Process-Driven Structural and Property Evolution in Laser Powder Bed Fusion of a Newly Developed AISI 316L Stainless Steel

Abstract

1. Introduction

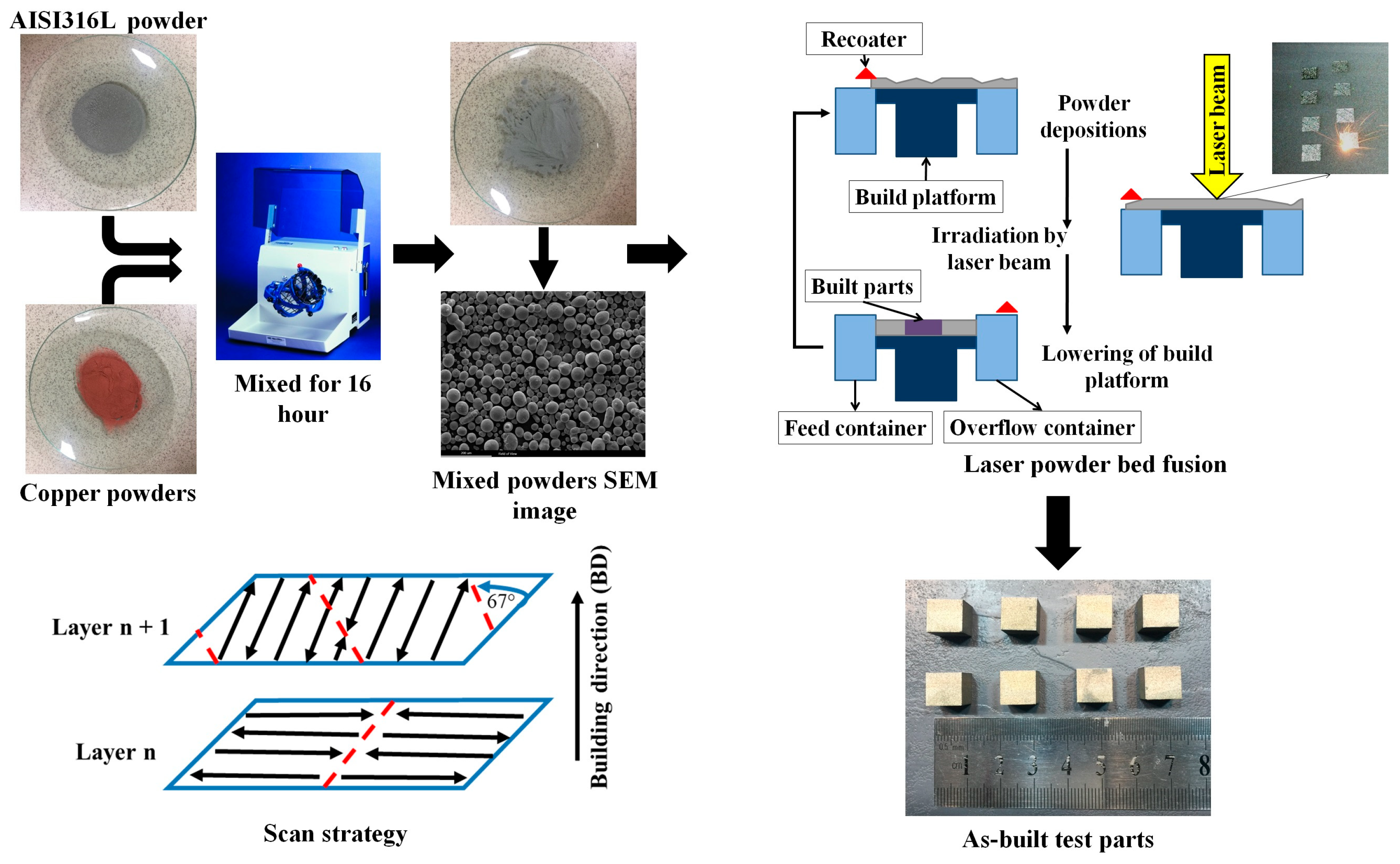

2. Materials and Methods

2.1. Feedstock Preparation

2.2. Sample Production

2.3. Materials Characterization

3. Results and Discussion

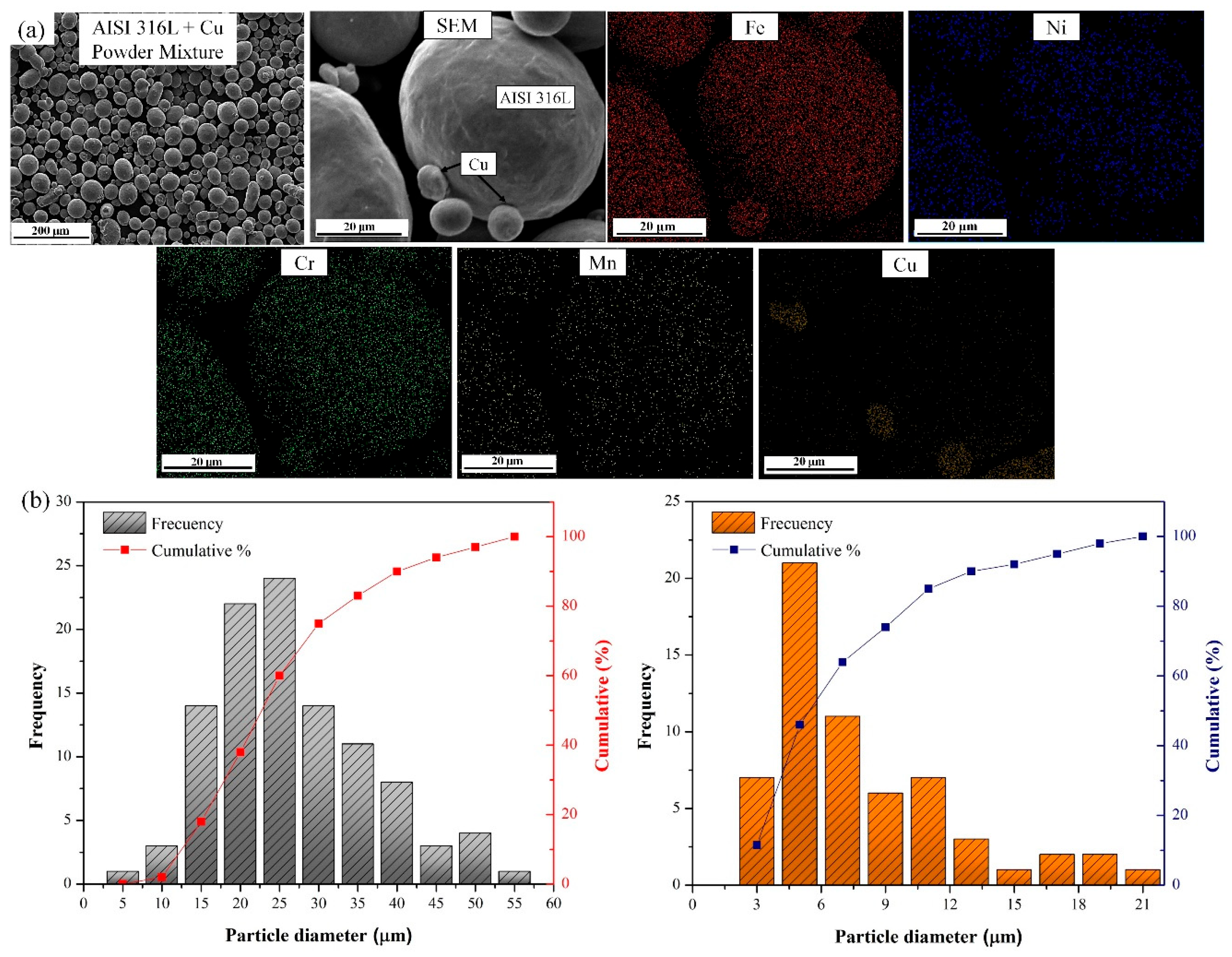

3.1. Powder Characterization

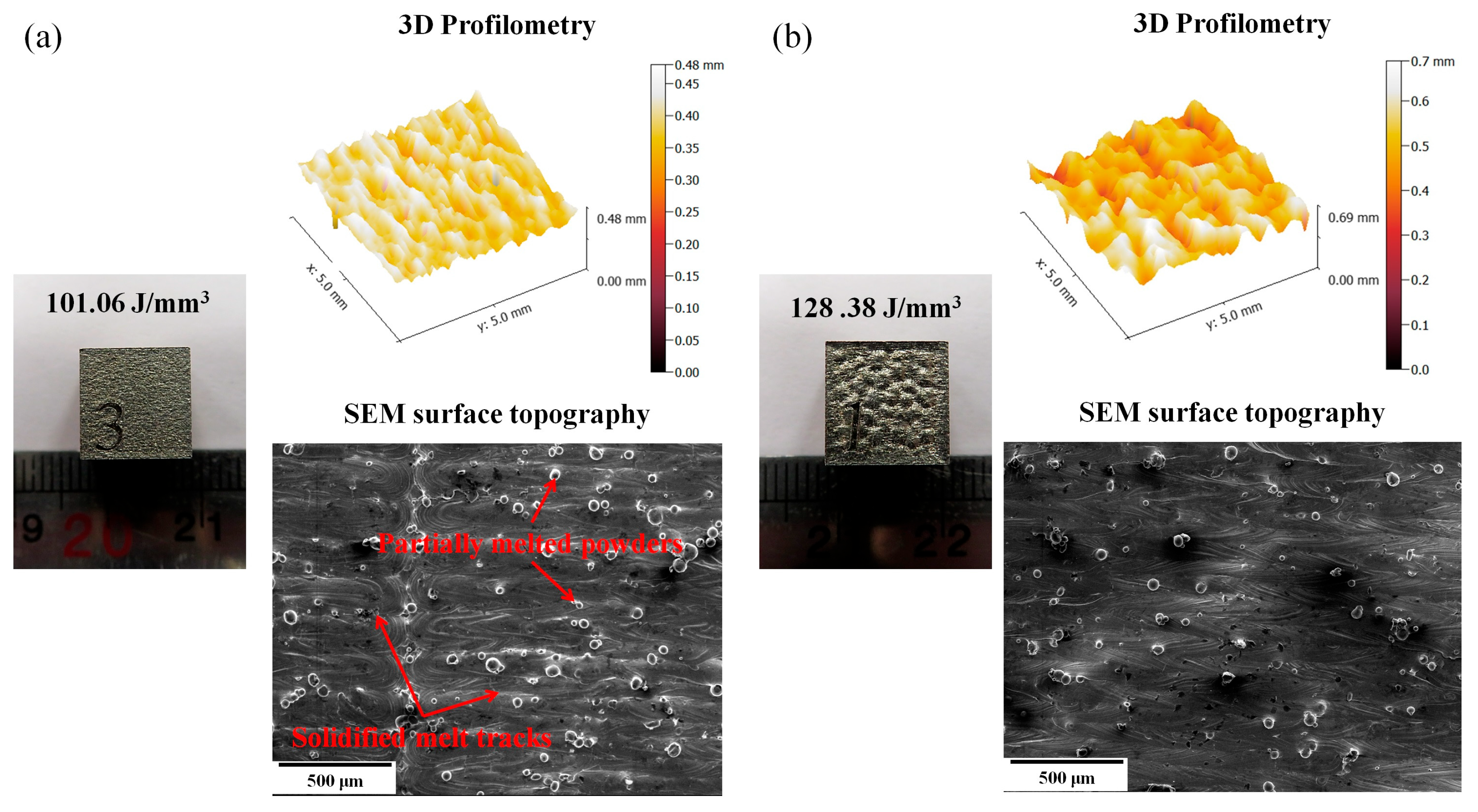

3.2. As-Built Quality Evaluation

3.3. Microstructural Characterization

4. Conclusions

- The feasibility of in situ alloying of an AISI 316L-Cu alloy utilizing the laser powder bed fusion process from powder mixing was demonstrated.

- The optimum process parameters that can guarantee the lowest porosity fraction, as well as low surface roughness for the newly developed AISI 316L-Cu alloy, were reported.

- The research indicates that the surface roughness is significantly influenced by the VED, with a trend of decreasing surface roughness as VED increases until reaching an optimal surface condition. Subsequent increases in VED beyond this point are found to have a negative impact on the surface quality. Moreover, adjusting the VED values can lead to the fabrication of dense components, as evidenced by creating cubes with a density of 99.71%, achieved by applying a laser energy density of 101 J/mm3.

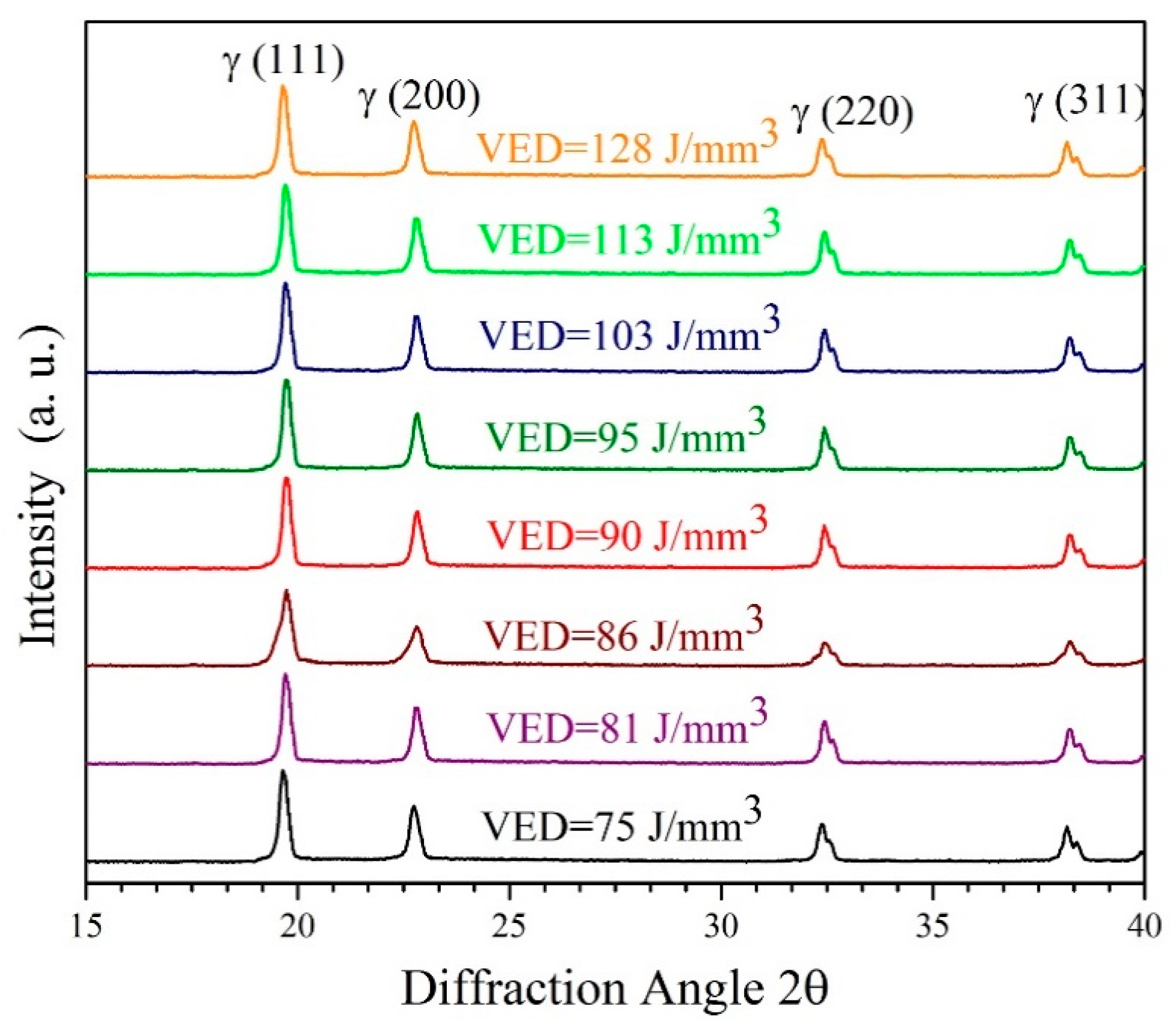

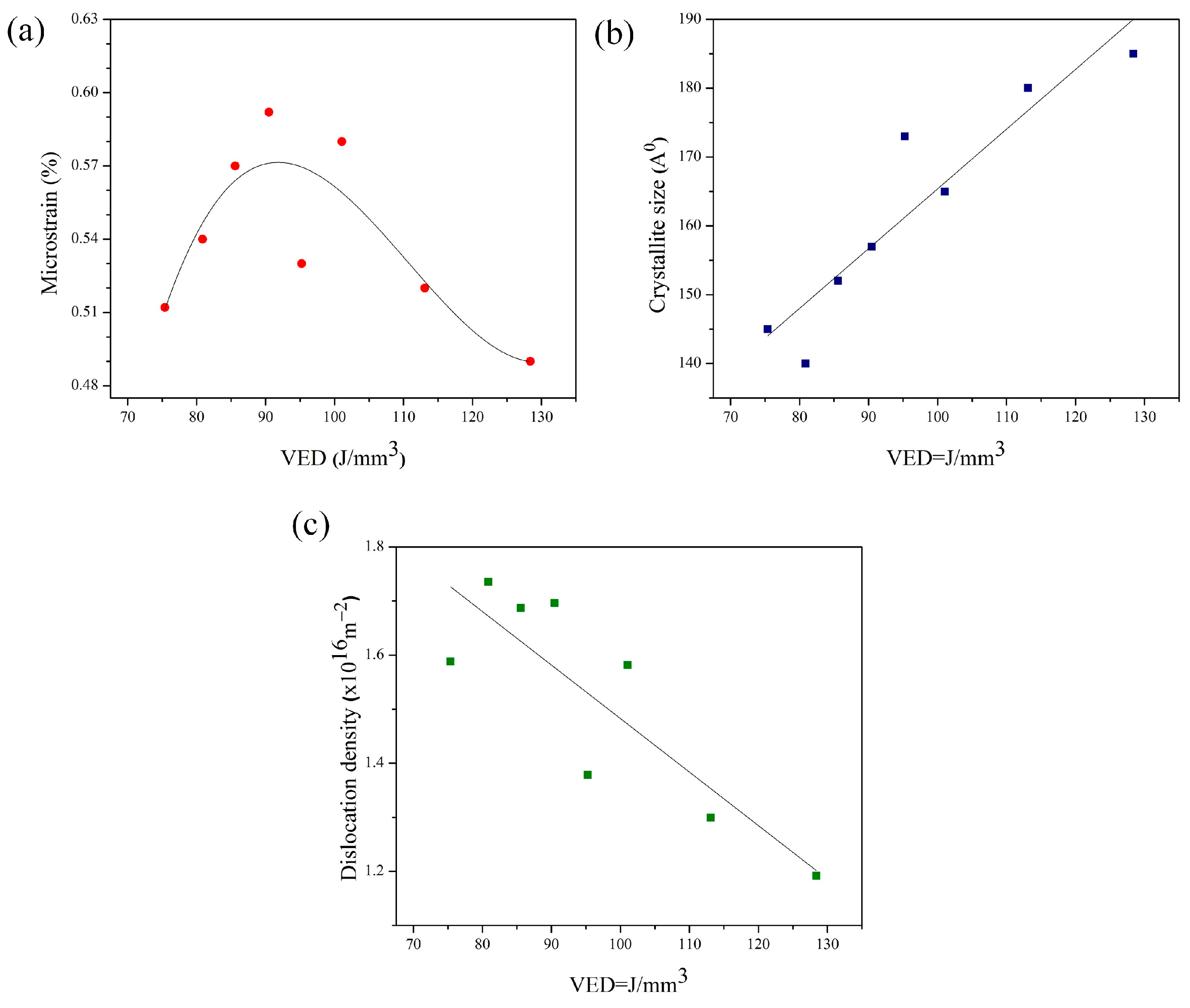

- Based on the XRD results, adding Cu in the present study did not influence the stability of the austenite phase of AISI 316L. The results suggest that increased values of VED lead to more opportunities for dislocation rearrangement and annihilation, resulting in reduced lattice distortion and a gradual increase in crystallite size.

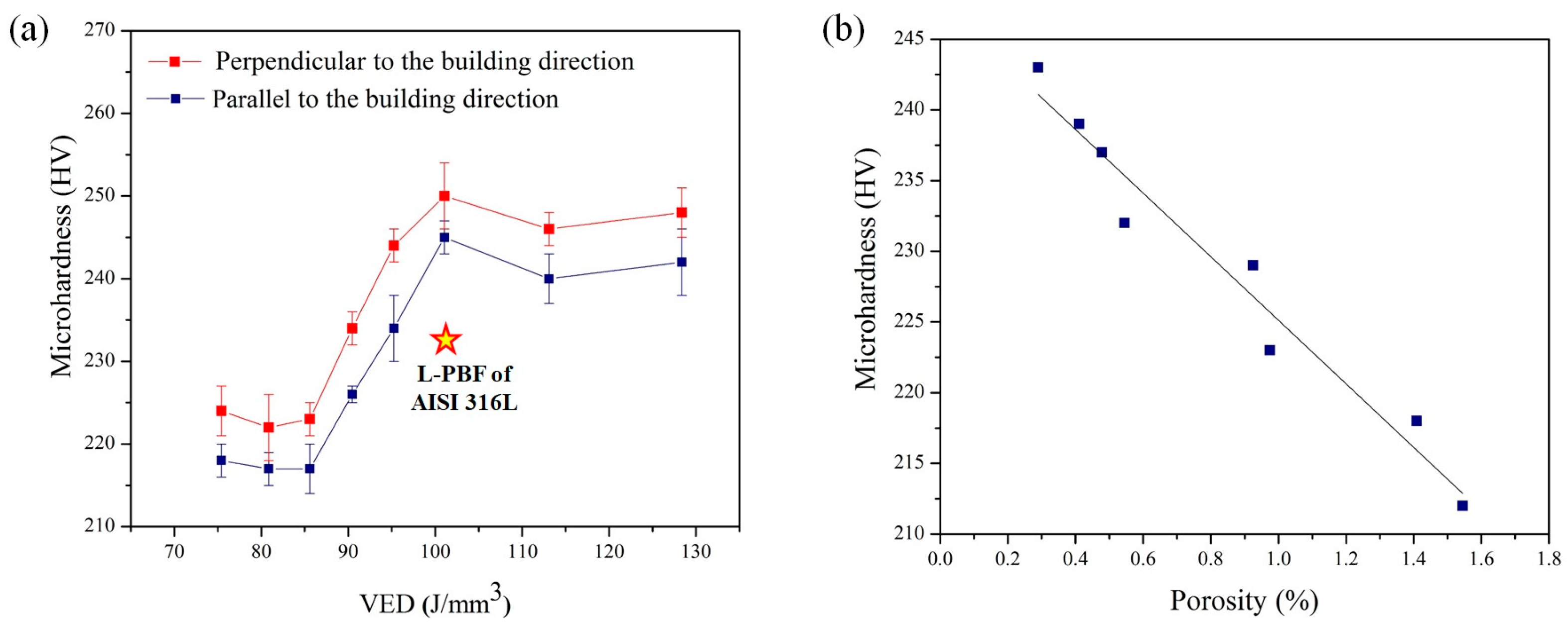

- The microhardness results indicated that increases in porosity and grain size, and decreases in crystal defects led to a reduction in hardness. Moreover, the microhardness of AISI 316L-Cu alloys was higher than that of AISI 316L produced through L-PBF, primarily attributed to the enhanced solid solution strengthening effect resulting from the presence of Cu element.

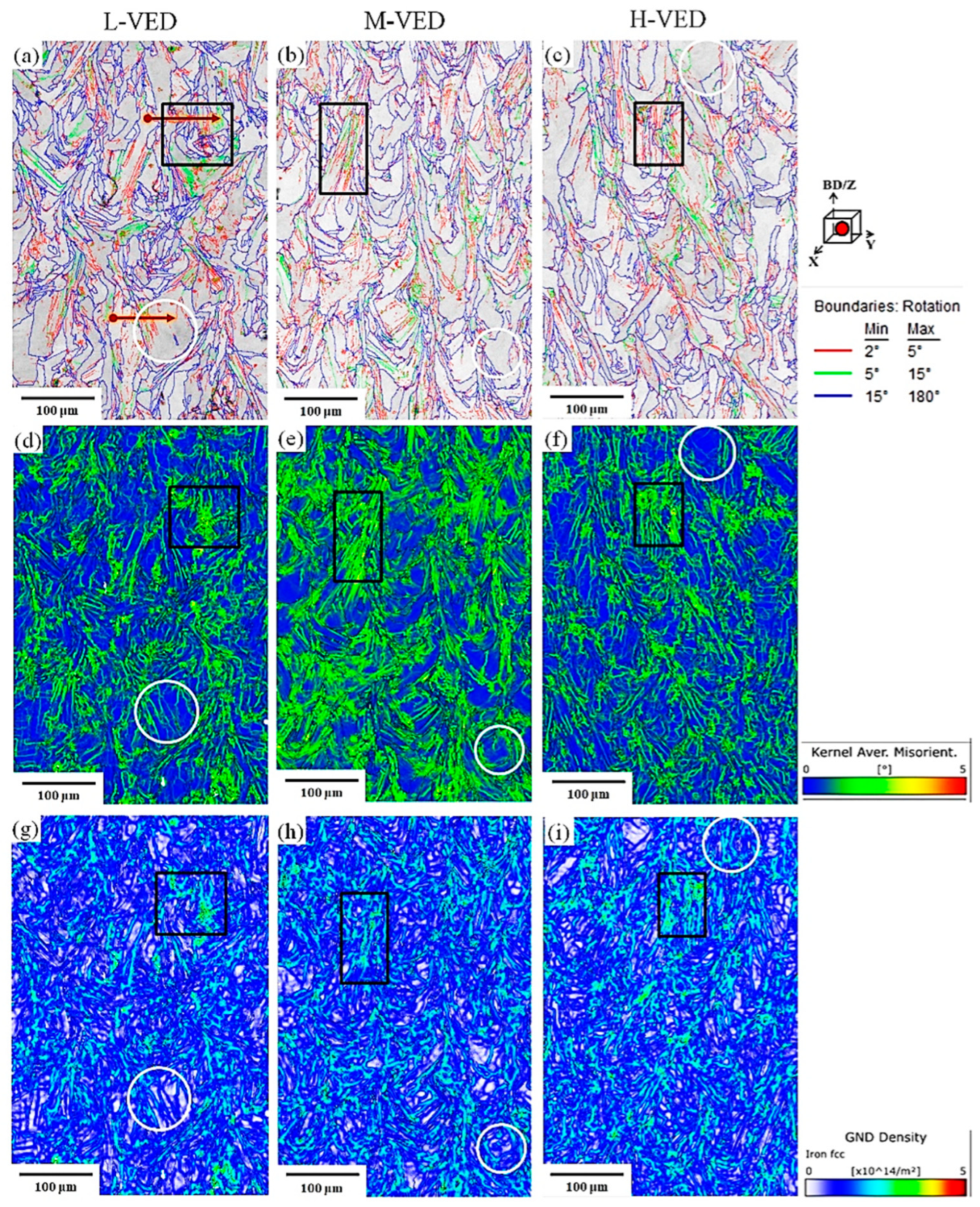

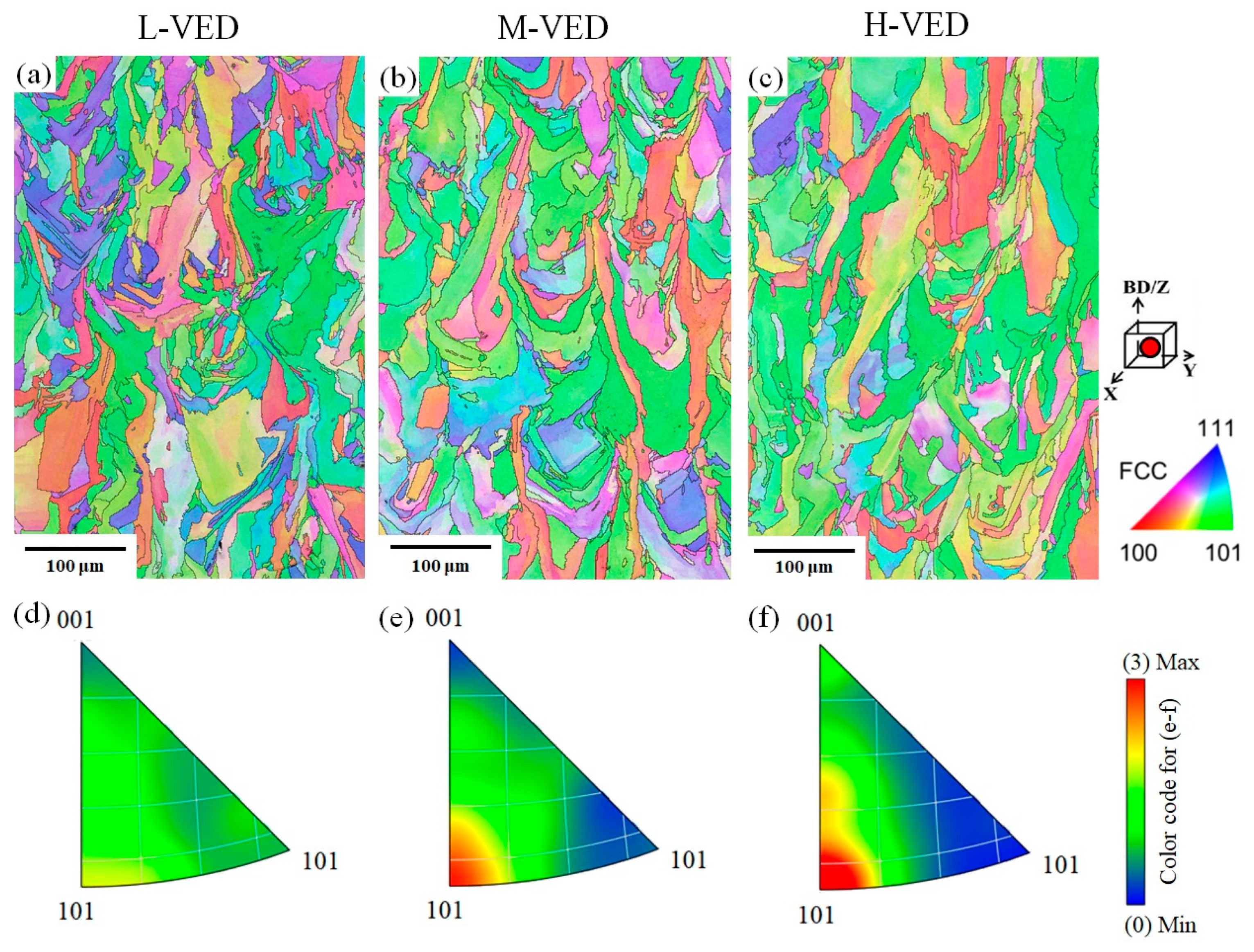

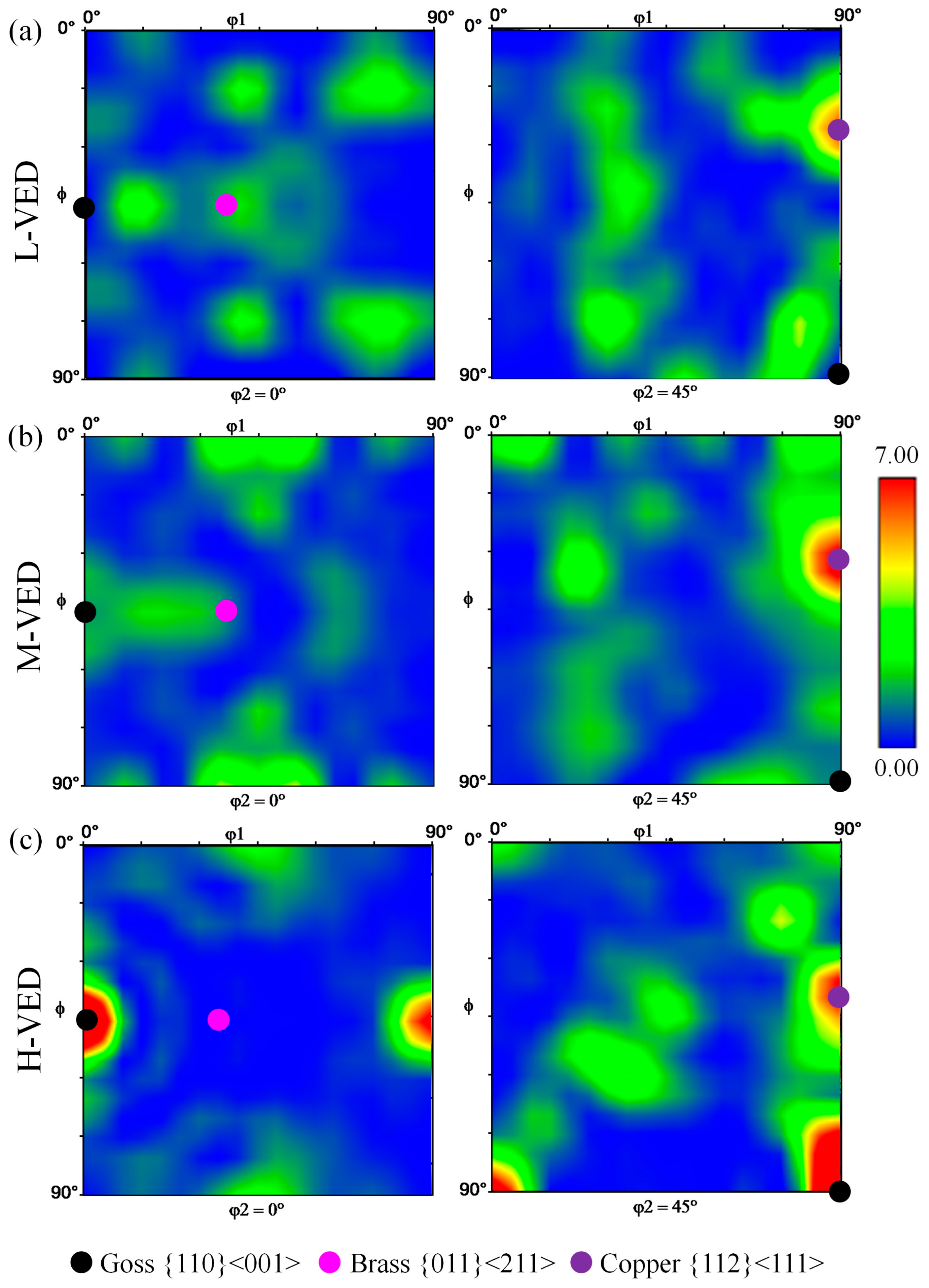

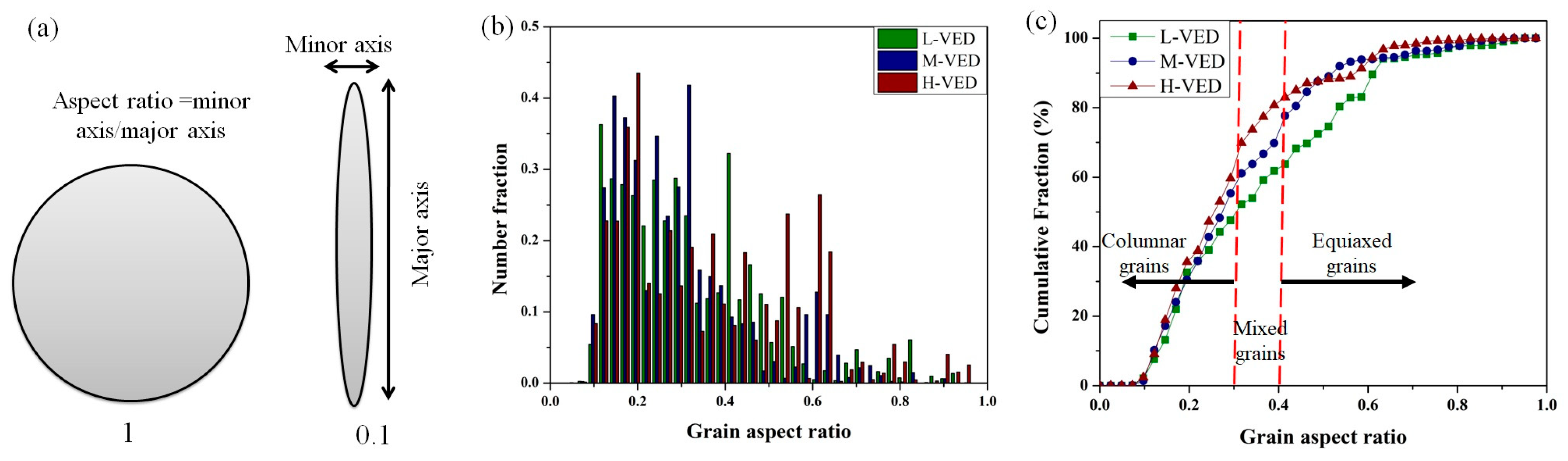

- By integrating the findings from the XRD analysis and EBSD characterization, it can be inferred that increasing VED from L to M and H conditions tends to increase the grain size, reduce the proportion of low-angle boundaries, and decrease local microstrain and dislocation density.

- IPF maps revealed that 〈101〉 ∥ BD texture tends to increase from L to M and H conditions, as evidenced by the increase from 22% to 53% in the fraction of grains orienting at <101> in the BD. The ODF section analysis showed that the Goss texture was enhanced when moving from L to M and H conditions. However, all the samples possessed a strong Copper texture regardless of the conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lo, K.H.; Shek, C.H.; Lai, J.K.L. Recent Developments in Stainless Steels. Mater. Sci. Eng. R Rep. 2009, 65, 39–104. [Google Scholar] [CrossRef]

- Fan, H.; Shi, Q.; Wang, C.; Tian, Y.; Zhou, K.; Yang, S. Laser Powder Bed Fusion of Bimetallic Stainless Steel/Nickel-Based Superalloy: Interface and Mechanical Properties. Mater. Sci. Eng. A 2023, 877, 145193. [Google Scholar] [CrossRef]

- Haghdadi, N.; Laleh, M.; Moyle, M.; Primig, S. Additive Manufacturing of Steels: A Review of Achievements and Challenges. J. Mater. Sci. 2021, 56, 64–107. [Google Scholar] [CrossRef]

- Clare, A.T.; Mishra, R.S.; Merklein, M.; Tan, H.; Todd, I.; Chechik, L.; Li, J.; Bambach, M. Alloy Design and Adaptation for Additive Manufacture. J. Mater. Process. Technol. 2021, 299, 117358. [Google Scholar] [CrossRef]

- de Lima, M.S.F.; Sankaré, S. Microstructure and Mechanical Behavior of Laser Additive Manufactured AISI 316 Stainless Steel Stringers. Mater. Des. 2014, 55, 526–532. [Google Scholar] [CrossRef]

- Nouri, A.; Wen, C. Stainless Steels in Orthopedics. In Structural Biomaterials; Elsevier: Amsterdam, The Netherlands, 2021; pp. 67–101. [Google Scholar]

- Nagesha, B.K.; Dhinakaran, V.; Varsha Shree, M.; Manoj Kumar, K.P.; Chalawadi, D.; Sathish, T. Review on Characterization and Impacts of the Lattice Structure in Additive Manufacturing. Mater. Today Proc. 2020, 21, 916–919. [Google Scholar] [CrossRef]

- Zhong, T.; He, K.; Li, H.; Yang, L. Mechanical Properties of Lightweight 316L Stainless Steel Lattice Structures Fabricated by Selective Laser Melting. Mater. Des. 2019, 181, 108076. [Google Scholar] [CrossRef]

- Davoodi, E.; Montazerian, H.; Mirhakimi, A.S.; Zhianmanesh, M.; Ibhadode, O.; Shahabad, S.I.; Esmaeilizadeh, R.; Sarikhani, E.; Toorandaz, S.; Sarabi, S.A.; et al. Additively Manufactured Metallic Biomaterials. Bioact. Mater. 2022, 15, 214–249. [Google Scholar] [CrossRef] [PubMed]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of Selective Laser Melting: Materials and Applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive Manufacturing of Metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Salman, O.O.; Gammer, C.; Eckert, J.; Salih, M.Z.; Abdulsalam, E.H.; Prashanth, K.G.; Scudino, S. Selective Laser Melting of 316L Stainless Steel: Influence of TiB2 Addition on Microstructure and Mechanical Properties. Mater. Today Commun. 2019, 21, 100615. [Google Scholar] [CrossRef]

- Behjat, A.; Shamanian, M.; Iuliano, L.; Saboori, A. Laser Powder Bed Fusion in Situ Alloying of AISI 316L-2.5%Cu Alloy: Microstructure and Mechanical Properties Evolution. Prog. Addit. Manuf. 2024, 9, 2031–2039. [Google Scholar] [CrossRef]

- Yakout, M.; Elbestawi, M.A.; Veldhuis, S.C. A Review of Metal Additive Manufacturing Technologies. In Proceedings of the Manufacturing Engineering and Process VII; Trans Tech Publications Ltd.: Miami, FL, USA, 2018; Volume 278, pp. 1–14. [Google Scholar]

- Jia, Q.; Gu, D. Selective Laser Melting Additive Manufacturing of Inconel 718 Superalloy Parts: Densification, Microstructure and Properties. J. Alloys Compd. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Aristizabal, M.; Jamshidi, P.; Saboori, A.; Cox, S.C.; Attallah, M.M. Laser Powder Bed Fusion of a Zr-Alloy: Tensile Properties and Biocompatibility. Mater. Lett. 2020, 259, 126897. [Google Scholar] [CrossRef]

- Yue, M.; Liu, Y.; He, G.; Lian, L. Microstructure and Mechanical Performance of Zirconium, Manufactured by Selective Laser Melting. Mater. Sci. Eng. A 2022, 840, 142900. [Google Scholar] [CrossRef]

- Hamidi Nasab, M.; Giussani, A.; Gastaldi, D.; Tirelli, V.; Vedani, M. Effect of Surface and Subsurface Defects on Fatigue Behavior of AlSi10Mg Alloy Processed by Laser Powder Bed Fusion (L-PBF). Metals 2019, 9, 1063. [Google Scholar] [CrossRef]

- Chen, K.; Lu, Q.; Yong, X.; Zhang, P.; Yan, H.; Shi, H. Process Parameter Optimization of SLM AlSi10Mg Based on Box-Behnken Design and Experimental Study on Microstructure and Mechanical Properties. Mater. Today Commun. 2025, 46, 112740. [Google Scholar] [CrossRef]

- Mosallanejad, M.H.; Abdi, A.; Karpasand, F.; Nassiri, N.; Iuliano, L.; Saboori, A. Additive Manufacturing of Titanium Alloys; Processability, Properties and Applications. Adv. Eng. Mater. 2023, 25, 2301122. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Prokoshkin, S. New Biocompatible Near-Beta Ti-Zr-Nb Alloy Processed by Laser Powder Bed Fusion: Process Optimization. J. Mater. Process. Technol. 2018, 252, 821–829. [Google Scholar] [CrossRef]

- Rahmani, R.; Resende, P.R.; Couto, R.; Lopes, S.I.; Kumar, R.; Maurya, H.S.; Karimi, J.; Afonso, A.M.; Hussain, A.; Abrantes, J.C.C. Structural Analysis of Selective Laser Melted Copper-Tin Alloy. J. Alloys Metall. Syst. 2024, 7, 100097. [Google Scholar] [CrossRef]

- Huang, J.; Yan, X.; Chang, C.; Xie, Y.; Ma, W.; Huang, R.; Zhao, R.; Li, S.; Liu, M.; Liao, H. Pure Copper Components Fabricated by Cold Spray (CS) and Selective Laser Melting (SLM) Technology. Surf. Coatings Technol. 2020, 395, 125936. [Google Scholar] [CrossRef]

- Viale, V.; Stavridis, J.; Salmi, A.; Bondioli, F.; Saboori, A. Optimisation of Downskin Parameters to Produce Metallic Parts via Laser Powder Bed Fusion Process: An Overview. Int. J. Adv. Manuf. Technol. 2022, 123, 2159–2182. [Google Scholar] [CrossRef]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the Effect of Process Parameters on Microstructural and Physical Properties of 316L Stainless Steel Parts by Selective Laser Melting. Int. J. Adv. Manuf. Technol. 2015, 76, 869–879. [Google Scholar] [CrossRef]

- Saboori, A.; Toushekhah, M.; Aversa, A.; Lai, M.; Lombardi, M.; Biamino, S.; Fino, P. Critical Features in the Microstructural Analysis of AISI 316L Produced By Metal Additive Manufacturing. Metallogr. Microstruct. Anal. 2020, 9, 92–96. [Google Scholar] [CrossRef]

- Behjat, A.; Shamanian, M.; Taherizadeh, A.; Lannunziata, E.; Bagherifard, S.; Gadalińska, E.; Saboori, A.; Iuliano, L. Microstructure-Electrochemical Behavior Relationship in Post Processed AISI316L Stainless Steel Parts Fabricated by Laser Powder Bed Fusion. J. Mater. Res. Technol. 2023, 23, 3294–3311. [Google Scholar] [CrossRef]

- Nezhadfar, P.D.; Anderson-Wedge, K.; Daniewicz, S.R.; Phan, N.; Shao, S.; Shamsaei, N. Improved High Cycle Fatigue Performance of Additively Manufactured 17-4 PH Stainless Steel via in-Process Refining Micro-/Defect-Structure. Addit. Manuf. 2020, 36, 101604. [Google Scholar] [CrossRef]

- Roy, S.; Silwal, B.; Nycz, A.; Noakes, M.; Cakmak, E.; Nandwana, P.; Yamamoto, Y. Investigating the Effect of Different Shielding Gas Mixtures on Microstructure and Mechanical Properties of 410 Stainless Steel Fabricated via Large Scale Additive Manufacturing. Addit. Manuf. 2021, 38, 101821. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive Manufacturing of Functionally Graded Materials: A Review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Ghanavati, R.; Naffakh-Moosavy, H.; Moradi, M. Additive Manufacturing of Thin-Walled SS316L-IN718 Functionally Graded Materials by Direct Laser Metal Deposition. J. Mater. Res. Technol. 2021, 15, 2673–2685. [Google Scholar] [CrossRef]

- Mosallanejad, M.H.; Niroumand, B.; Aversa, A.; Saboori, A. In-Situ Alloying in Laser-Based Additive Manufacturing Processes: A Critical Review. J. Alloys Compd. 2021, 872, 159567. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Traxel, K.D.; Lang, M.; Juhasz, M.; Eliaz, N.; Bose, S. Alloy Design via Additive Manufacturing: Advantages, Challenges, Applications and Perspectives. Mater. Today 2022, 52, 207–224. [Google Scholar] [CrossRef]

- Behjat, A.; Sanaei, S.; Mosallanejad, M.H.; Atapour, M.; Sheikholeslam, M.; Saboori, A.; Iuliano, L. A Novel Titanium Alloy for Load-Bearing Biomedical Implants: Evaluating the Antibacterial and Biocompatibility of Ti536 Produced via Electron Beam Powder Bed Fusion Additive Manufacturing Process. Biomater. Adv. 2024, 163, 213928. [Google Scholar] [CrossRef] [PubMed]

- Pollock, T.M.; Clarke, A.J.; Babu, S.S. Design and Tailoring of Alloys for Additive Manufacturing. Metall. Mater. Trans. A 2020, 51, 6000–6019. [Google Scholar] [CrossRef]

- Zhai, W.; Zhou, W.; Nai, S.M.L. Grain Refinement of 316L Stainless Steel through In-Situ Alloying with Ti in Additive Manufacturing. Mater. Sci. Eng. A 2022, 840, 142912. [Google Scholar] [CrossRef]

- Quan, J.; Lin, K.; Gu, D. Selective Laser Melting of Silver Submicron Powder Modified 316L Stainless Steel: Influence of Silver Addition on Microstructures and Performances. Powder Technol. 2020, 364, 478–483. [Google Scholar] [CrossRef]

- Yin, X.; Zhai, Q.; Zhang, Q.; Wang, K.; Meng, L.; Ma, Z.; Chen, G.; Wang, S.; Wang, L. Effect of Tungsten Particles on Microstructure and Properties of 316 L Stainless Steel Manufactured by Selective Laser Melting. J. Manuf. Process. 2021, 68, 210–221. [Google Scholar] [CrossRef]

- Tanprayoon, D.; Srisawadi, S.; Sato, Y.; Tsukamoto, M.; Suga, T. Microstructure and Hardness Response of Novel 316L Stainless Steel Composite with TiN Addition Fabricated by SLM. Opt. Laser Technol. 2020, 129, 106238. [Google Scholar] [CrossRef]

- Zhai, W.; Zhou, W.; Nai, S.M.L. Grain Refinement and Strengthening of 316L Stainless Steel through Addition of TiC Nanoparticles and Selective Laser Melting. Mater. Sci. Eng. A 2022, 832, 142460. [Google Scholar] [CrossRef]

- Vukkum, V.B.; Ozdemir, F.; Storck, S.; Gupta, R.K. Corrosion Performance of Feedstock Modified—Additively Manufactured Stainless Steel. Corros. Sci. 2022, 209, 110724. [Google Scholar] [CrossRef]

- Vukkum, V.B.; Christudasjustus, J.; Darwish, A.A.; Storck, S.M.; Gupta, R.K. Enhanced Corrosion Resistance of Additively Manufactured Stainless Steel by Modification of Feedstock. npj Mater. Degrad. 2022, 6, 2. [Google Scholar] [CrossRef]

- Zhang, E.-L.; Fu, S.; Wang, R.-X.; Li, H.-X.; Liu, Y.; Ma, Z.-Q.; Liu, G.-K.; Zhu, C.-S.; Qin, G.-W.; Chen, D.-F. Role of Cu Element in Biomedical Metal Alloy Design. Rare Met. 2019, 38, 476–494. [Google Scholar] [CrossRef]

- Sokkalingam, R.; Åsberg, M.; Krakhmalev, P. In-Situ Alloying of Cu in 316L Stainless Steel by PBF-LB: Influence of Laser Power and Rescanning Strategy. J. Mater. Res. Technol. 2025, 35, 6137–6146. [Google Scholar] [CrossRef]

- Kun, L.; Wang, I.L.; Tam, L.M.; Lo, K.H.; Li, R.; Chan, C.W.; Cristino, V.A.M.; Kwok, C.T. In-Situ Surface Modification and Bulk Alloying of Anti-Bacterial Cu-Bearing Stainless Steel Using Selective Laser Melting. Mater. Des. 2025, 254, 114110. [Google Scholar] [CrossRef]

- Wang, Q.; Ren, L.; Li, X.; Zhang, S.; Sercombe, T.B.; Yang, K. Antimicrobial Cu-Bearing Stainless Steel Scaffolds. Mater. Sci. Eng. C 2016, 68, 519–522. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yang, J.; Yang, H.; Li, K.; Qiu, Y.; Zhang, W.; Zhou, S. Cu-Bearing 316L Stainless Steel Coatings Produced by Laser Melting Deposition: Microstructure and Corrosion Behavior in Simulated Body Fluids. Surf. Coat. Technol. 2021, 428, 127868. [Google Scholar] [CrossRef]

- Mirzababaei, S.; Doddapaneni, V.V.K.; Lee, K.; Paul, G.E.; Pirgazi, H.; Tan, K.-S.; Ertorer, O.; Chang, C.; Paul, B.K.; Pasebani, S. Remarkable Enhancement in Thermal Conductivity of Stainless-Steel Leveraging Metal Composite via Laser Powder Bed Fusion: 316L-Cu Composite. Addit. Manuf. 2023, 70, 103576. [Google Scholar] [CrossRef]

- Behjat, A.; Shamanian, M.; Sadeghi, F.; Iuliano, L.; Saboori, A. Additive Manufacturing of a Novel In-Situ Alloyed AISI316L-Cu Stainless Steel: Microstructure and Antibacterial Properties. Mater. Lett. 2024, 355, 135363. [Google Scholar] [CrossRef]

- ISO 80601-2-12:2023; Medical Electrical Equipment. Part 2-12: Particular Requirements for Basic Safety and Essential Performance of Critical Care Ventilators. ISO: Geneva, Switzerland, 2023.

- Hemmasian Ettefagh, A.; Guo, S.; Raush, J. Corrosion Performance of Additively Manufactured Stainless Steel Parts: A Review. Addit. Manuf. 2021, 37, 101689. [Google Scholar] [CrossRef]

- Laleh, M.; Hughes, A.E.; Xu, W.; Gibson, I.; Tan, M.Y.; Laleh, M.; Hughes, A.E.; Xu, W.; Gibson, I.; Tan, M.Y. A Critical Review of Corrosion Characteristics of Additively Manufactured Stainless Steels. Int. Mater. Rev. 2020, 66, 563–599. [Google Scholar] [CrossRef]

- Sander, G.; Tan, J.; Balan, P.; Gharbi, O.; Feenstra, D.R.; Singer, L.; Thomas, S.; Kelly, R.G.; Scully, J.R.; Birbilis, N. Corrosion of Additively Manufactured Alloys: A Review. Corrosion 2018, 9312, 1318–1350. [Google Scholar] [CrossRef] [PubMed]

- Vukkum, V.B.; Gupta, R.K. Review on Corrosion Performance of Laser Powder-Bed Fusion Printed 316L Stainless Steel: Effect of Processing Parameters, Manufacturing Defects, Post-Processing, Feedstock, and Microstructure. Mater. Des. 2022, 221, 110874. [Google Scholar] [CrossRef]

- Choo, H.; Sham, K.-L.; Bohling, J.; Ngo, A.; Xiao, X.; Ren, Y.; Depond, P.J.; Matthews, M.J.; Garlea, E. Effect of Laser Power on Defect, Texture, and Microstructure of a Laser Powder Bed Fusion Processed 316L Stainless Steel. Mater. Des. 2019, 164, 107534. [Google Scholar] [CrossRef]

- Ahmed, M.; Uı, M.; Raghavendra, R.; Conway, A.; Souto, C.; Tormey, D. Comparison of the Porosity and Mechanical Performance of 316L Stainless Steel Manufactured on Different Laser Powder Bed Fusion Metal Additive Manufacturing Machines. J. Mater. Res. Technol. 2021, 13, 2361–2374. [Google Scholar] [CrossRef]

- Kan, W.H.; Chiu, L.N.S.; Lim, C.V.S.; Zhu, Y.; Tian, Y.; Jiang, D.; Huang, A. A Critical Review on the Effects of Process-Induced Porosity on the Mechanical Properties of Alloys Fabricated by Laser Powder Bed Fusion. J. Mater. Sci. 2022, 57, 9818–9865. [Google Scholar] [CrossRef]

- Chowdhury, S.; Yadaiah, N.; Prakash, C.; Ramakrishna, S.; Dixit, S.; Gupta, L.R.; Buddhi, D. Laser Powder Bed Fusion: A State-of-the-Art Review of the Technology, Materials, Properties & Defects, and Numerical Modelling. J. Mater. Res. Technol. 2022, 20, 2109–2172. [Google Scholar] [CrossRef]

- Taha, M.A.; Yousef, A.F.; Gany, K.A.; Sabour, H.A. On Selective Laser Melting of Ultra High Carbon Steel: Effect of Scan Speed and Post Heat Treatment. Materwiss. Werksttech. 2012, 43, 913–923. [Google Scholar] [CrossRef]

- Cacace, S.; Pagani, L.; Colosimo, B.M.; Semeraro, Q. The Effect of Energy Density and Porosity Structure on Tensile Properties of 316L Stainless Steel Produced by Laser Powder Bed Fusion. Prog. Addit. Manuf. 2022, 7, 1053–1070. [Google Scholar] [CrossRef]

- Hao, L.; Dadbakhsh, S.; Seaman, O.; Felstead, M. Selective Laser Melting of a Stainless Steel and Hydroxyapatite Composite for Load-Bearing Implant Development. J. Mater. Process. Technol. 2009, 209, 5793–5801. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Unal, O.; Bandini, M.; Farrahi, G.H.; Guagliano, M. Introducing Gradient Severe Shot Peening as a Novel Mechanical Surface Treatment. Sci. Rep. 2021, 11, 22035. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Dong, M.; Zhou, Z.; Sun, X.; Kikuchi, K.; Nomura, N.; Kawasaki, A. In Situ Formation of Uniformly Dispersed Al4C3 Nanorods during Additive Manufacturing of Graphene Oxide/Al Mixed Powders. Carbon N. Y. 2019, 141, 67–75. [Google Scholar] [CrossRef]

- Simson, T.; Emmel, A.; Dwars, A.; Böhm, J. Residual Stress Measurements on AISI 316L Samples Manufactured by Selective Laser Melting. Addit. Manuf. 2017, 17, 183–189. [Google Scholar] [CrossRef]

- Xi, T.; Shahzad, M.B.; Xu, D.; Sun, Z.; Zhao, J.; Yang, C.; Qi, M.; Yang, K. Effect of Copper Addition on Mechanical Properties, Corrosion Resistance and Antibacterial Property of 316L Stainless Steel. Mater. Sci. Eng. C 2017, 71, 1079–1085. [Google Scholar] [CrossRef] [PubMed]

- Ma, M.; Wang, Z.; Zeng, X. A Comparison on Metallurgical Behaviors of 316L Stainless Steel by Selective Laser Melting and Laser Cladding Deposition. Mater. Sci. Eng. A 2017, 685, 265–273. [Google Scholar] [CrossRef]

- Todaro, C.J.; Easton, M.A.; Qiu, D.; Brandt, M.; StJohn, D.H.; Qian, M. Grain Refinement of Stainless Steel in Ultrasound-Assisted Additive Manufacturing. Addit. Manuf. 2021, 37, 101632. [Google Scholar] [CrossRef]

- Leicht, A.; Yu, C.H.; Luzin, V.; Klement, U.; Hryha, E. Effect of Scan Rotation on the Microstructure Development and Mechanical Properties of 316L Parts Produced by Laser Powder Bed Fusion. Mater. Charact. 2020, 163, 110309. [Google Scholar] [CrossRef]

- Dépinoy, S. Influence of Solidification Conditions on Chemical Heterogeneities and Dislocations Patterning in Additively Manufactured 316L Stainless Steel. Materialia 2022, 24, 101472. [Google Scholar] [CrossRef]

- de Sonis, E.; Dépinoy, S.; Giroux, P.-F.; Maskrot, H.; Lemarquis, L.; Hercher, O.; Villaret, F.; Gourgues-Lorenzon, A.-F. Dependency of Recrystallization Kinetics on the Solidification Microstructure of 316L Stainless Steel Processed by Laser Powder Bed Fusion (LPBF). Mater. Charact. 2022, 194, 112370. [Google Scholar] [CrossRef]

- Sabzi, H.E.; Aboulkhair, N.T.; Liang, X.; Li, X.-H.; Simonelli, M.; Fu, H.; Rivera-Díaz-del-Castillo, P.E.J. Grain Refinement in Laser Powder Bed Fusion: The Influence of Dynamic Recrystallization and Recovery. Mater. Des. 2020, 196, 109181. [Google Scholar] [CrossRef]

- Pinto, F.C.; Aota, L.S.; Souza Filho, I.R.; Raabe, D.; Sandim, H.R.Z. Recrystallization in Non-Conventional Microstructures of 316L Stainless Steel Produced via Laser Powder-Bed Fusion: Effect of Particle Coarsening Kinetics. J. Mater. Sci. 2022, 57, 9576–9598. [Google Scholar] [CrossRef]

- Wei, H.L.; Mazumder, J.; DebRoy, T. Evolution of Solidification Texture during Additive Manufacturing. Sci. Rep. 2015, 5, 16446. [Google Scholar] [CrossRef] [PubMed]

- Kumar, D.; Shankar, G.; Prashanth, K.G.; Suwas, S. Control of Texture and Microstructure in Additive Manufacturing of Stainless Steel 316 L. J. Alloys Compd. 2024, 976, 173040. [Google Scholar] [CrossRef]

- Cobbinah, P.V.; Matsunaga, S.; Yamabe-Mitarai, Y. Controlled Crystallographic Texture Orientation in Structural Materials Using the Laser Powder Bed Fusion Process—A Review. Adv. Eng. Mater. 2023, 25, 2300819. [Google Scholar] [CrossRef]

- Wang, X.; Muñiz-Lerma, J.A.; Attarian Shandiz, M.; Sanchez-Mata, O.; Brochu, M. Crystallographic-Orientation-Dependent Tensile Behaviours of Stainless Steel 316L Fabricated by Laser Powder Bed Fusion. Mater. Sci. Eng. A 2019, 766, 138395. [Google Scholar] [CrossRef]

- Marattukalam, J.J.; Karlsson, D.; Pacheco, V.; Beran, P.; Wiklund, U.; Jansson, U.; Hjörvarsson, B.; Sahlberg, M. The Effect of Laser Scanning Strategies on Texture, Mechanical Properties, and Site-Specific Grain Orientation in Selective Laser Melted 316L SS. Mater. Des. 2020, 193, 108852. [Google Scholar] [CrossRef]

- Niendorf, T.; Leuders, S.; Riemer, A.; Richard, H.A.; Tröster, T.; Schwarze, D. Highly Anisotropic Steel Processed by Selective Laser Melting. Metall. Mater. Trans. B 2013, 44, 794–796. [Google Scholar] [CrossRef]

- Sun, S.-H.; Ishimoto, T.; Hagihara, K.; Tsutsumi, Y.; Hanawa, T.; Nakano, T. Excellent Mechanical and Corrosion Properties of Austenitic Stainless Steel with a Unique Crystallographic Lamellar Microstructure via Selective Laser Melting. Scr. Mater. 2019, 159, 89–93. [Google Scholar] [CrossRef]

- Zhang, P.; Han, W.; Huang, Z.; Li, G.; Zhang, M. Microstructure Evolution and Corrosion Behavior of 316L Stainless Steel Subjected to Torsion Microstructure Evolution and Corrosion Behavior of 316L Stainless Steel Subjected to Torsion. Mater. Res. Express 2021, 8, 086519. [Google Scholar] [CrossRef]

- Coen, V.; Goossens, L.; Hooreweder, B. Van Methodology and Experimental Validation of Analytical Melt Pool Models for Laser Powder Bed Fusion. J. Mater. Process. Technol. 2022, 304, 117547. [Google Scholar] [CrossRef]

- Hagihara, K.; Nakano, T. Control of Anisotropic Crystallographic Texture in Powder Bed Fusion Additive Manufacturing of Metals and Ceramics—A Review. JOM 2021, 74, 1760–1773. [Google Scholar] [CrossRef]

- Charmi, A.; Falkenberg, R.; Ávila, L.; Mohr, G.; Sommer, K.; Ulbricht, A.; Sprengel, M.; Saliwan Neumann, R.; Skrotzki, B.; Evans, A. Mechanical Anisotropy of Additively Manufactured Stainless Steel 316L: An Experimental and Numerical Study. Mater. Sci. Eng. A 2021, 799, 140154. [Google Scholar] [CrossRef]

- Leffers, T.; Ray, R.K. The Brass-Type Texture and Its Deviation from the Copper-Type Texture. Prog. Mater. Sci. 2009, 54, 351–396. [Google Scholar] [CrossRef]

- Aota, L.S.; Bajaj, P.; Zilnyk, K.D.; Jägle, E.A.; Ponge, D.; Sandim, H.R.Z.; Raabe, D. Recrystallization Kinetics, Mechanisms, and Topology in Alloys Processed by Laser Powder-Bed Fusion: AISI 316L Stainless Steel as Example. Materialia 2021, 20, 101236. [Google Scholar] [CrossRef]

- Pham, M.-S.; Dovgyy, B.; Hooper, P.A.; Gourlay, C.M.; Piglione, A. The Role of Side-Branching in Microstructure Development in Laser Powder-Bed Fusion. Nat. Commun. 2020, 11, 749. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Wang, X.; Yang, X.; Yang, X.; Zhang, Z.; Dai, R.; Gu, J.; Zhang, T.; Wu, G.; Gong, J. An Integrated Simulation Approach for Directing the Texture Control of Austenitic Stainless Steel through Laser Beam Powder Bed Fusion. J. Mater. Process. Technol. 2025, 336, 118707. [Google Scholar] [CrossRef]

- Kumar, D.; Shankar, G.; Prashanth, K.G.; Suwas, S. Texture Dependent Strain Hardening in Additively Manufactured Stainless Steel 316L. Mater. Sci. Eng. A 2021, 820, 141483. [Google Scholar] [CrossRef]

- Biscuola, V.B.; Martorano, M.A. Mechanical Blocking Mechanism for the Columnar to Equiaxed Transition. Metall. Mater. Trans. A 2008, 39, 2885–2895. [Google Scholar] [CrossRef]

| Elements | Cr | Ni | Mo | Cu | C | Mn | Si | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| AISI 316L-Cu (wt. %) | 17.72 | 12.50 | 2.04 | 3.42 | 0.02 | 2.21 | 0.48 | 0.022 | 0.01 | Bal. |

| Sample No. | P [W] | h [mm] | v [mm/s] | t [mm] | VED [J·mm−3] |

|---|---|---|---|---|---|

| 1 | 95 | 0.074 | 400 | 0.025 | 128.38 |

| 2 | 0.084 | 400 | 113.10 | ||

| 3 | 0.094 | 400 | 101.06 | ||

| 4 | 0.084 | 475 | 95.24 | ||

| 5 | 0.084 | 500 | 90.48 | ||

| 6 | 0.074 | 600 | 85.59 | ||

| 7 | 0.094 | 500 | 80.85 | ||

| 8 | 0.084 | 600 | 75.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Behjat, A.; Shamanian, M.; Sadeghi, F.; Mosallanejad, M.H.; Saboori, A. Process-Driven Structural and Property Evolution in Laser Powder Bed Fusion of a Newly Developed AISI 316L Stainless Steel. Materials 2025, 18, 3343. https://doi.org/10.3390/ma18143343

Behjat A, Shamanian M, Sadeghi F, Mosallanejad MH, Saboori A. Process-Driven Structural and Property Evolution in Laser Powder Bed Fusion of a Newly Developed AISI 316L Stainless Steel. Materials. 2025; 18(14):3343. https://doi.org/10.3390/ma18143343

Chicago/Turabian StyleBehjat, Amir, Morteza Shamanian, Fazlollah Sadeghi, Mohammad Hossein Mosallanejad, and Abdollah Saboori. 2025. "Process-Driven Structural and Property Evolution in Laser Powder Bed Fusion of a Newly Developed AISI 316L Stainless Steel" Materials 18, no. 14: 3343. https://doi.org/10.3390/ma18143343

APA StyleBehjat, A., Shamanian, M., Sadeghi, F., Mosallanejad, M. H., & Saboori, A. (2025). Process-Driven Structural and Property Evolution in Laser Powder Bed Fusion of a Newly Developed AISI 316L Stainless Steel. Materials, 18(14), 3343. https://doi.org/10.3390/ma18143343