Investigation of the Wear Resistance of Hard Anodic Al2O3/IF-WS2 Coatings Deposited on Aluminium Alloys

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Research Methods

3. Results and Discussion

4. Conclusions

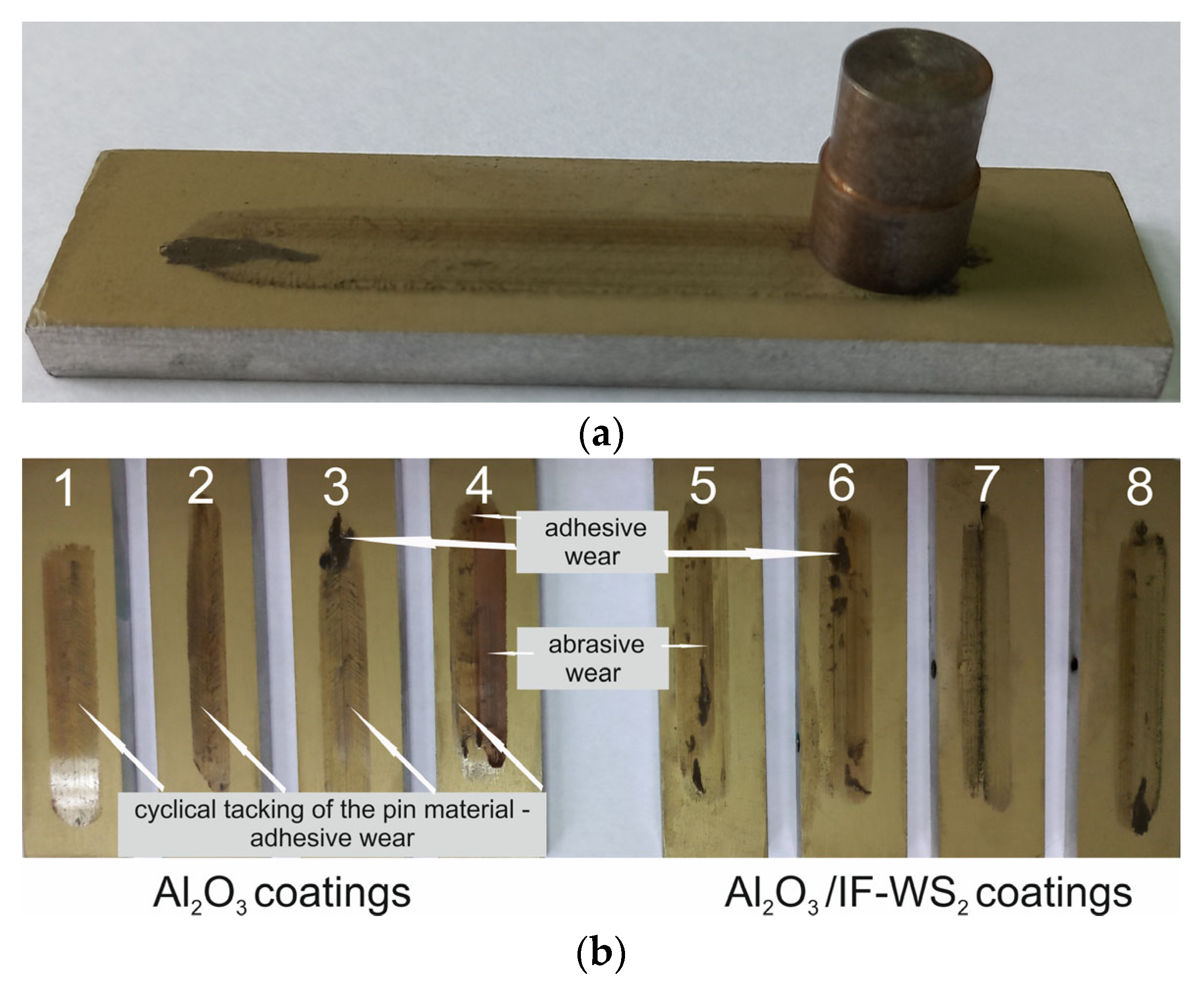

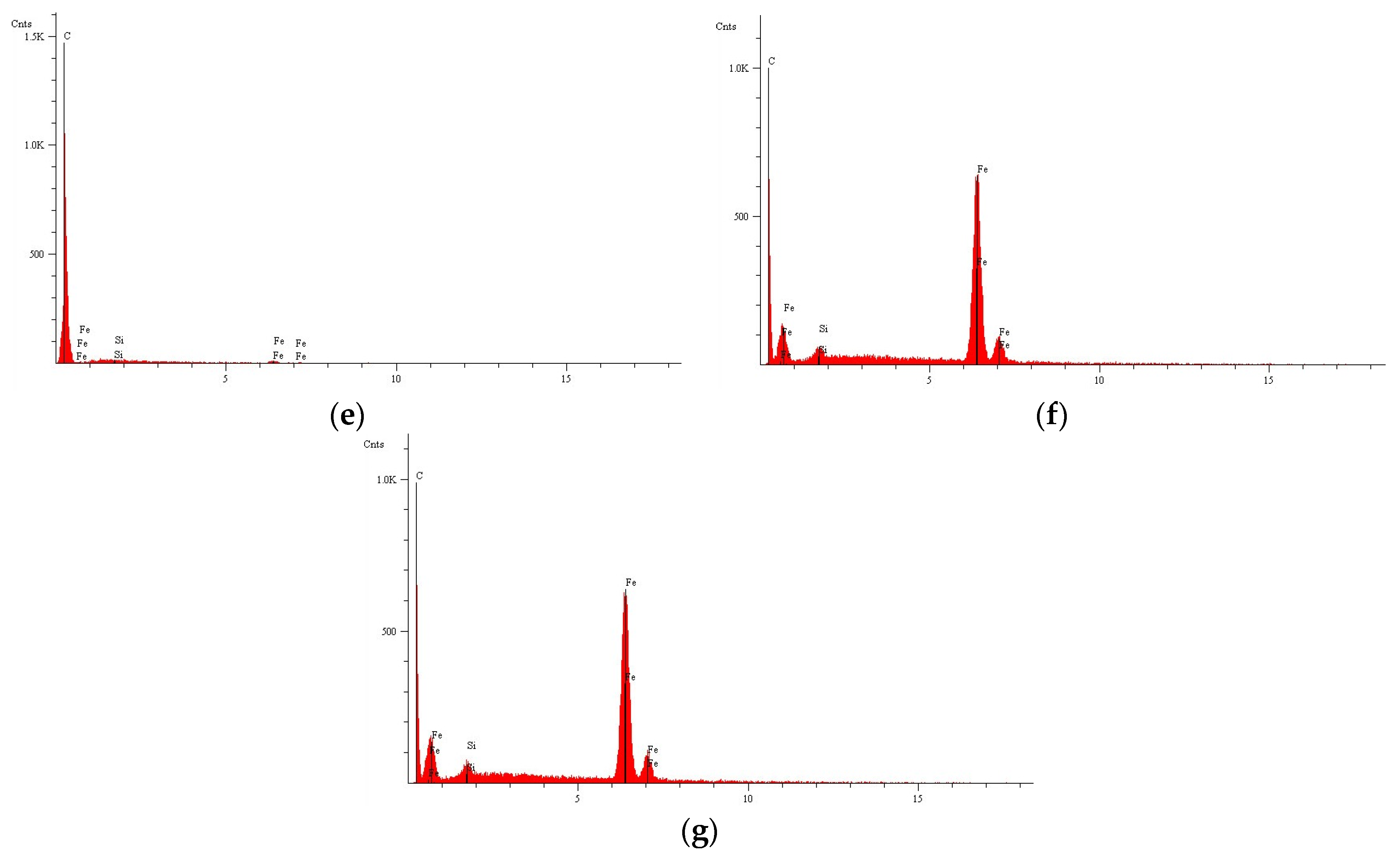

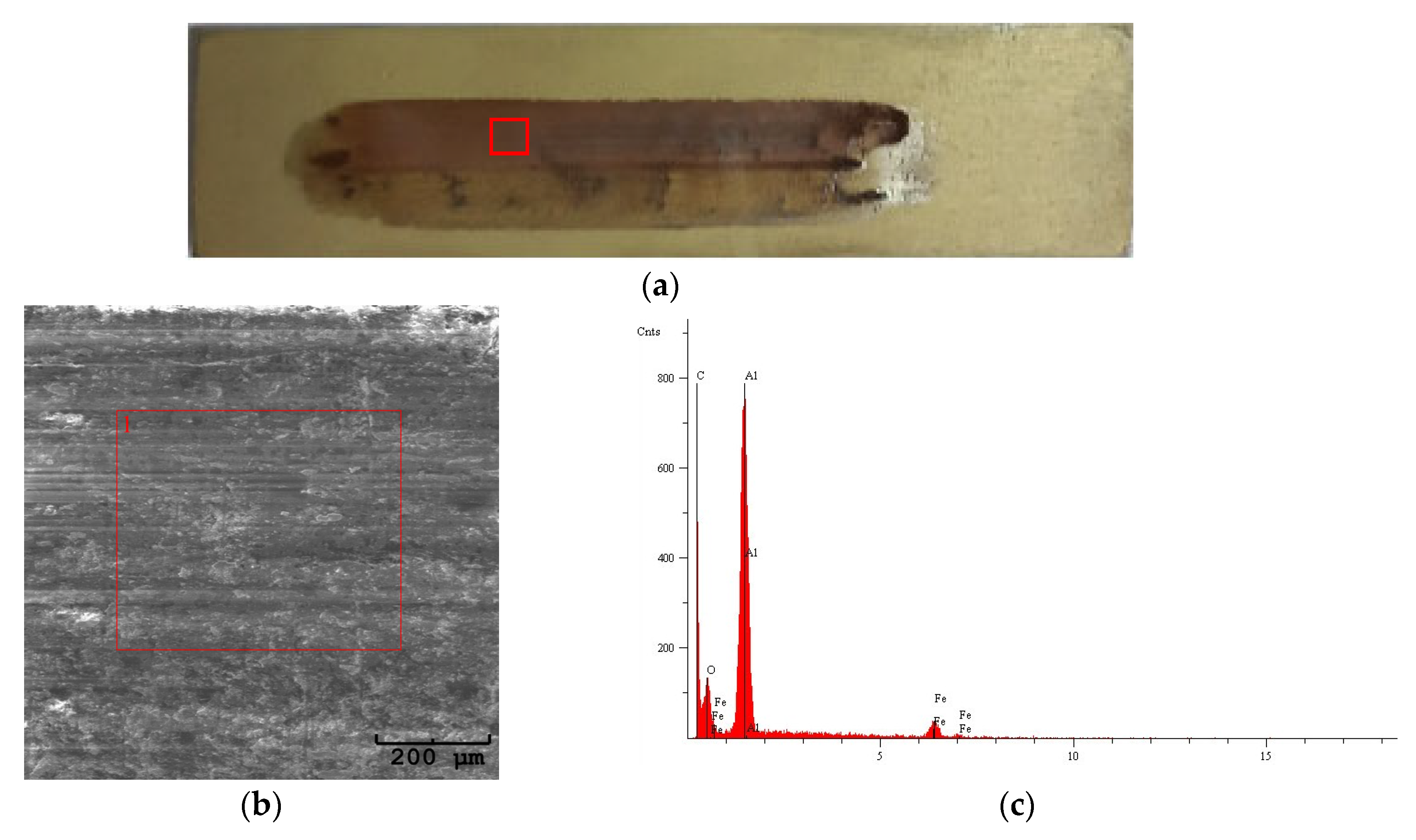

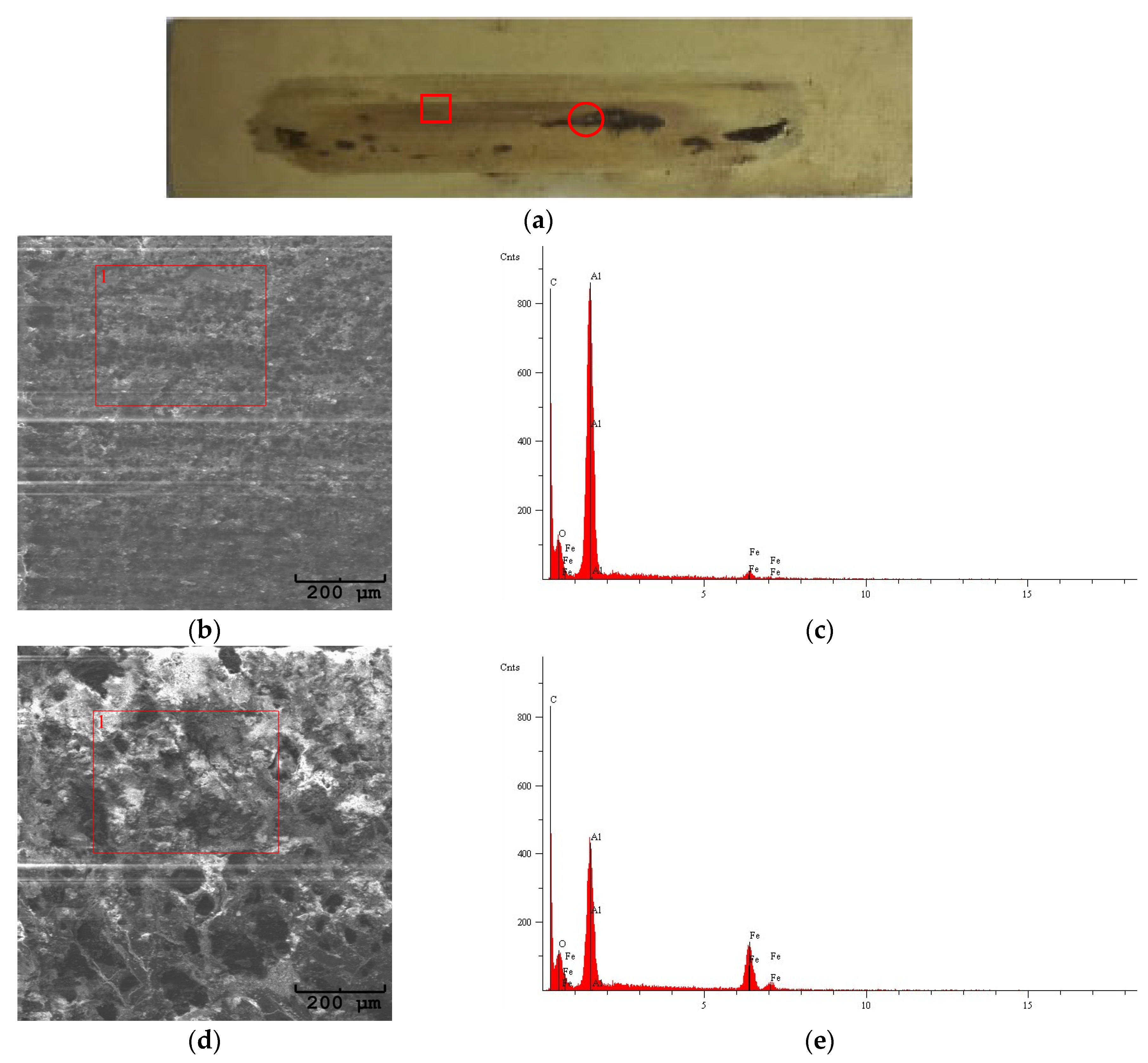

- SEM/EDS analysis confirmed the transfer of pin material onto the fabricated Al2O3 coatings. In some cases, adhesive junctions were observed, with localised accumulations of transferred spheroidal graphite iron.

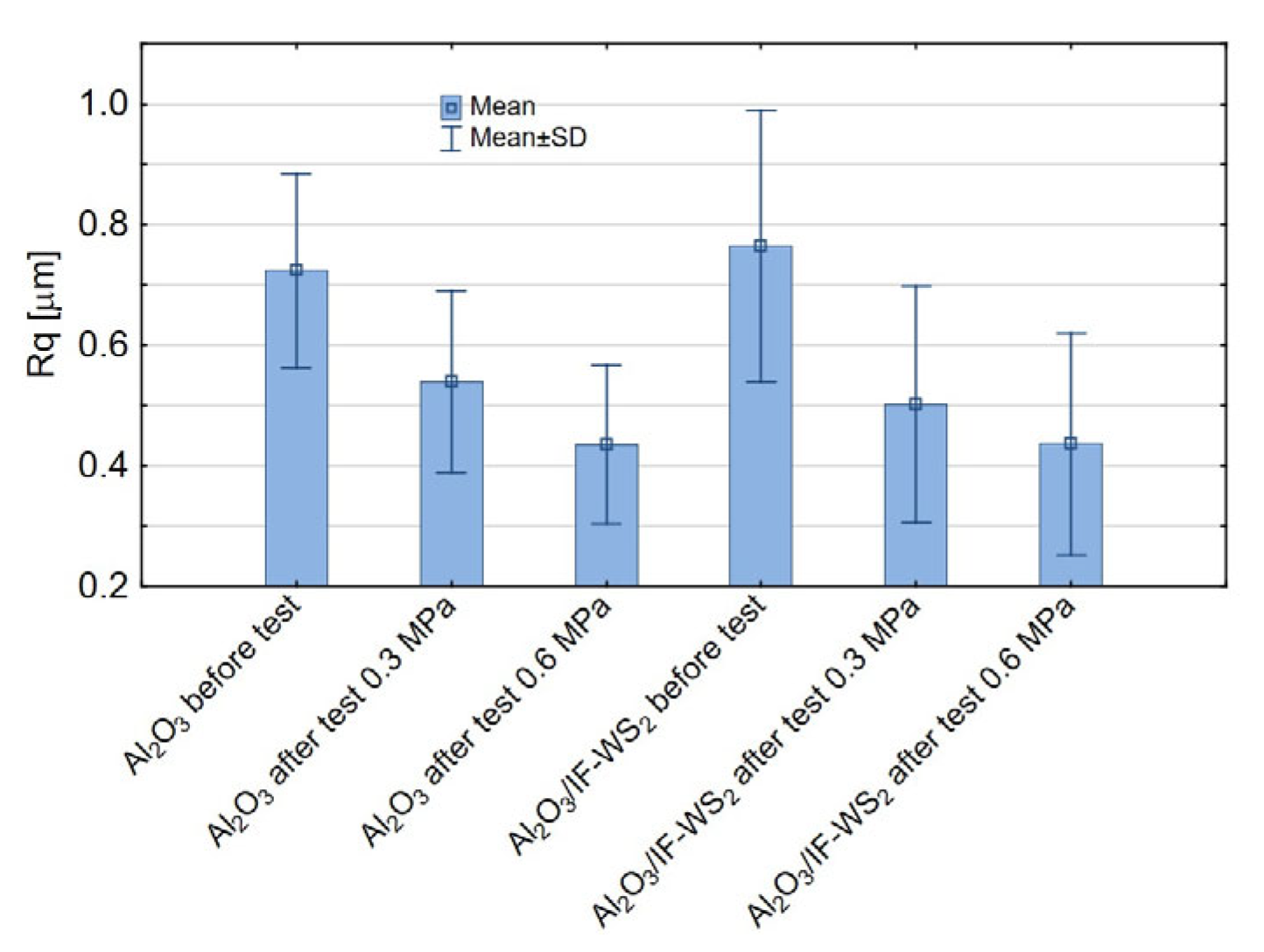

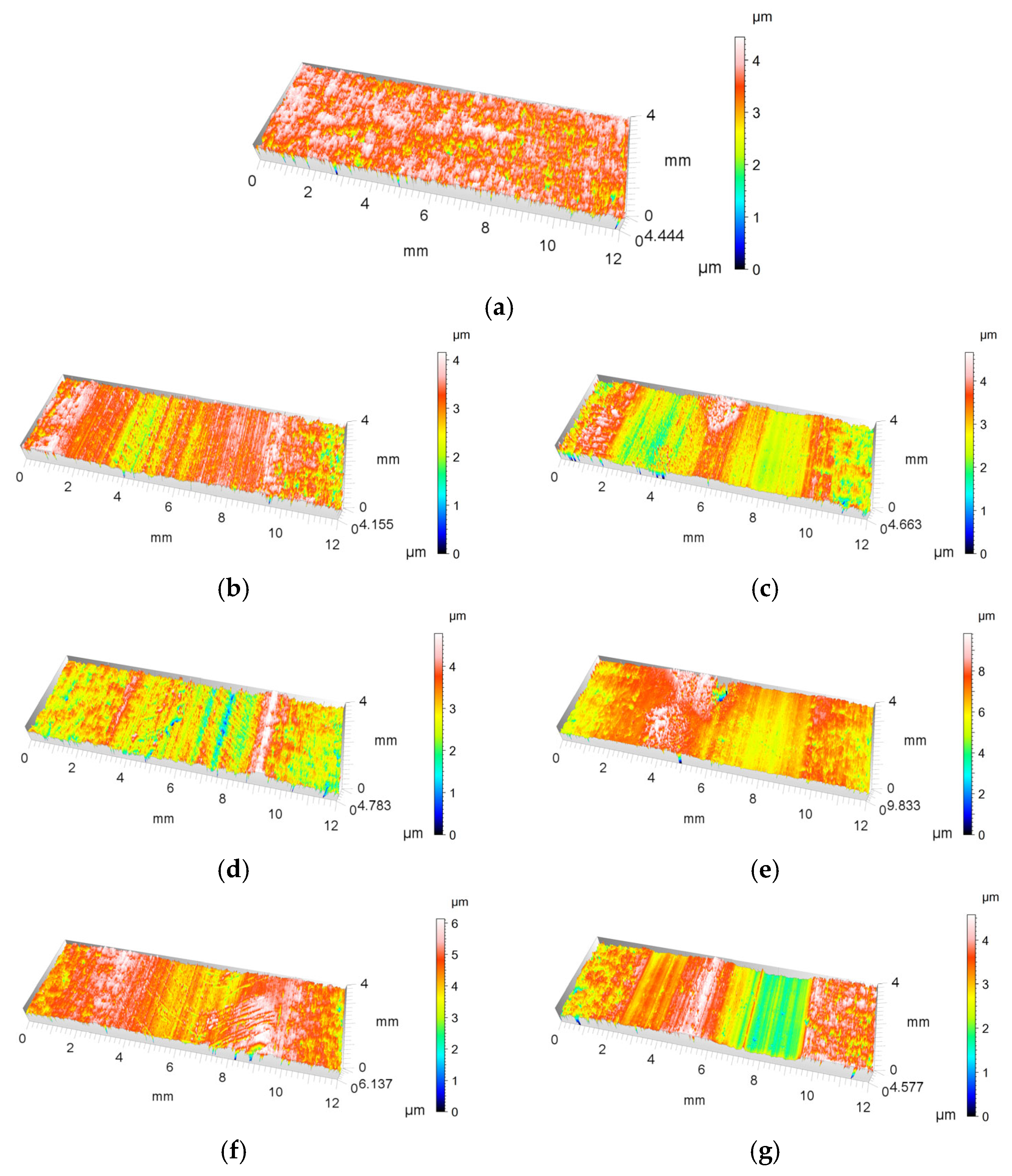

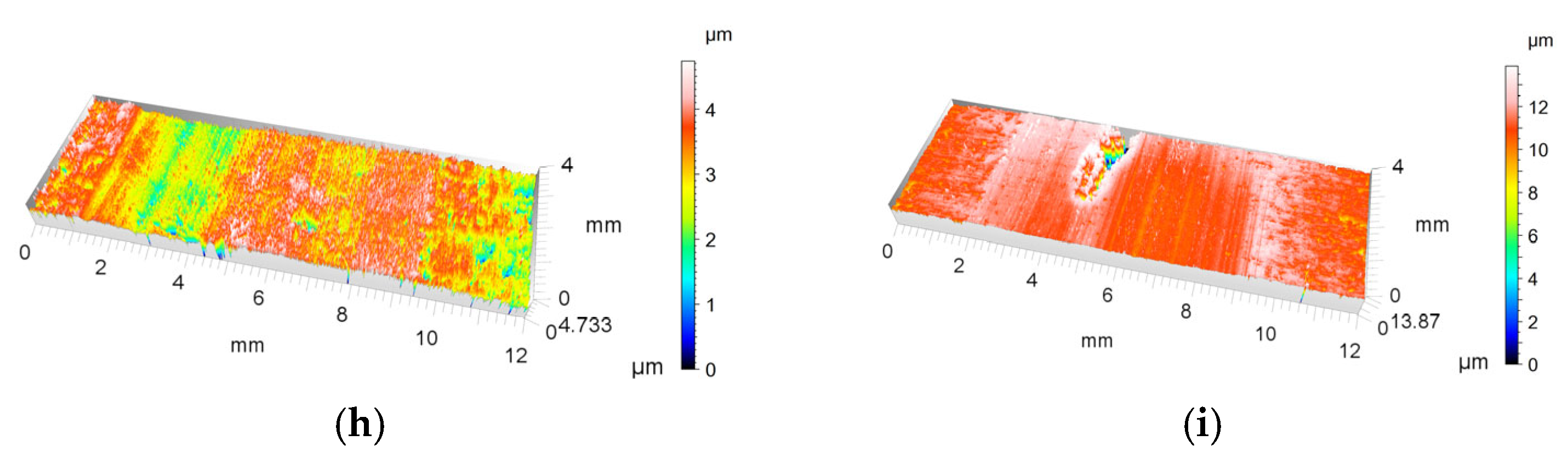

- Three-dimensional surface imaging revealed that the unmodified and IF-WS2-modified Al2O3 coatings exhibited minor subsurface deformation due to sliding contact with the cast iron pin.

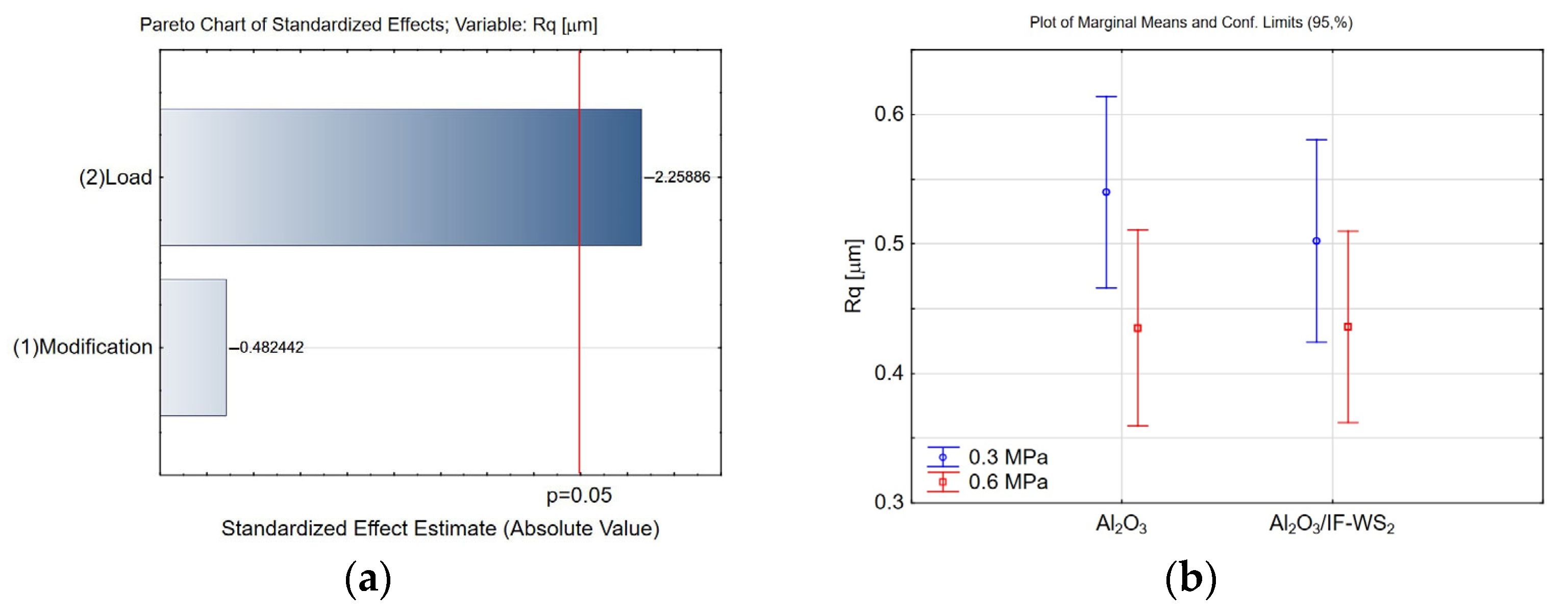

- In the analysed test setup, the applied load significantly influenced the Rq roughness parameter, while the IF-WS2 nanomodifier did not considerably affect surface roughness. This suggests that load conditions are more critical than material modification in the context of improving roughness (and potentially friction).

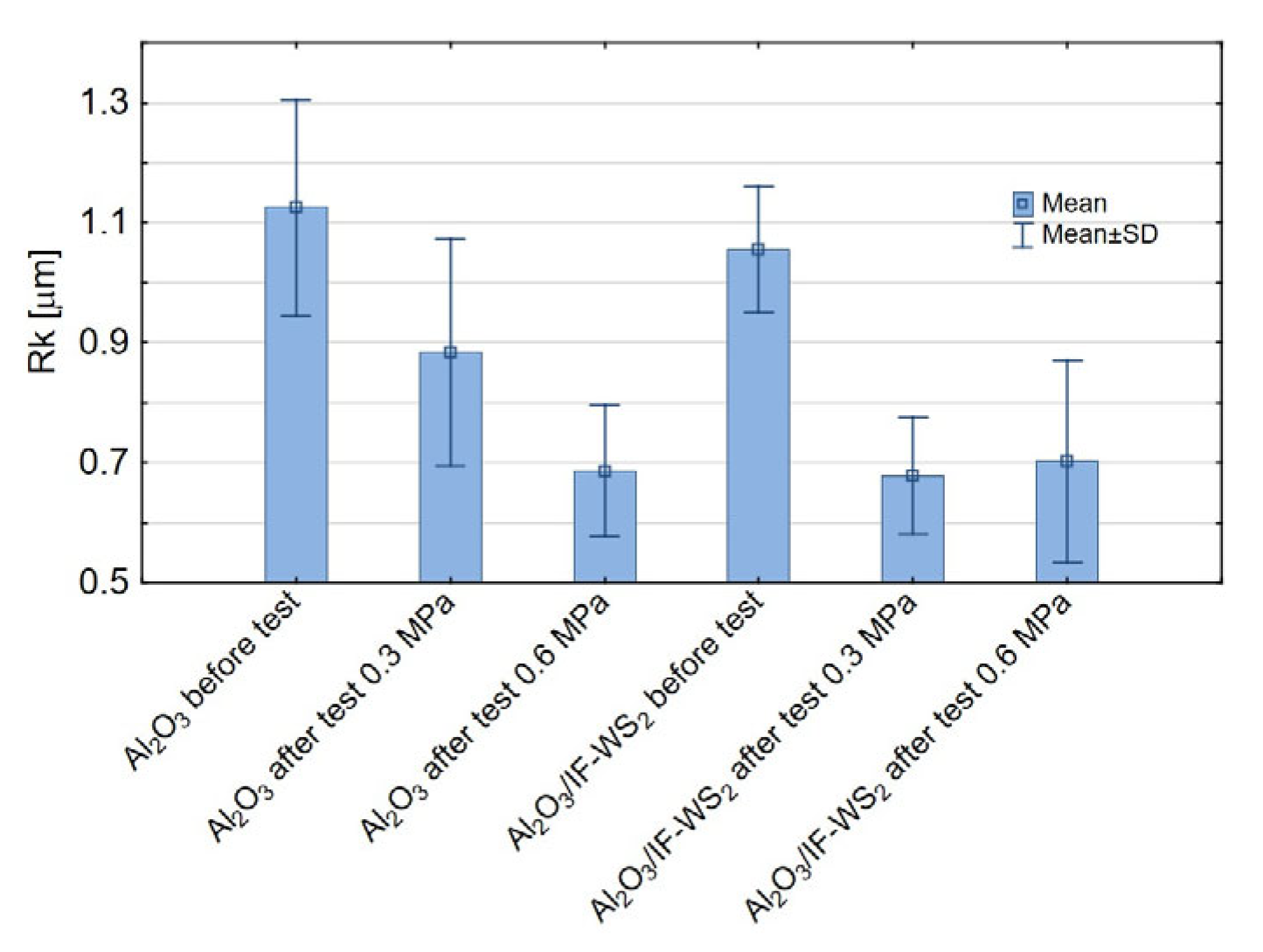

- The two-level factorial analysis demonstrated that modification and load significantly influenced the Rk load-bearing parameter. Incorporating the nanomodifier and increased load enhanced the load-bearing capacity of the surface by reducing the Rk value, thereby improving the tribological durability of the tested pairs.

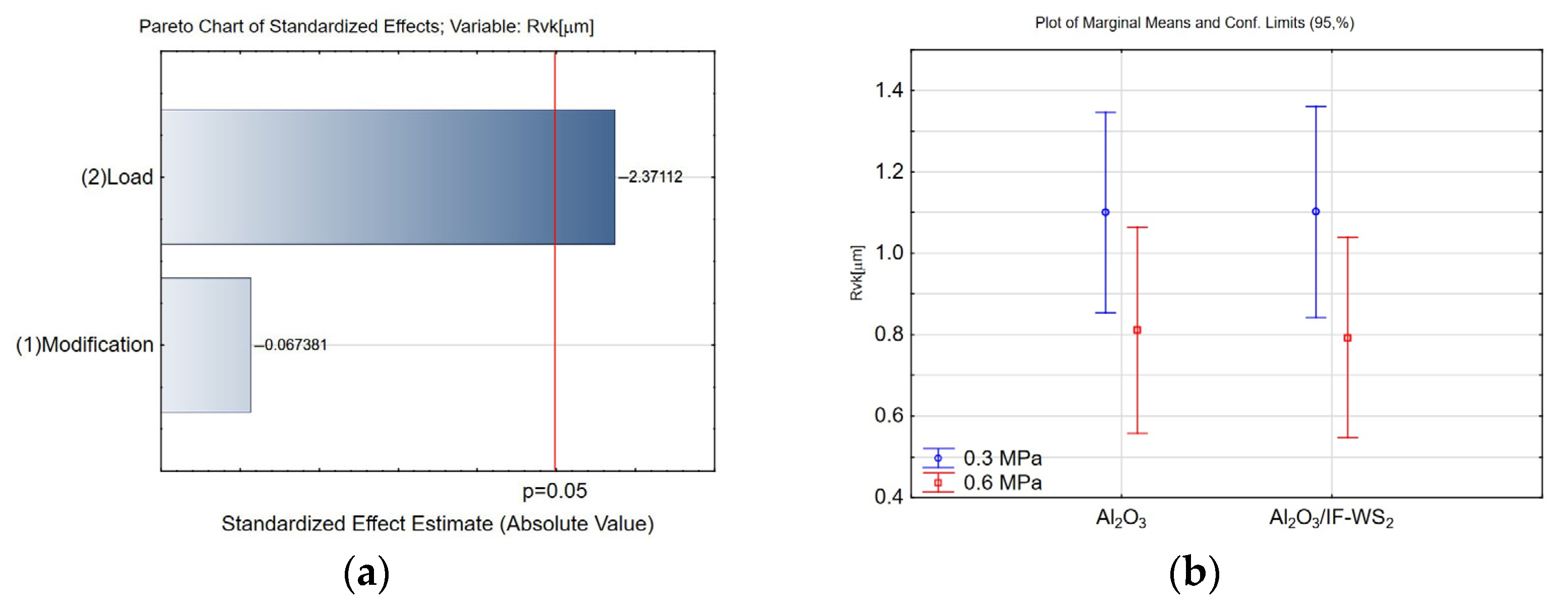

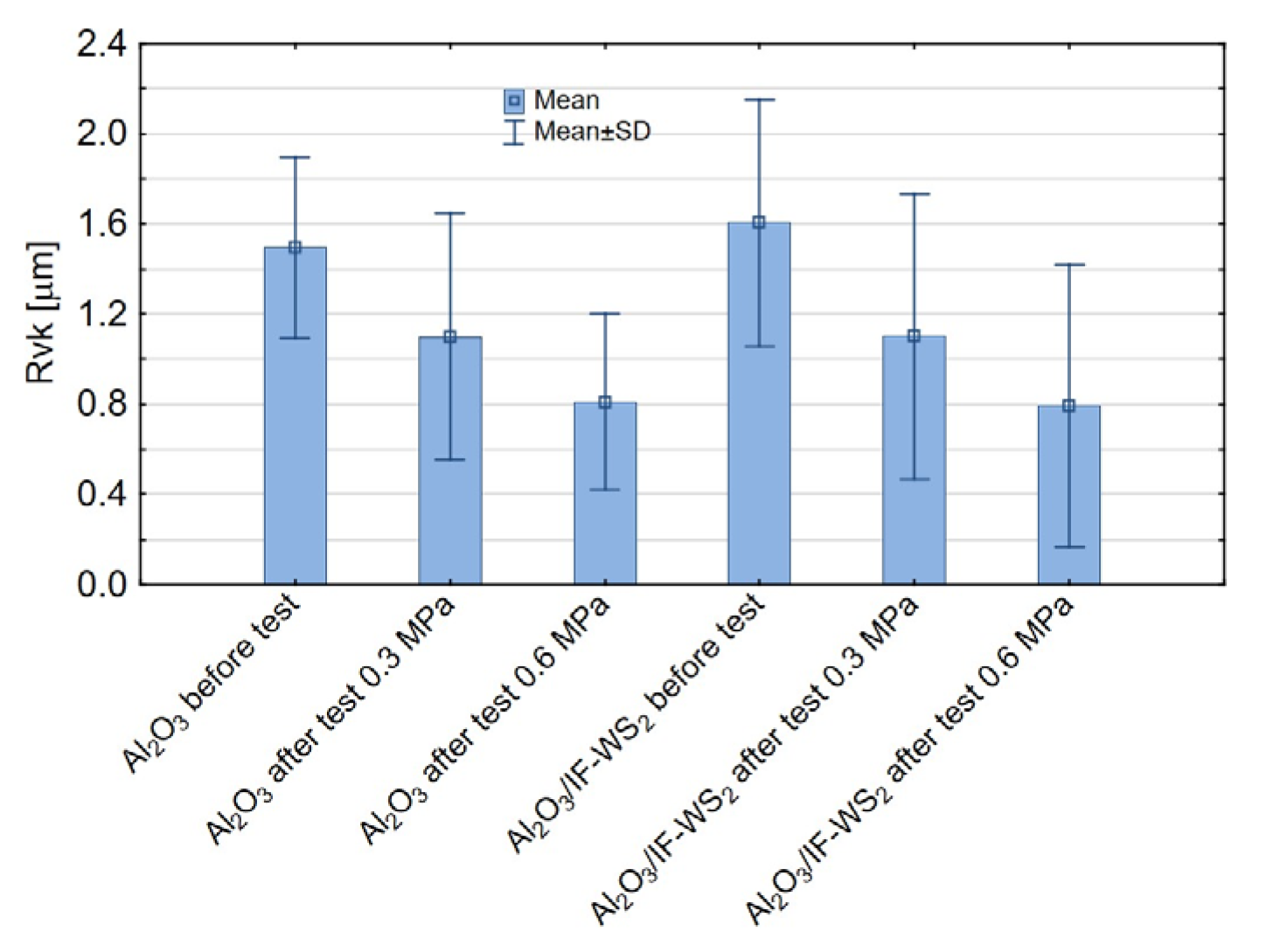

- The Rvk parameter, related to valley depth for lubricant retention, depended solely on the load—lower loads helped preserve valleys within the coating structure. In contrast, higher loads led to valley reduction due to surface flattening and filling with pin material.

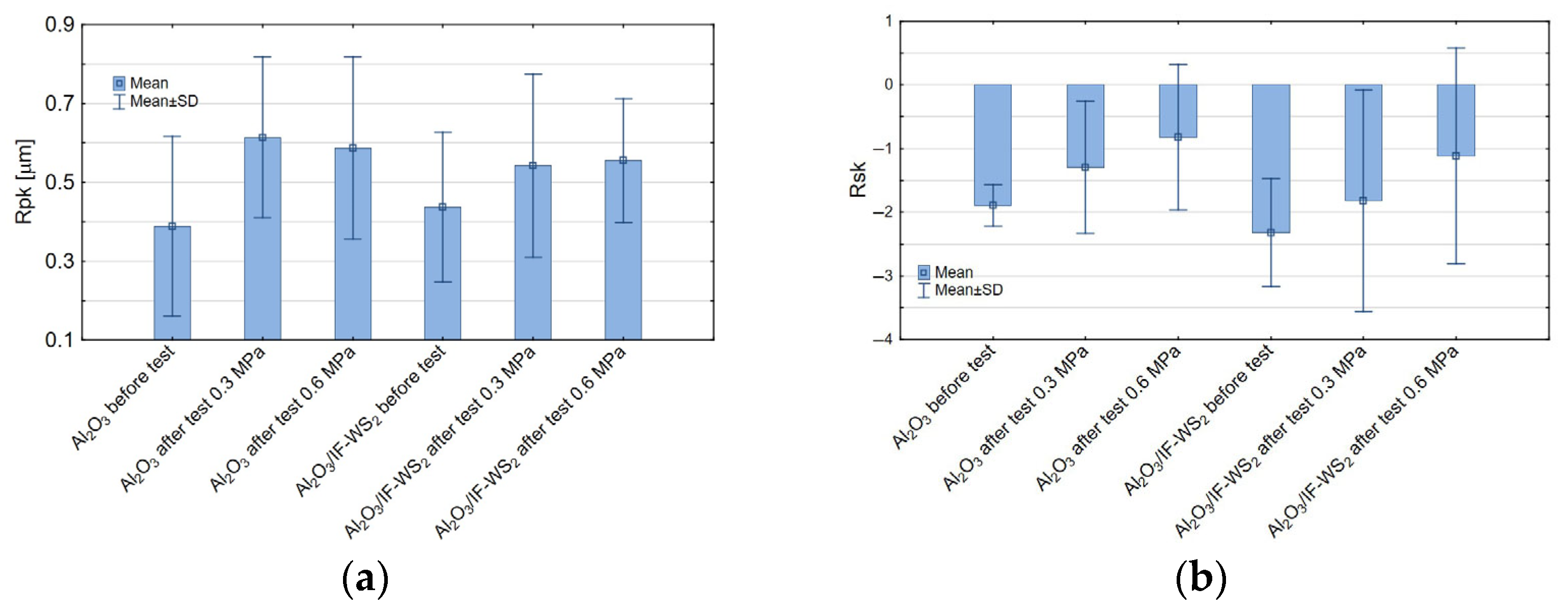

- Parameters Rpk (reduced peak height) and Rsk (profile skewness) showed no significant dependency on the input variables. However, higher loads increased Rpk, and the negative Rsk values indicated a valley-dominant surface morphology, which can enhance lubricant retention and reduce friction, albeit potentially at the expense of load-bearing capacity.

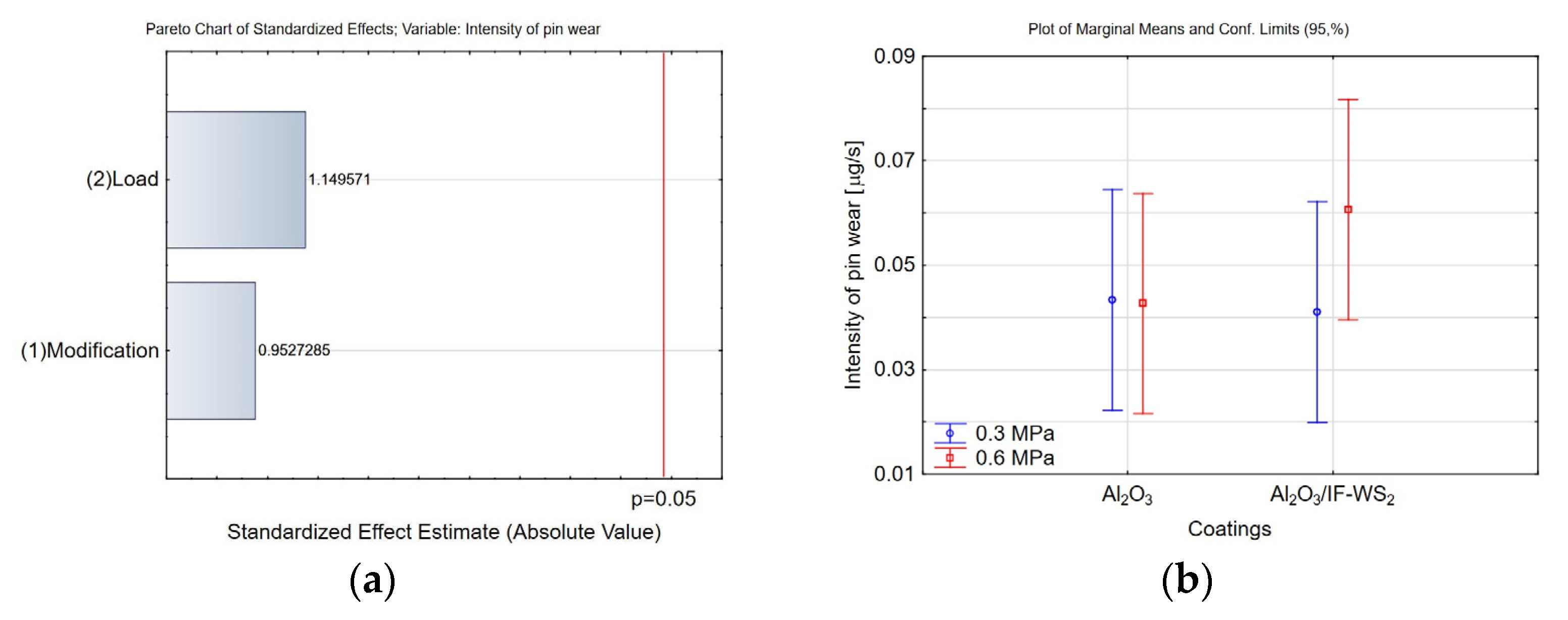

- Neither modification nor load significantly influenced the wear intensity of the cast iron pin.

- Both load and modification had a notable effect on the friction coefficient. The use of IF-WS2-modified Al2O3 coatings reduced the friction coefficient, and the coefficient also decreased with increasing load, by approximately 9% at a load of 0.3 MPa and 15% at a load of 0.6 MPa, suggesting enhanced lubricating performance under higher contact stress.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Davis, J.R. Aluminum and Aluminum Alloys. Alloy. Underst. Basics 2001, 351–416. [Google Scholar] [CrossRef]

- Runge, J.M. The Metallurgy of Anodizing Aluminum: Connecting Science to Practice; Springer International Publishing: Cham, Switzerland, 2018; ISBN 9783319721774. [Google Scholar]

- Oh, J.; Park, H.D.; Gwak, M.; Lee, J.; Son, S.; Amanov, A.; Kim, H.S.; Seol, J.B.; Sung, H.; Kim, J.G. Mechanical Property Enhancement in Gradient Structured Aluminum Alloy by Ultrasonic Nanocrystalline Surface Modification. Mater. Sci. Eng. A 2021, 812, 141101. [Google Scholar] [CrossRef]

- Efe, Y.; Karademir, I.; Husem, F.; Maleki, E.; Karimbaev, R.; Amanov, A.; Unal, O. Enhancement in Microstructural and Mechanical Performance of AA7075 Aluminum Alloy via Severe Shot Peening and Ultrasonic Nanocrystal Surface Modification. Appl. Surf. Sci. 2020, 528, 146922. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Costa, H.L.; Baykara, M.Z.; Martini, A. Synergetic Effects of Surface Texturing and Solid Lubricants to Tailor Friction and Wear—A Review. Tribol. Int. 2021, 155, 106792. [Google Scholar] [CrossRef]

- Betts, J.C. Laser Surface Modification of Aluminium and Magnesium Alloys. In Surface Engineering of Light Alloys: Aluminium, Magnesium and Titanium Alloys; Hanshan, D., Ed.; Woodhead Publishing: Cambridge, UK, 2010; pp. 444–474. [Google Scholar] [CrossRef]

- Huang, Q.; Shi, X.; Xue, Y.; Zhang, K.; Wu, C. Recent Progress on Surface Texturing and Solid Lubricants in Tribology: Designs, Properties, and Mechanisms. Mater. Today Commun. 2023, 35, 105854. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Z.; Shen, Q. Enhancing Tribological Performance by Anodizing Micro-Textured Surfaces with Nano-MoS2 Coatings Prepared on Aluminum-Silicon Alloys. Tribol. Int. 2018, 122, 84–95. [Google Scholar] [CrossRef]

- Nie, C.; Cao, F.; Zhu, T.; Sun, Z.; Wang, D.; Wu, Y.; Ying, L. Study on the Tribological Properties and Corrosion Resistance of the In-Situ Grown Zn–Al-LDHs Film on Anodic Aluminum Surface. Mater. Sci. Eng. B 2023, 297, 116751. [Google Scholar] [CrossRef]

- Skeldon, P.; Wang, H.W.; Thompson, G.E. Formation and Characterization of Self-Lubricating MoS2 Precursor Films on Anodized Aluminium. Wear 1997, 206, 187–196. [Google Scholar] [CrossRef]

- Kumar, N.; Sharma, A.; Manoj, M.K.; Ahn, B. Taguchi Optimization of Tribological Properties and Corrosion Behavior of Self-Lubricating Al–Mg–Si/MoS2 Composite Processed by Powder Metallurgy. J. Mater. Res. Technol. 2023, 26, 1185–1197. [Google Scholar] [CrossRef]

- Kim, T.; Cho, H.; Choi, S.T.; Nam, W.; Lee, S.; Liang, H.; Kim, S. Controlled Deposition of Graphene Oxide on an Anodic Aluminum Oxide Substrate via Coffee-Ring Effect. J. Alloys Compd. 2023, 958, 170464. [Google Scholar] [CrossRef]

- Xiong, Z.; Zhang, W.; jin, S.; Wu, R.; Ma, F.; Wang, X.; Wang, G. One-Step Hydrothermal Fabrication of Co-MOFs/LDH Superhydrophobic Composite Coating with Corrosion Resistance and Wear Resistance on Anodic Aluminum Oxide. Appl. Surf. Sci. 2024, 677, 161023. [Google Scholar] [CrossRef]

- Stephan, J.; Kasneryk, V.; Serdechnova, M.; Scharnagl, N.; Gazenbiller, E.; Vaghefinazari, B.; Volovitch, P.; Starykevich, M.; Blawert, C.; Zheludkevich, M.L. Formation of Li-Al LDH Conversion Layer on AA2024 Alloy for Corrosion Protection. Appl. Surf. Sci. 2024, 659, 159919. [Google Scholar] [CrossRef]

- Xiong, Z.; Qi, Z.; Zhang, W.; Ji, M.; Ma, F.; Ying, L.; Wang, G. Enhancing Frictional and Corrosion Resistance Performance in Aluminum Alloy through in Situ Growth of NiZnAl-LDH Membrane and Its Modification. Surf. Interfaces 2024, 46, 104103. [Google Scholar] [CrossRef]

- Aerts, T.; Dimogerontakis, T.; De Graeve, I.; Fransaer, J.; Terryn, H. Influence of the Anodizing Temperature on the Porosity and the Mechanical Properties of the Porous Anodic Oxide Film. Surf. Coatings Technol. 2007, 201, 7310–7317. [Google Scholar] [CrossRef]

- Dervishi, E.; McBride, M.; Edwards, R.; Gutierrez, M.; Li, N.; Buntyn, R.; Hooks, D.E. Mechanical and Tribological Properties of Anodic Al Coatings as a Function of Anodizing Conditions. Surf. Coatings Technol. 2022, 444, 128652. [Google Scholar] [CrossRef]

- Kchaou, M. Friction Behavior of Anodic Oxide Layer Coating on 2017A T4 Aluminum Alloy under Severe Friction Solicitation: The Effect of Anodizing Parameters. Eng. Technol. Appl. Sci. Res. 2024, 14, 12574–12580. [Google Scholar] [CrossRef]

- Liu, Y.C.; Chen, Y.F.; Lin, Y.C.; Zheng, Y.H.; Lee, L.R.; Chang, M.H.; Ho, J.H.; Lin, Y.L.; Chen, J.T. Tailoring Nanopore Geometry in Anodic Aluminum Oxide Membranes through Physical Stretching and Controlled Anodization. Adv. Mater. Interfaces 2025, 12, 2400699. [Google Scholar] [CrossRef]

- Remešová, M.; Tkachenko, S.; Kvarda, D.; Ročňáková, I.; Gollas, B.; Menelaou, M.; Čelko, L.; Kaiser, J. Effects of Anodizing Conditions and the Addition of Al2O3/PTFE Particles on the Microstructure and the Mechanical Properties of Porous Anodic Coatings on the AA1050 Aluminium Alloy. Appl. Surf. Sci. 2020, 513, 145780. [Google Scholar] [CrossRef]

- Soffritti, C.; Fortini, A.; Nastruzzi, A.; Sola, R.; Merlin, M.; Garagnani, G.L. Dry Sliding Behavior of an Aluminum Alloy after Innovative Hard Anodizing Treatments. Materials 2021, 14, 3281. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.S.; Kim, D.H.; Lee, W.; Cho, S.J.; Hahn, J.H.; Ahn, H.S. Tribological Properties of Nanoporous Anodic Aluminum Oxide Film. Surf. Coatings Technol. 2010, 205, 1431–1437. [Google Scholar] [CrossRef]

- Hu, N.; Ge, S.; Fang, L. Tribological Properties of Nano-Porous Anodic Aluminum Oxide Template. J. Cent. South Univ. Technol. 2011, 18, 1004–1008. [Google Scholar] [CrossRef]

- Lee, G.S.; Choi, J.H.; Choi, Y.C.; Bu, S.D.; Lee, Y.Z. Tribological Effects of Pores on an Anodized Al Alloy Surface as Lubricant Reservoir. Curr. Appl. Phys. 2011, 11, S182–S186. [Google Scholar] [CrossRef]

- Takaya, M.; Hashimoto, K.; Toda, Y.; Maejima, M. Novel Tribological Properties of Anodic Oxide Coating of Aluminum Impregnated with Iodine Compound. Surf. Coatings Technol. 2003, 169–170, 160–162. [Google Scholar] [CrossRef]

- Maejima, M.; Saruwatari, K.; Takaya, M. Friction Behaviour of Anodic Oxide Film on Aluminum Impregnated with Molybdenum Sulfide Compounds. Surf. Coatings Technol. 2000, 132, 105–110. [Google Scholar] [CrossRef]

- Tao, X.; Jianmin, C.; Jiazheng, Z.; Hongxin, D. The Pore-Enlargement and Self-Lubrication Treatment of Anodic Oxide Film of Aluminum. Wear 1996, 196, 214–218. [Google Scholar] [CrossRef]

- Wang, H.W.; Skeldon, P.; Thompson, G.E. Development and Tribological Assessment of Self-Lubricating Anodic Films on Aluminium. Surf. Coatings Technol. 1997, 88, 269–273. [Google Scholar] [CrossRef]

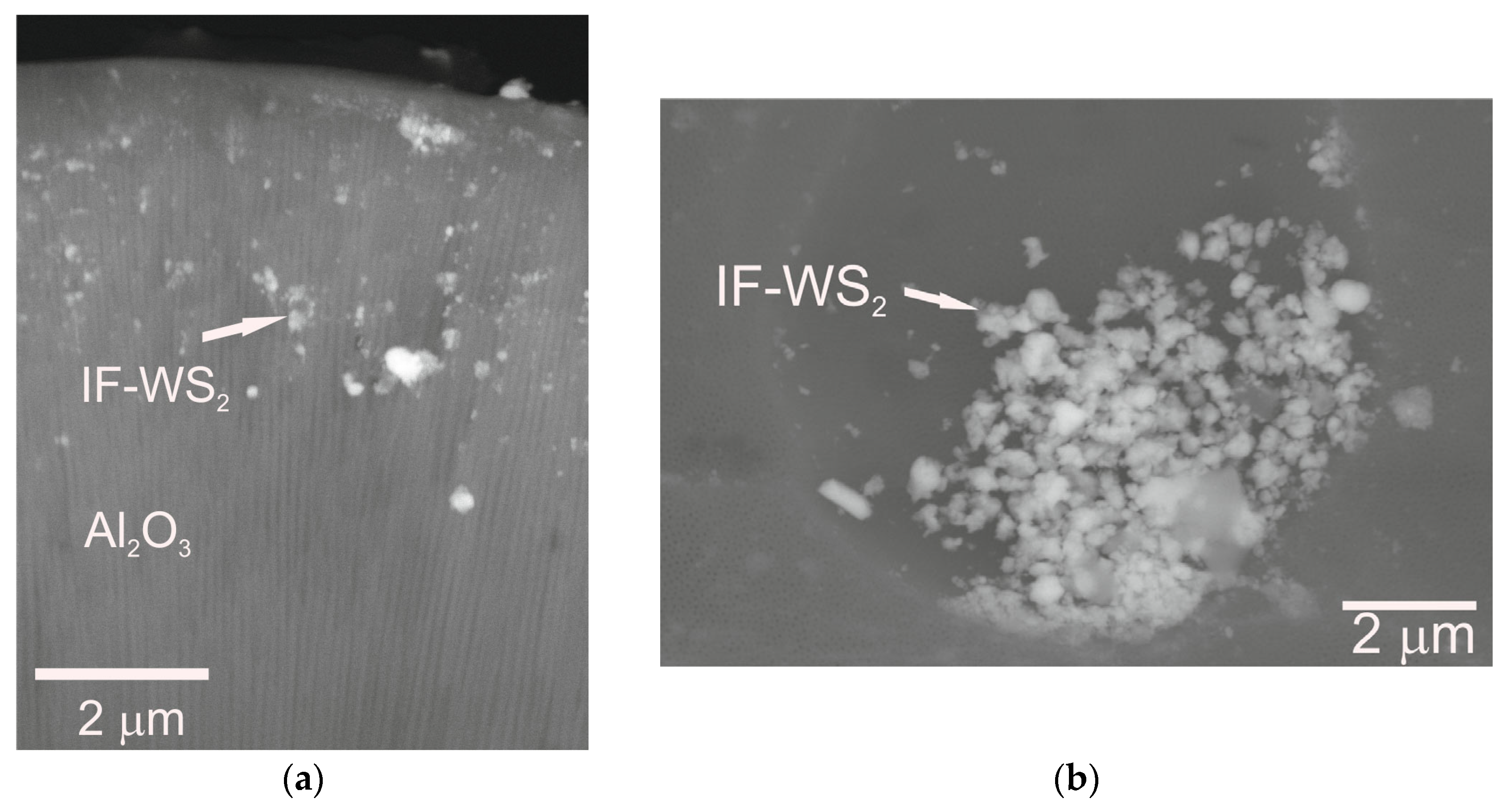

- Korzekwa, J.; Niedźwiedź, M.; Dercz, G.; Cwynar, K.; Sowa, M.; Bara, M.; Simka, W. Methods of Distributing the IF-WS2 Modifier for Its Introduction into the Structure of the Al2O3 Aluminum Oxide Coating. Coatings 2024, 14, 883. [Google Scholar] [CrossRef]

- Radek, N.; Pietraszek, J.; Gadek-Moszczak, A.; Orman, Ł.J.; Szczotok, A. The Morphology and Mechanical Properties of ESD Coatings before and after Laser Beam Machining. Materials 2020, 13, 2331. [Google Scholar] [CrossRef] [PubMed]

- Pietraszek, J.; Radek, N.; Goroshko, A.V.; Jana, A.; Ii, P. Challenges for the DOE Methodology Related to the Introduction of Industry 4.0. Prod. Eng. Arch. 2020, 26, 190–194. [Google Scholar] [CrossRef]

- Sieber, M.; Morgenstern, R.; Lampke, T. Anodic Oxidation of the AlCu4Mg1 Aluminium Alloy with Dynamic Current Control. Surf. Coatings Technol. 2016, 302, 515–522. [Google Scholar] [CrossRef]

- Kwolek, P.; Obłój, A.; Kościelniak, B.; Buszta, R.; Tokarski, T.; Krupa, K.; Gradzik, A.; Nowak, W.J.; Wojnicki, M.; Motyka, M. Wear Resistance of Hard Anodic Coatings Fabricated on 5005 and 6061 Aluminum Alloys. Arch. Civ. Mech. Eng. 2024, 24, 51. [Google Scholar] [CrossRef]

- ISO 21920-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2021.

- Meng, F.; Zhou, Y.; Zhang, H.; Wang, Z.; Liu, D.; Cao, S.; Cui, X.; Nong, Z.; Man, T.; Liu, T. Development and Research Status of Wear-Resistant Coatings on Copper and Its Alloys: Review. Crystals 2025, 15, 204. [Google Scholar] [CrossRef]

- Krella, A. Resistance of PVD Coatings to Erosive and Wear Processes: A Review. Coatings 2020, 10, 921. [Google Scholar] [CrossRef]

- Zak, A.; Feldman, Y.; Lyakhovitskaya, V.; Leitus, G.; Popovitz-Biro, R.; Wachtel, E.; Cohen, H.; Reich, S.; Tenne, R. Alkali Metal Intercalated Fullerene-like MS2 (M = W, Mo) Nanoparticles and Their Properties. J. Am. Chem. Soc. 2002, 124, 4747–4758. [Google Scholar] [CrossRef] [PubMed]

- Rapoport, L.; Bilik, Y.; Feldman, Y.; Homyonfer, M.; Cohen, S.R.; Tenne, R. Hollow Nanoparticles of WS2 as Potential Solid-State Lubricants. Nature 1997, 387, 791–793. [Google Scholar] [CrossRef]

| Dispersion Liquid | Time [min] | Power [kJ] | Frequency [kHz] |

|---|---|---|---|

| Ethanol +15 g/L of IF-WS2 NPs | 5 | 10 | 20 |

| Sample Designation | Test Input Variables | |

|---|---|---|

| Introducing IF-WS2 NPs | Load [MPa] | |

| 1 | No (−1) | 0.3 (−1) |

| 2 | No (−1) | 0.3 (−1) |

| 3 | No (−1) | 0.6 (1) |

| 4 | No (−1) | 0.6 (1) |

| 5 | Yes (1) | 0.3 (−1) |

| 6 | Yes (1) | 0.6 (1) |

| 7 | Yes (1) | 0.3 (−1) |

| 8 | Yes (1) | 0.6 (−1) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korzekwa, J.; Jarząbek, A.; Bara, M.; Niedźwiedź, M.; Cwynar, K.; Oleszak, D. Investigation of the Wear Resistance of Hard Anodic Al2O3/IF-WS2 Coatings Deposited on Aluminium Alloys. Materials 2025, 18, 3471. https://doi.org/10.3390/ma18153471

Korzekwa J, Jarząbek A, Bara M, Niedźwiedź M, Cwynar K, Oleszak D. Investigation of the Wear Resistance of Hard Anodic Al2O3/IF-WS2 Coatings Deposited on Aluminium Alloys. Materials. 2025; 18(15):3471. https://doi.org/10.3390/ma18153471

Chicago/Turabian StyleKorzekwa, Joanna, Adam Jarząbek, Marek Bara, Mateusz Niedźwiedź, Krzysztof Cwynar, and Dariusz Oleszak. 2025. "Investigation of the Wear Resistance of Hard Anodic Al2O3/IF-WS2 Coatings Deposited on Aluminium Alloys" Materials 18, no. 15: 3471. https://doi.org/10.3390/ma18153471

APA StyleKorzekwa, J., Jarząbek, A., Bara, M., Niedźwiedź, M., Cwynar, K., & Oleszak, D. (2025). Investigation of the Wear Resistance of Hard Anodic Al2O3/IF-WS2 Coatings Deposited on Aluminium Alloys. Materials, 18(15), 3471. https://doi.org/10.3390/ma18153471