3. Result and Discussion

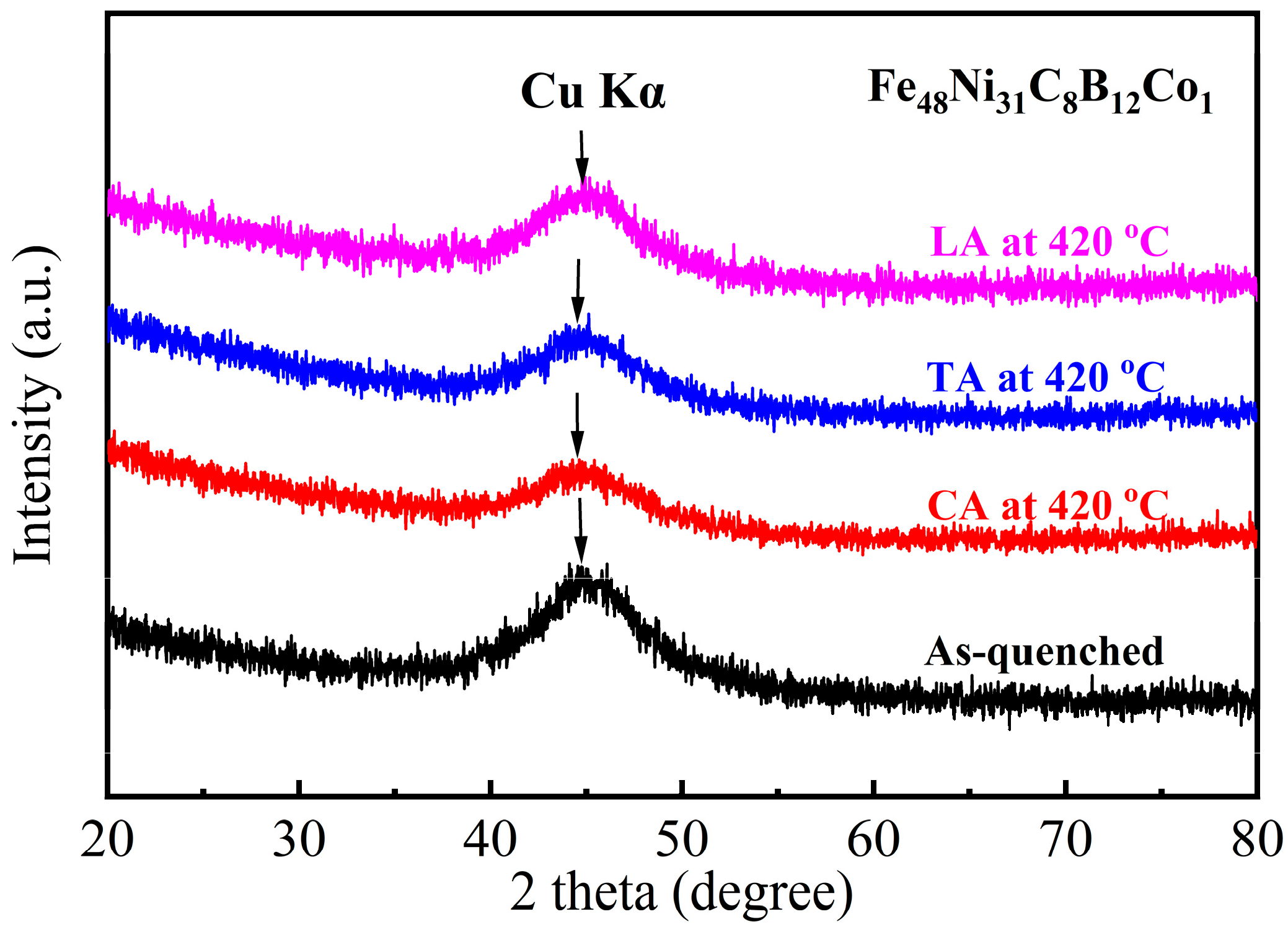

The XRD patterns obtained from the as-quenched and annealed samples are shown in

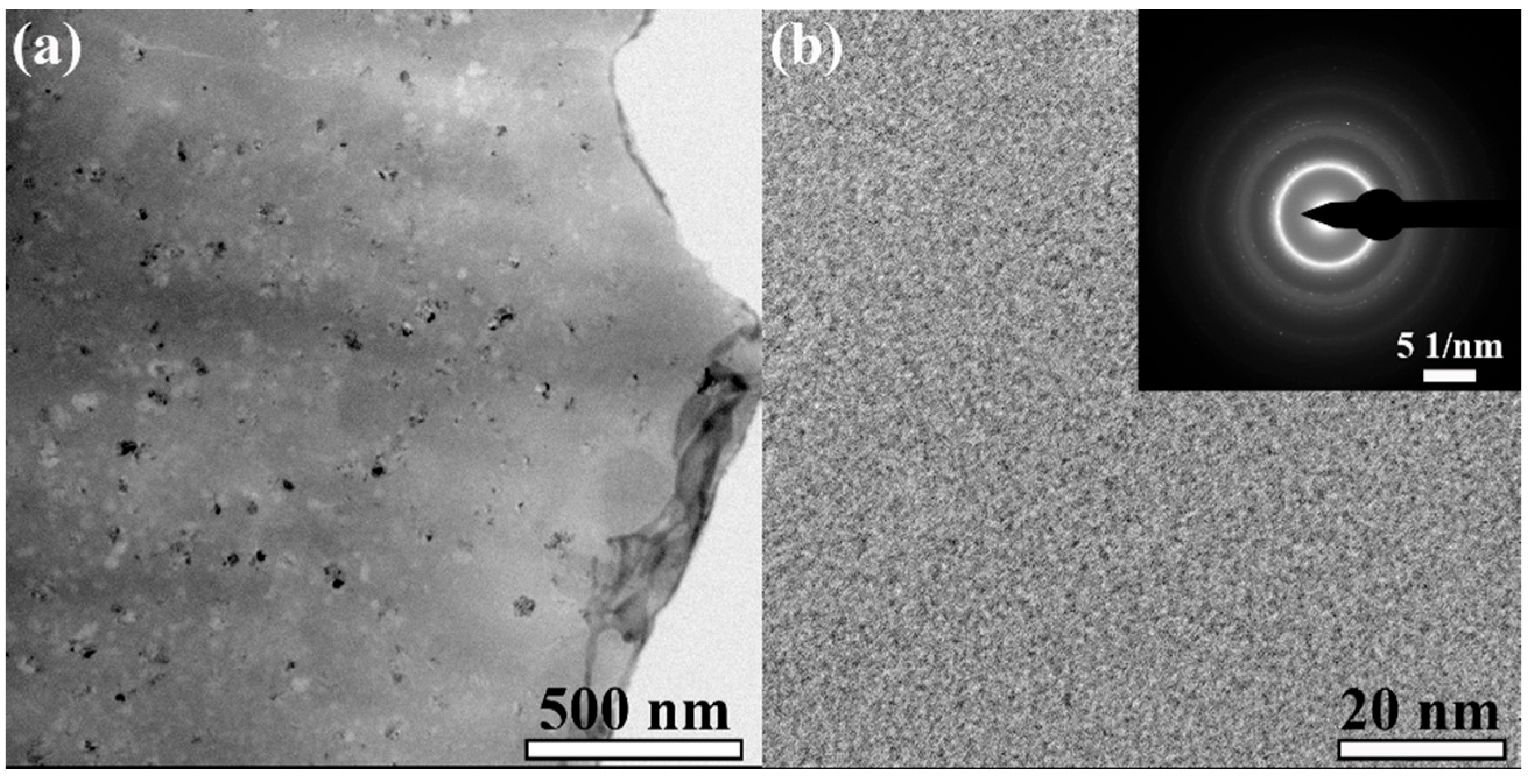

Figure 1. Obviously, there is an amorphous halo characteristic for the melt-spun sample. In comparison, the samples annealed at 420 °C also display a similar hump peak as the as-quenched sample. It is hard to identify whether nanocrystallization occurs in the annealed samples. TEM analysis was carried out to obtain more structural information. As shown in the TEM images of

Figure 2, the CA sample displays a certain number of nanoparticles embedded into an amorphous matrix (

Figure 2a). The degree of nanocrystallization is not very high, which is supported by the amorphous ring (

Figure 2b) and unclear nanocrystalline rings.

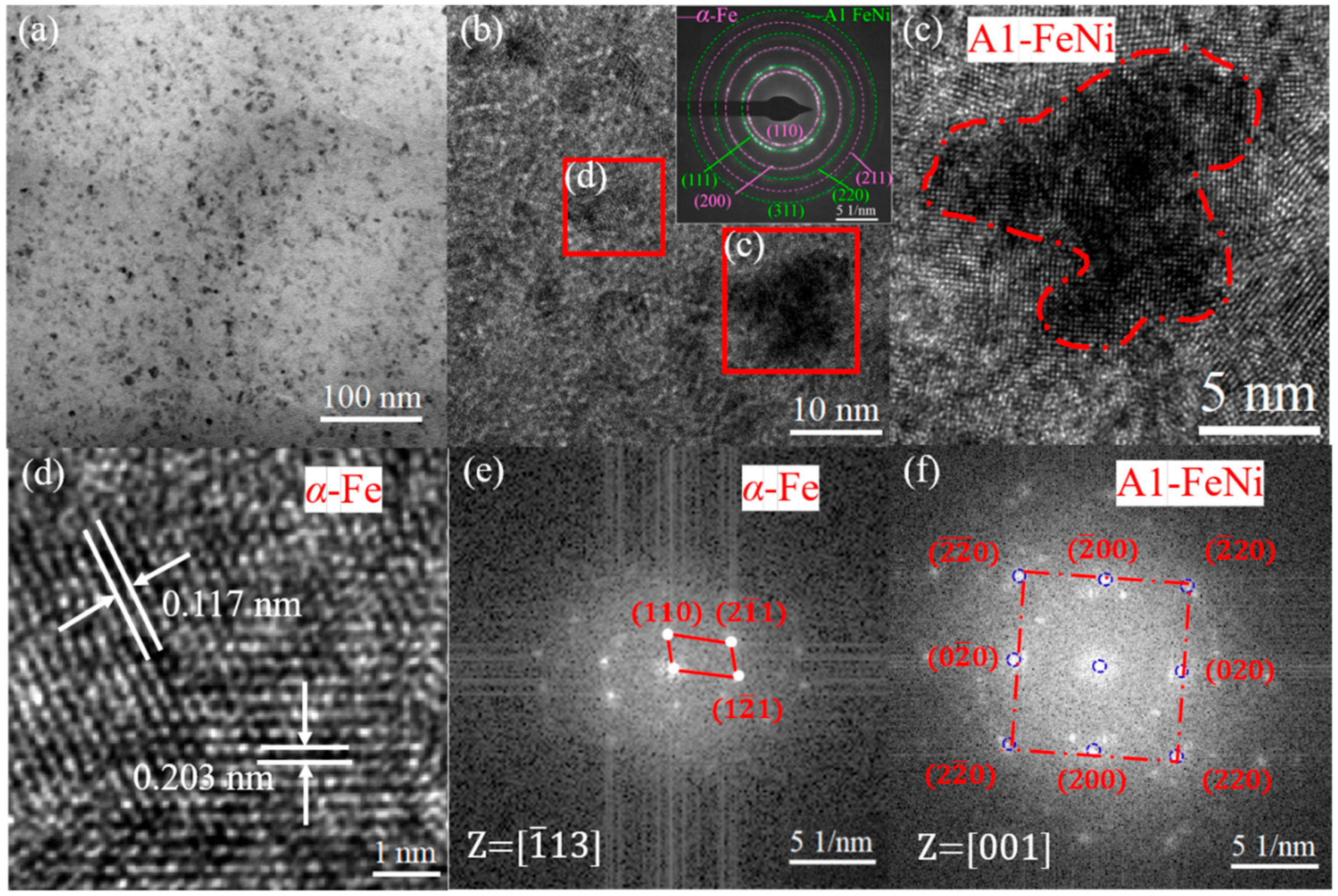

The TEM images of

Figure 3a,b show that the strips have an obvious amorphous nanocrystalline structure after longitudinal magnetic annealing treatment, and more clusters and grains precipitated in the matrix, as can be clearly seen in the low magnification morphology. The diffraction rings in the illustration were analyzed and compared, corresponding, respectively, to the (110), (200), and (211) crystal planes of the α-Fe grains and the (111), (220), and (311) crystal planes of the A1 FeNi grains.

Figure 3c is an enlarged image of the same area, clearly revealing the coherent interface formed between the A1 FeNi nanocrystals and the α-Fe grains on the matrix. This is primarily due to the fact that during magnetic field annealing, the nanocrystal precursor α-Fe grains precipitate first in the matrix. Under the influence of thermal activation energy and the magnetic field, Ni atoms accumulate on the precursor α-Fe grains and gradually dissolve into Fe to form FeNi grains. The clusters and nanocrystals in the selected area were enlarged by inverse Fourier transform to calculate the crystal plane spacing and the corresponding indexed fast Fourier transform images, as shown in

Figure 3d–f. The interplanar spacings are 0.203 nm and 0.117 nm, corresponding to the (110) and (211) crystal planes of α-Fe grains with a body-centered cubic structure. Through the corresponding Fourier transform, it was determined that this nanocrystal is consistent with the (220) crystal plane of the face-centered cubic structured A1 FeNi grains.

It can be clearly observed in

Figure 4 that the strip surface exhibits an uneven surface morphology, which is attributed to the contrast between the precipitated A1 FeNi nanocrystals (bright white particles) and the amorphous matrix during the annealing process. The elemental distribution is visualized through color mapping (Fe: cyan, Ni: green, C: purple, B: yellow, Co: blue). Overall, while thermodynamic considerations predict the elemental partitioning of Ni/Co between the FCC and BCC phases, the uniform distribution of Fe and Ni indicates that no significant elemental segregation occurred during annealing. This phenomenon is likely attributable to probe-broadening effects induced by specimen thickness variations, particularly in thicker regions where beam–sample interactions span multiple crystallites. However, localized regions exhibiting Fe and Ni enrichment are attributed to A1 FeNi nanocrystal precipitation; while the B element demonstrates a uniform distribution within the amorphous matrix, the C element exhibits negligible segregation, thereby corroborating the compositional stability of the designed alloy system.

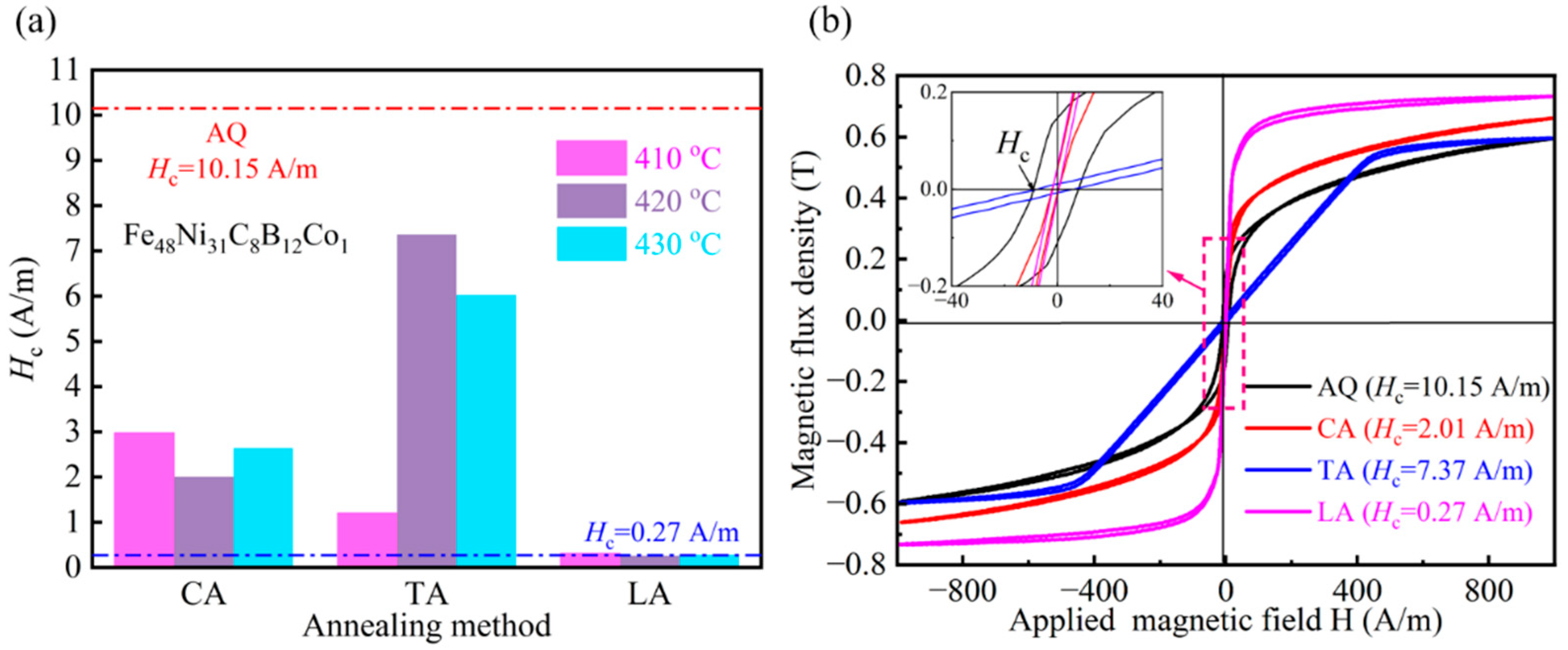

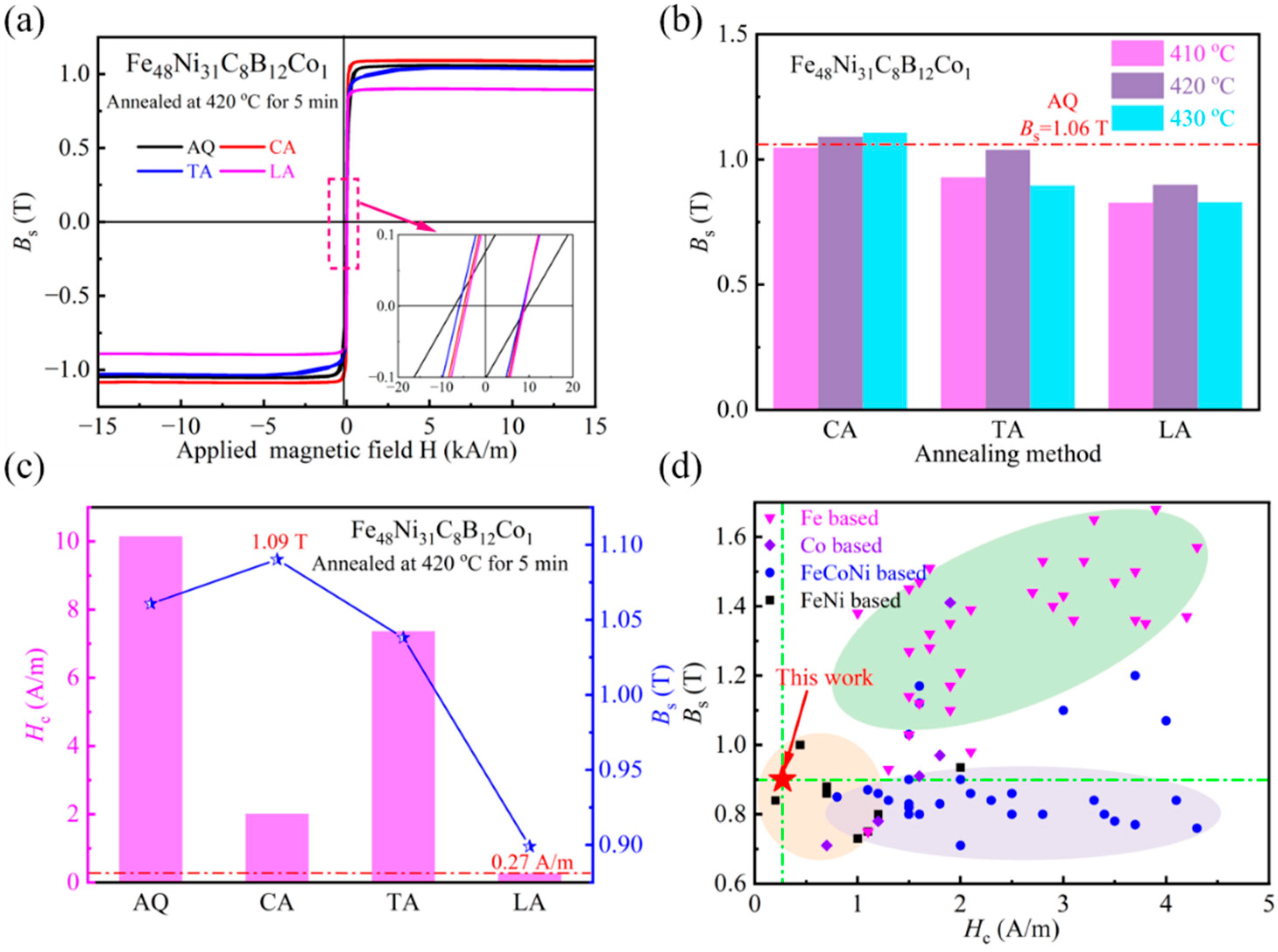

As can be seen in

Figure 5a, the coercivity of all the annealed strips exhibited varying decreases. Although the coercivity after transverse magnetic annealing was lower than that of the quenched state, it remained significantly higher than the 2 A/m value observed in the non-magnetic field annealed sample. Notably, the coercivity (

Hc) decreased dramatically from 10.15 A/m to 0.27 A/m following longitudinal magnetic field annealing. This reduction is attributed to the combined effects of magnetic field orientation and thermal activation promoting magnetic moment alignment. As shown in

Figure 3, STEM analysis revealed the precipitation of A1 FeNi nanocrystals during annealing, where the low magnetic crystalline anisotropy facilitated the magnetic domain wall motion [

21]. Furthermore, longitudinal magnetic field-induced atomic ordering effectively reduced residual stress, further diminishing the pinning effect on the magnetic domain walls.

As shown in

Figure 5b, the samples treated with CA and LA exhibited higher squareness of hysteresis loops and steeper rates of increase in magnetic flux density (dB/dH), while the hysteresis loop of TA-treated samples tended to flatten. This difference is directly related to the microstructural evolution induced by different annealing processes: CA and LA processes promote the uniform precipitation of A1 FeNi nanocrystals. The low magnetic crystalline anisotropy of the FCC structure reduces magnetostatic ‘pinning effects’, allowing magnetic moments to align easily along the external field direction, thereby enhancing permeability and loop squareness. In contrast, the TA process induces the localized enrichment of atomic clusters with higher magnetic crystalline anisotropy, which hinders the movement of domain walls. This results in a magnetization process dominated by magnetization rotation rather than wall motion, significantly reducing the rate of magnetic flux density increase and causing hysteresis loop flattening.

Analyzing in

Figure 6a the magnetic induction intensity comparison graph and in

Figure 6b the M-H curve, it can be seen that the saturation magnetic induction intensity of the two groups of magnetic field annealed strips showed a certain decrease, and that the decrease in the longitudinal magnetic treatment was more obvious. This is due to the dual action of the thermal activation energy and the magnetic field, which promotes the amorphous matrix of α-Fe and the combination of Ni atoms to form the A1 FeNi grains. A review of the literature reveals that amorphous alloys with high Fe content possess high saturation magnetic induction strength (see reference [

22]). However, following magnetic field annealing, the volume fraction of α-Fe in the matrix diminishes, concomitant with the induction of magnetic anisotropy within the matrix due to the effect of the applied magnetic field. This, in turn, results in a reduction in the saturation magnetic induction strength of the alloy. As demonstrated in

Figure 6c,d, the saturation magnetic induction strength of the present experimental alloy is lower than that of Fe-based amorphous alloys due to the low Fe content, but at the same time, it has a smaller coercivity. Within the same system of alloys, the untreated alloy exhibits a higher

Bs (1.09 T); although there is a slight decrease, it remains in the range of 0.9 T or more, whereas other alloys exhibit a more moderate level. Concurrently, after treatment, the alloy demonstrates a lower

Hc (0.27 A/m) than the other components. In summary, this experiment focused on the preparation and treatment of strips, which exhibited satisfactory comprehensive soft magnetic properties. Subsequent composition adjustments were made to enhance the saturation magnetic induction strength of the system, thereby expanding its application scenarios.

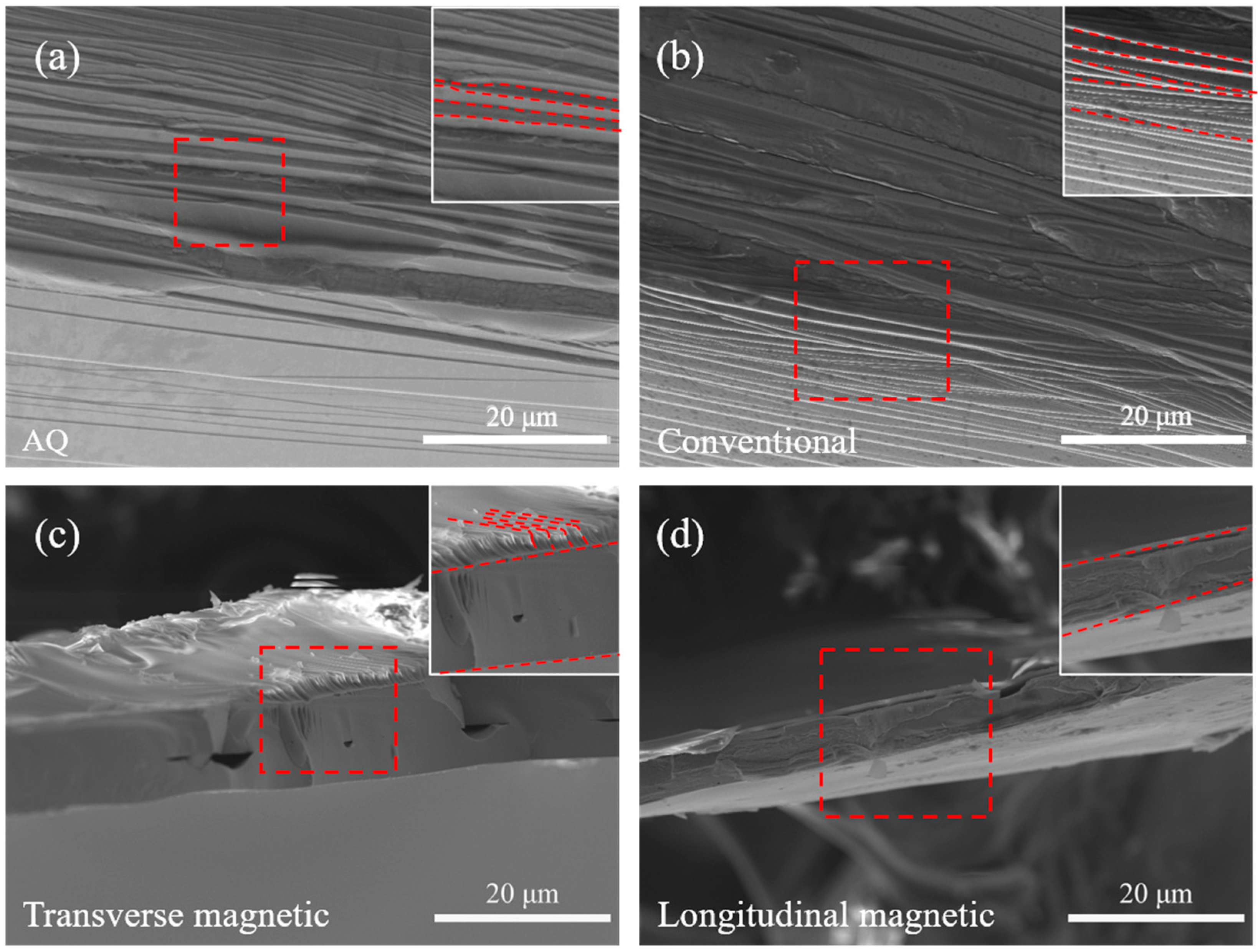

At present, amorphous strips can achieve excellent soft magnetic properties and improve the microhardness of amorphous alloys by heat treatment, but at the same time, it also brings the defect of increased brittleness. As can be seen from the

Figure 7 bending section SEM image, in addition to the transverse magnetic annealing fracture surface being very smooth, it shows obvious brittle fracture characteristics, while with the quenched state, conventional annealing and longitudinal magnetic annealing treatment of the fracture result in obvious fibrous toughness fracture characteristics. This indicates that the conventional annealing and longitudinal annealing of strips maintain better toughness, while seeming to obtain the best magnetic properties at the same time.

By studying the law of change of indenter load with indentation depth, we can understand the ability of the microstructure of the material to resist the deformation of external forces. The relationship between the load–combined displacement is obtained by fitting the unloading curve [

24]:

In the above equation, P is the load applied to the sample by the indenter; h is the indentation depth of the indenter; and α and m are the fitting parameters. The contact stiffness S is derived from h of the following equation:

The contact area C of the Berkovich indenter can be obtained by the empirical formula:

In this equation, represents a coefficient to be determined, related to the indenter. The contact depth, , can be obtained by using the following equation:

In the above equation, is the maximum load pressed in by the indenter; is the maximum displacement; θ is a constant associated with the indenter; and the θ of the Berkovich indenter is about 0.72. The contact area A, from which the hardness and elastic modulus of the material can be calculated, is then:

In the above equation, is the approximate modulus and is the shape constant of the indenter. The shape parameter of the Berkovich indenter used in this paper is 1.034.

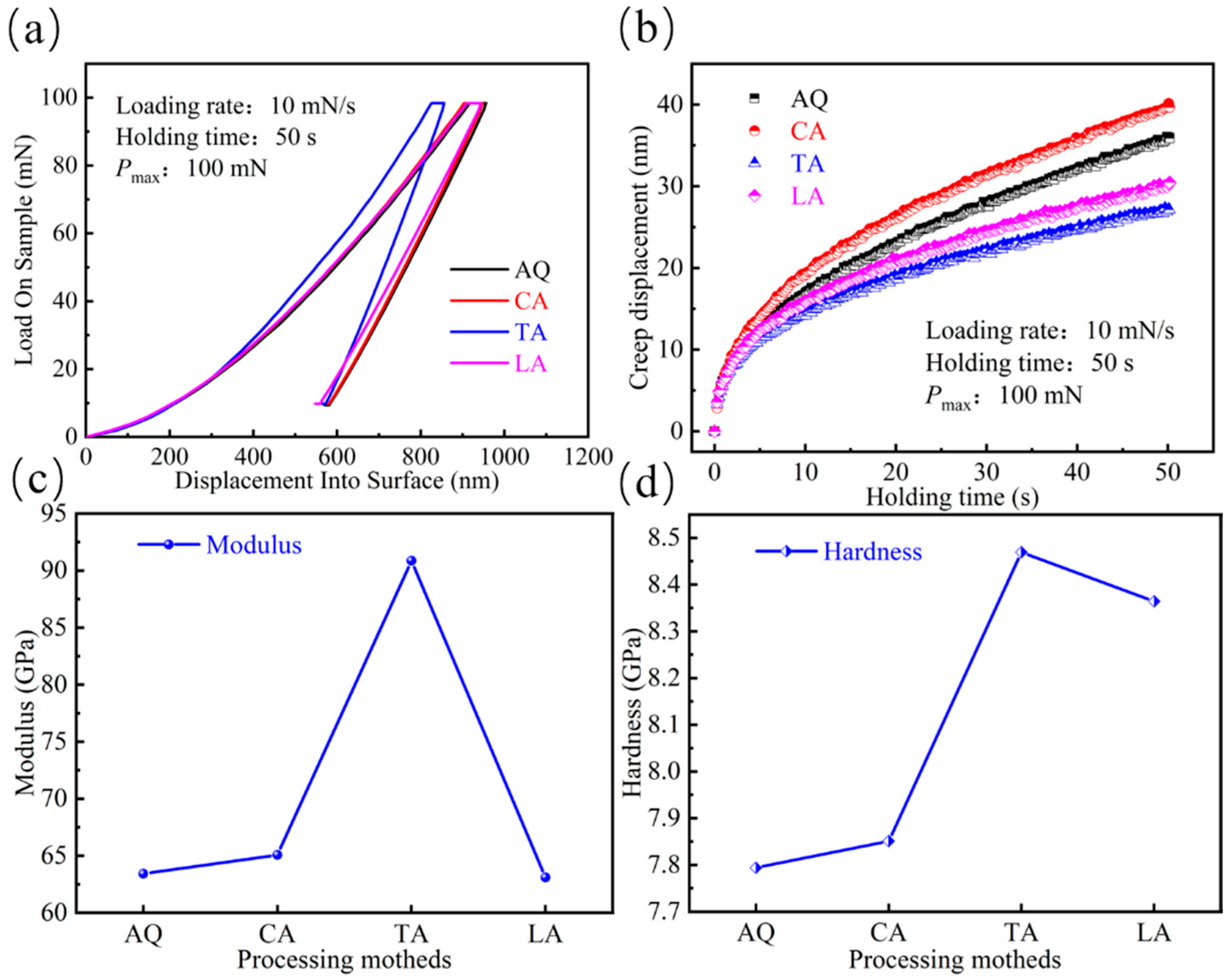

The load–displacement curves, shown in

Figure 8a, show that the indenter can penetrate the magnetically annealed strip much shallower than the other three. It is evident from the figure that the indenter can penetrate the strip that underwent transverse magnetic annealing to a lesser extent than the other three. Furthermore, it has been documented in the literature [

25] that the slope of the load–displacement curves is indicative of the material’s stiffness. This suggests that the transverse magnetically annealed strips exhibit higher levels of hardness and stiffness, accompanied by a degree of relaxation hardening.

When the indentation depth exceeds 400 nm, the load-bearing capacity of the transverse magnetic field annealed (TA) sample becomes significantly higher than the other three groups, and it exhibits a greater residual displacement recovery rate during the unloading phase. This phenomenon indicates that the TA sample possesses enhanced resistance to deformation during the plastic deformation stage, manifesting as a certain degree of relaxation hardening. This is mainly due to TA treatment-induced short-range ordering of Fe and Ni atoms, leading to a decrease in the free volume. Notably, the unique behavior of the TA sample during unloading suggests that mechanical loading may trigger localized microstructural transitions. Combined with the literature [

26], the clusters induced by transverse magnetic field annealing might form brittle fracture paths under high-stress conditions. Meanwhile, the higher recovery rate of the LA sample during unloading could be attributed to magnetic field-induced atomic ordering. In longitudinal magnetic field annealing, atoms align along the magnetization direction, forming locally anisotropic structures. These structures release stored elastic energy through magnetoelastic coupling effects during unloading, promoting atomic recoil and reducing residual displacement. In contrast, the amorphous matrices of AQ and CA samples lack ordered structures, making plastic deformation recovery difficult after unloading.

In order to investigate the relaxation hardening in the load displacement, the treatment analysis of the load-holding phase in the nanoindentation test was carried out to investigate the changes in the internal structure of the strip after the annealing treatment. From

Figure 8b, the following pattern of maximum creep displacement is observed: normal annealed (CA) > quenched state (AQ) > longitudinal annealed (LA) > transverse annealed (TA).

The maximum creep strain of the TA sample treated by magnetic field annealing was reduced by 40% compared to the CA sample, confirming a significant improvement in creep resistance. The research findings indicate that the performance differences between the LA and TA samples originate from microstructural regulation mechanisms: In LA samples, A1 FeNi nanocrystals synergistically enhance creep resistance through diffusion-suppression mechanisms (delaying viscous flow in quasi-liquid zones). Conversely, the presence of extensive atomic clusters within TA samples induces localized stress concentration, promoting microcrack nucleation and offsetting the material’s high hardness advantage. Additionally, short-range diffusion may accelerate localized plastic deformation processes. Combined with the brittle fracture morphology shown in

Figure 8, this confirms that atomic cluster structures enhance hardness but weaken creep resistance by restricting energy dissipation pathways.

As demonstrated in

Figure 8c,d, the hardness and Young’s modulus demonstrate analogous trends, thereby corroborating the preceding outcomes of the load–displacement curves. The transverse magnetically annealed strip exhibits the highest values for both Young’s modulus and hardness, with respective measurements of 90.8 GPa and 8.5 GPa. The elevated values of Young’s modulus and hardness suggest the presence of an accumulation of atoms within the strip or the formation of grains that precipitate and grow, thereby impeding the diffusion and reorganisation of atoms within the liquid-like region. Similar to conventional annealing, the thermal energy during magnetic field annealing promotes atomic diffusion motion, driving structural relaxation in the material. This process reduces the excess free volume and increases the atomic packing density, thereby enhancing the material’s hardness and strength. However, it is typically accompanied by a decline in toughness, as the nucleation and propagation of shear bands require higher stress, leading to more localized deformation. Nevertheless, when a longitudinal magnetic field is applied during annealing, it induces the alignment of magnetic moments along the field direction, generating an effective uniaxial magnetic anisotropy in the matrix. This magnetically induced anisotropy partially counteracts the negative impact of relaxation on plasticity by controlling the propagation direction of shear bands—orienting them parallel to the band length. As a result, the material may even exhibit relatively improved toughness.

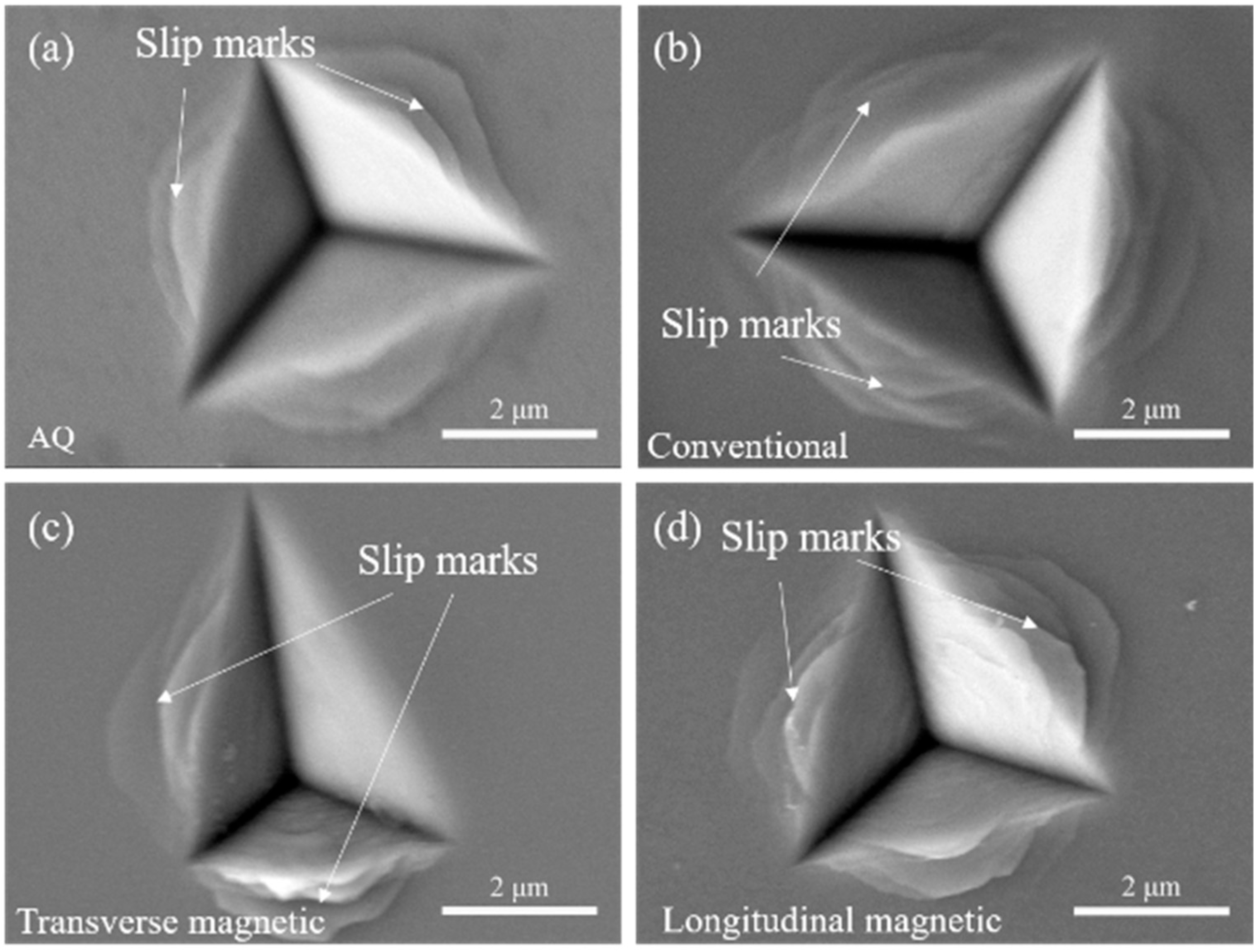

In

Figure 9a,b, the indentation contact regions of the as-quenched and conventionally annealed samples appear relatively smooth, with plastic deformation primarily accommodated by a large number of relatively uniformly distributed shear bands propagating outward from the indentation edges. In contrast, the indentation contact regions of the magnetically annealed samples exhibit higher surface roughness, particularly in the TA samples, where

Figure 9c reveals more pronounced surface undulations and possible microscale features. This increased roughness is closely related to the microstructural anisotropy induced by magnetic annealing. Under transverse magnetic annealing conditions, the tendency of magnetization alignment toward ordered states guides the directional development of short-/medium-range ordered structures at the atomic scale during annealing, potentially forming submicron-scale topographic features on the surface associated with anisotropy. This rough surface leads to uneven contact between the indenter and the sample, resulting in localized stresses significantly higher than the apparent contact stress, which greatly promotes the nucleation of shear bands beneath the indenter. Simultaneously, the magnetically induced structural anisotropy restricts the free propagation of shear bands, and the combination of localized high stress facilitates the nucleation of dense shear bands, causing plastic deformation to concentrate more intensely directly beneath the indentation and potentially inducing localized microcracks. The combined effect manifests as shallower but more irregularly shaped indentations, along with an increased tendency toward brittle fracture.

Additionally, the number of shear band slip steps observed around the indentations in the longitudinally magnetically annealed and conventionally annealed samples is significantly higher than in the as-quenched and transversely magnetically annealed samples. This reflects that the LA and CA samples triggered more shear bands to accommodate deformation during the indentation plastic deformation process. For the LA samples, the magnetic field-induced easy magnetization axis being perpendicular to the strip length may provide a relatively low-energy barrier path for shear bands to propagate in the direction perpendicular to the strip length, allowing more shear bands to form, as shown in

Figure 9d. The “stacking” degree of the shear band slip steps primarily reflects the total amount and localization extent of plastic deformation—numerous, widely distributed slip steps indicate relatively dispersed deformation, whereas fewer, confined slip steps suggest highly localized deformation.

In contrast to prior investigations [

21], our investigations show that longitudinal magnetic field annealing preferentially induces A1 FeNi nanocrystals in FeNi amorphous alloys, which is attributed to atomic diffusion pathways regulated by the magnetic field direction. Comprehensive nanoindentation creep data showed a reduction in the maximum creep displacement of magnetic field-annealed specimens compared to quenched specimens, suggesting that the electrolytic microstructure suppresses plastic deformation while maintaining toughness. This finding provides a new strategy for the development of non-ferromagnetic alloys with synergistically enhanced soft magnetic properties and high toughness, bridging the gap in optimizing mechanical properties through magnetic annealing systems.