Thermoelectric Properties of NbCoNixSn (x = 0–1)

Abstract

1. Introduction

2. Experimental Methods

3. Results and Discussion

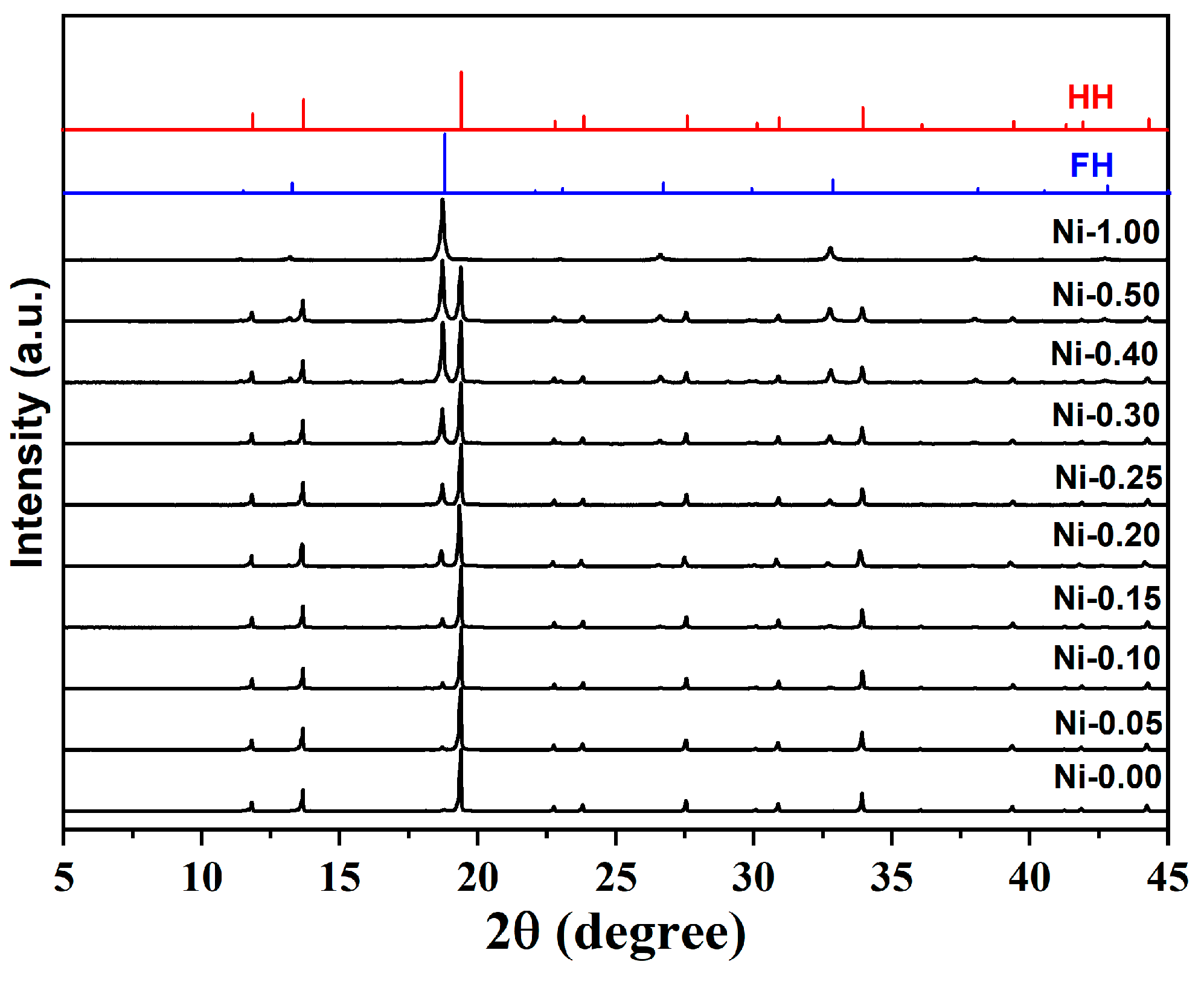

3.1. Phase Composition and Microstructure Characterisation

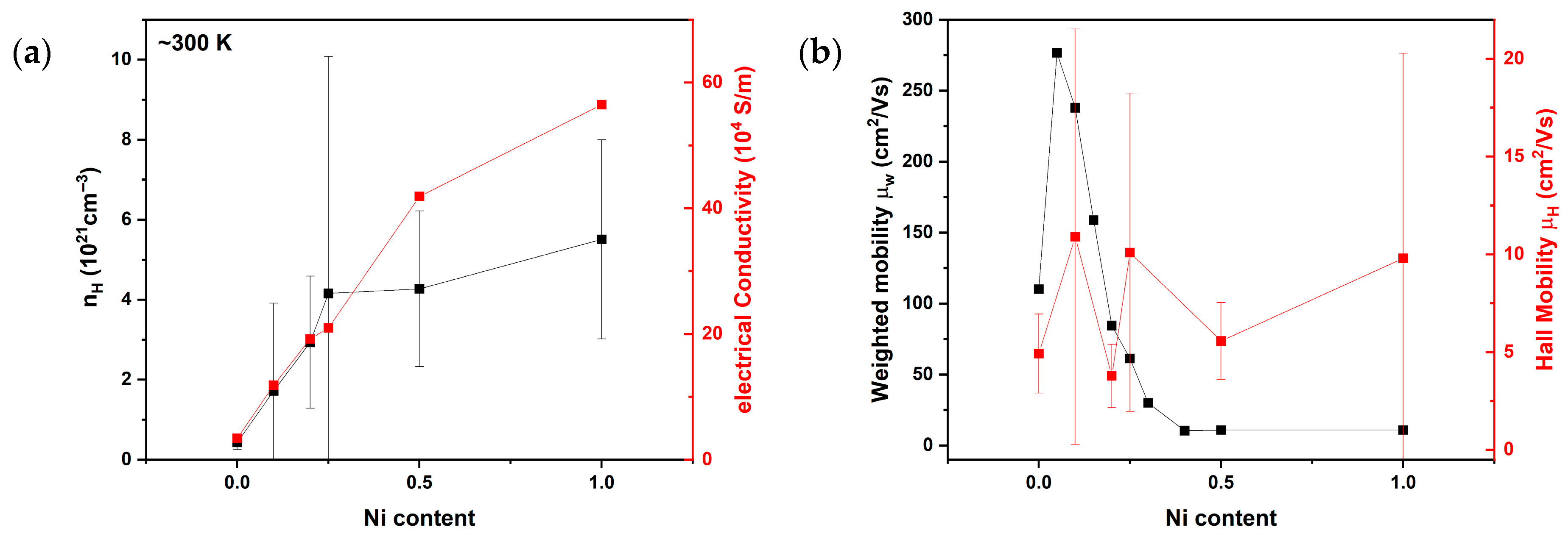

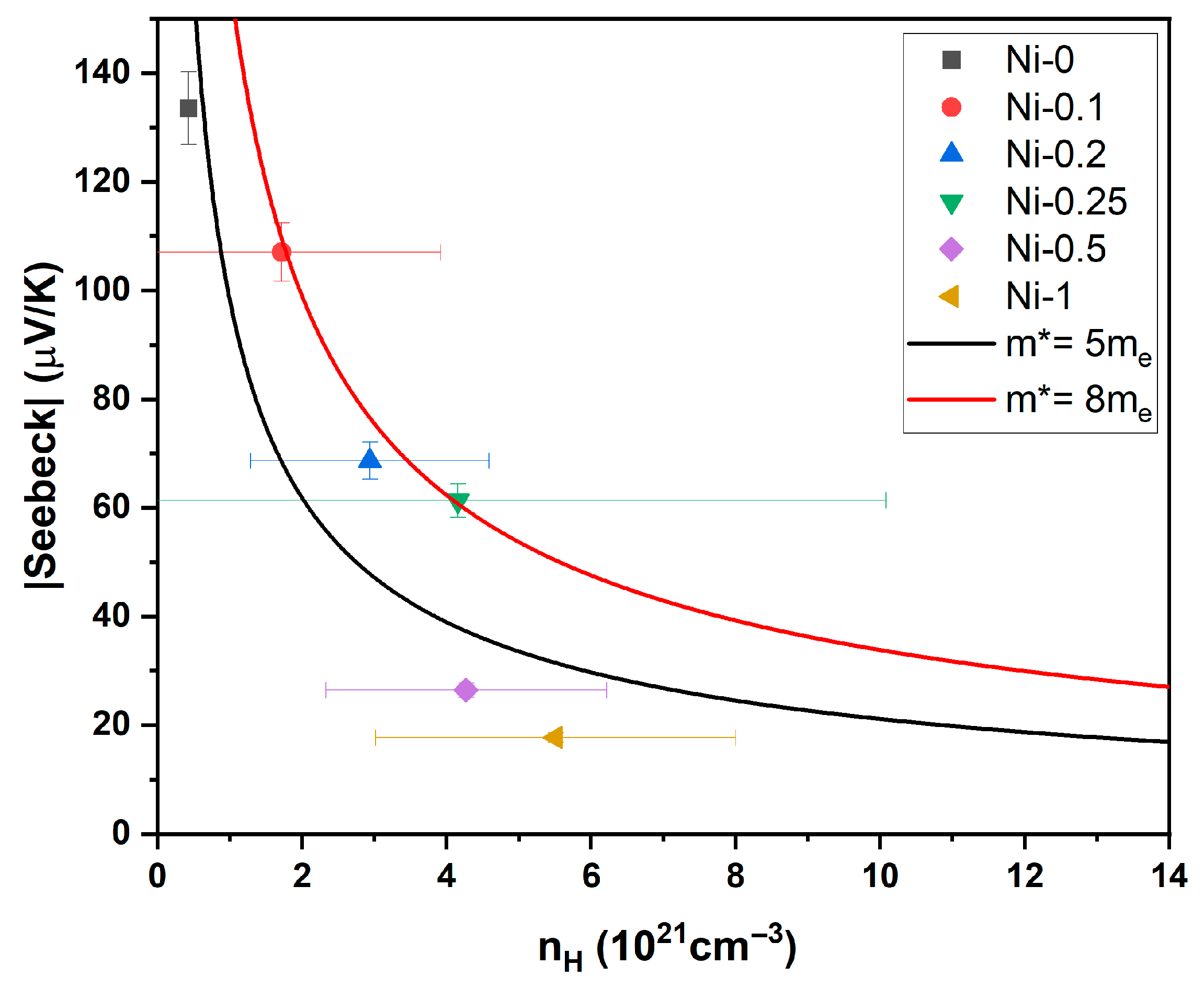

3.2. Transport Properties

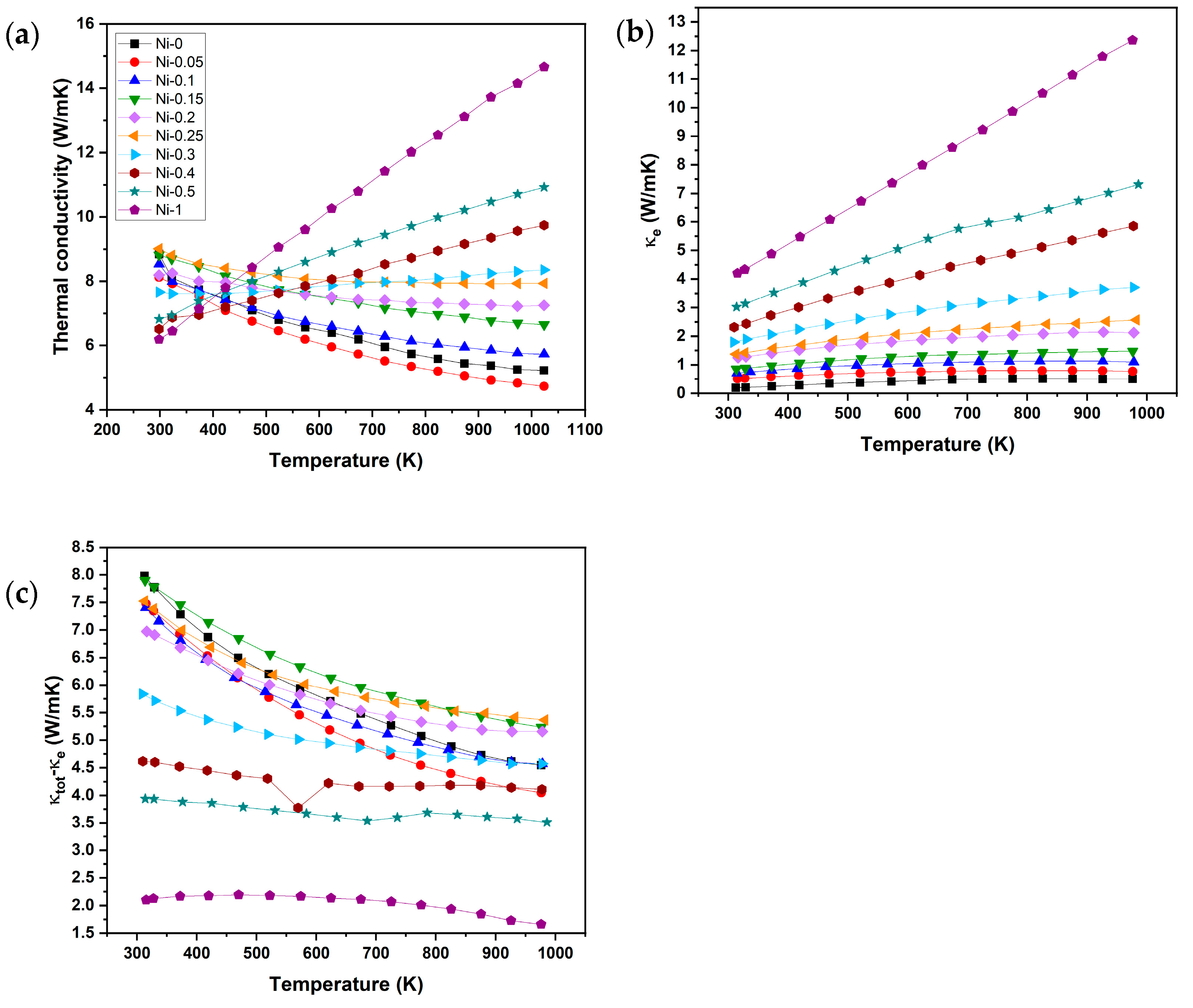

3.3. Thermal Transport Properties

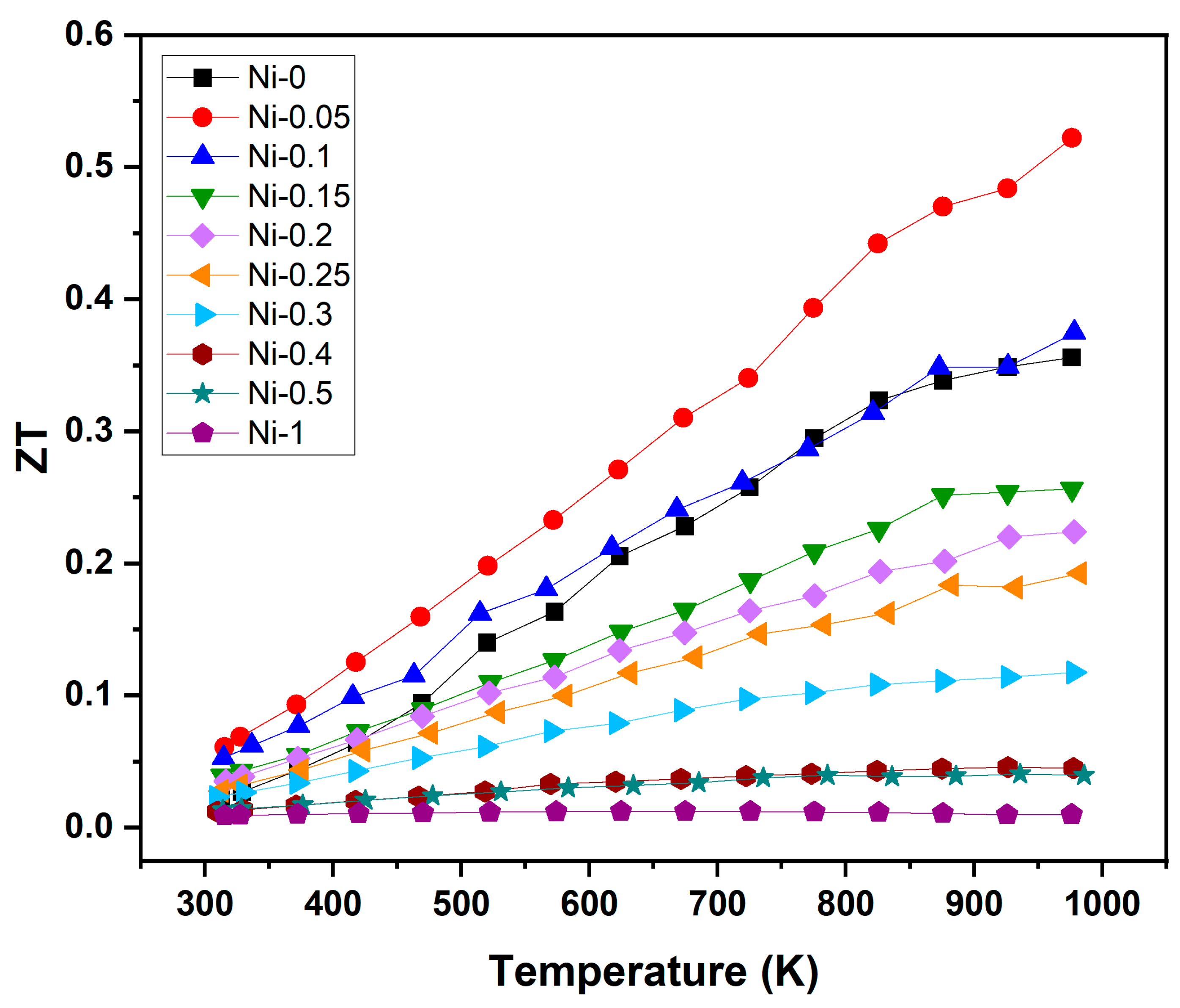

3.4. Figure of Merit

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Houghton, J. Global warming. Rep. Prog. Phys. 2005, 68, 1343. [Google Scholar] [CrossRef]

- Jackson, R.B.; Le Quéré, C.; Andrew, R.M.; Canadell, J.G.; Korsbakken, J.I.; Liu, Z.; Peters, G.P.; Zheng, B. Global energy growth is outpacing decarbonization. Environ. Res. Lett. 2018, 13, 120401. [Google Scholar] [CrossRef]

- Burnete, N.V.; Mariasiu, F.; Depcik, C.; Barabas, I.; Moldovanu, D. Review of thermoelectric generation for internal combustion engine waste heat recovery. Prog. Energy Combust. Sci. 2022, 91, 101009. [Google Scholar] [CrossRef]

- Mirhosseini, M.; Rezania, A.; Rosendahl, L. Power optimization and economic evaluation of thermoelectric waste heat recovery system around a rotary cement kiln. J. Clean. Prod. 2019, 232, 1321–1334. [Google Scholar] [CrossRef]

- Sootsman, J.R.; Chung, D.Y.; Kanatzidis, M.G. New and old concepts in thermoelectric materials. Angew. Chem. Int. Ed. 2009, 48, 8616–8639. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Hong, M.; Shi, X.; Li, M.; Sun, Q.; Chen, Q.; Dargusch, M.; Zou, J.; Chen, Z.-G. Computation-guided design of high-performance flexible thermoelectric modules for sunlight-to-electricity conversion. Energy Environ. Sci. 2020, 13, 3480–3488. [Google Scholar] [CrossRef]

- He, R.; Schierning, G.; Nielsch, K. Thermoelectric devices: A review of devices, architectures, and contact optimization. Adv. Mater. Technol. 2018, 3, 1870016. [Google Scholar] [CrossRef]

- Russ, B.; Glaudell, A.; Urban, J.J.; Chabinyc, M.L.; Segalman, R.A. Organic thermoelectric materials for energy harvesting and temperature control. Nat. Rev. Mater. 2016, 1, 16050. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Wang, J.; Zhang, M.; Jia, M.; Wang, Q. Man-portable cooling garment with cold liquid circulation based on thermoelectric refrigeration. Appl. Therm. Eng. 2022, 200, 117730. [Google Scholar] [CrossRef]

- Pedersen, S.V.; Croteau, J.R.; Kempf, N.; Zhang, Y.; Butt, D.P.; Jaques, B.J. Novel synthesis and processing effects on the figure of merit for NbCoSn, NbFeSb, and ZrNiSn based half-Heusler thermoelectrics. J. Solid State Chem. 2020, 285, 121203. [Google Scholar] [CrossRef]

- Rogl, G.; Sauerschnig, P.; Rykavets, Z.; Romaka, V.V.; Heinrich, P.; Hinterleitner, B.; Grytsiv, A.; Bauer, E.; Rogl, P. (V,Nb)-doped half Heusler alloys based on {Ti,Zr,Hf}NiSn with high ZT. Acta Mater. 2017, 131, 336–348. [Google Scholar] [CrossRef]

- Zhu, H.; He, R.; Mao, J.; Zhu, Q.; Li, C.; Sun, J.; Ren, W.; Wang, Y.; Liu, Z.; Tang, Z.; et al. Discovery of ZrCoBi based half Heuslers with high thermoelectric conversion efficiency. Nat. Commun. 2018, 9, 2497. [Google Scholar] [CrossRef] [PubMed]

- Zhu, T.; Fu, C.; Xie, H.; Liu, Y.; Zhao, X. High efficiency half-Heusler thermoelectric materials for energy harvesting. Adv. Energy Mater. 2015, 5, 1500588. [Google Scholar] [CrossRef]

- Klaer, P.; Kallmayer, M.; Blum, C.G.F.; Graf, T.; Barth, J.; Balke, B.; Fecher, G.H.; Felser, C.; Elmers, H.J. Tailoring the electronic structure of half-metallic Heusler alloys. Phys. Rev. B 2009, 80, 144405. [Google Scholar] [CrossRef]

- Klaer, P.; Bos, T.; Kallmayer, M.; Blum, C.G.F.; Graf, T.; Barth, J.; Balke, B.; Fecher, G.H.; Felser, C.; Elmers, H.J. Charge transfer and tunable minority band gap at the Fermi energy of a quaternary Co2(MnxTi1−x)Ge Heusler alloy. Phys. Rev. B 2010, 82, 104410. [Google Scholar] [CrossRef]

- Poon, S. Recent advances in thermoelectric performance of half-Heusler compounds. Metals 2018, 8, 989. [Google Scholar] [CrossRef]

- Sakurada, S.; Shutoh, N. Effect of Ti substitution on the thermoelectric properties of (Zr,Hf)NiSn half-Heusler compounds. Appl. Phys. Lett. 2005, 86, 82105. [Google Scholar] [CrossRef]

- Xie, W.; Weidenkaff, A.; Tang, X.; Zhang, Q.; Poon, J.; Tritt, T.M. Recent advances in nanostructured thermoelectric half-Heusler compounds. Nanomaterials 2012, 2, 379–412. [Google Scholar] [CrossRef]

- Yan, R.; Xie, R.; Xie, W.; Shen, C.; Li, W.; Balke, B.; Yoon, S.; Zhang, H.; Weidenkaff, A. Effects of doping Ni on the microstructures and thermoelectric properties of Co-excessive NbCoSn half-Heusler compounds. ACS Appl. Mater. Interfaces 2021, 13, 34533–34542. [Google Scholar] [CrossRef]

- Bos, J.-W.G.; Downie, R.A. Half-Heusler thermoelectrics: A complex class of materials. J. Phys. Condens. Matter 2014, 26, 433201. [Google Scholar] [CrossRef]

- Yang, J.; Meisner, G.P.; Chen, L. Strain field fluctuation effects on lattice thermal conductivity of ZrNiSn-based thermoelectric compounds. Appl. Phys. Lett. 2004, 85, 1140–1142. [Google Scholar] [CrossRef]

- Ghosh, S.; Shankar, G.; Karati, A.; Rogl, G.; Rogl, P.; Bauer, E.; Murty, B.S.; Suwas, S.; Mallik, R.C. Thermoelectric properties enhancement of Ba0·2Co4Sb12 through dispersion of GaSb inclusions. Phys. B Condens. Matter 2021, 606, 412440. [Google Scholar] [CrossRef]

- Fu, C.; Zhu, T.; Liu, Y.; Xie, H.; Zhao, X. Band engineering of high performance p-type FeNbSb based half-Heusler thermoelectric materials for figure of merit zT > 1. Energy Environ. Sci. 2015, 8, 216–220. [Google Scholar] [CrossRef]

- He, R.; Huang, L.; Wang, Y.; Samsonidze, G.; Kozinsky, B.; Zhang, Q.; Ren, Z. Enhanced thermoelectric properties of n-type NbCoSn half-Heusler by improving phase purity. APL Mater. 2016, 4, 104804. [Google Scholar] [CrossRef]

- Serrano-Sánchez, F.; Luo, T.; Yun, J.; Xie, W.; Le, C.; Auffermann, G.; Weidenkaff, A.; Zhu, T.; Zhao, X.; Alonso, J.A.; et al. Thermoelectric properties of n-type half-Heusler NbCoSn with heavy-element Pt substitution. J. Mater. Chem. A 2020, 8, 14822–14828. [Google Scholar] [CrossRef]

- Wang, Q.; Huang, J.; Wang, C.; Luo, P.; Li, Z.; Liu, R.; Ma, Q.; Luo, J. Enhancement of thermoelectric properties in n-type NbCoSn half-Heusler compounds via Ta alloying. ACS Appl. Energy Mater. 2021, 4, 12458–12465. [Google Scholar] [CrossRef]

- Graf, T.; Felser, C.; Parkin, S.S. Simple rules for the understanding of Heusler compounds. Prog. Solid State Chem. 2011, 39, 1–50. [Google Scholar] [CrossRef]

- Jeitschko, W. Transition metal stannides with MgAgAs and MnCu2Al type structure. Metall. Mater. Trans. B 1970, 1, 3159–3162. [Google Scholar] [CrossRef]

- Xi, L.; Yang, J.; Wu, L.; Yang, J.; Zhang, W. Band engineering and rational design of high-performance thermoelectric materials by first-principles. J. Materiomics 2016, 2, 114–130. [Google Scholar] [CrossRef]

- Kimura, Y.; Tamura, Y.; Kita, T. Thermoelectric properties of directionally solidified half-Heusler compound NbCoSn alloys. Appl. Phys. Lett. 2008, 92, 12105. [Google Scholar] [CrossRef]

- Li, S.; Zhu, H.; Mao, J.; Feng, Z.; Li, X.; Chen, C.; Cao, F.; Liu, X.; Singh, D.J.; Ren, Z.; et al. n-Type TaCoSn-based half-Heuslers as promising thermoelectric materials. ACS Appl. Mater. Interfaces 2019, 11, 41321–41329. [Google Scholar] [CrossRef] [PubMed]

- Yan, R.; Xie, W.; Balke, B.; Chen, G.; Weidenkaff, A. Realizing p-type NbCoSn half-Heusler compounds with enhanced thermoelectric performance via Sc substitution. Sci. Technol. Adv. Mater. 2020, 21, 122–130. [Google Scholar] [CrossRef]

- Chauhan, N.S.; Bathula, S.; Gahtori, B.; Mahanti, S.D.; Bhattacharya, A.; Vishwakarma, A.; Bhardwaj, R.; Singh, V.N.; Dhar, A. Compositional tailoring for realizing high thermoelectric performance in hafnium-free n-type ZrNiSn half-Heusler alloys. ACS Appl. Mater. Interfaces 2019, 11, 47830–47836. [Google Scholar] [CrossRef]

- Fu, C.; Yao, M.; Chen, X.; Maulana, L.Z.; Li, X.; Yang, J.; Imasato, K.; Zhu, F.; Li, G.; Auffermann, G.; et al. Revealing the intrinsic electronic structure of 3D half-Heusler thermoelectric materials by angle-resolved photoemission spectroscopy. Adv. Sci. 2020, 7, 1902409. [Google Scholar] [CrossRef]

- Buffon, M.L.C.; Laurita, G.; Verma, N.; Lamontagne, L.; Ghadbeigi, L.; Lloyd, D.L.; Sparks, T.D.; Pollock, T.M.; Seshadri, R. Enhancement of thermoelectric properties in the Nb–Co–Sn half-Heusler/Heusler system through spontaneous inclusion of a coherent second phase. J. Appl. Phys. 2016, 120, 75104. [Google Scholar] [CrossRef]

- Dat, D.T.D.; Mahanti, S.D.; Pulikkoti, J.J. Electronic structure of Zr–Ni–Sn systems: Role of clustering and nanostructures in half-Heusler and Heusler limits. J. Phys. Condens. Matter 2014, 26, 275501. [Google Scholar]

- Miyamoto, K.; Kimura, A.; Sakamoto, K.; Ye, M.; Cui, Y.; Shimada, K.; Namatame, H.; Taniguchi, M.; Fujimori, S.; Saitoh, Y.; et al. In-gap electronic states responsible for the excellent thermoelectric properties of Ni-based half-Heusler alloys. Appl. Phys. Express 2008, 1, 81901. [Google Scholar] [CrossRef]

- Liu, Y.; Sahoo, P.; Makongo, J.P.A.; Zhou, X.; Kim, S.-J.; Chi, H.; Uher, C.; Pan, X.; Poudeu, P.F.P. Large enhancements of thermopower and carrier mobility in quantum dot engineered bulk semiconductors. J. Am. Chem. Soc. 2013, 135, 7486–7495. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.; Anand, S.; Brod, M.K.; Zhang, Y.; Snyder, G.J. Conduction band engineering of half-Heusler thermoelectrics using orbital chemistry. J. Mater. Chem. A 2022, 10, 3051–3057. [Google Scholar] [CrossRef]

- Snyder, G.J.; Snyder, A.H.; Wood, M.; Gurunathan, R.; Snyder, B.H.; Niu, C. Weighted mobility. Adv. Mater. 2020, 32, e2001537. [Google Scholar] [CrossRef]

- Ferluccio, D.A.; Smith, R.I.; Buckman, J.; Bos, J.-W.G. Impact of Nb vacancies and p-type doping of the NbCoSn-NbCoSb half-Heusler thermoelectrics. Phys. Chem. Chem. Phys. 2018, 20, 3979–3987. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-S.; Gibbs, Z.M.; Tang, Y.; Wang, H.; Snyder, G.J. Characterization of Lorenz number with Seebeck coefficient measurement. APL Mater. 2015, 3, 041506. [Google Scholar] [CrossRef]

| Sample | Measured Density [g/cm3] | Theoretical Density [g/cm3] | Percentage (%) |

|---|---|---|---|

| Ni-0 | 8.510 | 8.522 | 99.86 |

| Ni-0.05 | 8.537 | 8.566 | 99.67 |

| Ni-0.1 | 8.516 | 8.610 | 98.91 |

| Ni-0.15 | 8.645 | 8.654 | 99.90 |

| Ni-0.2 | 8.668 | 8.698 | 99.66 |

| Ni-0.25 | 8.757 | 8.742 | 100.17 |

| Ni-0.3 | 8.785 | 8.786 | 99.99 |

| Ni-0.4 | 8.828 | 8.874 | 99.48 |

| Ni-0.5 | 8.943 | 8.962 | 99.79 |

| Ni-1 | 9.258 | 9.401 | 98.48 |

| Nominal Composition | Actual Phase Composition Light Phase | Actual Phase Composition Dark Phase |

|---|---|---|

| NbCoSn | Nb0.89Co1.12Sn | |

| NbCoNi0.05Sn | Nb0.89Co1.12Ni0.03Sn | Nb0.90Co1.12Ni0.04Sn |

| NbCoNi0.10Sn | Nb0.89Co1.12Ni0.12Sn | Nb0.71Co1.12Ni0.69Sn |

| NbCoNi0.15Sn | Nb0.93Co1.04Ni0.10Sn | Nb0.73Co1.35Ni0.51Sn |

| NbCoNi0.20Sn | Nb0.90Co1.10Ni0.15Sn | Nb0.82Co1.67Ni0.47Sn |

| NbCoNi0.25Sn | Nb0.90Co0.97Ni0.10Sn | Nb0.75Co1.30Ni0.71Sn |

| NbCoNi0.30Sn | Nb0.89Co1.04Ni0.12Sn | Nb0.74Co1.60Ni0.61Sn |

| NbCoNi0.40Sn | Nb0.87Co0.98Ni0.13Sn | Nb0.72Co1.37Ni0.74Sn |

| NbCoNi0.50Sn | Nb0.87Co0.99Ni0.13Sn | Nb0.79Co1.35Ni0.80Sn |

| NbCoNi1.00Sn | Nb0.91Co1.10Ni1.10Sn | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thiem, M.; Yan, R.; Weidenkaff, A.; Xie, W. Thermoelectric Properties of NbCoNixSn (x = 0–1). Materials 2025, 18, 3189. https://doi.org/10.3390/ma18133189

Thiem M, Yan R, Weidenkaff A, Xie W. Thermoelectric Properties of NbCoNixSn (x = 0–1). Materials. 2025; 18(13):3189. https://doi.org/10.3390/ma18133189

Chicago/Turabian StyleThiem, Moritz, Ruijuan Yan, Anke Weidenkaff, and Wenjie Xie. 2025. "Thermoelectric Properties of NbCoNixSn (x = 0–1)" Materials 18, no. 13: 3189. https://doi.org/10.3390/ma18133189

APA StyleThiem, M., Yan, R., Weidenkaff, A., & Xie, W. (2025). Thermoelectric Properties of NbCoNixSn (x = 0–1). Materials, 18(13), 3189. https://doi.org/10.3390/ma18133189