Performance Evolution and Prediction Model of Dam Polyurethane Insulation Materials Under Multi-Field Coupling Conditions in Hot Summer and Cold Winter Climate Zones

Abstract

1. Introduction

2. Experiment

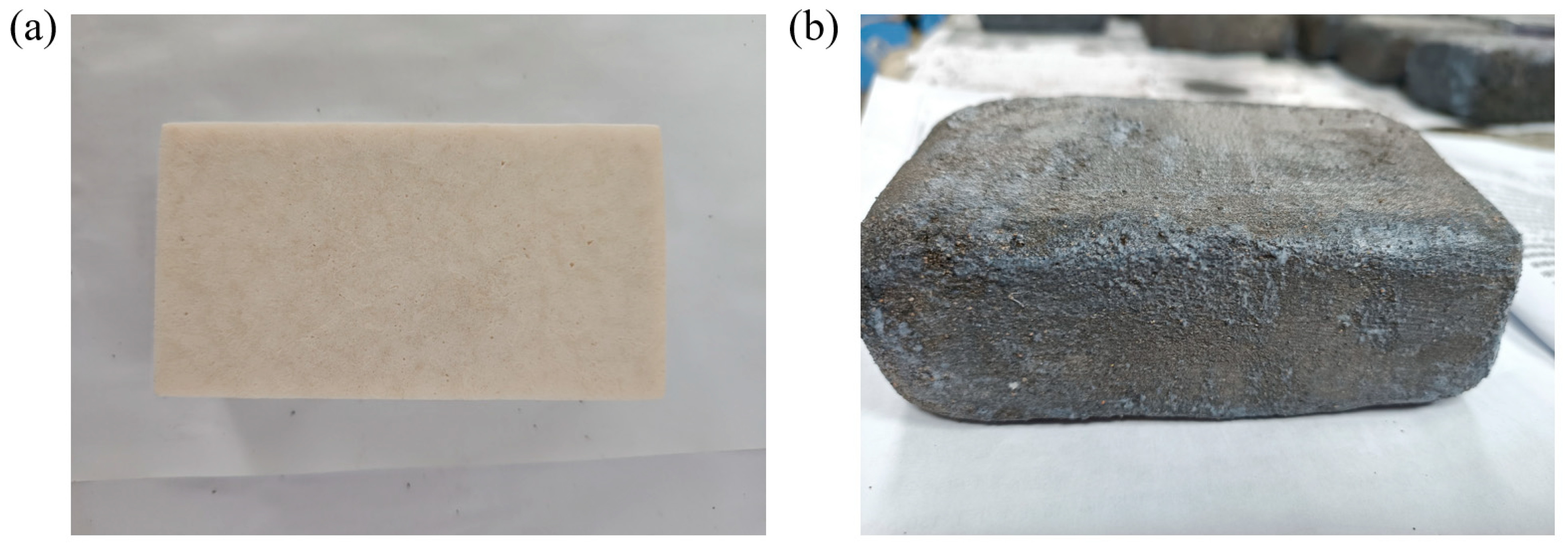

2.1. Experimental Materials

2.2. Experimental Methods and Equipment

3. Analysis of Experimental Results

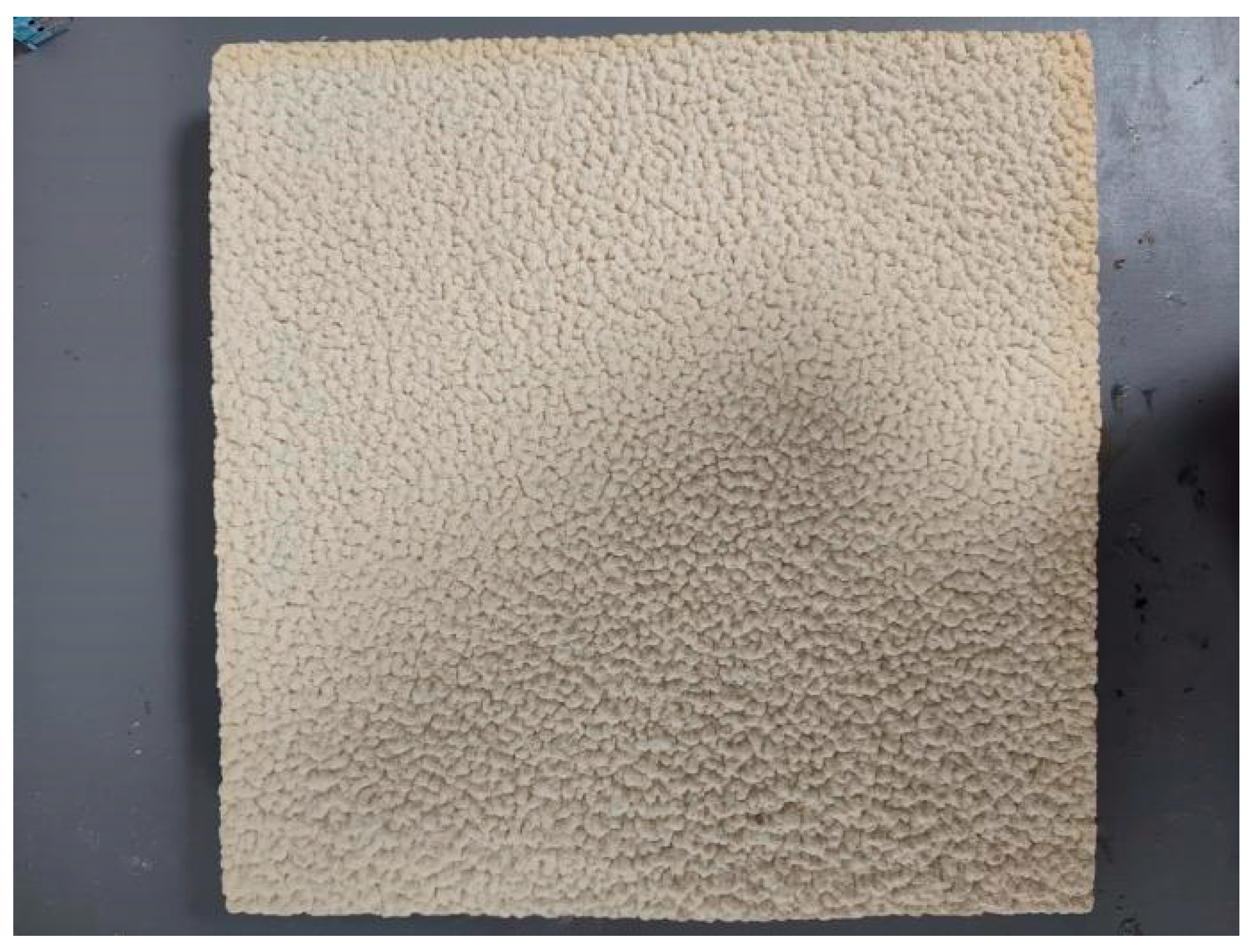

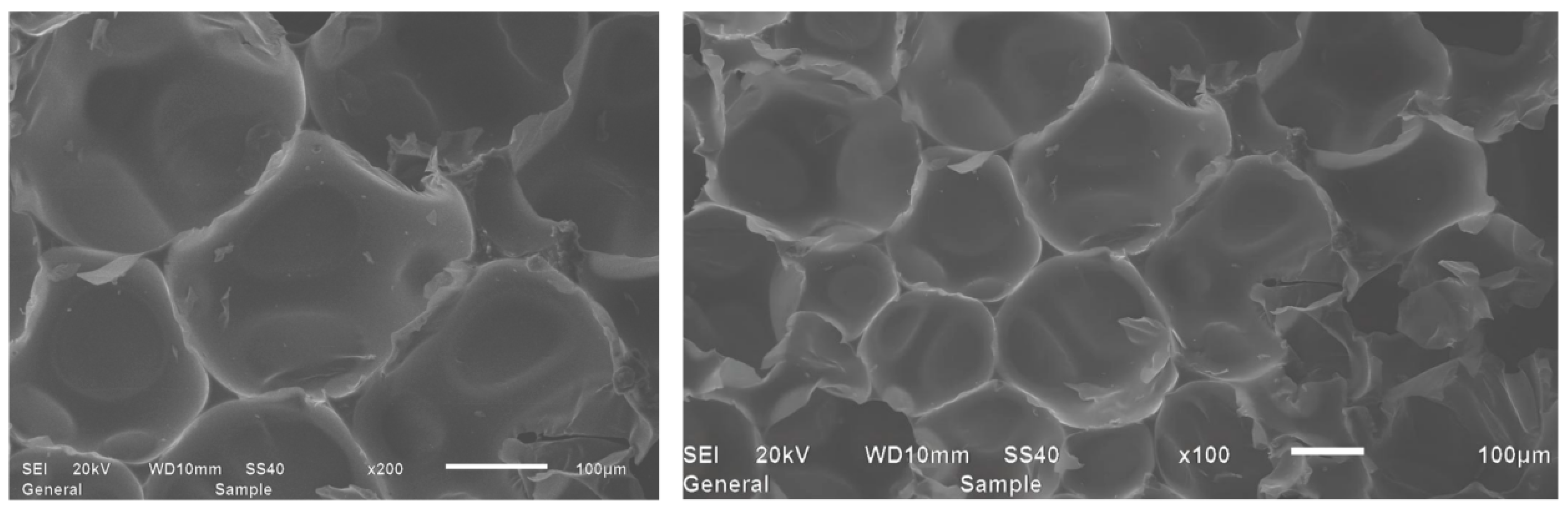

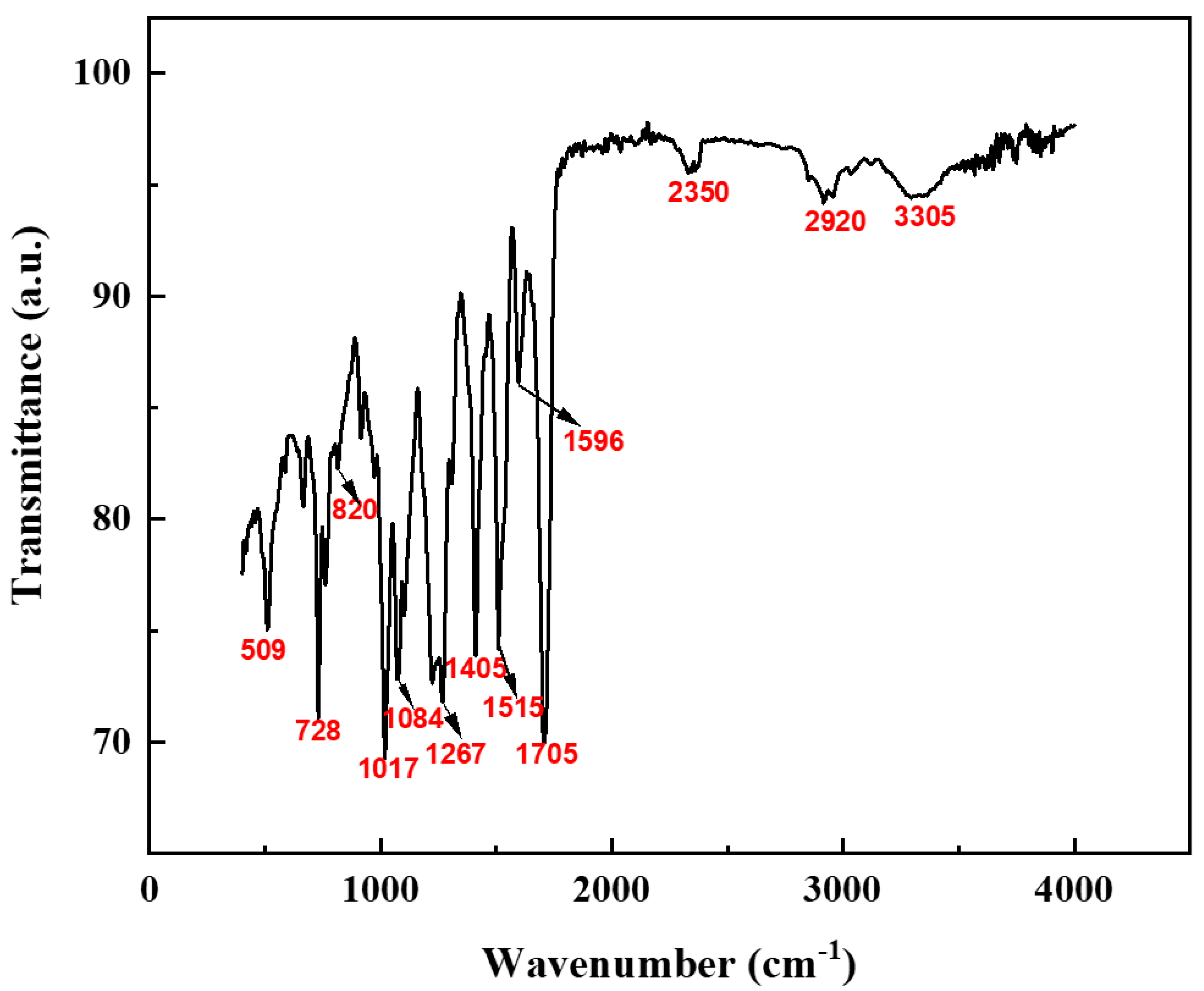

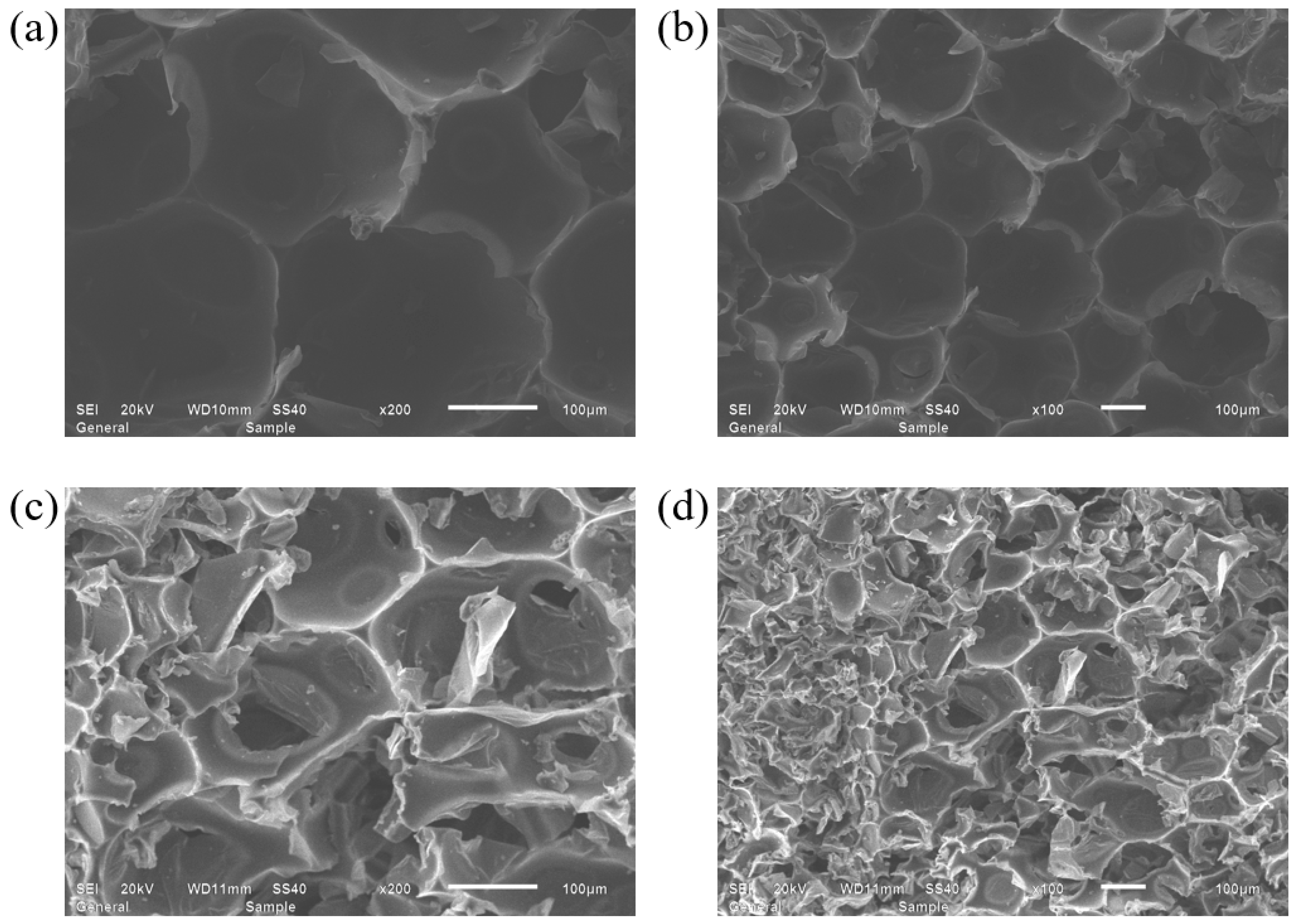

3.1. Microstructure and Morphological Characterization of Original Spray RPUF

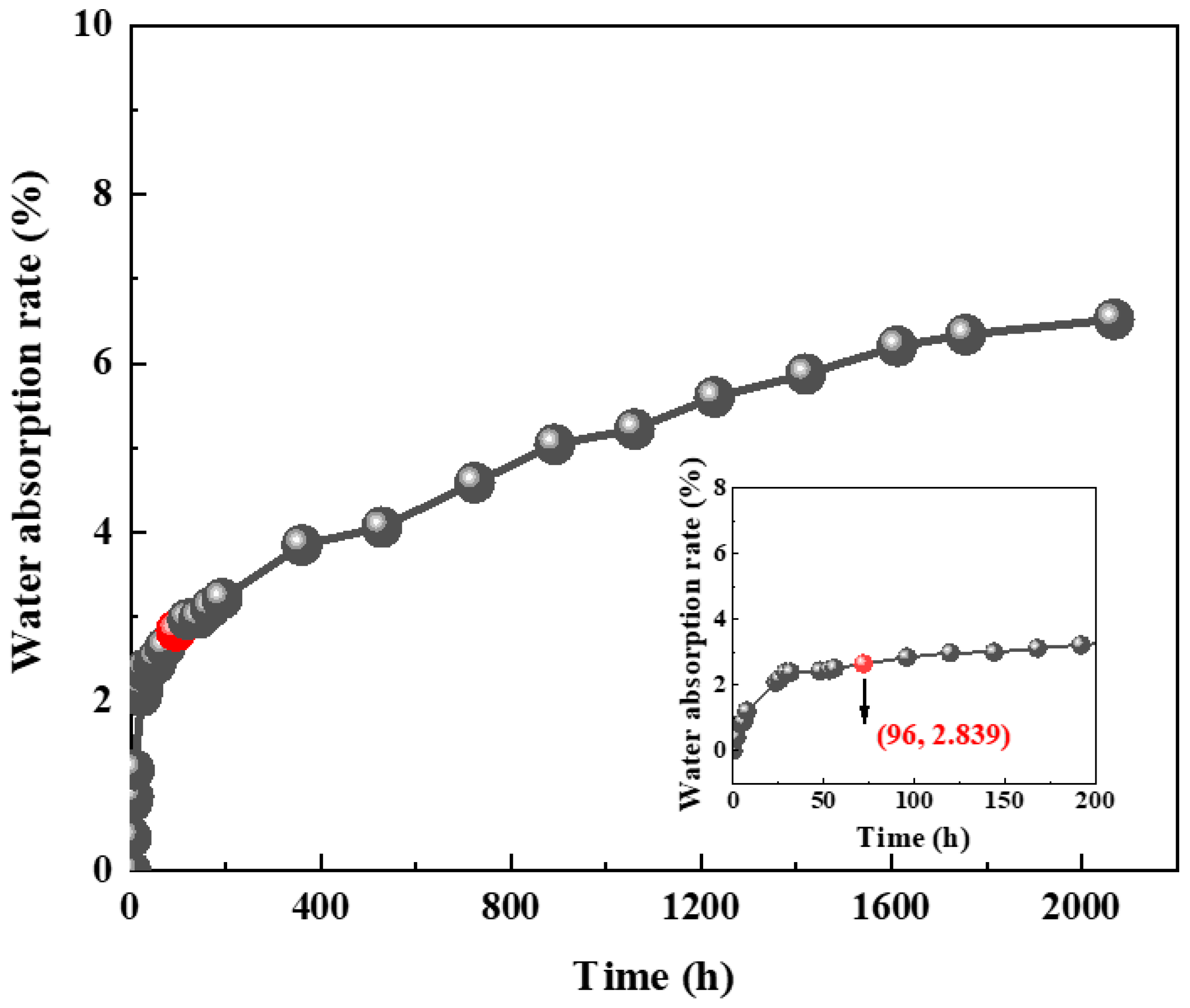

3.2. Water Absorption Characteristics of Original Spray RPUF

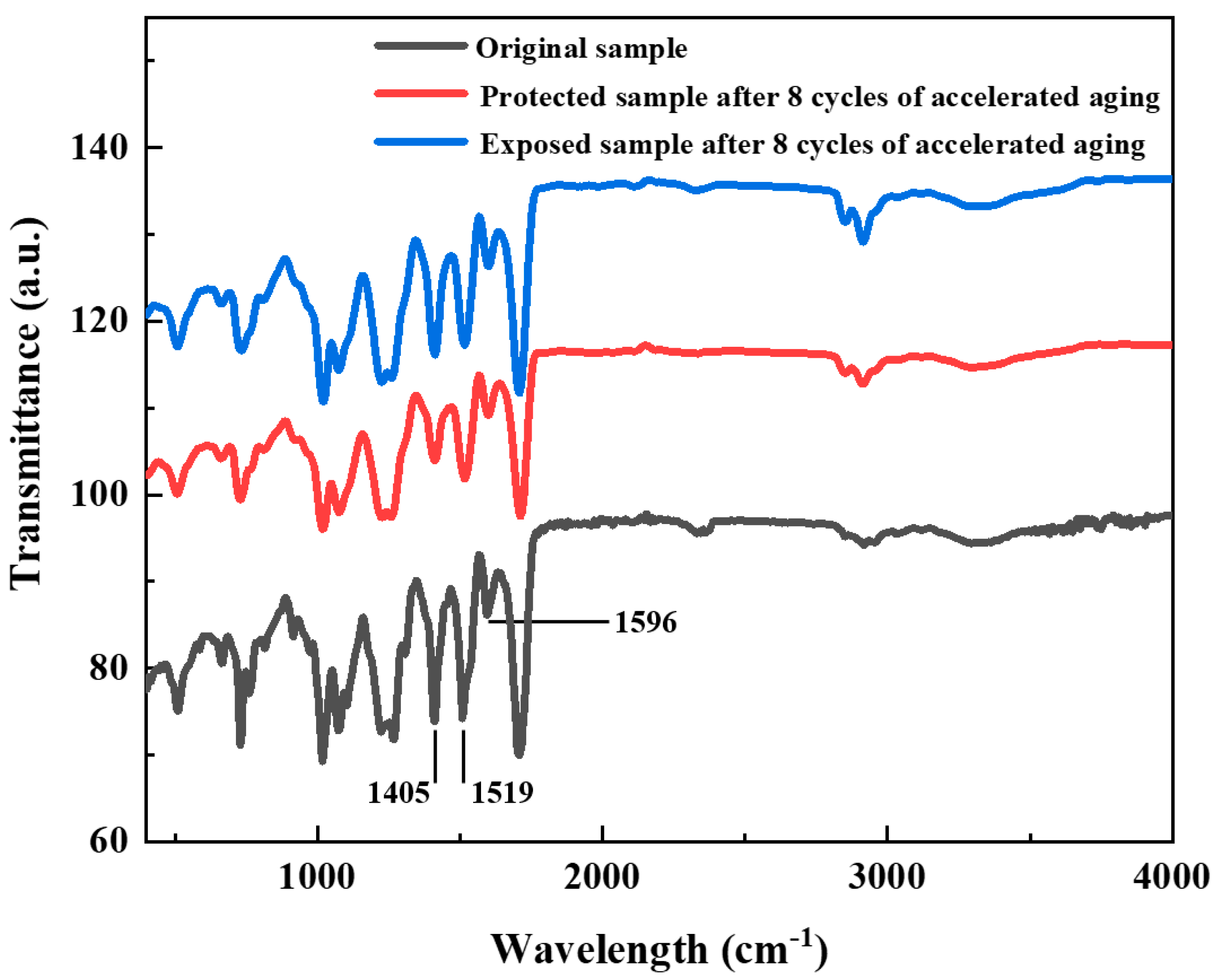

3.3. Analysis of Indoor Accelerated Aging Test Results

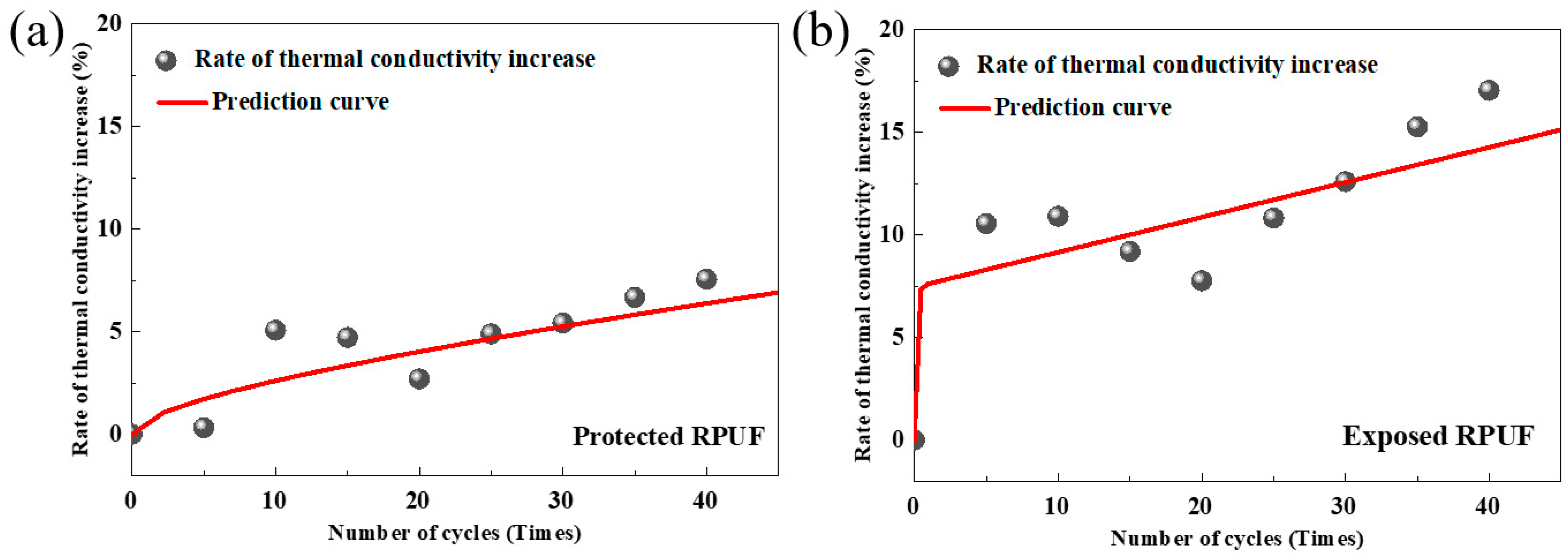

3.4. Time-Dependent Prediction Model for Thermal Conductivity of RPUF in Different States

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, P.; Du, B.; Liu, G.; Xu, Z. Effectiveness Analysis of Polyurethane Rigid Foam for Thermal Insulation and Moisture Retention in Shimenzi Roller-Compacted Concrete Arch Dam. Water Resour. Hydropower Eng. 2002, 33, 37–38. [Google Scholar]

- Chen, B.; He, M.; Huang, Z.; Wu, Z. Long-tern field test and numerical simulation of foamed polyurethane insulation on concrete dam in severely cold region. Constr. Build. Mater. 2019, 212, 618–634. [Google Scholar] [CrossRef]

- Chapman, T.M.; Rakiewicz-Nemeth, D.M.; Swestock, J.; Benrashid, R. Polyurethane elastomers with hydrolytic and thermooxidative stability. I. Polyurethanes with N-alkylated polyamide soft blocks. J. Polym. Sci. Part A Polym. Chem. 1990, 28, 1473–1482. [Google Scholar] [CrossRef]

- Boubakri, A.; Guermazi, N.; Elleuch, K.; Ayedi, H.F. Study of UV-aging of thermoplastic polyurethane material. Mater. Sci. Eng. A 2010, 527, 1649–1654. [Google Scholar] [CrossRef]

- Wilkes, K.E.; Gabbard, W.A.; Weaver, F.J.; Booth, J.R. Aging of Polyurethane Foam Insulation in Simulated Refrigerator Panels—Two-Year Results with Third-Generation Blowing Agents. J. Cell. Plast. 2001, 37, 400–428. [Google Scholar] [CrossRef]

- Wilkes, K.E.; Yarbrough, D.W.; Gabbard, W.A.; Nelson, G.E.; Booth, J.R. Aging of Polyurethane Foam Insulation in Simulated Refrigerator Panels–Three-Year Results with Third-Generation Blowing Agents. J. Cell. Plast. 2002, 38, 317–339. [Google Scholar] [CrossRef]

- Holcroft, N. Temperature dependency of the long-term thermal conductivity of spray polyurethane foam. J. Build. Phys. 2022, 45, 571–603. [Google Scholar] [CrossRef]

- EN 253:2009+A2:2015; District Heating Pipes—Preinsulated Bonded Pipe Systems forDirectly Buried Hot Water Networks—Pipe Assembly of Steel Service Pipe. Polyurethane Thermal Insulation and Outer Casing of Polyethylene. The British Standards Institution: London, UK, 2015.

- Winkler-Skalna, A.; Łoboda, B. Determination of the thermal insulation properties of cylindrical PUR foam products throughout the entire life cycle using accelerated aging procedures. J. Build. Eng. 2020, 31, 101348. [Google Scholar] [CrossRef]

- Tian, Q.; Krakovský, I.; Yan, G.; Bai, L.; Liu, J.; Sun, G.; Rosta, L.; Chen, B.; Almásy, L. Microstructure Changes in Polyester Polyurethane upon Thermal and Humid Aging. Polymers 2016, 8, 197. [Google Scholar] [CrossRef]

- Alvey, J.B.; Patel, J.; Stephenson, L.D. Experimental study on the effects of humidity and temperature on aerogel composite and foam insulations. Energy Build. 2017, 144, 358–371. [Google Scholar] [CrossRef]

- Boubakri, A.; Elleuch, K.; Guermazi, N.; Ayedi, H. Investigations on hygrothermal aging of thermoplastic polyurethane material. Mater. Des. 2009, 30, 3958–3965. [Google Scholar] [CrossRef]

- Boubakri, A.; Haddar, N.; Elleuch, K.; Bienvenu, Y. Influence of thermal aging on tensile and creep behavior of thermoplastic polyurethane. Comptes Rendus Mec. 2011, 339, 666–673. [Google Scholar] [CrossRef]

- Liu, Z.; Han, F.; Li, J.; Huang, Y.; Zhang, X.; Geng, Q. Deterioration Law of Organic Thermal Insulation Materials for Cold Region-Tunnels under Natural Water Immersion and Freeze-Thaw Conditions. Tunn. Constr. 2022, 42, 1453–1460. [Google Scholar]

- Ristić, I.; Krakovsky, T.; Janić, S.; Cakić, A.; Miletić, M.; Jotanović, T. Radusin, The influence of the nanofiller on thermal properties of thermoplastic polyurethane elastomers. J. Therm. Anal. Calorim. 2018, 134, 895–901. [Google Scholar] [CrossRef]

- Cheng, X. Experimental Investigation on the Long-Term In-Situ Service Performance of Polyurethane Thermal Insulation Layers in Reservoir Dams. Jianghuai Water Resour. Sci. Technol. 2024, 02, 7–12. [Google Scholar]

- Wang, Z.; Xiang, R.; Sun, J.; Yu, A. Thermal Behavior of Roof Insulation Materials under Multiphysics Coupling in Cold Climates. J. Build. Mater. 2020, 31, 101348. [Google Scholar]

- ISO 2896:2001; Rigid Cellular Plastics—Determination of Water Absorption. International Organization for Standardization: Geneva, Switzerland, 2001.

- DIN 51589-1:1991; Bestimmung des Wasserabscheidevermögens nach Dampfbehandlung. Intertek Inform: Sydney, Australia, 1991.

- Bourih, K.; Kaddouri, W.; Kanit, T.; Djebara, Y.; Imad, A. Modelling of Void Shape Effect on Effective Thermal Conductivity of Lotus-Type Porous Materials. Mech. Mater. 2020, 151, 103626. [Google Scholar] [CrossRef]

- Shen, Y.; Xu, P.; Qiu, S.; Rao, B.; Yu, B. A generalized thermal conductivity model for unsaturated porous media with fractal geometry. Int. J. Heat Mass Transf. 2020, 152, 119540. [Google Scholar] [CrossRef]

- Rottmann, M.; Beikircher, T.; Ebert, H.-P. Thermal Conductivity of Evacuated Expanded Perlite Measuredwith Guarded Hot-Plate and Transient-Hot-Wire Methodat Temperatures between 295 K and 1073 K. Int. J. Therm. Sci. 2020, 152, 106338. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, K.; Liu, Y.; Wang, D.; Liu, J. The Impact of Temperature and Relative Humidity Dependent Thermal Conductivity of Insulation Materials on Heat Transfer through the Building Envelope. J. Build. Eng. 2022, 46, 103700. [Google Scholar] [CrossRef]

- Islam, S.; Bhat, G. A model for predicting thermal conductivity of porous composite materials. Heat Mass Transf. 2023, 59, 2023–2034. [Google Scholar] [CrossRef]

- Yin, Y.; Li, Z. Investigation on the Freeze-Thaw Resistance of Concrete in Representative Cities of China. Low Temp. Archit. Technol. 2015, 37, 12–15. [Google Scholar]

| Parameter | Performance Index |

|---|---|

| Apparent Density (kg/m3) | 49 |

| Thermal Conductivity (W/(m·K), Mean temperature: 25 °C) | 0.023 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, L.; Liang, H.; Zhao, T.; Han, W.; Dong, Y.; Zhang, D.; Su, Z. Performance Evolution and Prediction Model of Dam Polyurethane Insulation Materials Under Multi-Field Coupling Conditions in Hot Summer and Cold Winter Climate Zones. Materials 2025, 18, 3208. https://doi.org/10.3390/ma18133208

Liao L, Liang H, Zhao T, Han W, Dong Y, Zhang D, Su Z. Performance Evolution and Prediction Model of Dam Polyurethane Insulation Materials Under Multi-Field Coupling Conditions in Hot Summer and Cold Winter Climate Zones. Materials. 2025; 18(13):3208. https://doi.org/10.3390/ma18133208

Chicago/Turabian StyleLiao, Lingmin, Hui Liang, Ting Zhao, Wei Han, Yun Dong, Da Zhang, and Zhenhua Su. 2025. "Performance Evolution and Prediction Model of Dam Polyurethane Insulation Materials Under Multi-Field Coupling Conditions in Hot Summer and Cold Winter Climate Zones" Materials 18, no. 13: 3208. https://doi.org/10.3390/ma18133208

APA StyleLiao, L., Liang, H., Zhao, T., Han, W., Dong, Y., Zhang, D., & Su, Z. (2025). Performance Evolution and Prediction Model of Dam Polyurethane Insulation Materials Under Multi-Field Coupling Conditions in Hot Summer and Cold Winter Climate Zones. Materials, 18(13), 3208. https://doi.org/10.3390/ma18133208