The Influence of Er and Zr on the Microstructure and Durability of the Mechanical Properties of an Al-Mg Alloy Containing 7 wt.% of Mg

Abstract

1. Introduction

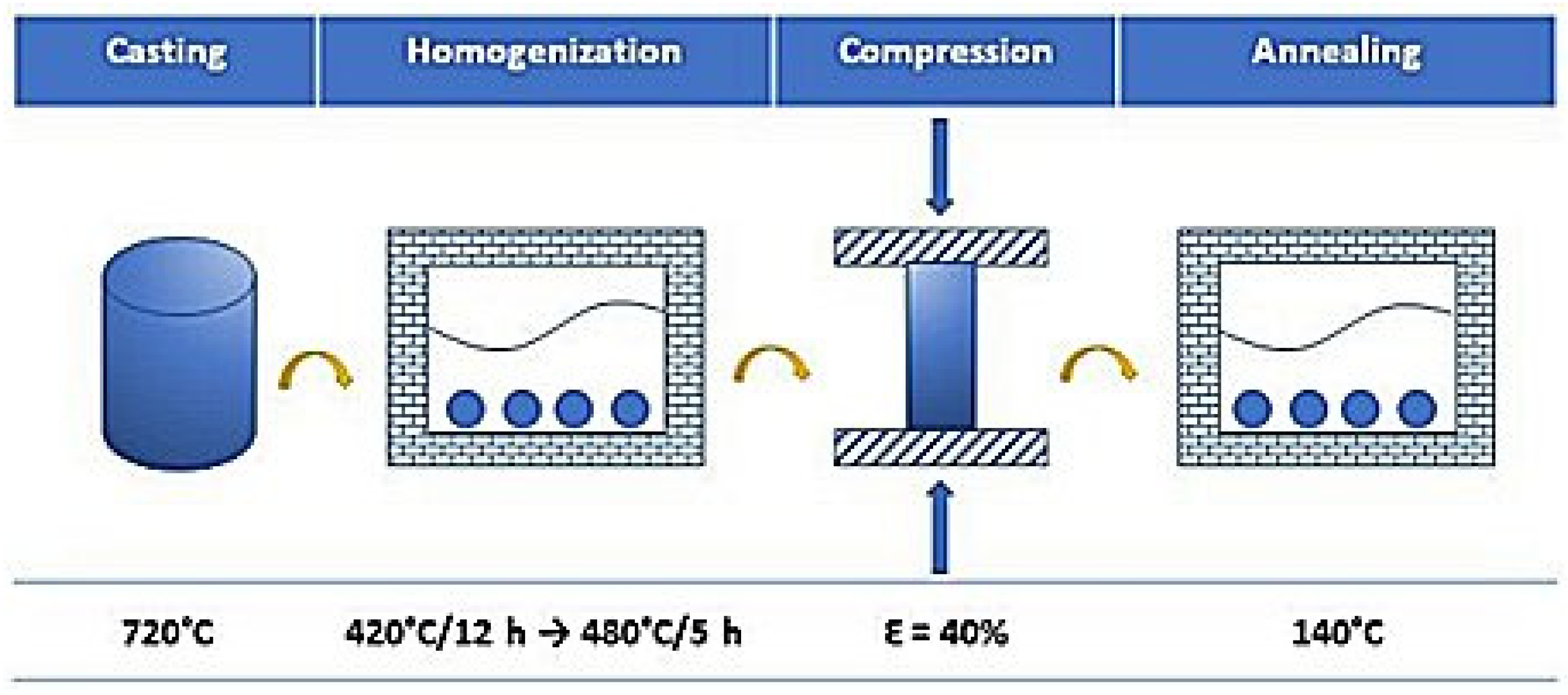

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

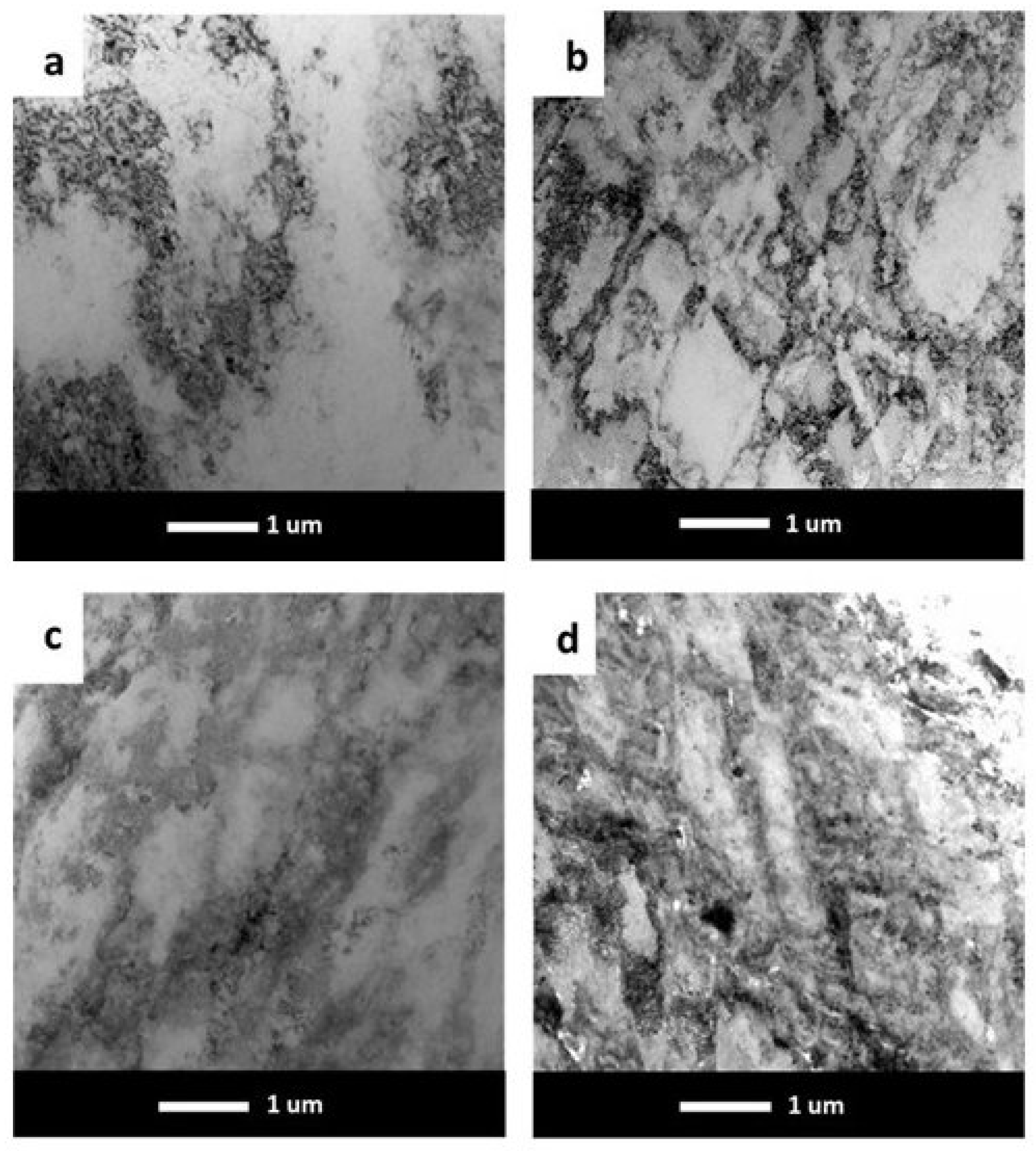

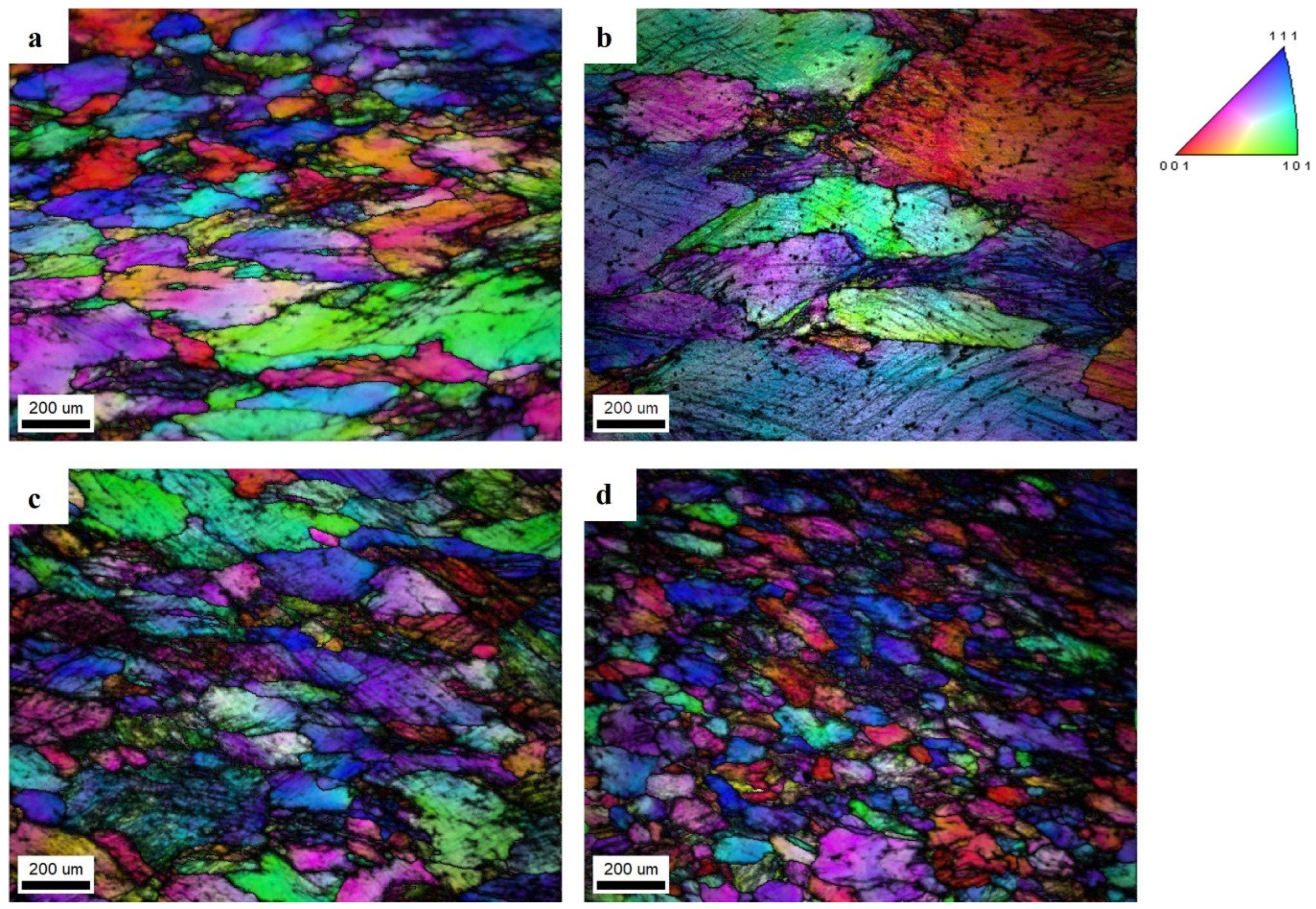

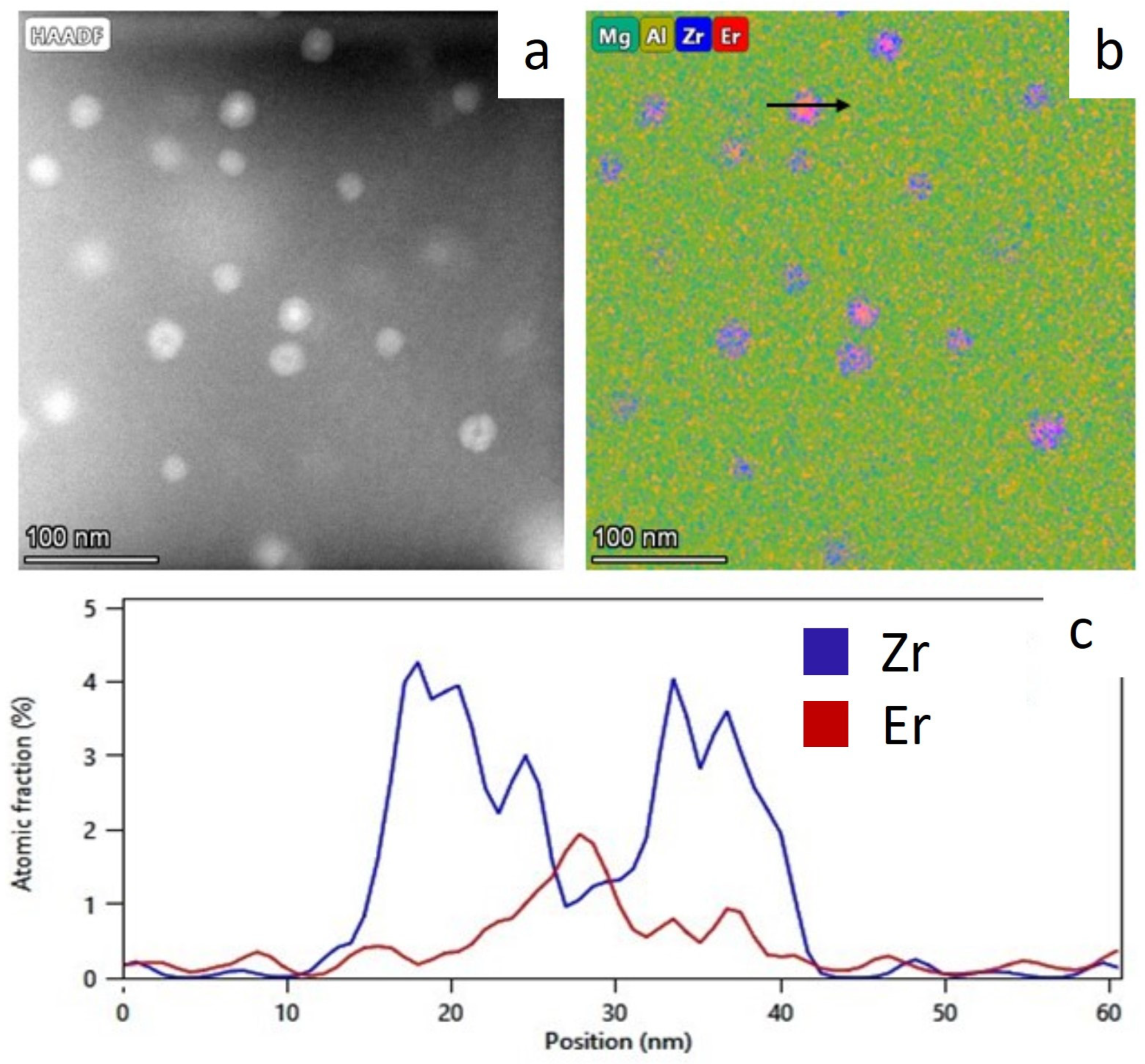

- Micro-alloying elements resulted in a reduction in the average grain size in the ingots by almost four times. The alloys with micro-additions were characterized by a homogeneous structure comprising equiaxed grains. The grain refinement was caused by the presence of small precipitates of primary phases containing Er and Zr, which crystallize first in the liquid melt and constitute crystallization nuclei for the solid aluminum solution.

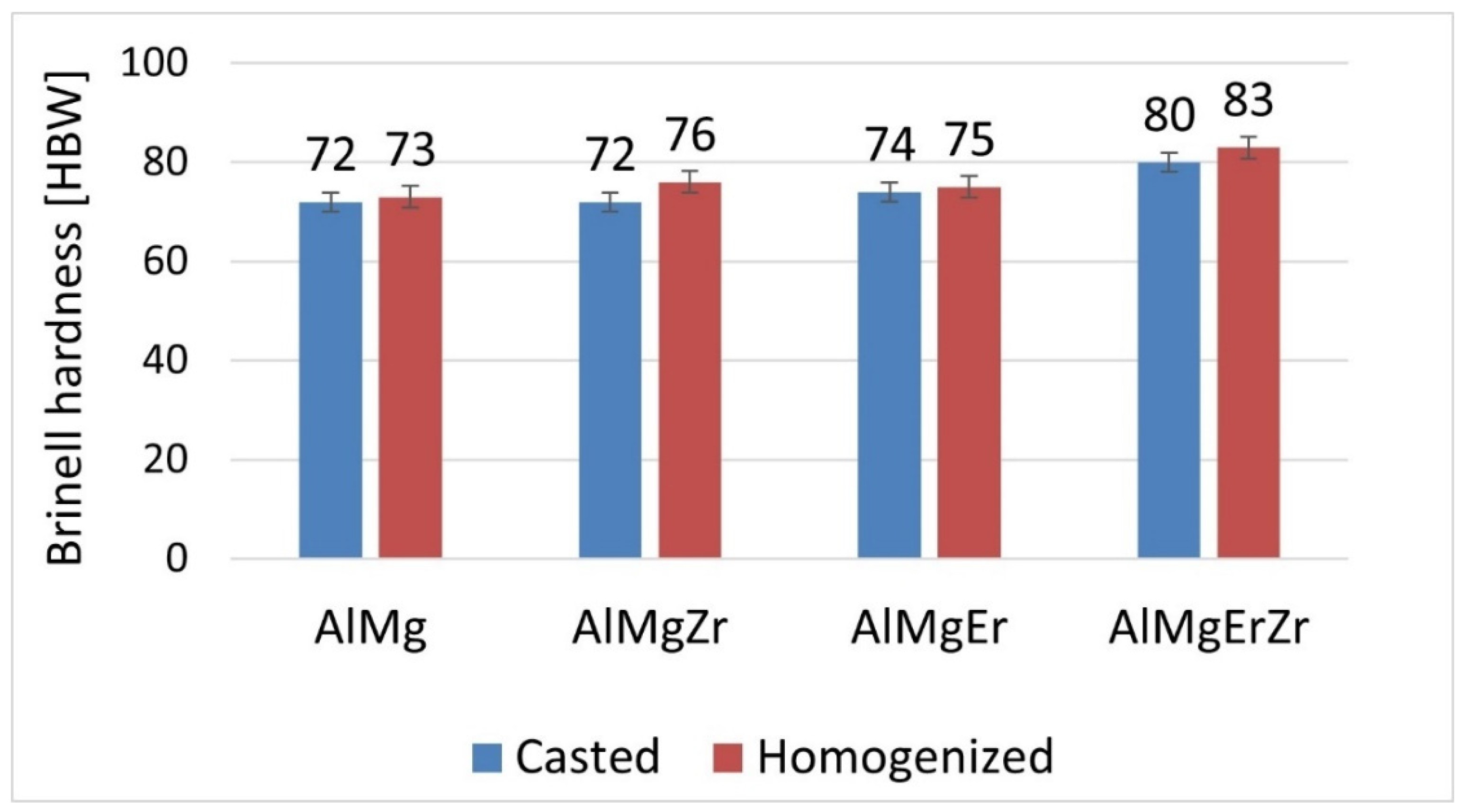

- Due to the solid solution and work-hardening after the static compression test, the Brinell hardness of all tested alloys increased by about 60 HB compared to the Brinell hardness of the ingots, which is the result of an increase in the density of dislocations.

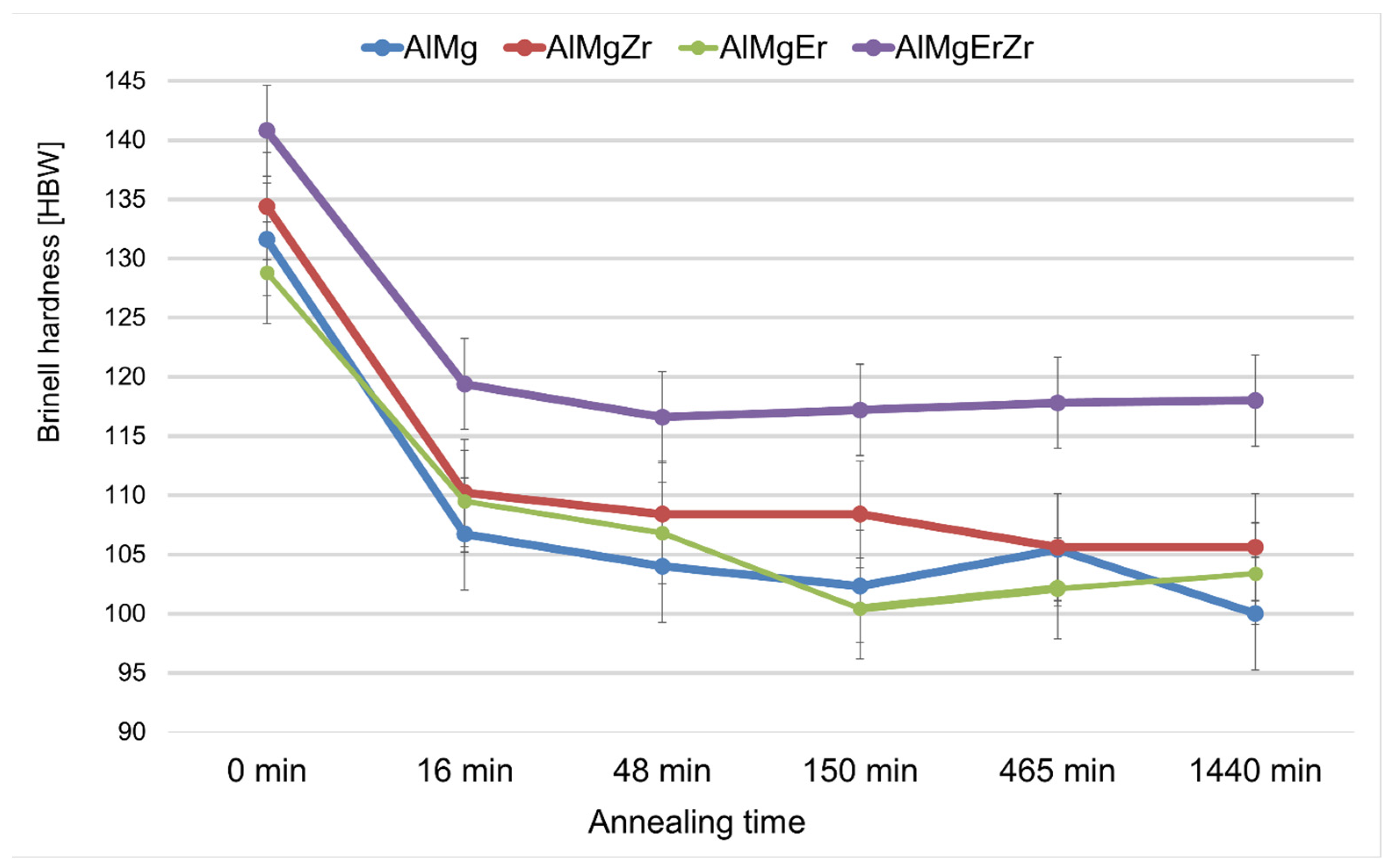

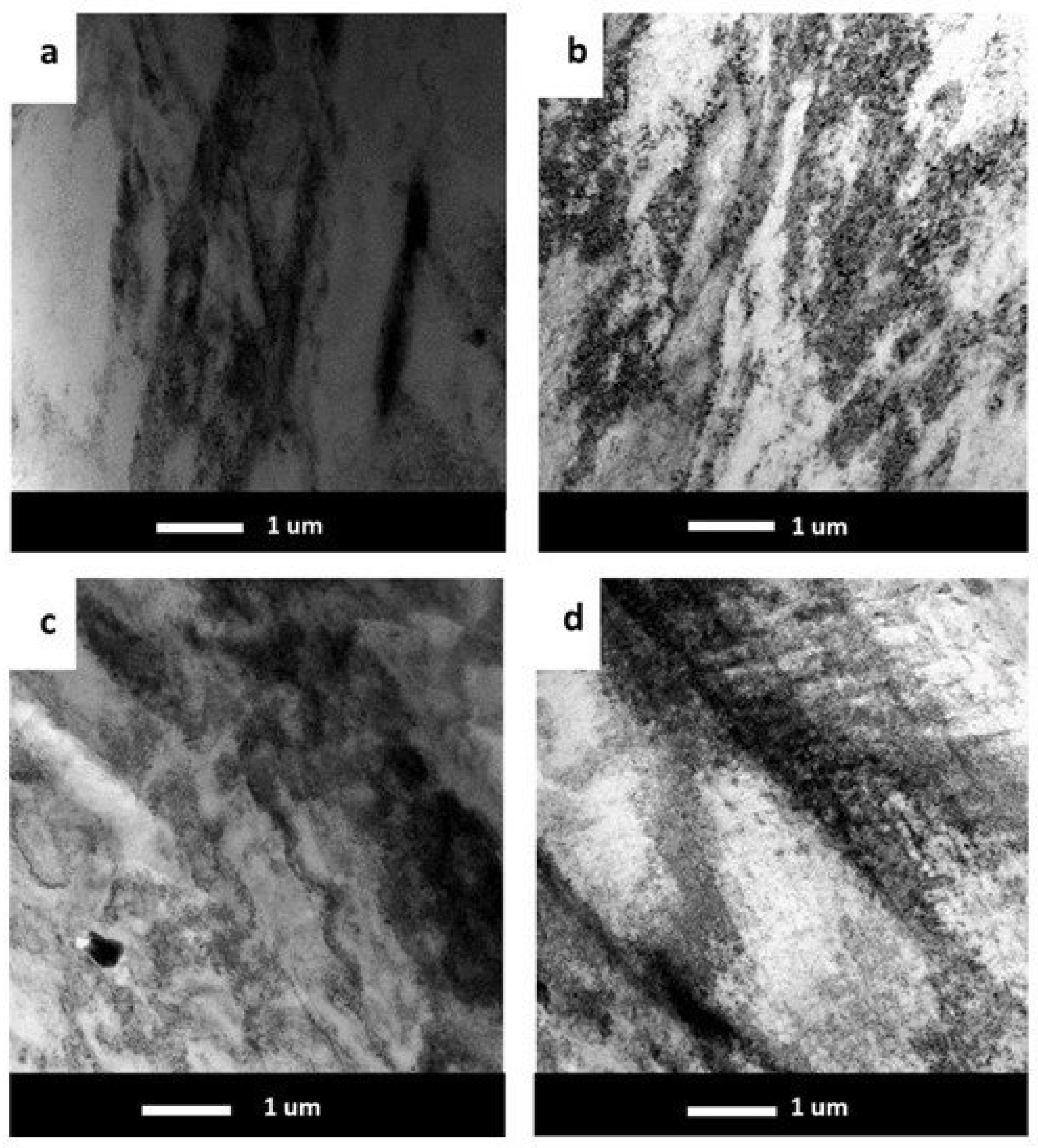

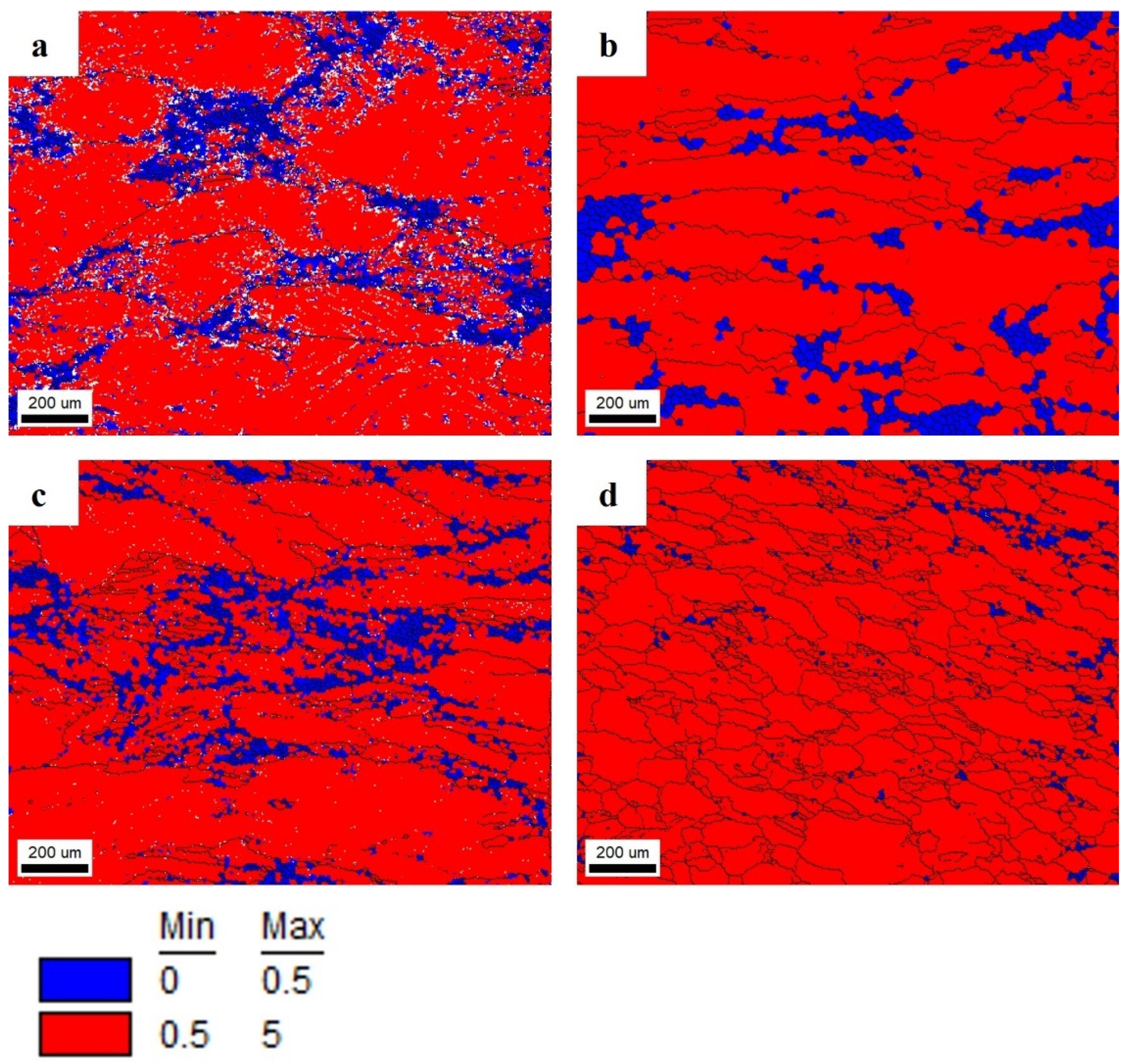

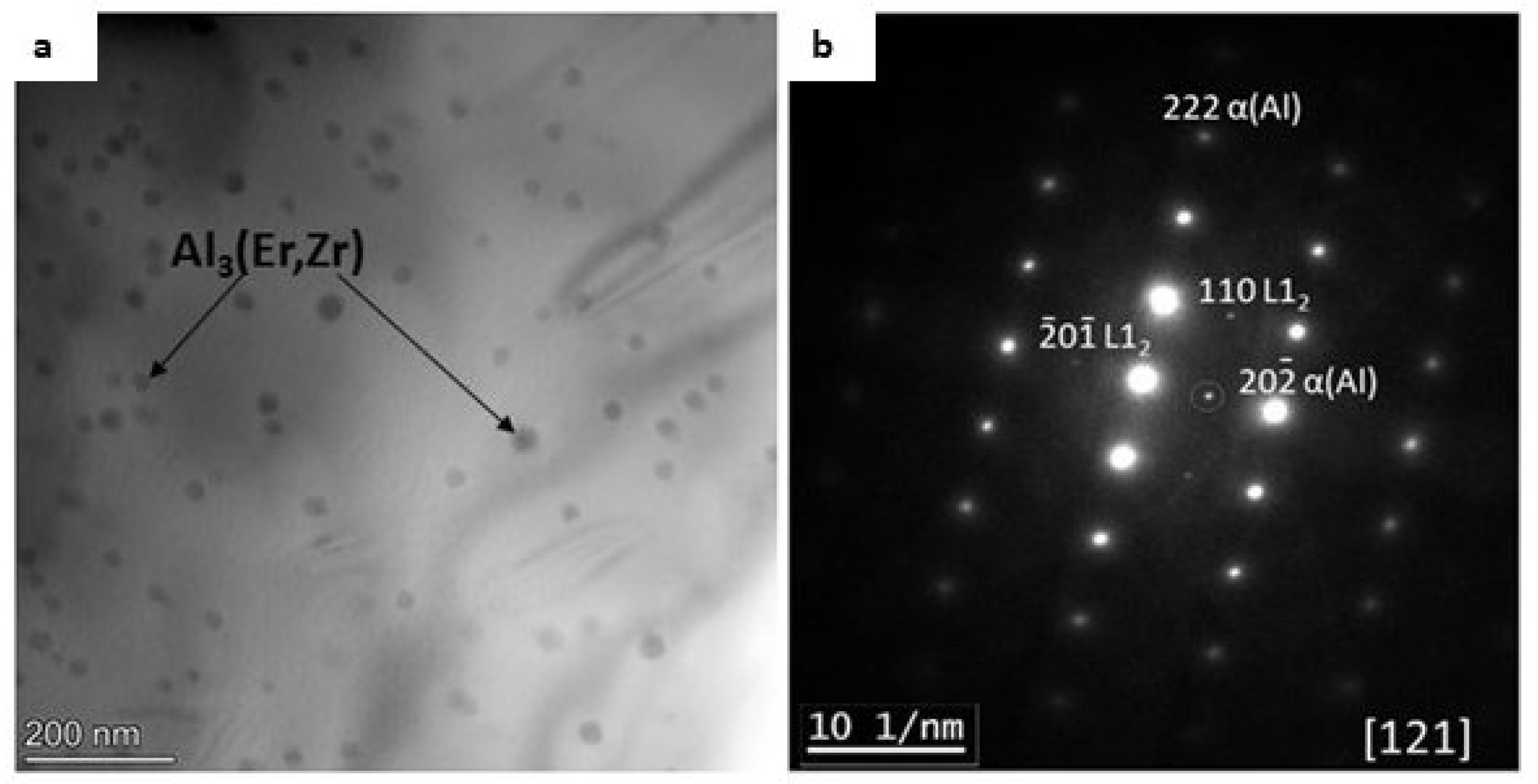

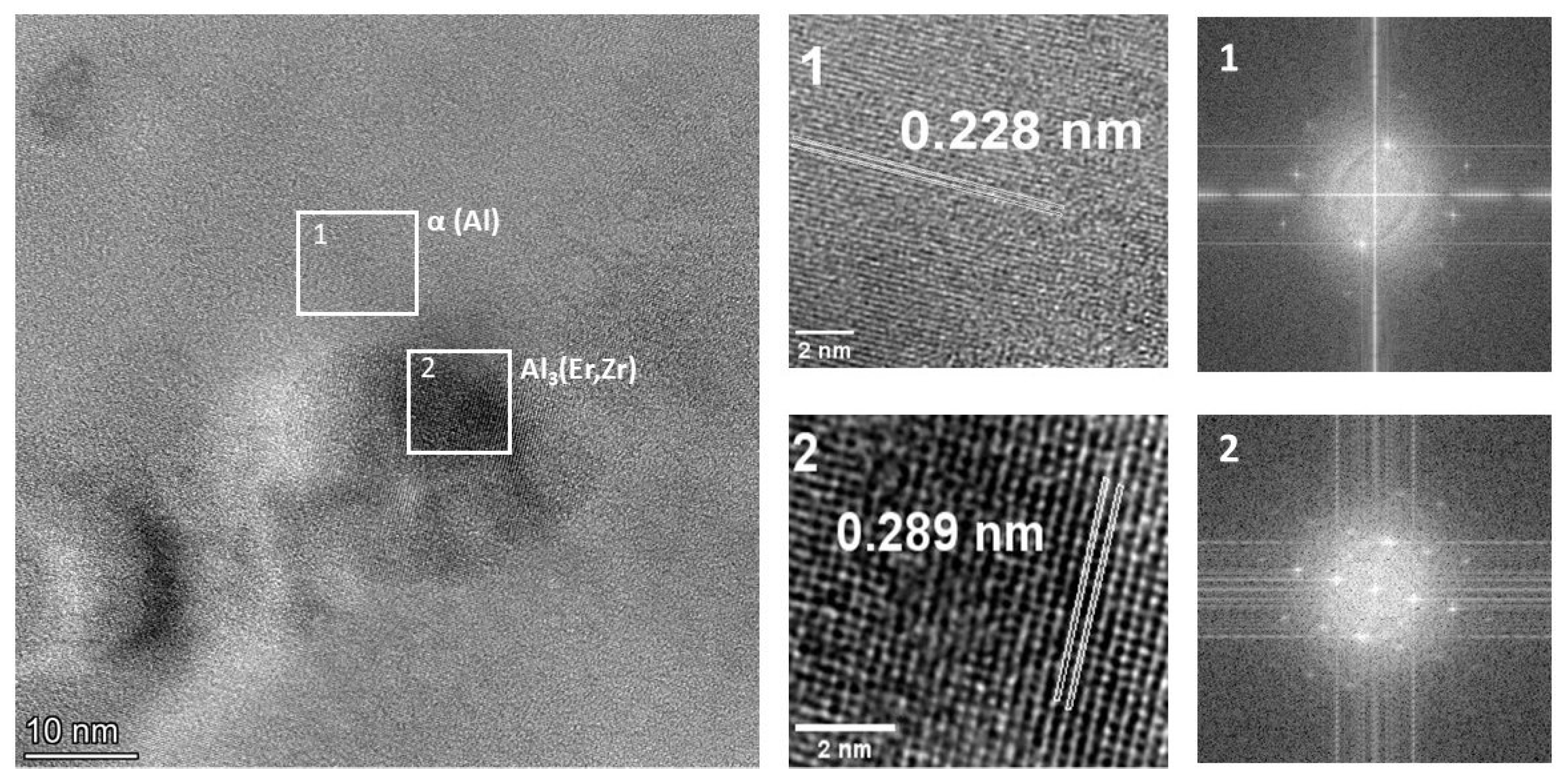

- The simultaneous addition of Er and Zr to AlMg7 significantly improved the durability of the mechanical properties after annealing. It was caused by forming spherical Al3(Er, Zr) dispersoids with a diameter of about 20 nm, which inhibited the movement of dislocations during annealing. The pinning effect of Al3(Er, Zr) dispersoids supported sub-structure strengthening at an elevated temperature, resulting in the formation of an alloy characterized by stable mechanical properties. The fractions of recrystallized grains based on the GAM ≤ 0.5° parameter were about 5%. The Er and Zr single additives of AlMg7 slightly restrained the decrease in the Brinell hardness after annealing but did not inhibit the processes of its decrease after annealing. The fractions of recrystallized grains based on the GAM ≤ 0.5° parameter were about 20%. The highest decrease in Brinell hardness revealed the alloy without micro-alloying elements. This was caused by the microstructure reconstruction during annealing, which resulted in the dislocation annihilation. The fraction of recrystallized grains based on the GAM ≤ 0.5° parameter was about 35% for the AlMg7 alloy. These results correlated with a strengthening analysis based on the Brinell hardness measurement, as the highest decrease in hardness was demonstrated in AlMg7, AlMg7Zr, and AlMg7Er alloys. The share of the fraction after recovery and recrystallization based on the GAM parameter in the alloys was over three times higher than in the AlMgErZr alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jang, D.H.; Park, Y.B.; Kim, W.J. Significant strengthening in superlight Al-Mg alloy with an exceptionally large amount of Mg (13 wt %) after cold rolling. Mater. Sci. Eng. 2019, 74, 36–44. [Google Scholar] [CrossRef]

- Senczyk, D. Mikronaprężenia; Wydawnictwo Politechniki Poznańskiej: Poznań, Poland, 1997; ISBN 83-7143-107-4. [Google Scholar]

- Harada, Y.; Jiang, N.; Kumai, S. Mechanical Properties of Cold-Rolled and Annealed Al-12%Mg Alloy Sheet with High Mg Solid Solubility Fabricated from Vertical-Type High-Speed Twin-Roll Cast Strip. Mater. Trans. 2019, 60, 2435–2441. [Google Scholar] [CrossRef]

- Mondolfo, L.F. Metallography of Aluminium Alloys; John Wiley & Sons Inc.: New York, NY, USA, 1943. [Google Scholar]

- Kotov, A.D.; Mochugovskiy, A.G.; Mosleh, A.O.; Kishchik, A.A.; Rofman, O.V.; Mikhaylovskaya, A.V. Microstructure, superplasticity, and mechanical properties of Al–Mg–Er–Zr alloys. Mater. Charact. 2022, 186, 111825. [Google Scholar] [CrossRef]

- Fu, L.; Li, Y.; Jiang, F.; Huang, J.; Xu, G.; Yin, Z. On the role of Sc or Er micro-alloying in the microstructure evolution of Al-Mg alloy sheets during annealing. Mater. Charact. 2019, 157, 109918. [Google Scholar] [CrossRef]

- Robson, J.D.; Prangnell, P.B. Dispersoid precipitation and process modelling in zirconium containing commercial aluminium alloys. Acta Mater. 2001, 49, 599–613. [Google Scholar] [CrossRef]

- Ding, Y.; Gao, K.; Xiong, X.; Huang, H.; Wen, S.; Wu, X.; Nie, Z.; Shao, R.; Huang, C.; Guo, S.; et al. High corrosion resistance and strain hardening of high Mg Al-alloy with Er and Zr by using a new reverse stabilization process. Scr. Mater. 2019, 171, 26–30. [Google Scholar] [CrossRef]

- Michajłowska, A.V.; Mochugovskiy, A.G.; Lewczenko, C.S.; Tabachkowa, N.Y.; Mufalo, W.; Portnoj, V.K. Precipitation behavior of L12 Al3Zr phase in Al-Mg-Zr alloy. Mater. Charact. 2018, 139, 30–37. [Google Scholar]

- Nie, Z.R.; Jin, T.N.; Zou, J.X.; Fu, J.B.; Yang, J.J.; Zuo, T.Y. Development on research of advanced rare-earth aluminum alloy. Trans. Nonferrous Met. Soc. China 2003, 13, 509–514. [Google Scholar]

- Xue, D.; Wei, W.; Wen, S.; Wu, X.; Shi, W.; Zhou, X.; Gao, K.; Huang, H.; Nie, Z. Microstructural evolution of Al-Mg-Er-Zr alloy by equal channel angular extrusion at room temperature. Mater. Lett. 2023, 334, 133759. [Google Scholar] [CrossRef]

- Pan, S.; Wang, Z.; Li Ch Wan, D.; Chen Xi Chen, K.; Li, Y. Achieving superior dispersion-strengthening effect in an AA5xxx Al-Mg-Mn alloy by mico-alloying. Mater. Des. 2023, 226, 111647. [Google Scholar] [CrossRef]

- Robson, J.D.; Prangnell, P.B. Modelling Al3Zr dispersoid precipitation in multicomponent aluminium alloys. Mater. Sci. Eng. A 2003, 352, 240–250. [Google Scholar] [CrossRef]

- Morere, B.; Shahani, R.; Maurice, C.; Driver, J. The influence of Al3Zr dispersoids on the recrystallization of hot-deformed AA 7010 alloys. Metall. Mater. Trans. A 2001, 32, 625–632. [Google Scholar] [CrossRef]

- Xu, G.F.; Mou, S.Z.; Yang, J.J.; Jin, T.N.; Nie, Z.R.; Yin, Z.M. Effect of trace rare earth element Er on Al-Zn-Mg alloy. Trans. Nonferrous Met. Soc. China 2006, 16, 598–603. [Google Scholar] [CrossRef]

- Wen, S.P.; Xing, Z.B.; Huang, H.; Li, B.L.; Wang, W.; Nie, Z.R. Scientific principles of making an alloying addition of mechanical properties of Al–Mg–Mn–Zr alloy. Mater. Sci. Eng. A 2009, 516, 42–49. [Google Scholar] [CrossRef]

- Massalski, T.B. Binary Alloy Phase Diagrams; ASM International: Materials Park, OH, USA, 1990; Volume XXII. [Google Scholar]

- Wen, S.P.; Gao, K.Y.; Huang, H.; Wang, W.; Nie, Z.R. Precipitation evolution in Al–Er–Zr alloys during aging at elevated temperature. J. Alloys Compd. 2013, 574, 92–97. [Google Scholar] [CrossRef]

- Glavatskikh, M.V.; Gorlov, L.E.; Loginova, I.S.; Barkov, R.Y.; Khomutov, M.G.; Churyumov, A.Y.; Pozdniakov, A.V. Effect of Er on the Hot Deformation Behavior of the Crossover Al3Zn3Mg3Cu0.2Zr Alloy. Metals 2024, 14, 1114. [Google Scholar] [CrossRef]

- Wang, M.; Wei, W.; Shi, W.; Zhou, X.; Wen, S.; Wu, X.; Gao, K.; Rong, L.; Qi, P.; Huang, H.; et al. Synergistic effect of Al3(Er, Zr) precipitation and hot extrusion on the microstructural evolution of a novel Al–Mg–Si–Er–Zr alloy. J. Mater. Res. Technol. 2023, 22, 947–957. [Google Scholar] [CrossRef]

- Pozdniakov, A.V.; Yarasu, V.; Barkov, R.Y.; Yakovtseva, O.A.; Makhov, S.V.; Napalkov, V.I. Microstructure and mechanical properties of novel Al-Mg-Mn-Zr-Sc-Er alloy. Mater. Lett. 2017, 202, 116–119. [Google Scholar] [CrossRef]

- Zha, M.; Meng, X.T.; Zhang, H.M.; Zhang, X.H.; Jia, H.L.; Li, Y.J.; Zhang, J.Y.; Wang, H.Y.; Jiang, Q.C. High strength and ductile high solid solution Al–Mg alloy processed by a novel hard-plate rolling route. J. Alloys Compd. 2017, 728, 872–877. [Google Scholar] [CrossRef]

- Song, M.; Du, K.; Huang, Z.Y.; Huang, H.; Nie, Z.R.; Ye, H.Q. Deformation-induced dissolution and growth of precipitates in an Al–Mg–Er alloy during high-cycle fatigue. Acta Mater. 2014, 81, 409–419. [Google Scholar] [CrossRef]

- Marumo, T.; Fujikawa, S.; Hirono, K. Diffusion of zirconium in aluminum. J. Jpn. Inst. Met. 1973, 23, 17–25. [Google Scholar] [CrossRef]

- Van Dalen MEKarnesky, R.A.; Cabotaje, J.R.; Dunand, D.C.; Seidman, D.N. Erbium and ytterbium solubilities and diffu-404 sivities in aluminum as determined by nanoscale characterization of precipitates. Acta Mater. 2009, 57, 4081–4089. [Google Scholar] [CrossRef]

- Yu, M.; Zhang, Y.; Li, X.; Wen, K.; Lin, H.; Zhou, H.; Shi, G.; Li, Z.; Xiong, B. The role of recrystallization on fatigue crack propagation of a high alloying Al-Zn-Mg-Cu alloy. Mater. Lett. 2022, 311, 131564. [Google Scholar] [CrossRef]

- Gao, Z.; Ma, T.; Li, H.; Yang, H.; Wei, W.; Huang, H.; Nie, Z. Microstructure and mechanical properties of a novel Al–Mg–Er–Zr-Sc alloy fabricated by selective laser melting. JMR&T 2023, 27, 6880–6891. [Google Scholar]

| Alloy | Chemical Composition [wt.%] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fe | Si | Mg | Mn | Cr | V | Zr | Be | Er | Al | |

| AlMg7 | 0.055 | 0.091 | 7.01 | 0.006 | 0.0003 | 0.002 | 0.002 | Remainder | ||

| AlMgZr | 0.051 | 0.053 | 6.96 | 0.002 | 0.0005 | 0.004 | 0.198 | 0.001 | Remainder | |

| AlMgEr | 0.06 | 0.097 | 6.81 | 0.007 | 0.0004 | 0.002 | 0.002 | 0.12 | Remainder | |

| AlMgErZr | 0.054 | 0.062 | 6.97 | 0.39 | 0.0008 | 0.004 | 0.204 | 0.002 | 0.27 | Remainder |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Limanówka, K.; Boczkal, S.; Mitka, M.; Szymańska, E.; Hrabia-Wiśnios, J.; Kapinos, D.; Augustyn, B.; Skrzyńska, R.; Grzebinoga, Ł.; Czaja, P.; et al. The Influence of Er and Zr on the Microstructure and Durability of the Mechanical Properties of an Al-Mg Alloy Containing 7 wt.% of Mg. Materials 2024, 17, 5295. https://doi.org/10.3390/ma17215295

Limanówka K, Boczkal S, Mitka M, Szymańska E, Hrabia-Wiśnios J, Kapinos D, Augustyn B, Skrzyńska R, Grzebinoga Ł, Czaja P, et al. The Influence of Er and Zr on the Microstructure and Durability of the Mechanical Properties of an Al-Mg Alloy Containing 7 wt.% of Mg. Materials. 2024; 17(21):5295. https://doi.org/10.3390/ma17215295

Chicago/Turabian StyleLimanówka, Kamila, Sonia Boczkal, Monika Mitka, Elżbieta Szymańska, Joanna Hrabia-Wiśnios, Dawid Kapinos, Bogusław Augustyn, Renata Skrzyńska, Łukasz Grzebinoga, Paweł Czaja, and et al. 2024. "The Influence of Er and Zr on the Microstructure and Durability of the Mechanical Properties of an Al-Mg Alloy Containing 7 wt.% of Mg" Materials 17, no. 21: 5295. https://doi.org/10.3390/ma17215295

APA StyleLimanówka, K., Boczkal, S., Mitka, M., Szymańska, E., Hrabia-Wiśnios, J., Kapinos, D., Augustyn, B., Skrzyńska, R., Grzebinoga, Ł., Czaja, P., Góral, A., & Czeppe, T. (2024). The Influence of Er and Zr on the Microstructure and Durability of the Mechanical Properties of an Al-Mg Alloy Containing 7 wt.% of Mg. Materials, 17(21), 5295. https://doi.org/10.3390/ma17215295