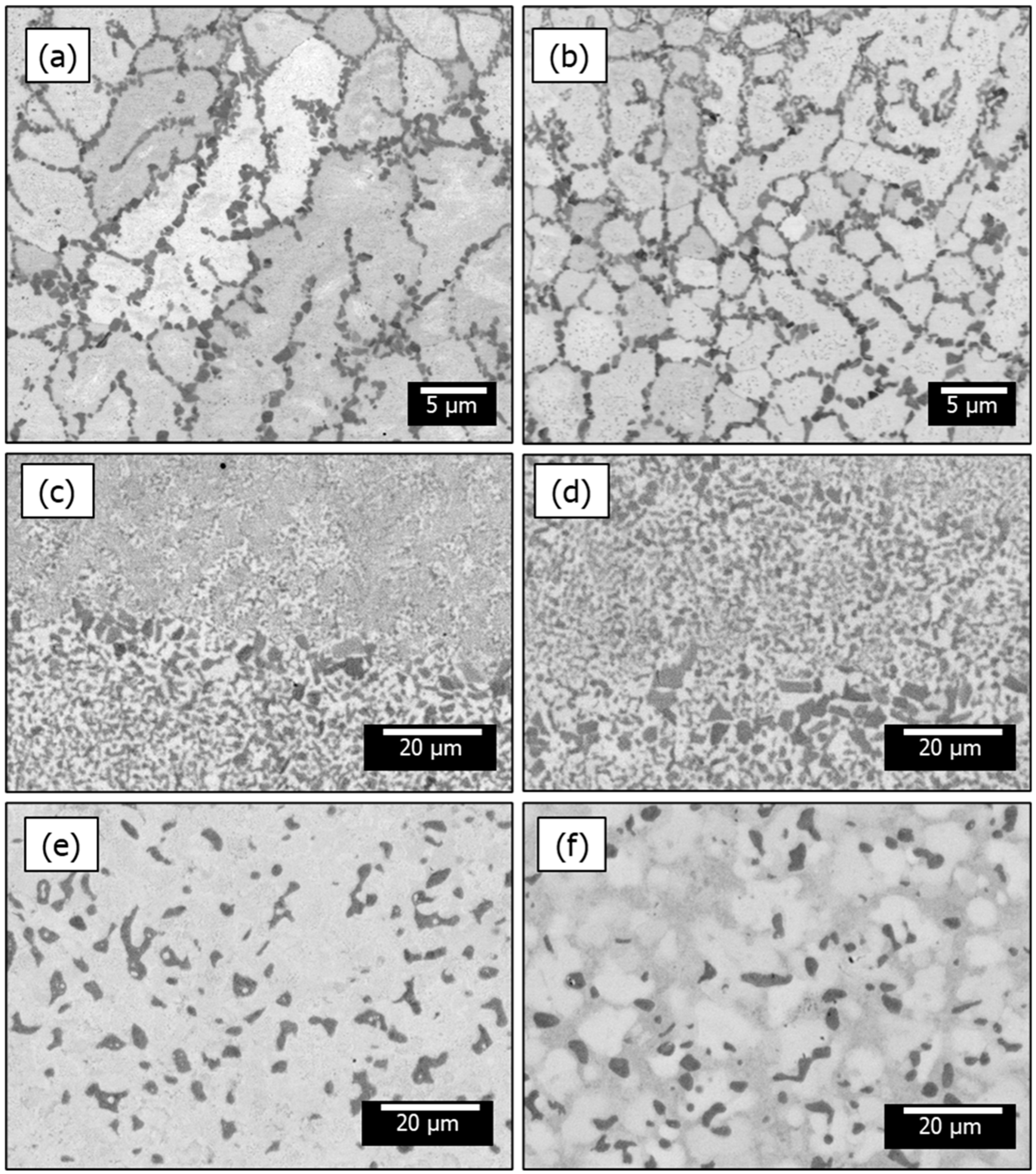

3.3. Microstructural Dependence on Processing Conditions

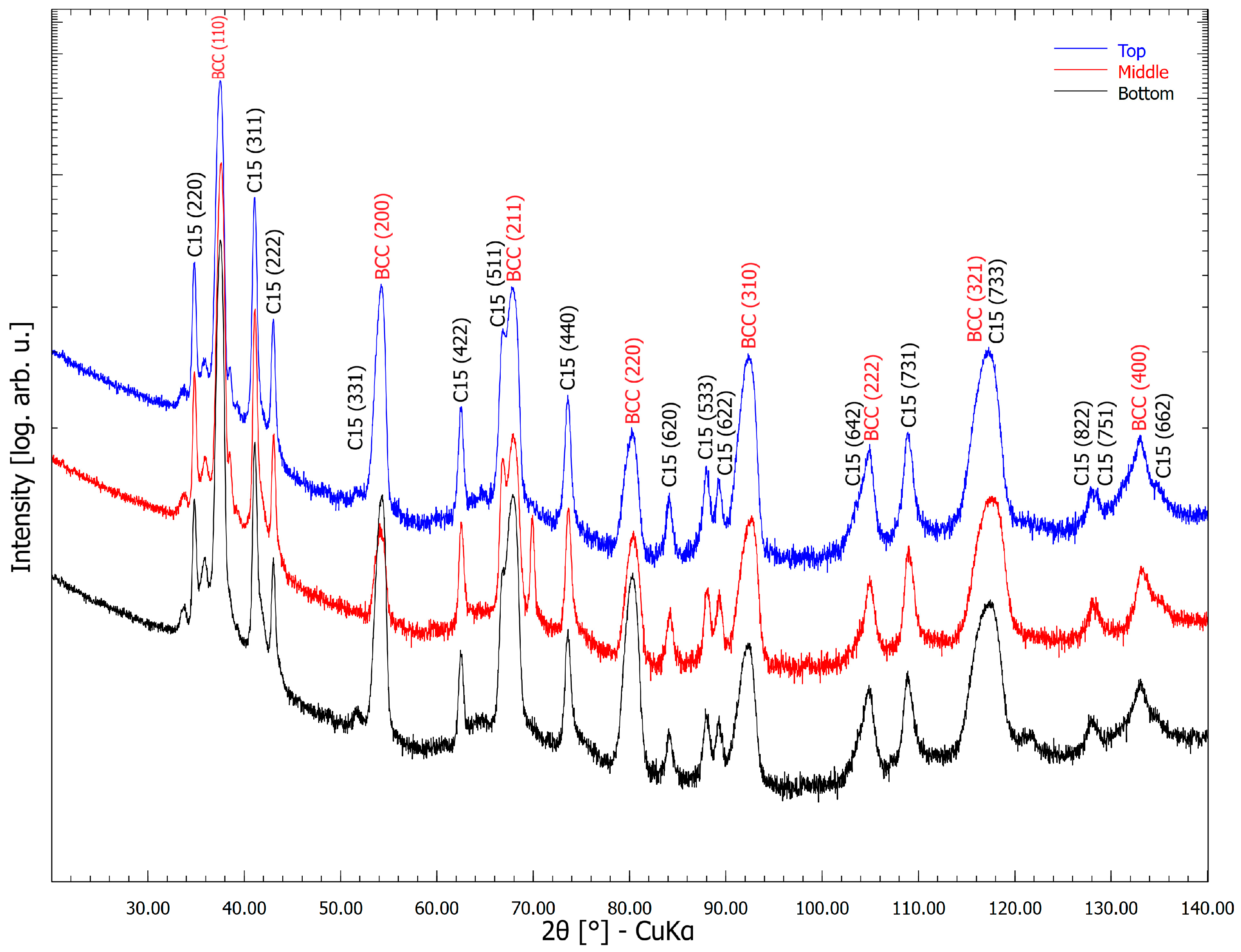

3.4. Phase Composition

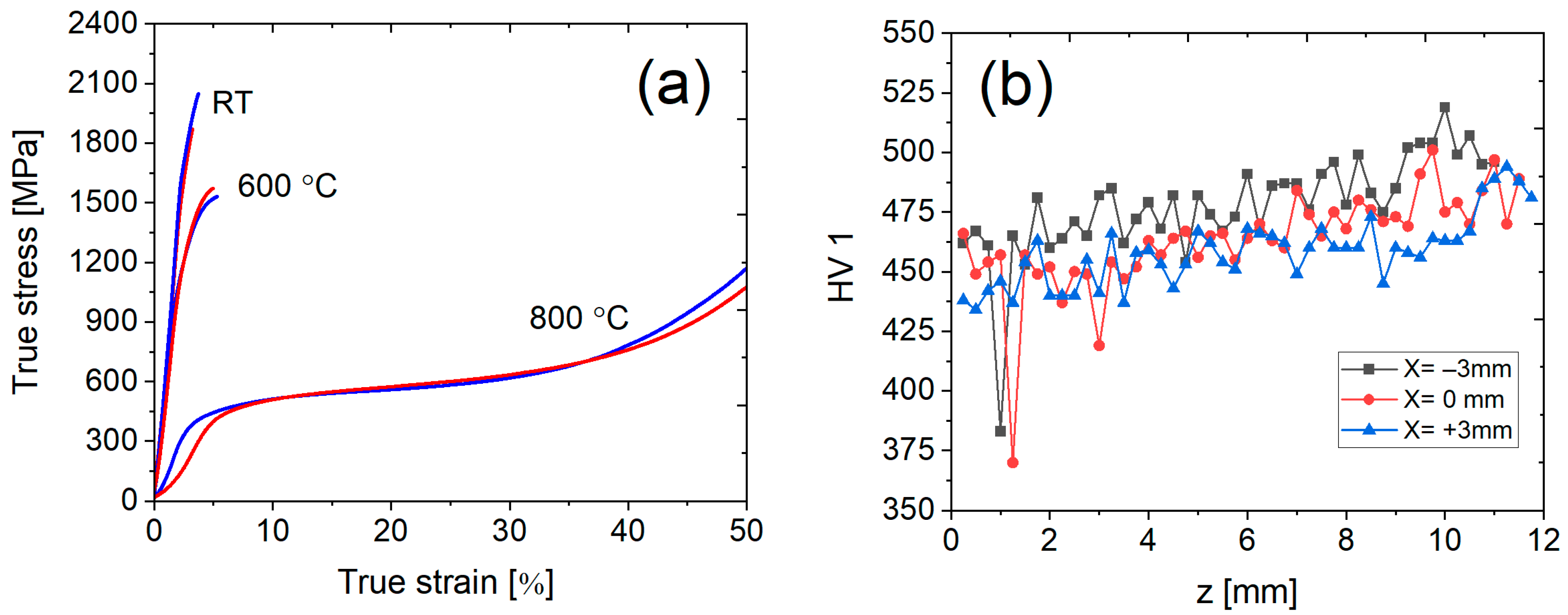

3.5. Mechanical Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HEA | High Entropy Alloy |

| DED | Directed Energy Deposition |

| L-DED | Laser Directed Energy Deposition |

| SEM | Scanning Electron Microscope |

| OM | Optical Microscope |

| EDS | Energy Dispersive Spectroscopy |

| CCA | Complex Concentrated Alloy |

| RCCA | Refractory Complex Concentrated Alloy |

| SD | Scanning direction |

| BD | Build direction |

References

- Eswarappa Prameela, S.; Pollock, T.M.; Raabe, D.; Meyers, M.A.; Aitkaliyeva, A.; Chintersingh, K.-L.; Cordero, Z.C.; Graham-Brady, L. Materials for extreme environments. Nat. Rev. Mater. 2022, 8, 81–88. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Senkov, O.N.; Zhang, C.; Pilchak, A.L.; Payton, E.J.; Woodward, C.; Zhang, F. CALPHAD-aided development of quaternary multi-principal element refractory alloys based on NbTiZr. J. Alloys Compd. 2019, 783, 729–742. [Google Scholar] [CrossRef]

- Chen, B.; Zhuo, L. Latest progress on refractory high entropy alloys: Composition, fabrication, post processing, performance, simulation and prospect. Int. J. Refract. Met. Hard Mater. 2023, 110, 105993. [Google Scholar] [CrossRef]

- Mooraj, S.; Kim, G.; Fan, X.; Samuha, S.; Xie, Y.; Li, T.; Tiley, J.S.; Chen, Y.; Yu, D.; An, K.; et al. Additive manufacturing of defect-free TiZrNbTa refractory high-entropy alloy with enhanced elastic isotropy via in-situ alloying of elemental powders. Commun. Mater. 2024, 5, 14. [Google Scholar] [CrossRef]

- Lang, E.; Burns, K.; Wang, Y.; Kotula, P.G.; Kustas, A.B.; Rodriguez, S.; Aitkaliyeva, A.; Hattar, K. Compositional Effects of Additively Manufactured Refractory High-Entropy Alloys under High-Energy Helium Irradiation. Nanomaterials 2022, 12, 2014. [Google Scholar] [CrossRef]

- Melia, M.A.; Whetten, S.R.; Puckett, R.; Jones, M.; Heiden, M.J.; Argibay, N.; Kustas, A.B. High-throughput additive manufacturing and characterization of refractory high entropy alloys. Appl. Mater. Today 2020, 19, 100560. [Google Scholar] [CrossRef]

- Wang, H.; Gould, B.; Moorehead, M.; Haddad, M.; Couet, A.; Wolff, S.J. In situ X-ray and thermal imaging of refractory high entropy alloying during laser directed deposition. J. Mater. Process. Technol. 2022, 299, 117363. [Google Scholar] [CrossRef]

- Dobbelstein, H.; Gurevich, E.L.; George, E.P.; Ostendorf, A.; Laplanche, G. Laser metal deposition of a refractory TiZrNbHfTa high-entropy alloy. Addit. Manuf. 2018, 24, 386–390. [Google Scholar] [CrossRef]

- Dobbelstein, H.; Gurevich, E.L.; George, E.P.; Ostendorf, A.; Laplanche, G. Laser metal deposition of compositionally graded TiZrNbTa refractory high-entropy alloys using elemental powder blends. Addit. Manuf. 2019, 25, 252–262. [Google Scholar] [CrossRef]

- Dobbelstein, H.; George, E.P.; Gurevich, E.L.; Kostka, A.; Ostendorf, A.; Laplanche, G. Laser metal deposition of refractory high-entropy alloys for high-throughput synthesis and structure-property characterization. Int. J. Extrem. Manuf. 2020, 3, 015201. [Google Scholar] [CrossRef]

- Cheng, W.; Ji, L.; Zhang, L.; Wang, H.; Sun, W. Refractory high-entropy alloys fabricated using laser technologies: A concrete review. J. Mater. Res. Technol. 2023, 24, 7497–7524. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, H.; Li, D.; Chen, Z.; Huang, S.; Lu, Z.; Yan, H. W(x)NbMoTa Refractory High-Entropy Alloys Fabricated by Laser Cladding Deposition. Materials 2019, 12, 533. [Google Scholar] [CrossRef]

- Krajňák, T.; Janeček, M.; Preisler, D.; Stráský, J.; Kozlík, J.; Škraban, T.; Brázda, M.; Džugan, J. Microstructure evolution in compositionally graded Ti(4–12 wt% Mo) prepared by laser directed energy deposition. J. Mater. Res. Technol. 2023, 23, 4527–4537. [Google Scholar] [CrossRef]

- Moorehead, M.; Bertsch, K.; Niezgoda, M.; Parkin, C.; Elbakhshwan, M.; Sridharan, K.; Zhang, C.; Thoma, D.; Couet, A. High-throughput synthesis of Mo-Nb-Ta-W high-entropy alloys via additive manufacturing. Mater. Des. 2020, 187, 108358. [Google Scholar] [CrossRef]

- Preisler, D.; Krajňák, T.; Janeček, M.; Kozlík, J.; Stráský, J.; Brázda, M.; Džugan, J. Directed energy deposition of bulk Nb-Ta-Ti-Zr refractory complex concentrated alloy. Mater. Lett. 2023, 337, 133980. [Google Scholar] [CrossRef]

- Dobbelstein, H.; Thiele, M.; Gurevich, E.L.; George, E.P.; Ostendorf, A. Direct Metal Deposition of Refractory High Entropy Alloy MoNbTaW. Phys. Procedia 2016, 83, 624–633. [Google Scholar] [CrossRef]

- Yurchenko, N.; Panina, E.; Moskovskikh, D.; Kapustin, D.; Zhilina, M.; Shekhawat, L.; Novikov, V.; Geller, A.; Salishchev, G.; Zherebtsov, S.; et al. Strength and oxidation resistance of Laves phase-containing refractory Nb-Ti-Zr-Cr alloys: Effect of chemical complexity. Scr. Mater. 2024, 243, 115978. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, Q.; Yang, C.; Yang, Z.; Yin, B.; Yang, Y. Initial oxidation behavior of AlCrMoNbTi high-entropy alloys studied by DFT calculations and experiments. Intermetallics 2025, 176, 108549. [Google Scholar] [CrossRef]

- Chen, H.; Kauffmann, A.; Gorr, B.; Schliephake, D.; Seemüller, C.; Wagner, J.N.; Christ, H.J.; Heilmaier, M. Microstructure and mechanical properties at elevated temperatures of a new Al-containing refractory high-entropy alloy Nb-Mo-Cr-Ti-Al. J. Alloys Compd. 2016, 661, 206–215. [Google Scholar] [CrossRef]

- Senkov, O.N.; Rao, S.; Chaput, K.J.; Woodward, C. Compositional effect on microstructure and properties of NbTiZr-based complex concentrated alloys. Acta Mater. 2018, 151, 201–215. [Google Scholar] [CrossRef]

- Senkov, O.N.; Gorsse, S.; Miracle, D.B. High temperature strength of refractory complex concentrated alloys. Acta Mater. 2019, 175, 394–405. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Woodward, C.; Miracle, D.B. Low-density, refractory multi-principal element alloys of the Cr–Nb–Ti–V–Zr system: Microstructure and phase analysis. Acta Mater. 2013, 61, 1545–1557. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Miracle, D.B.; Woodward, C. Mechanical properties of low-density, refractory multi-principal element alloys of the Cr–Nb–Ti–V–Zr system. Mater. Sci. Eng. A 2013, 565, 51–62. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, Y.; Marussi, S.; Fan, X.; Fitzpatrick, M.; Bhagavath, S.; Majkut, M.; Lukic, B.; Jakata, K.; Rack, A.; et al. Pore evolution mechanisms during directed energy deposition additive manufacturing. Nat. Commun. 2024, 15, 1715. [Google Scholar] [CrossRef] [PubMed]

- Krajňák, T.; Preisler, D.; Kout, J.; Stráský, J.; Kozlík, J.; Harcuba, P.; Casas-Luna, M.; Janeček, M.; Džugan, J. Microstructure and high temperature mechanical properties of refractory Cr-Nb-Ti-Zr alloy prepared by laser directed energy deposition. Mater. Today Commun. 2025, 47, 112951. [Google Scholar] [CrossRef]

- Mooraj, S.; Dong, X.; Zhang, S.; Zhang, Y.; Ren, J.; Guan, S.; Li, C.; Naorem, R.; Argibay, N.; Chen, W.; et al. Crack mitigation in additively manufactured AlCrFe2Ni2 high-entropy alloys through engineering phase transformation pathway. Commun. Mater. 2024, 5, 101. [Google Scholar] [CrossRef]

- ISO 6507-1:2023; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. ISO: Geneva, Switzerland, 2023.

- Samanta, B.; Jain, A. Experimental investigation of lattice thermal expansion and specific heat capacity of C15–Cr2Zr Laves phase intermetallic compound by HTXRD and DSC. Intermetallics 2022, 148, 107634. [Google Scholar] [CrossRef]

- Krajňák, T.; Janeček, M.; Kozlík, J.; Preisler, D.; Stráský, J.; Brázda, M.; Kout, J.; Halmešová, K.; Džugan, J. Influence of the thermal history on the phase composition of laser directed energy deposited Ti-8.5 wt% Mo alloy. Mater. Des. 2022, 222, 111049. [Google Scholar] [CrossRef]

| Powder | Cr | Nb | Ti | Zr |

|---|---|---|---|---|

| Supplier | Stanford Advanced Materials, Lake Forest, CA, USA | Camex, Měšice, Czechia | AP&C, Boisbriand, QC, Canada | Camex, Měšice, Czechia |

| Particle size | 50–150 µm | 50–150 µm | 45–150 µm | 50–150 µm |

| Declared Purity | 99.9% | 99.9% | ASTM Grade 2 | 99.9% |

| Oxygen concentration (wt. %) | 0.02 | 0.15 | 0.17 | 0.22 |

| Nitrogen concentration (wt. %) | 0.01 | 0.04 | 0.02 | 0.03 |

| Laser Spot Diameter (µm) | Laser Power (W) | Scanning Velocity (mm/min) | Hatch Spacing (µm) | Layer Thickness (µm) | Powder Feed Rate (g/min) |

|---|---|---|---|---|---|

| 400 | 500 | 850 | 300 | 150 | 0.5 |

| Section | Cr | Nb | Ti | Zr |

|---|---|---|---|---|

| Top | 21 ± 2 | 28 ± 2 | 27 ± 3 | 23 ± 2 |

| Bottom | 17 ± 3 | 29 ± 2 | 28 ± 3 | 25 ± 2 |

| Position | Bottom | Top | ||||||

|---|---|---|---|---|---|---|---|---|

| Cr | Nb | Ti | Zr | Cr | Nb | Ti | Zr | |

| Dendritic regions (bright) | 9 ± 1 | 38 ± 2 | 27 ± 1 | 26 ± 2 | 10 ± 1 | 34 ± 2 | 29 ± 1 | 27 ± 1 |

| Inter-dendritic regions (dark) | 29 ± 4 | 19 ± 3 | 22 ± 2 | 30 ± 2 | 33 ± 3 | 19 ± 2 | 20 ± 2 | 28 ± 1 |

| Temperature | Section | σ0.2 (MPa) | σmax (MPa) | εf (%) |

|---|---|---|---|---|

| 800 °C | Top | 436 ± 21 | 1171 ± 58 | >50% |

| Bottom | 388 ± 19 | 1077 ± 53 | >50% | |

| 600 °C | Top | 1237 ± 61 | 1496 ± 74 | 5.3 ± 0.3 |

| Bottom | 1026 ± 51 | 1452 ± 72 | 5.6 ± 0.3 | |

| RT | Top | 1800 ± 90 | 1973 ± 98 | 3.8 ± 0.2 |

| Bottom | 1669 ± 83 | 1810 ± 90 | 3.4 ± 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kout, J.; Krajňák, T.; Salvetr, P.; Podaný, P.; Brázda, M.; Preisler, D.; Janeček, M.; Harcuba, P.; Stráský, J.; Džugan, J. Crack-Mitigating Strategy in Directed Energy Deposition of Refractory Complex Concentrated CrNbTiZr Alloy. Materials 2025, 18, 3653. https://doi.org/10.3390/ma18153653

Kout J, Krajňák T, Salvetr P, Podaný P, Brázda M, Preisler D, Janeček M, Harcuba P, Stráský J, Džugan J. Crack-Mitigating Strategy in Directed Energy Deposition of Refractory Complex Concentrated CrNbTiZr Alloy. Materials. 2025; 18(15):3653. https://doi.org/10.3390/ma18153653

Chicago/Turabian StyleKout, Jan, Tomáš Krajňák, Pavel Salvetr, Pavel Podaný, Michal Brázda, Dalibor Preisler, Miloš Janeček, Petr Harcuba, Josef Stráský, and Jan Džugan. 2025. "Crack-Mitigating Strategy in Directed Energy Deposition of Refractory Complex Concentrated CrNbTiZr Alloy" Materials 18, no. 15: 3653. https://doi.org/10.3390/ma18153653

APA StyleKout, J., Krajňák, T., Salvetr, P., Podaný, P., Brázda, M., Preisler, D., Janeček, M., Harcuba, P., Stráský, J., & Džugan, J. (2025). Crack-Mitigating Strategy in Directed Energy Deposition of Refractory Complex Concentrated CrNbTiZr Alloy. Materials, 18(15), 3653. https://doi.org/10.3390/ma18153653