An Annealing Strategy for Inhibiting Recrystallization in Nickel-Based Single-Crystal Superalloys

Abstract

1. Introduction

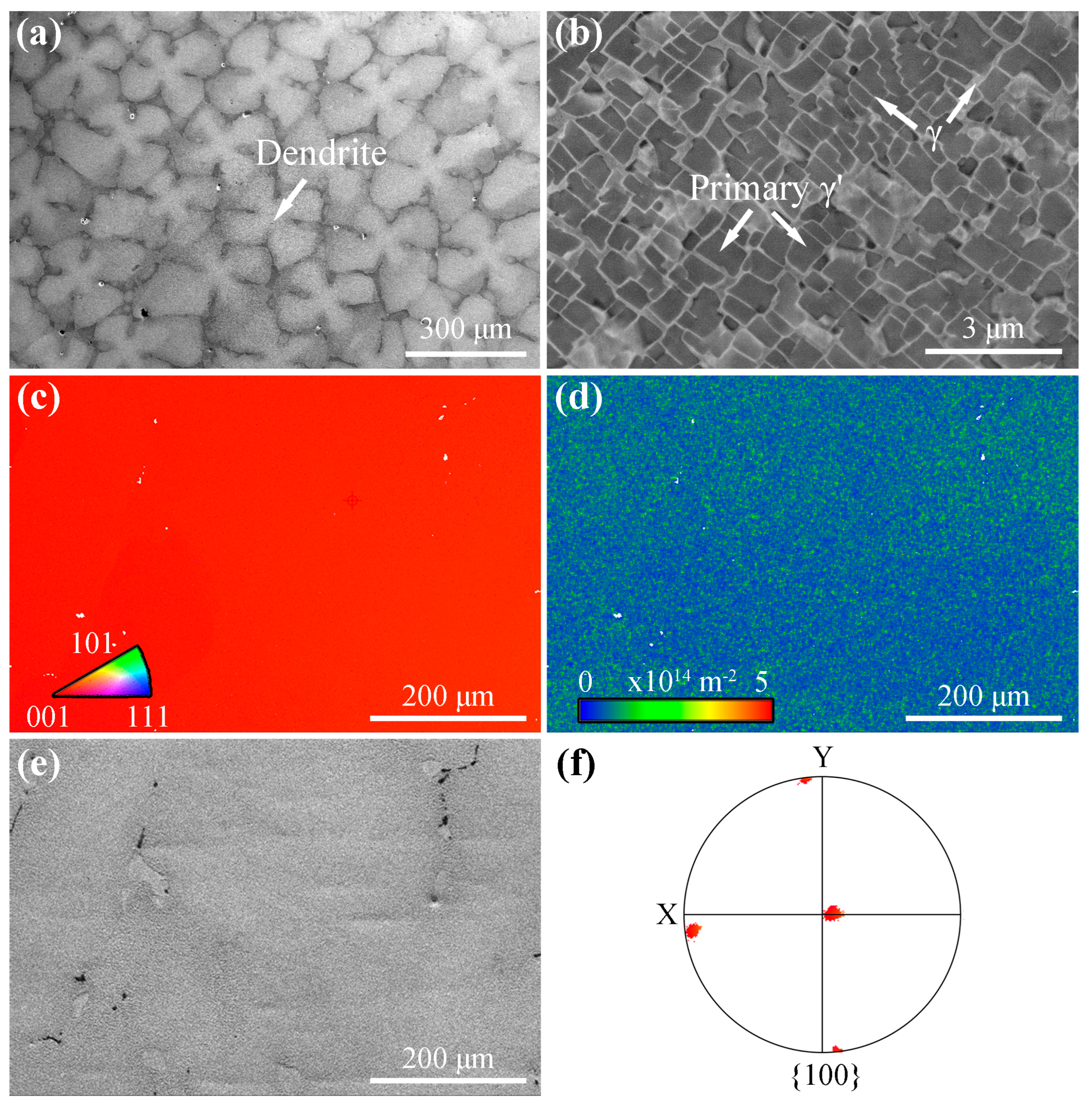

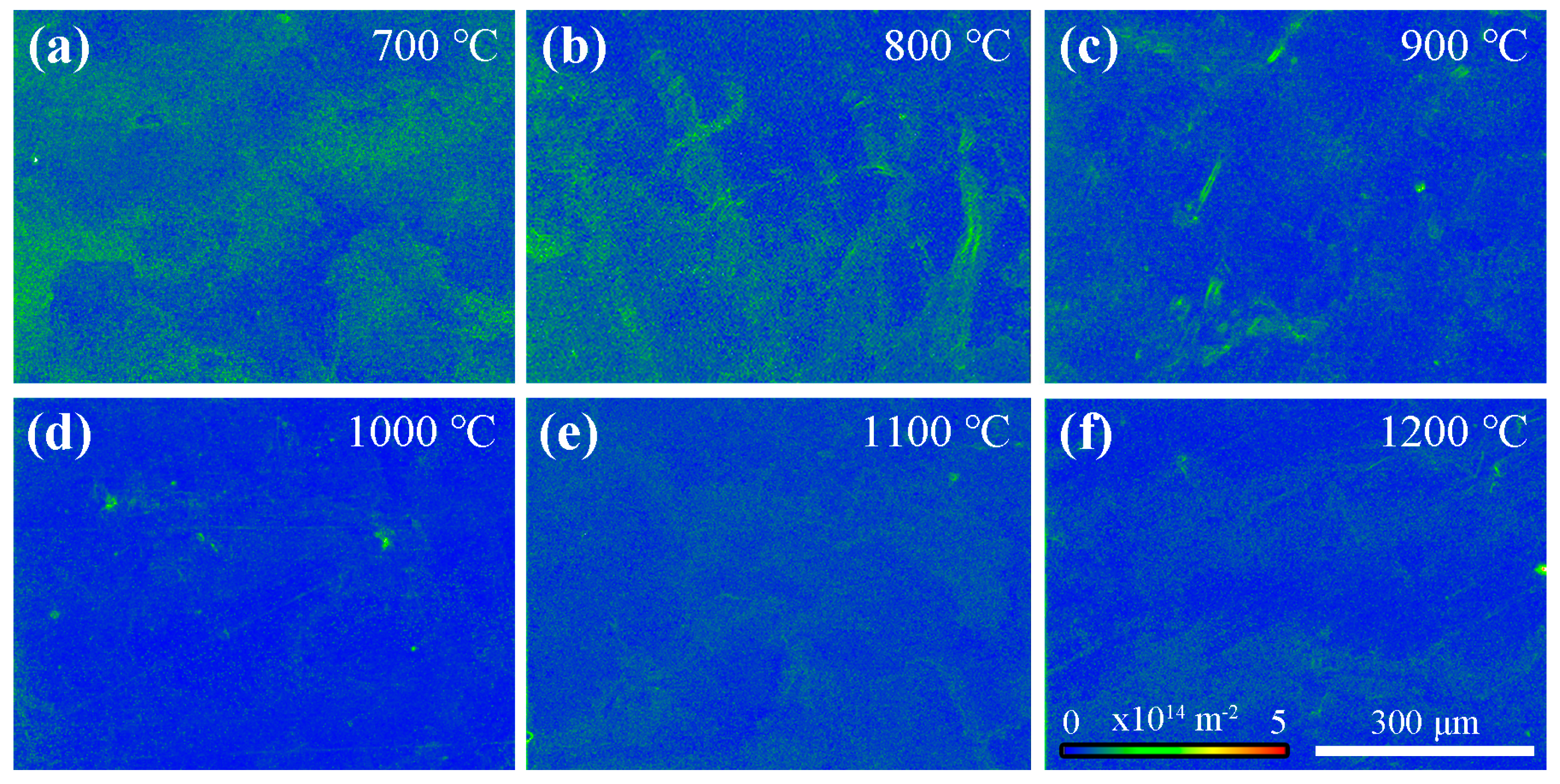

2. Materials and Methods

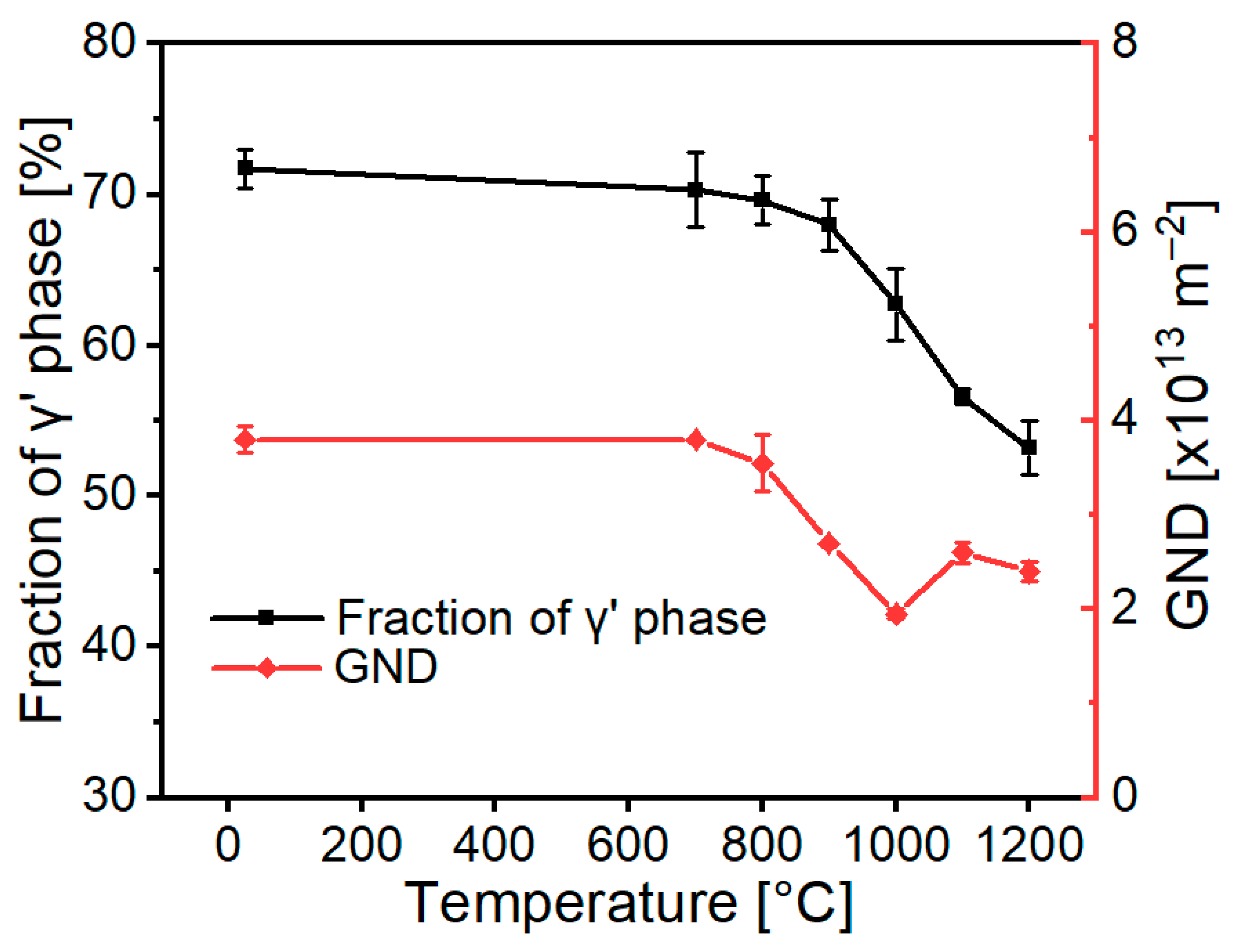

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006; pp. 1–28. [Google Scholar]

- Xie, G.; Lou, L.H. Influence of the characteristic of recrystallization grain boundary on the formation of creep cracks in a directionally solidified Ni-base superalloy. Mater. Sci. Eng. A 2012, 532, 579–584. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, W.G.; Lou, L.H. The deformation and the recrystallization initiation in the dendrite core and interdendritic regions of a directionally solidified nickel-based superalloy. J. Alloys Compd. 2015, 629, 247–254. [Google Scholar] [CrossRef]

- Xu, F.; Lin, Y.; Ma, D.; Xiong, W.; He, D.; Liu, G.; Zhao, Y. Effects of Crystal Orientation and External Stress on the Static Recrystallization Behavior of an Ni-Based Single-Crystal Superalloy. Materials 2024, 17, 3123. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Shi, H.-J. In situ SEM studies of the low cycle fatigue behavior of DZ4 superalloy at elevated temperature: Effect of partial recrystallization. Int. J. Fatigue 2014, 61, 255–263. [Google Scholar] [CrossRef]

- Panwisawas, C.; Mathur, H.; Gebelin, J.-C.; Putman, D.; Rae, C.M.F.; Reed, R.C. Prediction of recrystallization in investment cast single-crystal superalloys. Acta Mater. 2013, 61, 51–66. [Google Scholar] [CrossRef]

- Cox, D.C.; Roebuck, B.; Rae, C.M.F.; Reed, R.C. Recrystallisation of single crystal superalloy CMSX–4. Mater. Sci. Technol. 2013, 19, 440–446. [Google Scholar] [CrossRef]

- Long, M.; Leriche, N.; Niane, N.T.; Labergere, C.; Badreddine, H.; Grange, D. A new experimental and simulation methodology for prediction of recrystallization in Ni-based single crystal superalloys during investment casting. J. Mater. Process. Technol. 2022, 306, 117624. [Google Scholar] [CrossRef]

- Jo, C.Y.; Cho, H.Y.; Kim, H.M. Effect of recrystallisation on microstructural evolution and mechanical properties of single crystal nickel base superalloy CMSX-2 Part 1—Microstructural evolution during recrystallisation of single crystal. Mater. Sci. Technol. 2013, 19, 1665–1670. [Google Scholar] [CrossRef]

- Xiong, J.; Li, J.; Liu, S. Surface Recrystallization in Nickel Base Single Crystal Superalloy DD6. Chin. J. Aeronaut. 2010, 23, 478–485. [Google Scholar]

- Li, Z.; Zhang, D.; Su, X.; Xu, Q.; Liu, B. Role of as-cast dendritic microstructure in recrystallization of a Ni-based single crystal superalloy. J. Alloys Compd. 2016, 660, 115–124. [Google Scholar]

- Li, Z.; Xu, Q.; Liu, B. Experimental investigation on recrystallization mechanism of a Ni-base single crystal superalloy. J. Alloys Compd. 2016, 672, 457–469. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, H.; Hu, B.; Shang, Y.; Ru, Y.; Zhang, H.; Qu, W.; Pei, Y.; Li, S.; Gong, S. Recrystallization behavior of a high γ′-fraction Ni-based single crystal superalloy induced by residual strain. Mater. Des. 2024, 244, 113200. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, H.; Li, L.; Lu, S.; Xie, G.; Zhang, J.; Feng, Q. Recrystallization in a Ni-based single-crystal superalloy traced by quasi-in-situ EBSD. Scr. Mater. 2025, 255, 116369. [Google Scholar] [CrossRef]

- Xu, Y.; Gong, Y.; Zhang, W.; Wen, X.; Yin, G.; Li, J.; Zhao, J. Microstructure evolution and dynamic recrystallization mechanism induced by grinding of Ni-based single crystal superalloy. J. Mater. Process. Technol. 2022, 310, 117784. [Google Scholar] [CrossRef]

- Okazaki, M.; Ohtera, I.; Harada, Y. Damage repair in CMSX-4 alloy without fatigue life reduction penalty. Metall. Mater. Trans. A 2004, 35, 535–542. [Google Scholar] [CrossRef]

- Li, Y.; Luo, Y.; Chen, J.; Zhao, S.; Wang, L. Effect of ultrasonic shot peening surface alloying on recrystallisation of a single crystal superalloy. Vacuum 2023, 209, 111748. [Google Scholar] [CrossRef]

- Xiong, J.C.; Li, J.R.; Liu, S.Z.; Zhao, J.Q.; Han, M. Effects of carburization on recrystallization behavior of a single crystal superalloy. Mater Charact. 2010, 61, 749–755. [Google Scholar] [CrossRef]

- Wang, L.; Xie, G.; Lou, L.H. Effect of carbon content on the recrystallization of a single crystal nickel-based superalloy. Mater. Lett. 2013, 109, 154–157. [Google Scholar] [CrossRef]

- Rettberg, L.H.; Callahan, P.G.; Goodlet, B.R.; Pollock, T.M. Rejuvenation of Directionally Solidified and Single-Crystal Nickel-Base Superalloys. Metall. Mater. Trans. A 2021, 52, 1609–1631. [Google Scholar] [CrossRef]

- Lin, S.; Chen, K.; Zeng, Q.; Ramamurty, U. A method for increasing the supersolvus critical strain for recrystallization in single-crystal superalloys. Mater. Res. Lett. 2023, 11, 856–862. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, K.; Lin, S.; Fu, R.; Zhang, B.; Ding, J.; Feng, Z.; Huang, X.; Ma, E. Recovery facilitated by interphase boundary motion circumvents recrystallization in superalloy single crystals. Mater. Res. Lett. 2024, 12, 180–189. [Google Scholar] [CrossRef]

- Bond, S.D.; Martin, J.W. Surface recrystallization in a single crystal nickel-based superalloy. J. Mater. Sci. 1984, 19, 3867–3872. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, Z.; Li, L.; Xie, G.; Zhang, J.; Feng, Q. Effect of Re Addition on the Sensitivity to Recrystallization in As-Cast Ni-Based SX Superalloys. In Proceedings of the 15th International Symposium on Superalloys, Champion, PA, USA, 8 September 2024. [Google Scholar]

- Wu, X.; Makineni, S.K.; Liebscher, C.H.; Dehm, G.; Rezaei Mianroodi, J.; Shanthraj, P.; Svendsen, B.; Bürger, D.; Eggeler, G.; Raabe, D.; et al. Unveiling the Re effect in Ni-based single crystal superalloys. Nat. Commun. 2020, 11, 389. [Google Scholar] [CrossRef]

- Xiong, W.; Huang, Z.; Xie, G.; Ge, Z.; Wang, X.; Lu, Y.; Zheng, W.; Lou, L.; Zhang, J. The effect of deformation temperature on recrystallization in a Ni-based single crystal superalloys. Mater. Des. 2022, 222, 111042. [Google Scholar] [CrossRef]

- Yao, X.; Ding, Q.; Zhao, X.; Wei, X.; Wang, J.; Zhang, Z.; Bei, H. Microstructural rejuvenation in a Ni-based single crystal superalloy. Mater. Today Nano 2022, 17, 100152. [Google Scholar] [CrossRef]

- Mathur, H.N.; Panwisawas, C.; Jones, C.N.; Reed, R.C.; Rae, C.M.F. Nucleation of recrystallisation in castings of single crystal Ni-based superalloys. Acta Mater. 2017, 129, 112–123. [Google Scholar] [CrossRef]

- Perry, S.J.; D’Souza, N.; Collins, D.M.; Roebuck, B.; Dong, H.B. An In Situ Resistance-Based Method for Tracking the Temporal Evolution of Recovery and Recrystallization in Ni-Base Single-Crystal Superalloy at Super-Solvus Temperatures. Metall. Mater. Trans. A 2022, 54, 1582–1596. [Google Scholar] [CrossRef]

- Lopez-Galilea, I.; Hecker, L.; Epishin, A.; Bürger, D.; Ruttert, B.; Thome, P.; Weber, S.; Theisen, W. Super-Solidus Hot Isostatic Pressing Heat Treatments for Advanced Single Crystal Ni-Base Superalloys. Metall. Mater. Trans. A 2022, 54, 1509–1525. [Google Scholar] [CrossRef]

- Xu, J.; Zhao, X.; Yue, Q.; Xia, W.; Duan, H.; Gu, Y.; Zhang, Z. A morphological control strategy of γ′ precipitates in nickel-based single-crystal superalloys: An aging design, fundamental principle, and evolutionary simulation. Mater. Today Nano 2023, 22, 100335. [Google Scholar] [CrossRef]

- Rakoczy, Ł.; Milkovič, O.; Rutkowski, B.; Cygan, R.; Grudzień-Rakoczy, M.; Kromka, F.; Zielińska-Lipiec, A. Characterization of γ′ Precipitates in Cast Ni-Based Superalloy and Their Behaviour at High-Homologous Temperatures Studied by TEM and in Situ XRD. Materials 2020, 13, 2397. [Google Scholar] [CrossRef]

- Grosdidier, T.; Hazotte, A.; Simon, A. Precipitation and dissolution processes in γ/γ′ single crystal nickel-based superalloys. Mat. Sci. Eng. A 1998, 256, 183–196. [Google Scholar] [CrossRef]

- Dirand, L.; Cormier, J.; Jacques, A.; Chateau-Cornu, J.-P.; Schenk, T.; Ferry, O.; Bastie, P. Measurement of the effective γ/γ′ lattice mismatch during high temperature creep of Ni-based single crystal superalloy. Mater. Charact. 2013, 77, 32–46. [Google Scholar] [CrossRef]

- Baldan, A. Progress in Ostwald ripening theories and their applications to the γ-precipitates in nickel-base superalloys Part II Nickel-base superalloys. J. Mater. Sci. 2002, 37, 2379–2405. [Google Scholar] [CrossRef]

- Qin, L.; Pei, Y.; Li, S.; Zhao, X.; Gong, S.; Xu, H. Effect of thermal stability of γ′ phase on the recrystallization behaviors of Ni-based single crystal superalloys. Mater. Des. 2017, 130, 69–82. [Google Scholar] [CrossRef]

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propul. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Masoumi, F.; Jahazi, M.; Shahriari, D.; Cormier, J. Coarsening and dissolution of γ′ precipitates during solution treatment of AD730™ Ni-based superalloy: Mechanisms and kinetics models. J. Alloys Compd. 2016, 658, 981–995. [Google Scholar] [CrossRef]

- Humphreys, F.J. Grain and subgrain characterisation by electron backscatter diffraction. J. Mater. Sci. 2001, 36, 3833–3854. [Google Scholar] [CrossRef]

- Porter, A.; Ralph, B. The recrystallization of nickel-base superalloys. J. Mater. Sci. 1981, 16, 707–713. [Google Scholar] [CrossRef]

- Zambaldi, C.; Roters, F.; Raabe, D.; Glatzel, U. Modeling and experiments on the indentation deformation and recrystallization of a single-crystal nickel-base superalloy. Mat. Sci. Eng. A 2007, 454–455, 433–440. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, L.; Yang, Y.; Lv, P. Effect of heat treatment on the microstructure and recrystallization of an SLM nickel-based superalloy. Mater. Today Commun. 2024, 39, 109253. [Google Scholar] [CrossRef]

- Verma, A.; Johnson, O.K.; Thompson, G.B.; Ogata, S.; Homer, E.R. Solute influence in transitions from non-Arrhenius to stick-slip Arrhenius grain boundary migration. Acta Mater. 2024, 265, 119605. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Oxford, UK, 2004; p. 219. [Google Scholar]

- Zhao, Y.; Wang, Z.; Shi, L.; Gao, S.; Qian, D.; Chen, K.; Li, Y.; Pantleon, W. Simultaneous strength optimization and recrystallization prevention in induction-heating-assisted laser additively manufactured Ni-based superalloys. Mater. Res. Lett. 2025, 13, 632–641. [Google Scholar] [CrossRef]

- Manohar, P.A.; Ferry, M.; Chandra, T. Five decades of the Zener equation. ISIJ Int. 1998, 38, 913–924. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Xu, F.; Gao, M.; Xia, S.; Liang, S.; Huang, C.; Ma, D.; Li, Q. An Annealing Strategy for Inhibiting Recrystallization in Nickel-Based Single-Crystal Superalloys. Materials 2025, 18, 3341. https://doi.org/10.3390/ma18143341

Hu X, Xu F, Gao M, Xia S, Liang S, Huang C, Ma D, Li Q. An Annealing Strategy for Inhibiting Recrystallization in Nickel-Based Single-Crystal Superalloys. Materials. 2025; 18(14):3341. https://doi.org/10.3390/ma18143341

Chicago/Turabian StyleHu, Xing, Fuze Xu, Menglin Gao, Shengjun Xia, Shuaiheng Liang, Chunfa Huang, Dexin Ma, and Qiulin Li. 2025. "An Annealing Strategy for Inhibiting Recrystallization in Nickel-Based Single-Crystal Superalloys" Materials 18, no. 14: 3341. https://doi.org/10.3390/ma18143341

APA StyleHu, X., Xu, F., Gao, M., Xia, S., Liang, S., Huang, C., Ma, D., & Li, Q. (2025). An Annealing Strategy for Inhibiting Recrystallization in Nickel-Based Single-Crystal Superalloys. Materials, 18(14), 3341. https://doi.org/10.3390/ma18143341