Molecular Dynamics Insights into Bio-Oil-Enhanced Self-Healing of Aged Asphalt

Abstract

1. Introduction

2. Materials and Methods

2.1. Asphalt and Regeneration Agent

2.2. Dynamic Shear Rheometer Test

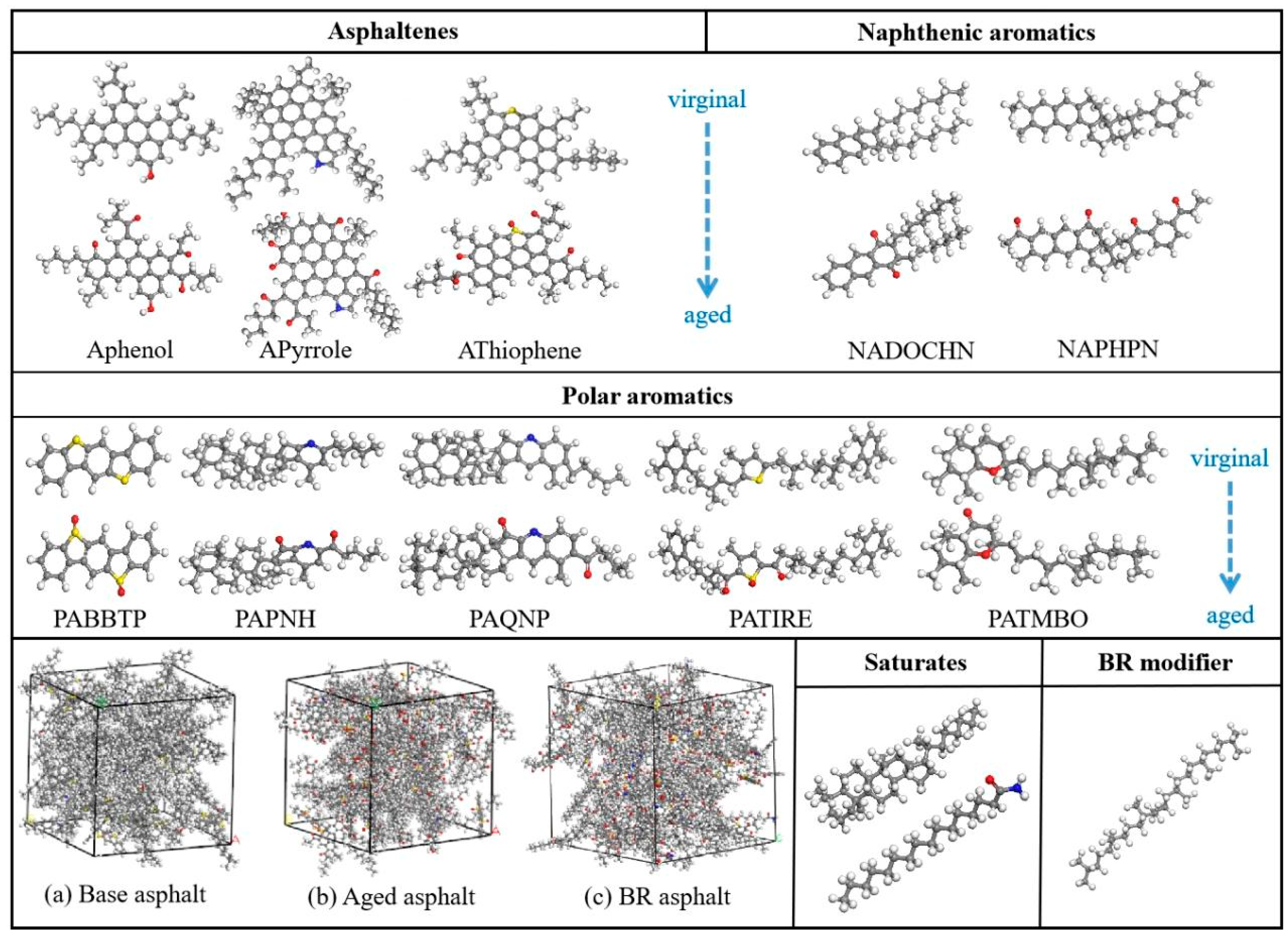

2.3. Molecular Model of Asphalt Components

2.4. Molecular Model of Healing

3. Analysis of Experimental Results

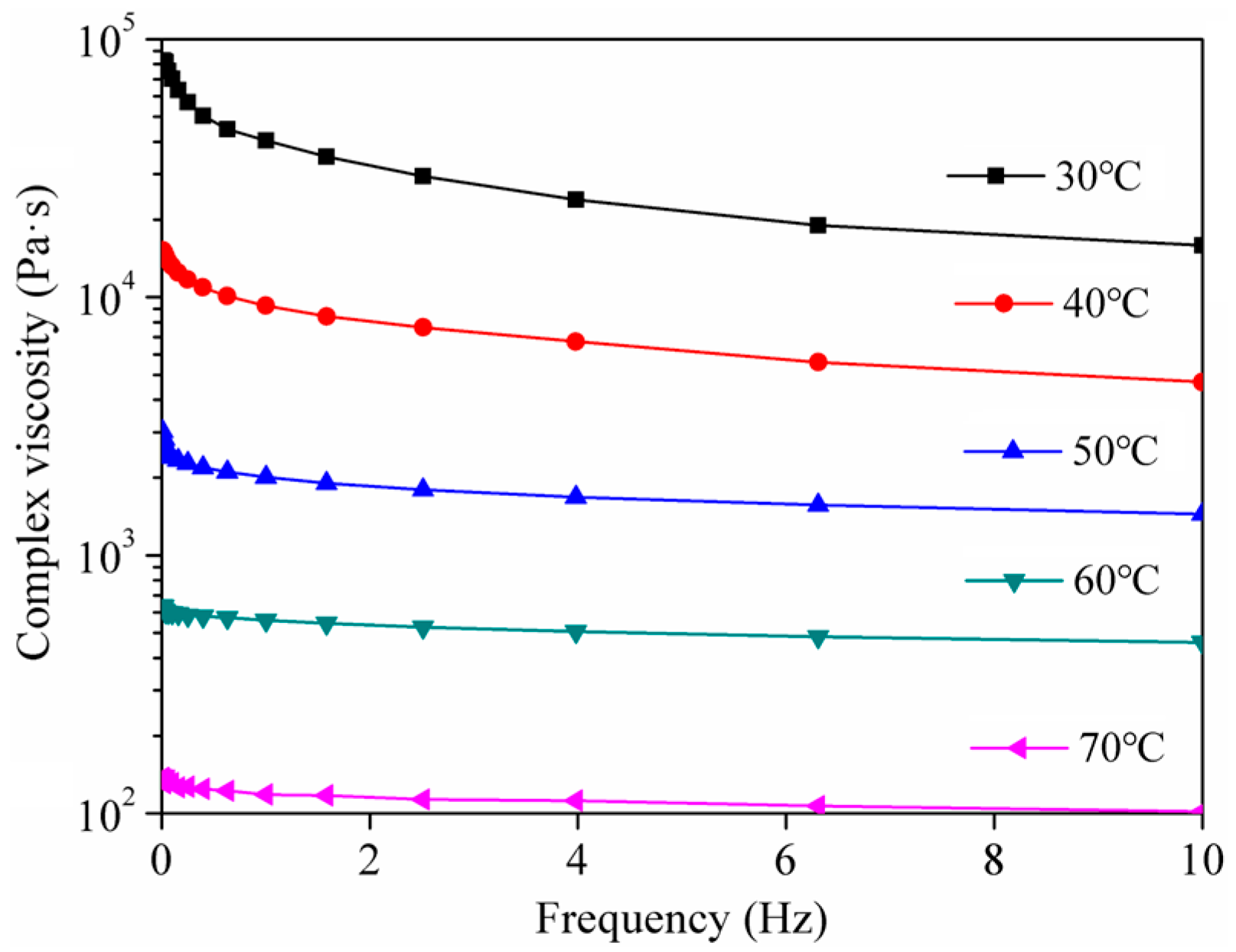

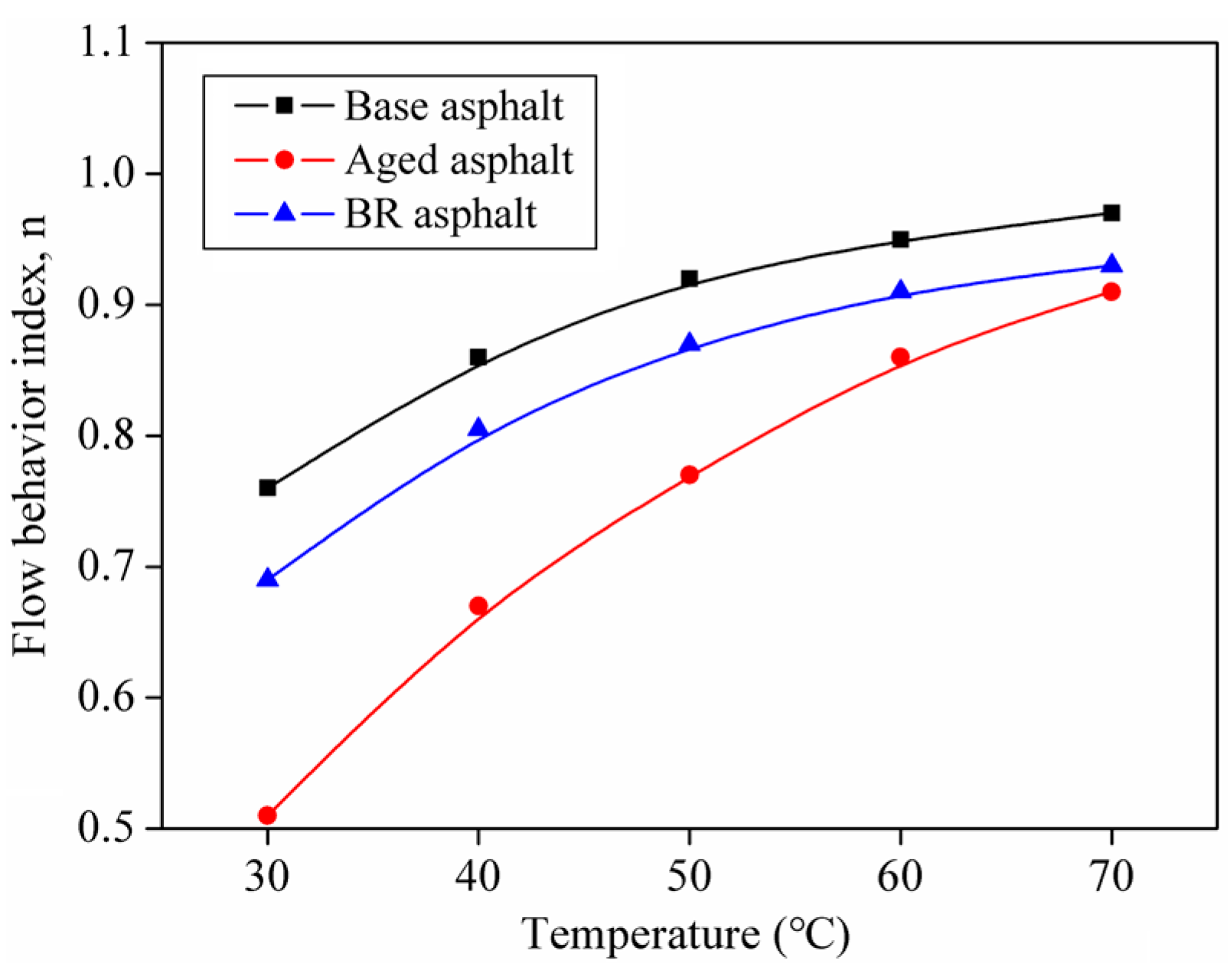

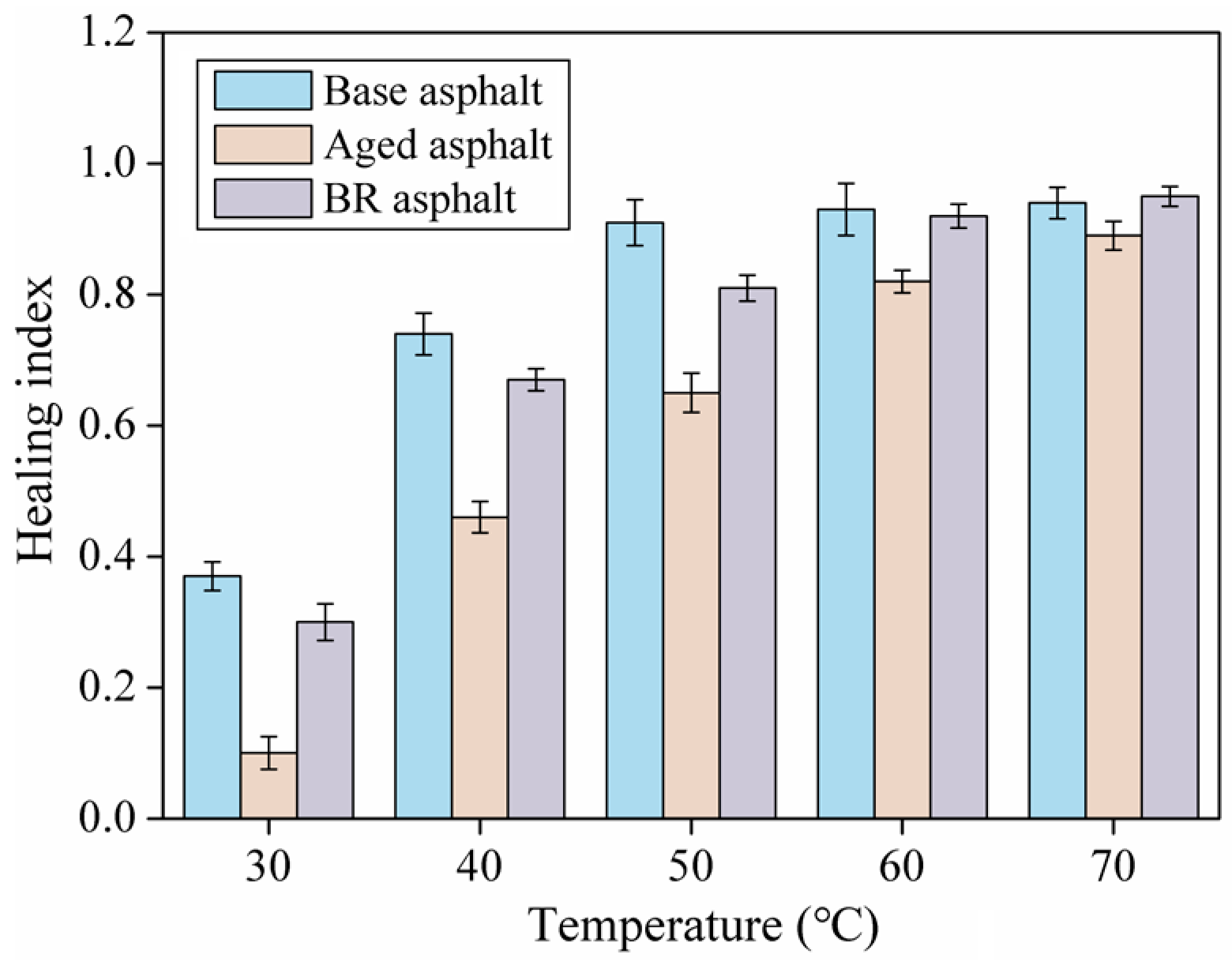

3.1. Dynamic Shear Rheometer Scan Results

3.2. Molecular Dynamics Simulation Results

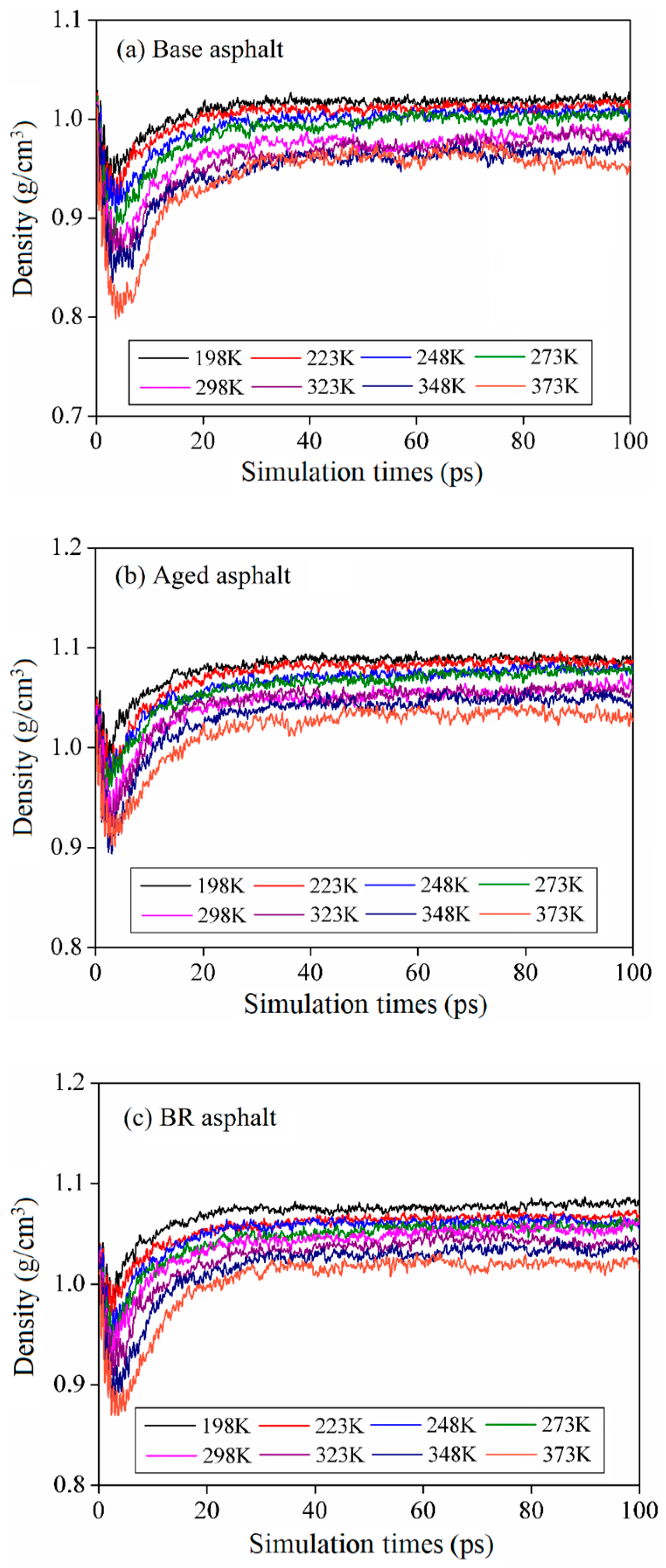

3.2.1. Validation of Asphalt Molecular Model

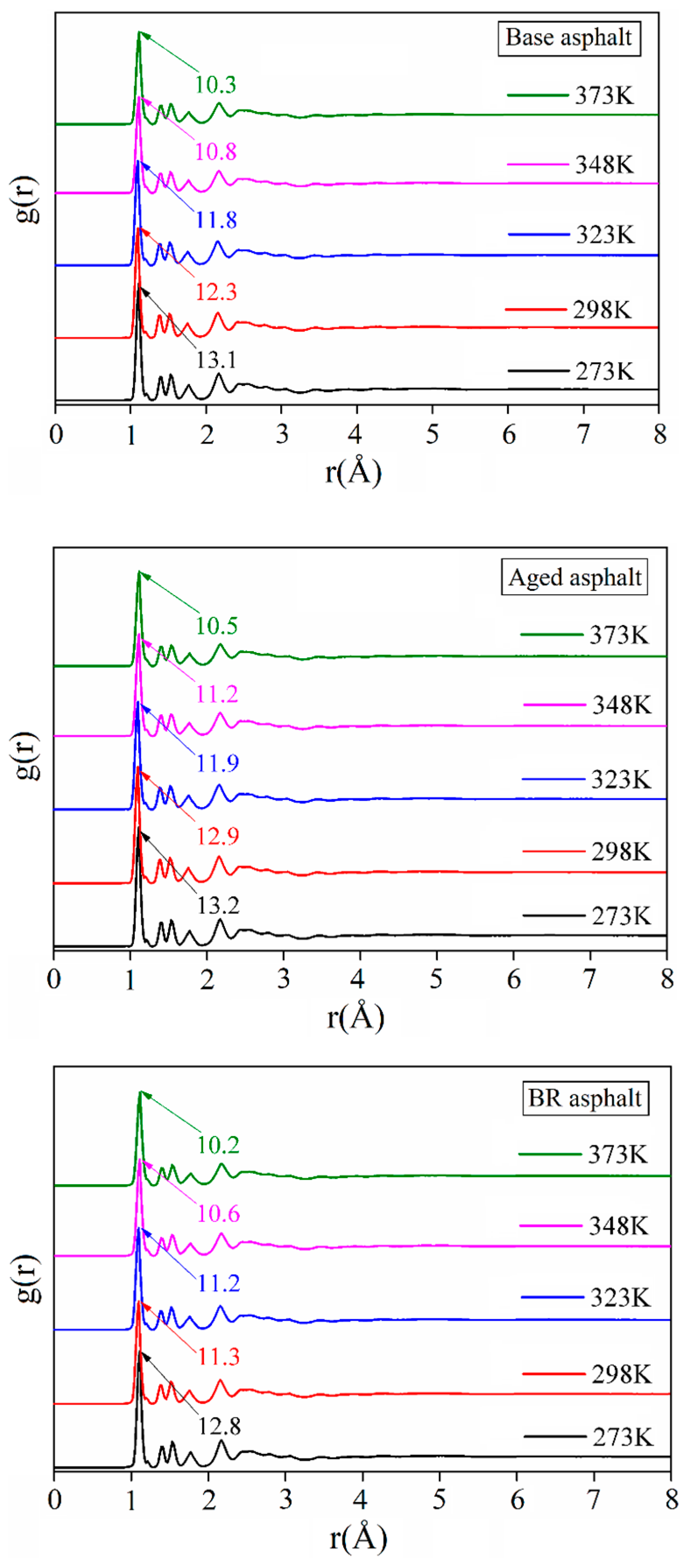

3.2.2. Radial Distribution Function

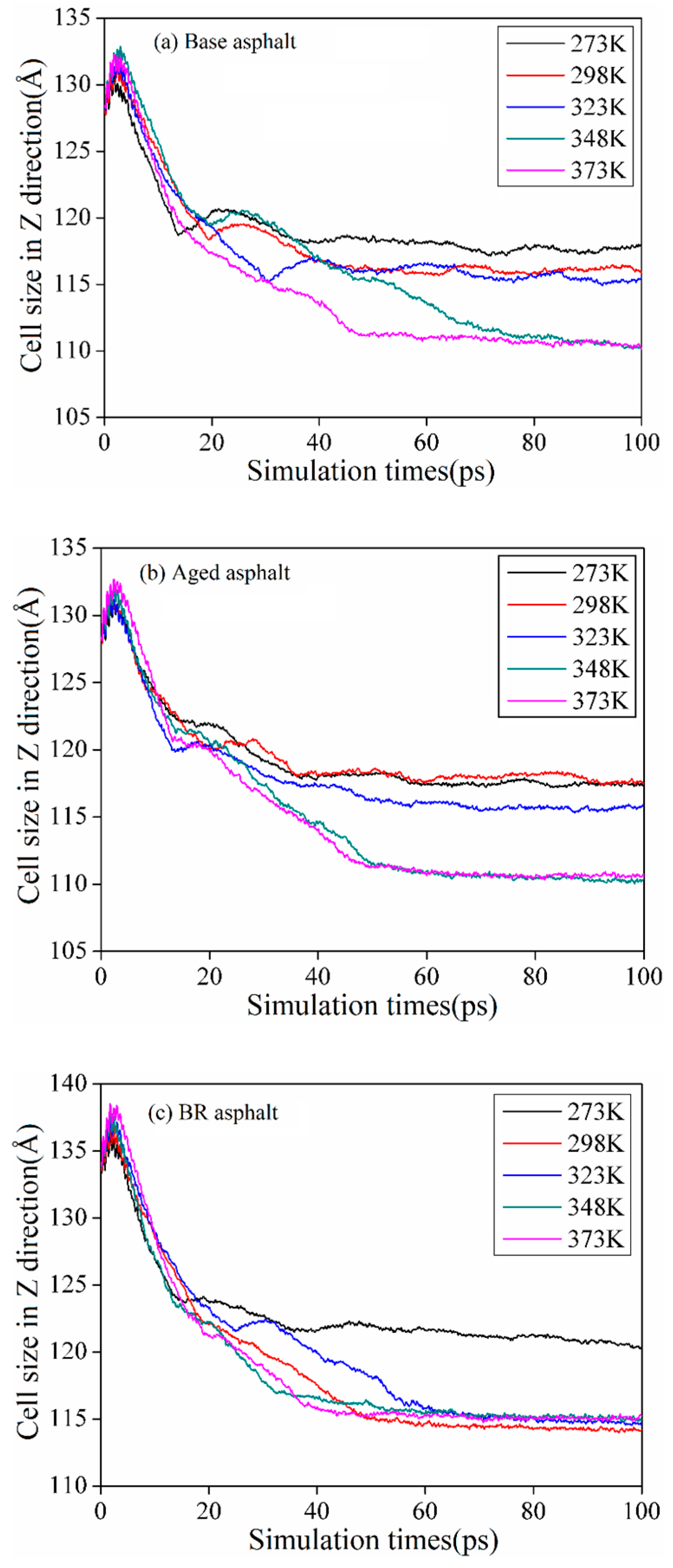

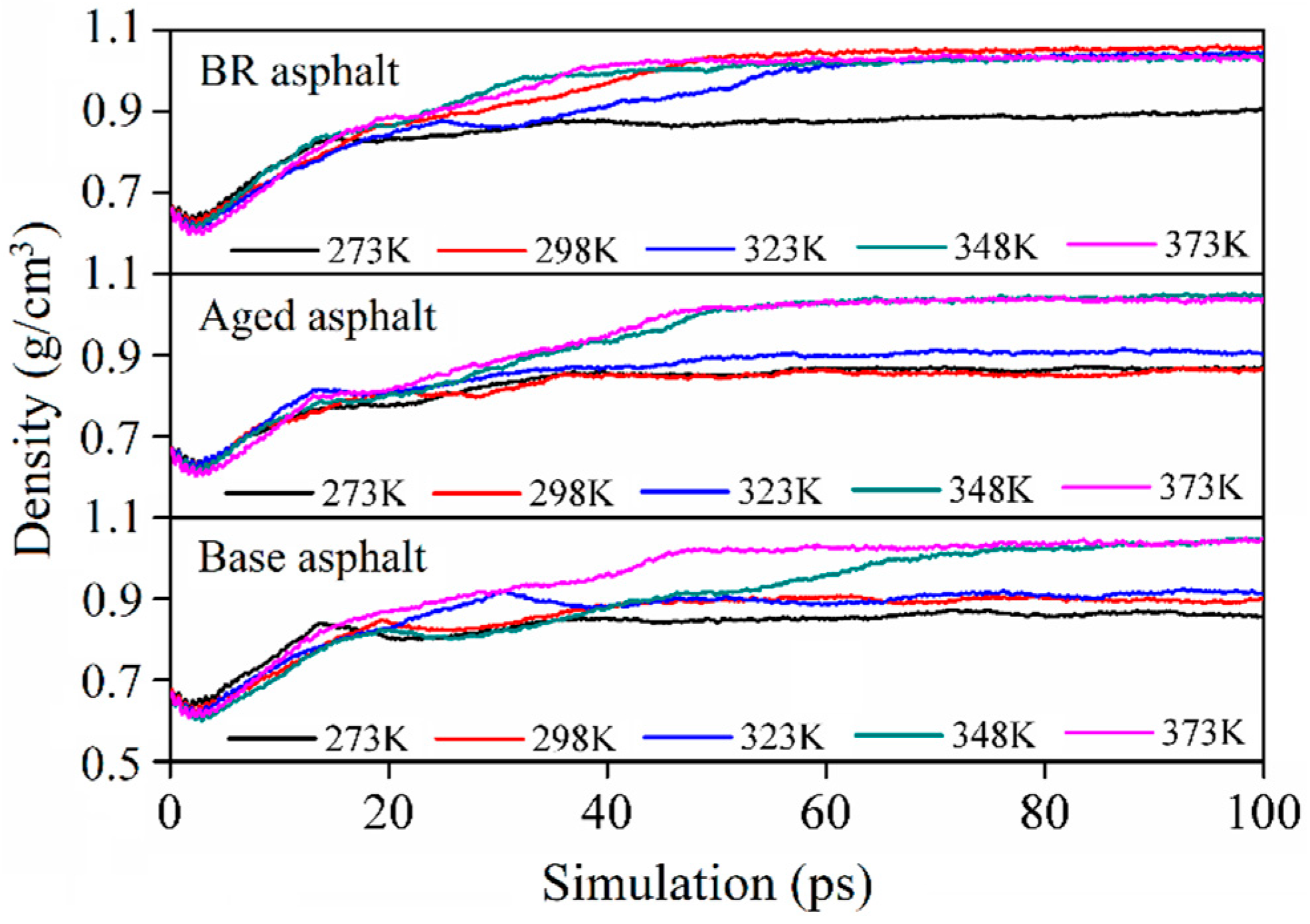

3.2.3. Size and Density

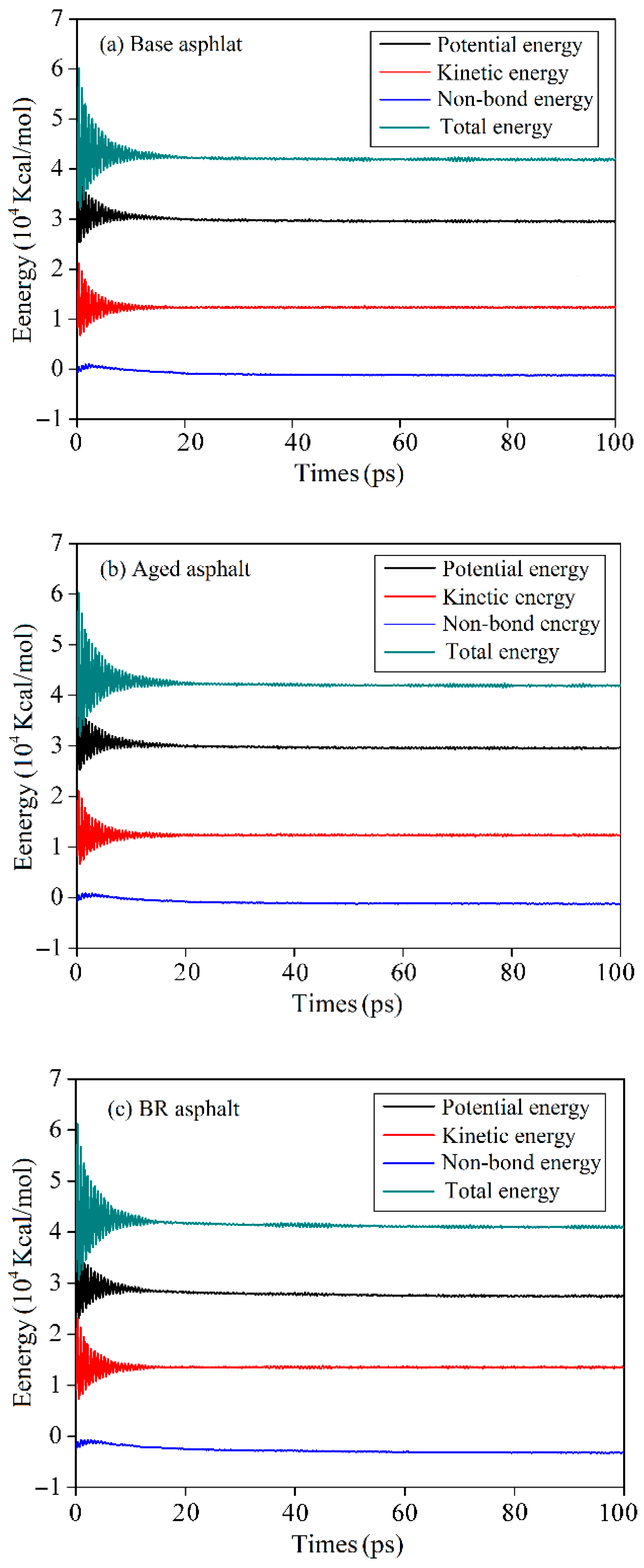

3.2.4. Energy Distribution

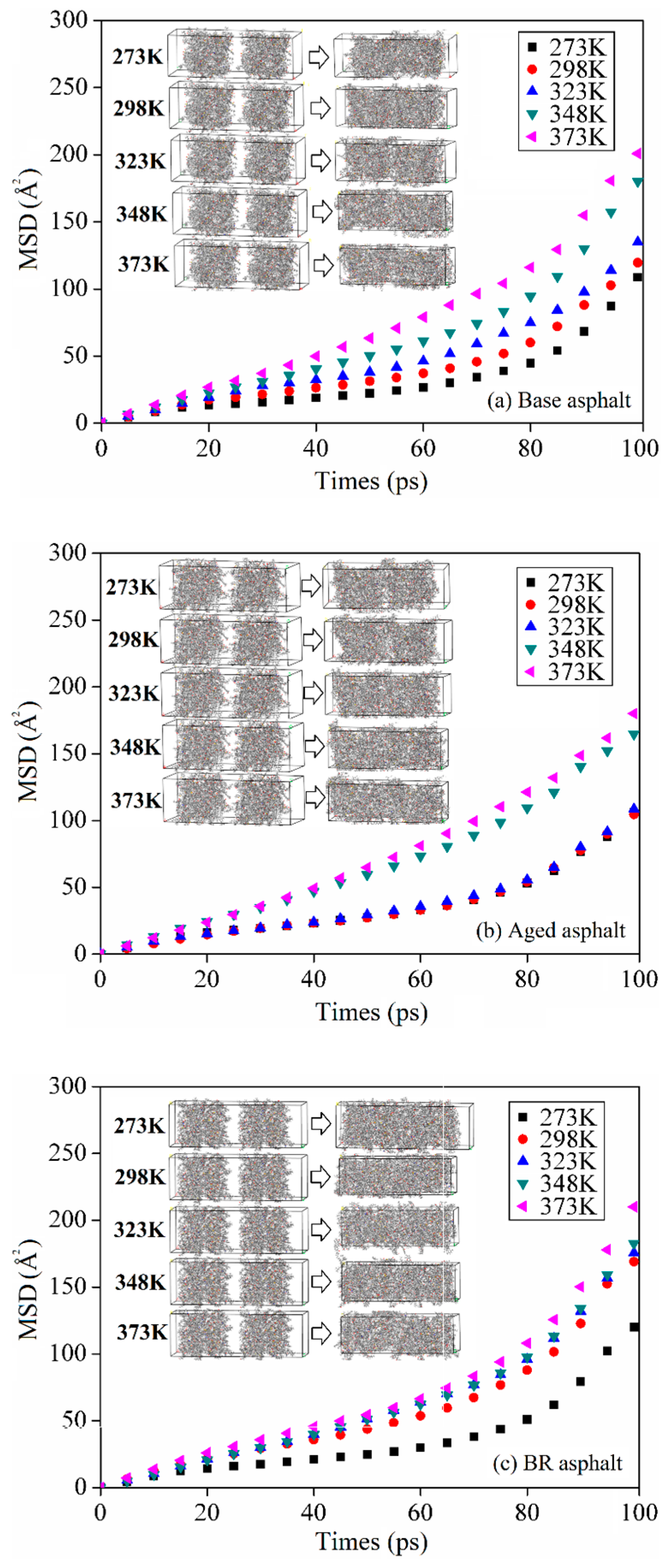

3.2.5. Mean Square Displacement

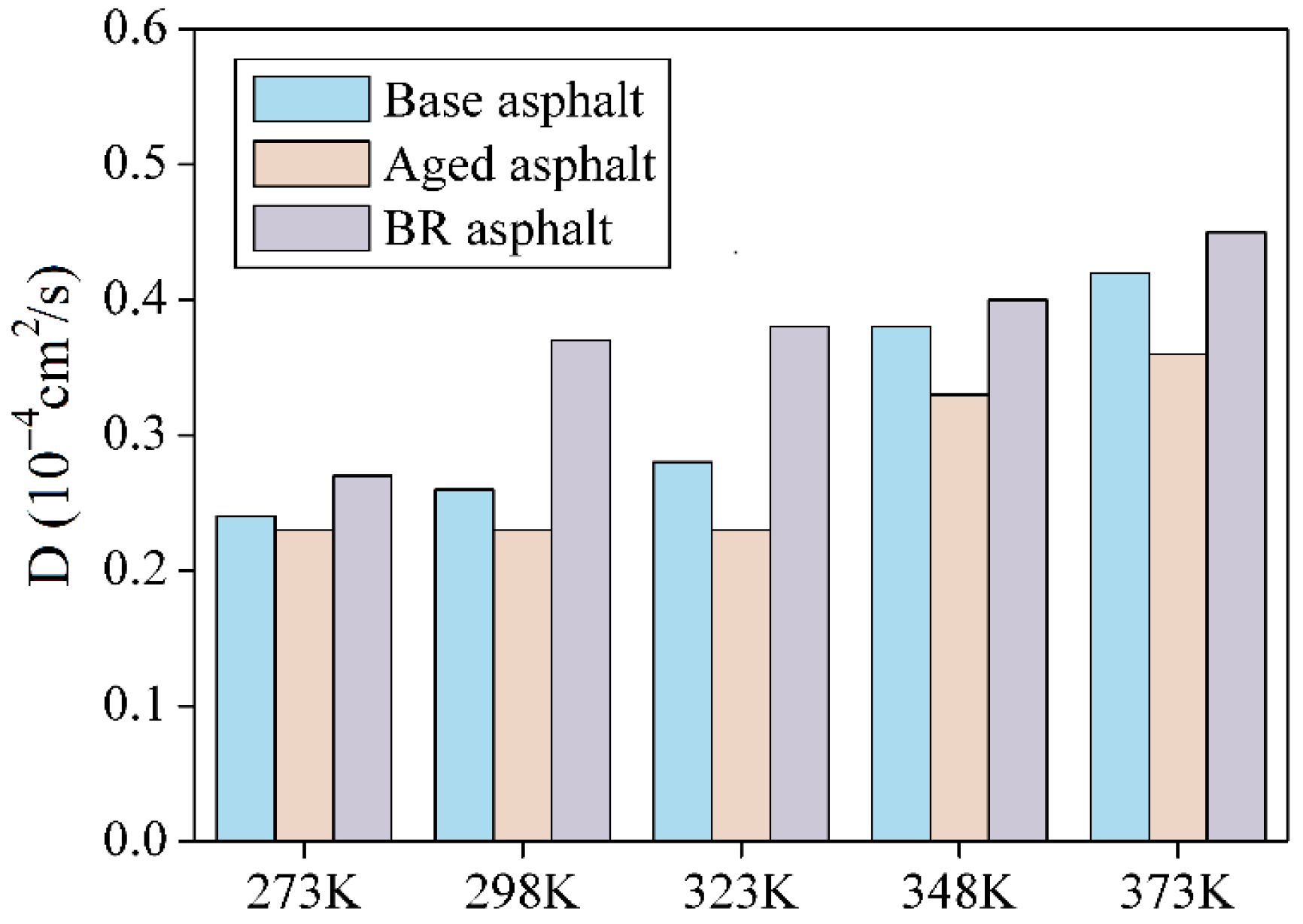

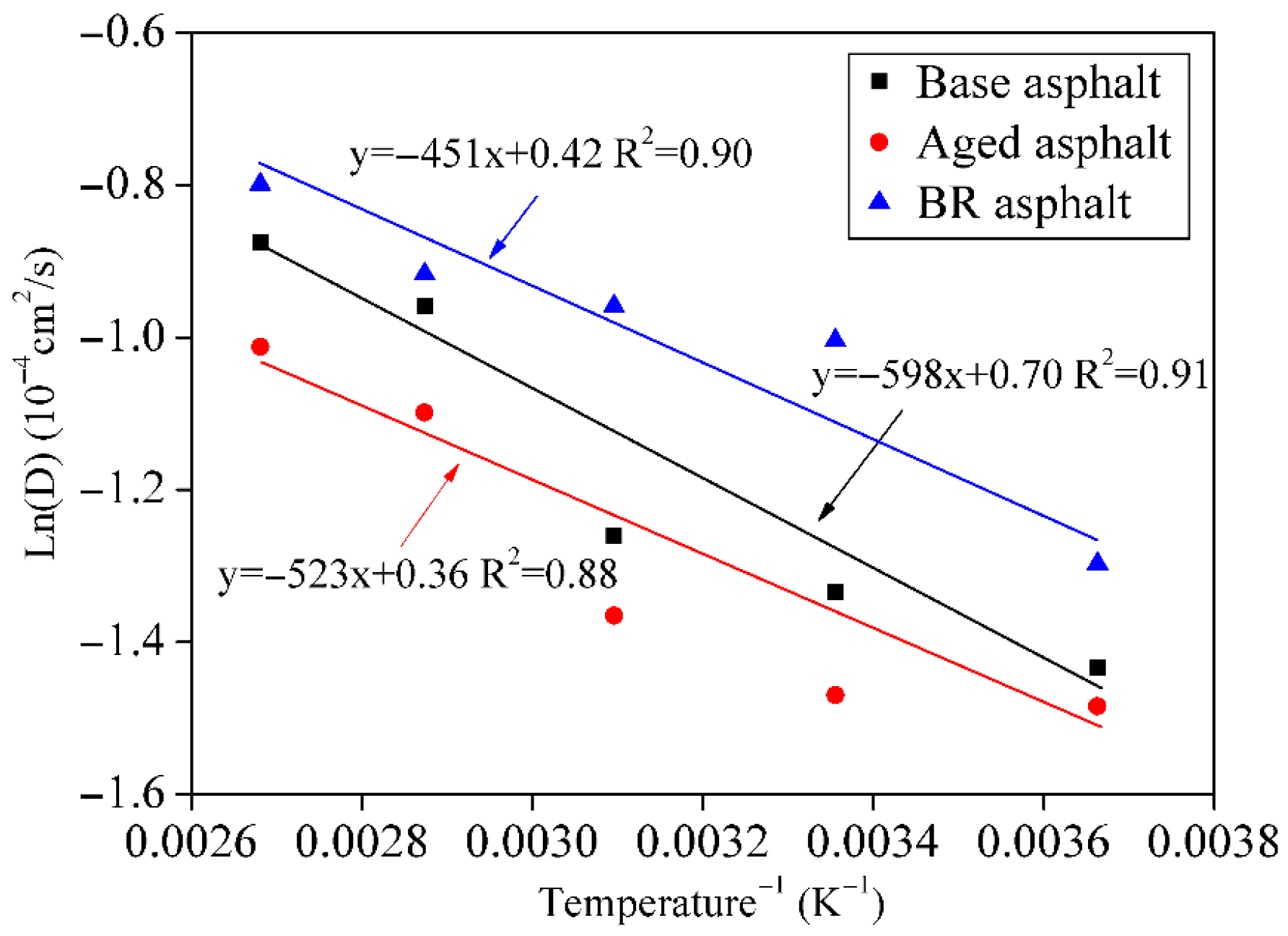

3.2.6. Diffusion Coefficient

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Suo, Z.; Wong, W.G. Analysis of fatigue crack growth behavior in asphalt concrete material in wearing course. Constr. Build. Mater. 2009, 23, 462–468. [Google Scholar] [CrossRef]

- Bazin, P.; Saunier, J. Deformability, fatigue and healing properties of asphalt mixes. In Proceedings of the International Conference on the Structural Design of Asphalt Pavements, Ann Arbor, MI, USA, 1 January 1967. [Google Scholar]

- Zhang, L.; Liu, Q.; Wu, S.; Rao, Y.; Sun, Y.; Xie, J.; Pan, P. Investigation of the flow and self-healing properties of UV aged asphalt binders. Constr. Build. Mater. 2018, 174, 401–409. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Liu, G.; Pei, J. Effects of material characteristics on asphalt and filler interaction ability. Int. J. Pavement Eng. 2019, 20, 928–937. [Google Scholar] [CrossRef]

- Yang, S.H.; Suciptan, T. Rheological behavior of Japanese cedar-based biobinder as partial replacement for bituminous binder. Constr. Build. Mater. 2016, 114, 127–133. [Google Scholar] [CrossRef]

- Raman, N.A.A.; Hainin, M.R.; Hassan, N.A.; Ani, F.N. A review on the application of bio-oil as an additive for asphalt. J. Teknol. 2015, 72, 105–110. [Google Scholar] [CrossRef]

- Peng, X.; Xie, N.; Xia, C.; Zhou, X.; Zhao, P.; Ma, S.; Zhang, C.; Lv, S. Laboratory evaluation of different bio-oil recycled aged asphalts: Conventional performances and microscopic characteristics. J. Clean. Prod. 2023, 428, 139442. [Google Scholar] [CrossRef]

- Cabette, M.; Micaelo, R.; Pais, J. The use of bio-oil from biodiesel production for enhancing the bitumen healing. Constr. Build. Mater. 2023, 409, 134033. [Google Scholar] [CrossRef]

- Wang, J.; Lv, S.; Liu, J.; Peng, X.; Lu, W.; Wang, Z.; Xie, N. Performance evaluation of aged asphalt rejuvenated with various bio-oils based on rheological property index. J. Clean. Prod. 2023, 385, 135593. [Google Scholar] [CrossRef]

- GARCÍA, Á. Self-healing of open cracks in asphalt mastic. Fuel 2012, 93, 264–272. [Google Scholar] [CrossRef]

- Li, B.; Han, J.; Wei, D.; Ji, H.; Yao, T.; Wang, H.; Han, J.; Zhang, Y. A molecular dynamics simulation study on the recovery performance of aged asphalt binder by waste vegetable oil rejuvenators. J. Clean. Prod. 2024, 442, 140796. [Google Scholar] [CrossRef]

- Ruan, Y.; Zhang, X.; Yin, C.; Zhang, X. Properties of waste vegetable oil recycled asphalt-binder: A molecular simulation study. Mol. Simul. 2024, 50, 588–599. [Google Scholar] [CrossRef]

- Zhang, H.; Zheng, F.; Zhang, J.; Hu, D.; Yu, X.; Chen, Z.; Pei, J. Unveiling micro-macro links in asphalt: An in-depth analysis of characterization and simulation approaches. Fuel 2025, 379, 132823. [Google Scholar] [CrossRef]

- Yu, M.; Zhang, H.; Wang, J.; Sun, J.; Liu, D.; Sun, Y.; Chen, J. Multi-scale analysis of virgin/aged/recycled asphalt self-healing performance based on molecular simulation and micro-macro tests. Constr. Build. Mater. 2024, 431, 136535. [Google Scholar] [CrossRef]

- Sun, D.; Yu, F.; Li, L.; Lin, T.; Zhu, X. Effect of chemical composition and structure of asphalt binders on self-healing. Constr. Build. Mater. 2017, 133, 495–501. [Google Scholar] [CrossRef]

- Xu, N.; Wang, H.; Chen, Y.; Hossiney, N.; Ma, Z.; Wang, H. Insight into the effects of waste vegetable oil on self-healing behavior of bitumen binder. Constr. Build. Mater. 2023, 363, 129888. [Google Scholar] [CrossRef]

- Liu, S.; Wang, H.; Yang, J.; Luo, S.; Liu, Y.; Huang, W.; Hu, J.; Xu, G.; Min, Z. Biomass waste to produce bio oil as rejuvenator for asphalt based on pyrolysis technology. Int. J. Pavement Eng. 2023, 25, 2287695. [Google Scholar] [CrossRef]

- Hu, Y.; Ryan, J.; Sreeram, A.; Allanson, M.; Pasandín, A.R.; Zhou, L.; Singh, B.; Wang, H.; Airey, G.D. Optimising the dosage of bio-rejuvenators in asphalt recycling: A rejuvenation index based approach. Constr. Build. Mater. 2024, 433, 136761. [Google Scholar] [CrossRef]

- Sun, G.; Li, B.; Sun, D.; Zhang, J.; Wang, C.; Zhu, X. Roles of aging and bio-oil regeneration on self-healing evolution behavior of asphalts within wide temperature range. J. Clean. Prod. 2021, 329, 129712. [Google Scholar] [CrossRef]

- Zheng, X.; Xu, W.; Cao, K.; Li, K. Self-healing behavior of recycled asphalt prepared by residue oil of straw liquefaction based on molecular dynamics simulation. Sci. Rep. 2022, 12, 2718. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Wu, S.; Liu, Q.; Zeng, W.; Chen, Z.; Ye, Q.; Pan, P. Self-healing performance of asphalt mixtures through heating fibers or aggregate. Constr. Build. Mater. 2017, 150, 673–680. [Google Scholar] [CrossRef]

- Franesqui, M.A.; Yepes, J.; García-González, C. Top-down cracking self-healing of asphalt pavements with steel filler from industrial waste applying microwaves. Constr. Build. Mater. 2017, 149, 612–620. [Google Scholar] [CrossRef]

- JTG E20—2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- García, A.; Norambuena-Contreras, J.; Bueno, M.; Partl, M.N. Influence of steel wool fibers on the mechanical, termal, and healing properties of dense asphalt concrete. J. Test. Eval. 2014, 42, 1107–1118. [Google Scholar] [CrossRef]

- Ding, H.; Wang, H.; Qu, X.; Varveri, A.; Gao, J.; You, Z. Towards an understanding of diffusion mechanism of bio-rejuvenators in aged asphalt binder through molecular dynamics simulation. J. Clean. Prod. 2021, 299, 126927. [Google Scholar] [CrossRef]

- Pahlavan, F.; Mousavi, M.; Hung, A.M.; Fini, E.H. Characterization of oxidized asphaltenes and the restorative effect of a bio-modifier. Fuel 2018, 212, 593–604. [Google Scholar] [CrossRef]

- Heyes, D.M.; Mitchell, P.J.; Visscher, P.B. Viscoelasticity and near-newtonian behaviour of concentrated dispersions by Brownian dynamics simulations. Trends Colloid Interface Sci. VIII 1994, 97, 179–182. [Google Scholar]

- Zahoor, M.; Nizamuddin, S.; Madapusi, S.; Giustozzi, F. Recycling asphalt using waste bio-oil: A review of the production processes, properties and future perspectives. Process Saf. Environ. Prot. 2021, 147, 1135–1159. [Google Scholar] [CrossRef]

- Sun, D.; Sun, G.; Zhu, X.; Ye, F.; Xu, J. Intrinsic temperature sensitive self-healing character of asphalt binders based on molecular dynamics simulations. Fuel 2018, 211, 609–620. [Google Scholar] [CrossRef]

- Zhang, X.; Ning, Y.; Zhou, X.; Xu, X.; Chen, X. Quantifying the rejuvenation effects of soybean-oil on aged asphalt-binder using molecular dynamics simulations. J. Clean. Prod. 2021, 317, 128375. [Google Scholar] [CrossRef]

- Teltayev, B.; Amirbayev, E.; Radovskiy, B. Evaluating the Effect of Polymer Modification on the Low-Temperature Rheological Properties of Asphalt Binder. Polymers 2022, 14, 2548. [Google Scholar] [CrossRef] [PubMed]

- He, L.; Li, G.; Lv, S.; Gao, J.; Kowalski, K.J.; Valentin, J.; Alexiadis, A. Self-healing behavior of asphalt system based on molecular dynamics simulation. Constr. Build. Mater. 2020, 254, 119225. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Lin, P.; Erkens, S.; Gao, Y. Chemical characterizations and molecular dynamics simulations on different rejuvenators for aged bitumen recycling. Fuel 2022, 324, 124550. [Google Scholar] [CrossRef]

- Ding, Y.; Huang, B.; Shu, X.; Zhang, Y.; Woods, M.E. Use of molecular dynamics to investigate diffusion between virgin and aged asphalt binders. Fuel 2016, 174, 267–273. [Google Scholar] [CrossRef]

- Guo, F.; Zhang, J.; Pei, J.; Zhou, B.; Falchetto, A.C.; Hu, Z. Investigating the interaction behavior between asphalt binder and rubber in rubber asphalt by molecular dynamics simulation. Constr. Build. Mater. 2020, 252, 118956. [Google Scholar] [CrossRef]

- He, L.; Zheng, Y.; Alexiadis, A.; Falchetto, A.C.; Li, G.; Valentin, J.; Bergh, W.V.D.; Vasiliev, Y.E.; Kowalski, K.J.; Grenfell, J. Research on the self-healing behavior of asphalt mixed with healing agents based on molecular dynamics method. Constr. Build. Mater. 2021, 295, 123430. [Google Scholar] [CrossRef]

- Laidler, K.J. The development of the Arrhenius equation. J. Chem. Educ. 1984, 61, 494. [Google Scholar] [CrossRef]

- Sun, D.; Lin, T.; Zhu, X.; Tian, Y.; Liu, F. Indices for self-healing performance assessments based on molecular dynamics simulation of asphalt binders. Comput. Mater. Sci. 2016, 114, 86–93. [Google Scholar] [CrossRef]

| Components | Molecular Formula | Number of Atoms | Mass Percent (%) | ||

|---|---|---|---|---|---|

| Base Asphalt | Aged Asphalt | BR Asphalt | |||

| Squalane | C30H62 | 92 | 5.27 | 4.78 | 4.4 |

| SHopane | C35H62 | 97 | 6.02 | 6.54 | 6.09 |

| NAPHPN | C35H44 | 79 | 15.94 | 10.59 | 9.85 |

| NADOCHN | C30H46 | 76 | 16.49 | 9.84 | 9.16 |

| PAQNP | C40H59N | 100 | 5.18 | 7.89 | 7.34 |

| PATIRE | C40H60S | 101 | 7.15 | 8.36 | 7.78 |

| PATMBO | C29H56O | 86 | 6.56 | 6.87 | 6.39 |

| PAPNH | C36H57N | 94 | 6.28 | 7.2 | 6.70 |

| PABBTP | C18H10S2 | 30 | 13.58 | 13.1 | 12.19 |

| APhenol | C42H54O | 97 | 5.38 | 7.12 | 6.63 |

| APyrrole | C66H81N | 148 | 5.54 | 8.91 | 8.30 |

| AThiophene | C51H62S | 114 | 6.61 | 8.8 | 8.19 |

| BR | C16H33NO | 51 | / | / | 6.98 |

| Type | 198 K | 223 K | 248 K | 273 K | 298 K | 323 K | 348 K | 373 K |

|---|---|---|---|---|---|---|---|---|

| Base asphalt | 1.018 | 1.011 | 1.004 | 0.998 | 0.978 | 0.972 | 0.961 | 0.958 |

| Aged asphalt | 1.088 | 1.083 | 1.074 | 1.070 | 1.054 | 1.053 | 1.045 | 1.031 |

| BR asphalt | 1.076 | 1.064 | 1.061 | 1.054 | 1.050 | 1.039 | 1.030 | 1.018 |

| ID | Energy | 273 K | 298 K | 323 K | 348 K | 373 K |

|---|---|---|---|---|---|---|

| Base asphalt | Potential (Kcal/mol) | 28,556 | 29,632 | 30,810 | 31,867 | 32,874 |

| Kinetic (Kcal/mol) | 11,313 | 12,348 | 13,389 | 14,423 | 15,458 | |

| Non-bond (Kcal/mol) | −1233 | −1139 | −937 | −855 | −826 | |

| Total (Kcal/mol) | 39,869 | 41,981 | 44,200 | 46,290 | 48,333 | |

| Aged asphalt | Potential (Kcal/mol) | 28,530 | 29,650 | 30,780 | 31,770 | 32,890 |

| Kinetic (Kcal/mol) | 11,316 | 12,354 | 13,389 | 14,425 | 15,457 | |

| Non-bond (Kcal/mol) | −1252 | −1118 | −1007 | −941 | −820 | |

| Total (Kcal/mol) | 39,846 | 42,004 | 44,170 | 46,196 | 48,347 | |

| BR asphalt | Potential (Kcal/mol) | 26,520 | 27,678 | 28,969 | 30,115 | 31,303 |

| Kinetic (Kcal/mol) | 12,393 | 13,527 | 14,657 | 15,794 | 16,932 | |

| Non-bond (Kcal/mol) | −3067 | −2998 | −2802 | −2709 | −2616 | |

| Total (Kcal/mol) | 38,914 | 41,206 | 43,626 | 45,910 | 48,236 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Tan, S.; Deng, M.; Xiang, H.; Huang, J.; He, Z.; Kong, L. Molecular Dynamics Insights into Bio-Oil-Enhanced Self-Healing of Aged Asphalt. Materials 2025, 18, 3472. https://doi.org/10.3390/ma18153472

Chen L, Tan S, Deng M, Xiang H, Huang J, He Z, Kong L. Molecular Dynamics Insights into Bio-Oil-Enhanced Self-Healing of Aged Asphalt. Materials. 2025; 18(15):3472. https://doi.org/10.3390/ma18153472

Chicago/Turabian StyleChen, Liuxiao, Silu Tan, Mingyang Deng, Hao Xiang, Jiaxing Huang, Zhaoyi He, and Lin Kong. 2025. "Molecular Dynamics Insights into Bio-Oil-Enhanced Self-Healing of Aged Asphalt" Materials 18, no. 15: 3472. https://doi.org/10.3390/ma18153472

APA StyleChen, L., Tan, S., Deng, M., Xiang, H., Huang, J., He, Z., & Kong, L. (2025). Molecular Dynamics Insights into Bio-Oil-Enhanced Self-Healing of Aged Asphalt. Materials, 18(15), 3472. https://doi.org/10.3390/ma18153472