Examples of Reliability Models of a Renewable Technical Object in Relation to Special Vehicles

Abstract

1. Introduction

- (a)

- elements working until first failure,

- (b)

- repairable elements that regain their properties and nominal technical parameters after repair.

- (a)

- Post-damage restoration;

- (b)

- Preventive (pre-emptive) renewal.

- (a)

- We replace the damaged element or the entire technical object with a new one;

- (b)

- A damaged element or an entire technical object is repaired.

- (a)

- Complete restoration of the element’s ability to perform its functions.

- (b)

- Partial restoration of the ability of the element to perform its functions.

2. Materials and Methods

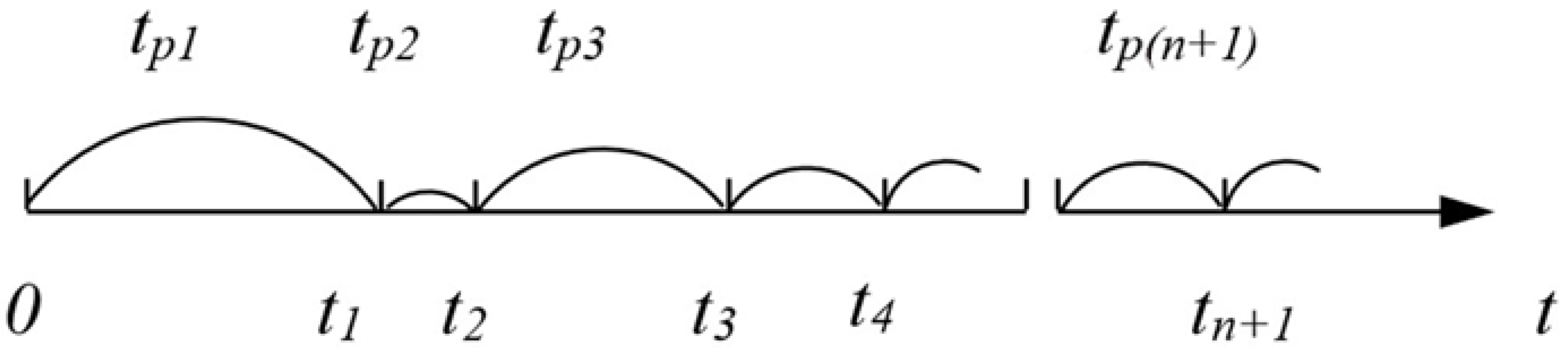

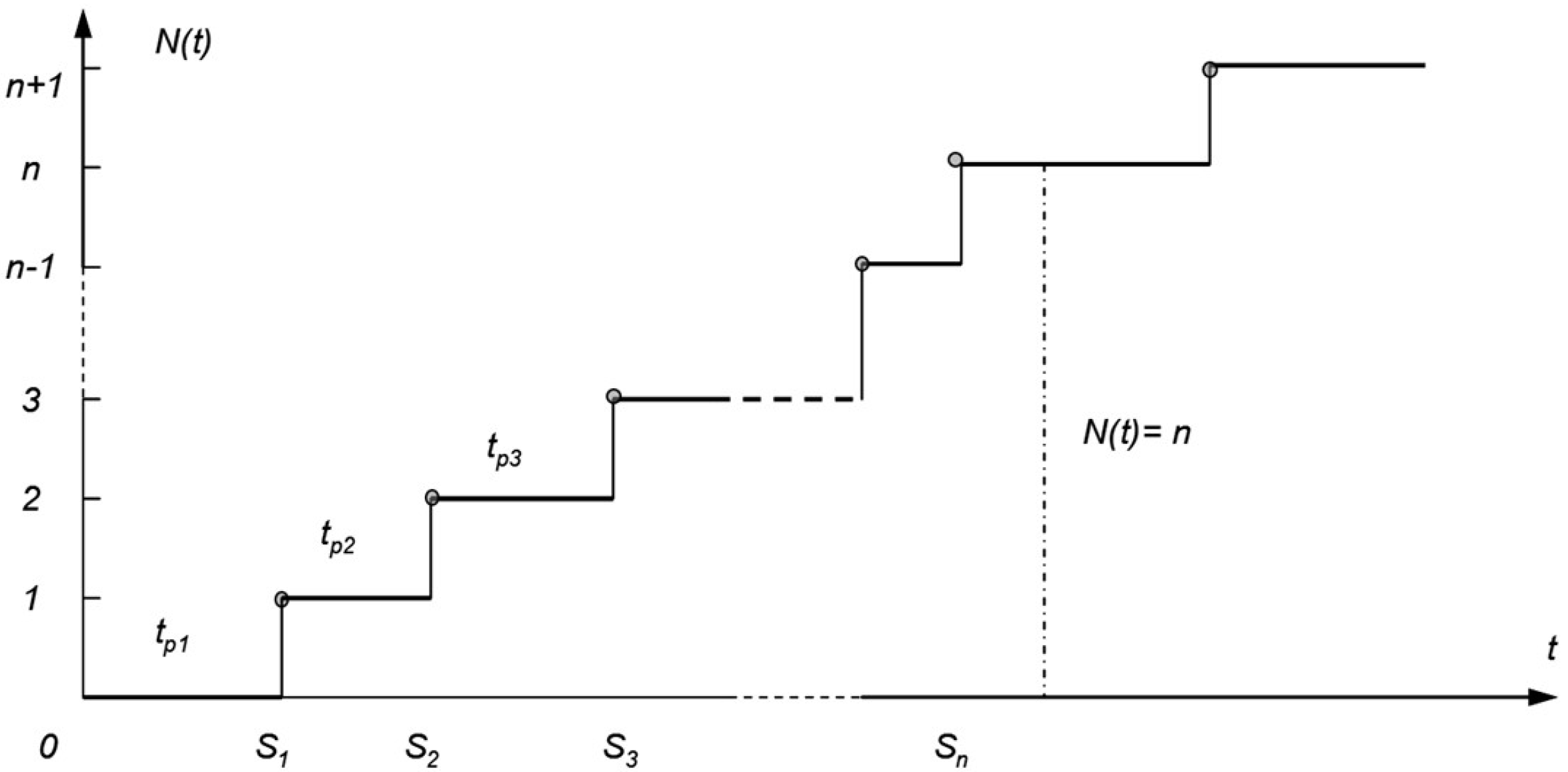

2.1. Description of the Damage Process

- (a)

- The guides of the collecting and pressing plate in the plate-type garbage truck;

- (b)

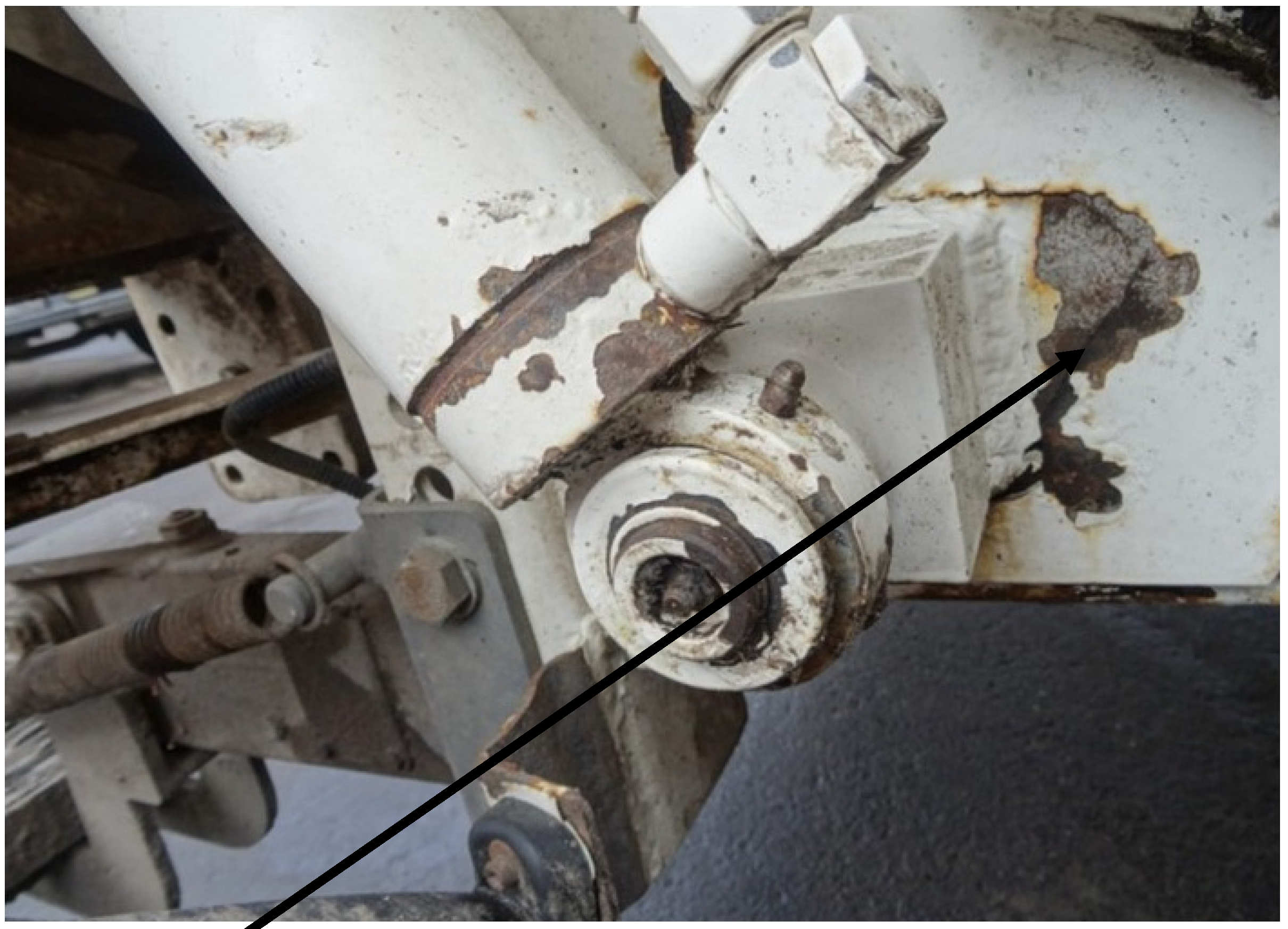

- The base of the pin fastening the eye of the container lifting cylinder of the loading device in a garbage truck with rear loading and plate compaction.

- (a)

- A model showing a damaged element, using the example of the guides of the collecting–pressing plate, where it is assumed that the guides in question are replaced with new ones.

- (b)

- A model showing a damaged element, using the example of a base for securing the eye of a container lifting cylinder, where it is assumed that the element is being repaired, and the result of the repair is the complete restoration of the ability of the element to perform its functions.

2.2. W.L. Smith’s Model of Renewal Theory

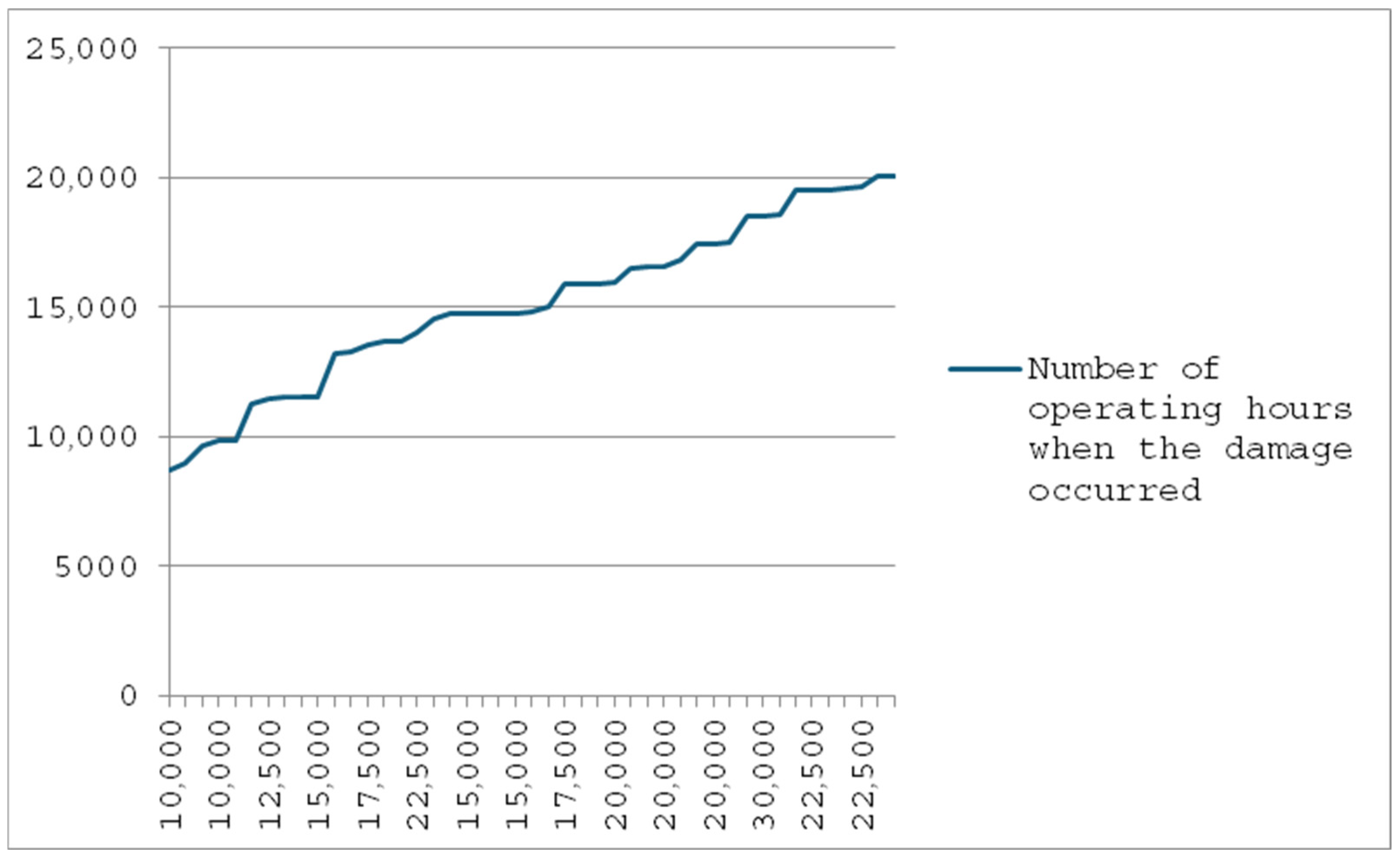

2.2.1. Example 1—Model Analysis Using the Example of the Base for Mounting the Eye of a Container Lifting Cylinder, Where It Is Assumed That This Element Is Being Repaired

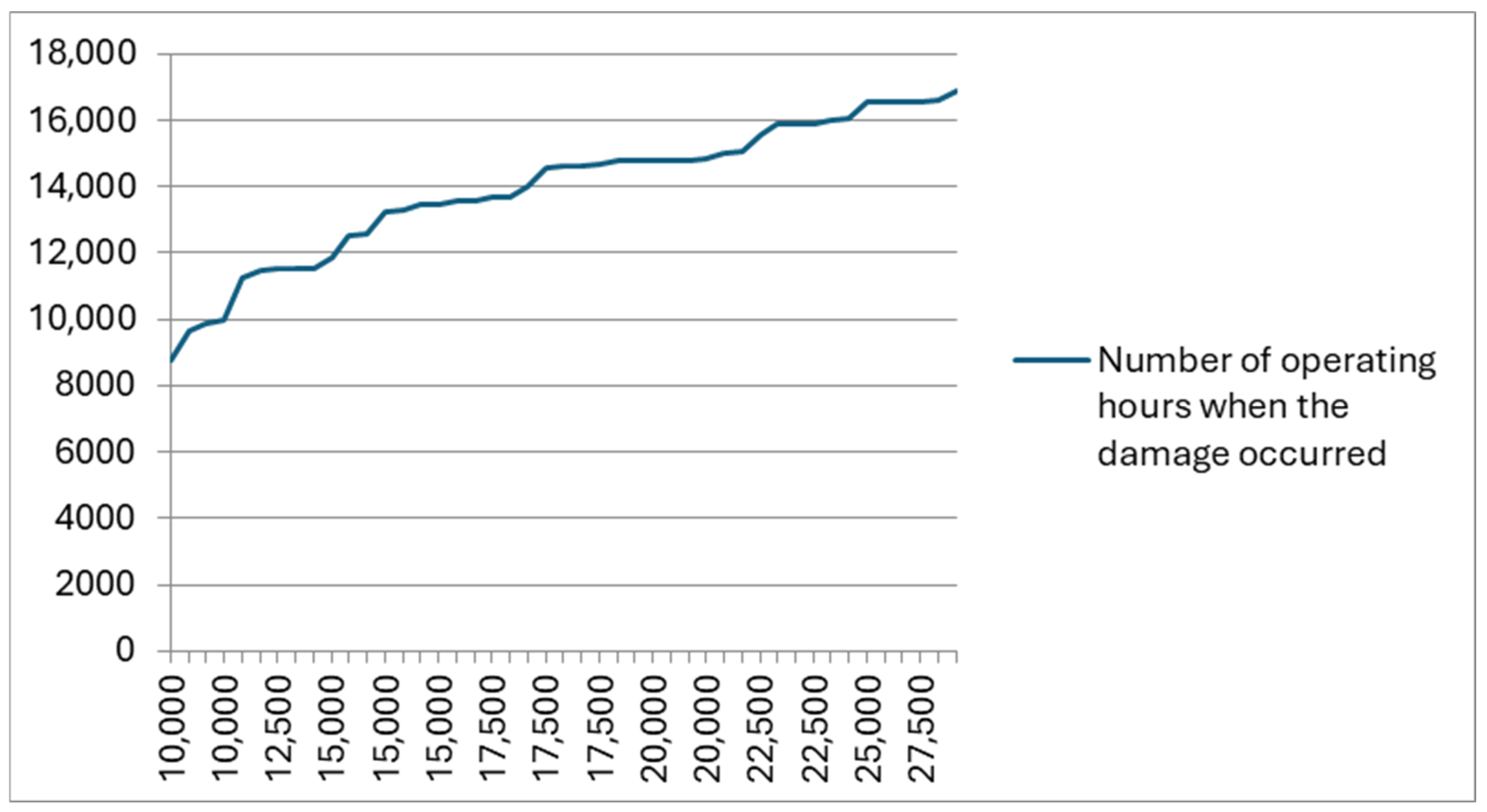

Mathematical Description of the Methodology for Solving the Presented Problem No. 1

2.2.2. Example 2—Analysis of the Model Using the Example of the Guides of the Collecting and Pressing Plate, Where It Was Assumed That the Guides in Question Were Replaced with New Ones

Mathematical Description of the Methodology for Solving the Presented Problem No. 2

- (a)

- elements have strictly increasing damage intensity,

- (b)

- we are interested in time t less than the expected value of the element’s operating time, .

- (a)

- ;

- (b)

- The process has independent increments, which means that for any 0≤ t1< t2 < …< tn random variables Xt1, Xt2 − Xt1, …, Xtn − Xtn−1 they are independent;

- (c)

- The process has uniform increments, i.e.,: Xt − Xs Xt−s (equality means equality of distributions);

- (d)

- For any t > 0 the random variable Xt has a Poisson distribution with parameter λt, i.e.,:

3. Discussion

- (a)

- How long should the repair of an element be carried out, the properties of which return to their nominal values after the repair?

- (b)

- How many pieces of consumables should be replaced with new ones within a given time? In this case, it is also worth considering the successive delivery of these items, knowing how many of these items will be damaged, on average, within a given time.The author compared the following models, assuming that

- (a)

- the elements work until the first failure,

- (b)

- the elements are repairable, and after the repair they regain their properties and nominal technical parameters.

- (a)

- Is the wear of selected components of special vehicles based on the analysis of the adopted mathematical models consistent with operational practice?

- (b)

- Which model is more appropriate for the nature of the wear of a given element, and in what context?

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kopociński, B. Outline of the Theory of Renewal and Reliability; PWN Publishing House: Warsaw, Poland, 1973. [Google Scholar]

- Karpiński, J.; Firkowicz, S. Principles of Prevention of Technical Objects; PWN Publishing House: Warsaw, Poland, 1981. [Google Scholar]

- Akbarpour, N.; Salehi-Amiri, A.; Hajiaghaei-Keshteli, M.; Oliva, D. An innovative waste management system in a smart city under stochastic optimization using vehicle routing. Problem Soft Comput. 2021, 25, 6707–6727. [Google Scholar] [CrossRef]

- Aringhieri, R.; Bruglieri, M.; Malucelli, F.; Nonato, M. A special vehicle routing problem arising in the optimization of waste disposal: A real case. Transp. Sci. 2018, 52, 229–496. [Google Scholar] [CrossRef]

- Kim, B.-I.; Kim, S.; Sahoo, S. Waste collection vehicle routing problem with time windows. Comput. Oper. Res. 2006, 33, 3624–3642. [Google Scholar] [CrossRef]

- Marković, D.; Marković, S.; Marinković, D.; Pamučar, D. Dynamic vehicle routing problem for smart waste collection. Facta Univ. Mech. Eng. 2024. [Google Scholar] [CrossRef]

- Bastola, A.; Stewart, D.; Dini, D. Three-dimensional finite element simulation and experimental validation of sliding wear. Wear 2022, 504–505, 204402. [Google Scholar] [CrossRef]

- Dai, W.; Liu, S.; Lv, S.; Hu, J.; Wang, X. Multi-stage tool wear prediction method based on multi-dimensional digital twin. J. Intell. Manuf. 2025. [Google Scholar] [CrossRef]

- Danish, M.; Gupta, M.K.; Irfan, S.A.; Ghazali, S.M.; Rathore, M.F.; Krolczyk, G.M.; Alsaady, A. Machine learning models for prediction and classification of tool wear in sustainable milling of additively manufactured 316 stainless steel. Results Eng. 2024, 22, 102015. [Google Scholar] [CrossRef]

- Fathi, R.; Chen, M.; Abdallah, M.; Saleh, B. Wear Prediction of Functionally Graded Composites Using Machine Learning. Materials. 2024, 17, 4523. [Google Scholar] [CrossRef]

- Feng, K.; Ji, J.C.; Ni, Q.; Beer, M. A review of vibration-based gear wear monitoring and prediction techniques. Mech. Syst. Signal Process. 2023, 182. [Google Scholar] [CrossRef]

- Fujisawa, K. Observation and transition point detection in transient two-body abrasive wear process using machine vision system and data-driven modeling. Int. J. Adv. Manuf. Technol. 2025, 136, 4511–4523. [Google Scholar] [CrossRef]

- Hasan, M.S.; Wong, T.; Rohatgi, P.; Nosonovsky, M. Analysis of the friction and wear of graphene reinforced aluminum metal matrix composites using machine learning models. Tribol. Int. 2022, 170, 107527. [Google Scholar] [CrossRef]

- He, R.; König, F.; Wang, Y.; Wirsing, F.; Tian, Z.; Zuo, M.; Ye, M. Wear and life predictions for bearings considering simulation-to reality variability. Mech. Syst. Signal Process. 2025, 229, 112498. [Google Scholar] [CrossRef]

- Kundu, P. Review of rotating machinery elements condition monitoring using acoustic emission signal. Expert Syst. Appl. 2024, 252, 124169. [Google Scholar] [CrossRef]

- Marian, M.; Berman, D.; Rota, A.; Jackson, R.L.; Rosenkranz, A. Layered 2D Nanomaterials to Tailor Friction and Wear in Machine Elements—A Review. Adv. Mater. Interfaces 2022, 9, 2101622. [Google Scholar] [CrossRef]

- Pashmforoush, F.; Araghizad, A.E.; Budak, E. Physics-informed tool wear prediction in turning process: A thermo-mechanical wear-included force model integrated with machine learning. J. Manuf. Syst. 2024, 77, 266–283. [Google Scholar] [CrossRef]

- Sharma, A.; Sadeghi, F. Effects of fretting wear on rolling contact fatigue. Tribol. Int. 2024, 192, 109204. [Google Scholar] [CrossRef]

- Sheikh, K.A.; Khan, M.M. Predictive modeling of abrasive wear in in-situ TiC reinforced ZA37 alloy: A machine learning approach. Tribol. Int. 2025, 202, 110291. [Google Scholar] [CrossRef]

- Singh, J.; Singh, S.; Vasudev, H.; Katiyar, J.K. Artificial neural network model for wear characteristic analysis of WC-10Co4Cr and Stellite 6 thermal spray coatings. Tribol. Int. 2024, 199, 109924. [Google Scholar] [CrossRef]

- Prajapati, D.K.; Prakash, C.; Saxena, K.; Gupta, M.; Mehta, J.S. Prediction of contact response using boundary element method (BEM) for different surface topography. Int. J. Interact. Des. Manuf. 2024, 18, 2725–2732. [Google Scholar] [CrossRef]

- Pressas, I.; Pantazopoulos, G. Failure analysis and numerical modeling of a fractured chain element from a drawing machine in a metallurgical production plant. Eng. Fail. Anal. 2025, 171, 109406. [Google Scholar] [CrossRef]

- Shah, R.; Jaramillo, R.; Thomas, G.; Rayhan, T.; Hossain, N.; Kchaou, M.; Profito, F.J.; Rosenkranz, A. Artificial Intelligence and Machine Learning in Tribology: Selected Case Studies and Overall Potential. Adv. Eng. Mater. 2025. [Google Scholar] [CrossRef]

- Springis, G.; Boiko, I. Comparative Analysis of Wear Models for Accurate Wear Predictions. Lubricants. 2025, 13, 100. [Google Scholar] [CrossRef]

- Wei, A.; Li, Y.; Feng, L.; Feng, Y.; Xie, Z. Frictional Study on 30CrNi2MoVA Steel Based on Experiments and Finite Element Simulation: Wear Prediction. Coatings 2024, 14, 265. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, H.; Zhu, C.; Ge, Y. Simulation of the fatigue-wear coupling mechanism of an aviation gear. Friction. 2021, 9, 1616–1634. [Google Scholar] [CrossRef]

- Barlow, R.E.; Proschan, F.; Hunter, L.C. Mathematical Theory of Reliability; J. Wiley and Sons: New York, NY, USA, 1965. [Google Scholar]

- Blackwell, D. A renewal theorem. Duke Math. J. 1948, 15, 145–150. [Google Scholar] [CrossRef]

- Bobrowski, D. Mathematical Models and Methods of Reliability Theory in Examples and Tasks; Scientific and Technical Publishing Houses: Warsaw, Poland, 1985. [Google Scholar]

- Czaplicki, J.M. Elements of Mathematical Statistics and Their Applications in Mining Engineering and Earthworks; Silesian University of Technology Publishing House: Gliwice, Poland, 2011. [Google Scholar]

- Czaplicki, J.M. Reliability in the Issues of Mining and Earthworks Mechanization; Silesian University of Technology Publishing House: Gliwice, Poland, 2012. [Google Scholar]

- Gnidenko, B.V.; Belyaev, Y.K.; Soloviev, A.D. Mathematical Methods in Organizational Theory; Nauka Publishing House: Moscow, Russia, 1965. [Google Scholar]

- Sadowski, W. Mathematical Statistics; PWE Publishing House: Warsaw, Poland, 1969. [Google Scholar]

- Smith, W.L. Regenerative stochastic processes. Proc. R. Soc. Ser. A. 1955, 232, 6–31. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stawowiak, M.; Gwiazda, A.; Topolska, S.; Olender-Skóra, M. Examples of Reliability Models of a Renewable Technical Object in Relation to Special Vehicles. Materials 2025, 18, 3552. https://doi.org/10.3390/ma18153552

Stawowiak M, Gwiazda A, Topolska S, Olender-Skóra M. Examples of Reliability Models of a Renewable Technical Object in Relation to Special Vehicles. Materials. 2025; 18(15):3552. https://doi.org/10.3390/ma18153552

Chicago/Turabian StyleStawowiak, Michał, Aleksander Gwiazda, Santina Topolska, and Małgorzata Olender-Skóra. 2025. "Examples of Reliability Models of a Renewable Technical Object in Relation to Special Vehicles" Materials 18, no. 15: 3552. https://doi.org/10.3390/ma18153552

APA StyleStawowiak, M., Gwiazda, A., Topolska, S., & Olender-Skóra, M. (2025). Examples of Reliability Models of a Renewable Technical Object in Relation to Special Vehicles. Materials, 18(15), 3552. https://doi.org/10.3390/ma18153552