Sustainable Management of Photovoltaic Waste Through Recycling and Material Use in the Construction Industry

Abstract

1. Introduction

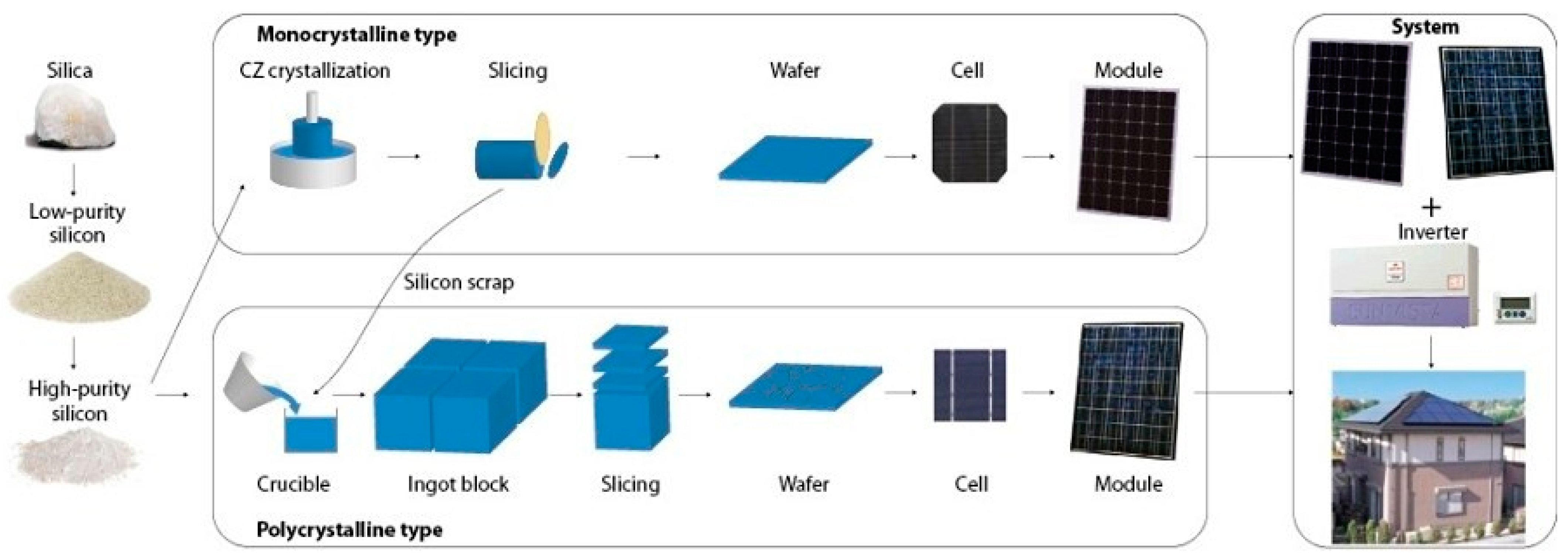

2. PV Construction

- Photovoltaic Cells: These semiconductor elements are capable of generating current through the photovoltaic phenomenon. They are made of p–n junctions and silicon cells. Two types of silicon are used:

- -

- Monocrystalline cells are characterized by high efficiency and are made from a single silicon crystal, produced by the Czochralski process [22].

- -

- Polycrystalline cells are less expensive but less efficient and made from multiple silicon crystals.

- Protective Layers: These layers protect the photovoltaic cells using toughened glass for weather protection and ethylene vinyl acetate (EVA) film, which laminates the cells and holds them in place for transparency. The back sheet provides additional protection against moisture and dust.

- Aluminum Frame: This frame protects the panel edges from mechanical damage and corrosion, ensures rigidity, and facilitates installation.

- Multi-contact Connectors and Cabling: These components electrically connect the panels and other system components, protecting them from the elements. The cables are made of tin-plated copper with double insulation and are UV radiation-resistant.

- Anti-reflective Coating: This coating is made of titanium oxide (TiOx) or silicon nitride (SiNx) increases light absorption by reducing its reflection [23].

- Bypass Diodes: These diodes allow current to flow, bypassing damaged cells to prevent power loss and overheating.

3. Types of Photovoltaic Panels

- -

- Monocrystalline (Mono-Si) Cells: These are made from a single, continuous silicon crystal, offering higher efficiency and a uniform appearance.

- -

- Polycrystalline (Multi-Si) Cells: These are comprised of multiple silicon crystals; they are less efficient but more cost-effective to produce. In 2016, multi-Si panels dominated the market with a 55% share, while mono-Si panels held 45%.

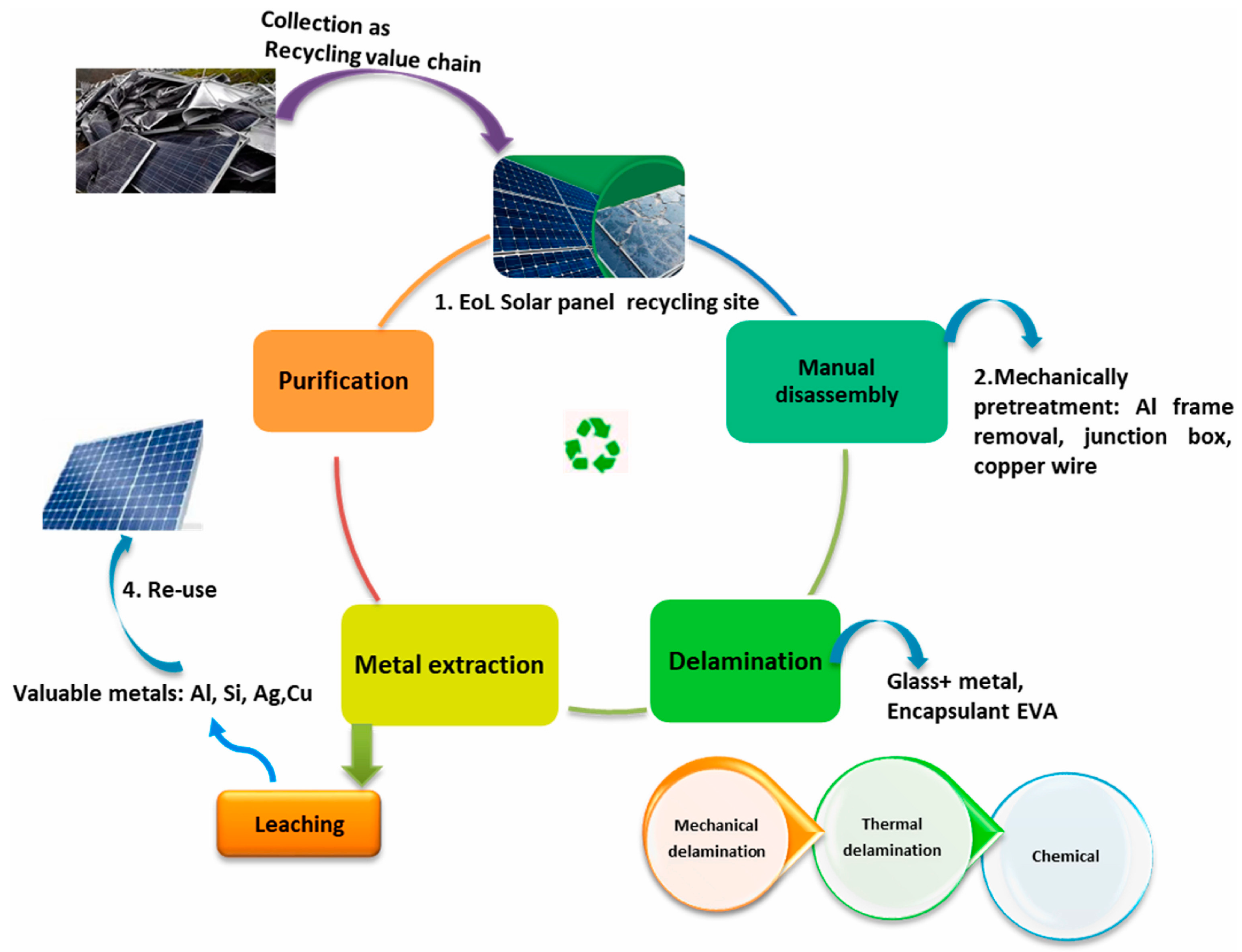

4. Assessment of Photovoltaic Waste Management and Recycling Practices

4.1. Mechanical Recycling

4.2. Thermal Recycling

4.3. Chemical Recycling

4.4. Reuse

4.5. Landfilling

4.6. Full Recycling Procedure

4.7. Utilization and Recycling of Photovoltaic Panels

4.8. Emerging Trends in Sustainable Recycling Practice

5. Utilization of Waste Glass in Cement Production: Assessment of Innovative Strategies

5.1. Waste Glass from Recycled Photovoltaic Panels

- -

- Significantly improving the quality, strength, and structural stability of cement, as well as its mechanical properties;

- -

- Reducing the extraction and consumption of natural aggregates such as sand and gravel;

- -

- Beneficially impacting the environment by reducing its degradation;

- -

- Increasing resistance to chemical corrosion, resulting in higher durability of building structures under varying environmental conditions;

- -

- Reducing waste volumes;

- -

- Supporting the objectives of sustainability legislation.

5.2. Cullet in Cement Production

5.3. Use of Photovoltaic Panel Elements in the Cement and Concrete Industry

6. Future Prospects

- Research and Development: Future research should focus on optimizing the processing techniques for glass waste to enhance its properties as a cement additive. Investigating various particle sizes, shapes, and compositions can lead to improved performance in concrete mixtures. Additionally, studies should explore the long-term durability and environmental impact of using glass waste in cement.

- Technological Innovations: Advancements in recycling technologies are essential to streamline the extraction and processing of glass from end-of-life PV panels. Innovations such as automated sorting systems and eco-friendly solvents can facilitate the recycling process, making it more efficient and cost-effective.

- Regulatory Frameworks: Establishing supportive regulations and standards for the use of recycled materials in construction will be vital. Policymakers should encourage the integration of recycled glass in cement production through incentives and guidelines that promote sustainable practices.

- Industry Collaboration: Collaboration among the renewable energy sector, construction industry, and waste management organizations can foster a circular economy. By working together, stakeholders can develop comprehensive strategies for the collection, processing, and utilization of PV glass waste, ensuring that it contributes positively to both environmental sustainability and economic growth.

- Public Awareness and Education: Raising awareness about the benefits of using recycled materials in construction is crucial. Educational initiatives can inform builders, architects, and the general public about the advantages of incorporating glass waste into cement, promoting a shift towards more sustainable building practices.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gorjian, S.; Ebadi, H. Introduction. In Photovoltaic Solar Energy Conversion: Technologies, Applications, and Environmental Impacts; Gorjian, S., Shukla, A., Eds.; Academic Press: Cambridge, UK, 2020; Volume 1, pp. 1–26. [Google Scholar] [CrossRef]

- Shin, J.; Park, J.; Park, N. A method to recycle silicon wafer from end-of-life photovoltaic module and solar panels by using recycled silicon wafers. Sol. Energy Mater. Sol. Cells 2017, 162, 1–6. [Google Scholar] [CrossRef]

- Backus, C.E. Photovoltaics state-of-the-art. In Proceedings of the Third International PLEA Conference, Mexico City, Mexico, 6–11 August 1984. [Google Scholar] [CrossRef]

- Deb, D.; Bhargava, K. Thin-film photovoltaics. In Degradation, Mitigation, and Forecasting Approaches in Thin Film Photovoltaics; Deb, D., Bhargava, K., Eds.; Academic Press: Cambridge, UK, 2021; Volume 2, pp. 19–37. [Google Scholar] [CrossRef]

- Wang, Y.L.; Ye, J.Y. Review and Development of Crystalline Silicon Solar Cell with Intelligent Materials. Adv. Mater. Res. 2011, 321, 196–199. [Google Scholar] [CrossRef]

- Daljit Singh, J.K.; Molinari, G.; Bui, J.; Soltani, B.; Tajarathnam, G.P.; Abbas, A. Life Cycle Assessment of Disposed and Recycled End-of-Life Photovoltaic Panels in Australia. Sustainability 2021, 13, 11025. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Toing, S.K.; Sopian, K.; Amin, N. An overview of solar photovoltaic panels’ end-of-life material recycling. Energy Strategy Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Koebrich, S.; Bowen, T.; Sharpe, A. 2018 Renewable Energy Data Book; U.S. Department of Energy (DOE), Office of Energy Efficiency & Renewable Energy (EERE): Washington, DC, USA, 2018.

- Kang, S.; Yoo, S.; Lee, J.; Boo, B.; Ryu, H. Experimental investigations for recycling of silicon and glass from waste photovoltaic modules. Renew. Energy 2012, 47, 152–159. [Google Scholar] [CrossRef]

- Jo, W.; Ham, N.; Kim, J.; Kim, J. The Cleaning Effect of Photovoltaic Modules According to Precipitation in the Operation Stage of a Large-Scale Solar Power Plant. Energies 2023, 16, 6180. [Google Scholar] [CrossRef]

- Tao, J.; Yu, S. Review on feasible recycling pathways and technologies of solar photovoltaic modules. Sol. Energy Mater. Sol. Cells 2015, 141, 108–124. [Google Scholar] [CrossRef]

- Rout, S.; Jana, P.; Borra, C.R.; Önal, M.B. Unlocking Silver from End-of-Life Photovoltaic Panels: A Concise Review. Renew. Sustain. Energy Rev. 2025, 210, 115205. [Google Scholar] [CrossRef]

- Uzum, A.; Hamdi, A.; Nagashima, S.; Suzuki, S.; Suzuki, H.; Yoshiba, S.; Dhamrin, M.; Sato, H.; Katsuma, K.; Kato, K. Selective emitter formation process using single screen-printed phosphorus diffusion source. Sol. Energy Mater. Sol. Cells 2013, 109, 288–293. [Google Scholar] [CrossRef]

- Hegedus, S.S.; Luque, A. Status, Trends, Challenges and the Bright Future of Solar Electricity from Photovoltaics. In Handbook of Photovoltaic Science and Engineering, 1st ed.; Luque, A., Hegedus, S., Eds.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2003; Volume 1, pp. 1–43. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Radiation. In Solar Engineering of Thermal Processes, 4th ed.; Duffie, J.A., Beckman, W.A., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; Volume 1, pp. 3–42. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Available Solar Radiation. In Solar Engineering of Thermal Processes, 4th ed.; Duffie, J.A., Beckman, W.A., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; Volume 2, pp. 43–137. [Google Scholar] [CrossRef]

- Papírek, J. Možnosti Likvidace a Recyklace Fotovoltaických Panelů v ČR. Master’s Thesis, Brno University of Technology, Brno, Czech Republic, 2020. [Google Scholar]

- Qu, Y.; Zhu, Q.; Sarkis, J.; Geng, Y.; Zhong, Y. A review of developing an e-wastes collection system in Dalian, China. J. Clean. Prod. 2013, 52, 176–184. [Google Scholar] [CrossRef]

- Tesárek, J. Dopad Likvidace Fotovoltaických Panelů na ŽP. Bachelor’s Thesis, Czech Technical University in Prague, Prague, Czech Republic, 2015. [Google Scholar]

- Paiano, A. Photovoltaic waste assessment in Italy. Renew. Sustain. Energy Rev. 2015, 41, 99–112. [Google Scholar] [CrossRef]

- Messenger, R.; Ventre, J. Introduction. In Photovoltaic Systems Engineering, 3rd ed.; Messenger, R., Ventre, J., Eds.; University of Pennsylvania Press: Philadelphia, PA, USA, 2010. [Google Scholar]

- Yu, X.; Yang, D. Growth of Crystalline Silicon for Solar Cells: Czochralski Si. In Handbook of Photovoltaic Silicon; Yang, D., Ed.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1–45. [Google Scholar] [CrossRef]

- Saga, T. Advances in crystalline silicon solar cell technology for industrial mass production. NPG Asia Mater. 2010, 2, 96–102. [Google Scholar] [CrossRef]

- Bošnjaković, M. Advance of Sustainable Energy Materials: Technology Trends for Silicon-Based Photovoltaic Cells. Sustainability 2024, 16, 7962. [Google Scholar] [CrossRef]

- Nowak, S.; Musztyfaga, M. Krystaliczne ogniwa słoneczne i ich praktyczne zastosowanie. Sokół PSKN, 2014; 28, 2014. [Google Scholar]

- Kanneboina, V.; Sadasivuni, H. The use of back surface field and passivation layer to enhance the performance of silicon heterojunction solar cells. Mater. Today 2023, 92 Pt 2, 972–975. [Google Scholar] [CrossRef]

- Narasimha, S.; Rohatgi, A.; Weeber, A.W. An Optimized Rapid Aluminum Back Surface Field Technique for Silicon Solar Cells. IEEE Trans. Electron Devices 1999, 46, 1363–1370. [Google Scholar] [CrossRef]

- Cieślak, M. Wytwarzanie i Badanie Warstw Epitaksjalnych Krzemu w Zastosowaniu Do Ogniw Słonecznych; Lublin University of Technology: Lublin, Poland, 2010. [Google Scholar]

- Lorenz, A.; Linse, M.; Frintrup, H.; Jeitler, M.; Mette, A.; Lehner, M.; Greutmann, R.; Brocker, H.; König, M.; Erath, D.; et al. Screen Printed Thick Film Metallization of Silicon Solar Cells—Recent Developments and Future Perspectives. In Proceedings of the 35th European PV Solar Energy Conference and Exhibition, Brussels, Belgium, 24–28 September 2018. [Google Scholar]

- Sailor, D.J.; Anand, J.; King, R.R. Photovoltaics in the Built Environment: A Critical Review. Energy Build. 2021, 253, 111479. [Google Scholar] [CrossRef]

- Al-Ezzi, A.S.; Ansari, M.N.M. Photovoltaic Solar Cells: A Review. Appl. Syst. Innov. 2022, 5, 67. [Google Scholar] [CrossRef]

- Bayindir, R.; Demirbas, S.; Irmak, E.; Cetinkaya, U.; Ova, A.; Yesil, M. Effects of Renewable Energy Sources on the Power System. In Proceedings of the 2016 IEEE International Power Electronics and Motion Control Conference (PEMC), Varna, Bulgaria, 25–28 September 2016; pp. 388–393. [Google Scholar] [CrossRef]

- Macek, M.; Drygała, A. Ogólna charakterystyka krzemowych ogniw fotowoltaicznych. Sokół PSKN 2010, 26, 2010. [Google Scholar]

- Lazaroiu, A.C.; Osman, M.G.; Strejoiu, C.; Lazaroiu, G. A Comprehensive Overview of Photovoltaic Technologies and Their Efficiency for Climate Neutrality. Sustainability 2023, 15, 16297. [Google Scholar] [CrossRef]

- Jäger-Waldau, A. Research, Solar Cell Production and Market Implementation of Photovoltaics. In PV Status Report; European Commission: Luxembourg, 2011. [Google Scholar] [CrossRef]

- Solar Cell Central. Available online: http://solarcellcentral.com (accessed on 30 November 2024).

- Shah, A.; Torres, P.; Tscharner, R.; Wyrsch, N.; Keppner, H. Photovoltaic Technology: The Case for Thin-Film Solar Cells. Science 1999, 285, 692–698. [Google Scholar] [CrossRef] [PubMed]

- Benda, V.; Černá, L. PV Cells and Modules—State of the Art, Limits and Trends. Heliyon 2020, 6, e05666. [Google Scholar] [CrossRef]

- Buitenhuis, A.J.; Pearce, J.M. Open-Source Development of Solar Photovoltaic Technology. Energy Sustain. Dev. 2012, 16, 379–388. [Google Scholar] [CrossRef]

- Shaheen, A.M.; Ginidi, A.R.; El-Sehiemy, R.A.; El-Fergany, A.; Elsayed, A.M. Optimal Parameters Extraction of Photovoltaic Triple Diode Model Using an Enhanced Artificial Gorilla Troops Optimizer. Energy 2023, 283, 129034. [Google Scholar] [CrossRef]

- Bulińska, S.; Sujak, A.; Pyzalski, M. From Waste to Renewables: Challenges and Opportunities in Recycling Glass Fibre Composite Products from Wind Turbine Blades for Sustainable Cement Production. Sustainability 2024, 16, 5150. [Google Scholar] [CrossRef]

- Mukwevho, N.; Mkhohlakali, A.; Ntsasa, N.; Sehata, J.; Chimuka, L.; Tshilongo, J.; Letsoalo, M.R. Methodological approaches for resource recovery from end-of-life panels of different generations of photovoltaic technologies—A review. Renew. Sustain. Energy Rev. 2025, 207, 114980. [Google Scholar] [CrossRef]

- Chen, P.; Chen, W.; Lee, C.; Wu, J. Comprehensive Review of Crystalline Silicon Solar Panel Recycling: From Historical Context to Advanced Techniques. Sustainability 2024, 16, 60. [Google Scholar] [CrossRef]

- Mahmoudi, S.; Huda, N.; Alavi, Z.; Islam, M.T.; Behnia, M. End-of-life photovoltaic modules: A systematic quantitative literature review. Resour. Conserv. Recycl. 2019, 146, 1–16. [Google Scholar] [CrossRef]

- Granata, G.; Pagnanelli, F.; Moscardini, E.; Havlik, T.; Toro, L. Recycling of Photovoltaic Panels by Physical Operations. Sol. Energy Mater. Sol. Cells 2014, 123, 239–248. [Google Scholar] [CrossRef]

- Pagnanelli, F.; Moscardini, E.; Granata, G.; Atia, T.A.; Altimari, P.; Havlik, T.; Toro, L. Physical and Chemical Treatment of End-of-Life Panels: An Integrated Automatic Approach Viable for Different Photovoltaic Technologies. Waste Manag. 2017, 59, 422–431. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.-Y.; Hsiao, J.-C.; Du, C.-H. Recycling of Materials from Silicon-Based Solar Cell Module. In Proceedings of the 2012 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, J. Dissolution of Ethylene Vinyl Acetate in Crystalline Silicon PV Modules Using Ultrasonic Irradiation and Organic Solvent. Sol. Energy Mater. Sol. Cells 2012, 98, 317–322. [Google Scholar] [CrossRef]

- Tammaro, M.; Rimauro, J.; Fiandra, V.; Salluzzo, A. Thermal Treatment of Waste Photovoltaic Module for Recovery and Recycling: Experimental Assessment of the Presence of Metals in the Gas Emissions and in the Ashes. Renew. Energy 2015, 81, 103–112. [Google Scholar] [CrossRef]

- Chitra; Sah, D.; Lodhi, K.; Kant, C.; Saini, P.; Kumar, S. Structural Composition and Thermal Stability of Extracted EVA from Silicon Solar Modules Waste. Sol. Energy 2020, 211, 74–81. [Google Scholar] [CrossRef]

- Dias, P.; Schmidt, L.; Gomes, L.B.; Bettanin, A.; Veit, H.; Bernardes, A.M. Recycling Waste Crystalline Silicon Photovoltaic Modules by Electrostatic Separation. J. Sustain. Metall. 2018, 4, 176–186. [Google Scholar] [CrossRef]

- Bombach, E.; Röver, I.; Müller, A.; Schlenker, S.; Wambach, K.; Kopecek, R.; Wefringhaus, E. Technical Experience during Thermal and Chemical Recycling of a 23-Year-Old PV Generator Formerly Installed on Pellworm Island. In Proceedings of the 21st European Photovoltaic Solar Energy Conference, Dresden, Germany, 4–8 September 2006. [Google Scholar]

- Zeng, D.-W.; Born, M.; Wambach, K. Pyrolysis of EVA and Its Application in Recycling of Photovoltaic Modules. J. Environ. Sci. 2004, 16, 889–893. [Google Scholar]

- Mapari, R.; Narkhede, S.; Navale, A.; Babrah, J. Automatic Waste Segregator and Monitoring System. Int. J. Adv. Comput. Res. 2020, 10, 171. [Google Scholar] [CrossRef]

- Lovato, E.S.; Donato, L.M.; Lopes, P.P.; Tanabe, E.H.; Bertuol, D.A. Application of Supercritical CO2 for Delaminating Photovoltaic Panels to Recover Valuable Materials. J. CO2 Util. 2021, 46, 101477. [Google Scholar] [CrossRef]

- Kumar, R.; Sahu, J.; Yadav, A.; Agarwal, A.; Mishra, A. Solid Waste Management and Its Impact on Environment: A Review. Waste Manag. 2023, 144, 115205. [Google Scholar] [CrossRef]

- Zhao, P.; Guo, J.; Yan, G.; Zhu, G. A novel and efficient method for resources recycling in waste photovoltaic panels: High voltage pulse crushing. J. Clean. Prod. 2020, 257, 120442. [Google Scholar] [CrossRef]

- Deng, R.; Zhuo, Y.; Shen, Y. Recent progress in silicon photovoltaic module recycling processes. Resour. Conserv. Recycl. 2022, 187, 106612. [Google Scholar] [CrossRef]

- Song, B.P.; Zhang, M.Y.; Fan, Y.; Jiang, L.; Kang, J.; Gou, T.T.; Zhang, C.L.; Yang, N.; Zhang, G.J.; Zhou, X. Recycling Experimental Investigation on End-of-Life Photovoltaic Panels by Application of High Voltage Fragmentation. Waste Manag. 2020, 101, 180–187. [Google Scholar] [CrossRef]

- Akimoto, Y.; Iizuka, A.; Shibata, E. High-Voltage Pulse Crushing and Physical Separation of Polycrystalline Silicon Photovoltaic Panels. Miner. Eng. 2018, 125, 1–9. [Google Scholar] [CrossRef]

- Salama, A.; Richard, G.; Medles, K.; Zeghloul, T.; Dascalescu, L. Distinct Recovery of Copper and Aluminum from Waste Electric Wires Using a Roll-Type Electrostatic Separator. Waste Manag. 2018, 76, 207–216. [Google Scholar] [CrossRef] [PubMed]

- Dias, P.R.; Benevit, M.G.; Veit, H. Photovoltaic Solar Panels of Crystalline Silicon: Characterization and Separation. Waste Manag. Res. 2016, 34, 235–245. [Google Scholar] [CrossRef]

- Dias, P.; Javimczik, S.; Benevit, M.; Veit, H. Recycling WEEE: Polymer characterization and pyrolysis study for waste of crystalline silicon photovoltaic modules. Waste Manag. 2017, 60, 716–722. [Google Scholar] [CrossRef] [PubMed]

- Sica, D.; Malandrino, O.; Supino, S.; Testa, M.; Lucchetti, M.C. Management of end-of-life photovoltaic panels as a step towards a circular economy. Renew. Sustain. Energy Rev. 2018, 83 Pt 3, 2934–2945. [Google Scholar] [CrossRef]

- Zhang, M.; Buekens, A.; Li, X. Brominated flame retardants and the formation of dioxins and furans in fires and combustion. J. Hazard. Mater. 2016, 304, 26–39. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Song, E.; Zhang, C.; Zhuang, X.; Ma, E.; Bai, J.; Yuan, W.; Wang, J. Pyrolysis-based separation mechanism for waste crystalline silicon photovoltaic modules by a two-stage heating treatment. RSC Adv. 2019, 9, 18115–18123. [Google Scholar] [CrossRef]

- Chen, W.; Chen, Y.; Lee, C.; Cheng, Y.; Chen, Y.; Liu, F.; Wang, Y.; Chueh, Y. Recovery of Valuable Materials from the Waste Crystalline-Silicon Photovoltaic Cell and Ribbon. Processes 2021, 9, 712. [Google Scholar] [CrossRef]

- Preet, S. A review on the outlook of thermal management of photovoltaic panel using phase change material. Energy Clim. Chang. 2021, 2, 100033. [Google Scholar] [CrossRef]

- Luo, M.; Liu, F.; Zhou, Z.; Jiang, L.; Jia, M.; Lai, Y.; Li, J.; Zhang, Z. A comprehensive hydrometallurgical recycling approach for the environmental impact mitigation of EoL solar cells. J. Environ. Chem. Eng. 2021, 9, 106830. [Google Scholar] [CrossRef]

- Yang, E.; Lee, J.; Lee, J.; Ahn, Y.; Kang, G.; Cho, C. Environmentally friendly recovery of Ag from end-of-life c-Si solar cell using organic acid and its electrochemical purification. Hydrometallurgy 2017, 167, 129–133. [Google Scholar] [CrossRef]

- Padoan, F.C.S.M.; Altimari, P.; Pagnanelli, F. Recycling of end of life photovoltaic panels: A chemical prospective on process development. Sol. Energy 2019, 177, 746–761. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E. Recycling of Photovoltaic Solar Cells and Modules-The State-of-Art; Lambert Academic Publishing: Saarbrücken, Germany, 2014. [Google Scholar]

- Palitzsch, W.; Loser, U. A new and intelligent de-metalization step of broken silicon cells and silicon cell production waste in the recycling procedure of crystalline Si modules. In Proceedings of the 2011 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011. [Google Scholar] [CrossRef]

- Nieland, S.; Neuhaus, U.; Pfaff, T.; Rädlein, E. New approaches for component recycling of crystalline solar modules. In Proceedings of the 2012 Electronics Goes Green 2012+, Berlin, Germany, 9–12 September 2012. [Google Scholar]

- Lee, C.-H.; Hung, C.-E.; Tsai, S.-L.; Popuri, S.R.; Liao, C.-H. Resource recovery of scrap silicon solar battery cell. Waste Manag. Res. 2013, 31, 518–524. [Google Scholar] [CrossRef] [PubMed]

- Hiskey, J.; Sanchez, V. Mechanistic and kinetic aspects of silver dissolution in cyanide solutions. J. Appl. Electrochem. 1990, 20, 479–487. [Google Scholar] [CrossRef]

- Min, R.; Li, K.; Wang, D.; Xiao, W.; Liu, C.; Wang, Z.; Bian, S. A novel method for layer separation of photovoltaic modules by using green reagent EGDA. Sol. Energy 2023, 252, 117–126. [Google Scholar] [CrossRef]

- Komoto, K.; Lee, J.S.; Zhang, J.; Ravikumar, D.; Sinha, P.; Wade, A.; Heath, G.A. End-of-Life Management of Photovoltaic Panels: Trends in PV Module Recycling Technologies (No. NREL/TP-6A20-73847); National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2018.

- Gernon, M. Environmental benefits of methanesulfonic acid. Comparative properties and advantages. Green Chem. 1999, 1, 127–140. [Google Scholar] [CrossRef]

- Jung, B.; Park, J.; Seo, D.; Park, N. Sustainable system for raw-metal recovery from crystalline silicon solar panels: From noble-metal extraction to lead removal. ACS Sustain. Chem. Eng. 2016, 4, 4079–4083. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E.; Ostrowski, P. Chemical treatment of crystalline silicon solar cells as a method of recovering pure silicon from photovoltaic modules. Renew. Energy 2010, 35, 1751–1759. [Google Scholar] [CrossRef]

- Lee, J.-K.; Lee, J.-S.; Ahn, Y.-S.; Kang, G.-H.; Song, H.-E.; Lee, J.-I.; Kang, M.-G.; Cho, C.-H. Photovoltaic performance of c-Si wafer reclaimed from end-of-life solar cell using various mixing ratios of HF and HNO3. Sol. Energy Mater. Sol. Cells 2017, 160, 301–306. [Google Scholar] [CrossRef]

- Sinha, P. Potential environmental hazards of photovoltaic panel disposal: Discussion of Tammaro et al. (2015). J. Hazard. Mater. 2017, 323 Pt B, 733–734. [Google Scholar] [CrossRef]

- Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on waste electrical and electronic equipment (WEEE). Off. J. Eur. Union 2012, 197, 38–71.

- Latunussa, C.; Mancini, L.; Blengini, G.; Ardente, F.; Pennington, D. Analysis of Material Recovery from Silicon Photovoltaic Panels; Publications Office of the European Union: Luxembourg, 2016. [Google Scholar] [CrossRef]

- Gerold, E.; Antrekowitsch, H. Advancements and Challenges in Photovoltaic Cell Recycling: A Comprehensive Review. Sustainability 2024, 16, 2542. [Google Scholar] [CrossRef]

- Martinez, M.; Barrueto, Y.; Jimenes, Y.P.; Veja-Garcia, D.; Jamett, I. Technological Advancement in Solar Photovoltaic Recycling: A Review. Minerals 2024, 14, 638. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Rosa, P. End-of-life of used photovoltaic modules: A financial analysis. Renew. Sustain. Energy Rev. 2015, 47, 552–561. [Google Scholar] [CrossRef]

- Khetri, M.; Gupta, M.C. Recycling of silver from silicon solar cells by laser debonding. Sol. Energy 2024, 270, 112381. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E.; Ostrowski, P.; Cenian, A.; Sawczak, M. Chemical, thermal and laser processes in recycling of photovoltaic silicon solar cells and modules. Ecol. Chem. Eng. S 2010, 17, 385–391. [Google Scholar]

- Fernández, L.J.; Ferrer, R.; Aponte, D.; Fernandez, P. Recycling Silicon Solar Cell Waste in Cement-Based Systems. Sol. Energy Mater. Sol. Cells 2011, 95, 1701–1706. [Google Scholar] [CrossRef]

- Zele, S.; Joshi, A.; Gogate, N.; Marathe, D.; Shitole, A. Experimental investigation on utilization of crushed solar panel waste as sand replacement in concrete. Sol. Energy 2024, 269, 112338. [Google Scholar] [CrossRef]

- Máčalová, K.; Václavík, V.; Dvorský, T.; Figmig, R.; Charvát, J.; Lupták, M. The Use of Glass from Photovoltaic Panels at the End of Their Life Cycle in Cement Composites. Materials 2021, 14, 6655. [Google Scholar] [CrossRef]

- Uliasz-Bocheńczyk, A.; Pawluk, A.; Pyzalski, M. Characteristics of Ash from the Combustion of Biomass in Fluidized Bed Boilers. Miner. Resour. Manag. 2016, 32, 149–162. [Google Scholar] [CrossRef]

- Uliasz-Bocheńczyk, A.; Pawluk, A.; Pyzalski, M. The mineral sequestration of CO2 with the use of fly ash from the co-combustion of coal and biomass. Miner. Resour. Manag. 2017, 33, 143–156. [Google Scholar] [CrossRef][Green Version]

- Madhkhan, M.; Katirai, R. Effect of pozzolanic materials on mechanical properties and aging of glass fibre reinforced concrete. Constr. Build. Mater. 2019, 225, 146–158. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Y.; Riefl, C.; Wang, H. Characteristics and pozzolanic reactivity of glass powders. Cem. Concr. Res. 2005, 35, 987–993. [Google Scholar] [CrossRef]

- Fernandez-Jimenez, A.; Palomo, A. Composition and microstructure of alkali activated fly ash binder: Effect of the activator. Cem. Concr. Res. 2005, 35, 1984–1992. [Google Scholar] [CrossRef]

- Reig, L.; Tashima, M.M.; Borrachero, M.V.; Monzo, J.; Cheeseman, C.R.; Paya, J. Properties and microstructure of alkali-activated red clay brick waste. Constr. Build. Mater. 2013, 43, 98–106. [Google Scholar] [CrossRef]

- Mascolo, G. Hydration products of synthetic glasses similar to blast-furnace slags. Cem. Concr. Res. 1973, 3, 207–213. [Google Scholar] [CrossRef]

- Kiventera, J.; Lancellotti, I.; Catauro, M.; Poggetto, F.D.; Leonelli, C.; Illikainen, M. Alkali activation as new option for gold mine tailings inertization. J. Clean. Prod. 2018, 187, 76–84. [Google Scholar] [CrossRef]

- Shayan, A.; Xu, A. Value-added utilisation of waste glass in concrete. Cem. Concr. Res. 2004, 34, 81–89. [Google Scholar] [CrossRef]

- Islam, S.G.; Rahman, M.H.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built. Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef]

- Idir, R.; Cyr, M.; Tagnit-Hamou, A. Use of fine glass as ASR inhibitor in glass aggregate mortars. Constr. Build. Mater. 2010, 24, 1309–1312. [Google Scholar] [CrossRef]

- Johnston, C.D. Waste glass as coarse aggregate for concrete. J. Test. Eval. 1974, 2, 344–350. [Google Scholar] [CrossRef]

- Saccani, A.; Bignozzi, M.C. ASR expansion behavior of recycled glass fine aggregates in concrete. Cem. Concr. Res. 2010, 40, 531–536. [Google Scholar] [CrossRef]

- Longarini, N.; Crespi, P.; Zucca, M.; Giordano, N.; Silvestro, G. The advantages of fly ash use in concrete structures. Inż. Miner. 2014, 15, 141–145. [Google Scholar]

- Pike, R.G.; Hubbard, D.; Newman, E.S. Silicate glasses in the study of alkali aggregate reaction. High Res. Board Bull. 1960, 275, 39–44. [Google Scholar]

- Shao, Y.; Lefort, T.; Moras, S.; Rodriguez, D. Studies on concrete containing ground waste glass. Cem. Concr. Res. 2000, 30, 91–100. [Google Scholar] [CrossRef]

- Schwarz, N.; Cam, H.; Neithalath, N. Influence of a fine glass powder on the durability characteristics of concrete and its comparison to fly ash. Cem. Concr. Compos. 2008, 30, 486–496. [Google Scholar] [CrossRef]

- Yang, H.L.; Usman, M.; Hanif, A. Suitability of liquid crystal display (LCD) glass waste as supplementary cementing material (SCM): Assessment based on strength, porosity, and durability. J. Build. Eng. 2021, 42, 102793. [Google Scholar] [CrossRef]

- Shen, Z.; Chen, C.; Lee, M. Recovery of cutting fluids and silicon carbide from slurry waste. J. Hazard. Mater. 2019, 362, 115–123. [Google Scholar] [CrossRef] [PubMed]

- Skibsted, J.; Snellings, R. Reactivity of supplementary cementitious materials (SCMs) in cement blends. Cem. Concr. Res. 2019, 124, 105799. [Google Scholar] [CrossRef]

- Arif, M.; Gupta, V.; Choudhary, H.; Kumar, S.; Basu, P. Performance evaluation of cement concrete containing sandstone slurry. Constr. Build. Mater. 2018, 184, 432–439. [Google Scholar] [CrossRef]

- Zhang, Z.; Scherer, G.W. Evaluation of drying methods by nitrogen adsorption. Cem. Concr. Res. 2019, 120, 13–26. [Google Scholar] [CrossRef]

- Gastaldi, D.; Canonico, F.; Capelli, L.; Buzzi, L.; Boccaleri, E.; Irico, S. An investigation on the recycling of hydrated cement from concrete demolition waste. Cem. Concr. Compos. 2015, 61, 29–35. [Google Scholar] [CrossRef]

- Xu, Y.; Li, J.; Tan, Q.; Peters, A.L.; Yang, C. Global status of recycling waste solar panels: A review. Waste Manag. 2018, 75, 450–458. [Google Scholar] [CrossRef]

| Method | High-Voltage Fragmentation | Cement Matrices | Thermal Treatment | Electro-Hydraulic Fragmentation |

|---|---|---|---|---|

| Use | Separation and recovery materials | Recycling materials | Glass recovery | Metals recovery |

| Recovery Rate | - | - | +/−85% | 99% Cu, 60% Ag, 80% Pb/Sn/Al |

| Recovered Materials | Glass, Cu, Sn, Pb, Ag | - | Glass | Si, Ag, Cu, Sn, Pb, Al |

| Challenges | Improved recovery | Less mechanical strength, high porosity | Emissions management | - |

| Impact | Commercial viability | - | Reduces consumption of energy and chemical | Economical |

| Advantages | Separation and recovery of materials | Create insulation and soundproofing materials | High glass recovery rate | Easy metal recovery |

| Disadvantages | Need to use another method for recovery of higher Ag | Does not recover materials for direct reuse | Further processing for metal recovery | - |

| Method | Triple Crushing | Electrostatic Separation | High-Voltage Fragmentation | Supercritical CO2 |

|---|---|---|---|---|

| Use | Recycling | Separation waste wires | Recovery metals | Separation of solar cell from encapsulation and glass layer |

| Recovery Rate | 91% | 68.6% Cu with over 100% purity | 95% Cu and 96% Ag | >96% |

| Recovered Materials | Glass, Al, Cu, (Ag) | Cu, Al | Cu, Al, Pb, Ag, Sn | Glass, Pb filaments, back sheet |

| Impact | Economically feasible | - | - | Use of toluene |

| Advantages | Less thermal waste | High purity | Various size crushing | Less solvent usage |

| Disadvantages | - | Need to find new model improvement for Al particles | - | - |

| Method | Thermal Treatment and Mechanical Force | Pyrolysis 500 °C | Organic Solvents | Thermal Treatment | Two-Stage Heating |

|---|---|---|---|---|---|

| Significant Findings | Obtaining EVA extracted similar properties to commercial | 75% of polymers degrade | Silicon recovery of over 86% with high purity | Detection of metals | Integral recovery of TPT backing materials; EVA binder removed |

| Advantages | Eco-friendly | Over 100% removal of polymers | Efficient silicon recovery | Highlights hazardous metal emissions | Detailed analysis of EVA pyrolysis |

| Challenges and Limitations | - | Mass loss | - | Need to adequately emissions | Treatment of pyrolysis products |

| Applications | Reuse of extracted EVA | - | New method of silicon supply and costs | - | Efficient recycling of waste PV panels |

| Method | Mechanical and Nitric Acid Leaching | Nitric Acid Leaching | Organic Solvent | Organic |

|---|---|---|---|---|

| Target Material | Ag | Si, Cu, Ag, Pb | Si | Si |

| Key Process | Leaching in HNO3, precipitating use NaCl | 5 M nitric acid, agitation at 200 rpm | Trichloroethylene at 80 °C with mechanical pressure | o-Dichlorobenzene at 120 °C |

| Efficiency | High yield silver concentration | Si: 80%, Cu: 79%, Ag: 90%, Pb: 93% | Recovered without damage after 8 days | Recovered without damage after 1 week |

| Concerns | Energy consumption | Handling of acids | Swelling and cracking | Cracking EVA |

| Method | Solvent Extraction and Electrowinning | Acid Precipitation | Sulfurization and Neutralization Treatment | Chemical Etching |

|---|---|---|---|---|

| Target Material | Cu | Ag | Pb | Si |

| Key Process | LIX84-I extraction, H2SO4 stripping, electrowinning | HCl precipitation, NaOH, hydrazine hydrate reduction, electrolytic refining | NaOH neutralization, Na2S sulfurization | HNO3, H2SO4, CH3COOH |

| Efficiency | - | Over 100% purity | Over 93% removal | Yield 86%, over 100% purity |

| Concerns | Chemicals | Chemicals, high-temperature processes | Toxic compounds | Strong acids |

| Method | Ultrasonic Irradiation | Chemical Refinement | Chemical Refabrication | Chemical Recovery and Electrorefining |

|---|---|---|---|---|

| Target Material | EVA | Si | Si | Ag |

| Key Process | O-DCB, TCE, benzene, toluene, ultrasonic power | Thermal or chemical separation followed by chemical refinement | Wet chemical process using a mixture of HNO3 and HF | Methanesulfonic acid (MSA) mixed with H2O2, purification by electrorefining |

| Efficiency | Complete dissolution | Silicon recovery | Re-fabrication with high efficiency—17.6% | Purity of Ag over 100% after electrorefining |

| Concerns | Damage in other solvents | Absence of antireflective coating on resultant cells | The optimal ratio of HNO3/HF to avoid incomplete etching or deposition of Ag particles | Excessive H2O2 decomposition and ensuing H2O generation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bulińska, S.; Sujak, A.; Pyzalski, M. Sustainable Management of Photovoltaic Waste Through Recycling and Material Use in the Construction Industry. Materials 2025, 18, 284. https://doi.org/10.3390/ma18020284

Bulińska S, Sujak A, Pyzalski M. Sustainable Management of Photovoltaic Waste Through Recycling and Material Use in the Construction Industry. Materials. 2025; 18(2):284. https://doi.org/10.3390/ma18020284

Chicago/Turabian StyleBulińska, Sandra, Agnieszka Sujak, and Michał Pyzalski. 2025. "Sustainable Management of Photovoltaic Waste Through Recycling and Material Use in the Construction Industry" Materials 18, no. 2: 284. https://doi.org/10.3390/ma18020284

APA StyleBulińska, S., Sujak, A., & Pyzalski, M. (2025). Sustainable Management of Photovoltaic Waste Through Recycling and Material Use in the Construction Industry. Materials, 18(2), 284. https://doi.org/10.3390/ma18020284