Features of the Structure of Layered Epoxy Composite Coatings Formed on a Metal-Ceramic-Coated Aluminum Base

Highlights

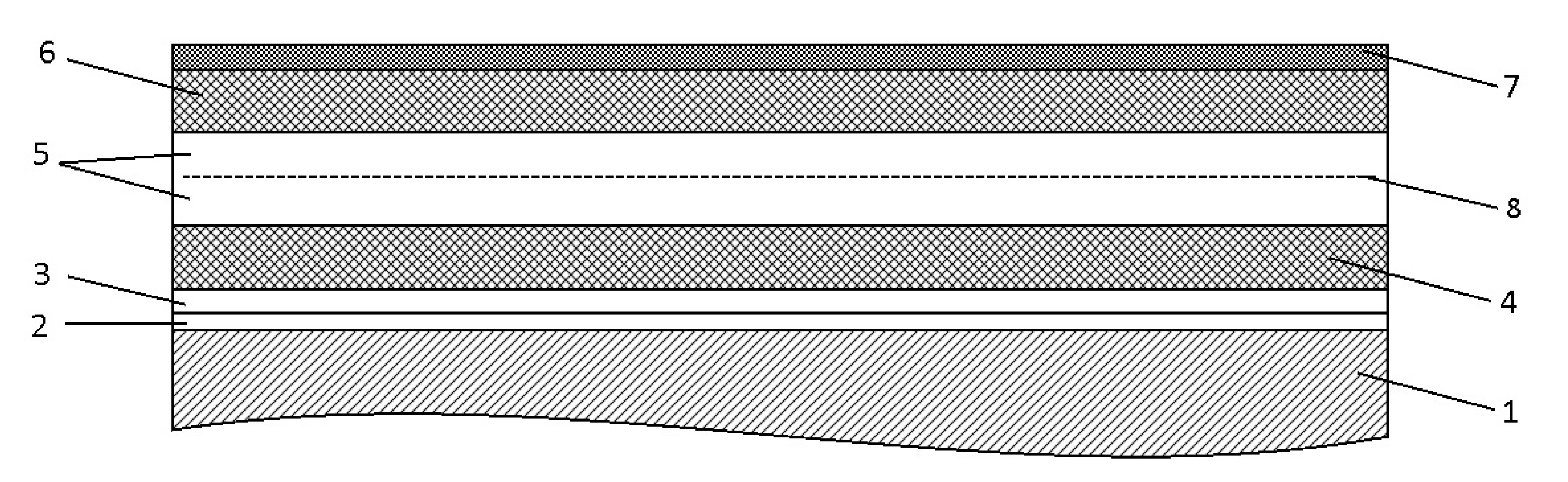

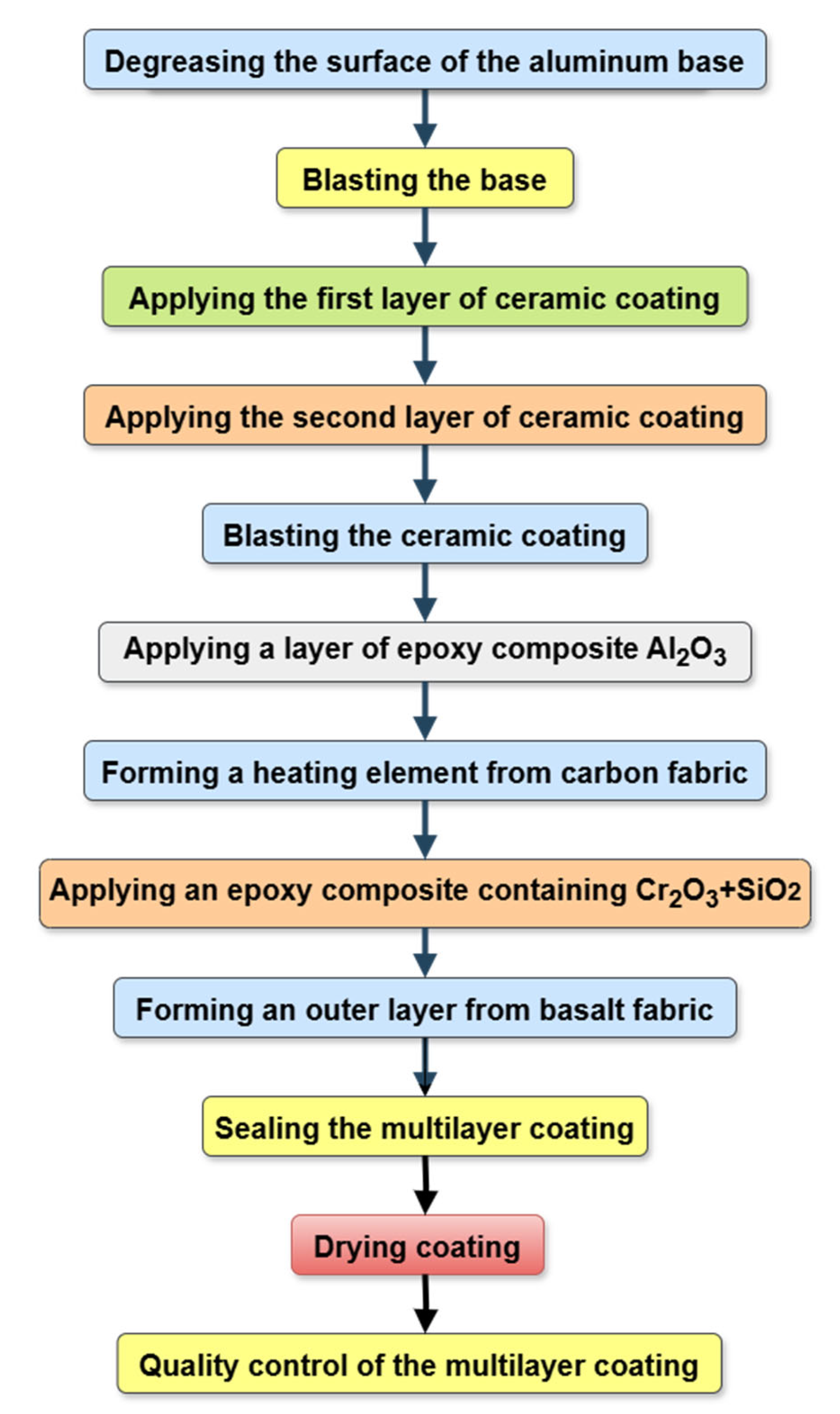

- The developed multilayer coating is created by cumulative detonation spraying of metal-ceramic layers onto an aluminum base, applying layers of epoxy composites, forming a heating resistive element from carbon fabric and a protective outer layer from basalt fabric.

- The coating demonstrates excellent workability and ensures effective removal of ice, frost and water from the working reflecting surface of the parabolic antenna.

- The coating maintains excellent mechanical strength and chemical resistance throughout 9 years of operational testing of the parabolic antenna and continues to function.

- The coating demonstrates outstanding anti-icing properties compared to other methods of heating parabolic antennas.

Abstract

1. Introduction

- –

- To develop a technology for applying a multilayer coating by a combined method that includes spraying metal-ceramic layers Al2O3 + 5% Al onto an aluminum substrate, applying an epoxy composite layer, containing aluminum oxide, forming a working layer of a heating element from carbon fabric (impregnated with epoxy resin), applying a layer of an epoxy composite containing chromium oxide and silicon oxide, followed by the formation of an outer layer of basalt fabric;

- –

- To establish the structural features and study the physical, mechanical, and electrical properties of the developed multilayer coating.

2. Materials and Methods

2.1. Research Materials

- –

- Epoxy-diane binder CYD-128, CAS No 25068-38-6 (Zhengzhou Meiya Chemical Products Co., LTD, Zhengzhou, China);

- –

- Polyethylene-polyamines (hardener epoxy-diane binder) CAS No 68131-73-7 (Shanghai Kean Technology Co., LTD., Minhang, Shanghai, China);

- –

- Aluminum oxide (Al2O3) with a dispersion of 10–20 μm;

- –

- Aerosil (SiO2) with a dispersion of 100 nm (CAS No 112945-52-5 (Ningbo Samreal Chemical Co., LTD, Ningbo, China);

- –

- Chromium oxide (Cr2O3) with a dispersion of 100 nm, CAS No 1308-38-9 (Ningbo Samreal Chemical Co., LTD, Ningbo, China);

- –

- Carbon fabric with a thickness of 200 μm brand GG-200 (ANGELONI, Group S.r.l., Quarto d’Altino, Italy);

- –

- Basalt fabric with a thickness of 200 μm brand BWP-200 (Changzhou Jlon Composite Co., LTD, Taihu Rd, Changzhou, Jiangsu, China).

- –

- Aluminum oxide (Al2O3) grade F16 with a grain size of 1.2 mm (Luoyang Weixiang Abrasives Co., Ltd, Henan, China).

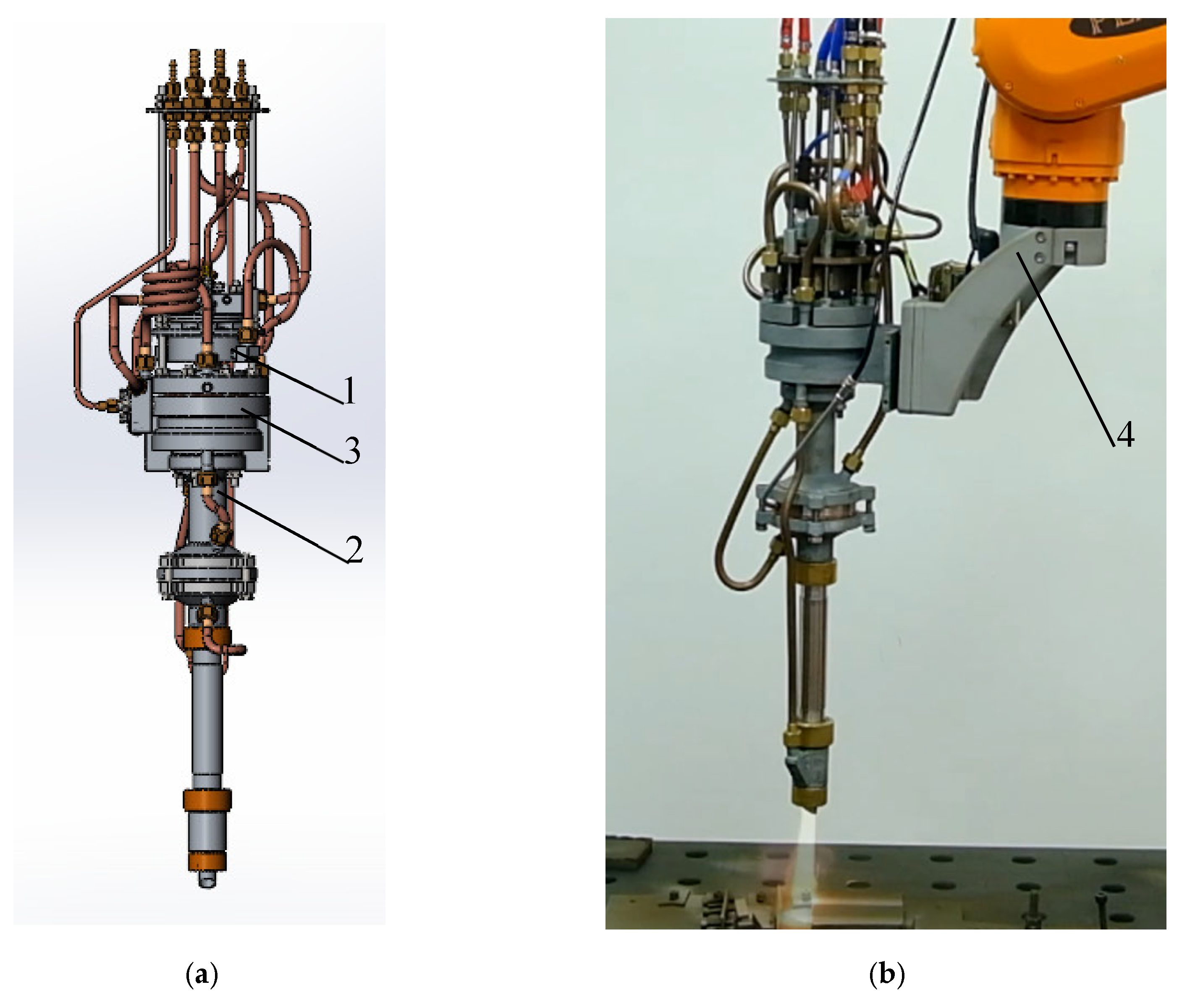

2.2. Technology of Layered Coating Formation

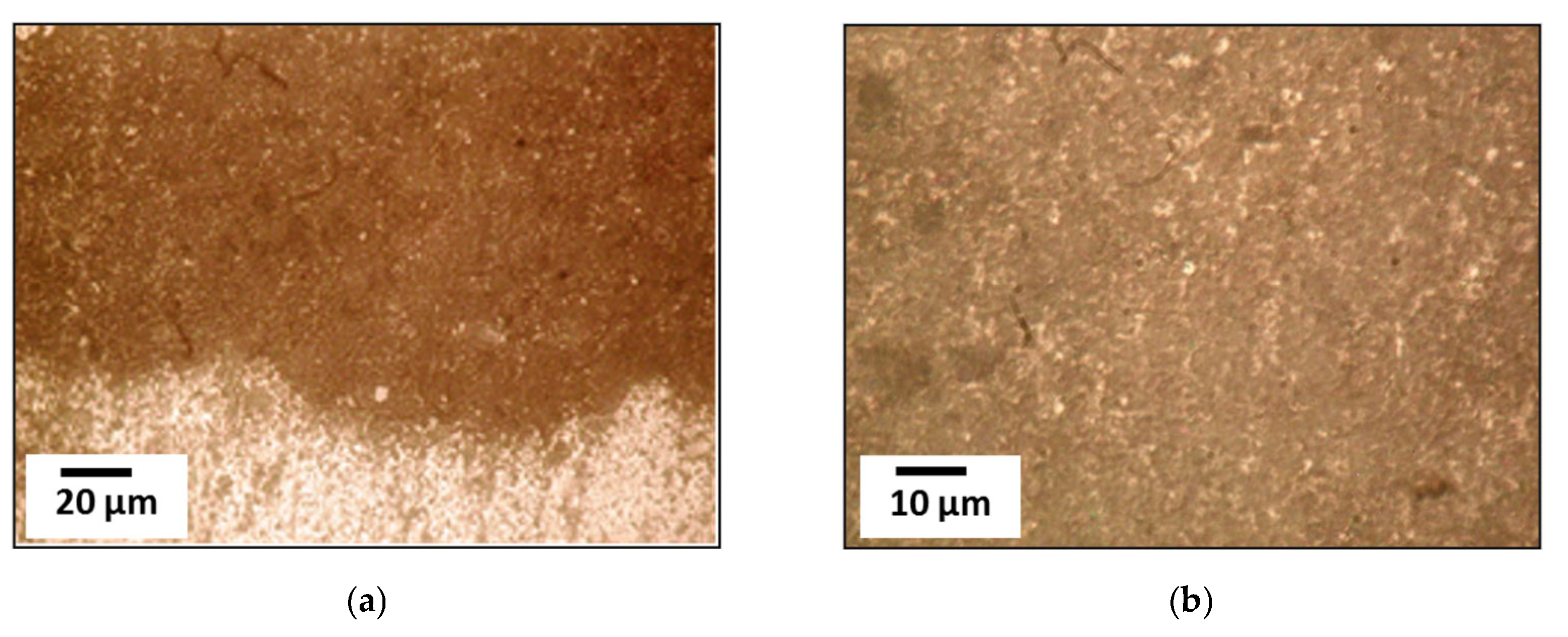

2.3. Methods for Researching the Structure and Properties of Coatings

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gamboa-Soto, F.; Bautista-García, R.; Llanes-Gil López, D.I.; Berme, J.E.; Tinoco Mendiola, R.; Olive-Méndez, S.F.; González-Hernández, A. Heat Treatment-Driven Structural and Morphological Transformation under Non-Parametric Tests on Metal–Ceramic-Sputtered Coatings. Ceramics 2025, 8, 25. [Google Scholar] [CrossRef]

- Imbirovych, N.; Povstyanoy, O.; Zaleta, O.; Shymchuk, S.; Priadko, O. The Influence of Synthesis Regimes on Operational Properties of Oxide Ceramic Coatings on an Aluminum Alloy. In Advances in Design, Simulation and Manufacturing, Proceedings of the 4th International Conference on Design, Simulation, Manufacturing: The Innovation Exchange, DSMIE 2021, Lviv, Ukraine, 8–11 June 2021; Ivanov, V., Trojanowska, J., Pavlenko, I., Zajac, J., Peraković, D., Eds.; Lecture Notes in Mechanical Engineering; Springer Science and Business Media GmbH: Cham, Switzerland, 2021; pp. 536–545. [Google Scholar] [CrossRef]

- Baranovska, O.V.; Bagliuk, G.A.; Buketov, A.V.; Sapronov, O.O.; Baranovskyi, D.I. The Influence of the Dispersed Filler of the Ni–Fe–Si–C System on the Physicomechanical Properties and Structure of Epoxy Composites. Mater. Sci. 2024, 59, 608–615. [Google Scholar] [CrossRef]

- Buketov, A.V.; Bagliuk, G.A.; Sizonenko, O.M.; Sapronov, O.O.; Smetankin, S.O.; Torpakov, A.S. Effect of Particulate Ti–Al–TiC Reinforcements on the Mechanical Properties of Epoxy Polymer Composites. Powder Metall. Met. Ceram. 2023, 61, 586–596. [Google Scholar] [CrossRef]

- Baglyuk, G.A.; Baranovska, O.V.; Buketov, A.V.; Sapronov, O.O.; Smetankin, S.O.; Bykov, O.M.; Baranovskyi, D.I. Physicomechanical Properties and Structure of Multicomponent Titanium-Matrix-Base Alloy Dispersion Epoxy Composites. Strength Mater. 2023, 55, 534–543. [Google Scholar] [CrossRef]

- Baranovska, O.; Bagliuk, G.; Buketov, A.; Sapronov, O.; Baranovskyi, D. Exploration of Titanium-Based Fine-Particle Additive Influence on Cohesive and Adhesive Strength Enhancement in Epoxy-Polymer Composites. Phys. Chem. Solid State 2024, 25, 453–460. [Google Scholar] [CrossRef]

- Dobrotvor, I.G.; Stukhlyak, P.D.; Mykytyshyn, A.G.; Stukhlyak, D.P. Influence of Thickness and Dispersed Impurities on Residual Stresses in Epoxy Composite Coatings. Strength Mater. 2021, 53, 283–290. [Google Scholar] [CrossRef]

- Kuzmych-Ianchuk, I.K.; Borisov, Y.S.; Bernatskyy, A.V. Laser-Microplasma Reactive Powder Spraying of Titanium Coatings with Nitride Phases. Appl. Mech. Mater. 2014, 682, 276–281. [Google Scholar] [CrossRef]

- Markashova, L.; Tyurin, Y.; Berdnikova, O.; Kolisnichenko, O.; Polovetskyi, I.; Titkov, Y. Effect of Nano-Structured Factors on the Properties of the Coatings Produced by Detonation Spraying Method. In Advances in Thin Films, Nanostructured Materials, and Coatings; Pogrebnjak, A., Novosad, V., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2019; pp. 109–117. [Google Scholar] [CrossRef]

- Baranovska, O.V.; Bykov, O.I.; Bagliuk, G.A.; Kyryliuk, S.F. Influence of the Mechanical Activation of Charge on the Structure and Phase Composition of Sintered Multicomponent Composites Based on Titanium. Mater. Sci. 2021, 57, 201–208. [Google Scholar] [CrossRef]

- Yuan, N.; Fang, W.; Xu, H.; Liu, Y.; Wang, D. Titanium-Based Metal–Organic Frameworks Deposited on Cement-Based Materials: Self-Cleaning and the Adhesion Mechanisms. J. Build. Eng. 2025, 104, 112241. [Google Scholar] [CrossRef]

- Baranovska, O.; Bagliuk, G.; Olifan, O.; Korichev, S.; Sytnyk, Y.; Ahanov, A. Structural and Phase Transformations in Titanium Alloys Induced by Ferrosilicon Alloying. BOHR Int. J. Mater. Sci. Eng. 2024, 1, 1–7. [Google Scholar] [CrossRef]

- Berdnikova, O.; Kushnaryova, O.; Bernatskyi, A.; Alekseienko, T.; Polovetskyi, Y.; Khokhlov, M. Structure Features of Surface Layers in Structural Steel after Laser-Plasma Alloying with 48(WC–WC) + 48Cr + 4Al Powder. In Proceedings of the 2021 IEEE 9th International Conference on Nanomaterials: Applications & Properties (NAP-2021), Odessa, Ukraine, 5–11 September 2021; IEEE: Piscataway, NL, USA, 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Bhat, V.S.; Kapatkar, S.B.; Naik, I.; Hegde, S. Investigation of Impact of Al2O3 Nanoparticles on Optical, Electrical and Structural Properties of PFO/PMMA Films for Optoelectronic Applications. Discov. Mater. 2025, 5, 68. [Google Scholar] [CrossRef]

- Shaik, M.B.; Nasina, V.; Mamilla, R.S. Experimental Investigation into Nano-Finishing of Pure Copper Built Using Atomic Diffusion Additive Manufacturing. Rapid Prototyp. J. 2025, 31, 998–1013. [Google Scholar] [CrossRef]

- Chen, B.; Xu, M. Preparation and Performance Analysis of Micro-Nano Composite Coatings Reinforced with WC Particles. Mater. Res. Express 2024, 11, 026508. [Google Scholar] [CrossRef]

- Fialko, N.; Dinzhos, R.; Sherenkovskii, J.; Meranova, N.; Navrodska, R.; Izvorska, D.; Korzhyk, V.; Lazarenko, M.; Koseva, N. Establishing Patterns in the Effect of Temperature Regime When Manufacturing Nanocomposites on Their Heat-Conducting Properties. East.-Eur. J. Enterp. Technol. 2021, 4, 21–26. [Google Scholar] [CrossRef]

- Refino, A.D.; Yulianto, N.; Priyono, S.; Manawan, M.; Hernandha, R.F.H.; Adhitama, E.; Kottmeier, J.; Dietzel, A.; Peiner, E.; Wasisto, H.S. Carbon-Coating Effect on the Performance of Photolithographically-Structured Si Nanowires for Lithium-Ion Microbattery Anodes. Commun. Mater. 2025, 6, 32. [Google Scholar] [CrossRef]

- Buketov, A.; Stukhlyak, P.; Maruschak, P.; Panin, S.; Menou, A. Physical and Chemical Aspects of Formation of Epoxy Composite Material with Microfilling Agent. Key Eng. Mater. 2016, 712, 143–148. [Google Scholar] [CrossRef]

- Povstianoi, O.Y.; Rud, V.D.; Imbirovych, N.Y.; Halchuk, T.N.; Chetverzhuk, T.I.; Smal, M.V.; Dziubynskyi, A.V. Optimization of the Properties of Multilayer Porous Permeable Materials. Mater. Sci. 2021, 56, 530–535. [Google Scholar] [CrossRef]

- Buketov, A.V.; Sapronov, O.O.; Brailo, M.V. Investigation of the Physico-Mechanical and Thermophysical Properties of Epoxy Composites with a Two-Component Bidisperse Filler. Strength Mater. 2014, 46, 717–723. [Google Scholar] [CrossRef]

- Buketov, A.V.; Brailo, M.V.; Kobel’nyk, O.S.; Akimov, O.V. Tribological Properties of Epoxy Composites Filled with Dispersed Particles and Thermoplastics. Mater. Sci. 2016, 52, 25–32. [Google Scholar] [CrossRef]

- Buketov, A.; Smetankin, S.; Lysenkov, E.; Yurenin, K.; Akimov, A.; Yakushchenko, S.; Lysenkova, I. Electrophysical Properties of Epoxy Composite Materials Filled with Carbon Black Nanopowder. Adv. Mater. Sci. Eng. 2020, 2020, 6361485. [Google Scholar] [CrossRef]

- Sapronov, O.O.; Buketov, A.V.; Zinchenko, D.O.; Yatsyuk, V.M. Features of Structural Processes in Epoxy Composites Filled with Silver Carbonate on Increase in Temperature. Compos. Mech. Comput. Appl. Int. J. 2017, 8, 47–65. [Google Scholar] [CrossRef]

- Buketov, A.V.; Smetankin, S.A.; Akimov, A.V.; Kulinich, A.G. Epoxy Composite Modifications Influence on the Energy Activation’s of Thermal Destruction. Funct. Mater. 2019, 26, 403–411. [Google Scholar] [CrossRef]

- Coşkun, Ö.; Fidan, S.; Özsoy, M.İ.; Bora, M.Ö.; Ürgün, S.; Şahin, A.E.; Yılmaz, T. Enhancing Wear Resistance and Adhesion of Primer Coatings on Laser-Textured Milled Carbon Fiber-Filled Basalt Composites. Polymers 2025, 17, 1150. [Google Scholar] [CrossRef] [PubMed]

- Hao, J.; Yang, K.; Wu, J.; Wu, M.; Li, Y. Overview of Recent Developments in Composite Epoxy Resin in Organic Coating on Steel (2020–2024). Materials 2025, 18, 1531. [Google Scholar] [CrossRef]

- Pavlović, M.; Dojčinović, M.; Nikolić, J.; Aleksić, S.; Tucović, N.; Čeganjac, Z.; Drmanić, S. Cavitation Erosion of Protective Coating Based on Cordierite Filler and Epoxy Matrix. Materials 2025, 18, 1034. [Google Scholar] [CrossRef]

- Kopei, B.; Kopei, I.; Kopei, V.; Onysko, O.; Mykhailiuk, V. Comparison of the Main Parameters of the Steel and Carbon-Fiber-Reinforced Plastic Band Traction Units for Long-Stroke Oil Well Pumps. In Proceedings of the International Conference on New Technologies, Development and Application VI. NT 2023, Sarajevo, Bosnia and Herzegovina, 22–24 June 2023; Karabegovic, I., Kovačević, A., Mandzuka, S., Eds.; Lecture Notes in Networks and Systems LNNS. Springer: Cham, Switzerland, 2023; Volume 687, pp. 86–97. [Google Scholar] [CrossRef]

- Yao, Y.; Huang, W.; Rao, M.; Cao, Y.; Huang, C.; Liang, Y.; Tan, C.; Mo, Y. Comparative Study on the Anti-Corrosion Performance of Epoxy Coatings Containing BIB and HFTC. Coatings 2025, 15, 271. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, H.; Gao, Z.; Huang, Z.; Wu, Y.; Lv, K. Enhancement of the Corrosion and Wear Resistance of an Epoxy Coating Using a Combination of Mullite Powder and PVB. Coatings 2025, 15, 41. [Google Scholar] [CrossRef]

- Mao, Y.; Liu, S.; Liu, S.; Wu, G.; Liu, Q.; Du, X. Synergistic Effect of CNT and N-Doped Graphene Foam on Improving the Corrosion Resistance of Zn Reinforced Epoxy Composite Coatings. Polymers 2024, 16, 3513. [Google Scholar] [CrossRef]

- Abd El-Mageed, A.I.A.; Desouky, M.M.; El-Sayed, M.; Salem, T.; Radwan, A.B.; Hassan, M.K.; Al-Oufy, A.K.; El-Dessouky, H.M. Carbon Fiber-Reinforced Thermoplastic Composite Coatings for Steel Pipelines. Polymers 2024, 16, 3417. [Google Scholar] [CrossRef]

- Shelly, D.; Singhal, V.; Singh, S.; Nanda, T.; Mehta, R.; Lee, S.-Y.; Park, S.-J. Exploring the Impact of Nanoclay on Epoxy Nanocomposites: A Comprehensive Review. J. Compos. Sci. 2024, 8, 506. [Google Scholar] [CrossRef]

- Dagdag, O.; Kim, H. Recent Advances in Fire Safety of Carbon Fiber-Reinforced Epoxy Composites for High-Pressure Hydrogen Storage Tanks. Polymers 2024, 16, 3343. [Google Scholar] [CrossRef]

- Huang, X.; Yang, C.; Chen, J.; Qiao, X.; Zhang, S.; Song, D. Enhanced Protective Performance of Carbon Nanotube-Reinforced Waterborne Epoxy Zinc-Rich Coatings for Corrosion Protection of Steel Structures. Coatings 2024, 14, 1493. [Google Scholar] [CrossRef]

- Narongdej, P.; Gomez, R.; Tseng, D.; Barjasteh, E.; Moghtadernejad, S. Characterization of Mechanical Properties and Surface Wettability of Epoxy Resin/Benzoxazine Composites in a Simulated Acid Rain Environment. Coatings 2024, 14, 1279. [Google Scholar] [CrossRef]

- Fan, D.; Wang, H.; Xu, H.; He, T. Chloride Resistance of Assembled Bridge Piers Reinforced with Epoxy-Coated Steel Bars. Appl. Sci. 2024, 14, 6609. [Google Scholar] [CrossRef]

- Abenojar, J.; Ballesteros, Y.; Bahrami, M.; Martínez, M.A.; del Real, J.C. Wear Behavior of Epoxy Resin Reinforced with Ceramic Nano- and Microparticles. Polymers 2024, 16, 878. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Cheng, F.; Zuo, S.; Zhang, J.; Huang, W.; Fan, T.; Hu, X. Constructing Micro-/Nano-Aramid Pulp (MAP)–Epoxy Coatings on Laser-Engraved Titanium Alloy Surfaces for Stronger Adhesive Bonding with Carbon Fiber-Reinforced Polymer Panel. Coatings 2025, 15, 221. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, J.; Cheng, F.; Li, J.; Wu, B.; Zhao, Z. Forming Epoxy Coatings on Laser-Engraved Surface of Aluminum Alloy to Reinforce the Bonding Joint with a Carbon Fiber Composite. Coatings 2024, 14, 1201. [Google Scholar] [CrossRef]

- Paranjpe, N.; Uddin, M.N.; Rahman, A.S.; Asmatulu, R. Effects of Surface Treatment on Adhesive Performance of Composite-to-Composite and Composite-to-Metal Joints. Processes 2024, 12, 2623. [Google Scholar] [CrossRef]

- Kopey, B.V.; Maksymuk, A.V.; Shcherbyna, N.N. Analysis of contact stresses in structural joints of composite shell with steel banding. Mech. Compos. Mater. 2000, 36, 67–74. [Google Scholar] [CrossRef]

- Krechkovska, H.; Bakun, B.; Kopey, I.; Student, O. Feature of fatigue fracture of the composite sucker rod. Procedia Struct. Integr. 2024, 59, 292–298. [Google Scholar] [CrossRef]

- Zhang, R.; Yang, K.; Dang, B.; Zhan, M.; Zhang, P.; Li, S. Anti-Corrosion and Wave-Absorbing Properties of Epoxy-Based Coatings on Q235 Steel. Coatings 2024, 14, 1315. [Google Scholar] [CrossRef]

- Yan, S.; Chen, X.; Zhang, A.; Tang, J. In Situ Synthesis of an Epoxy Resin Microwave Absorption Coating with Anti-Ultraviolet Aging Effects. Coatings 2024, 14, 514. [Google Scholar] [CrossRef]

- Lei, D.; Liu, J.; Liu, C.; Dong, C.; Yang, D.; Li, Y.; Zhang, J.; Han, F.; Guo, Z. Metal–Organic Frameworks-Derived FeCo/C–CNT Nanocomposites Modified Epoxy Resin for Electromagnetic Protection Coatings for Buildings. Buildings 2024, 14, 1096. [Google Scholar] [CrossRef]

- Acha, F.; Scheff, T.; Diaz Armas, N.; Mead, J.; Johnston, S.; Zhang, J. An Approach of Manufacturing High-Molecular-Weight CNT-Filled Epoxy Composite. Materials 2025, 18, 264. [Google Scholar] [CrossRef]

- Syed, J. Effective Multi-Layered Structure Design with Carbon-Based Hybrid Polymer Nanocomposites Using Evolutionary Algorithms. J. Compos. Sci. 2024, 8, 537. [Google Scholar] [CrossRef]

- Li, X.; Yu, B.; Chen, J.; Huo, D.; Liu, J.; Nan, D. Optimized Functionalization of Graphene Oxide for Enhanced Mechanical Properties in Epoxy Resin Composites. Coatings 2024, 14, 609. [Google Scholar] [CrossRef]

- Li, Y.; Liu, S.; Feng, F.; Li, Y.; Han, Y.; Tong, X.; Gao, X. Preparation and Characterization of Graphene Oxide/Carbon Nanotube/Polyaniline Composite and Conductive and Anticorrosive Properties of Its Waterborne Epoxy Composite Coatings. Polymers 2024, 16, 2641. [Google Scholar] [CrossRef] [PubMed]

- Sharifov, D.; Niyazbekova, R.; Mirzo, A.; Shansharova, L.; Serekpayeva, M.; Aldabergenova, S.; Ibzhanova, A.; Machnik, R.; Bembenek, M. The Study of Composite Materials Properties Based on Polymers and Nano-Additives from Industrial Wastes from Kazakhstan. Materials 2024, 17, 2959. [Google Scholar] [CrossRef] [PubMed]

- Şomoghi, R.; Mihai, S.; Teodorescu, G.-M.; Vuluga, Z.; Gabor, A.R.; Nicolae, C.-A.; Trică, B.; Vătău, D.M.S.; Oancea, F.; Stănciulescu, C.M. Influence of HNT-ZnO Nanofillers on the Performance of Epoxy Resin Composites for Marine Applications. Coatings 2024, 14, 532. [Google Scholar] [CrossRef]

- Duriagina, Z.A.; Kovbasyuk, T.M.; Bespalov, S.A. The analysis of competitive methods of improvement of operational properties of functional layers of flat heating elements. Usp. Fiz. Met. 2016, 17, 29–51. [Google Scholar] [CrossRef]

- Bembenek, M.; Makoviichuk, M.; Shatskyi, I.; Ropyak, L.; Pritula, I.; Gryn, L.; Belyakovskyi, V. Optical and Mechanical Properties of Layered Infrared Interference Filters. Sensors 2022, 22, 8105. [Google Scholar] [CrossRef]

- Fayomi, O.S.; Akande, I.G.; Okokpujie, I.P.; Ayodele, T.A.; Popoola, A.P.I. Composite Coating and Its Industrial Applications: The Impact and Trends. Procedia Manuf. 2019, 35, 1013–1017. [Google Scholar] [CrossRef]

- Sathish, M.; Radhika, N.; Saleh, B. A Critical Review on Functionally Graded Coatings: Methods, Properties, and Challenges. Compos. Part B Eng. 2021, 225, 109278. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, S.; Shi, Q.; Zhang, Y.; Wang, H. Multilayer Coatings for Tribology: A Mini Review. Nanomaterials 2022, 12, 1388. [Google Scholar] [CrossRef] [PubMed]

- Shatskyi, I.; Makoviichuk, M.; Ropyak, L.; Velychkovych, A. Analytical Model of Deformation of a Functionally Graded Ceramic Coating under Local Load. Ceramics 2023, 6, 1879–1893. [Google Scholar] [CrossRef]

- Najm Obaid, A.; Al-Bermany, E. Impact of graphene nanosheets on adhesion and corrosion performance of reinforced polyurethane coating for aerospace aluminium alloy 2024-T3. Int. J. Adhes. Adhes. 2024, 132, 103695. [Google Scholar] [CrossRef]

- Cortés, A.; Esperanza, A.; Gómez-Sánchez, J.; Sanchez-Romate, X.F.; Prolongo, S.G.; Jiménez-Suárez, A. Combining de-icing and self-healing for wind blades through an innovative multilayer coating approach. Polym. Compos. 2025, 46, 4469–4481. [Google Scholar] [CrossRef]

- Xavier, J.R.; Srinivasan, S. Multilayer epoxy/GO/silane/Nb2C nanocomposite: A promising coating material for the aerospace applications. J. Adhes. Sci. Technol. 2024, 38, 44–69. [Google Scholar] [CrossRef]

- Lebeau, A.; Casetta, M.; Bellayer, S.; Walter, A.; Suel, S.; Jimenez, M. Self-stratifying epoxy/thermoplastic polyurethane coatings designed for aerospace applications. Prog. Org. Coat. 2025, 208, 109478. [Google Scholar] [CrossRef]

- Jiang, X.; Zhou, C.; Su, J.; Tang, S.; Li, N. Enhanced anti-icing and drag reduction of multilayer composite structure superhydrophobic surface. Appl. Surf. Sci. 2025, 686, 162178. [Google Scholar] [CrossRef]

- Antonyuk, V.S.; Bondarenko, Y.Y.; Bilokin’, S.O.; Andrienko, V.O.; Bondarenko, M.O. Research of microhardness of thin ceramic coatings formed by combined electron-beam method on dielectric materials. J. Nano-Electron. Phys. 2019, 11, 06024. [Google Scholar] [CrossRef]

- Sieber, M.; Mehner, T.; Dietrich, D.; Alisch, G.; Nickel, D.; Meyer, D.; Scharf, I.; Lampke, T. Wear-resistant coatings on aluminium produced by plasma anodizing—A correlation of wear properties, microstructure, phase composition and distribution. Surf. Coat. Technol. 2014, 240, 96–102. [Google Scholar] [CrossRef]

- Sikdar, S.; Menezes, P.V.; Maccione, R.; Jacob, T.; Menezes, P.L. Plasma Electrolytic Oxidation (PEO) Process—Processing, Properties, and Applications. Nanomaterials 2021, 11, 1375. [Google Scholar] [CrossRef]

- Gamba, M.; Cristoforetti, A.; Fedel, M.; Ceriani, F.; Ormellese, M.; Brenna, A. Plasma Electrolytic Oxidation (PEO) coatings on aluminum alloy 2024: A review of mechanisms, processes, and corrosion resistance enhancement. Appl. Surf. Sci. Adv. 2025, 26, 100707. [Google Scholar] [CrossRef]

- Student, M.M.; Shmyrko, V.V.; Klapkiv, M.D.; Lyasota, I.M.; Dobrovol’ska, L.N. Evaluation of the Mechanical Properties of Combined Metal-Oxide-Ceramic Layers on Aluminum Alloys. Mater. Sci. 2014, 50, 290–295. [Google Scholar] [CrossRef]

- Ropyak, L.; Shihab, T.; Velychkovych, A.; Dubei, O.; Tutko, T.; Bilinskyi, V. Design of a Two-Layer Al–Al2O3 Coating with an Oxide Layer Formed by the Plasma Electrolytic Oxidation of Al for the Corrosion and Wear Protections of Steel. Prog. Phys. Met. 2023, 24, 319–365. [Google Scholar] [CrossRef]

- Dai, W.; Li, C.; He, D.; Yang, H.; Dong, C. Mechanism of Residual Stress and Surface Roughness of Substrate on Fatigue Behavior of Micro-Arc Oxidation Coated AA7075-T6 Alloy. Surf. Coat. Technol. 2019, 380, 125014. [Google Scholar] [CrossRef]

- Ropyak, L.; Shihab, T.; Velychkovych, A.; Bilinskyi, V.; Malinin, V.; Romaniv, M. Optimization of Plasma Electrolytic Oxidation Technological Parameters of Deformed Aluminum Alloy D16T in Flowing Electrolyte. Ceramics 2023, 6, 146–167. [Google Scholar] [CrossRef]

- Student, M.M.; Ivasenko, I.B.; Posuvailo, O.V.; Veselivs’ka, H.H.; Pokhmurs’kyi, A.Y.; Sirak, Y.Y.; Yus’kiv, V.M. Influence of the Porosity of a Plasma-Electrolytic Coating on the Corrosion Resistance of D16 Alloy. Mater. Sci. 2019, 54, 899–906. [Google Scholar] [CrossRef]

- Simchen, F.; Sieber, M.; Kopp, A.; Lampke, T. Introduction to Plasma Electrolytic Oxidation—An Overview of the Process and Applications. Coatings 2020, 10, 628. [Google Scholar] [CrossRef]

- Student, M.M.; Pohrelyuk, I.M. Modification of the Surfaces of Aluminum and Titanium Alloys Aimed at the Improvement of Their Wear Resistance and Tribological Characteristics. Mater. Sci. 2021, 57, 377–386. [Google Scholar] [CrossRef]

- Ahmed, W.K.; Mourad, A.-H.I. Strengthening of Misaligned Welded Pipes with Outer Circumferentially Crack Using FRP Bandage Finite Element Analysis. J. Mech. Eng. Technol. 2013, 1, 66–73. [Google Scholar] [CrossRef]

- Shatskyi, I.P.; Makoviichuk, M.V.; Shcherbii, A.B. Equilibrium of Cracked Shell with Flexible Coating. In Shell Structures: Theory and Applications; Pietraszkiewicz, W., Witkowski, W., Eds.; CRC Press: Leiden, The Netherlands, 2018; Volume 4, pp. 165–168. [Google Scholar] [CrossRef]

- Shats’kyi, I.P.; Makoviichuk, M.V.; Shcherbii, A.B. Influence of a Flexible Coating on the Strength of a Shallow Cylindrical Shell with Longitudinal Crack. J. Math. Sci. 2019, 238, 165–173. [Google Scholar] [CrossRef]

- Dutkiewicz, M.; Dalyak, T.; Shatskyi, I.; Venhrynyuk, T.; Velychkovych, A. Stress Analysis in Damaged Pipeline with Composite Coating. Appl. Sci. 2021, 11, 10676. [Google Scholar] [CrossRef]

- Shatskyi, I.P.; Makoviichuk, M.V.; Shcherbii, A.B. Influence of Flexible Coating on the Limit Equilibrium of a Spherical Shell with Meridional Crack. Mater. Sci. 2020, 55, 484–491. [Google Scholar] [CrossRef]

- Makoviichuk, M.V.; Shatskyi, I.P.; Shcherbii, A.B. On the Distribution of Stresses Near the Crack in a Toroidal Shell with a Flexible Coating. Bull. Taras Shevchenko Natl. Univ. Kyiv Phys. Math. 2021, 3, 67–70. [Google Scholar] [CrossRef] [PubMed]

- Buketov, A.V.; Sapronova, A.V.; Sapronov, O.O.; Buketova, N.M.; Sotsenko, V.V.; Brailo, M.V.; Yakushchenko, S.V.; Maruschak, P.O.; Panin, S.V.; Smetankin, S.O.; et al. Influence of the structure of epoxy composite filled with discrete fibers on impact fracture of vehicle parts. Compos. Mech. Comput. Appl. 2020, 11, 113–127. [Google Scholar] [CrossRef]

- Stukhlyak, P.D.; Mytnyk, M.M.; Orlov, V.O. Influence of Boundary Interlayers on Properties of Composite Polymeric Materials (a Review). Mater. Sci. 2001, 37, 80–86. [Google Scholar] [CrossRef]

- Sapronov, O.; Maruschak, P.; Sotsenko, V.; Buketova, N.; Bertem, A.; Sapronova, A.; Prentkovskis, O. Development and Use of New Polymer Adhesives for the Restoration of Marine Equipment Units. J. Mar. Sci. Eng. 2020, 8, 527. [Google Scholar] [CrossRef]

- Dobrotvor, I.H.; Stukhlyak, P.D.; Buketov, A.V. Investigation of the Formation of External Surface Layers in Epoxy Composites. Mater. Sci. 2009, 45, 582–588. [Google Scholar] [CrossRef]

- Totosko, O.; Stukhlyak, P.; Mytnyk, M.; Dolgov, N.; Zolotiy, R.; Stukhlyak, D. Investigation of Corrosion Resistance of Two-Layer Protective Coatings. In Proceedings of the 3rd International Conference on Challenges to National Defence in Contemporary Geopolitical Situation, CNDCGS 2022, Vilnius, Lithuania, 15–16 September 2022; General Jonas Zemaitis Military Academy of Lithuania: Vilnius, Lithuania, 2022; Volume 1, pp. 50–54. [Google Scholar] [CrossRef]

- Bagliuk, G.; Baranovska, O.; Varchenko, V.; Buketov, A.; Sapronov, O.; Ivanchenco, S. Tribological Properties of Epoxy Matrix Composites Filled with Particles of Multicomponent Titanium-Based Alloy. J. Mater. Sci. Mater. Eng. 2025, 20, 18. [Google Scholar] [CrossRef]

- Korzhyk, V.; Kushnarova, O.; Berdnikova, O.; Stukhliak, P.; Kolisnichenko, O.; Totosko, O. Influence of Structure on the Properties of Coatings during Multi-Chamber Detonation Spraying of Al2O3 Powder on Steel. In Proceedings of the 2024 IEEE 14th International Conference on Nanomaterials: Applications & Properties (NAP), Riga, Latvia, 8–13 September 2024; IEEE: Piscataway, NL, USA, 2024; pp. 1–4. [Google Scholar] [CrossRef]

- Buketov, A.; Brailo, M.; Yakushchenko, S.; Sapronova, A. Development of Epoxy-Polyester Composite with Improved Thermophysical Properties for Restoration of Details of Sea and River Transport. Adv. Mater. Sci. Eng. 2018, 2018, 6378782. [Google Scholar] [CrossRef]

- Panda, A.; Dyadyura, K.; Valíček, J.; Harničárová, M.; Kušnerová, M.; Ivakhniuk, T.; Hrebenyk, L.; Sapronov, O.; Sotsenko, V.; Vorobiov, P.; et al. Ecotoxicity Study of New Composite Materials Based on Epoxy Matrix DER-331 Filled with Biocides Used for Industrial Applications. Polymers 2022, 14, 3275. [Google Scholar] [CrossRef]

- Duriagina, Z.A.; Tepla, T.L.; Kulyk, V.V. Evaluation of Di erences between Fe3O4 Micro- and Nanoparticles Properties. Acta Phys. Pol. A 2018, 133, 869–872. [Google Scholar] [CrossRef]

- Buketov, A.; Smetankin, S.; Maruschak, P.; Yurenin, K.; Sapronov, O.; Matvyeyev, V.; Menou, A. New Black-Filled Epoxy Coatings for Repairing Surfaces of Marine Ship Equipment. Transport 2020, 35, 679–690. [Google Scholar] [CrossRef]

- Sirota, V.V.; Gevorkyan, É.S.; Kovaleva, M.G.; Ivanisenko, V.V. Structure and properties of nanoporous ceramic Al2O3 obtained by isostatic pressing. Glass Ceram. 2013, 69, 342–345. [Google Scholar] [CrossRef]

- Gevorkyan, E.S.; Nerubatskyi, V.P.; Vovk, R.V.; Chyshkala, V.O.; Kislitsa, M.V. Structure Formation in Silicon Carbide–Alumina Composites during Electroconsolidation. J. Superhard Mater. 2022, 44, 339–349. [Google Scholar] [CrossRef]

- ISO 209:2024; Wrought Aluminium and Aluminium Alloys—Chemical Composition. International Organization for Standardization: Geneva, Switzerland, 2024.

- ISO 9001:2015; Quality Management Systems—Requirements. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 14001:2015; Environmental Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2015.

- Kolisnichenko, O.V.; Tyurin, Y.N.; Tovbin, R. Efficiency of process of coating spraying using multichamber detonation unit. Avtom. Svarka 2017, 10, 28–34. [Google Scholar] [CrossRef]

- Korzhyk, V.; Stukhliak, P.; Berdnikova, O.; Zhao, J.; Lepilina, K.; Skachkov, I. Metal-Ceramic and Epoxy Composite Materials Nanostructure Coatings. In Proceedings of the 2023 IEEE 13th International Conference Nanomaterials: Applications and Properties, NAP 2023, Bratislava, Slovakia, 10–15 September 2023; pp. MTFC031–MTFC034. [Google Scholar] [CrossRef]

- Kaushal, G.; Singh, H.; Prakash, S. Surface Engineering, by Detonation-Gun Spray Coating, of 347H Boiler Steel to Enhance Its High-Temperature Corrosion Resistance. Mater. High Temp. 2011, 28, 1–11. [Google Scholar] [CrossRef]

- Borysov, Y.S.; Borysova, A.L.; Vigilyanska, N.V.; Gryshchenko, O.P.; Kolomytsev, M.V. Coatings Based on Fe–Al Intermetallics Produced by Plasma and Supersonic Plasma Gas-Air Spraying. Paton Weld. J. 2020, 7, 29–37. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, H.; Ren, C.; Li, Z.; Hou, S. Microstructure and Properties of Stellite 6/WC Composite Coatings Prepared by Laser Cladding. Lasers Manuf. Mater. Process. 2023, 10, 645–658. [Google Scholar] [CrossRef]

- Das, R.; Bandyopadhyay, P.P. Influence of Load, Sliding Speed, and Temperature on the Tribological Behavior of Plasma-Sprayed BaF2-Doped YSZ Composite Coatings. J. Eur. Ceram. Soc. 2025, 45, 117476. [Google Scholar] [CrossRef]

- Kryl’, Y.A.; Prysyazhnyuk, P.M. Structure formation and properties of NbC-Hadfield steel cermets. J. Superhard Mater. 2013, 35, 292–297. [Google Scholar] [CrossRef]

- Shihab, S.T.A.; Prysyazhnyuk, P.; Andrusyshyn, R.; Lutsak, L.; Ivanov, O.; Tsap, I. Forming the structure and the properties of electric arc coatings based on high manganese steel alloyed with titanium and niobium carbides. East.-Eur. J. Enterp. Technol. 2020, 1, 38–44. [Google Scholar] [CrossRef]

- Prysyazhnyuk, P.; Shlapak, L.; Semyanyk, I.; Kotsyubynsky, V.; Troshchuk, L.; Korniy, S.; Artym, V. Analysis of the effects of alloying with Si and Cr on the properties of manganese austenite based on AB INITIO modelling. East.-Eur. J. Enterp. Technol. 2020, 6, 28–36. [Google Scholar] [CrossRef]

- Prysyazhnyuk, P.; Di Tommaso, D. The thermodynamic and mechanical properties of Earth-abundant metal ternary boride Mo2(Fe,Mn)B2 solid solutions for impact- and wear-resistant alloys. Mater. Adv. 2023, 4, 3822–3838. [Google Scholar] [CrossRef]

- ISO 1463:2021; Metallic and Oxide Coatings—Measurement of Coating Thickness—Microscopical Method. International Organization for Standardization: Geneva, Switzerland, 2021.

- Budnik, A.; Berladir, K.; Sviderskiy, V.; Budnik, O.; Rudenko, P.; Ilinyh, A. Physical and chemical aspects of mechanical activation of polytetrafluoroethylene composite in obtaining and recycling. East.-Eur. J. Enterp. Technol. 2014, 2, 9–15. [Google Scholar] [CrossRef]

- Yang, H.-Q.; Zhang, Q.; Li, Y.-M.; Liu, G.; Huang, Y. Effects of mechanical stress and cathodic protection on the performance of a marine organic coating on mild steel. Mater. Chem. Phys. 2021, 261, 124233. [Google Scholar] [CrossRef]

- Liu, J.; Lu, Z.; Zhang, L.; Li, C.; Ding, R.; Zhao, X.; Zhang, P.; Wang, B.; Cui, H. Studies of corrosion behaviors of a carbon steel/copper-nickel alloy couple under epoxy coating with artificial defect in 3.5 wt.% NaCl solution using the WBE and EIS techniques. Prog. Org. Coat. 2020, 148, 105909. [Google Scholar] [CrossRef]

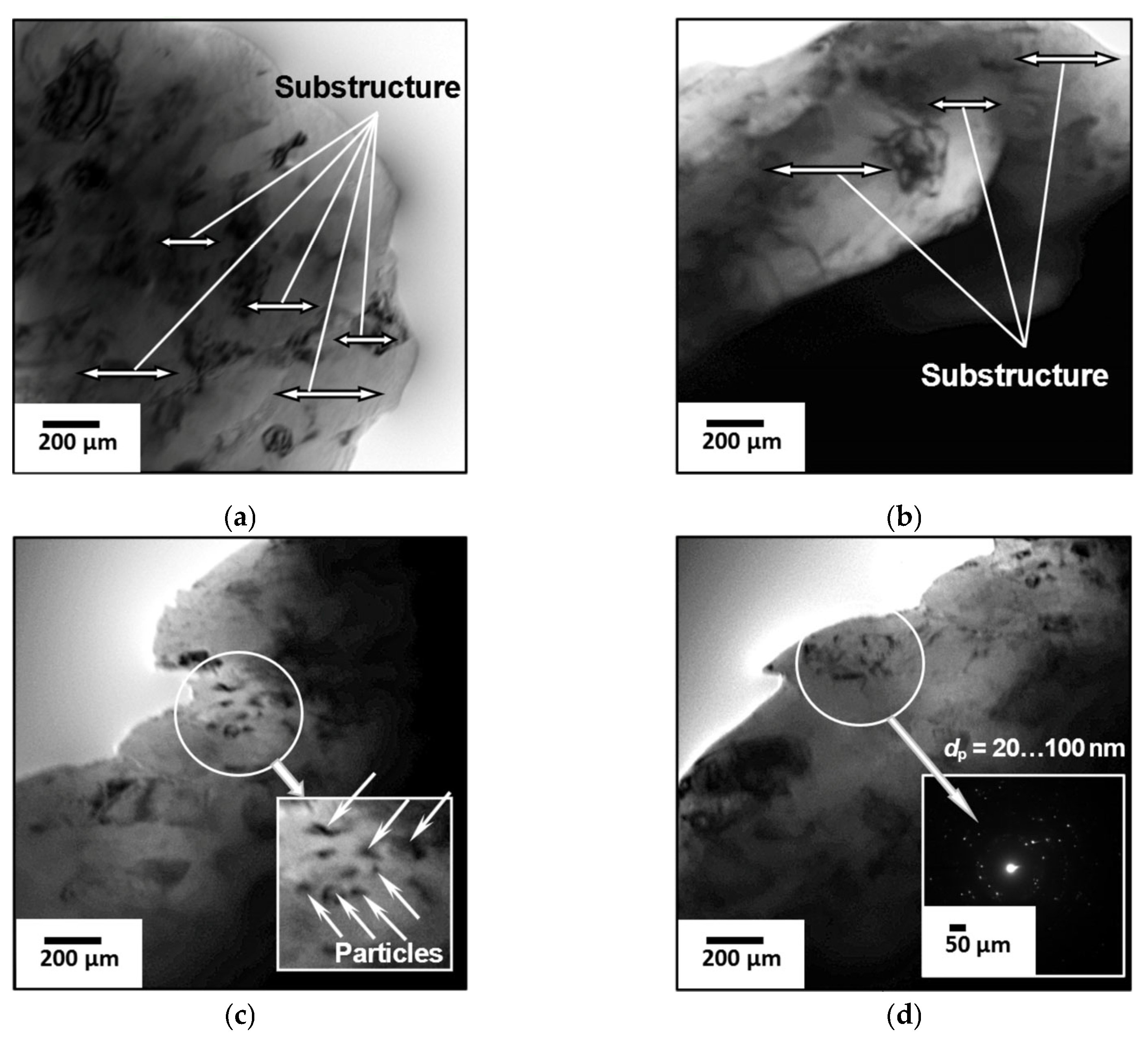

| Thin Structure Parameters | Strengthening, MPa | ||

|---|---|---|---|

| ds, nm | 100–600 | Subgrain (ΔσS) | 100–875 |

| dp, nm | 10–120 | Dispersion (ΔσD.H.) | 884–1256 |

| λp, nm | 15–60 | ||

| ρ (coating), cm–2 | (2–3) × 109 | Dislocation (ΔσD) | 124–152 |

| ρ (F/L), cm–2 | (4–5) × 1010 | 196–215 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korzhyk, V.; Kopei, V.; Stukhliak, P.; Berdnikova, O.; Kushnarova, O.; Kolisnichenko, O.; Totosko, O.; Stukhliak, D.; Ropyak, L. Features of the Structure of Layered Epoxy Composite Coatings Formed on a Metal-Ceramic-Coated Aluminum Base. Materials 2025, 18, 3620. https://doi.org/10.3390/ma18153620

Korzhyk V, Kopei V, Stukhliak P, Berdnikova O, Kushnarova O, Kolisnichenko O, Totosko O, Stukhliak D, Ropyak L. Features of the Structure of Layered Epoxy Composite Coatings Formed on a Metal-Ceramic-Coated Aluminum Base. Materials. 2025; 18(15):3620. https://doi.org/10.3390/ma18153620

Chicago/Turabian StyleKorzhyk, Volodymyr, Volodymyr Kopei, Petro Stukhliak, Olena Berdnikova, Olga Kushnarova, Oleg Kolisnichenko, Oleg Totosko, Danylo Stukhliak, and Liubomyr Ropyak. 2025. "Features of the Structure of Layered Epoxy Composite Coatings Formed on a Metal-Ceramic-Coated Aluminum Base" Materials 18, no. 15: 3620. https://doi.org/10.3390/ma18153620

APA StyleKorzhyk, V., Kopei, V., Stukhliak, P., Berdnikova, O., Kushnarova, O., Kolisnichenko, O., Totosko, O., Stukhliak, D., & Ropyak, L. (2025). Features of the Structure of Layered Epoxy Composite Coatings Formed on a Metal-Ceramic-Coated Aluminum Base. Materials, 18(15), 3620. https://doi.org/10.3390/ma18153620