MICP-Treated Coral Aggregate and Its Application in Marine Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Sample Preparation and Experimental Methods

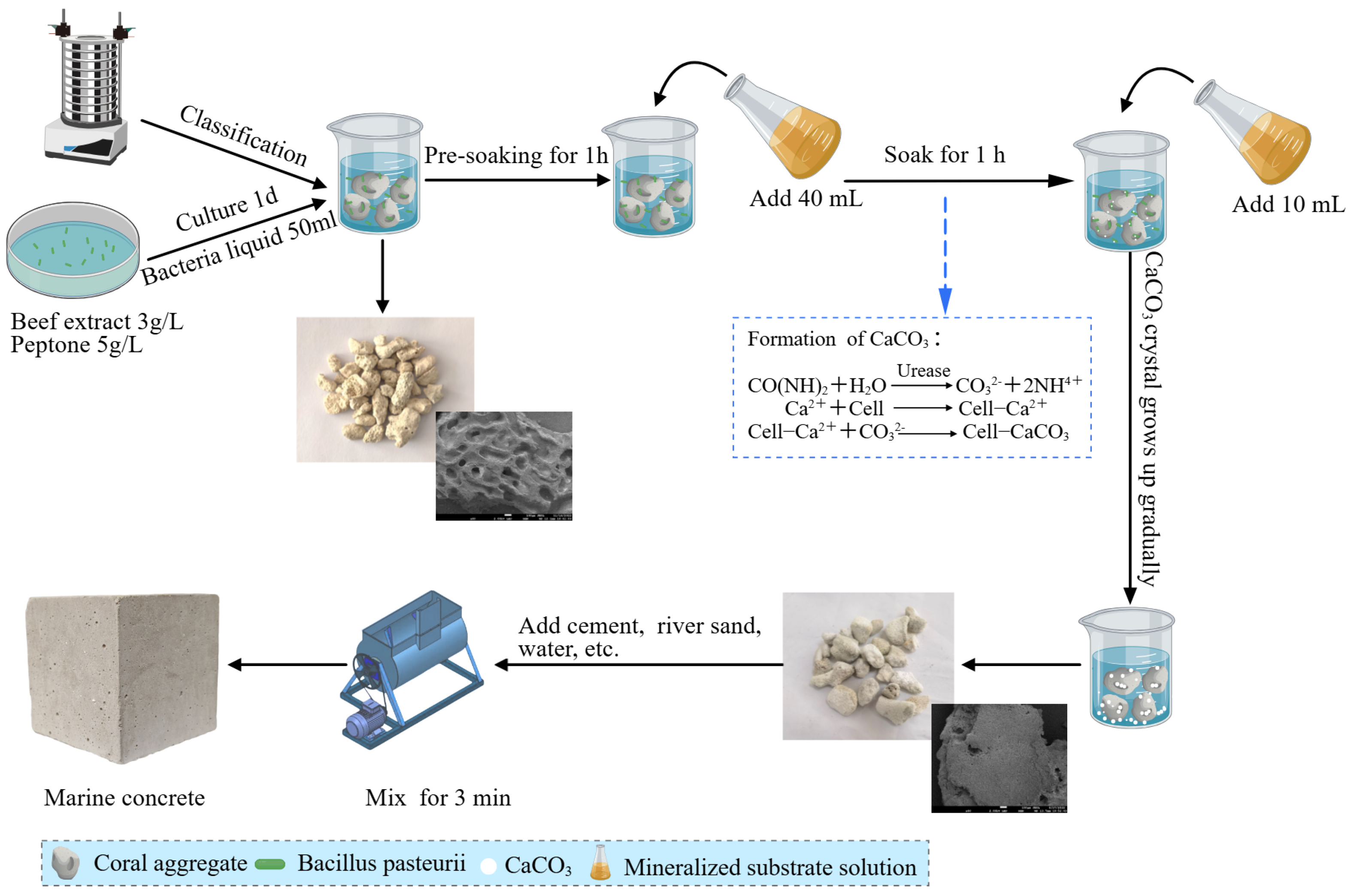

2.2.1. Treatment and Experimental Methods for Coral Aggregates

2.2.2. Preparation and Experimental Method of Coral Concrete

2.3. Experimental Characterization

2.3.1. Water Absorption and Apparent Density of Coral Aggregate

2.3.2. Deposition Efficiency

2.3.3. Basic Properties of Coral Concrete

- (1)

- Workability of fresh concrete

- (2)

- Mechanical behavior of concrete

2.3.4. Mineral Composition Analysis

2.3.5. Morphology Analysis

3. Results

3.1. MICP-Treated Coral Aggregates with Single Particle Size Fraction

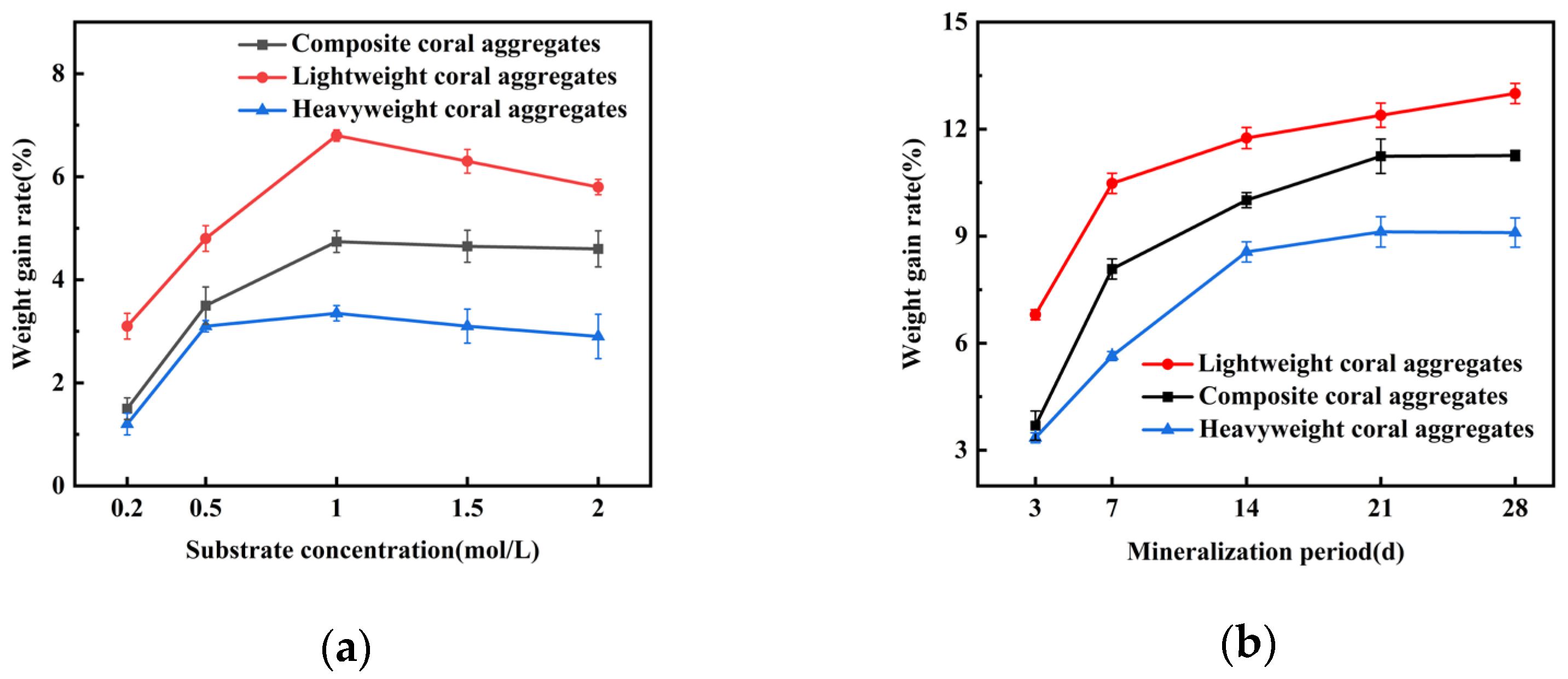

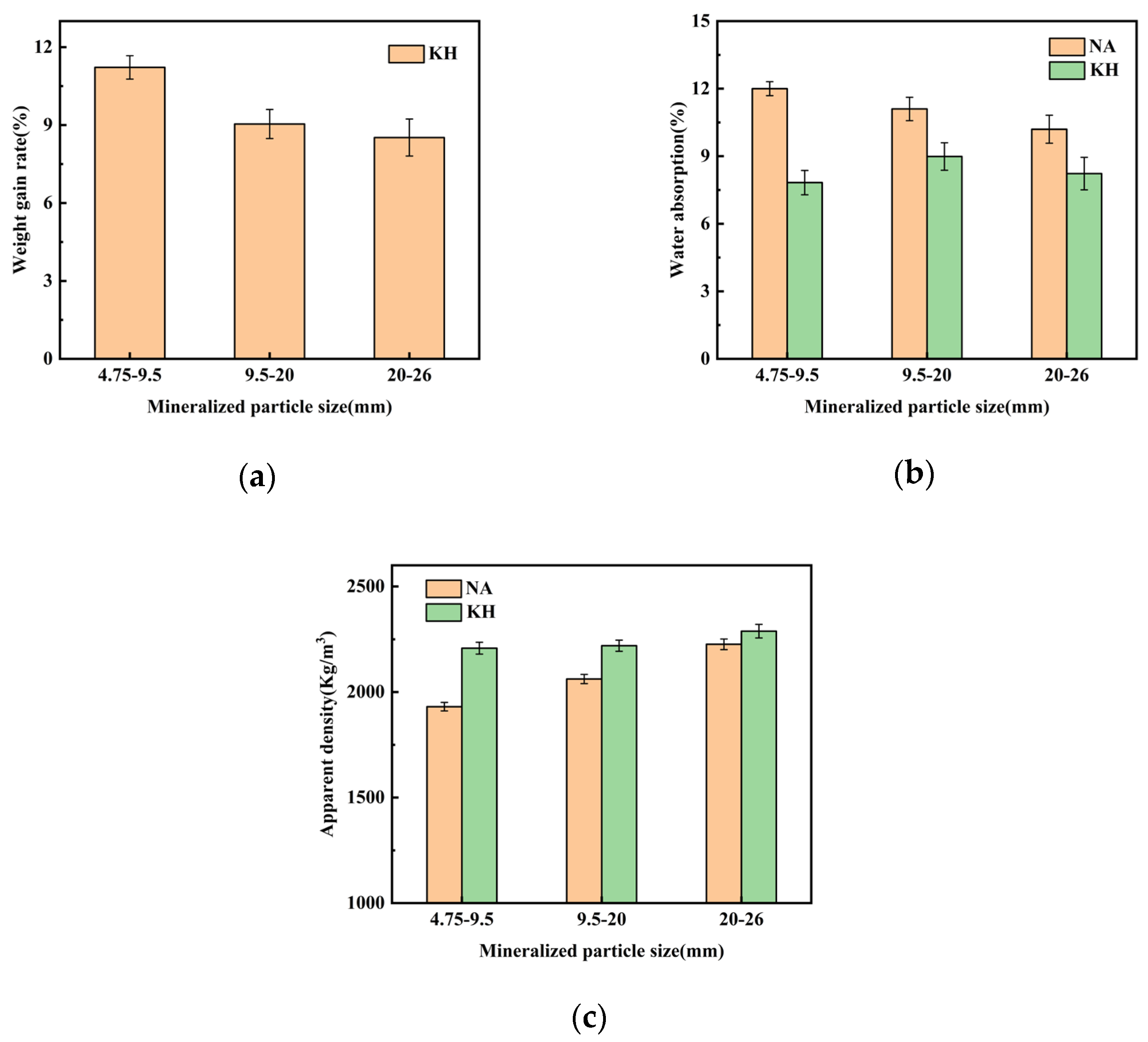

3.1.1. Weight Gain Rate

3.1.2. Water Absorption

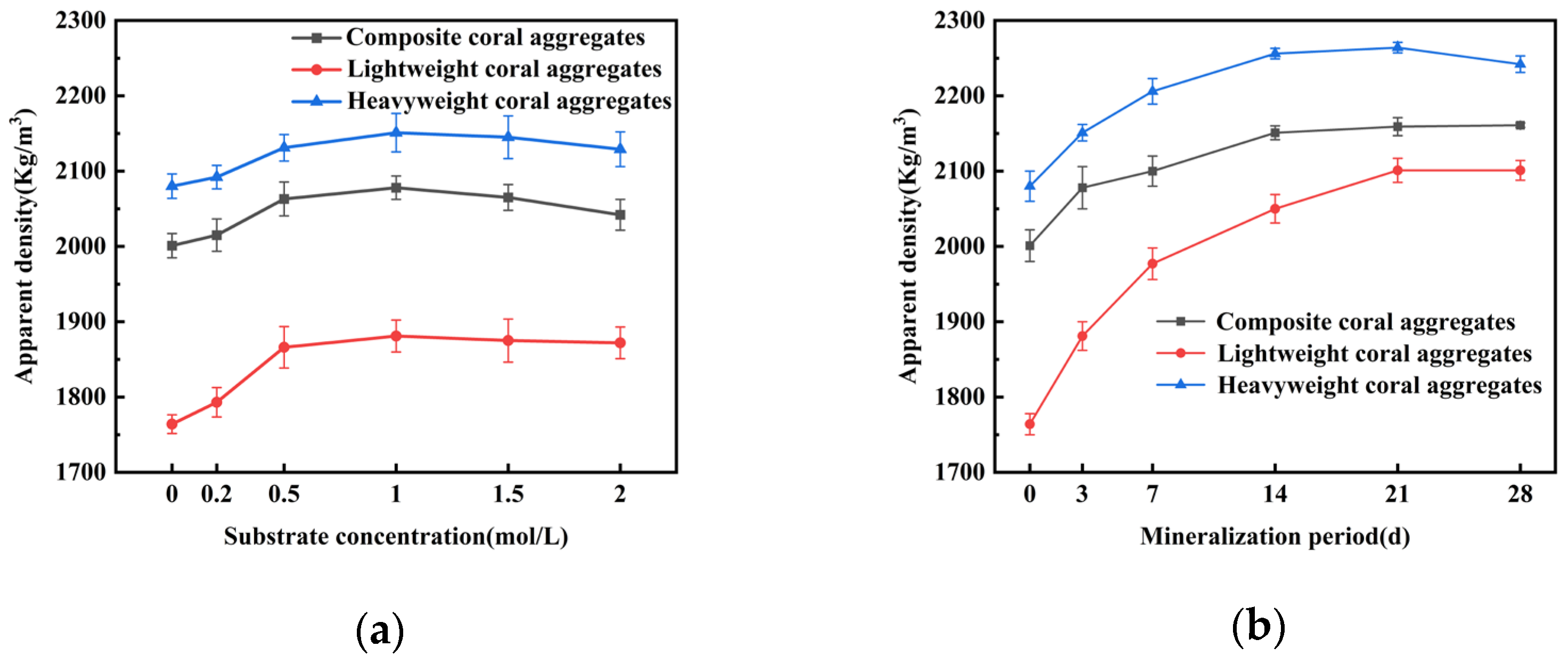

3.1.3. Apparent Density

3.2. MICP-Treated Coral Aggregates with Different Particle Size Fractions

3.3. Application of MICP-Treated Coral Aggregates in Marine Concrete

3.3.1. Concrete Workability

3.3.2. Concrete Compressive Strength

4. Discussion

4.1. Deposition Efficiency

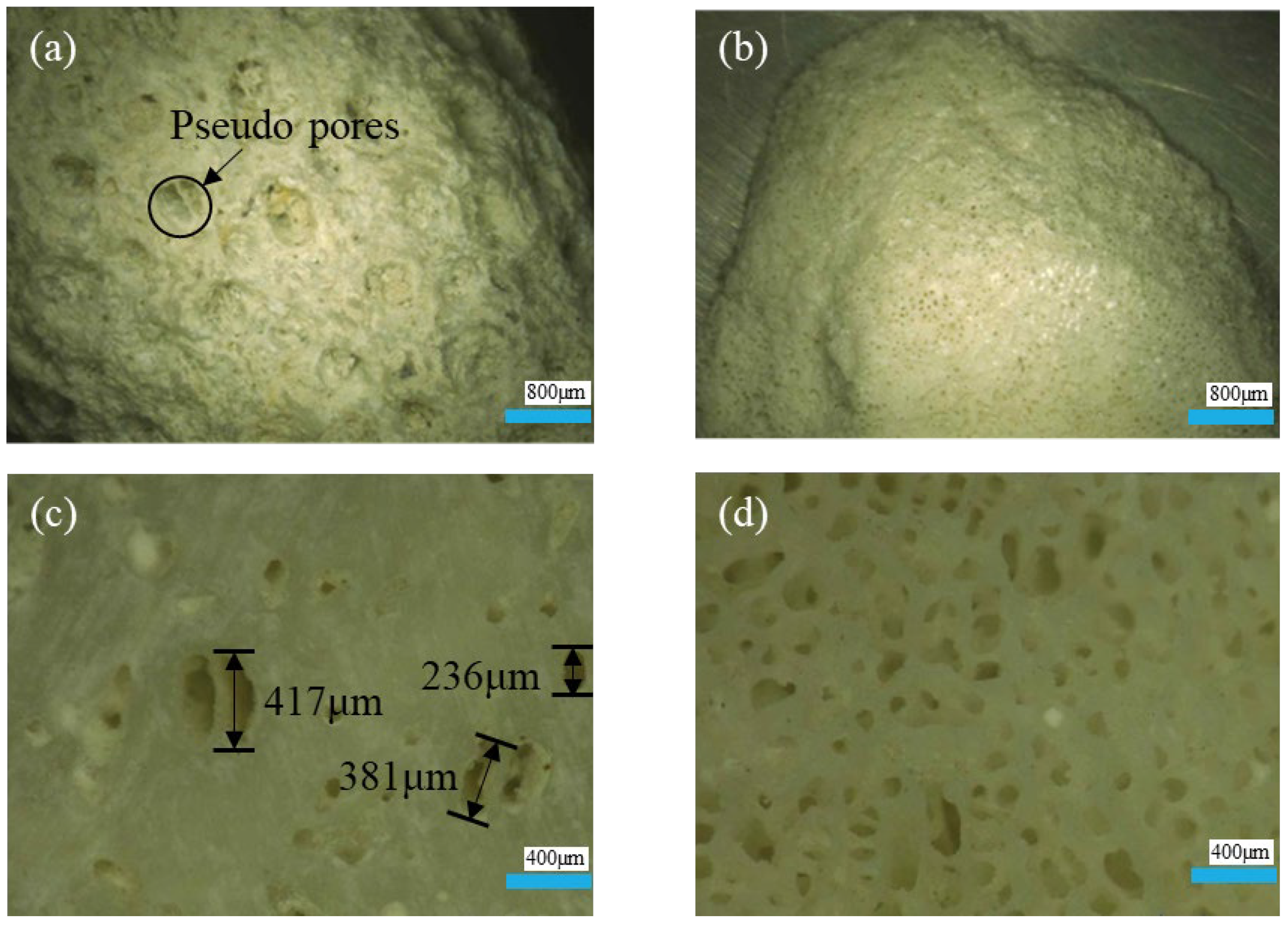

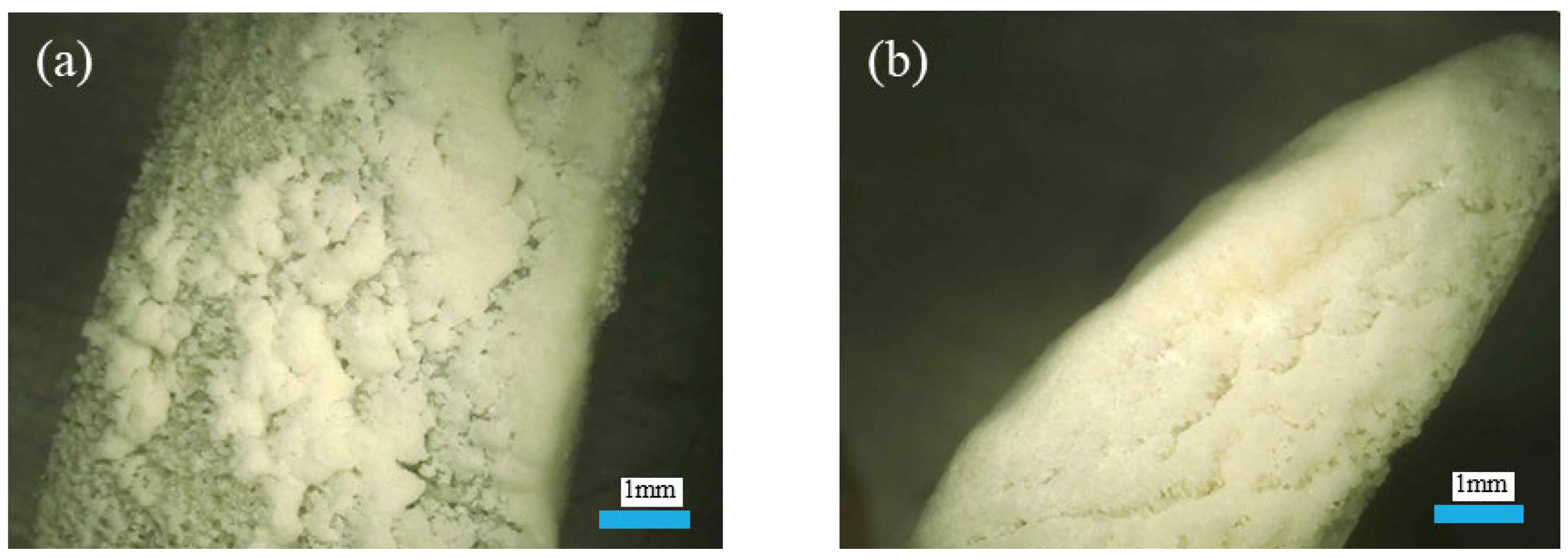

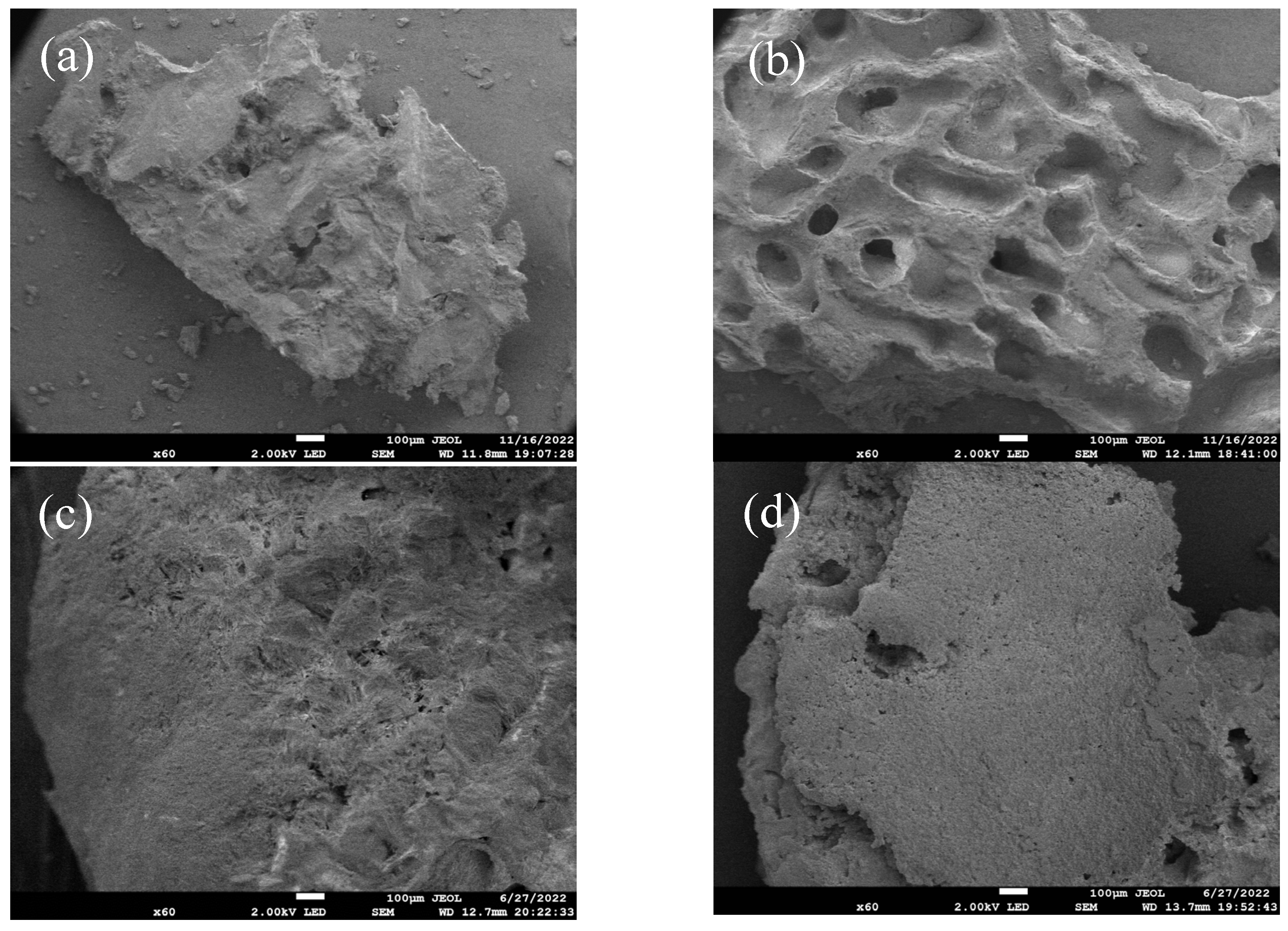

4.2. Apparent Morphology

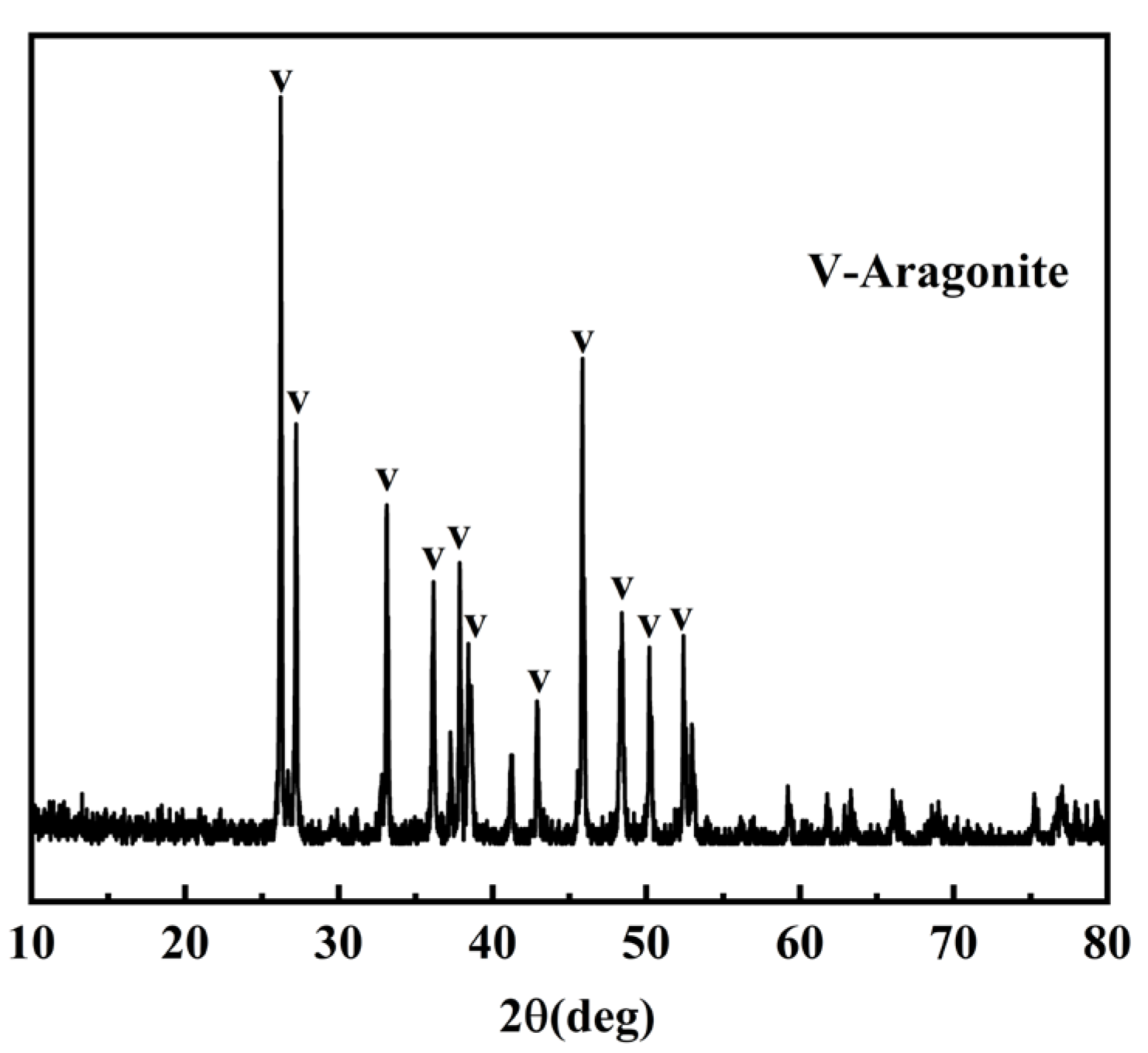

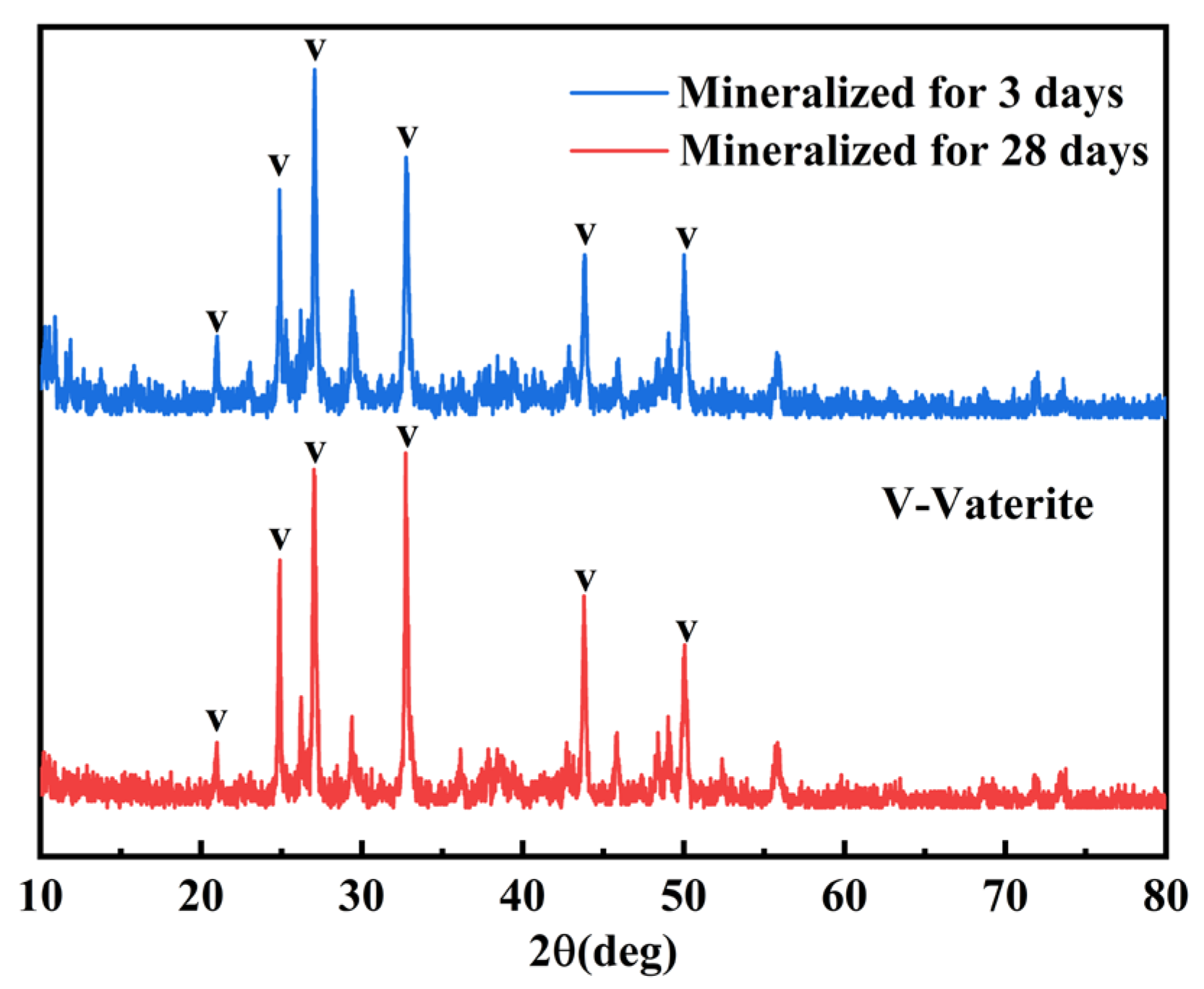

4.3. Phase Composition of Mineralization Products

4.4. Microstructure

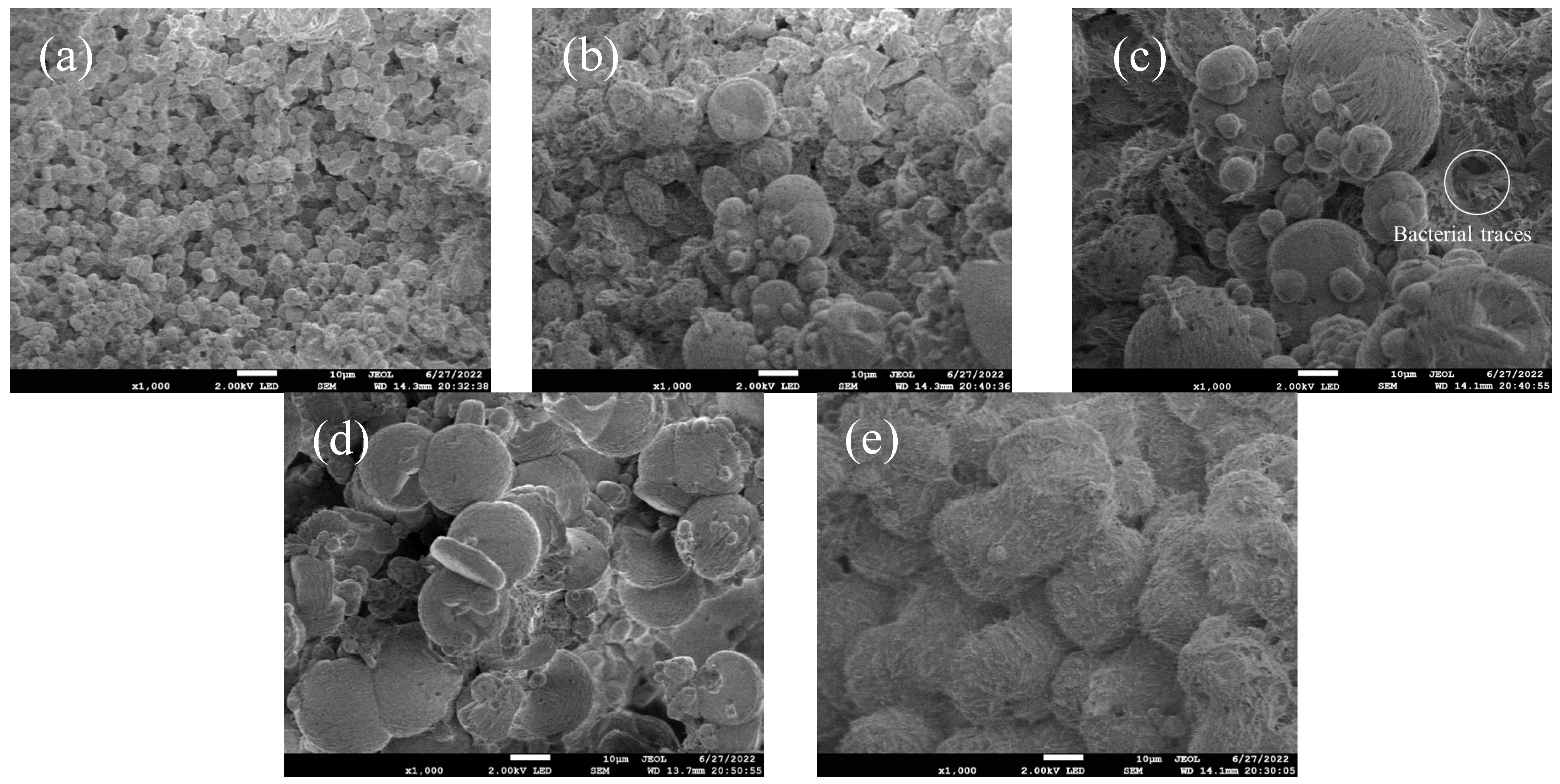

4.5. Modification Mechanism Analysis

- (1)

- Bacterial solution soaking stage

- (2)

- Mineralization reaction and deposition

- (3)

- Crystal growth stage

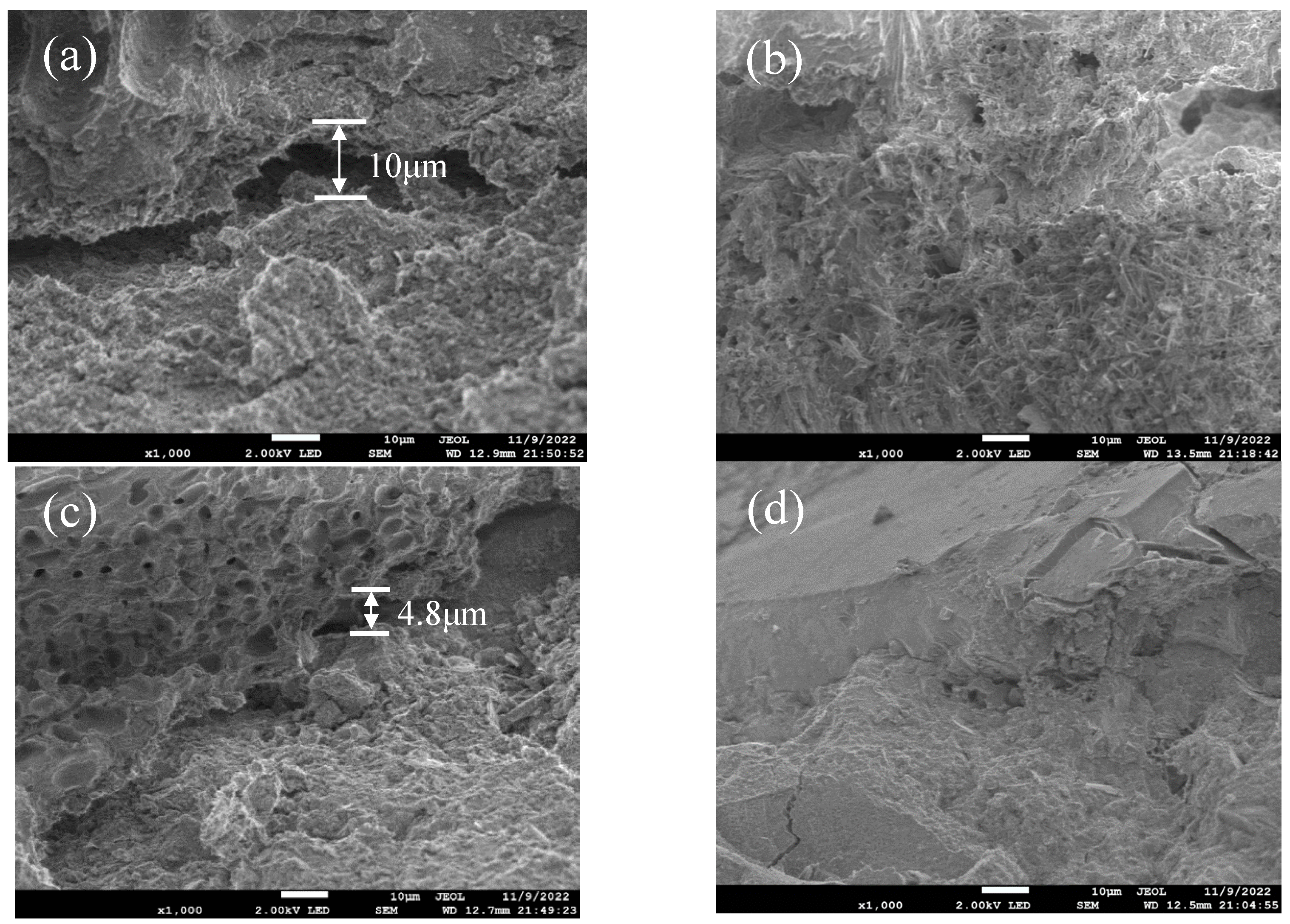

4.6. Microstructure of Concrete Interface Transition Zone

5. Conclusions

- (1)

- By evaluating the weight gain rate, water absorption rate, and apparent density, optimal mineralization conditions were established as a 1 mol/L substrate concentration and 14-day mineralization period. Under these conditions, lightweight coral aggregates and 4.75–9.5 mm aggregates achieved superior modification: their weight gain rates reached 11.75% and 11.22% and their water absorption decreased by 32.22% and 34.75%, while their apparent densities increased from 1764 kg/m3 to 2050 kg/m3 and 1930 kg/m3 to 2207 kg/m3, respectively.

- (2)

- XRD analysis confirmed vaterite as the exclusive CaCO3 polymorph in deposits. No crystal transformation occurred during mineralization. Ultra-depth microscopy and SEM revealed complete biogenic CaCO3 deposition in aggregate pores, with crystal size and inter-crystal connectivity increasing over the mineralization period.

- (3)

- After MICP treatment, all concrete groups exhibited enhanced workability and age-dependent strength gains. The workability of the three concrete groups was significantly improved, and the strength of the modified concrete was increased at each age. The 28-day compressive strengths reached 62.1 MPa (11.69% increase) for the 4.75–9.5 mm group, 46.2 MPa (6.94% increase) for the 9.5–20 mm group, and 60.1 MPa (14.91% increase) for the continuously graded group. These improvements stem from denser aggregate–cement matrix bonding after MICP treatment, which eliminates ITZ cracks and optimizes interfacial structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, F.; Sun, Y.-Z.; Xue, X.-Y.; Wang, N.; Zhou, J.-H.; Hua, J.-M. Mechanical properties of modified coral aggregate seawater sea-sand concrete: Experimental study and constitutive model. Case Stud. Constr. Mater. 2023, 18, e02095. [Google Scholar] [CrossRef]

- Wu, Z.-Y.; Yu, H.-F.; Ma, H.-Y.; Zhang, J.-H. Physical and mechanical properties of coral aggregates in the South China Sea. J. Build. Eng. 2022, 63, 105478. [Google Scholar] [CrossRef]

- Wang, A.-G.; Deng, M.; Sun, D.-S.; Li, B.; Tang, M.-S. Effect of crushed air-cooled blast furnace slag on mechanical properties of concrete. J. Wuhan Univ. Technol.-Mater. 2012, 27, 758–762. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Yang, Z.-Y.; Dong, Y.-R. BFRP bars reinforced geopolymer-based coral aggregate concrete beams with sustainable and high seawater erosion resistance: Flexural durability, economic, and ecological analysis. Eng. Struct. 2025, 330, 119910. [Google Scholar] [CrossRef]

- Wu, Z.-Y.; Zhang, J.-H.; Yu, H.-F.; Ma, H.-Y.; Fang, Q. 3D mesoscopic analysis on the compressive behavior of coral aggregate concrete accounting for coarse aggregate volume and maximum aggregate size. Compos. Struct. 2021, 273, 114271. [Google Scholar] [CrossRef]

- Da, B.; Yu, H.-F.; Ma, H.-Y.; Tan, Y.-S.; Mi, R.-J.; Dou, X.-M. Experimental investigation of whole stress-strain curves of coral concrete. Constr. Build. Mater. 2016, 122, 81–89. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Shah, K.-W.; Feng, P.; Dong, Z.-Q. Optimization of mix proportion of alkali-activated slag mortars prepared with seawater and coral sand. Constr. Build. Mater. 2021, 284, 122805. [Google Scholar] [CrossRef]

- Drake, J.-L.; Benayahu, Y.; Polishchuk, I.; Pokroy, B.; Pinkas, I.; Mass, T. Sclerites of the soft coral Ovabunda macrospiculata (Xeniidae) are predominantly the metastable CaCO3 polymorph vaterite. Acta Biomater. 2021, 135, 663–670. [Google Scholar] [CrossRef]

- Lyu, B.-C.; Wang, A.-G.; Zhang, Z.-H.; Liu, K.-W.; Xu, H.-Y.; Shi, L.; Sun, D.-S. Coral aggregate concrete: Numerical description of physical, chemical and morphological properties of coral aggregate. Cem. Concr. Compos. 2019, 100, 25–34. [Google Scholar] [CrossRef]

- Qin, Q.-L.; Wu, K.; Meng, Q.-S.; Gan, M.-G.; Yi, P.-P. Investigation of mechanical characterization and damage evolution of coral reef sand concrete using in-situ CT and digital volume correlation techniques. J. Build. Eng. 2024, 96, 110480. [Google Scholar] [CrossRef]

- Ming, Y.; Liang, Q.-Q.; Chen, X.-D. Insights on the microstructure and physical properties of coral aggregates at the pore scale: From experiments to numerical simulations. Constr. Build. Mater. 2024, 451, 138711. [Google Scholar] [CrossRef]

- Liu, J.-M.; Ju, B.-Y.; Xie, W.; Zhou, T.; Xiao, H.-Y.; Dong, S.-L.; Yang, W.-S. Evaluation of the effects of surface treatment methods on the properties of coral aggregate and concrete. Materials 2021, 14, 6784. [Google Scholar] [CrossRef] [PubMed]

- Tan, T.-Y.; Zhang, A. Study on sewage erosion resistance of nano titanium modified coral concrete. Case Stud. Constr. Mater. 2024, 21, e03936. [Google Scholar] [CrossRef]

- Chu, Y.-J.; Wang, A.-G.; Zhu, Y.-C.; Wang, H.; Liu, K.-W.; Ma, R.; Guo, L.-P.; Sun, D.-S. Enhancing the performance of basic magnesium sulfate cement-based coral aggregate concrete through gradient composite design technology. Compos. Part B 2021, 227, 109382. [Google Scholar] [CrossRef]

- Liu, J.-M.; Ju, B.-Y.; Yin, Q.; Xie, W.; Xiao, H.-Y.; Dong, S.-L.; Yang, W.-S. Properties of concrete prepared with silane coupling agent-impregnated coral aggregate and coral concrete. Materials 2021, 14, 6454. [Google Scholar] [CrossRef]

- Feng, C.-H.; Cui, B.-W.; Ge, H.-D.; Huang, Y.-H.; Zhang, W.-Y.; Zhu, J.-P. Reinforcement of recycled aggregate by Microbial-Induced mineralization and deposition of calcium carbonate-Influencing factors, mechanism and effect of reinforcement. Crystals 2021, 11, 887. [Google Scholar] [CrossRef]

- Das, R.; Sreelakshmi, N.; Muthukkumaran, K. Effect of Microbial Induced Partial Saturation on Liquefaction Mitigation of Sand of Different Relative Densities. Int. J. Civ. Eng. 2024, 22, 1463–1479. [Google Scholar] [CrossRef]

- Yuan, J.; Lei, D.-L.; Shan, Y.; Tong, H.-W.; Fang, X.-T.; Zhao, J.-T. Direct Shear Creep Characteristics of Sand Treated with Microbial-Induced Calcite Precipitation. Int. J. Civ. Eng. 2022, 20, 763–777. [Google Scholar] [CrossRef]

- Wang, Z.-K.; Tan, H.-M.; Sun, Y.-F.; Chen, F.-M. Bio-cementation of coral sand using microbial-induced calcite precipitation with sodium alginate. Mar. Geores. Geotechnol. 2024, 42, 1325–1336. [Google Scholar] [CrossRef]

- Eran, Y.-C. Self-Healing Performance of Biogranule Containing Microbial Self-Healing Concrete Under Intermittent Wet/Dry Cycles. Politek. Derg. 2021, 24, 323–332. [Google Scholar] [CrossRef]

- Wiktor, V.; Jonkers, H.-M. Quantification of crack-healing in novel bacteria-based self- healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Dick, J.; Windt, W.-D.; Graef, B.-D.; Saveyn, H.; Meeren, P.-V.-D.; Belie, N.-D.; Affiliation, W.-V. Bio-deposition of a calcium carbonate layer on degraded limestone by Bacillus species. Biodegradation 2006, 17, 357–367. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Qian, C.-X.; Xie, D.-M. Preparation of artificial aggregate using waste concrete powder and CO2 fixed by microorganisms. Clean Technol. Environ. Policy 2022, 24, 1453–1467. [Google Scholar] [CrossRef]

- Guan, X.; Liu, Y.-J.; Zhang, X.-D.; Xin, H.; Yang, H.-S. Enhancement mechanism of microbial mineralization modified coal gangue aggregate properties. Constr. Build. Mater. 2024, 440, 137477. [Google Scholar] [CrossRef]

- Li, J.-H.; Wang, T.; Du, C.-Y.; Wang, C.-X.; Cao, F.-B.; Su, T. Multi-faceted assessment of microbial-reinforced recycled brick aggregate concrete. Chem. Eng. J. 2024, 497, 154481. [Google Scholar] [CrossRef]

- Li, J.-X.; Zhang, L.; Zhang, Y.; Xu, R.; Zheng, X.-G.; Rong, H.; Yue, C.-S. A Binary Microorganism self-healing agent for concrete cracks comprising Bacillus pasteurii and Saccharomyces cerevisiae. J. Mater. Civ. Eng. 2024, 36, 04023601. [Google Scholar] [CrossRef]

- Wu, Z.-Y.; Li, J.-X.; Wang, T.-L.; Zhang, L.; Peng, B.; Yue, C.-S. Synergistic Effects of Ternary Microbial Self-Healing Agent Comprising Bacillus pasteurii, Saccharomyces cerevisiae, and Bacillus mucilaginosus on Self-Healing Performance in Mortar. Materials 2024, 17, 4834. [Google Scholar] [CrossRef]

- Hu, Y.-Y.; Liu, W.-T.; Zhang, Q.-T.; Hu, X.-L. Investigation on mineralization performance and spore germination conditions of calcium carbonate mineralizing bacteria. Mater. Res. Express. 2022, 9, 065403. [Google Scholar] [CrossRef]

- T/CECS 10090-2020; Coral Aggregate Used for Concrete. China Association for Engineering Construction Standardization: Beijing, China, 2020.

- Su, C.; Ma, H.-Y.; Yu, H.-F.; Yue, C.-J.; Zhang, Y.-D.; Mei, Q.-Q.; Sha, H.-Y.; Liu, T. Effect of Different Coral Aggregates on Mechanical Properties of Coral Concrete. J. Chin. Ceram. Soc. 2020, 48, 1771–1780. (In Chinese) [Google Scholar]

- Zeng, W.-L.; Zhao, Y.-X.; Poon, C.-S.; Feng, Z.-Y.; Lu, Z.-M.; Shah, S.-P. Using microbial carbonate precipitation to improve the properties of recycled aggregate. Constr. Build. Mater. 2019, 228, 116743. [Google Scholar] [CrossRef]

- Feng, C.-H.; Cui, B.-W.; Wang, J.; Guo, H.; Zhang, W.-Y.; Zhu, J.-P. Changing the soaking method of microbially induced calcium carbonate precipitation technology to improve the reinforcement effect of recycled concrete aggregates. J. Build. Eng. 2023, 68, 106128. [Google Scholar] [CrossRef]

- JGJ51-2002; Technical Specification for Lightweight Aggregate Concrete. China Academy of Building Research: Beijing, China, 2002.

- Wu, W.-J.; Wang, R.; Zhu, C.-Q.; Meng, Q.-S. The effect of fly ash and silica fume on mechanical properties and durability of coral aggregate concrete. Constr. Build. Mater. 2018, 185, 69–78. [Google Scholar] [CrossRef]

- GB/T 17431.2-2010; Lightweight Aggregates and Its Test Methods-Part 2: Test Methods for Lightweight Aggregates. China Standard Press: Beijing, China, 2010.

- Roussel, N. Rheology of fresh concrete: From measurements to predictions of casting processes. Mater. Struct. 2007, 40, 1001–1012. [Google Scholar] [CrossRef]

- Roussel, N. Correlation between yield stress and slump: Comparison between numerical simulations and concrete rheometers results. Mater. Struct. 2006, 39, 501–509. [Google Scholar] [CrossRef]

- Pereira, J.-B.; Sáo, Y.-T.; de Freitas Maciel, G. Numerical and experimental application of the automated slump test for yield stress evaluation of mineralogical and polymeric materials. Rheol. Acta 2022, 61, 163–182. [Google Scholar] [CrossRef]

- GB/T 50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Standard Press: Beijing, China, 2002.

- Guo, S.-J.; Zhang, J.-X.; Li, M.; Zhou, N.; Song, W.-J.; Wang, Z.-J.; Qi, S.-M. A preliminary study of solid-waste coal gangue based biomineralization as eco-friendly underground backfill material: Material preparation and macro-micro analyses. Sci. Total Environ. 2021, 770, 145241. [Google Scholar] [CrossRef]

- Ouyang, J.-Z.; Liu, K.-W.; Sun, D.-S.; Xu, W.-Y.; Wang, A.-G.; Ma, R. A focus on Ca2+ supply in microbial induced carbonate precipitation and its effect on recycled aggregate. J. Build. Eng. 2022, 51, 104334. [Google Scholar] [CrossRef]

- Ševčík, R.; Šašek, P.; Viani, A. Physical and nanomechanical properties of the synthetic anhydrous crystalline CaCO3 polymorphs: Vaterite, aragonite and calcite. J. Mater. Sci. 2018, 53, 4022–4033. [Google Scholar] [CrossRef]

| Bore Diameter (mm) | 26 | 20 | 9.5 | 4.75 | 2.36 |

|---|---|---|---|---|---|

| The cumulative triage (%) | 2.15 | 11.33 | 73.67 | 99 | 99.29 |

| Properties | CaO | SiO2 | Fe2O3 | Al2O3 | MgO | LOI |

|---|---|---|---|---|---|---|

| Coral aggregate | 52.69 | 1.7 | 0.6 | 0.36 | 0.78 | 41.3 |

| Properties | Al2O3 | CaO | Fe2O3 | K2O | MgO | Na2O | SO3 | SiO2 | TiO2 |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 8.47 | 51.90 | 4.04 | 0.55 | 3.02 | 0.36 | 1.84 | 21.29 | 0.48 |

| Fly ash | 41.56 | 4.16 | 4.93 | 0.67 | 0.42 | 0.012 | 0.78 | 43.45 | 1.85 |

| Silica fume | 0.704 | 0.588 | 0.216 | 1.1 | 0.986 | 0.342 | 0.216 | 95.6 | 0 |

| Particle Sizes (mm) | Porosity | Apparent Density | Water Absorption (%) | |

|---|---|---|---|---|

| (%) | (kg/m3) | 1 h | 24 h | |

| 4.75–9.5 | 53.1 | 1930 | 12 | 12.9 |

| 9.5–20 | 50.1 | 2061 | 11.1 | 11.23 |

| 20–26 | 47.7 | 2126 | 10.2 | 10.3 |

| Bulk Densities | Porosity | Apparent Density | Water Absorption (%) | |

|---|---|---|---|---|

| (%) | (kg/m3) | 1 h | 24 h | |

| Lightweight | 53.5 | 1764 | 19.8 | 19.9 |

| Heavyweight | 42.6 | 2080 | 8.47 | 8.51 |

| Composite | 50.1 | 2001 | 12.2 | 12.5 |

| Grade | Cement | Silica Fume | Fly Ash | River Sand | Coral Aggregate | Water Consumption | Water Reducer |

|---|---|---|---|---|---|---|---|

| C50 | 600 | 75 | 75 | 688 | 586 | 225 | 37.5 |

| Aggregate Gradation | 4.75–9.5 mm (NA) | 4.75–9.5 mm (KH) | 9.5–20 mm (NA) | 9.5–20 mm (KH) | Continuous Grading (NA) | Continuous Grading (KH) |

|---|---|---|---|---|---|---|

| Slump (mm) | 210 | 245 | 257 | 270 | 230 | 258 |

| Slump flow diameter (mm) | 490 | 612 | 585 | 643 | 542 | 661 |

| Slump/Slump flow diameter | 0.43 | 0.40 | 0.44 | 0.42 | 0.42 | 0.39 |

| Aggregate Gradation | 4.75–9.5 mm (NA) | 4.75–9.5 mm (KH) | 9.5–20 mm (NA) | 9.5–20 mm (KH) | Continuous Grading (NA) | Continuous Grading (KH) |

|---|---|---|---|---|---|---|

| 3 d | 42.2 | 45.2 | 34.4 | 35.6 | 37.6 | 41.2 |

| 7 d | 50.1 | 52.1 | 38.8 | 40.3 | 48.8 | 51.4 |

| 28 d | 55.6 | 62.1 | 43.2 | 46.2 | 52.3 | 60.1 |

| Concentration of Substrate (mol/L) | Actual Sediment Yield (g) | Theoretical Sedimentary Yield (g) | Deposition Efficiency (%) |

|---|---|---|---|

| 0.2 | 2 | 5 | 40 |

| 0.5 | 6.8 | 12.5 | 54.4 |

| 1 | 14 | 25 | 56 |

| 1.5 | 14.5 | 37.5 | 38.7 |

| 2 | 14.8 | 50 | 29.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, R.; Li, B.; Liu, X.; Peng, B.; Lu, G.; Yue, C.; Zhang, L. MICP-Treated Coral Aggregate and Its Application in Marine Concrete. Materials 2025, 18, 3619. https://doi.org/10.3390/ma18153619

Xu R, Li B, Liu X, Peng B, Lu G, Yue C, Zhang L. MICP-Treated Coral Aggregate and Its Application in Marine Concrete. Materials. 2025; 18(15):3619. https://doi.org/10.3390/ma18153619

Chicago/Turabian StyleXu, Rui, Baiyu Li, Xiaokang Liu, Ben Peng, Guanghua Lu, Changsheng Yue, and Lei Zhang. 2025. "MICP-Treated Coral Aggregate and Its Application in Marine Concrete" Materials 18, no. 15: 3619. https://doi.org/10.3390/ma18153619

APA StyleXu, R., Li, B., Liu, X., Peng, B., Lu, G., Yue, C., & Zhang, L. (2025). MICP-Treated Coral Aggregate and Its Application in Marine Concrete. Materials, 18(15), 3619. https://doi.org/10.3390/ma18153619