Site Application of Thermally Conductive Concrete Pavement: A Comparison of Its Thermal Effectiveness with Normal Concrete Pavement

Abstract

1. Introduction

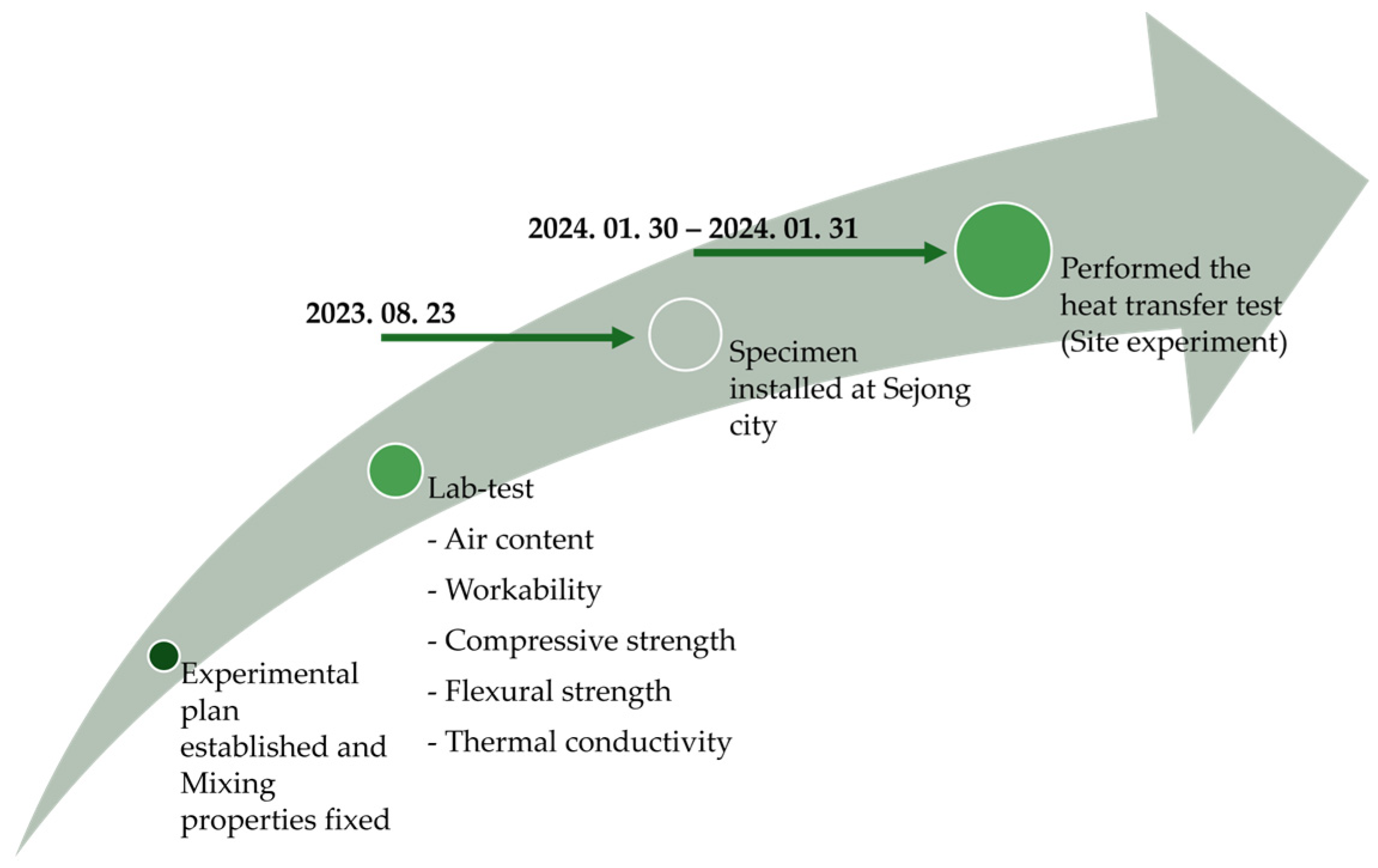

2. Materials and Experimental Plans

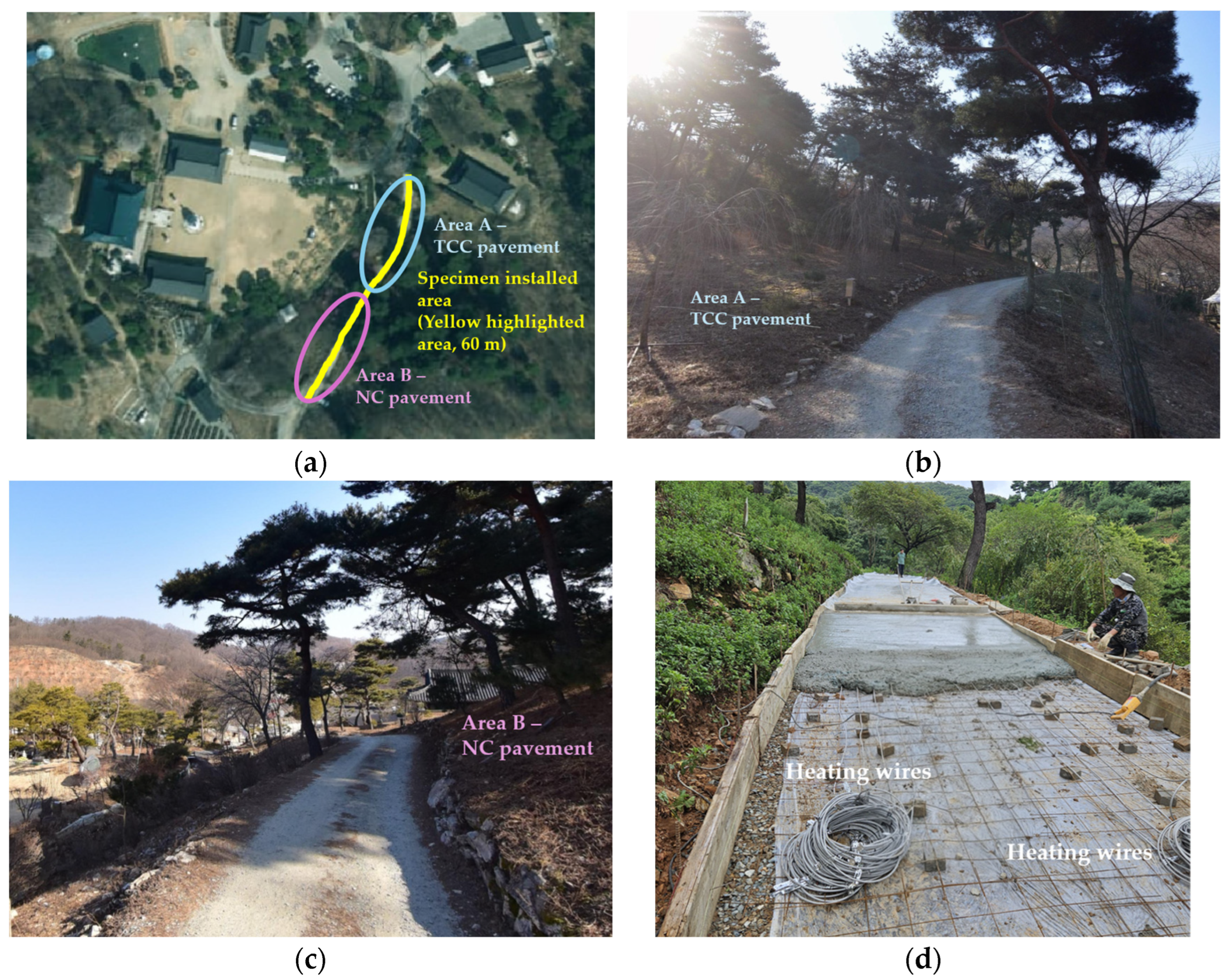

2.1. Specimen Installed Site

2.2. Cement

2.3. Aggregates

2.4. Silicon Carbide and Concrete Mix Properties

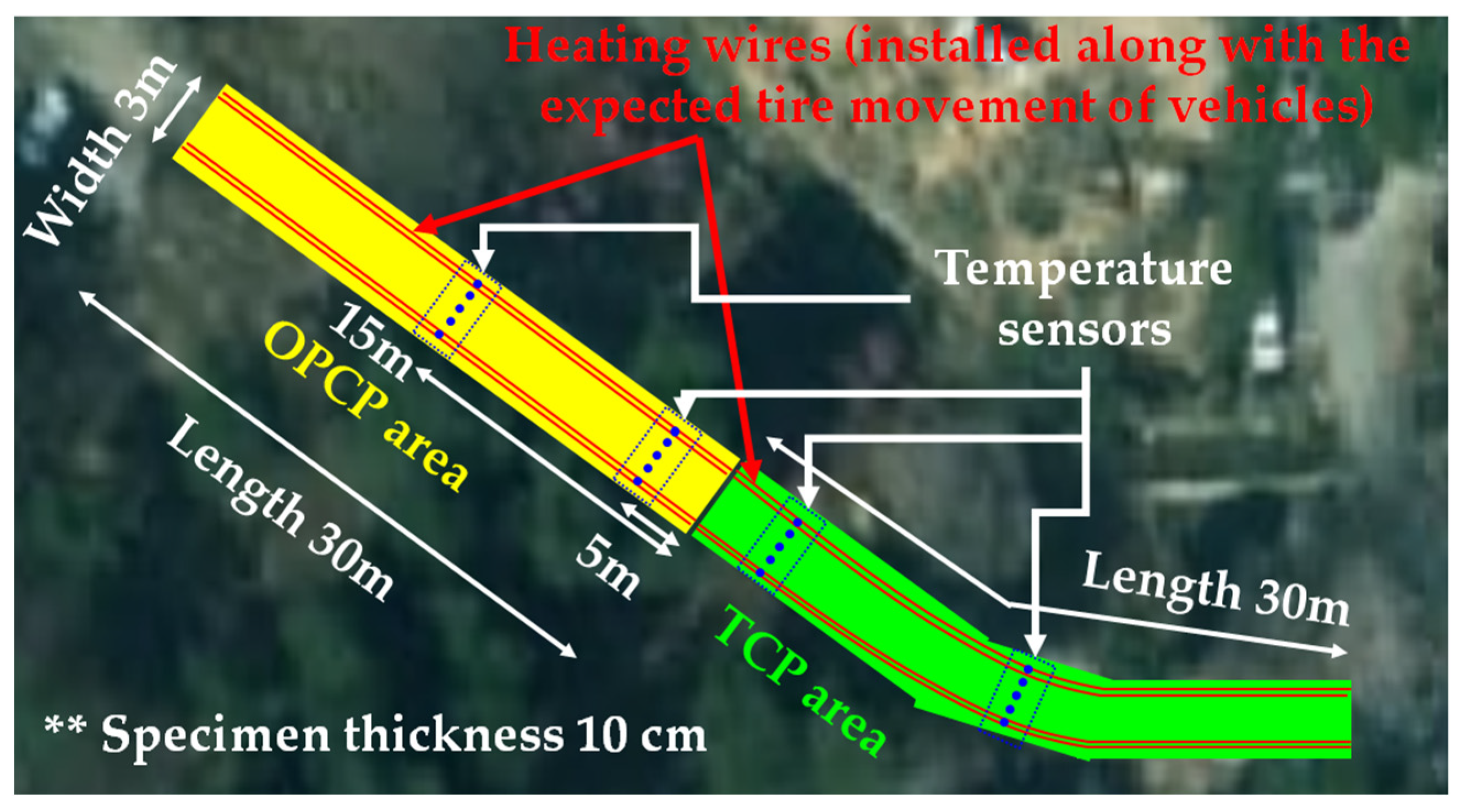

2.5. Plans for Heating Wires and Sensor Intallation

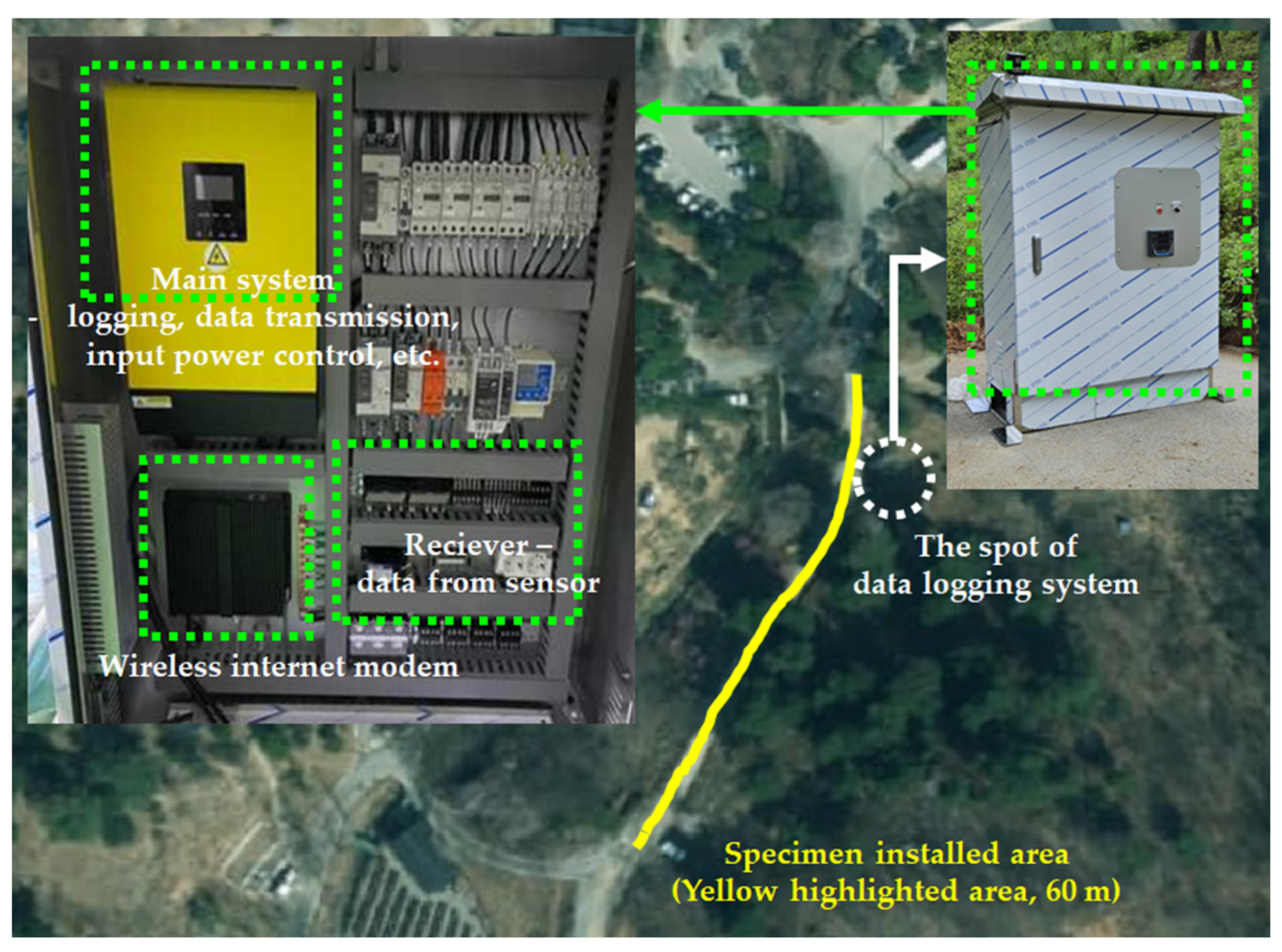

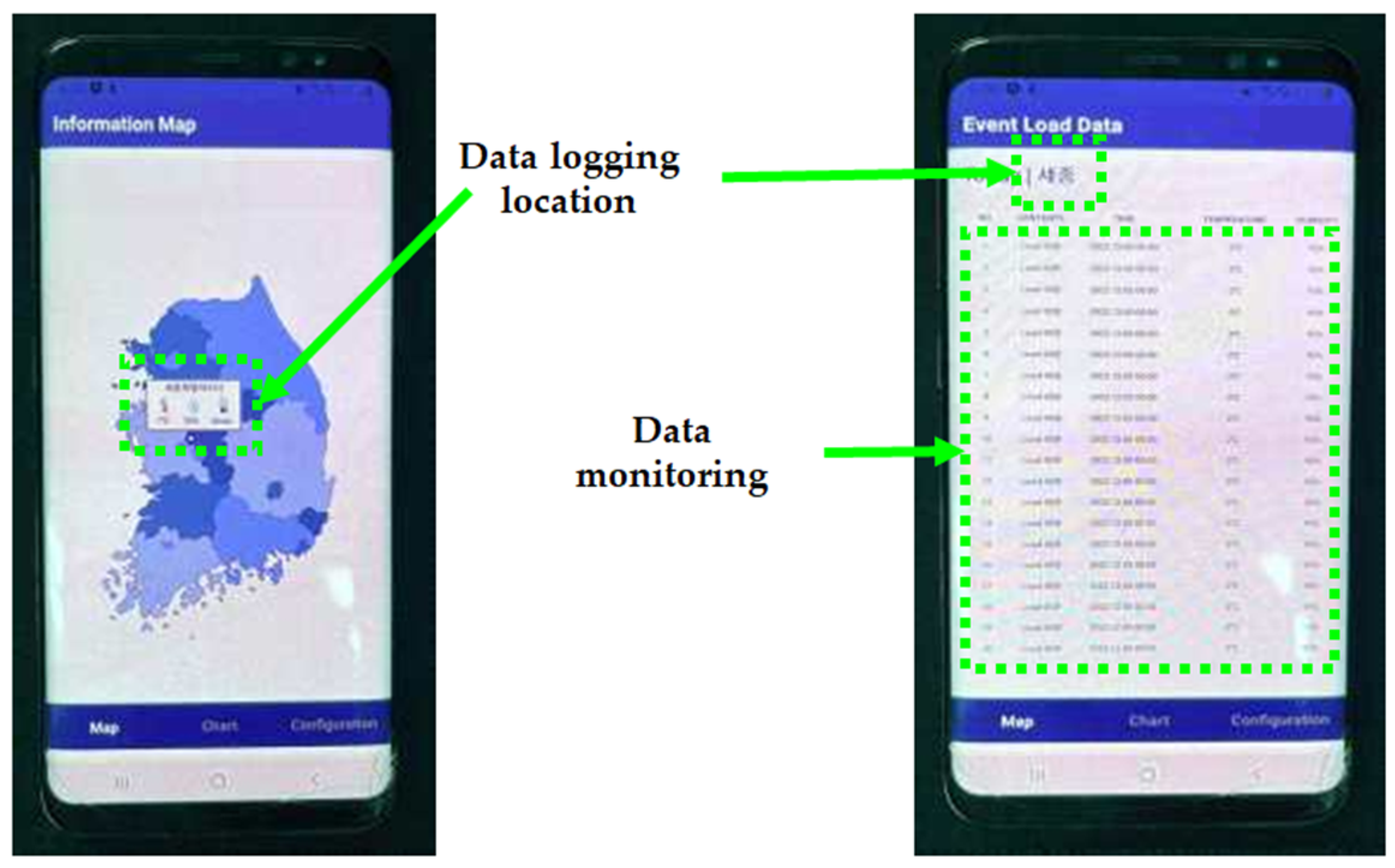

2.6. Data Logging System

2.7. Experimental Evaluation

2.7.1. Fresh State Evaluation

2.7.2. Compressive and Flexural Strength

2.7.3. Thermal Conductivity Measurement

2.7.4. Site Experimental Evaluation of Concrete Pavements Thermal Efficiency

3. Results and Discussion

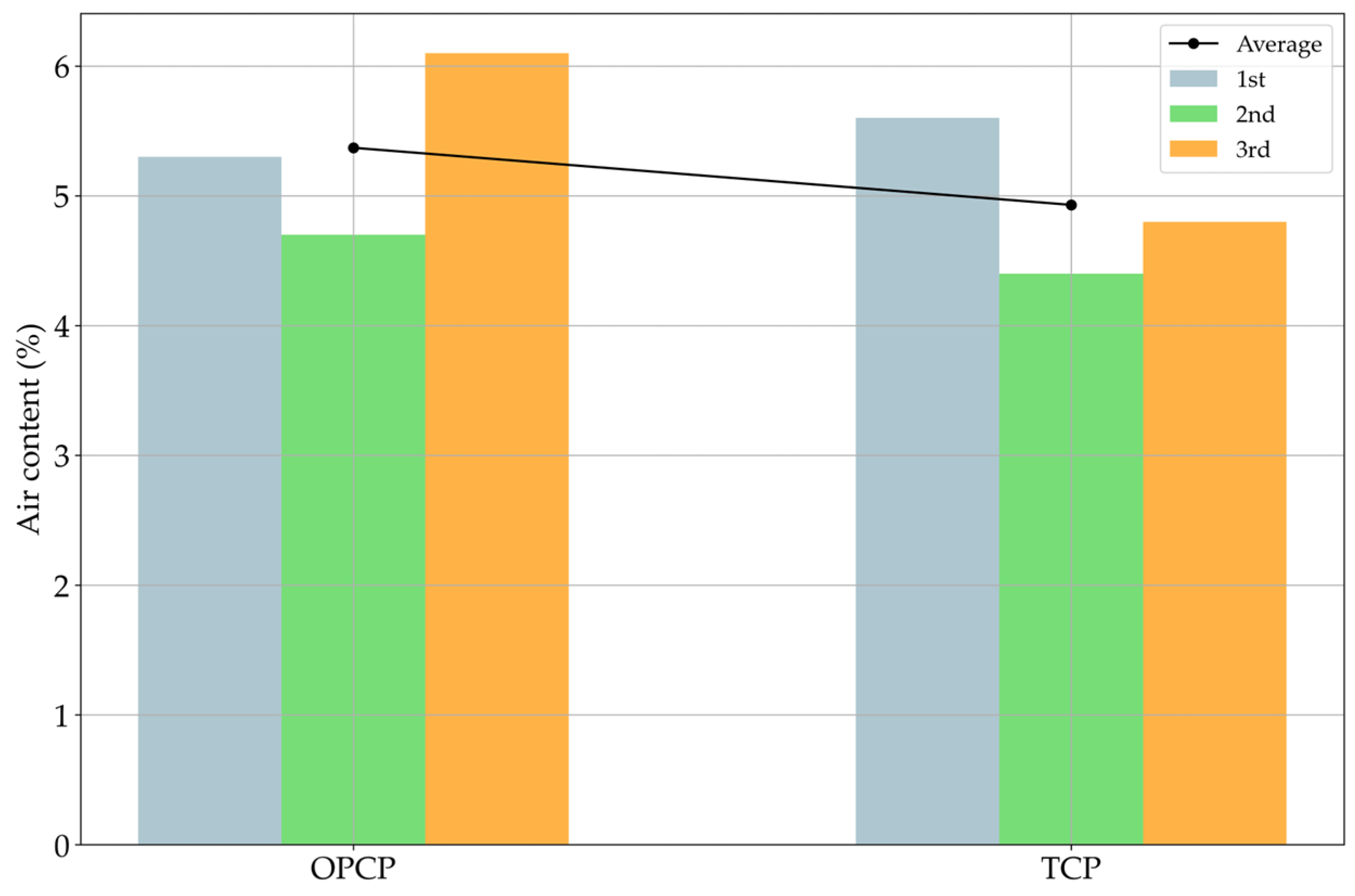

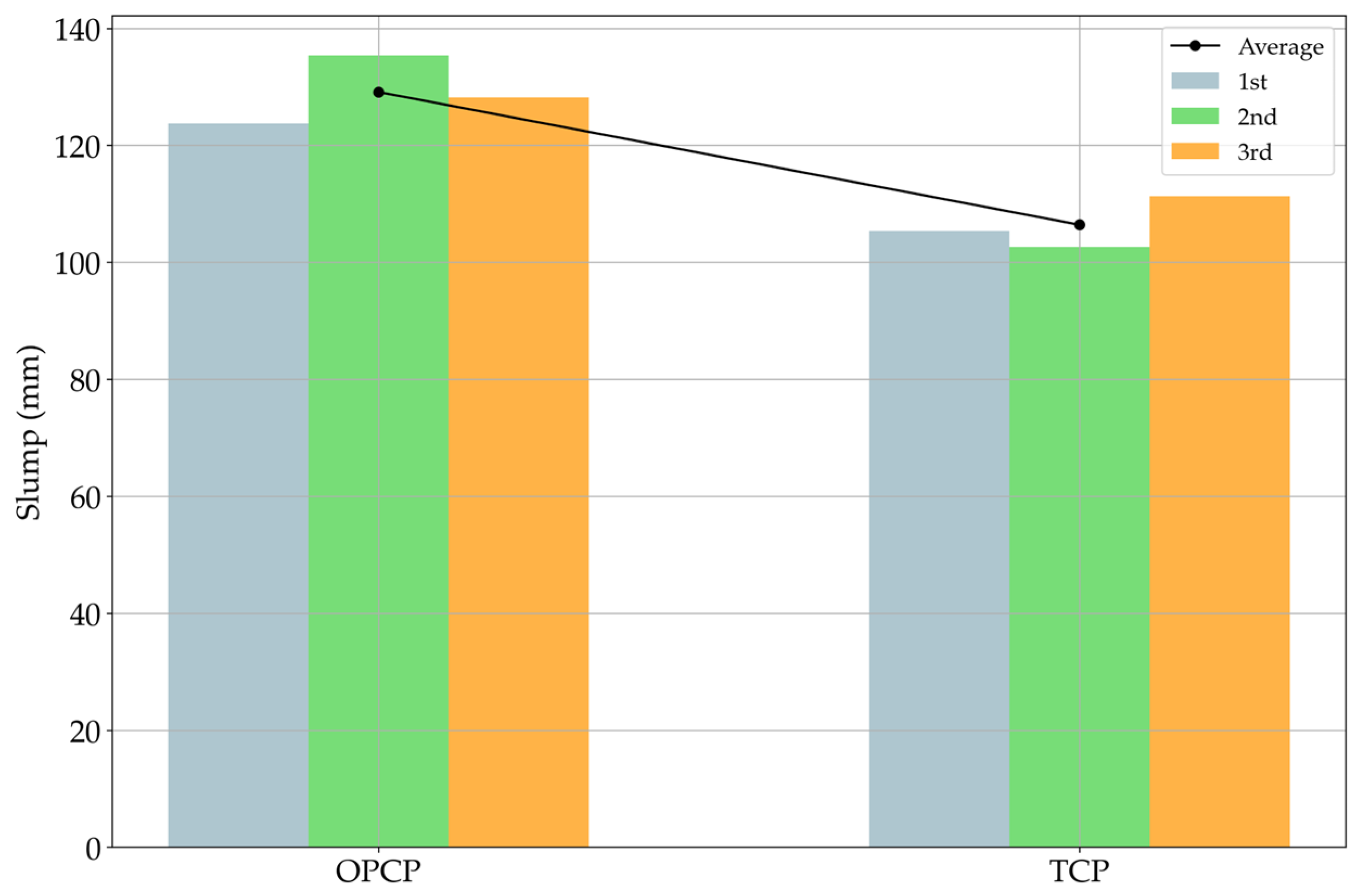

3.1. Air Content and Workability Test Results

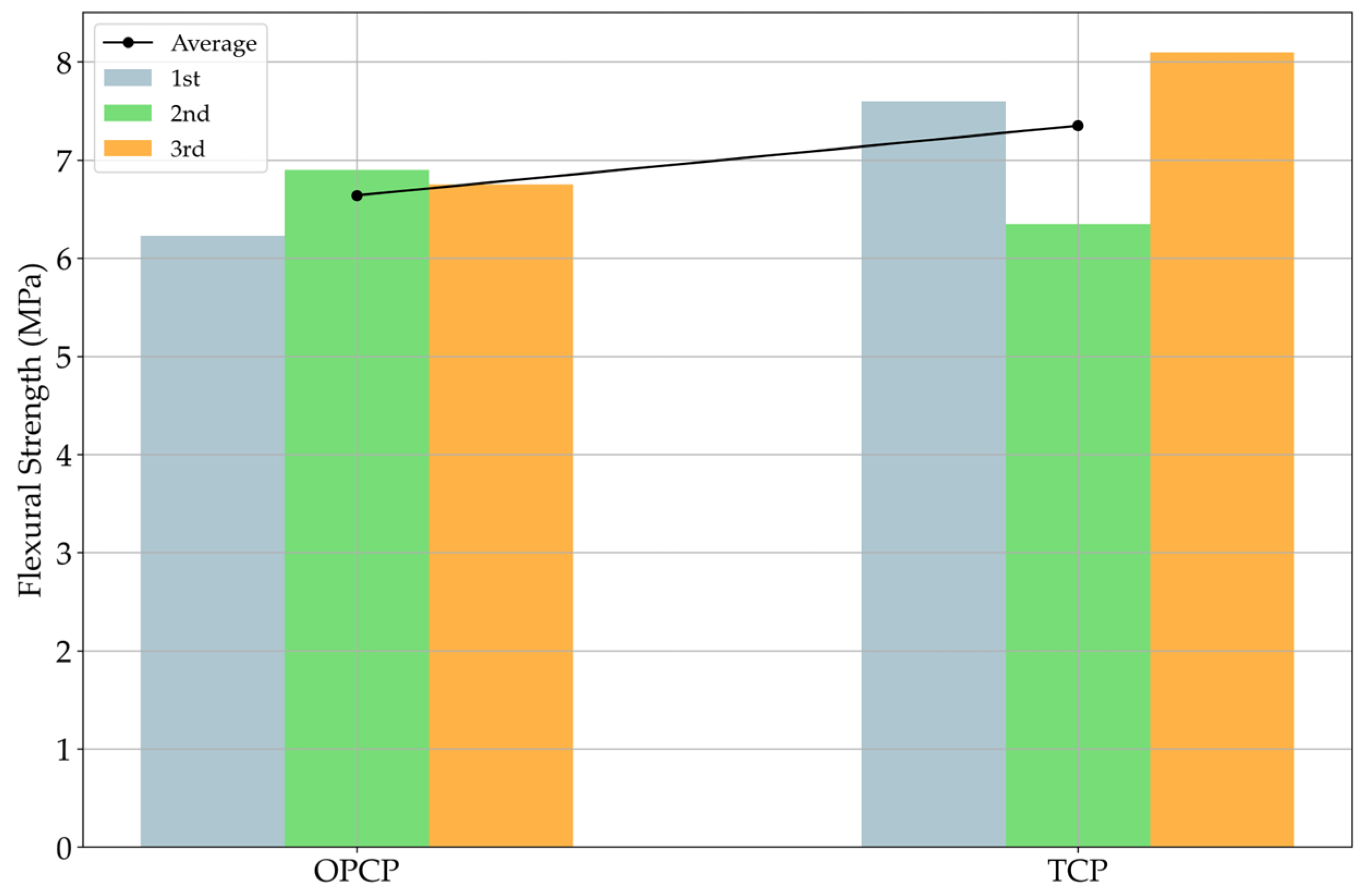

3.2. Compressive and Flexural Strength Results

3.3. Thermal Conductivity Measurement Results

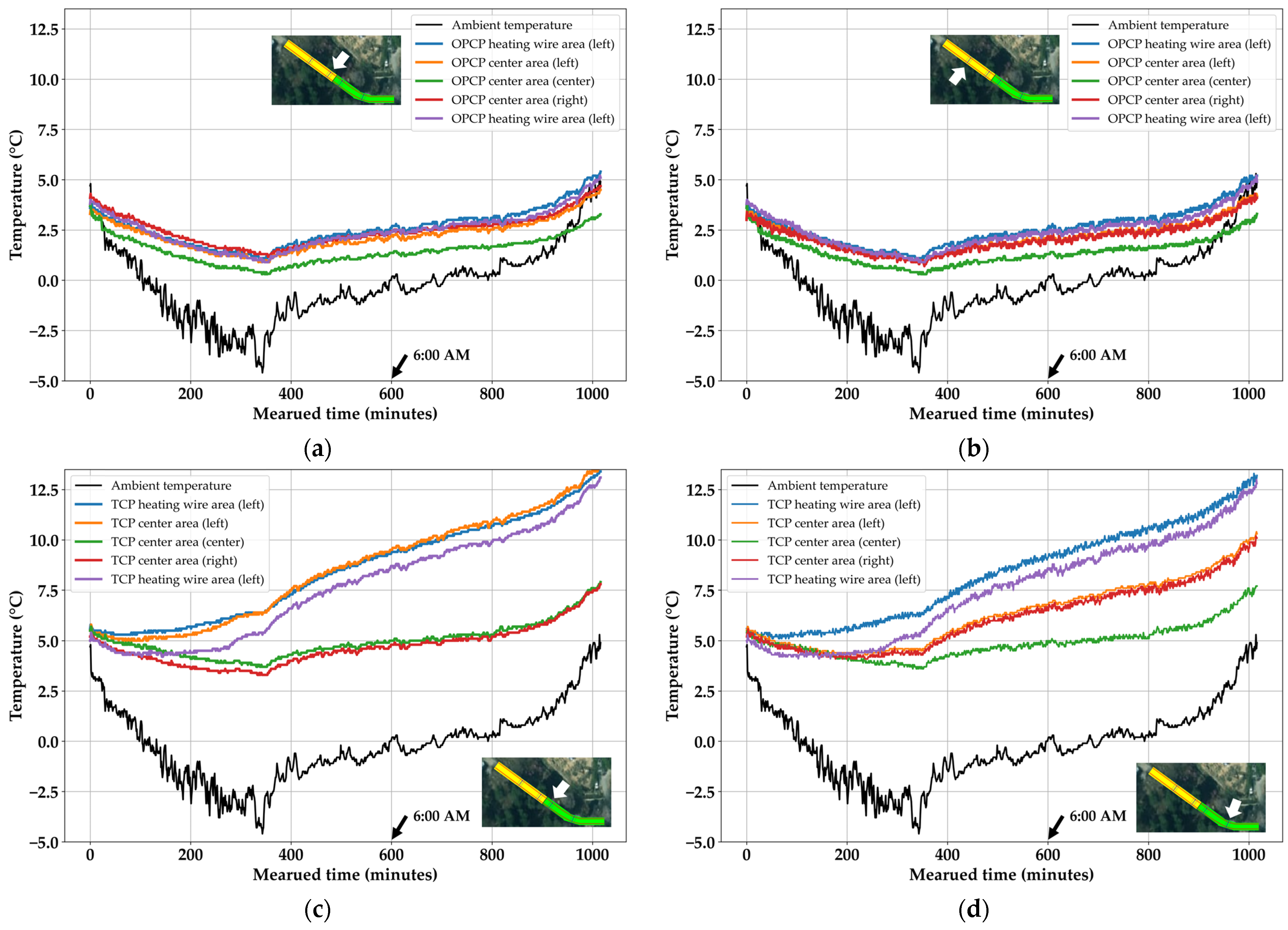

3.4. Site Experiment for Assessing the Heat Transfer Performance Results

4. Conclusions

- The experimental results show that both the OPCP and TCP mixtures met the Korean air content and workability standards. The TCP showed a slightly reduced air content and slump value due to the filler effect of SiC and the fine particle size. The filler effect reduced the porosity and contributed to the improvement in the compressive strength. The van der Waals interactions of SiC particles smaller than 100 μm induced local moisture retention, which affected the effective water utilization rate. Despite these changes, both mixtures showed properties suitable for practical field applications.

- Both the OPCP and TCP mixtures exceeded the compressive and flexural strength targets required by the Korean standard. The TCP showed higher mechanical performance due to the densification of the cement matrix due to the filler effect of fine SiC particles. In addition, van der Waals interactions contributed to the strength improvement through electrical interactions and particle dispersion behavior. Overall, the mechanical properties of both mixtures are suitable for field applications.

- The TCP showed approximately twice the thermal conductivity of OPCP (3.20 W/mK), effectively overcoming heat loss and enabling surface heat transfer. In the site experiment, TCP maintained higher temperatures at the center and heating wire zones, proving superior thermal performance. In contrast, the OPCP exhibited poor heat transfer and significant heat loss due to its low thermal conductivity. Therefore, partial substitution of SiC can enhance snow- and ice-melting performance, offering a practical solution for winter pavement systems.

- This experimental system is a prototype of a snow/ice-prevention system for concrete pavement. It is not a final version of the experiment; however, one aspect of heat transfer performance improvement was confirmed. As this technology is enhanced, a total solution of a snow/ice-prevention system containing wireless cloud system data logging will be completed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- National Transportation Safety Board. Multivehicle Crash in Icy Conditions on Interstate 35 West Highway Investigation Report 2021; National Transportation Safety Board: Washington, DC, USA, 2021; pp. 1–44. [Google Scholar]

- Farnam, Y.; Dick, S.; Wiese, A.; Davis, J.; Bentz, D.; Weiss, J. The Influence of Calcium Chloride Deicing Salt on Phase Changes and Damage Development in Cementitious Materials. Cem. Concr. Compos. 2015, 64, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Babiuc, O. Effect of Gritting Sand Quality on Road Dust Pollution in the School of Architecture and the Built Environment Civil and Architectural Engineering. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2016. [Google Scholar]

- Sergeevich, A.; Viktorovich, B.; Vladimirovich, S.; Slavent’evich, B.; Vladimirovich, S. Experimental Investigations of Snow Bank Formation during Milling and Rotary Snow Blower Operation. J. Appl. Eng. Sci. 2021, 19, 9–16. [Google Scholar] [CrossRef]

- Tobin, G.A.; Brinkmann, R. The Effectiveness of Street Sweepers in Removing Pollutants from Road Surfaces in Florida. J. Environ. Sci. Health Part A 2002, 37, 1687–1700. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-S.; Jang, C.; Kim, H.G.; Woo, B.-H. Snow-Melting Performance of the Thermally Conductive Concrete Pavement—Experimental Evaluation in Field Application. Constr. Build. Mater. 2024, 411, 134508. [Google Scholar] [CrossRef]

- Kim, K.W.; Park, K.T.; Ates, F.; Kim, H.G.; Woo, B.H. Effect of Pretreated Biomass Fly Ash on the Mechanical Properties and Durability of Cement Mortar. Case Stud. Constr. Mater. 2023, 18, e01754. [Google Scholar] [CrossRef]

- Sajid, H.U.; Jalal, A.; Kiran, R.; Al-Rahim, A. A Survey on the Effects of Deicing Materials on Properties of Cement-Based Materials. Constr. Build. Mater. 2022, 319, 126062. [Google Scholar] [CrossRef]

- Zheng, K.; Liu, H.; Feng, L.; Xie, N. Effects of Calcium-Based Deicing Chemicals on the Durability of Concrete Products. J. Mater. Civ. Eng. 2021, 33, 04021321. [Google Scholar] [CrossRef]

- Liu, Y.; Lai, Y.; Ma, D.X. Melting Snow on Airport Cement Concrete Pavement with Carbon Fibre Heating Wires. Mater. Res. Innov. 2015, 19, S10-95–S10-99. [Google Scholar] [CrossRef]

- Huang, C.; Li, J.; Xiao, H.; Gan, S.; Xie, X. Experimental Study of Ice Melting of Concrete Permeable Brick Sidewalks Using Embedded Carbon Fibre Heating Wire. Road Mater. Pavement Des. 2024, 25, 1191–1210. [Google Scholar] [CrossRef]

- Lai, Y.; Liu, Y.; Su, X.; Ma, D.X.; Wang, P. The Influence of Heat Flux on Melting Ice on Concrete Pavement with Carbon Fibre Heating Wire. IOP Conf. Ser. Mater. Sci. Eng. 2018, 392, 022021. [Google Scholar] [CrossRef]

- Farnam, Y.; Krafcik, M.; Liston, L.; Washington, T.; Erk, K.; Tao, B.; Weiss, J. Evaluating the Use of Phase Change Materials in Concrete Pavement to Melt Ice and Snow. J. Mater. Civ. Eng. 2016, 28, 04015161. [Google Scholar] [CrossRef]

- Deb, R.; He, J.; Mishra, G.; Farnam, Y. Investigating Temperature Change Rate and Pore Confinement Effect on Thermal Properties of Phase Change Materials for De-Icing and Low-Temperature Applications in Cementitious Composites. Constr. Build. Mater. 2024, 411, 134237. [Google Scholar] [CrossRef]

- Woo, B.-H.; Yoo, D.-H.; Jeon, I.-K.; Kim, J.-S.; Yoo, K.-S.; Kim, H.G. Estimation of the Thermal Conductivity of Cement Composites Using Bayesian Statistical Approach. Compos. B Eng. 2022, 243, 110073. [Google Scholar] [CrossRef]

- Woo, B.H.; Jeon, I.K.; Yoo, D.H.; Kim, H.G.; Ryou, J.-S. Ice-Melting Performance Assessment of Cement Composites Using Silicon Carbide as Fine Aggregate. Appl. Therm. Eng. 2021, 194, 117113. [Google Scholar] [CrossRef]

- Yoo, D.H.; Jeon, I.K.; Woo, B.H.; Kim, H.G. Performance of Energy Storage System Containing Cement Mortar and PCM/Epoxy/SiC Composite Fine Aggregate. Appl. Therm. Eng. 2021, 198, 117445. [Google Scholar] [CrossRef]

- Kim, H.G.; Qudoos, A.; Jeon, I.K.; Woo, B.H.; Ryou, J.S. Assessment of PCM/SiC-Based Composite Aggregate in Concrete: Energy Storage Performance. Constr. Build. Mater. 2020, 258, 119637. [Google Scholar] [CrossRef]

- Bae, J.-H.; Woo, B.H.; Kim, H.G.; Ryou, J.-S. Enhancing the Thermal Properties of Cement Composites through Substitution of the Fine Aggregate Using Metallic Material. Int. J. Pavement Eng. 2022, 24, 2144311. [Google Scholar] [CrossRef]

- Park, K.T.; Kim, H.G.; Kim, J.S.; Woo, B.H. Improving the Thermoelectric Performance of Cement Composites by Substituting Fine Aggregate with Silicon Carbide. Constr. Build. Mater. 2024, 416, 135068. [Google Scholar] [CrossRef]

- ASTM C150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2017.

- Ates, F.; Park, K.T.; Kim, K.W.; Woo, B.-H.; Kim, H.G. Effects of Treated Biomass Wood Fly Ash as a Partial Substitute for Fly Ash in a Geopolymer Mortar System. Constr. Build. Mater. 2023, 376, 131063. [Google Scholar] [CrossRef]

- Woo, B.-H.; Park, K.-T.; Yoo, K.-S.; Kim, J.-S. Member Size Effect in Seebeck Coefficient of Cement Composites Incorporating Silicon Carbide. Clean Technol. 2025, 7, 33. [Google Scholar] [CrossRef]

- Liu, H.; Li, Q. Preparation of Artificial Aggregates from Concrete Slurry Waste and Waste Brick Masonry Powder: CO2 Uptake and Performance Evaluation. Constr. Build. Mater. 2023, 382, 131356. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S.; Etxeberria, M. Influence of Recycled Aggregates on Long Term Mechanical Properties and Pore Size Distribution of Concrete. Cem. Concr. Compos. 2011, 33, 286–291. [Google Scholar] [CrossRef]

- Shuvo, A.K.; Sarker, P.K.; Shaikh, F.U.A.; Rajayogan, V. Improvement of Crushed Returned Concrete Aggregates by Wet Carbonation. Constr. Build. Mater. 2024, 448, 138253. [Google Scholar] [CrossRef]

- ASTM C33; Standard Specifications for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2003.

- Yinfei, D.; Wei, H.; Mingxin, D.; Weizheng, L. Using Silicon Carbide to Increase Thermal Conductivity of Cement Composite for Improving Heating Efficiency of Floor Heating System. Constr. Build. Mater. 2022, 325, 126707. [Google Scholar] [CrossRef]

- ASTM C231/C231M; Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C143/C143M; Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- Ahn, B.-H.; Lee, S.-J.; Park, C.-G. Physical and Mechanical Properties of Rural-Road Pavement Concrete in South Korea Containing Air-Cooled Blast-Furnace Slag Aggregates. Appl. Sci. 2021, 11, 5645. [Google Scholar] [CrossRef]

- ASTM C39/C39M; Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C78/C78M; Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2022.

- Korean Standards Association KS F 2409; Method of Test for Air Content of Freshly Mixed Concrete by the Pressure Method. Korean Agency for Technology and Standards: Eumseong, Republic of Korea, 2014.

- Chang, L.-Z.; Frid, K.; Kruse, R.; Jänicke, R.; Lundgren, K. Dual-Scale Study of Pre-Damage, Water Boundary Conditions and Frost Interaction in Concrete. Mater. Struct. 2025, 58, 74. [Google Scholar] [CrossRef]

- Zalegowski, K. Pore Structure Influence on Properties of Air-Entrained Concrete. Materials 2025, 18, 2885. [Google Scholar] [CrossRef] [PubMed]

- Woo, B.-H.; Yoo, D.-H.; Kim, S.-S.; Lee, J.-B.; Ryou, J.-S.; Kim, H.-G. Effects of Thermal Conductive Materials on the Freeze-Thaw Resistance of Concrete. Materials 2021, 14, 4063. [Google Scholar] [CrossRef] [PubMed]

- Woo, B.H.; Ryou, J.S.; Kim, J.Y.; Lee, B.; Gi Kim, H.; Kim, J.S. Freeze-Thaw Durability Estimation for Concrete through the Gaussian Process Regression with Kernel Convolution. Constr. Build. Mater. 2023, 400, 132825. [Google Scholar] [CrossRef]

- Lorenzoni, R.; Cunningham, P.; Fritsch, T.; Schmidt, W.; Kruschwitz, S.; Bruno, G. Microstructure Analysis of Cement-Biochar Composites. Mater. Struct. 2024, 57, 175. [Google Scholar] [CrossRef]

- Idrees, S.; Nugraha, J.A.; Tahir, S.; Choi, K.; Choi, J.; Ryu, D.-H.; Kim, J.-H. Automatic Concrete Slump Prediction of Concrete Batching Plant by Deep Learning. Dev. Built Environ. 2024, 18, 100474. [Google Scholar] [CrossRef]

- Morawietz, T.; Singraber, A.; Dellago, C.; Behler, J. How van Der Waals Interactions Determine the Unique Properties of Water. Proc. Natl. Acad. Sci. USA 2016, 113, 8368–8373. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Li, G.; Zhang, X. Electromagnetic Wave Absorption Characteristics of Silicon Carbide Modified Concrete Applied to Protective Engineering. Case Stud. Constr. Mater. 2024, 20, e03362. [Google Scholar] [CrossRef]

- Jeon, I.K.; Qudoos, A.; Jakhrani, S.H.; Kim, H.G.; Ryou, J.-S. Investigation of Sulfuric Acid Attack upon Cement Mortars Containing Silicon Carbide Powder. Powder Technol. 2020, 359, 181–189. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Grasley, Z.; Tyson, B.; Al-Rub, R.K.A. Distribution of Carbon Nanofibers and Nanotubes in Cementitious Composites. Transp. Res. Rec. J. Transp. Res. Board 2010, 2142, 89–95. [Google Scholar] [CrossRef]

- Khan, S.A.; Amjad, H.; Ahmad, F.; Khan, H.A. A Scientometric Review Summarizing the Impact of Nanomaterials on the Fresh, Hardened, and Durability Properties of Cement-Based Materials. Adv. Civ. Eng. 2024, 2024, 8639483. [Google Scholar] [CrossRef]

- He, S.; Chai, J.; Yang, Y.; Cao, J.; Qin, Y.; Xu, Z. Effect of Nano-Reinforcing Phase on the Early Hydration of Cement Paste: A Review. Constr. Build. Mater. 2023, 367, 130147. [Google Scholar] [CrossRef]

- Tanimola, J.O.; Efe, S. Recent Advances in Nano-Modified Concrete: Enhancing Durability, Strength, and Sustainability through Nano Silica (NS) and Nano Titanium (NT) Incorporation. Appl. Eng. Sci. 2024, 19, 100189. [Google Scholar] [CrossRef]

- Korean Standards Association KS F 2408; Method of Test for Slump of Fresh Concrete. Korean Agency for Technology and Standards: Eumseong, Republic of Korea, 2014.

| Chemical Composition (%) | Density (ton/m3) | |||||

|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | |

| 62.7 | 21.5 | 6.3 | 4.2 | 3.2 | 2.3 | 3.153 |

| Chemical Composition (%) | ||||

|---|---|---|---|---|

| Density (ton/m3) | Maximum Particle Size (μm) | Elastic Modulus (GPa) | Thermal Conductivity (W/mK) | Purity of SiC (%) |

| 3.2 | 120 | 193 | 25.5 | 94 |

| Specimens | Mix Properties (kg/m3) | |||||

|---|---|---|---|---|---|---|

| Water | Cement | Fine Agg | Coarse Agg | SiC | Water Reducer | |

| OPCP | 230 | 460 | 816 | 1073 | 0 | 4.6 |

| TCP | 571 | 245 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-Y.; Ryou, J.-S. Site Application of Thermally Conductive Concrete Pavement: A Comparison of Its Thermal Effectiveness with Normal Concrete Pavement. Materials 2025, 18, 3444. https://doi.org/10.3390/ma18153444

Kim J-Y, Ryou J-S. Site Application of Thermally Conductive Concrete Pavement: A Comparison of Its Thermal Effectiveness with Normal Concrete Pavement. Materials. 2025; 18(15):3444. https://doi.org/10.3390/ma18153444

Chicago/Turabian StyleKim, Joo-Young, and Jae-Suk Ryou. 2025. "Site Application of Thermally Conductive Concrete Pavement: A Comparison of Its Thermal Effectiveness with Normal Concrete Pavement" Materials 18, no. 15: 3444. https://doi.org/10.3390/ma18153444

APA StyleKim, J.-Y., & Ryou, J.-S. (2025). Site Application of Thermally Conductive Concrete Pavement: A Comparison of Its Thermal Effectiveness with Normal Concrete Pavement. Materials, 18(15), 3444. https://doi.org/10.3390/ma18153444