High-Performance Triboelectric Nanogenerator Based on PVDF Nanofibers Modified by a Charge Control Agent n-Propyl Gallate

Abstract

1. Introduction

2. Materials and Methods

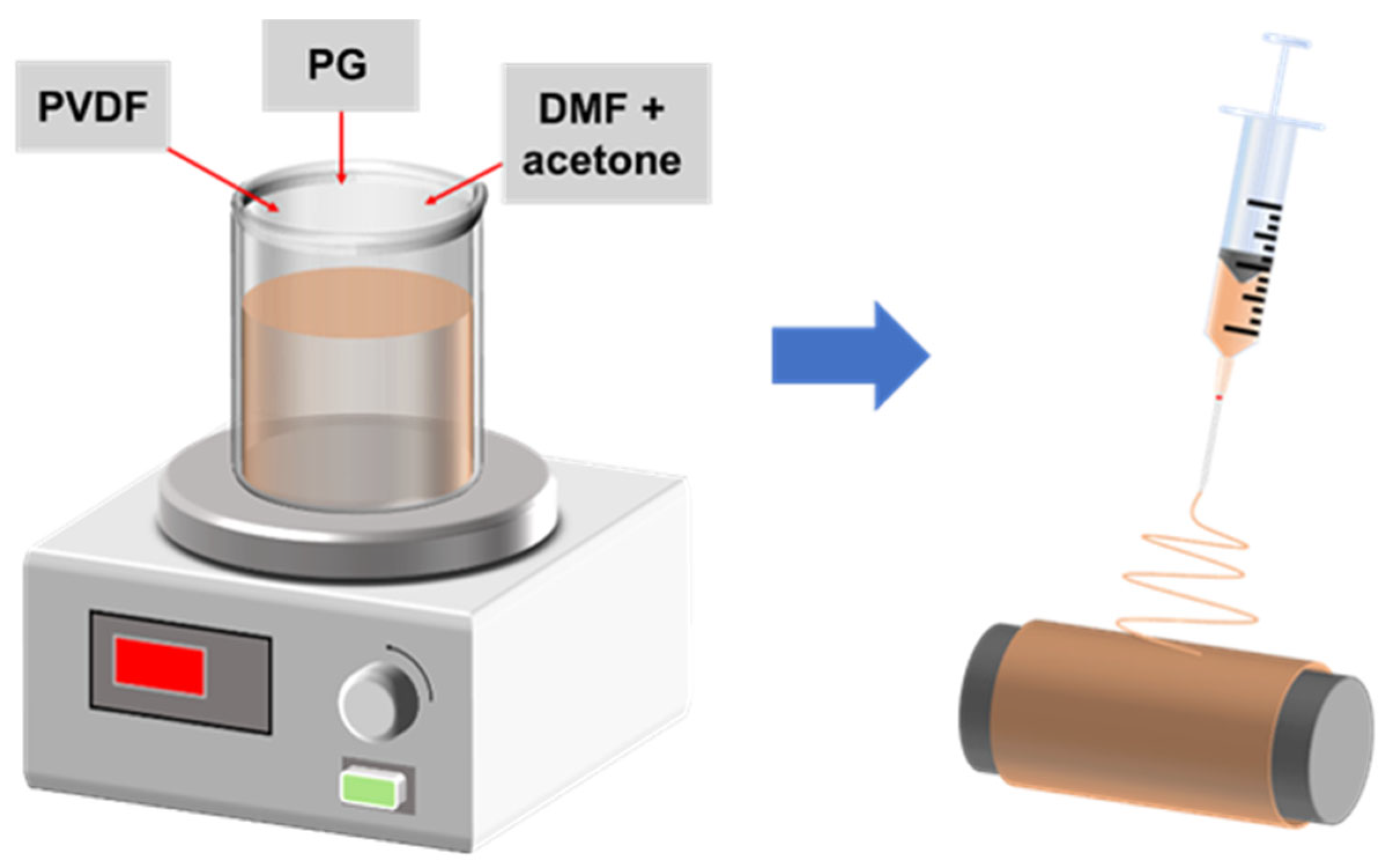

2.1. Preparation of PVDF/PG Composite Nanofiber Films and Structural Design of PG-TENGs

2.2. Measurement of the Electrical Properties of PG-TENGs

3. Results and Discussion

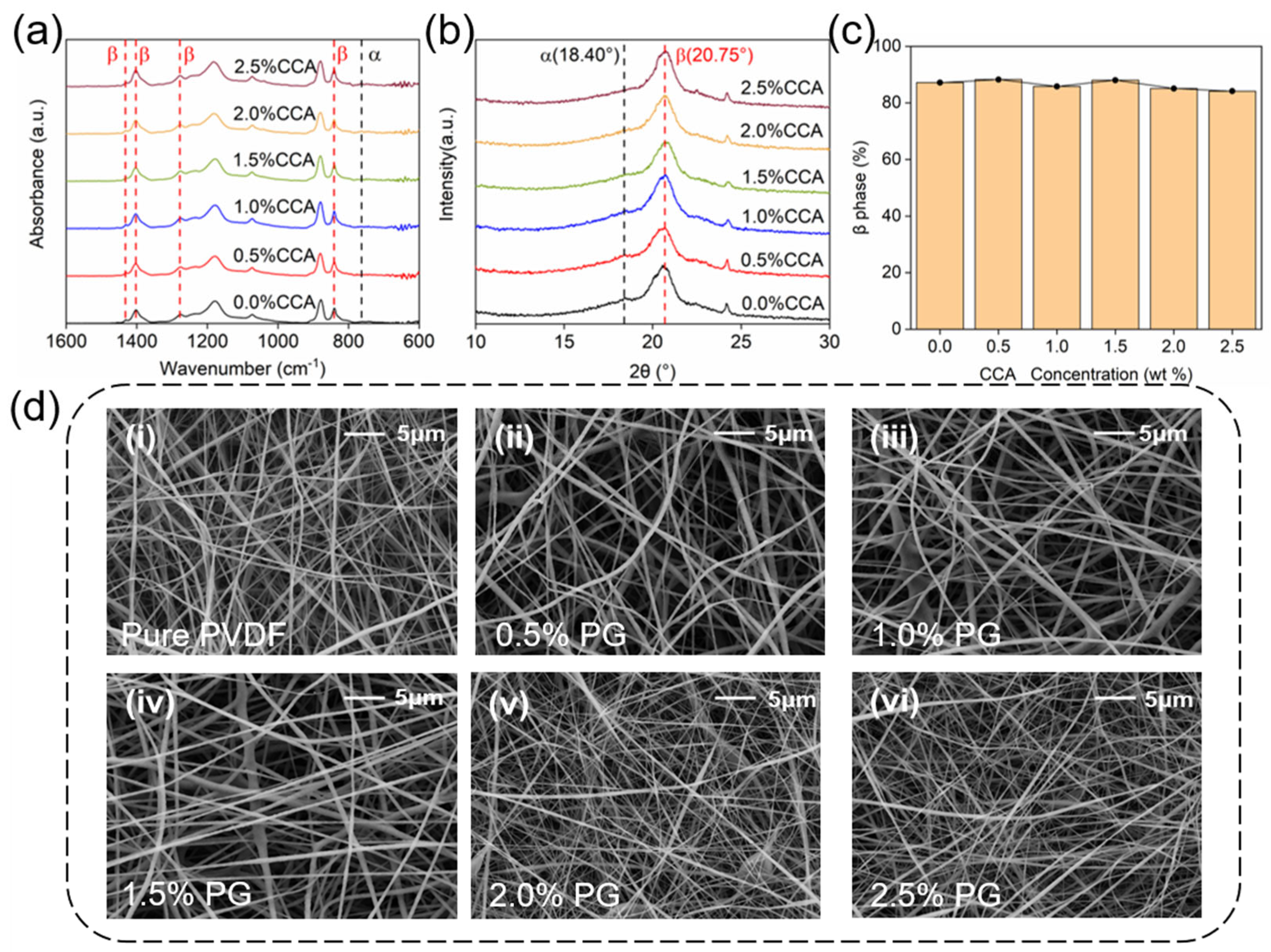

3.1. Analysis of β-Phase Content and Surface Morphology of PVDF/PG Composite Nanofiber Films

3.2. Electrical Performance of PG-TENGs

3.3. Exploration of Applications of PG-TENG

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tao, D.; Su, P.; Chen, A.; Gu, D.; Eginligil, M.; Huang, W. Electro-spun nanofibers-based triboelectric nanogenerators in wearable electronics: Status and perspectives. NPJ Flex. Electron. 2025, 9, 4. [Google Scholar] [CrossRef]

- Li, M.; Zang, H.; Long, J.; Sun, S.; Zhang, Y. Flexible pressure sensors based on polyvinylidene fluoride: A critical review. Materials 2025, 18, 615. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Zhang, X.; Deng, T. Nontoxic flexible TENG with robust piezoelectric enhancement through graphitic carbon nitride-incorporated PVDF for wearable sensors and power supplies. Energy 2024, 306, 132555. [Google Scholar] [CrossRef]

- Zhang, R.; Olin, H. Advances in inorganic nanomaterials for triboelectric nanogenerators. ACS Nanosci. Au 2022, 2, 12–31. [Google Scholar] [CrossRef]

- Prasanwong, C.; Harnchana, V.; Thongkrairat, P.; Pimanpang, S.; Jarernboon, W.; Thongbai, P.; Pimsawat, A.; Huynh, N.V.; Amornkitbamrung, V.; Treetong, A.; et al. Photoinduced charge generation of nanostructured carbon derived from human hair biowaste for performance enhancement in polyvinylidene fluoride based triboelectric nanogenerator. J. Colloid Interface Sci. 2024, 665, 720–732. [Google Scholar] [CrossRef]

- Kavarthapu, V.S.; Graham, S.A.; Manchi, P.; Paranjape, M.V.; Yu, J.S. Electrospun ZnSnO3/PVDF-HFP nanofibrous triboelectric films for efficient mechanical energy harvesting. Adv. Fiber Mater. 2023, 5, 1685–1698. [Google Scholar] [CrossRef]

- Choi, J.H.; Ra, Y.; Cho, S.; La, M.; Park, S.J.; Choi, D. Electrical charge storage effect in carbon based polymer composite for long-term performance enhancement of the triboelectric nanogenerator. Compos. Sci. Technol. 2021, 207, 108680. [Google Scholar] [CrossRef]

- Mizuguchi, J.; Iwataa, S.; Hitachi, A. Crystal structure of n-propyl gallate used as the charge-control agent of the negative type. J. Imag. Soc. Jpn. 2004, 43, 438–443. [Google Scholar] [CrossRef]

- Mizuguchi, J.; Hitachi, A.; Iwataa, A.; Makinoa, T. n-Propyl gallate-acetonitrile (2/1). Acta Cryst. E 2005, 61, 2593–2595. [Google Scholar] [CrossRef]

- Zhang, M.; Tan, Z.; Zhang, Q.; Shen, Y.; Mao, X.; Wei, L. Flexible self-powered friction piezoelectric sensor based on structured PVDF-based composite nanofiber films. ACS Appl. Mater. Interfaces 2023, 15, 30849–30858. [Google Scholar] [CrossRef]

- Lei, T.; Yu, L.; Zheng, G.; Wang, L.; Wu, D.; Sun, D. Electrospinning-induced preferred dipole orientation in PVDF fibers. J. Mater. Sci. 2015, 50, 4342–4347. [Google Scholar] [CrossRef]

- Chen, C.; Bai, Z.; Cao, Y.; Dong, M.; Jiang, K.; Zhou, Y.; Tao, Y.; Gu, S.; Xu, J.; Yin, X.; et al. Enhanced piezoelectric performance of BiCl3/PVDF nanofibers-based nanogenerators. Compos. Sci. Technol. 2020, 192, 108100. [Google Scholar] [CrossRef]

- Yousry, Y.M.; Yao, K.; Mohamed, A.M.; Liew, W.H.; Chen, S.; Ramakrishna, S. Theoretical model and outstanding performance from constructive piezoelectric and triboelectric mechanism in electrospun PVDF fiber film. Adv. Funct. Mater. 2020, 30, 1910592. [Google Scholar] [CrossRef]

- Suka, A.; Takeuchi, M.; Suganami, K.; Oguchi, T. Toner charge generated by CCA particles at the interface between toner and carrier. J. Imag. Soc. Jpn. 2006, 45, 127–132. [Google Scholar] [CrossRef]

- Wang, T.; Hu, J.; Hou, Z.; Yang, H. Antifouling and antioxidant properties of PVDF membrane modified with polyethylene glycol methacrylate and propyl gallate. Materials 2024, 17, 1867. [Google Scholar] [CrossRef] [PubMed]

- Im, S.; Frey, E.; Lacks, D.J.; Genzer, D.; Dickey, M.D. Enhanced triboelectric charge stability by air-stable radicals. Adv. Sci. 2023, 10, 2304459. [Google Scholar] [CrossRef]

- Liu, Q.; Xue, Y.; He, J.; Li, J.; Mu, L.; Zhao, Y.; Liu, H.; Sun, C.L.; Qu, M. Highly moisture-resistant flexible thin-film-based triboelectric nanogenerator for environmental energy harvesting and self-powered tactile sensing. ACS Appl. Mater. Interfaces 2024, 16, 38269–38282. [Google Scholar] [CrossRef]

- Rana, S.S.; Rahman, M.T.; Salauddin, M.; Sharma, S.; Maharjan, P.; Bhatta, T.; Cho, H.; Park, C.; Park, J.Y. Electrospun PVDF-TrFE/MXene nanofiber mat-based triboelectric nanogenerator for smart home appliances. ACS Appl. Mater. Interfaces 2021, 13, 4955–4967. [Google Scholar] [CrossRef]

- Babu, A.; Ruthvik, K.; Supraja, P.; Navaneeth, M.; Kumar, K.U.; Kumar, R.R.; Prakash, K.; Raju, N. High-performance triboelectric nanogenerator using ZIF-67/PVDF hybrid film for energy harvesting. J. Mater. Sci. Mater. Electron. 2023, 34, 2195. [Google Scholar] [CrossRef]

- Deng, T.; Zhang, X.; Yang, Z.; Xiang, G. Performance enhancement of triboelectric nanogenerator based on BaTiO3-incorporated PVDF-HFP nanofibers for self-powered wearable sensors. Sci. China Technol. Sci. 2025, 68, 1120203. [Google Scholar] [CrossRef]

- Qu, M.; Liu, H.; Xue, Y.; Li, J.; Liu, Q.; Yan, J.; Zhao, Y.; Mu, L.; Sun, C.L.; He, J. Stearic acid-enhanced triboelectric nanogenerators with high waterproof, output performance, and wear resistance for efficient harvesting of mechanical energy and self-powered sensing for human motion monitoring. ACS Appl. Electron. Mater. 2024, 6, 1651–1665. [Google Scholar] [CrossRef]

| TENGs | Triboelectric Pair | Output Voltage | Output Current | Max Power Density |

|---|---|---|---|---|

| P-TENG [17] | PVDF/PVC-TiO @ PET | 235 V | 35 μA | 1.4 W/m2 |

| EN-TENG [18] | PVDF/Mxene @ Nylon-11 | 270 V | 24.7 μA | 4.02 W/m2 |

| NP-TENG [6] | PVDF/ZnSnO3 @ Al | 138 V | 5 μA | 1.6 W/m2 |

| ZIF-TENG [19] | PVDF/ZIF-67 @ FEP | 395 V | 95 μA | 3.1 W/m2 |

| BaTiO3-TENG [20] | PVDF/BaTiO3 @ Al | 432 V | 44.2 µA | 2.25 W/m2 |

| SA-TENG [21] | PVDF/SA-PTFE @ Silk | 145 V | 18 μA | 2.6 W/m2 |

| PG1-TENG (This work) | PVDF/PG @ PET | 712 V | 10.66 μA | 5.27 W/m2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Yang, X.; Tang, X.; Yang, Y.; Shen, L.; Gu, D.; Eginligil, M. High-Performance Triboelectric Nanogenerator Based on PVDF Nanofibers Modified by a Charge Control Agent n-Propyl Gallate. Materials 2025, 18, 3089. https://doi.org/10.3390/ma18133089

Li C, Yang X, Tang X, Yang Y, Shen L, Gu D, Eginligil M. High-Performance Triboelectric Nanogenerator Based on PVDF Nanofibers Modified by a Charge Control Agent n-Propyl Gallate. Materials. 2025; 18(13):3089. https://doi.org/10.3390/ma18133089

Chicago/Turabian StyleLi, Chao, Xueying Yang, Xin Tang, Ying Yang, Linjiang Shen, Dawei Gu, and Mustafa Eginligil. 2025. "High-Performance Triboelectric Nanogenerator Based on PVDF Nanofibers Modified by a Charge Control Agent n-Propyl Gallate" Materials 18, no. 13: 3089. https://doi.org/10.3390/ma18133089

APA StyleLi, C., Yang, X., Tang, X., Yang, Y., Shen, L., Gu, D., & Eginligil, M. (2025). High-Performance Triboelectric Nanogenerator Based on PVDF Nanofibers Modified by a Charge Control Agent n-Propyl Gallate. Materials, 18(13), 3089. https://doi.org/10.3390/ma18133089