Use of Phalaris canariensis Extract as CO2 Corrosion Inhibitor of Brass

Abstract

1. Introduction

2. Experimental Procedure

2.1. Testing Material

2.2. Synthesis of the Inhibitor

2.3. Working Electrolyte

2.4. Electrochemical Techniques

3. Results and Discussion

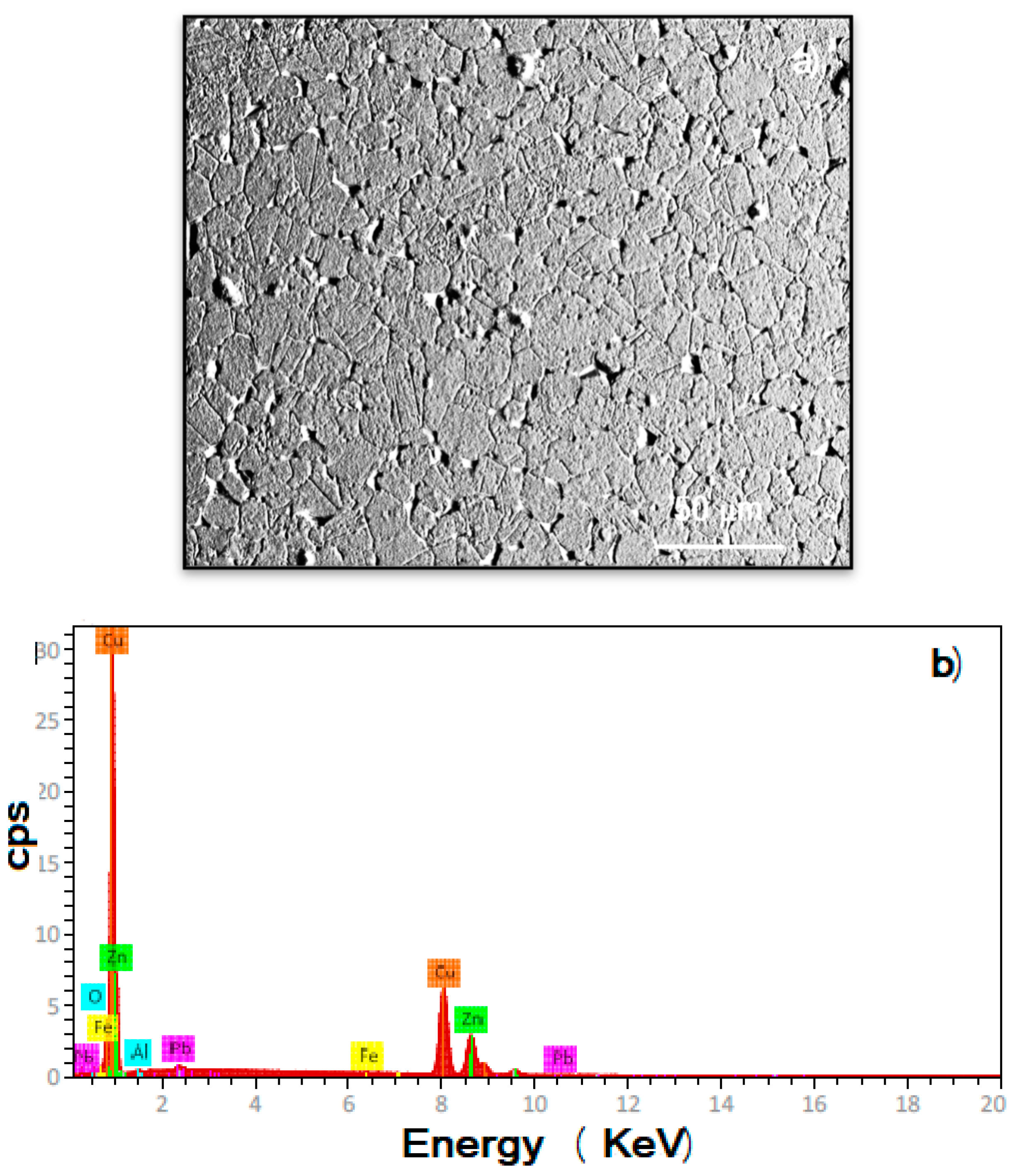

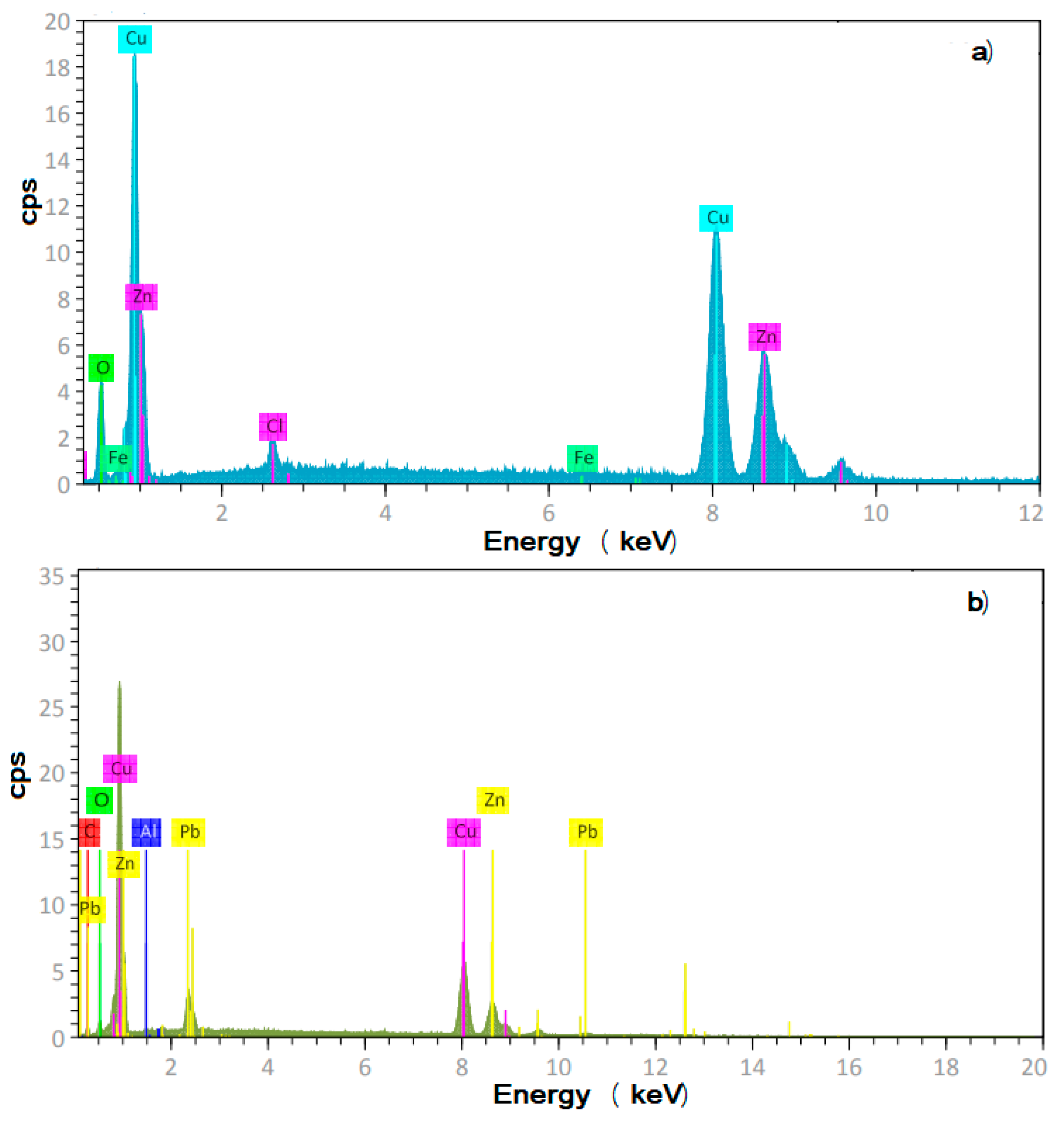

3.1. Metal Characterization

3.2. Chemical Analysis of the Inhibitor

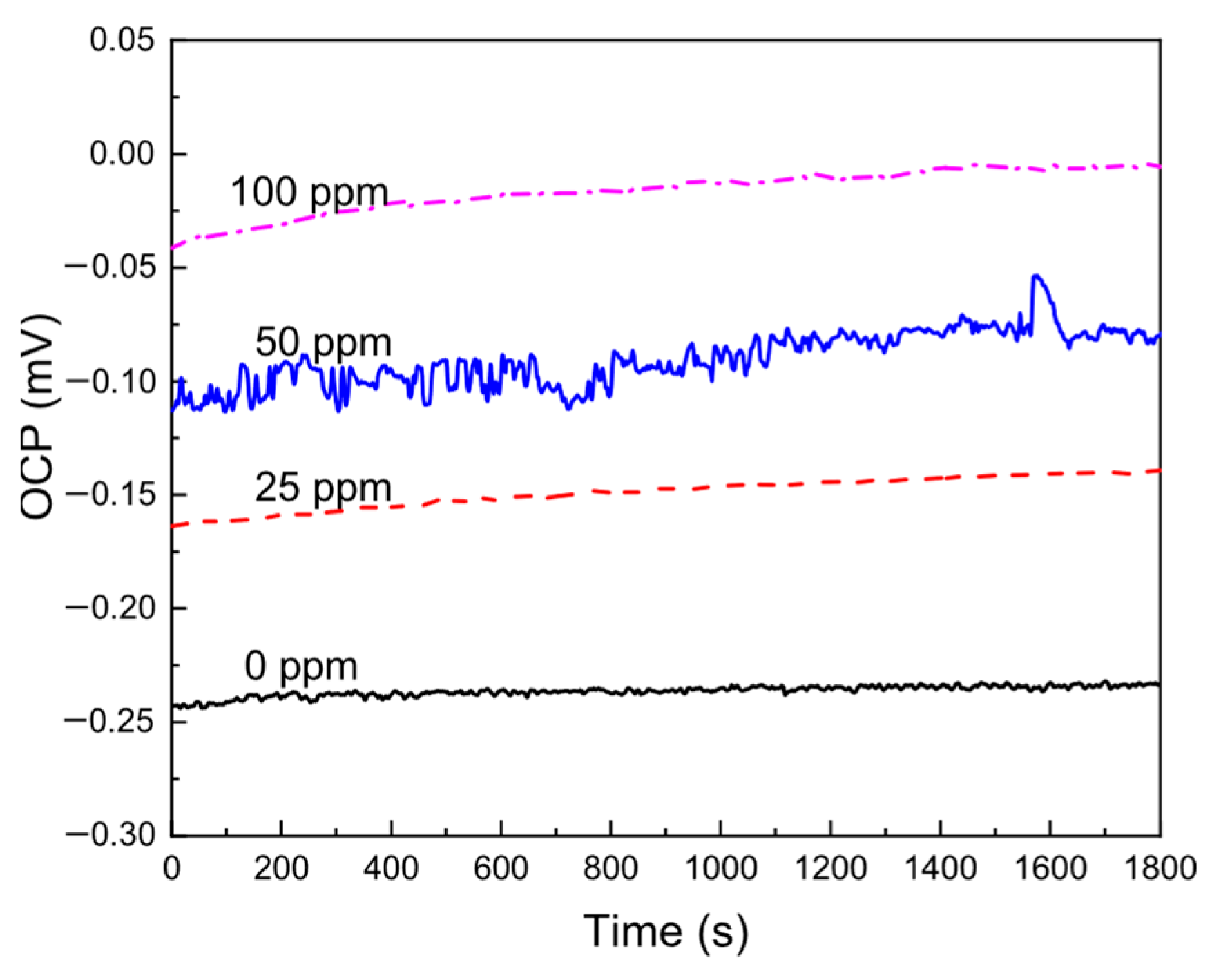

3.3. Open Circuit Potential

3.4. Potentiodynamic Polarization Curves

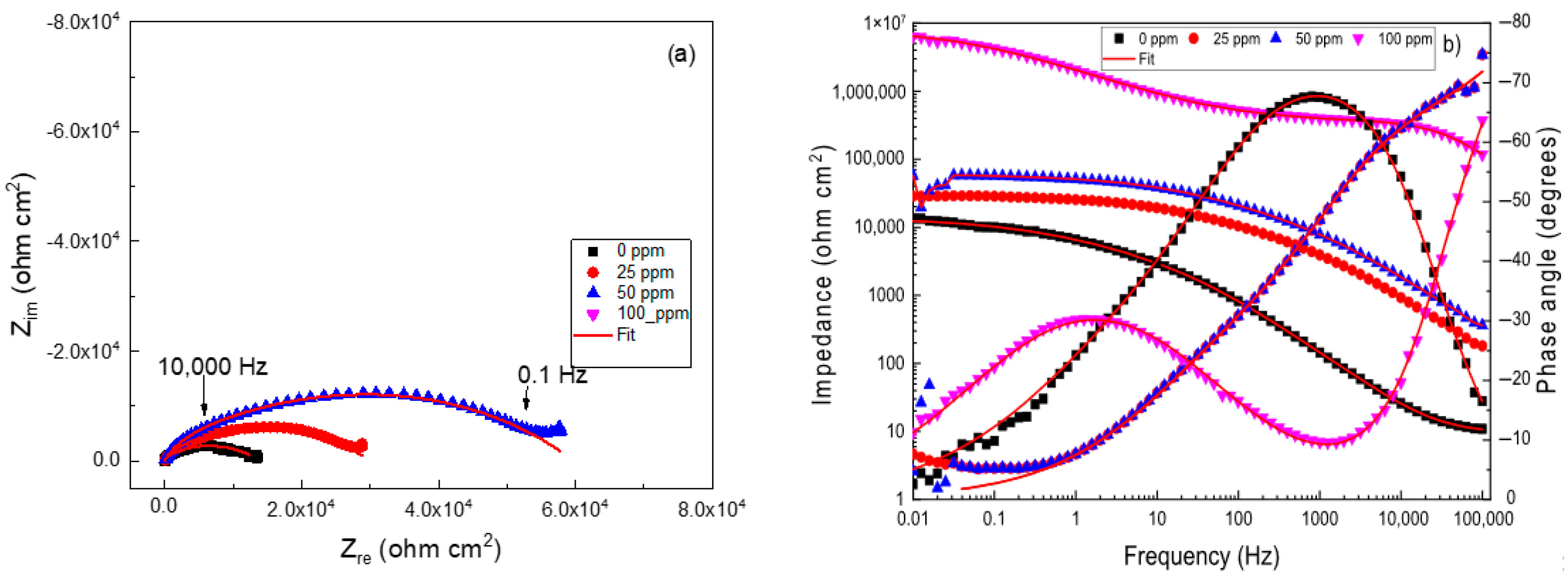

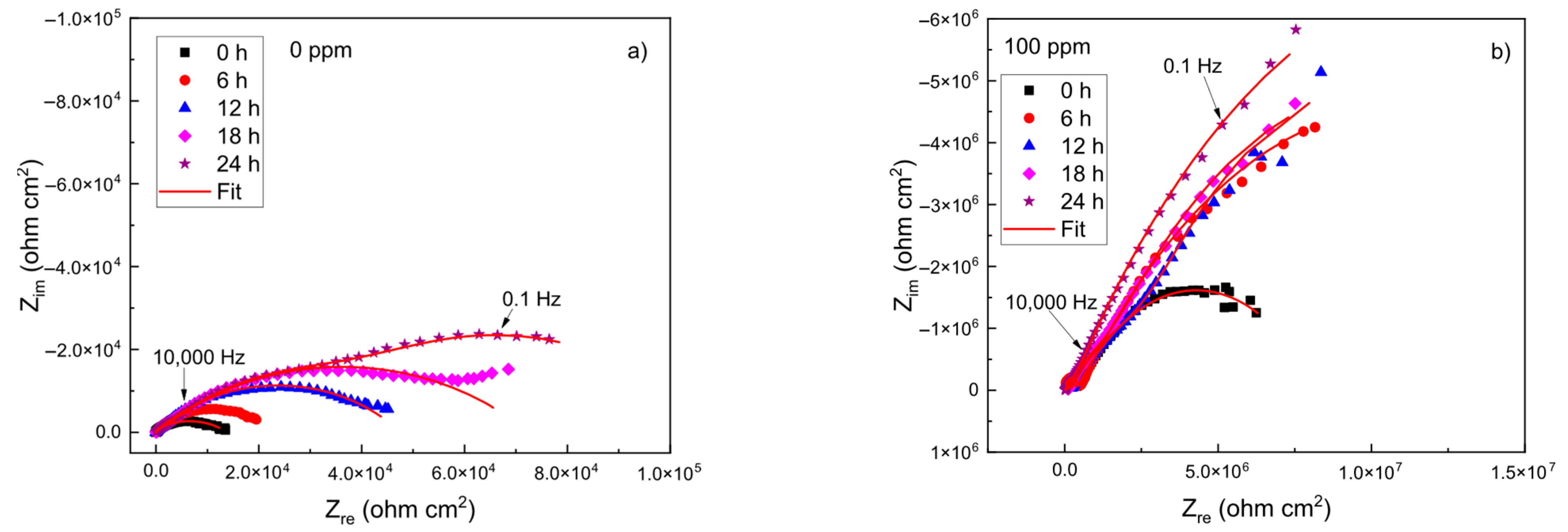

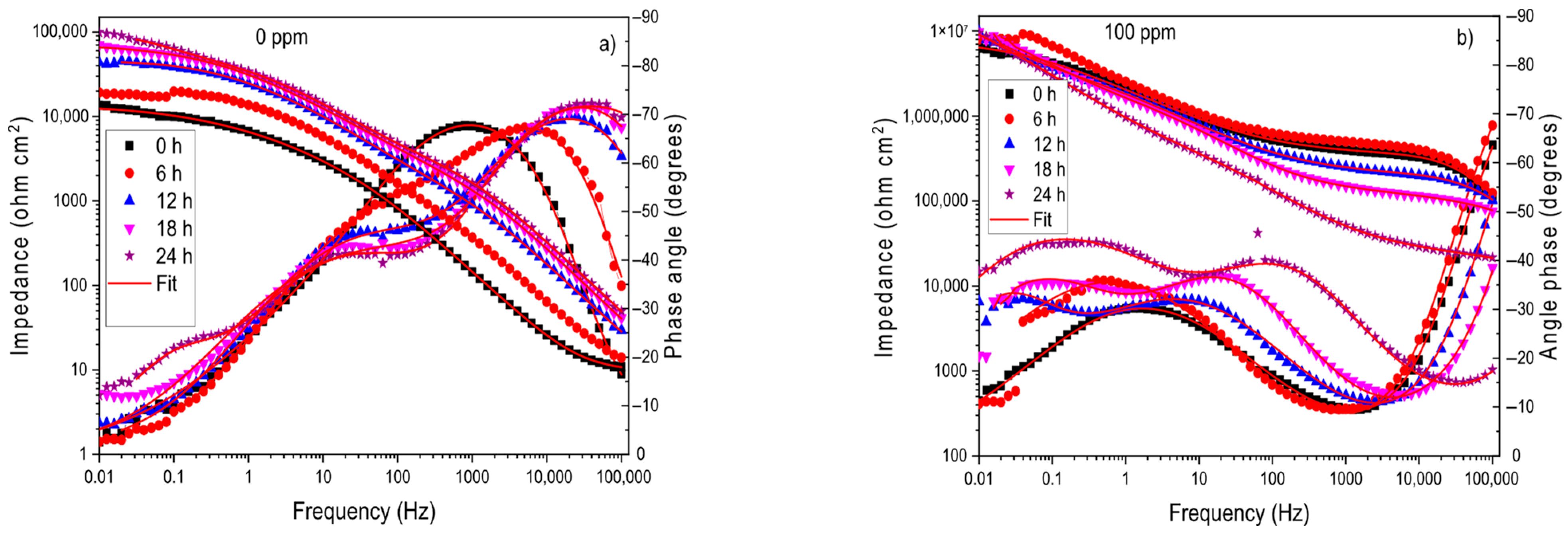

3.5. Electrochemical Impedance Spectroscopy Tests (EIS)

3.6. Surface Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yan, H.; Rashid, M.R.B.A.; Khew, S.Y.; Li, F.; Hong, M. Wettability transition of laser textured brass surfaces inside different mediums. Appl. Surf. Sci. 2018, 427, 369–375. [Google Scholar] [CrossRef]

- Lu, X.; Liu, Y.; Liu, M.; Wang, Z. Corrosion behavior of copper T2 and brass H62 in simulated Nansha marine atmosphere. J. Mater. Sci. Technol. 2019, 35, 1831–1839. [Google Scholar] [CrossRef]

- Chraka, A.; Seddik, N.B.; Raissouni, I.; Kassout, J.; Choukairi, M.; Ezzaki, M.; Zaraali, O.; Belcadi, H.; Janoub, F.; Ibn Mansour, A.; et al. Electrochemical explorations, SEM/EDX analysis, and quantum mechanics/molecular simulations studies of sustainable corrosion inhibitors on the Cu-Zn alloy in 3% NaCl solution. J. Mol. Liq. 2023, 387, 122715. [Google Scholar] [CrossRef]

- Dimitrijevic, S.P.; Dimitrijevic, S.B.; Koerdt, A.; Ivanovic, A.; Stefanovic, J.; Stankovic, T.; Gerengi, H. Comparison of Corrosion Resistance of Cu and Cu72Zn28 Metals in Apricot Fermentation Liquid. Materials 2025, 18, 1253. [Google Scholar] [CrossRef] [PubMed]

- Avdeev, Y.G.; Nenasheva, T.A.; Luchkin, A.Y.; Marshakov, A.I.; Kuznetsov, Y.I. Complex Inhibitor Protection of Some Steels in Hydrochloric Acid Solutions by 1,2,4-Triazole Derivatives. Materials 2025, 18, 464. [Google Scholar] [CrossRef] [PubMed]

- Sedik, A.; Athmani, S.; Saoudi, A.; Ferkous, H.; Ribouh, N.; Lerari, D.; Bachari, K.; Djellali, S.; Berredjem, M.; Solmaz, R.; et al. Experimental and theoretical insights into copper corrosion inhibition by protonated amino-acids. RSC Adv. 2022, 12, 23718–23735. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, M.P.S.; Do Nascimento, C.C.F.; Dos Santos, D.D.M.L. Evaluation of Palm Oil Corrosion Inhibition Through Image Analysis in Copper Pipes Used in Air Conditioning Systems. J. Bio. Tribo Corros. 2025, 11, 40–48. [Google Scholar] [CrossRef]

- Sowjanya, B.; Vykuntam, S.; Raj, A.A.; Arava, A.; King, P.; Vangalapati, M.; Myneni, V.R. Harnessing the potential of Aegle marmelos pulp extract for sustainable corrosion inhibition of brass in 1M H2SO4: Insights from characterization and optimization. Biomass Convers. Biorefin. 2024, 14, 30997–31008. [Google Scholar] [CrossRef]

- Idriss, H.O.; Seddik, N.B.; Achache, M.; Rami, S.; Zarki, Y.; Ennamri, A.; Janoub, F.; Bouchta, D.; Chaouket, F.; Raissouni, I. Shrimp shell waste-modified natural wood and its use as a reservoir of corrosion inhibitor (L-arginine) for brass in 3% NaCl medium: Experimental and theoretical studies. J. Mol. Liq. 2024, 398, 124330. [Google Scholar] [CrossRef]

- Hailou, H.; Taghzouti, S.; Lahcen, I.A.; Idrissi, M.B.; Touir, R.; Ebn Touhami, M.E.H. New aryl-himachalene benzylamines derivatives as eco-friendly corrosion inhibitors at low concentration for brass 62/38 in 200 ppm NaCl: Experimental, analyses and theoretical approach. J. Mol. Struct. 2025, 1319, 139345. [Google Scholar] [CrossRef]

- Liao, J.; Chu, Q.; Zhao, S.; Liu, Z.; Zhang, X. Recent advances in carbon dots as powerful ecofriendly corrosion inhibitors for copper and its alloy. Mater. Today Sustain. 2024, 26, 100706. [Google Scholar] [CrossRef]

- Megahed, M.M.; Abd ElRhiem, E.; Atta, W.; Ghany, N.A.; Abdelbar, M. Investigation and evaluation of the efficiency of palm kernel oil extract for corrosion inhibition of brass artifacts. Sci. Rep. 2025, 15, 4473. [Google Scholar] [CrossRef] [PubMed]

- Montaser, A.A.; El-Mahdy, M.S.; Mahmoud, E.E.E.; Fouda, A.S. Recycling of expired ciprofloxacin in synthetic acid rain (SAR) solution as a green corrosion inhibitor for copper: A theoretical and experimental evaluation. J. Appl. Electrochem. 2024, 54, 439–456. [Google Scholar] [CrossRef]

- Bustos Rivera-Bahena, G.; Ramírez-Arteaga, A.M.; Saldarriaga-Noreña, H.A.; Larios-Gálvez, A.K.; González-Rodríguez, J.G.; Romero-Aguilar, M.; López-Sesenes, R. Hexane extract of Persea schiedeana Ness as green corrosion inhibitor for the brass immersed in 0.5 M HCl. Sci. Rep. 2024, 14, 6512. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Rodriguez, J.G.; Gutierrez-Granda, D.G.; Larios-Galvez, A.K.; Lopez-Sesenes, R. Use of Thymus vulgaris Extract as Green Corrosion Inhibitor for Bronze in Acid Rain. J. Bio Tribo Corros. 2022, 8, 77–83. [Google Scholar] [CrossRef]

- Janoub, F.; Chraka, A.; Kassout, J.; Ben Seddik, N.; Ghajjou, A.; Chaouket, F.; Bouchta, D.; Draoui, K.; Benmessaoud, M.; Raissouni, I. Innovative Characterization of Coffee Waste Extracts and Their Derivatives as Efficient Ecological Corrosion Inhibitors for Copper Alloy in 3% NaCl: Phytochemical Investigations, Electrochemical Explorations, Morphological Assessment and New Computational Methodology. J. Bio Tribo Corros. 2024, 10, 95–104. [Google Scholar] [CrossRef]

- Fouda, A.S.; El-Dossoki, F.I.; Shady, I.A. Adsorption and corrosion inhibition behavior of polyethylene glycol on α-brass alloy in nitric acid solution. Green Chem. Lett. Rev. 2018, 11, 67–77. [Google Scholar] [CrossRef]

- Raeisi, S.; Yousefpour, M. The electrochemical study of the garlic extract as a corrosion inhibitor for brass in the nitric acid solution. Mater. Chem. Phys. 2024, 312, 128516. [Google Scholar] [CrossRef]

- Radovanović, M.B.; Tasić, Ž.Z.; Petrović, M.B.; Simonović, A.T.; Antonijević, M.M. Electrochemical and DFT studies of brass corrosion inhibition in 3% NaCl in the presence of environmentally friendly compounds. Sci. Rep. 2019, 9, 16081. [Google Scholar] [CrossRef] [PubMed]

- Vanangamudi, A.; Punniyakoti, S. Cocos nucifera-mediated electrochemical synthesis and coating of CuO/ZnO nanostructures on Fe ship strips for marine application. Green Chem. Lett. Rev. 2024, 17, 2356612. [Google Scholar] [CrossRef]

- Feng, B.; Zha, F.; Li, L.; Wei, J.; Liu, K. The Corrosion Behavior of T2 Brass in Power Plant Generator Stator Cooling Water. Russ. J. Electrochem. 2019, 55, 943–952. [Google Scholar] [CrossRef]

- Vigdorovich, V.I.; Tsygankova, L.E.; Dorohova, A.N.; Dorohov, A.V.; Knyazeva, L.G.; Uryadnikov, A.A. Protective ability of volatile inhibitors of IFKhAN series in atmospheric corrosion of brass and copper at high concentrations of CO2, NH3 and H2S in air. Int. J. Corros. Scale Inhib. 2018, 7, 331–339. [Google Scholar]

- Vigdorovich, V.I.; Knyazeva, L.G.; Zazulya, A.N.; Prokhorenkov, V.D.; Dorokhov, A.V.; Kuznetsova, E.G.; Uryadnikov, A.A.; Goncharova, O.A. Suppression of Atmospheric Corrosion of Brass Using Volatile Inhibitors. Russ. Agric. Sci. 2017, 43, 342–346. [Google Scholar] [CrossRef]

- Svoboda, R.; Plamer, D.A. Behavior of copper in generator stator cooling-water systems. Power Plant Chem. 2009, 11, 70–76. [Google Scholar]

- Duffeau, F.; Aspden, D.; Coetzee, G. Guide on stator water chemistry management. Study Comm. 2010, 4, 37–41. [Google Scholar]

- Pedersen, K.; Pilarczyk, M.; Quinkertz, R.; Glos, S.; Kuhn, M. Optimization of a CO2-Free Offshore Power Plant Using Supercritical CO2. In Proceedings of the ASME Turbo Expo 2024: Turbomachinery Technical Conference and Exposition. Supercritical CO2, London, UK, 24–28 June 2024; V011T28A028. ASME: New York, NY, USA, 2024; Volume 11. [Google Scholar] [CrossRef]

- Guo, H.; Xu, H.; Xu, C.; Xin, T. Off-design performance analysis and comparison of a coal-based semi-closed supercritical CO2 cycle under different operational strategies. Energy 2025, 315, 134441. [Google Scholar] [CrossRef]

- Abdel-Aal, E.S.M.; Hucl, P.J.; Sosulski, F.W.J. Structural and compositional characteristics of canaryseed (Phalaris canariensis L.). J. Agric. Food Chem. 1997, 45, 3049–3055. [Google Scholar] [CrossRef]

- May, W.E.; Train, J.C.; Greidanus, L. Response of annual canarygrass (Phalaris canariensis L.) to nitrogen fertilizer and fungicide applications. Can. J. Plant Sci. 2022, 102, 83–94. [Google Scholar] [CrossRef]

- Perera, S.P.; Hucl, P.; L’Hocine, L.; Nickerson, M.T. Microstructure and distribution of oil, protein, and starch in different compartments of canaryseed (Phalaris canariensis L.). Cereal Chem. 2021, 98, 405–422. [Google Scholar] [CrossRef]

- Maharaj, A.; Naidoo, Y.; Dewir, Y.H.; Rihan, H. Phytochemical Screening, and Antibacterial and Antioxidant Activities of Mangifera indica L. Leaves. Horticulturae 2022, 8, 909. [Google Scholar] [CrossRef]

- Galvan, E.; Larios Galvez, A.K.; Ramirez Arteaga, A.M.; Lopez Sesenes, R.; Gonzalez Rodriguez, J.G. Electrochemical, gravimetric and surface studies of Phalaris canariensis oil extract as corrosion inhibitor for 316 L type stainless steel in H2O-LiCl mixtures. Sci. Rep. 2024, 14, 23370. [Google Scholar] [CrossRef] [PubMed]

- Borko, T.; Bilic, G.; Žbulj, K.; Otmacic, J.; Curkovic, H. Individual and Joint Effect of Oleic Acid Imidazoline and CeCl3 on Carbon Steel Corrosion in CO2-Saturated Brine Solution. Coatings 2025, 15, 93. [Google Scholar] [CrossRef]

- Al-Sabagh, A.M.; Migahed, M.A.; Mishrif, M.R.; Abd-Elraouf, M.; Abd-El-Bary, H.M.; Mohamed, Z.M.; Hussein, B.M. Corrosion Inhibition Efficiency of Oleic Acid Surfactant Derivatives for Carbon Steel Pipelines in Petroleum Formation Water Saturated with CO2. In Proceedings of the Offshore Mediterranean Conference and Exhibition, Ravenna, Italy, 20–23 March 2013. [Google Scholar]

- Fayyad, E.M.; Sadasivuni, K.K.; Ponnamma, D.; Al-Maadeed, M.A.A. Oleic acid-grafted chitosan/graphene oxide composite coating for corrosion protection of carbon steel. Carbohydr. Polym. 2016, 151, 871–878. [Google Scholar] [CrossRef] [PubMed]

- Al-Edan, A.K.; Isahak, W.N.R.W.; Ramli, Z.A.C.; Al-Azzawi, W.K.A.; Kadhum, A.A.H.; Jabbar, H.S.; Al-Amiery, A. Palmitic acid-based amide as a corrosion inhibitor for mild steel in 1M HCl. Heliyon 2023, 9, e14657. [Google Scholar] [CrossRef] [PubMed]

- Tripathy, D.B.; Murmu, M.; Banerjee, P.; Quraishi, M.A. Palmitic acid based environmentally benign corrosion inhibiting formulation useful during acid cleansing process in MSF desalination plants. Desalination 2019, 472, 114128. [Google Scholar] [CrossRef]

- Zhao, H.R.; Xu, Y.L.; Chen, C.K.; Chen, Y.; Liu, Y.W.; Yang, Z.N. New Aspects of Copper Corrosion in a Neutral NaCl Solution in the Presence of Benzotriazole. Corrosion 2018, 74, 613–622. [Google Scholar] [CrossRef] [PubMed]

- Bian, C.; Ming, Z.; Han, X. Electrochemical response of mild steel in ferrous ion enriched and CO2 saturated solutions. Corros. Sci. 2015, 96, 42–58. [Google Scholar] [CrossRef]

- Paolinelli, L.D.; Perez, T.; Simison, S.N. The effect of pre-corrosion and steel microstructure on inhibitor performance in CO2 corrosion. Corr. Sci. 2008, 50, 2456–2560. [Google Scholar] [CrossRef]

- Jia, Z.; Li, X.; Du, C. Effect of acetic acid on CO2 corrosion of 3Crlow-alloy steel. Mater. Chem. Phys. 2012, 132, 258–263. [Google Scholar] [CrossRef]

- Onyeachu, I.B.; Obot, I.B.; Sorour, A.A.; Abdul-Rashid, M.I. Green corrosion inhibitor for oilfield application I: Electrochemical assessment of 2-(2-pyridyl) benzimidazole for API X60 steel under sweet environment in NACE brine ID196. Corros. Sci. 2019, 150, 183–193. [Google Scholar] [CrossRef]

- Karfa, R.P.; Adhikari, U.; Sukul, D. Corrosion inhibition of mild steel in acidic medium by polyacrylamide grafted Guar gum with various grafting percentage: Effect of intramolecular synergism. Corros. Sci. 2014, 88, 246–253. [Google Scholar] [CrossRef]

- Bustamante, R.A.; Silve, G.N.; Quijano, M.A.; Hernandez, H.H.; Romo, M.R.; Cuan, A.; Pardave, M.P. Electrochemical study of 2-mercaptoimidazole as a novel corrosion inhibitor for steels. Electrochim. Acta 2009, 54, 5393–5399. [Google Scholar] [CrossRef]

| RT (min) | Component | Chemical Formula | Area (%) |

|---|---|---|---|

| 9.02 | Oxirane, octyl | C10H20O | 4.69 |

| 9.56 | Biphenylene, 1,2,4a,4b,7,8,8a,8b-octahydro- | C12H16 | 3.53 |

| 0 | Biphenylene, 1,2,4a,4b,7,8,8a,8b-octahydro- | C12H16 | 4 |

| 11.39 | 13-Tetradecenal | C14H26O | 3.49 |

| 11.86 | 2,4-Decadienal, (E,E)- | C10H16O | 6.17 |

| 12.2 | 2,4-Decadienal, (E,E)- | C10H16O | 6.82 |

| 12.81 | cis-1,2-Cyclododecanediol | C12H24O2 | 3.52 |

| 13.34 | 17-Octadecynoic acid | C18H32O2 | 3.78 |

| 19.9 | n-Hexadecanoic acid | C16H32O2 | 60.2 |

| 21.66 | Oleic Acid | C18H34O2 | 100 |

| Cinh (ppm) | Ecorr (V) | Icorr (A/cm2) | βa (V/dec) | βc (V/dec) | I.E. (%) | θ |

|---|---|---|---|---|---|---|

| 0 | −0.265 | 3.7 × 10−7 | ------ | 270 | ----- | --- |

| 25 | −0.170 | 7.3 × 10−8 | 45 | 520 | 81 | 0.81 |

| 50 | −0.100 | 3.0 × 10−8 | 55 | 540 | 91 | 0.91 |

| 100 | −0.005 | 0.0 × 10−9 | ------ | 555 | 99 | 0.99 |

| Cinh (ppm) | Rct (ohm cm2) | CPEdl (F cm−2) | ndl | Rf (ohm cm2) | CPEf (F cm−2) | nf | I.E.(%) |

|---|---|---|---|---|---|---|---|

| 0 | 1777 | 0.7 | 10,503 | 0.7 | ---- | ||

| 25 | 6959 | 0.8 | 24,568 | 0.8 | 77 | ||

| 50 | 12,578 | 0.8 | 55,216 | 0.8 | 88 | ||

| 100 | 3.6 | 0.9 | 9 | 0.9 | 99 |

| Immersion Time (h) | Rct (ohm cm2) | CPEdl (F cm−2) | ndl | Rf (ohm cm2) | CPEf (F cm−2) | nf |

|---|---|---|---|---|---|---|

| 0 | 1777 | 0.7 | 10,503 | 0.7 | ||

| 6 | 1976 | 0.8 | 22,105 | 0.8 | ||

| 12 | 2125 | 0.8 | 46,186 | 0.8 | ||

| 18 | 2468 | 0.9 | 56,360 | 0.9 | ||

| 24 | 2797 | 0.9 | 90,613 | 0.9 |

| Immersion Time (h) | Rct (ohm cm2) | CPEdl (F cm−2) | ndl | Rf (ohm cm2) | CPEf (F cm−2) | nf | I.E. (%) |

|---|---|---|---|---|---|---|---|

| 0 | 3.6 | 0.9 | 9.8 | 0.9 | 99 | ||

| 6 | 0.5 | 1.5 | 0.9 | 99 | |||

| 12 | 0.5 | 0.9 | 99 | ||||

| 18 | 0.6 | 0.9 | 99 | ||||

| 24 | 0.6 | 0.9 | 99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salazar-Salazar, E.; Gutierrez-Granda, D.G.; Galvan, E.; Larios-Galvez, A.K.; Ramirez-Arteaga, A.M.; Lopez-Sesenes, R.; Brito-Franco, A.; Porcayo-Calderon, J.; Gonzalez-Rodriguez, J.G. Use of Phalaris canariensis Extract as CO2 Corrosion Inhibitor of Brass. Materials 2025, 18, 3449. https://doi.org/10.3390/ma18153449

Salazar-Salazar E, Gutierrez-Granda DG, Galvan E, Larios-Galvez AK, Ramirez-Arteaga AM, Lopez-Sesenes R, Brito-Franco A, Porcayo-Calderon J, Gonzalez-Rodriguez JG. Use of Phalaris canariensis Extract as CO2 Corrosion Inhibitor of Brass. Materials. 2025; 18(15):3449. https://doi.org/10.3390/ma18153449

Chicago/Turabian StyleSalazar-Salazar, Edgar, Dante Guillermo Gutierrez-Granda, Earvin Galvan, Ana Karen Larios-Galvez, America Maria Ramirez-Arteaga, Roy Lopez-Sesenes, Alfredo Brito-Franco, Jesus Porcayo-Calderon, and Jose Gonzalo Gonzalez-Rodriguez. 2025. "Use of Phalaris canariensis Extract as CO2 Corrosion Inhibitor of Brass" Materials 18, no. 15: 3449. https://doi.org/10.3390/ma18153449

APA StyleSalazar-Salazar, E., Gutierrez-Granda, D. G., Galvan, E., Larios-Galvez, A. K., Ramirez-Arteaga, A. M., Lopez-Sesenes, R., Brito-Franco, A., Porcayo-Calderon, J., & Gonzalez-Rodriguez, J. G. (2025). Use of Phalaris canariensis Extract as CO2 Corrosion Inhibitor of Brass. Materials, 18(15), 3449. https://doi.org/10.3390/ma18153449