Microstructural, Mechanical, and Thermal Properties of Textured Si3N4/BN Composite Ceramics Prepared Using Two-Step Sintering

Abstract

1. Introduction

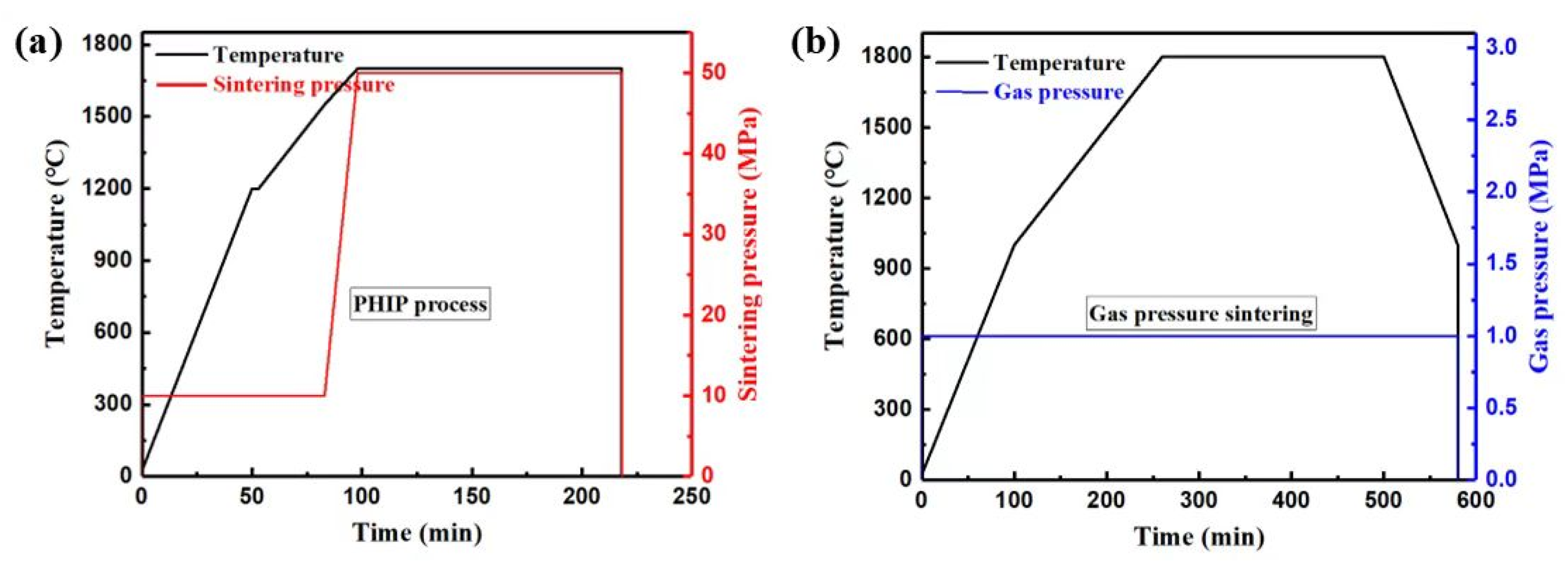

2. Experimental Procedures

3. Discussion

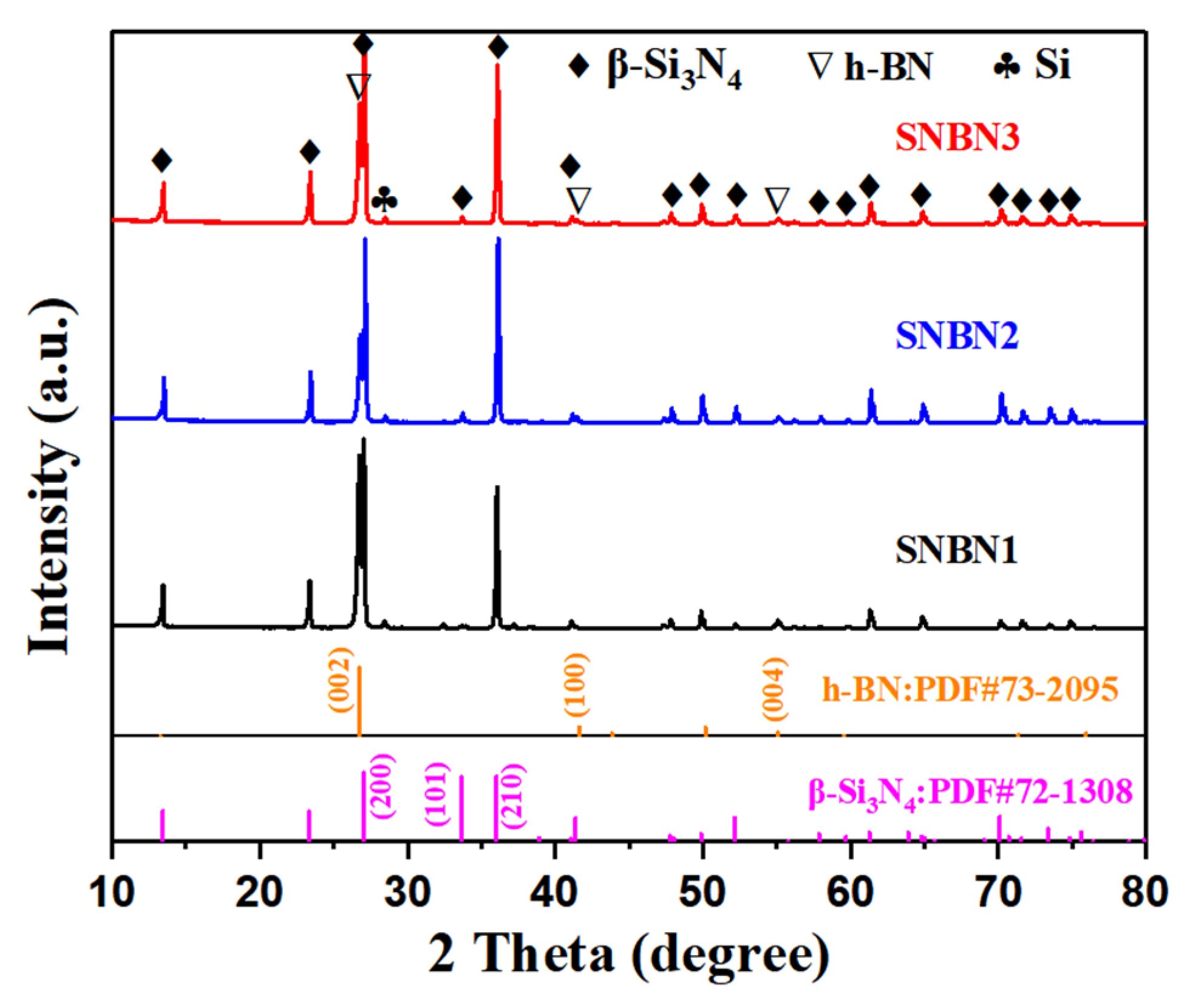

3.1. Phase Analysis

3.2. Microstructural Characterization

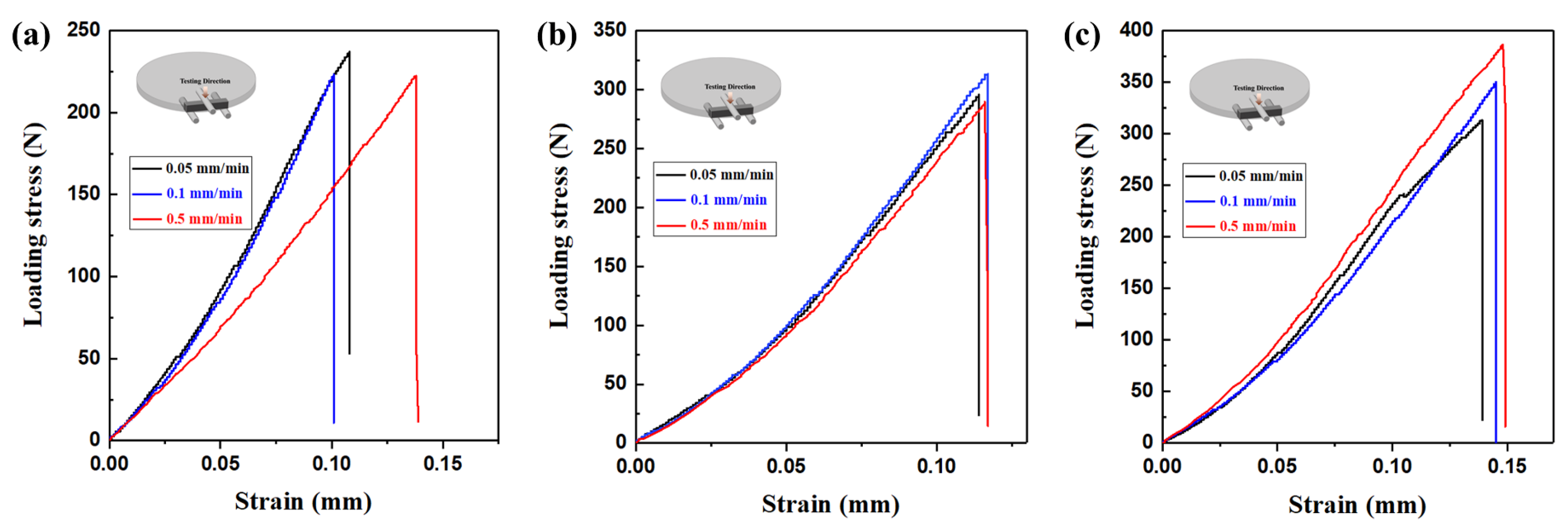

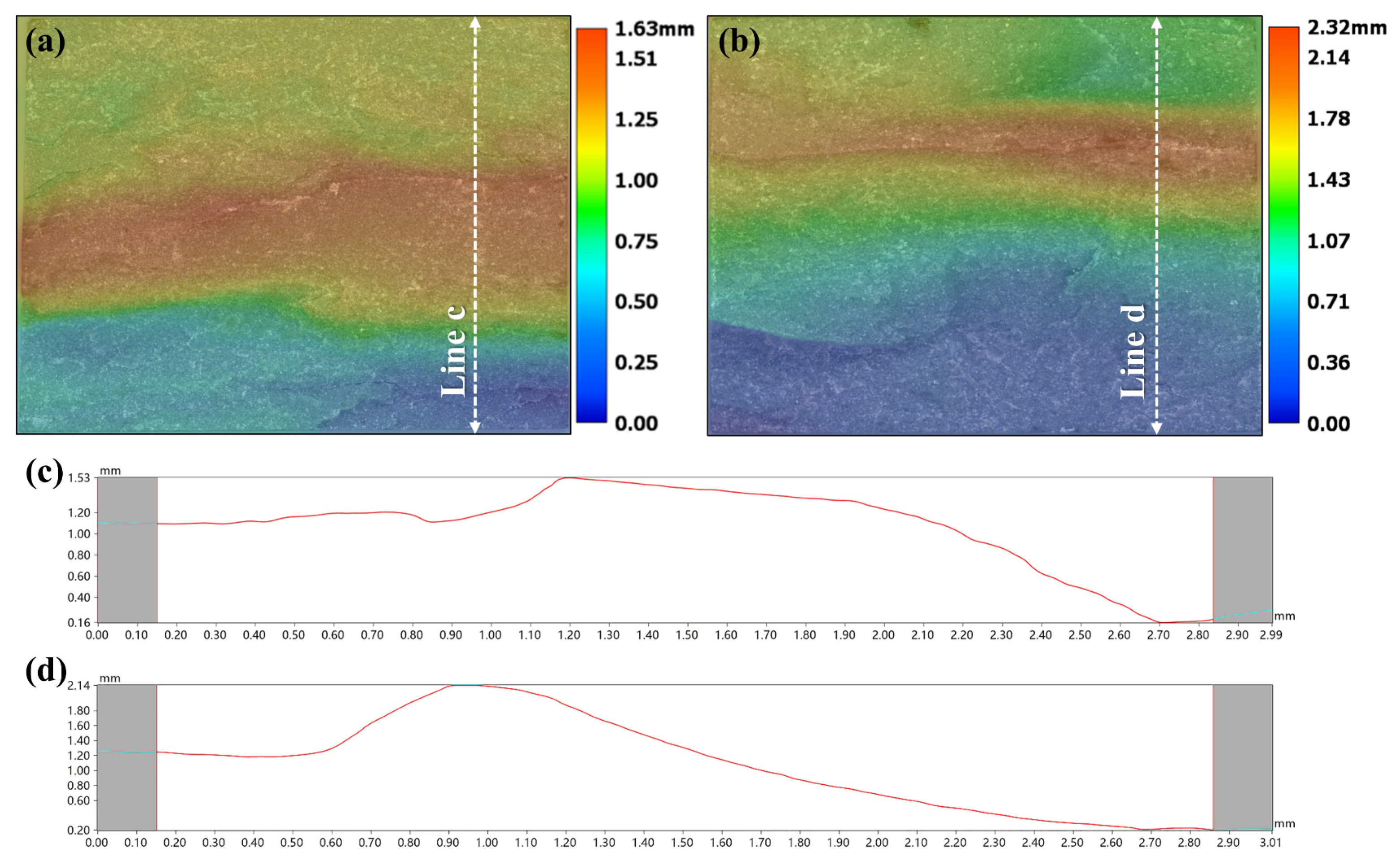

3.3. Anisotropy of Mechanical and Thermal Properties

4. Conclusions

- (1)

- The h-BN platelets and rod-like β-Si3N4 grains are distributed on the sintered plane in an orderly fashion. This textured microstructure yields a unique bimodal texture, which can be attributed to the orientation of anisotropic grains during the PHIP process.

- (2)

- (The h-BN grain size has a significant influence on the densification and mechanical properties of Si3N4/BN composite ceramics. A decrease in h-BN grain size is conducive to densification during sintering. However, the increased formation of the intergranular h-BN phase (< 500 nm) represents a structural flaw, worsening the mechanical properties. Therefore, fine h-BN powders with grain sizes > 500 nm are favorable for the fabrication of densified Si3N4/BN composite ceramics with beneficial mechanical properties.

- (3)

- The bimodal texture is advantageous in improving thermal conductivity and anisotropy. Under a low sintering temperature of 1800 °C and short dwelling time of 4 h, SNBN2 exhibits a high thermal conductivity of 92.61 W∙m−1∙K−1 and high thermal anisotropy of 2.17.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, Y.; Hyuga, H.; Kusano, D.; Yoshizawa, Y.-I.; Hirao, K. A Tough Silicon Nitride Ceramic with High Thermal Conductivity. Adv. Mater. 2011, 23, 4563–4567. [Google Scholar] [CrossRef]

- Aiyi, P.; Junguo, L.; Yang, C.; Meijuan, L.; Qiang, S. Low-temperature fabrication of Si3N4 ceramics with high thermal conductivities using a single Mg2Si sintering additive. Ceram. Int. 2023, 49, 39473–39478. [Google Scholar] [CrossRef]

- Liang, H.; Wang, W.; Zuo, K.; Xia, Y.; Yao, D.; Yin, J.; Zeng, Y. YB2C2: A new additive for fabricating Si3N4 ceramics with superior mechanical properties and medium thermal conductivity. Ceram. Int. 2020, 46, 5239–5243. [Google Scholar] [CrossRef]

- Wasanapiarnpong, T.; Wada, S.; Imai, M.; Yano, T. Effect of post-sintering heat-treatment on thermal and mechanical properties of Si3N4 ceramics sintered with different additives. J. Eur. Ceram. Soc. 2006, 26, 3467–3475. [Google Scholar] [CrossRef]

- Zhu, X.W.; Sakka, Y.; Zhou, Y.; Hirao, K.; Itatani, K. A strategy for fabricating textured silicon nitride with enhanced thermal conductivity. J. Eur. Ceram. Soc. 2014, 34, 2585–2589. [Google Scholar] [CrossRef]

- Wu, D.; Wang, C.; Hu, X.; Chen, W. Fabrication and characterization of highly thermal conductive Si3N4/diamond composite materials. Mater. Des. 2023, 225, 111482. [Google Scholar] [CrossRef]

- Yang, C.; Ye, F.; Ma, J.; Ding, J.; Zhang, B.; Liu, Q.; Zhang, H. Comparative study of fluoride and non-fluoride additives in high thermal conductive silicon nitride ceramics fabricated by spark plasma sintering and post-sintering heat treatment. Ceram. Int. 2018, 44, 23202–23207. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, B.; Li, C.; Wang, L.; Wang, S.; Shi, Z.; Yang, J. Fabrication of Si3N4 ceramics with high thermal conductivity and flexural strength via novel two-step gas-pressure sintering. J. Eur. Ceram. Soc. 2022, 42, 4846–4854. [Google Scholar] [CrossRef]

- Li, Y.; Kim, H.-N.; Wu, H.; Kim, M.-J.; Ko, J.-W.; Park, Y.-J.; Huang, Z.; Kim, H.-D. Enhanced thermal conductivity in Si3N4 ceramic by addition of a small amount of carbon. J. Eur. Ceram. Soc. 2019, 39, 157–164. [Google Scholar] [CrossRef]

- Liao, S.; Zhou, L.; Jiang, C.; Wang, J.; Zhuang, Y.; Li, S. Thermal conductivity and mechanical properties of Si3N4 ceramics with binary fluoride sintering additives. J. Eur. Ceram. Soc. 2021, 41, 6971–6982. [Google Scholar] [CrossRef]

- Wang, W.; Yao, D.; Liang, H.; Xia, Y.; Zuo, K.; Yin, J.; Zeng, Y.-P. Novel silicothermic reduction method to obtain Si3N4 ceramics with enhanced thermal conductivity and fracture toughness. J. Eur. Ceram. Soc. 2021, 41, 1735–1738. [Google Scholar] [CrossRef]

- Li, Y.; Kim, H.-N.; Wu, H.; Kim, M.-J.; Ko, J.-W.; Park, Y.-J.; Huang, Z.; Kim, H.-D. Microstructure and thermal conductivity of gas-pressure-sintered Si3N4 ceramic: The effects of Y2O3 additive content. J. Eur. Ceram. Soc. 2021, 41, 274–283. [Google Scholar] [CrossRef]

- He, H.; Peng, W.; Liu, J.; Chan, X.Y.; Liu, S.; Lu, L.; Le Ferrand, H. Microstructured BN Composites with Internally Designed High Thermal Conductivity Paths for 3D Electronic Packaging. Adv. Mater. 2022, 34, 2205120. [Google Scholar] [CrossRef]

- Hirosaki, N.; Ogata, S.; Kocer, C.; Kitagawa, H.; Nakamura, Y. Molecular dynamics calculation of the ideal thermal conductivity of single-crystal α- and β-Si3N4. Phys. Rev. B 2022, 65, 134110. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, J.; Ren, Y.; Wang, A.; He, Q.; He, Y.; Wang, H.; Wang, W.; Fu, Z. Prediction and fabrication of textured Si3N4 ceramics via grain rotation model. Mater. Des. 2024, 245, 113275. [Google Scholar] [CrossRef]

- Zhang, Z.; Duan, X.; Qiu, B.; Chen, L.; Zhang, P.; Cai, D.; He, P.; Zhang, H.; Wei, Z.; Yang, Z.; et al. Microstructure evolution and grain growth mechanisms of h-BN ceramics during hot-pressing. J. Eur. Ceram. Soc. 2020, 40, 2268–2278. [Google Scholar] [CrossRef]

- Gao, L.; Jin, X.; Li, J.; Li, Y.; Sun, J. BN/Si3N4 nanocomposite with high strength and good machinability. Mater. Sci. Eng. A 2006, 415, 145–148. [Google Scholar] [CrossRef]

- Li, Y.; Liu, P.; Wang, X.; Jin, H.; Yang, J.; Qiao, G. Interface structure and formation mechanism of BN/intergranular amorphous phase in pressureless sintered Si3N4/BN composites. Scr. Mater. 2010, 63, 185–188. [Google Scholar] [CrossRef]

- Jin, X.; Sun, Y.; Hu, Y.; Zhao, L.; Li, P.; Ran, S. Enhanced mechanical and dielectric properties of Si3N4−BN composite ceramics fabricated via reaction re-sinteirng process. Ceram. Int. 2025, 51, 1310–1317. [Google Scholar] [CrossRef]

- Chen, S.; Wang, L.; He, G.; Shao, G.; Wang, H.; Li, J.; Wang, C.-A. Preparation and characteristics of highly porous BN-Si3N4 composite ceramics by combustion synthesis. J. Eur. Ceram. Soc. 2022, 42, 4835–4845. [Google Scholar] [CrossRef]

- Xue, J.; Ren, F.; Dong, Y.; Wei, H.; Yang, F.; Cheng, L. Si3N4-BN-SiCN ceramics with unique hetero-interfaces for enhancing microwave absorption properties. Ceram. Int. 2021, 47, 12261–12268. [Google Scholar] [CrossRef]

- Wang, S.; Jia, D.; Yang, Z.; Duan, X.; Tian, Z.; Zhou, Y. Effect of BN content on microstructures, mechanical and dielectric properties of porous BN/Si3N4 composite ceramics prepared by gel casting. Ceram. Int. 2013, 39, 4231–4237. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Simonenko, N.P.; Gordeev, A.N.; Papynov, E.K.; Shichalin, O.O.; Kolesnikov, A.F.; Avramenko, V.A.; Sevastyanov, V.G.; Kuznetsov, N.T. Study of the Thermal Behavior of Wedge-Shaped Samples of HfB2–45 vol % SiC Ultra-High-Temperature Composite in a High-Enthalpy Air Flow. Russ. J. Inorg. Chem. 2018, 63, 421–432. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Gordeev, A.N.; Simonenko, N.P.; Vasilevskii, S.A.; Kolesnikov, A.F.; Papynov, E.K.; Shichalin, O.O.; Avramenko, V.A.; Sevastyanov, V.G.; Kuznetsov, N.T. Behavior of HfB2-SiC (10, 15, and 20 vol %) ceramic materials in high-enthalpy air flows. Russ. J. Inorg. Chem. 2016, 61, 1203–1218. [Google Scholar] [CrossRef]

- Sevast’yanov, V.G.; Simonenko, E.P.; Gordeev, A.N.; Simonenko, N.P.; Kolesnikov, A.F.; Papynov, E.K.; Shichalin, O.O.; Avramenko, V.A.; Kuznetsov, N.T. Production of ultrahigh temperature composite materials HfB2-SiC and the study of their behavior under the action of a dissociated air flow. Russ. J. Inorg. Chem. 2013, 58, 1269–1276. [Google Scholar] [CrossRef]

- Shi, Y.; He, Q.; Wang, A.; Wang, H.; Wang, W.; Fu, Z. Anisotropies in microstructure and properties of Si3N4/BN composite ceramics: Synergistic effect of bimodal texture. Mater. Sci. Eng. A 2025, 930, 148162. [Google Scholar] [CrossRef]

- Kübler, J. Fracture Toughness of Ceramics Using the Sevnb Method: Preliminary Results. In Ceramic Engineering and Science Proceedings, Proceedings of the 21st Annual Conference on Composites, Advanced Ceramics, Materials, and Structures—B, Cocoa Beach, FL, USA, 12–16 January 1997; American Ceramic Society: Westerville, OH, USA, 1997; pp. 155–162. [Google Scholar]

- Zhang, M.; Yang, D.; Luo, H.; Liang, Q.; Wu, J.; Tang, X. Super-structured defects modulation for synergistically optimizing thermoelectric property in SnTe-based materials. Mater. Today Phys. 2022, 23, 100645. [Google Scholar] [CrossRef]

- Luo, J.; Li, J.; Li, M.; Shen, Q.; Zhang, Y. Low-temperature densification by plasma activated sintering of Mg2Si-added Si3N4. Ceram. Int. 2019, 45, 15128–15133. [Google Scholar] [CrossRef]

- Shi, Y.; Ren, Y.; He, Q.; Wang, J.; Wang, A.; Wang, H.; Wang, W.; Fu, Z. Fabrication of continuously and symmetrically graded Si3N4-based ceramics under uniformly thermal field. Mater. Charact. 2025, 220, 114665. [Google Scholar] [CrossRef]

- Zhang, W.; Cao, X.; Zhang, J.; Zou, J.; Wang, W.; He, Q.; Ren, L.; Zhang, F.; Fu, Z. B4C-based hard and tough ceramics densified via spark plasma sintering using a novel Mg2Si sintering aid. Ceram. Int. 2023, 49, 145–153. [Google Scholar] [CrossRef]

- Tatarková, M.; Tatarko, P.; Kovalčíková, A.; Dlouhý, I.; Dusza, J.; Šajgalík, P. Influence of hexagonal boron nitride nanosheets on phase transformation, microstructure evolution and mechanical properties of Si3N4 ceramics. J. Eur. Ceram. Soc. 2021, 41, 5115–5126. [Google Scholar] [CrossRef]

- Wu, S.; Xia, Y.; Zhu, M.; Zhao, J.; Yao, D.; Zeng, Y.-P. The effect of h-BN content on mechanical properties, microstructure and machinability of hot-pressed h-BN/Si3N4 composites. Ceram. Int. 2024, 50, 30445–30452. [Google Scholar] [CrossRef]

- Zou, W.; Cai, D.; Wang, B.; Zhu, Q.; Yang, Z.; Duan, X.; Duan, W.; Jia, D.; Zhou, Y. Effect of boron nitride content on mechanical, dielectric and thermal shock resistance properties of Si3N4-BN-MAS composites. Ceram. Int. 2024, 50, 29866–29876. [Google Scholar] [CrossRef]

- Niu, B.; Cai, D.; Yang, Z.; Duan, X.; Sun, Y.; Li, H.; Duan, W.; Jia, D.; Zhou, Y. Anisotropies in structure and properties of hot-press sintered h-BN-MAS composite ceramics: Effects of raw h-BN particle size. J. Eur. Ceram. Soc. 2019, 39, 539–546. [Google Scholar] [CrossRef]

- Tian, Z.; Lu, J.; Feng, X.; Feng, B.; Yin, C.; Lin, Y.; Wang, J. Effects of cross-scale h-BN grains and orientation degree on the mechanical and thermal properties of BN-matrix textured ceramics. Ceram. Int. 2023, 49, 12481–12490. [Google Scholar] [CrossRef]

| Materials | Fabrication Method | Flexural Strength (MPa) | Fracture Toughness (MPa∙m1/2) | Thermal Conductivity (RT, W∙m−1∙K−1) | Reference |

|---|---|---|---|---|---|

| h-BN-MAS | Hot pressing: 1800 °C/30 MPa/1 h | 222.9 | 2.7 | 94.3 | [35] |

| h-BN-YAG | Hot pressing: 1750 °C/20 MPa/1 h | 74.1 | 3.0 | 72.8 | [36] |

| β-Si3N4 | Gas pressure sintering: 1525 °C/3 h→1850 °C/3 h | 801.0 | — | 79.42 | [8] |

| β-Si3N4 | Gas pressure sintering: 1900 °C/4 h | 857.6 | 7.7 | 76 | [7] |

| h-BN/Si3N4 | Hot pressing: 1800 °C/30 MPa/2 h | 862.0 | 10.3 | 43 | [33] |

| h-BN/Si3N4 | PHIP+GPS: 1700 °C/2 h→1800 °C/4 h | 540.6 | 7.5 | 92.6 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, D.; Zhou, Y.; Shi, Y.; He, Q. Microstructural, Mechanical, and Thermal Properties of Textured Si3N4/BN Composite Ceramics Prepared Using Two-Step Sintering. Materials 2025, 18, 3573. https://doi.org/10.3390/ma18153573

Gong D, Zhou Y, Shi Y, He Q. Microstructural, Mechanical, and Thermal Properties of Textured Si3N4/BN Composite Ceramics Prepared Using Two-Step Sintering. Materials. 2025; 18(15):3573. https://doi.org/10.3390/ma18153573

Chicago/Turabian StyleGong, Dexiang, Yi Zhou, Yunwei Shi, and Qianglong He. 2025. "Microstructural, Mechanical, and Thermal Properties of Textured Si3N4/BN Composite Ceramics Prepared Using Two-Step Sintering" Materials 18, no. 15: 3573. https://doi.org/10.3390/ma18153573

APA StyleGong, D., Zhou, Y., Shi, Y., & He, Q. (2025). Microstructural, Mechanical, and Thermal Properties of Textured Si3N4/BN Composite Ceramics Prepared Using Two-Step Sintering. Materials, 18(15), 3573. https://doi.org/10.3390/ma18153573