Energy-Efficient Gold Flotation via Coarse Particle Generation Using VSI and HPGR Comminution

Abstract

1. Introduction

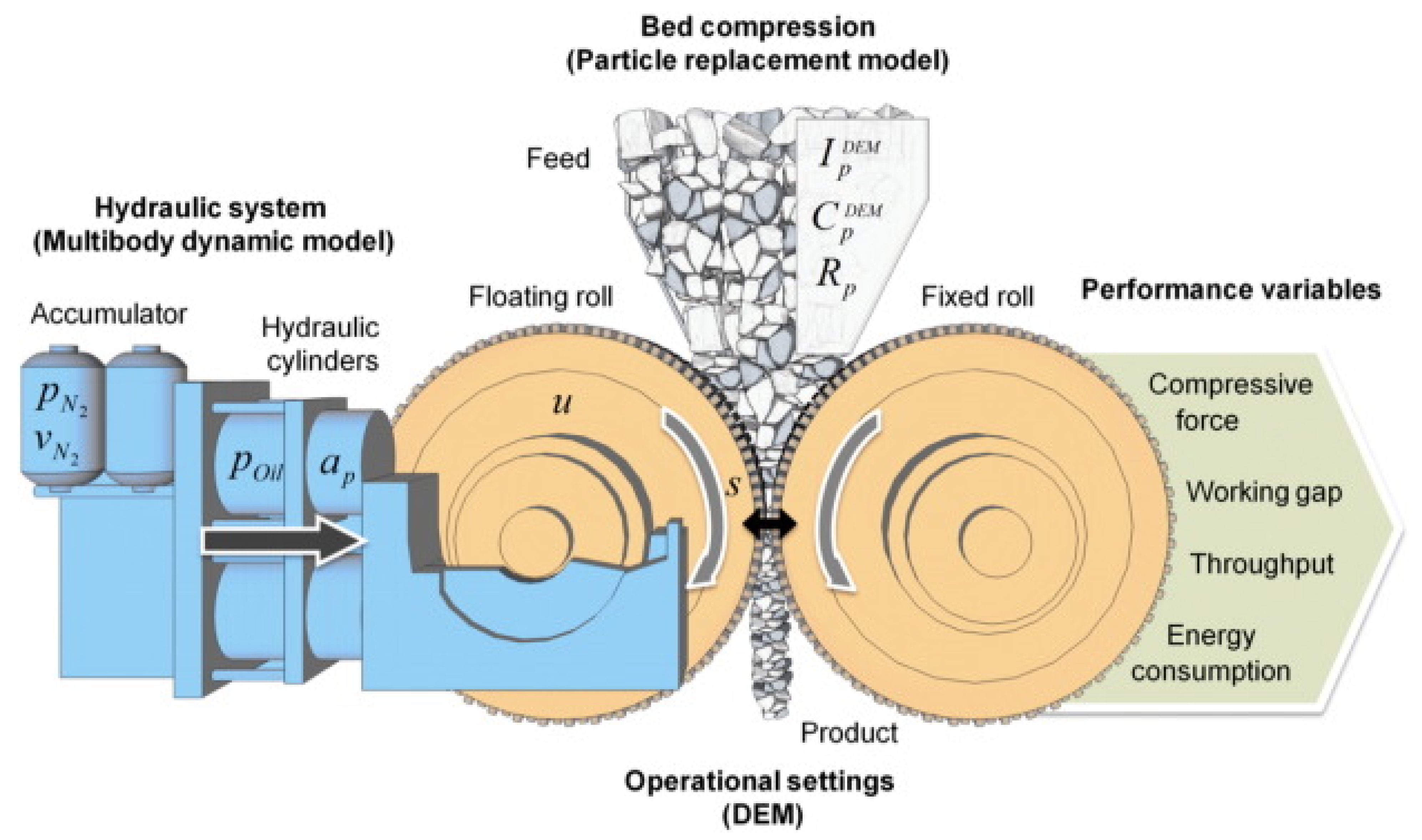

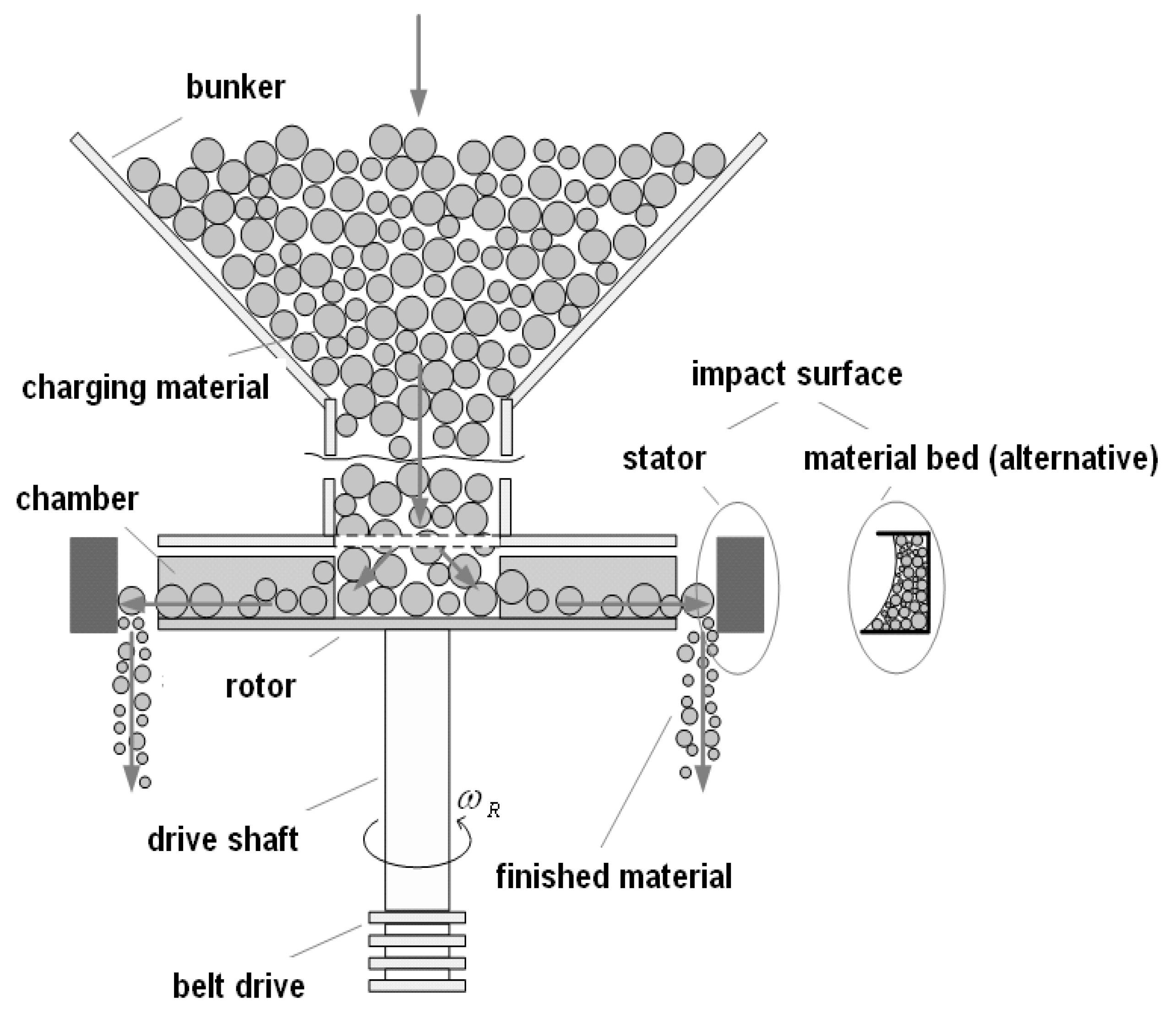

1.1. HPGR vs. VSI: Key Performance Differences

1.2. Overview of Flotation Efficiency

1.3. Objectives

2. Experimental Section

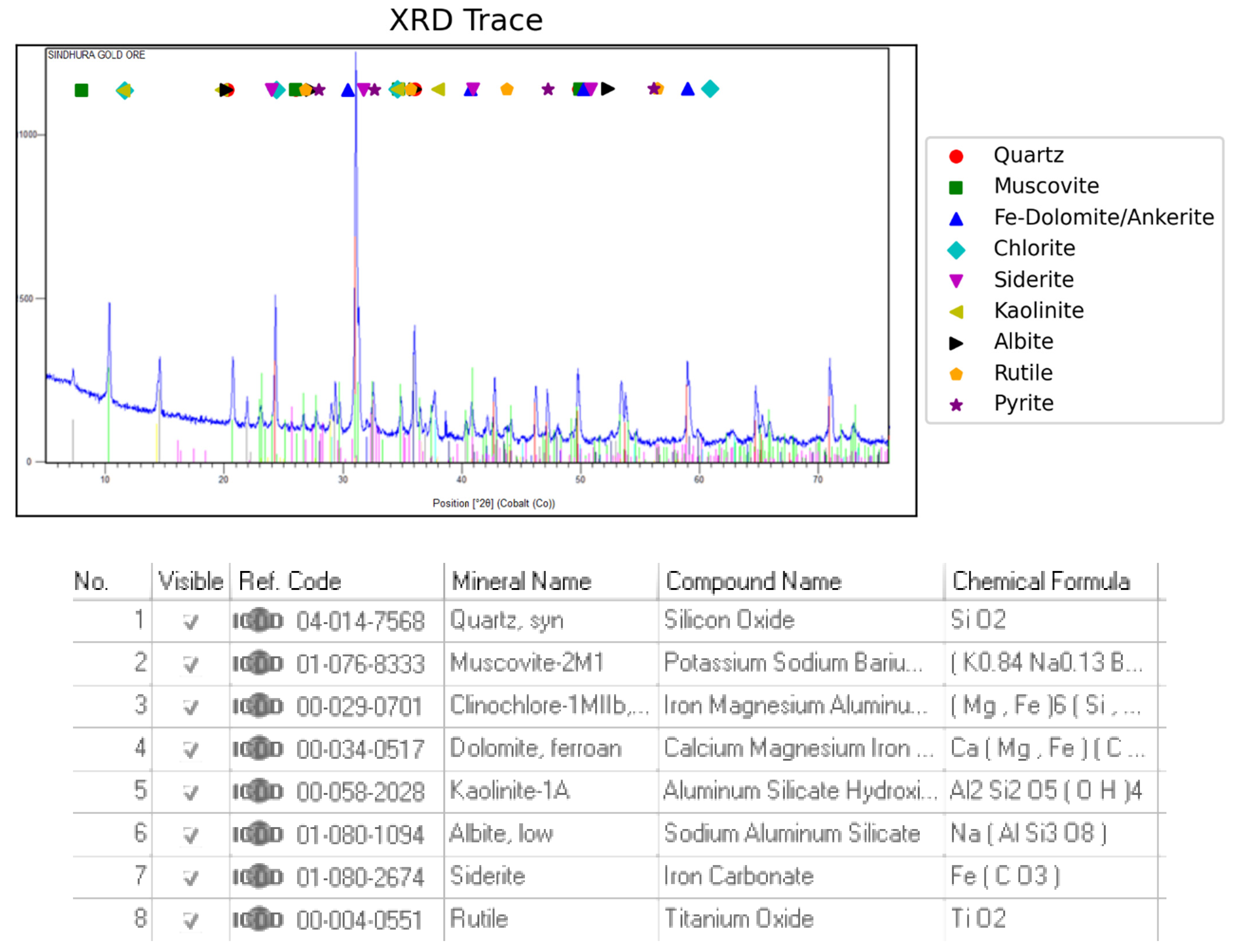

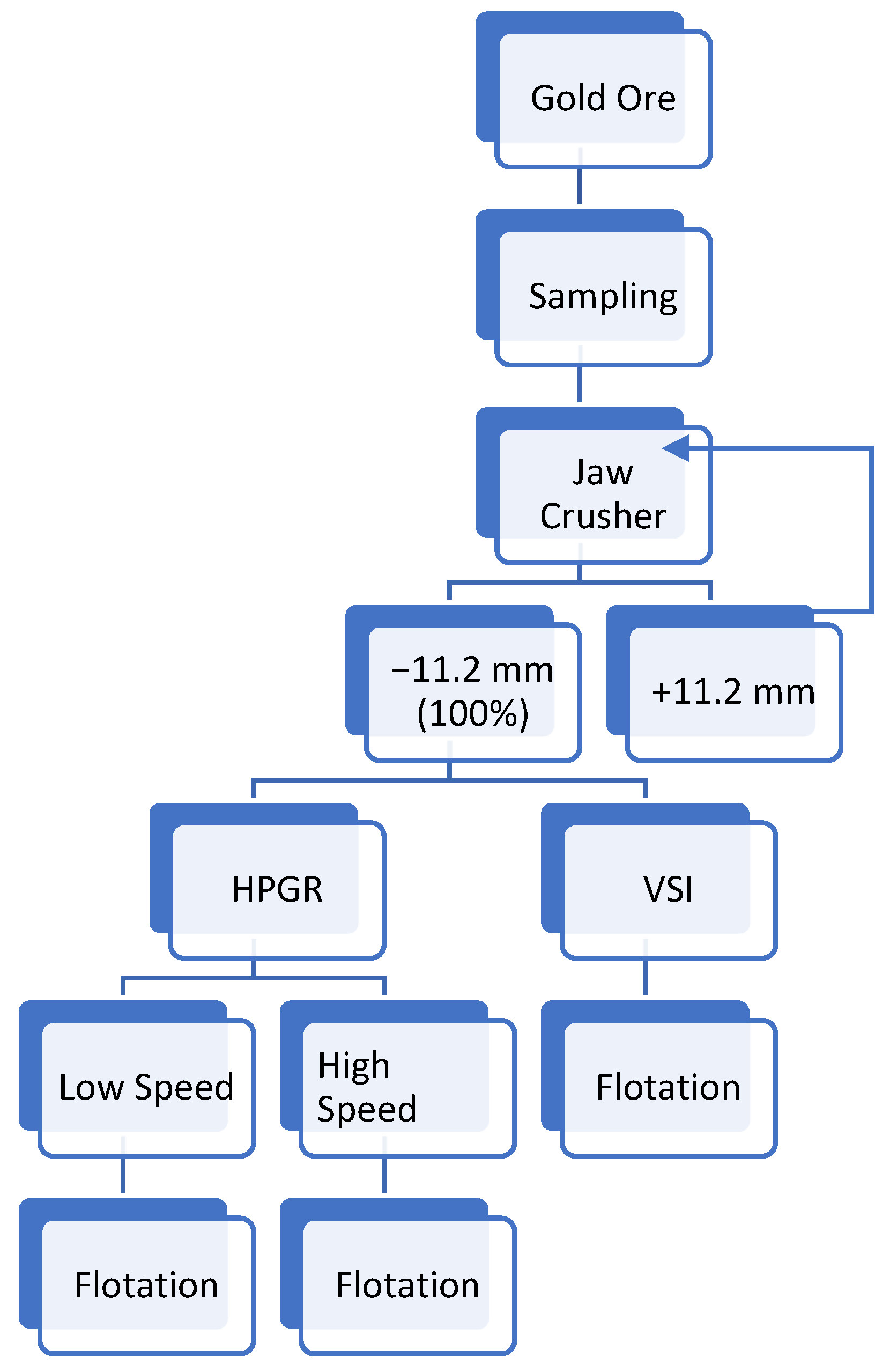

2.1. Sample Preparation

2.2. Expected Differential Breakage

2.2.1. Mineral-Specific Breakage Predictions

2.2.2. Implications for Liberation Efficiency

2.2.3. Optimization of Comminution Strategy

2.3. Methodology

2.3.1. Experiment Design for HPGR

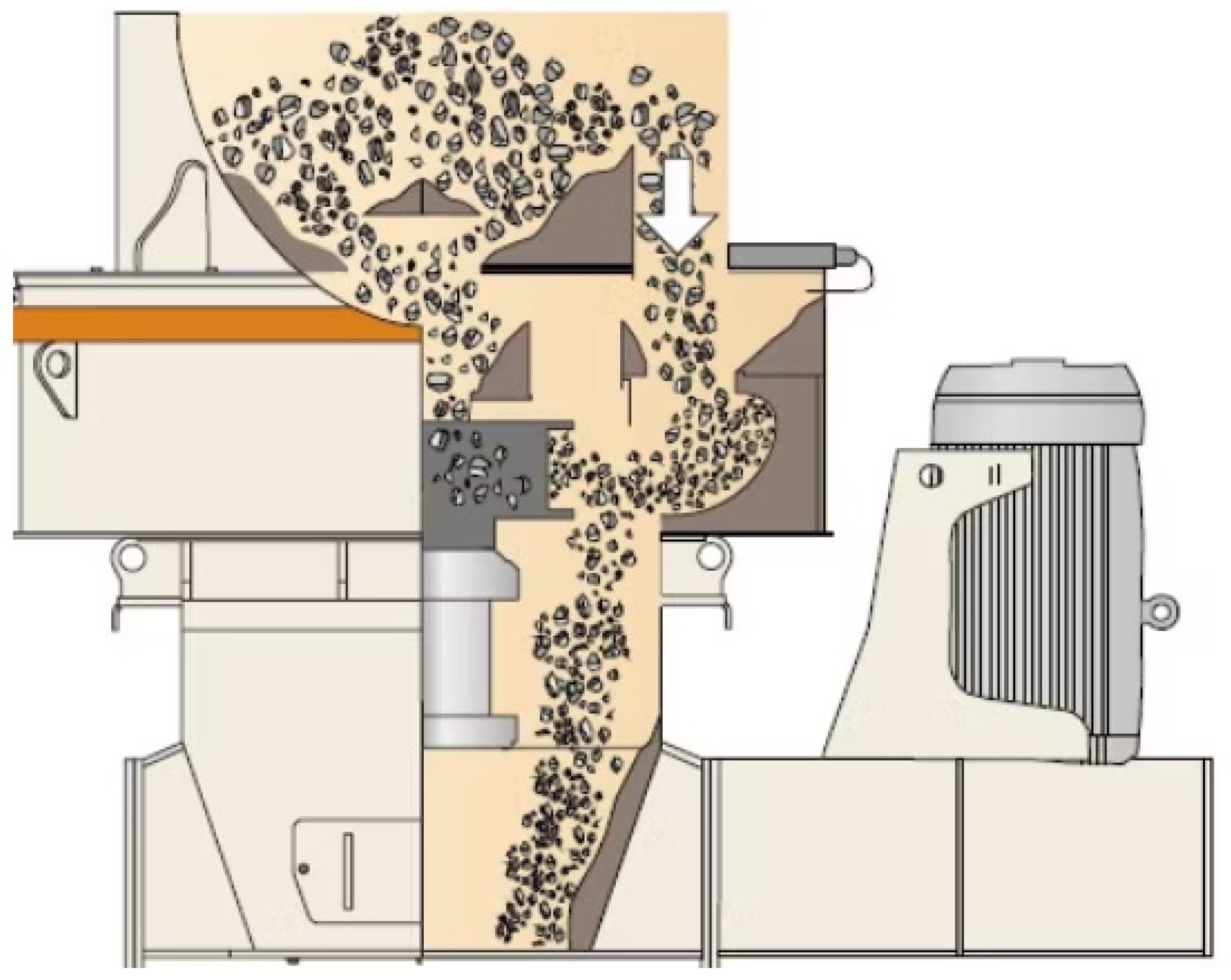

2.3.2. Experiment Process (VSI)

2.3.3. Froth Flotation Experiments

3. Results and Discussion

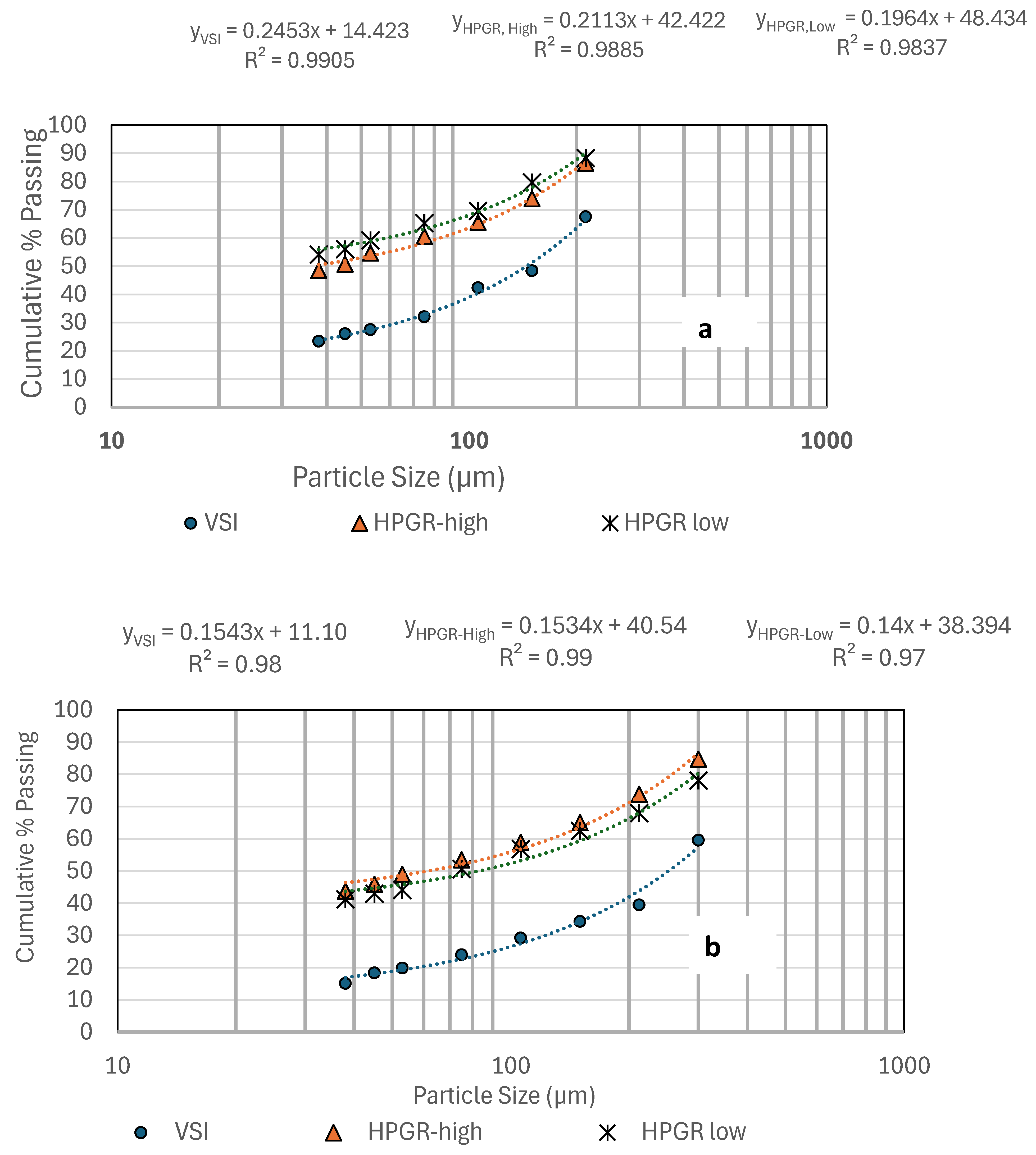

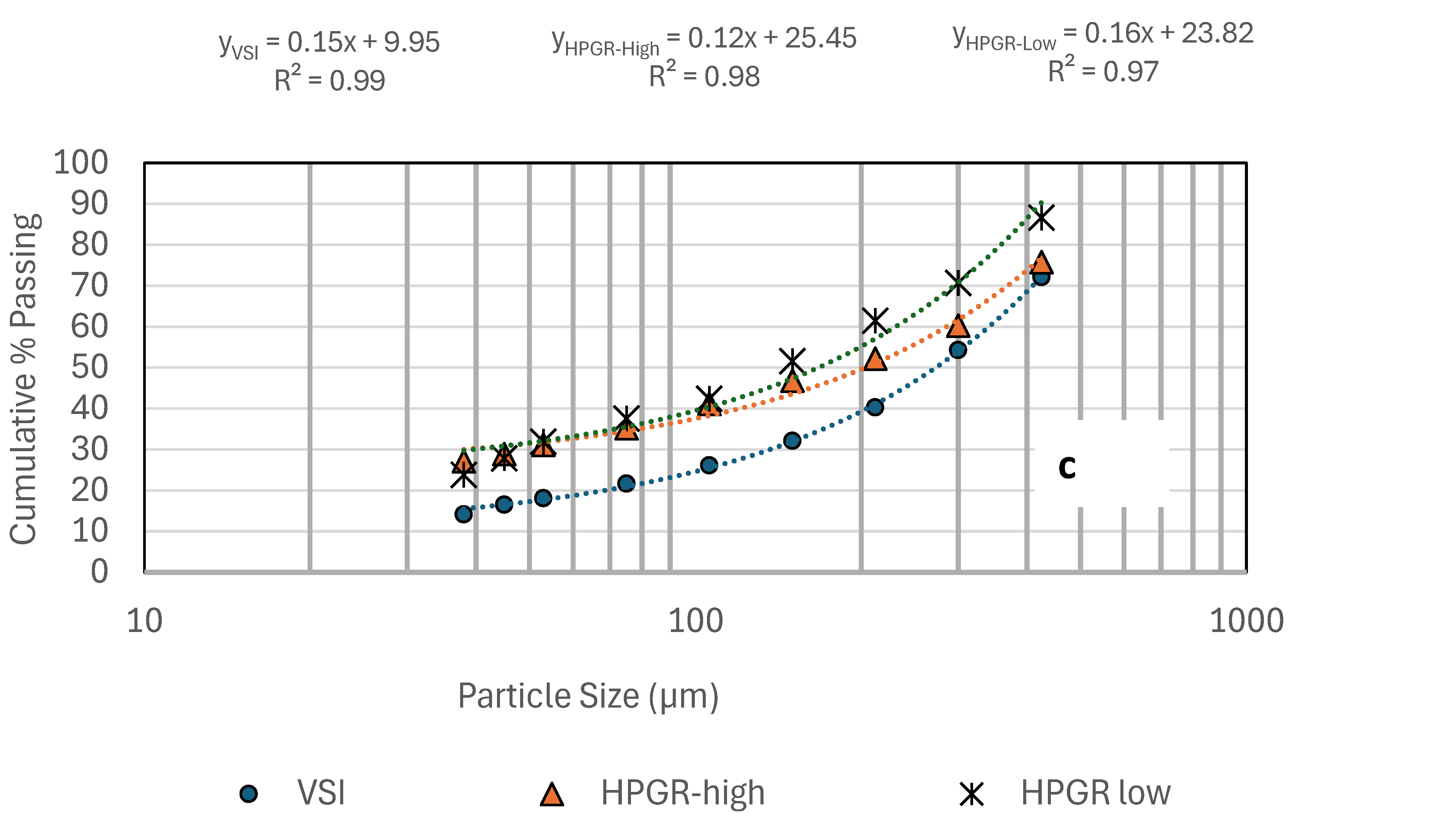

3.1. Product Size Distributions (PSDs)

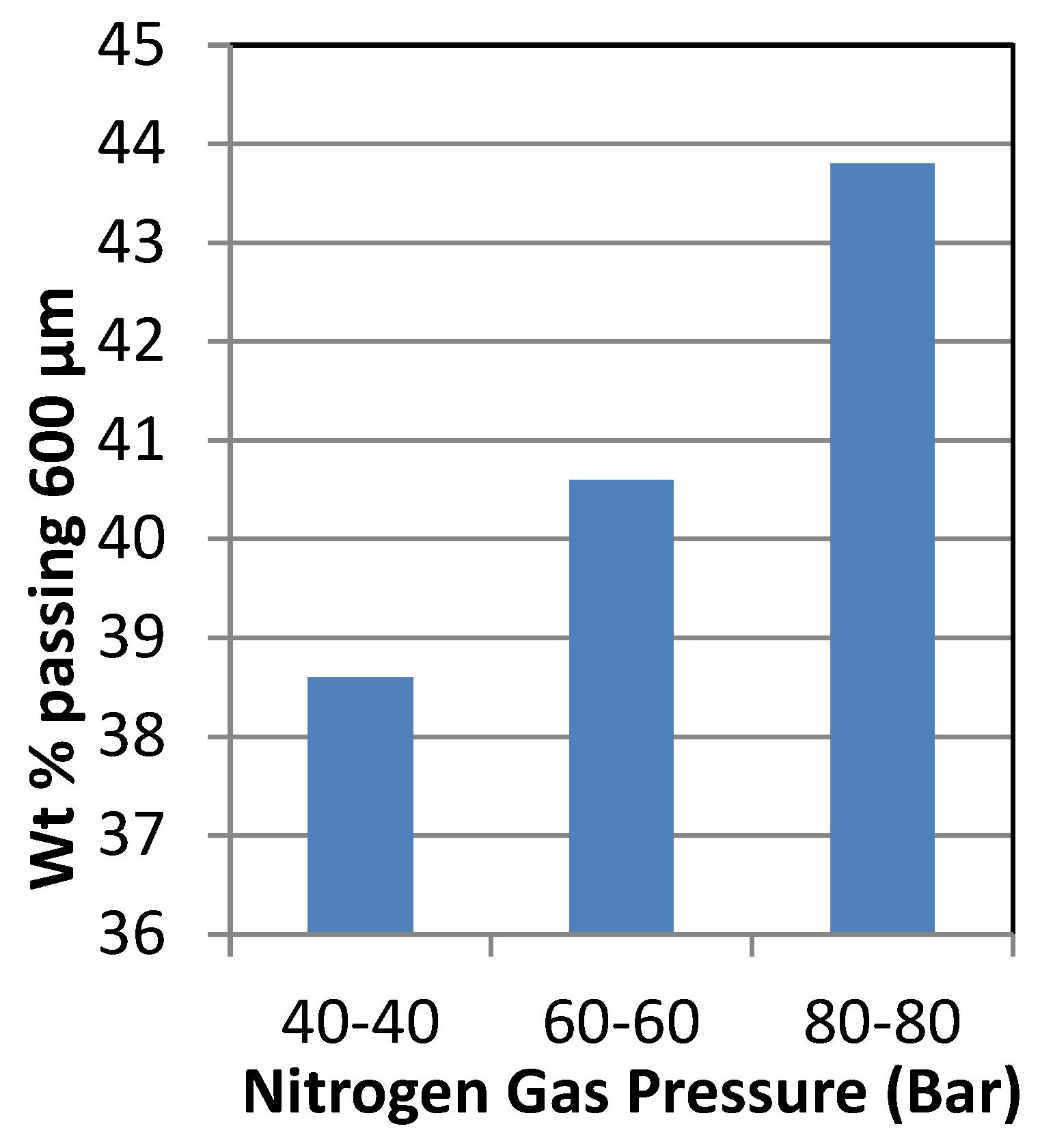

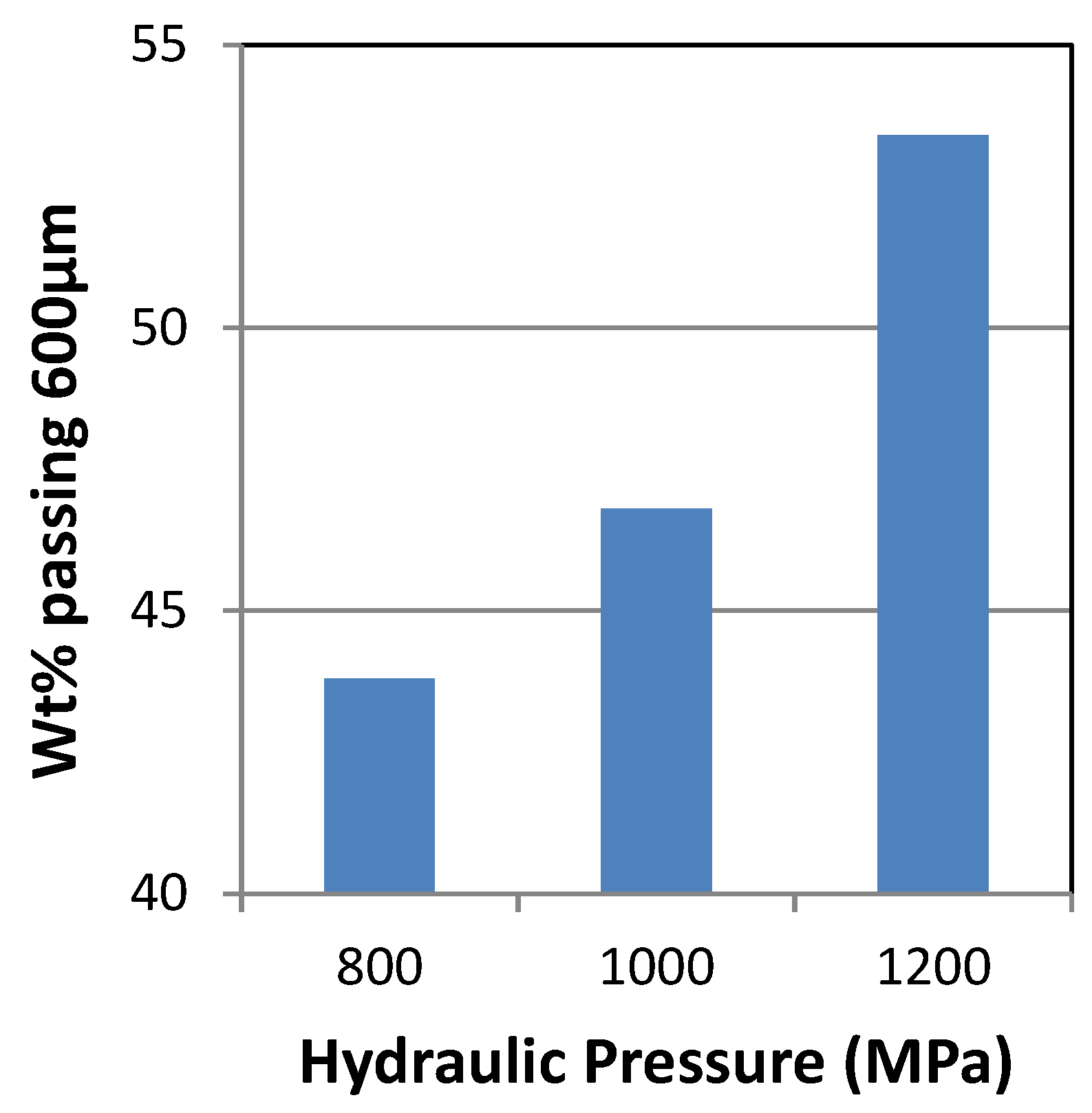

3.2. Effect of Nitrogen Gas Pressure on HPGR

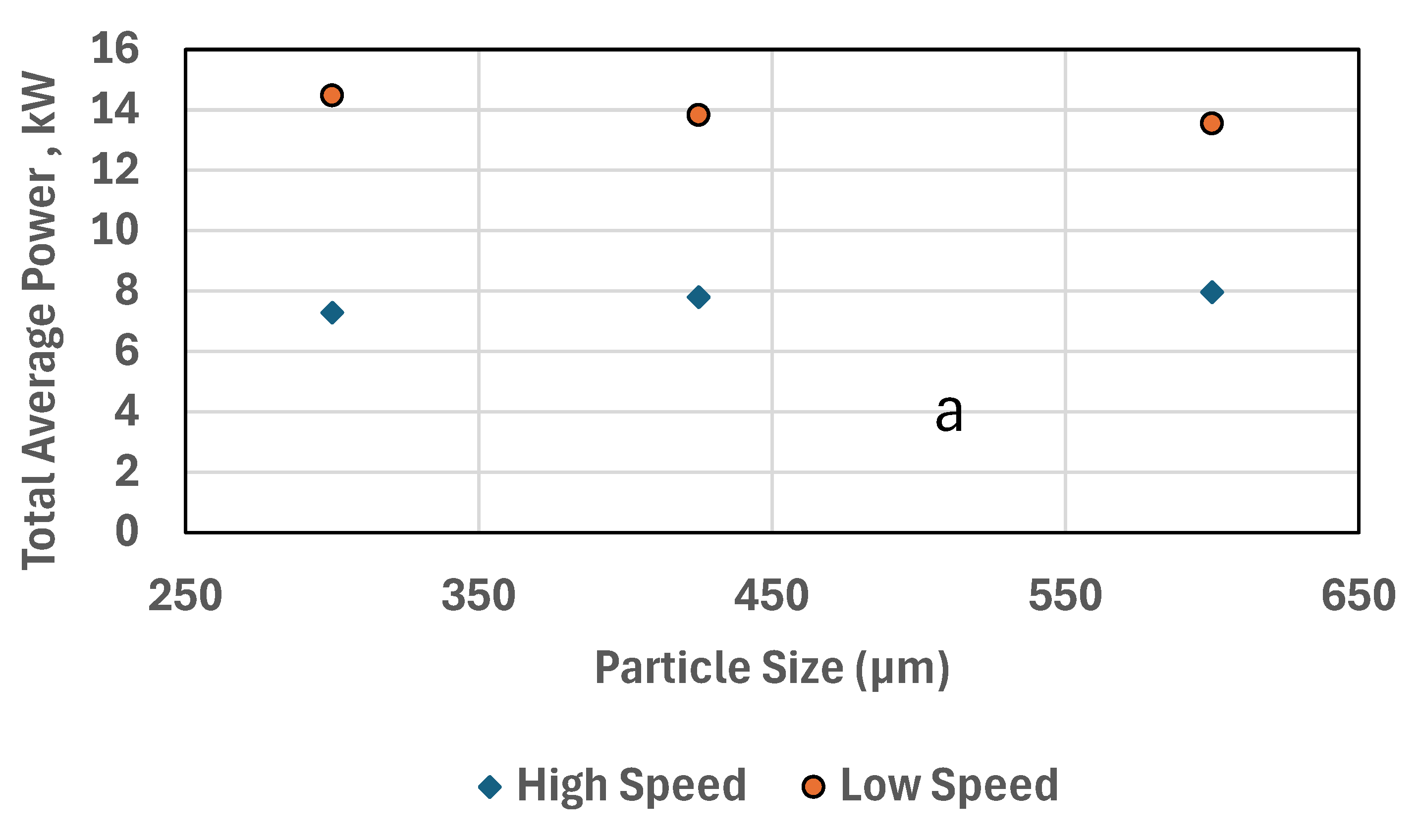

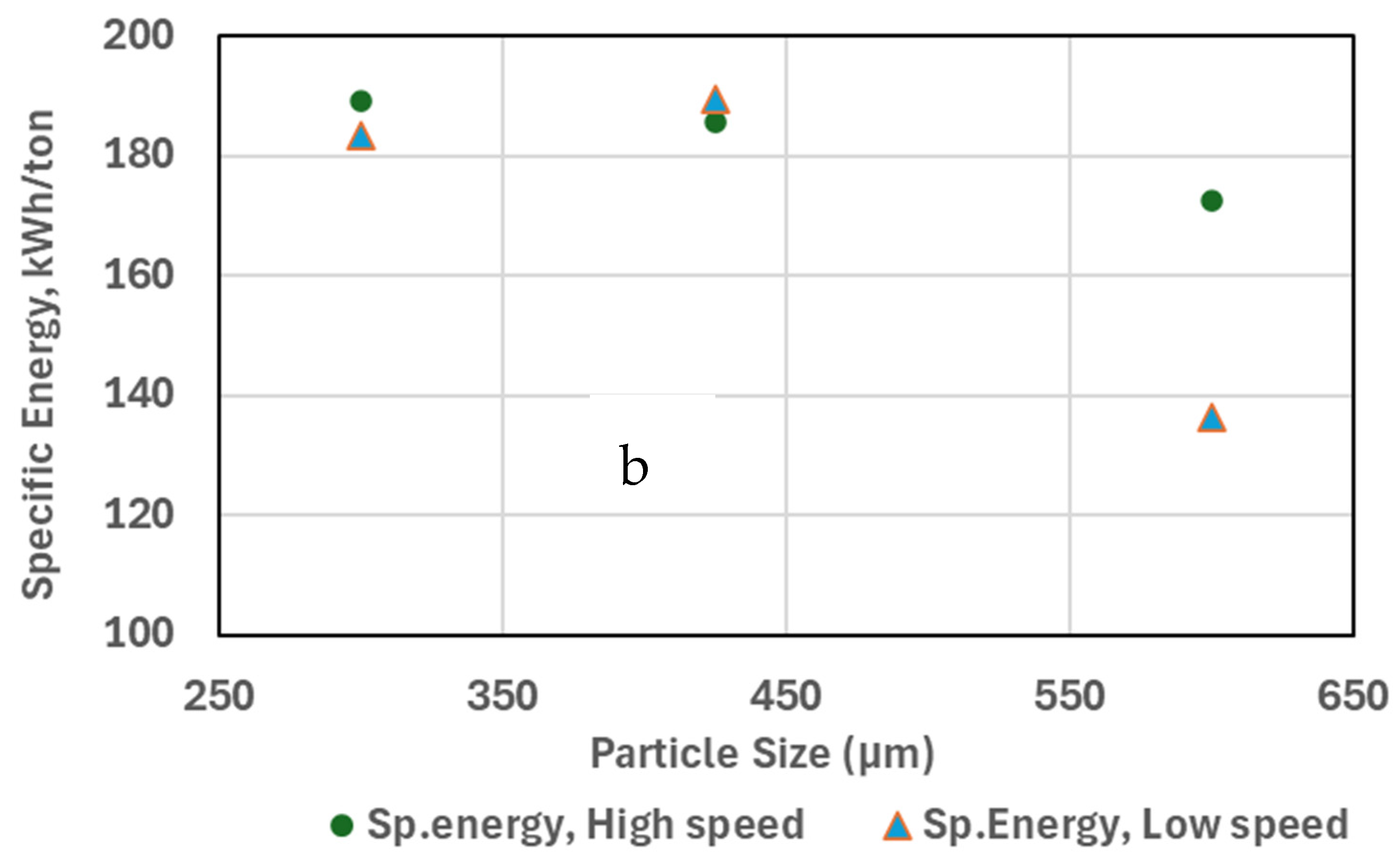

3.3. Power and Time Required for HPGR Experiments

3.4. Effect of Particle Size Versus Speed Versus Power Consumption

3.5. Flotation Gold Grade Recovery

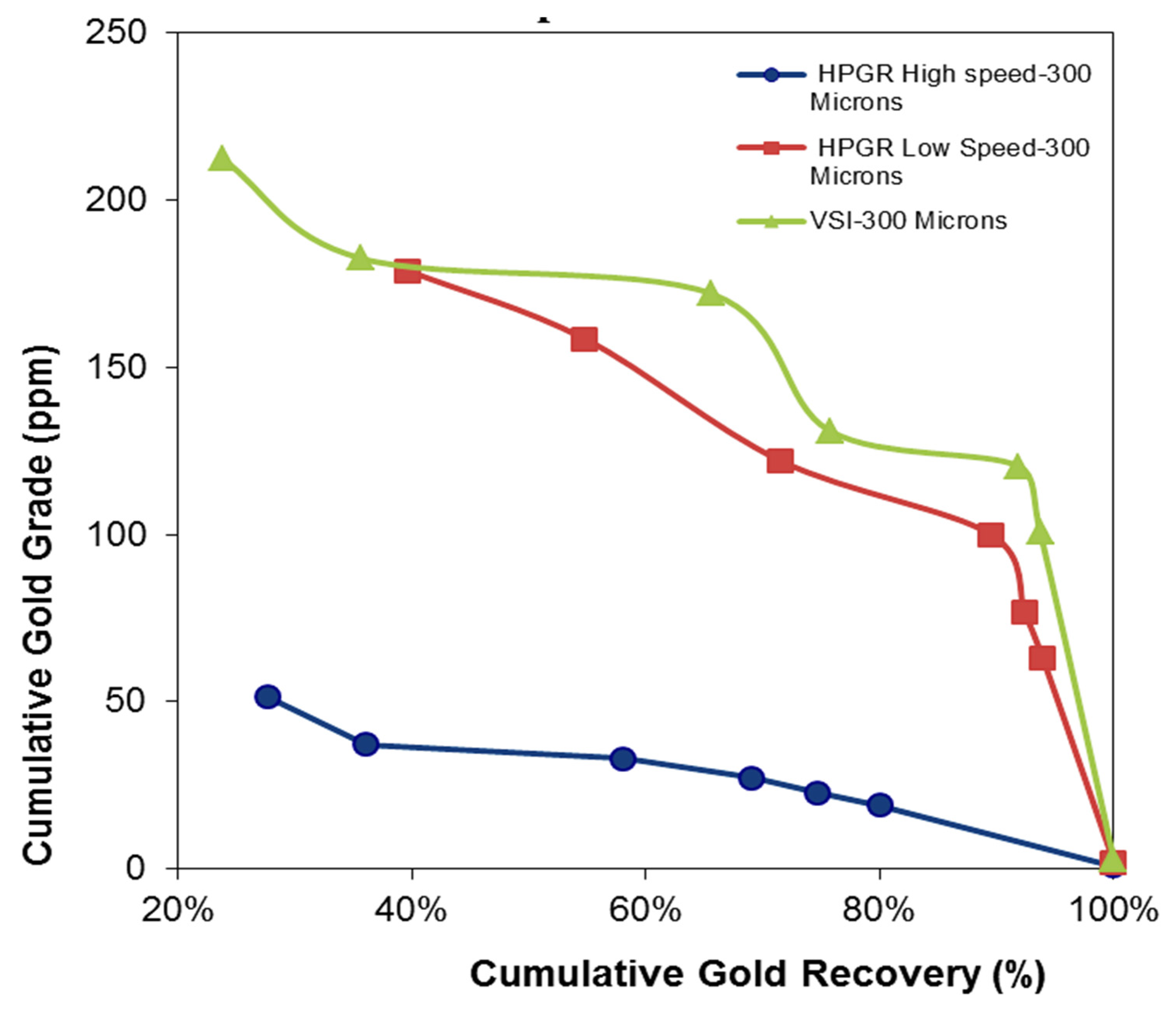

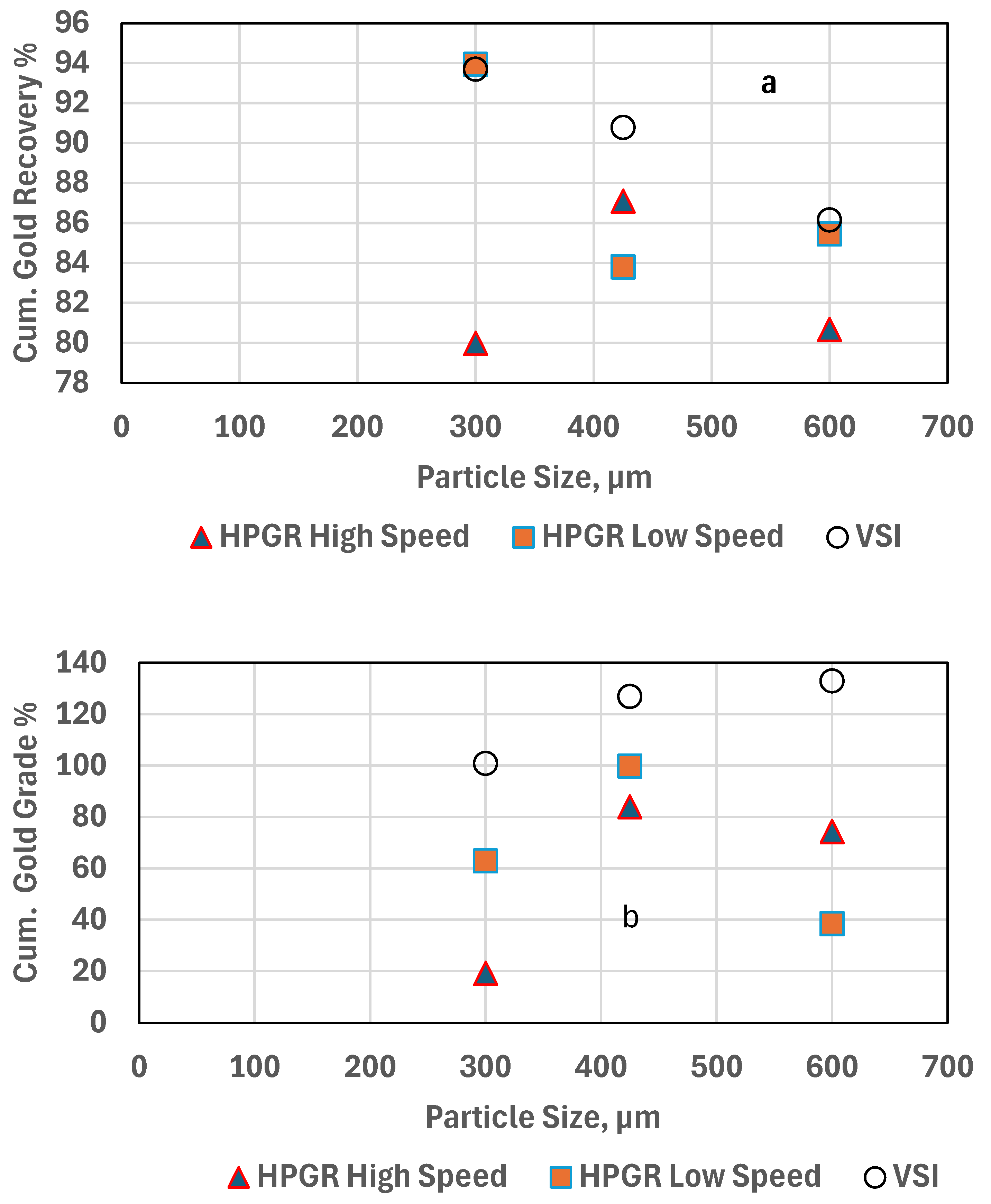

3.5.1. −300 µm Experiments

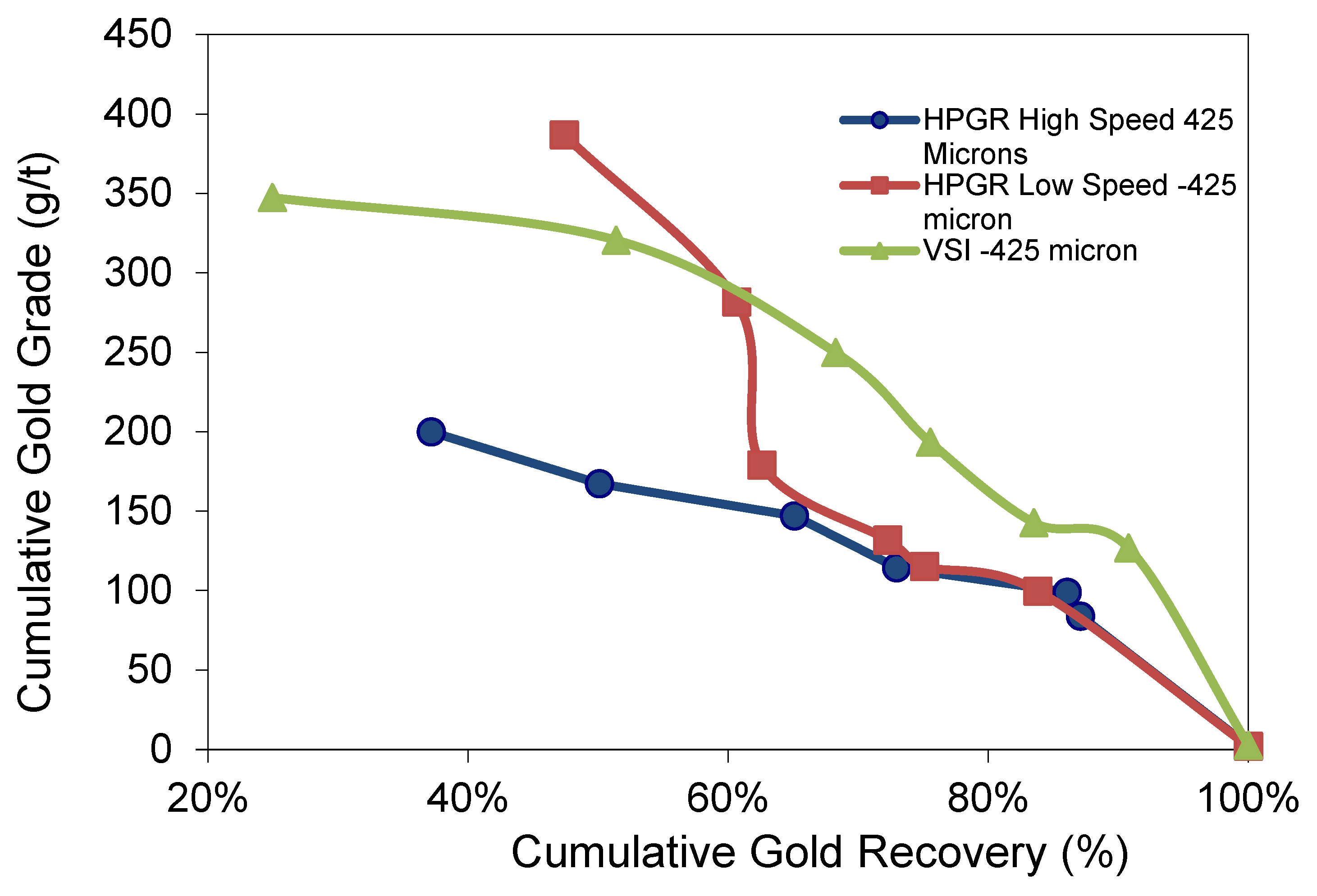

3.5.2. −425 µm Experiments

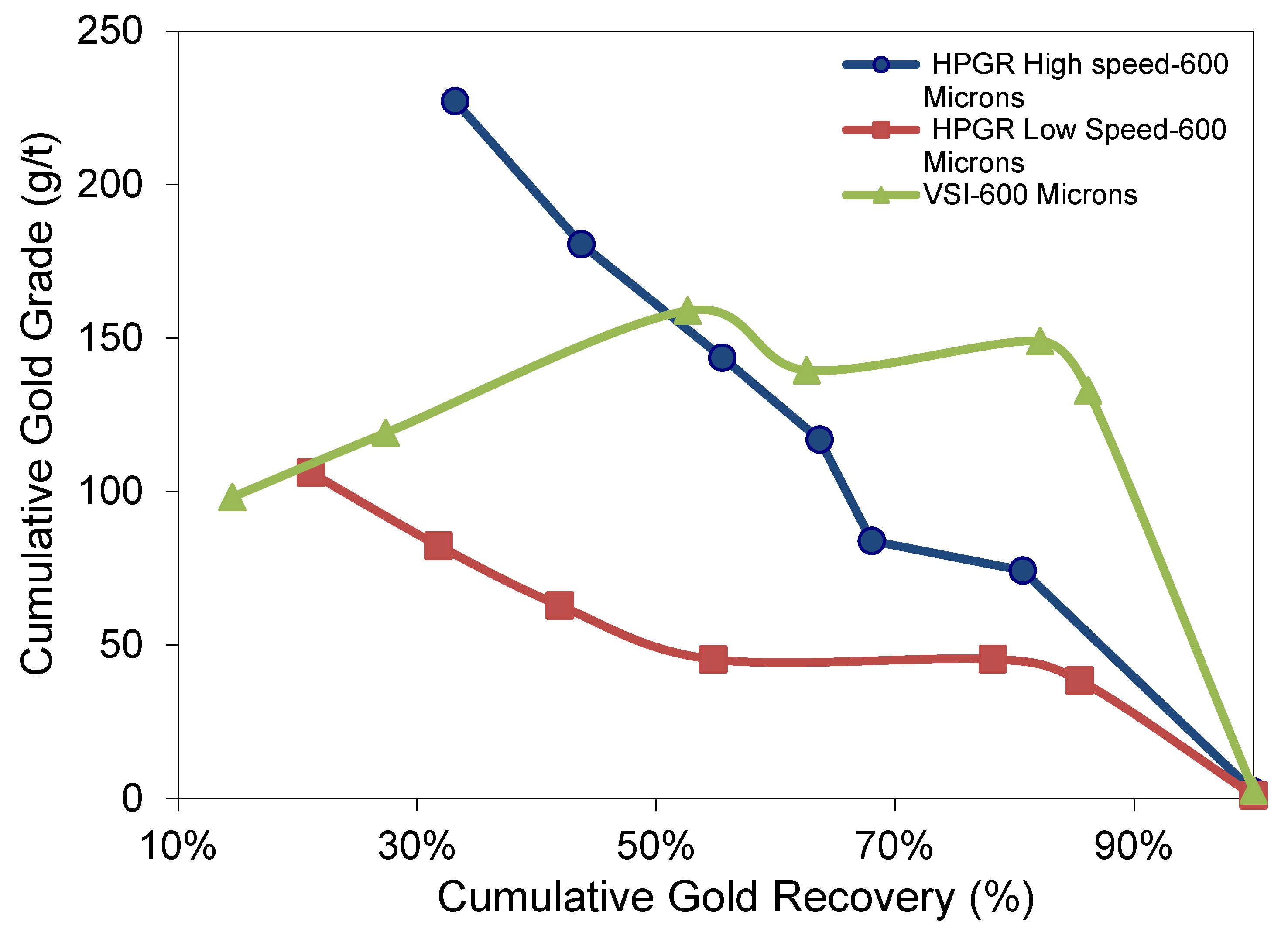

3.5.3. −600 µm Flotation Experiments

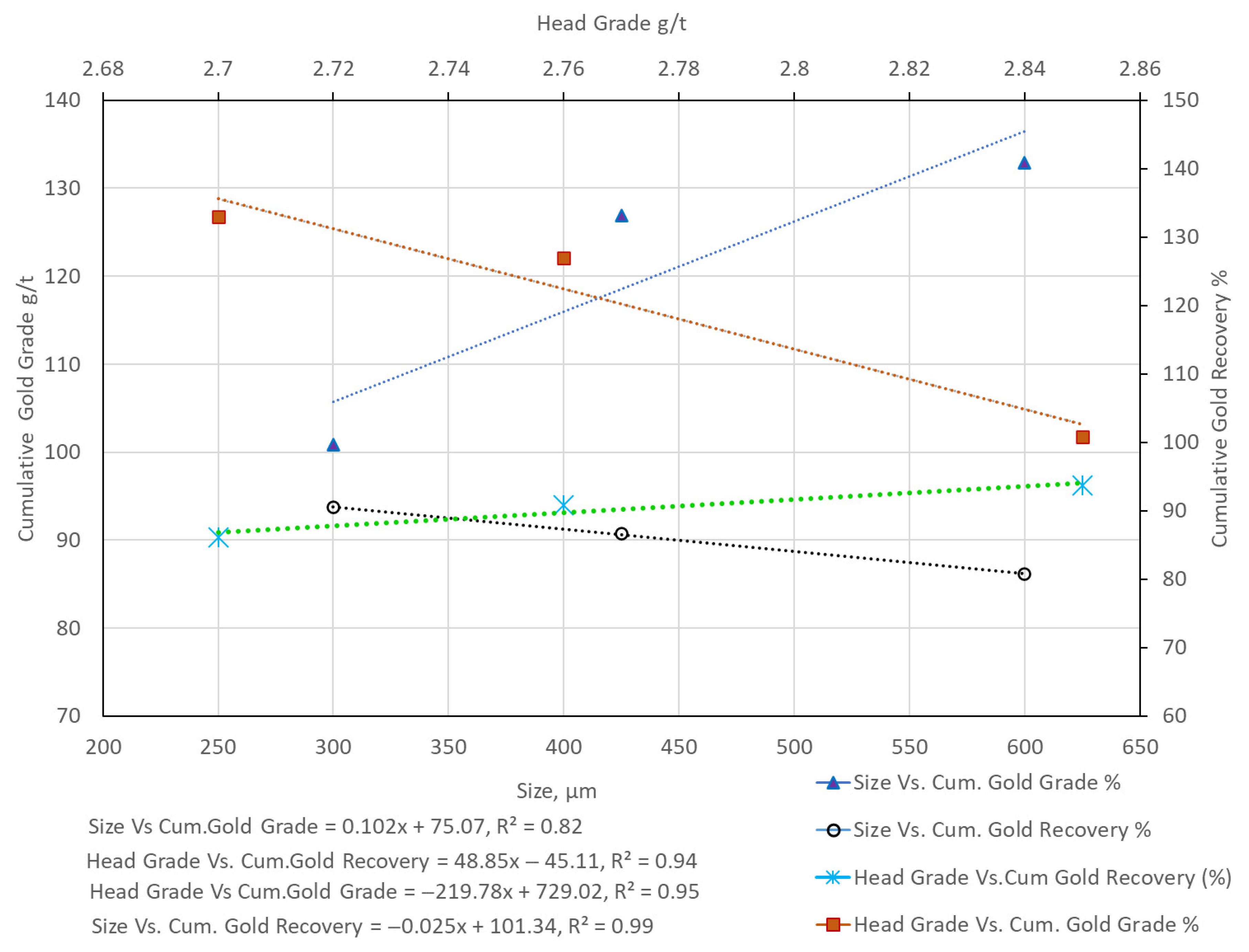

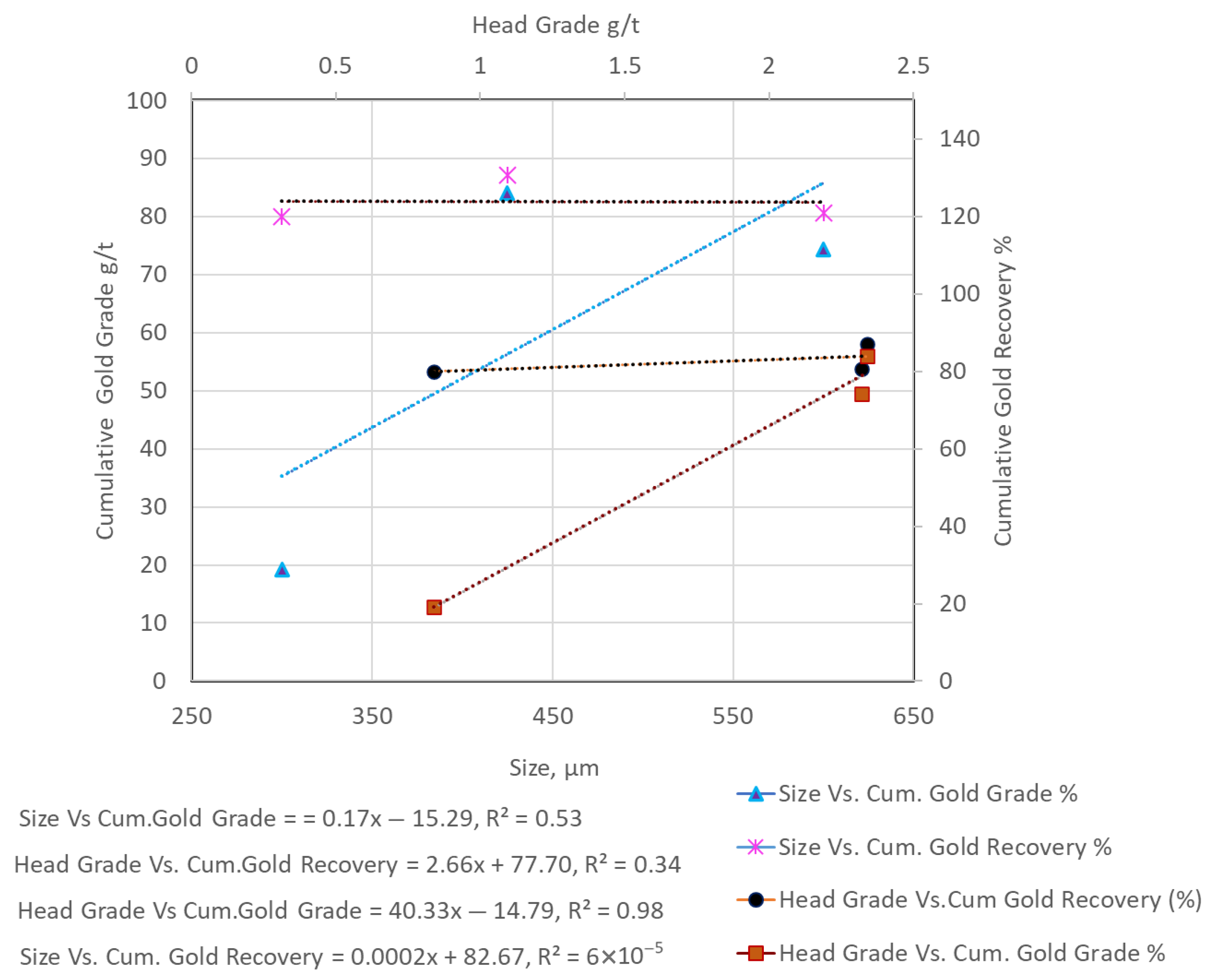

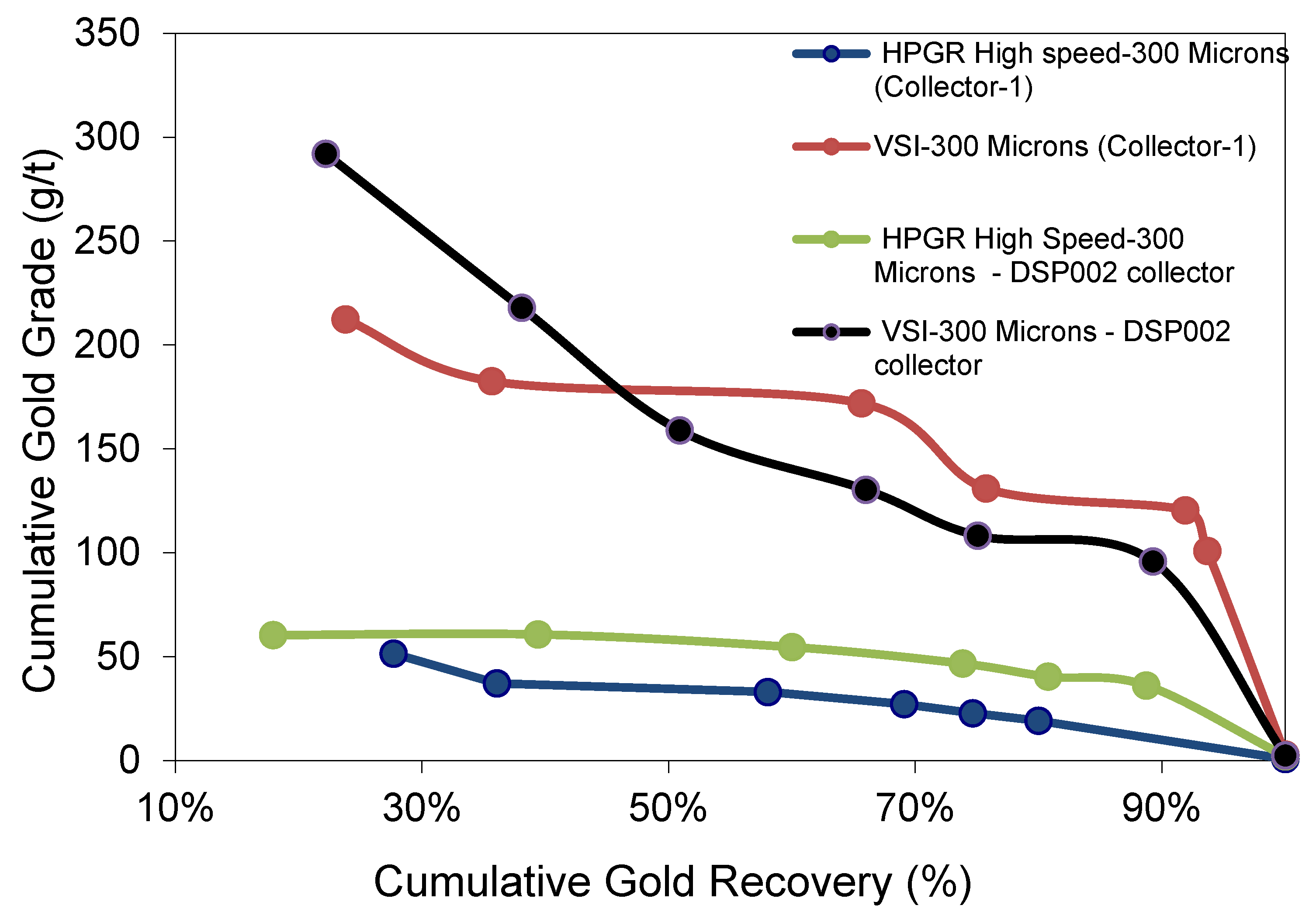

3.5.4. Recovery vs. Grade at Coarser Sizes

3.6. Influence of Collectors on Flotation (PAX Versus Dithiophosphate)

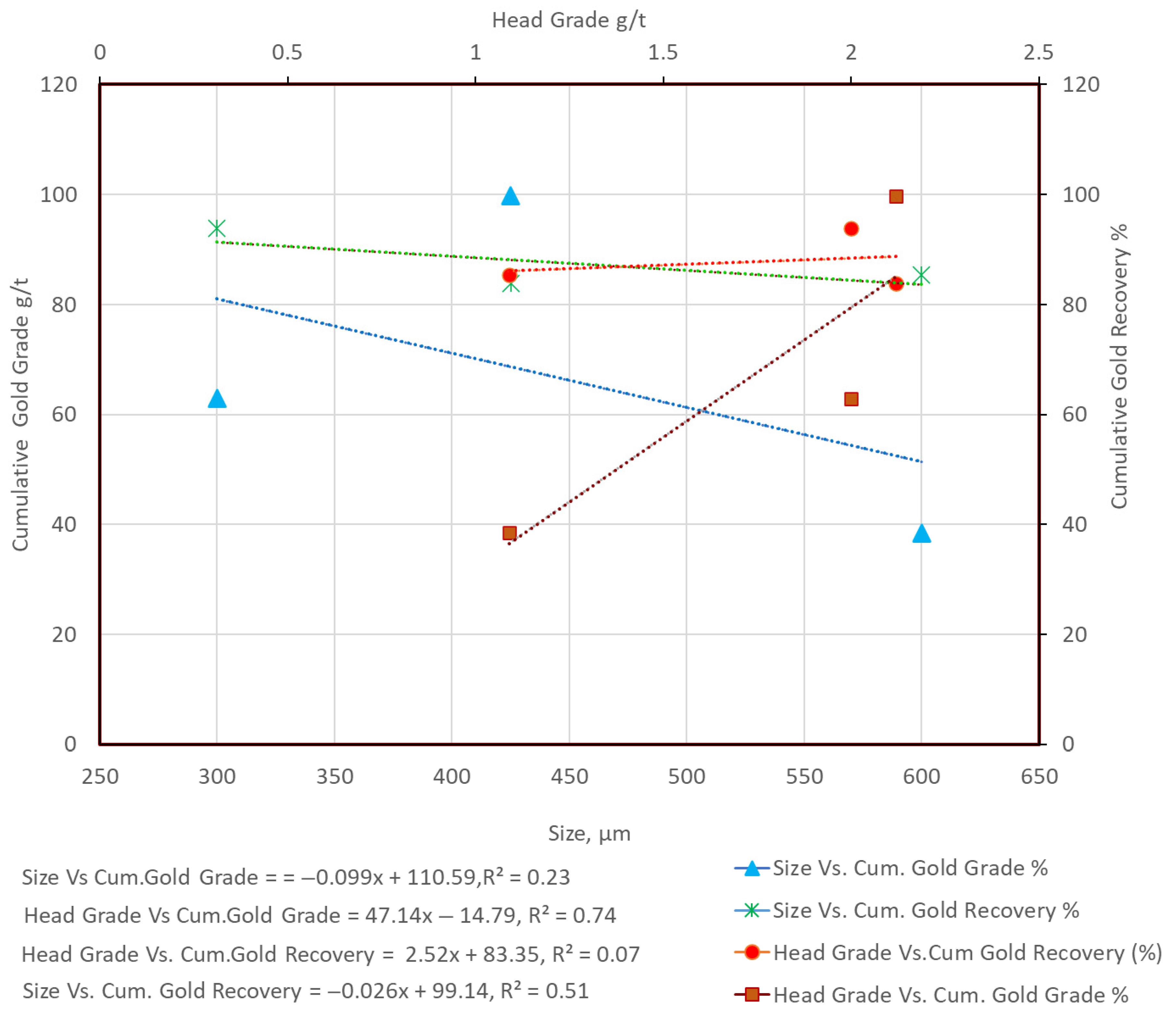

3.7. Indirect Evaluation of Liberation from Flotation Performance

- Increasing Cumulative Gold Recovery

- Decreasing Cumulative Gold Grade

- Implications for Liberation

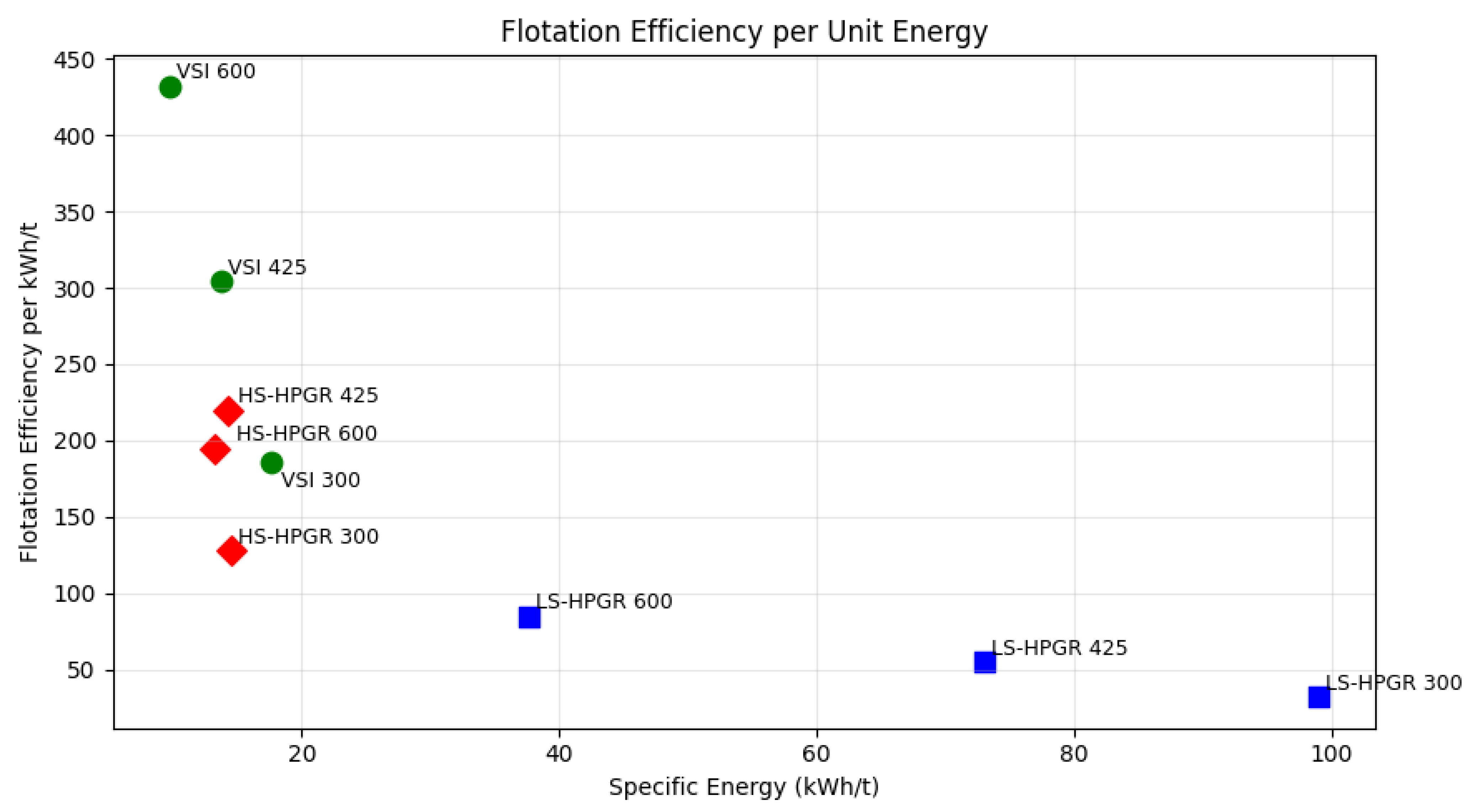

3.7.1. Flotation Efficiency

3.7.2. Key Observations and Interpretation

4. Discussion

4.1. Vertical Shaft Impactor (VSI)—Impact and Attrition Breakage

4.2. High-Pressure Grinding Rolls (HPGR)—Inter-Particle Compression and Micro-Crack Formation

4.3. Flotation Performance: Surface Chemistry and Recovery Trends

4.4. Particle Size Effects and Flotation Selectivity

4.5. Scale-Up Considerations

4.6. Collector Mechanisms and Particle Chemistry

4.7. Environmental and Sustainability Considerations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Banisi, S.; Finch, J.A. Testing and evaluation of modifying reagents in selective flotation. Miner. Eng. 2001, 14, 1643–1654. [Google Scholar]

- Von Michaelis, H. Real and potential metallurgical benefits of HPGR in hard rock ore processing. In Proceedings of the Randol Innovative Metallurgy Forum, Perth, WA, Australia, 21–24 August 2005. [Google Scholar]

- Fuerstenau, D.W.; Abouzeid, A.-Z.M. The energy efficiency of ball milling in comminution. Int. J. Miner. Process. 2002, 67, 161–185. [Google Scholar] [CrossRef]

- Shi, F.N.; Lambert, S.; Daniel, M.J. A study of the effects of HPGR treating platinum ores. In International Autogenous and Semi Autogenous Grinding Technology; SAG: Vancouver, BC, Canada, 2006. [Google Scholar]

- Wills, B.A.; Finch, J.A. Wills’ Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery, 8th ed.; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Szmigiel, A.; Apel, D.; Skrzypkowski, K.; Wojtecki, L.; Pu, Y. Advancements in Machine Learning for Optimal Performance in Flotation Processes: A Review. Minerals 2024, 14, 331. [Google Scholar] [CrossRef]

- Manouchehri, H. How Far the Crushing Performance Can Be Pushed? Con Crusher vs Vertical Shaft Impactor (VSI). In Comminution ’18; MEI: Cape Town, South Africa, 2018. [Google Scholar]

- Djordjevic, N.; Shi, F.; Morrison, R. Applying discrete element modelling to vertical and horizontal shaft impact crushers. Miner. Eng. 2003, 16, 983–991. [Google Scholar] [CrossRef]

- Al-Khasawneh, Y. Interpretation and optimization of vertical shaft crushers with DEEM. In Proceedings of the European Conference on Fracture (ECF-18), Bundesanstalt für Materialprüfung und -Forschung (BAM), Berlin, S. 1-8 (C.06.2-4), Berlin, Germany, 30 August–3 September 2010. [Google Scholar]

- AF Minerals Equipment. Vertical Shaft Impact Crusher. 2024. Available online: https://afmineral.com/vertical-shaft-impact-crusher/ (accessed on 13 July 2025).

- Tavares, L.M.; King, R.P. Single-particle fracture under impact loading. Int. J. Miner. Process. 1998, 54, 1–28. [Google Scholar] [CrossRef]

- Yalcin, E.; Kelebek, S. Flotation kinetics of a pyritic gold ore. Int. J. Min. Process 2011, 98, 48–54. [Google Scholar] [CrossRef]

- Napier-Munn, T.J.; Morrell, S.; Morrison, R.D.; Kojovic, T. Mineral Comminution Circuits: Their Operation and Optimisation; Napier-Munn, T.J., Ed.; Julius Kruttschnitt Mineral Research Centre, University of Queensland: Brisbane, Australia, 1996; Volume 2, p. 413. [Google Scholar]

- Rule, C.M.; Smit, I.; Cope, A.J.; Humphries, G.A. Commissioning of the Polycom 2.2/1.6 5.6MW HPGR at Anglo Platinum’s new Mogalakwena North Concentrator. In Comminution 08; MEI: Falmouth, UK, 2008. [Google Scholar]

- Goodbody. Coarse flotation aids sustainability. Mining Magazine, 14 July 2021. [Google Scholar]

- Hassanzadeh, A.; Safari, M.; Hoang, D. Fine, coarse and fine-coarse particle flotation in mineral processing with a particular focus on the technological assessments. In Proceedings of the 2nd International Electronic Conference on Mineral Science, Online, 1–15 March 2021; MDPI: Basel, Switzerland, 2021. [Google Scholar] [CrossRef]

- Klingmann, H.L. HPGR Benefits at Golden Queen Soledad Mountain Gold Heap Leaching Project; Randol Innovative Metallurgy Forum: Perth, Australia, 2005. [Google Scholar]

- Morley, C. High Pressure Grinding Rolls (HPGR): Technology Introduction and Benefits. Miner. Process. Extr. Metall. Rev. 2008, 29, 57–74. [Google Scholar]

- Smit, I. Bench Scale Ore Characterization Using the High-Pressure Grinding Roll; Randol HPGR Workshop: Perth, Australia, 2005. [Google Scholar]

- Otsuki, A.; Yue, C. Coal-oil gold agglomeration assisted flotation to recover gold from refractory ore. J. Phys. Conf. Ser. 2017, 879, 012021. [Google Scholar] [CrossRef]

- Forrest, K.D.; Yan, D.; Dunne, R. Optimisation of Gold Recovery by selective Gold Flotation for Copper-Gold-pyrite ores. Miner. Eng. 2001, 14, 227–241. [Google Scholar] [CrossRef]

- Teague, A.J. OMC Flotation Guidebook; Orica Mining Chemicals: Melbourne, Australia, 2009. [Google Scholar]

- Lins, F.; Adamian, R. The influence of some physical variables on gold flotation. Miner. Eng. 1993, 6, 267–277. [Google Scholar] [CrossRef]

- Daniel, M.; Morrell, S. HPGR model verification and scale-up. Miner. Eng. 2004, 17, 1149–1161. [Google Scholar] [CrossRef]

- Hilden, M.; Powell, M. Multiple-pass high pressure grinding rolls circuits. In Proceedings of the Centre for Sustainable Resource Processing 2nd Annual Conference (CSRP’08), Brisbane, Australia, 18–19 November 2008. [Google Scholar]

- Morrell, S.; Shi, F.; Tondo, L.A. Modelling and scale-up of high pressure Grinding rolls. In Proceedings of the XX International Mineral Processing Congress, Aachen, Germany, 21–26 September 1997; GDMB: Lower Saxony, Germany, 1997. [Google Scholar]

- Devasahayam, S. Advancing Flotation Process Modeling: Bayesian vs. Sklearn Approaches for Gold Grade Prediction. Minerals 2025, 15, 591. [Google Scholar] [CrossRef]

- Villiers, J.P.D. The Impact of Powder X-Ray Diffraction on Mineral; University of Pretori: Pretoria, South Africa, 2011. [Google Scholar]

- Habashi, F. Principles of Mineral Processing, Maurice C. Fuerstenau, Kenneth N. Han (Eds.), Society for Mining, Metallurgy, and Exploration, Littleton, CO (2003), x + 573 pages, 18.2 × 26 cm, hard cover, www.smenet.org, US$ 124, ISBN: 0-87335-167-3. Miner. Eng. 2005, 18, 907. [Google Scholar] [CrossRef]

- Pourghahramani, P. Effects of ore characteristics on product shape properties and breakage mechanisms in industrial SAG mills. Miner. Eng. 2012, 32, 30–37. [Google Scholar] [CrossRef]

- Lucas, P.; Edgar, S.; Raimon, T.-D.; Max, F. All About Particles: Modelling Ore Behaviour in Mineral Processing. Elements 2023, 19, 359–364. [Google Scholar] [CrossRef]

- Lindqvist, M. Energy considerations in compressive and impact crushing of rock. Miner. Eng. 2008, 21, 631–641. [Google Scholar] [CrossRef]

- Wang, X.-H.; Forssberg, K.E. Mechanisms of pyrite flotation with xanthates. Int. J. Miner. Process. 1991, 33, 275–290. [Google Scholar] [CrossRef]

- Klymowsky, R.; Patzelt, N.; Knecht, J.; Burchardt, E. Selection and sizing of high pressure grinding rolls. In Mineral Processing Plant Design, Practice, and Control Proceedings; SME: Littleton, CO, USA, 2002. [Google Scholar]

- Canica, V. Terex® Minerals Processing Systems. 1974. Available online: https://www.terex.com/mps/en/ (accessed on 13 July 2025).

- Luo, X.; Song, S.; Ma, M.; Wang, Y.; Zhou, Y.; Zhang, Y. Effect of particle size on flotation performance of hematite. Physicochem. Probl. Miner. Process 2019, 55, 479–493. [Google Scholar]

- Schonert, K. Aspects of the physics of breakage relevant to comminution. In Fourth Tewksbury Symposium; University of Melbourne: Melbourne, Australia, 1979. [Google Scholar]

- Schonert, K.; Knobloch, O. Energetische Aspekte des Zerkleinerns Spröder Stoffe. Zement-Kalk-Gips 1984, 37, 563–568. [Google Scholar]

- Zeng, G.; Weng, W.; Zhong, S.; Chi, X.; Cai, J.; Tan, W.; Chen, J. Amidoxime collectors: Lead-free flotation performance and adsorption mechanism in the separation of wolframite, quartz and calcite. Miner. Eng. 2025, 222, 109170. [Google Scholar] [CrossRef]

- Nghipulile, T.; Nkwanyana, S.; Lameck, N. The Effect of HPGR and Conventional Crushing on the Extent of Micro-Cracks, Milling Energy Requirements and the Degree of Liberation: A Case Study of UG2 Platinum Ore. Minerals 2023, 13, 1309. [Google Scholar] [CrossRef]

- Eriez. Flotation. 2024. Available online: https://www.eriez.com/Americas/Products/Flotation.htm (accessed on 13 July 2025).

| Size (μm) | Gold Recovery (%) | Sulfur Recovery (%) | Gold Grade (%) |

|---|---|---|---|

| 38–53 | 92.4 | 89.1 | 36.6 |

| 53–75 | 88.5 | 86.8 | 43.9 |

| 75–106 | 90.0 | 87.0 | 67.6 |

| 106–150 | 87.7 | 80.0 | 83.4 |

| 150–212 | 90.0 | >80.0 | 127.4 |

| 212–300 | 76.2 | 66.7 | 58.5 |

| Phase | Weight% |

|---|---|

| Quartz | 50 |

| Muscovite | 18 |

| Fe-Dolomite/ankerite | 11.5 |

| Chlorite | 7.9 |

| Siderite | 4.2 |

| Kaolinite | 3.4 |

| Albite | 3.3 |

| Rutile | 0.8 |

| Pyrite | 0.9 |

| Test | Power (kW) | Time (s) | Sample Mass (kg) | Specific Energy (kWh/t) |

|---|---|---|---|---|

| HS-HPGR 600 | 7.97 | 30 | 5 | 13.28 |

| LS-HPGR 600 | 13.55 | 41.5 | 5 | 37.65 |

| VSI 600 | 5.42 | 32.5 | 5 | 9.79 |

| HS-HPGR 425 | 7.8 | 33 | 5 | 14.3 |

| LS-HPGR 425 | 13.83 | 95 | 5 | 73.04 |

| VSI 425 | 5.52 | 45 | 5 | 13.8 |

| HS-HPGR 300 | 7.29 | 36 | 5 | 14.58 |

| LS-HPGR 300 | 14.48 | 122 | 5 | 98.94 |

| VSI 300 | 5.78 | 55 | 5 | 17.66 |

| Crusher/Size µm | Cumulative Gold Recovery (%) | Cumulative Gold Grade (g/t) | Head Grade, (g/t) | Flotation Efficiency |

|---|---|---|---|---|

| HS-HPGR (600 µm) | 80.67 | 74.32 | 2.32 | 2584.22 |

| LS-HPGR (600 µm) | 85.45 | 38.51 | 1.09 | 3018.97 |

| VSI (600 µm) | 86.15 | 132.92 | 2.7 | 4241.13 |

| HS-HPGR (425 µm) | 87.09 | 83.99 | 2.34 | 3125.94 |

| LS-HPGR (425 µm) | 83.8 | 99.77 | 2.12 | 3943.74 |

| VSI (425 µm) | 90.78 | 126.91 | 2.76 | 4174.24 |

| HS-HPGR (300 µm) | 79.98 | 19.15 | 0.84 | 1823.35 |

| LS-HPGR (300 µm) | 93.93 | 62.9 | 2 | 2954.10 |

| VSI (300 µm) | 93.69 | 100.85 | 2.85 | 3315.31 |

| Test | PAX | Di Butyl Dithiophosphate, DSP002 | ||||

|---|---|---|---|---|---|---|

| Cumulative Gold Recovery (%) | Cumulative Gold Grade (g/t) | Head Grade (g/t) | Cumulative Gold Recovery (%) | Cumulative Gold Grade (g/t) | Head Grade (g/t) | |

| HS-HPGR (300 µm) | 79.98 | 19.15 | 0.84 | 88.72 | 36.17 | 2.02 |

| VSI (300 µm) | 93.93 | 100.85 | 2.85 | 89.26 | 95.80 | 2.46 |

| Expected Trend | Observed in Data? | Explanation |

|---|---|---|

| HPGR improves liberation, but can reduce selectivity if too fine | Yes | LS-HPGR (600 and 425 µm) shows improved efficiency, but 300 µm struggles |

| VSI produces coarser, well-liberated particles with better flotation selectivity | Yes | VSI has the highest flotation efficiency across all sizes |

| Overgrinding (e.g., 300 µm) leads to slimes and flotation inefficiency | Yes | HS-HPGR (300 µm) has the lowest flotation efficiency |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thatipamula, S.; Devasahayam, S. Energy-Efficient Gold Flotation via Coarse Particle Generation Using VSI and HPGR Comminution. Materials 2025, 18, 3553. https://doi.org/10.3390/ma18153553

Thatipamula S, Devasahayam S. Energy-Efficient Gold Flotation via Coarse Particle Generation Using VSI and HPGR Comminution. Materials. 2025; 18(15):3553. https://doi.org/10.3390/ma18153553

Chicago/Turabian StyleThatipamula, Sindhura, and Sheila Devasahayam. 2025. "Energy-Efficient Gold Flotation via Coarse Particle Generation Using VSI and HPGR Comminution" Materials 18, no. 15: 3553. https://doi.org/10.3390/ma18153553

APA StyleThatipamula, S., & Devasahayam, S. (2025). Energy-Efficient Gold Flotation via Coarse Particle Generation Using VSI and HPGR Comminution. Materials, 18(15), 3553. https://doi.org/10.3390/ma18153553