Characterization of Hexagonal Close-Packed Zn-Cu-Ti Alloy Pyramid Drawpieces in Single-Point Incremental Sheet Forming Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

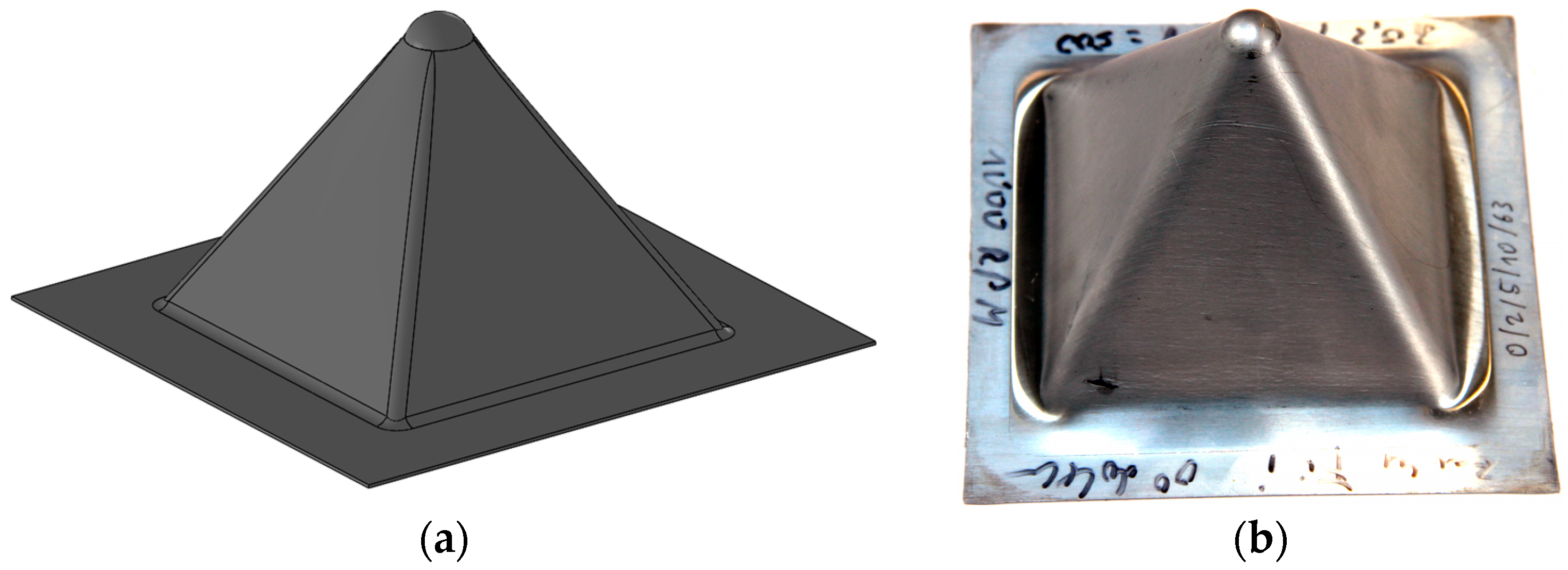

2.2. Formability Testing

2.3. Single-Point Incremental Forming Methodology

2.4. Analysis of Drawpieces After ISF

2.5. Analysis of Variance

3. Results and Discussion

3.1. Mechanical Properties of Test Material

3.2. SPIF of Zn-Cu-Ti Zinc Alloy Sheet

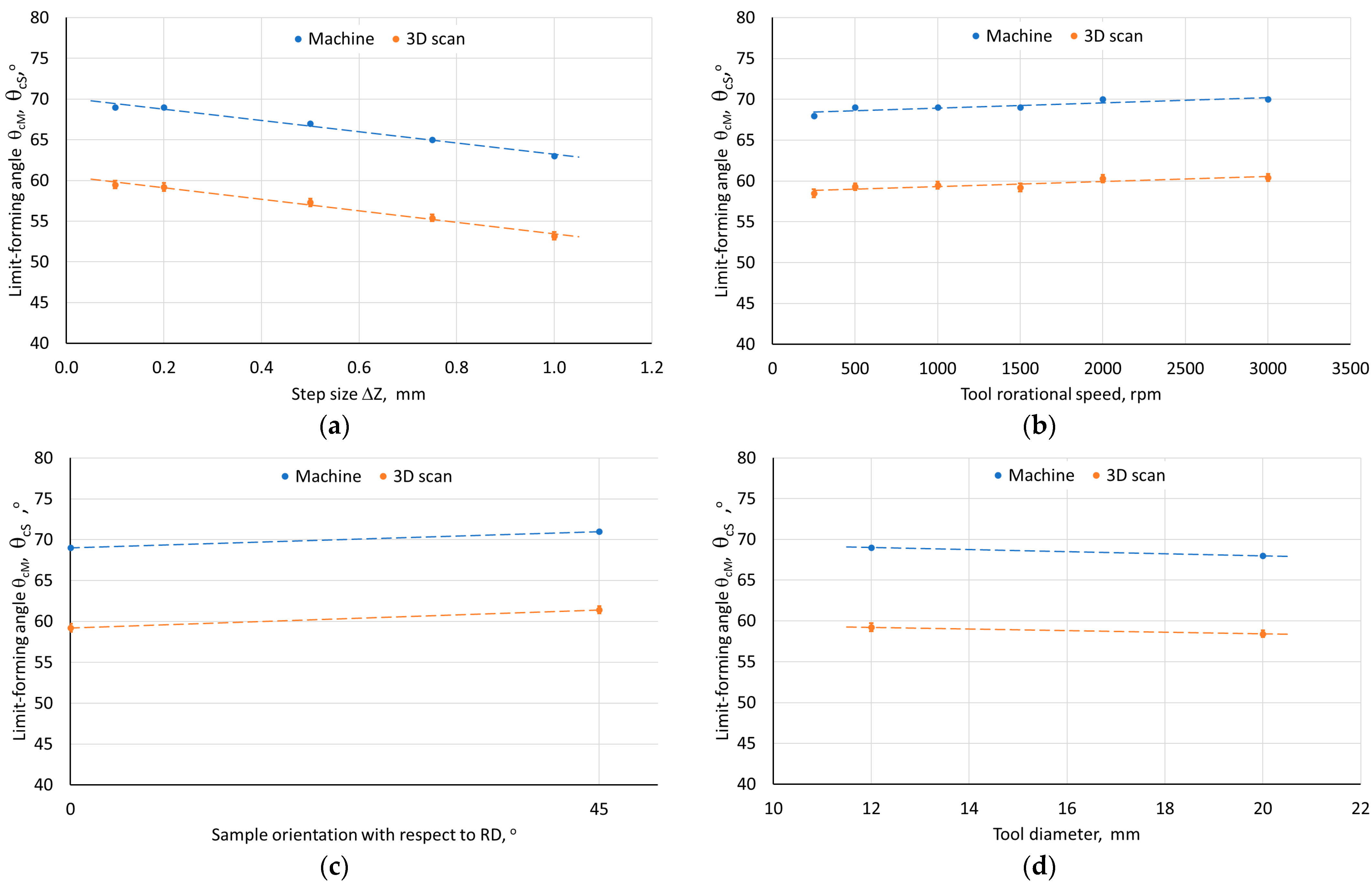

3.2.1. The Limit-Forming Angle

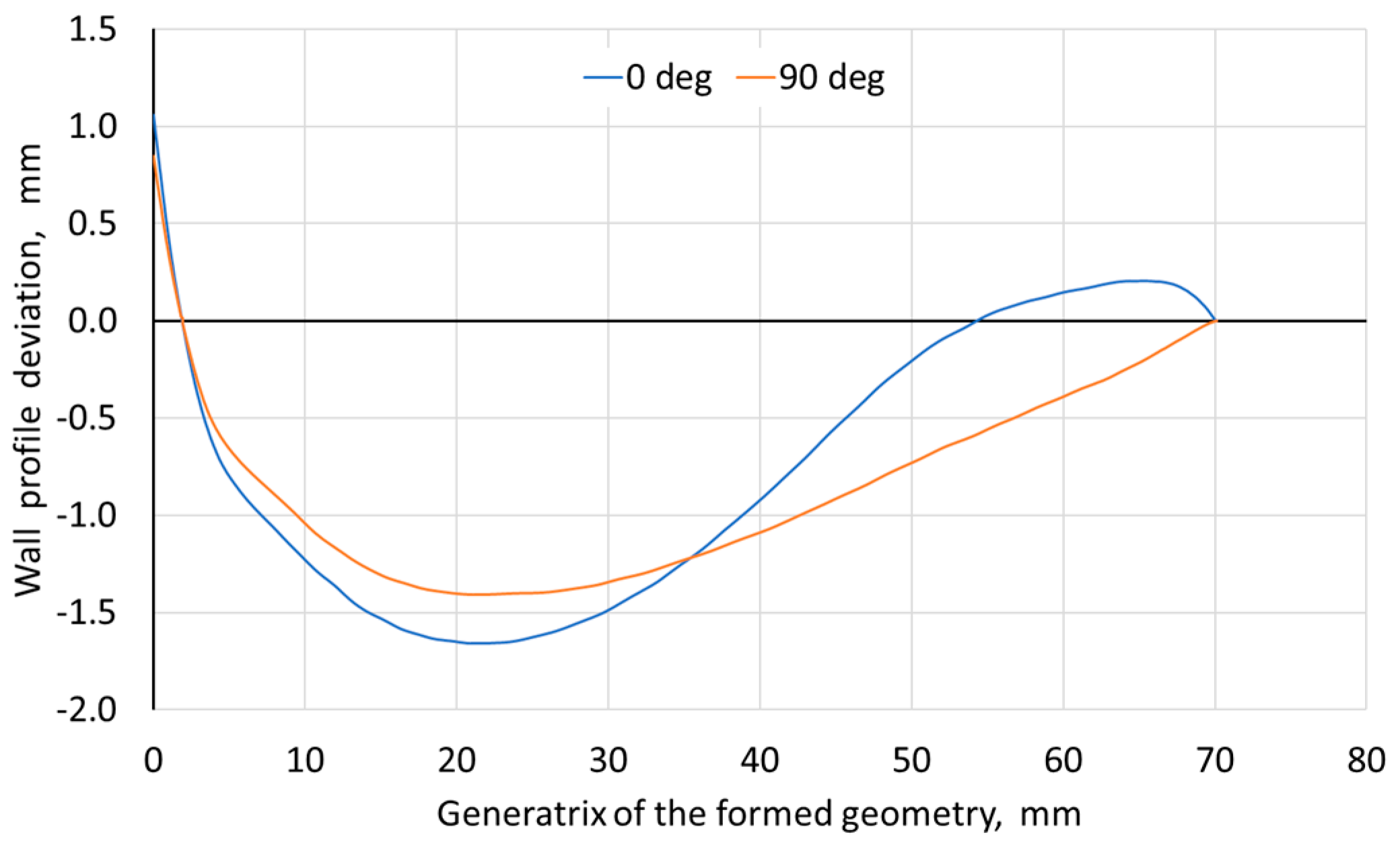

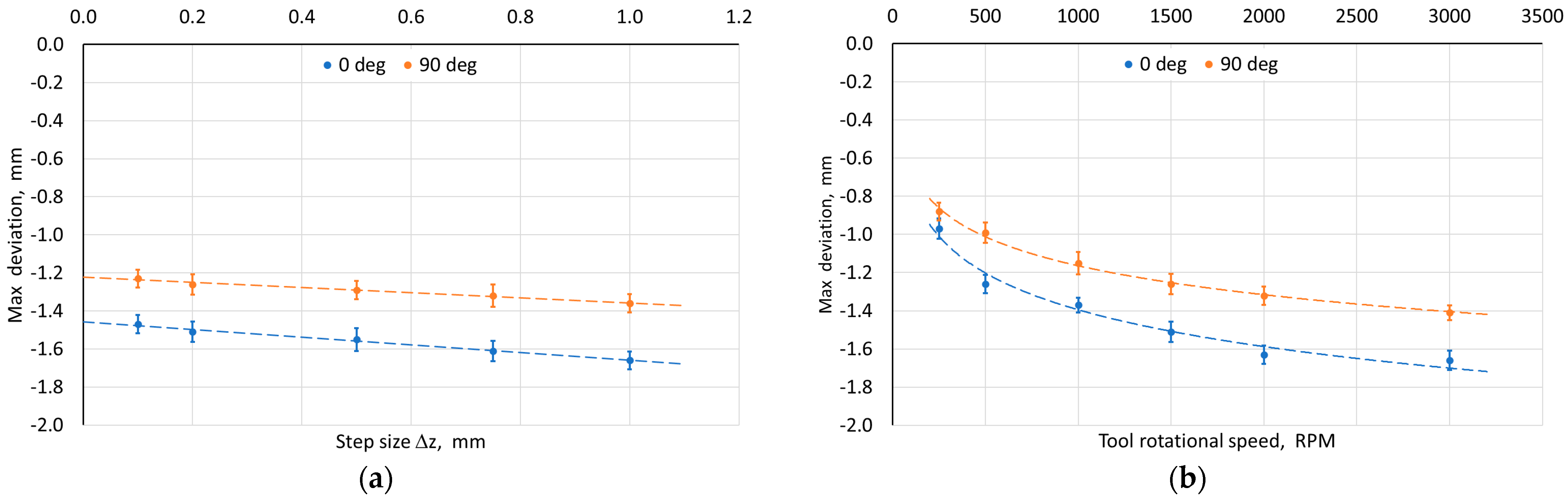

3.2.2. Profile of the Wall of the Drawpieces

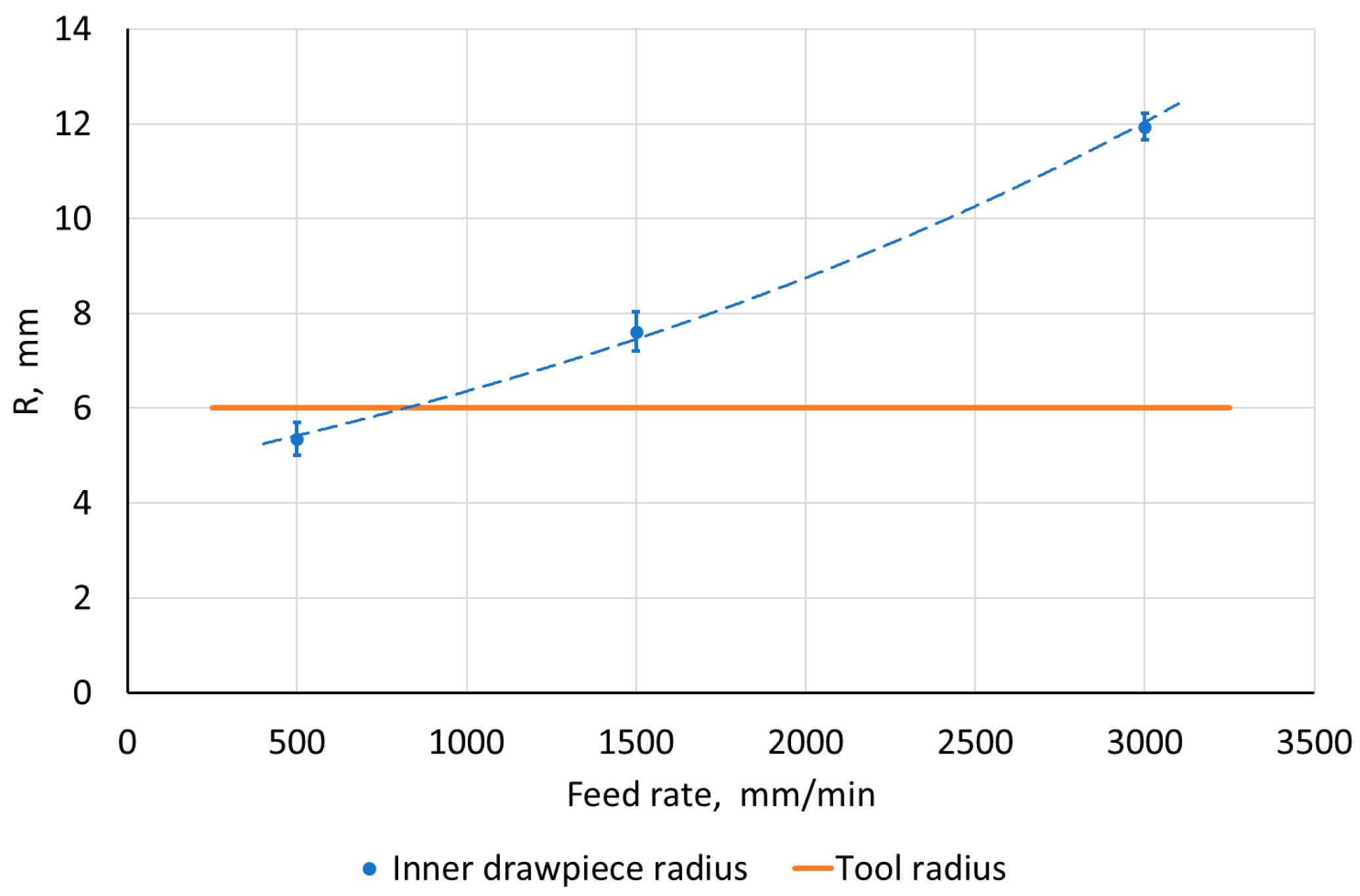

3.2.3. Radius of the Side Edge of the Drawpiece

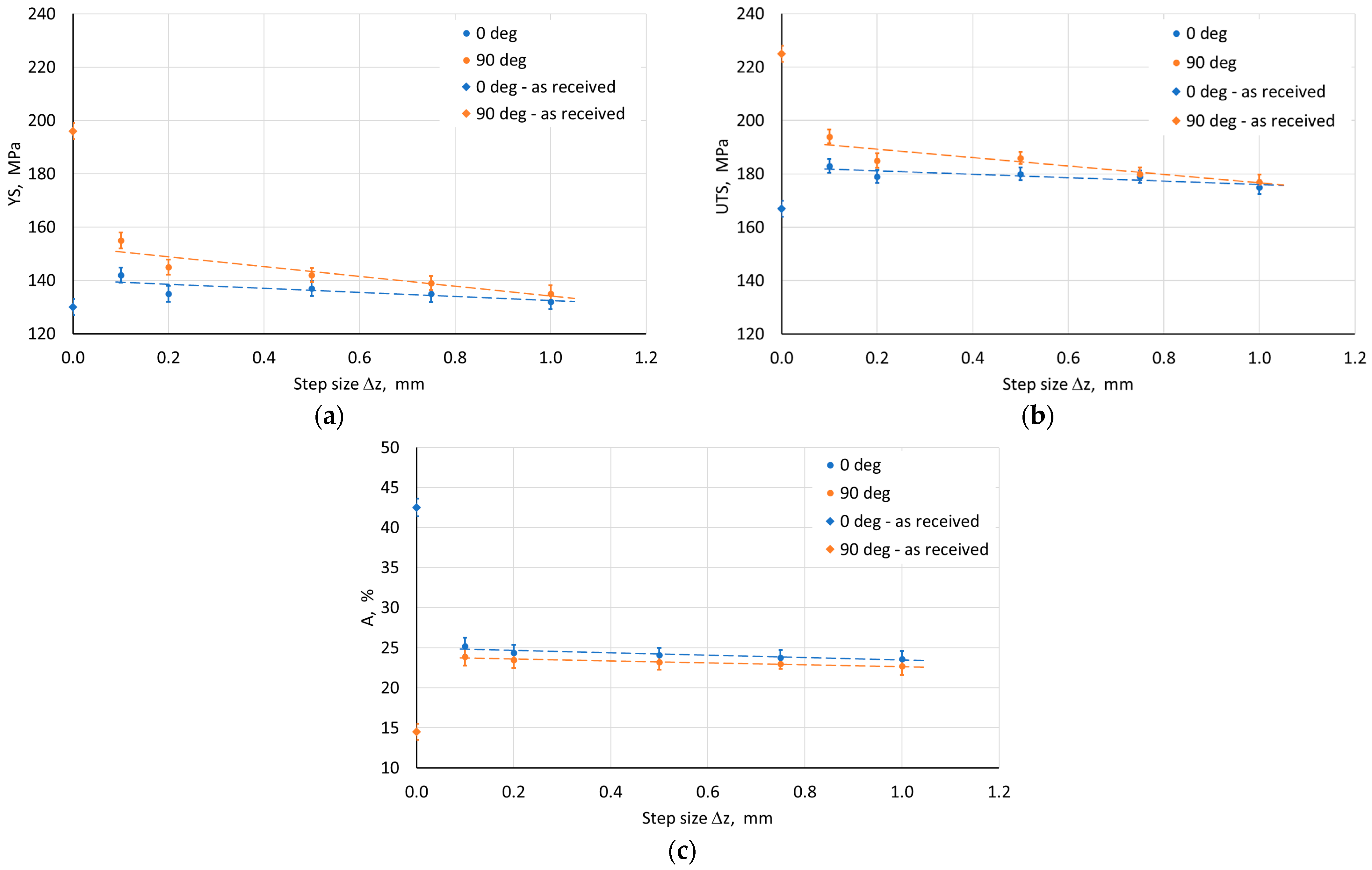

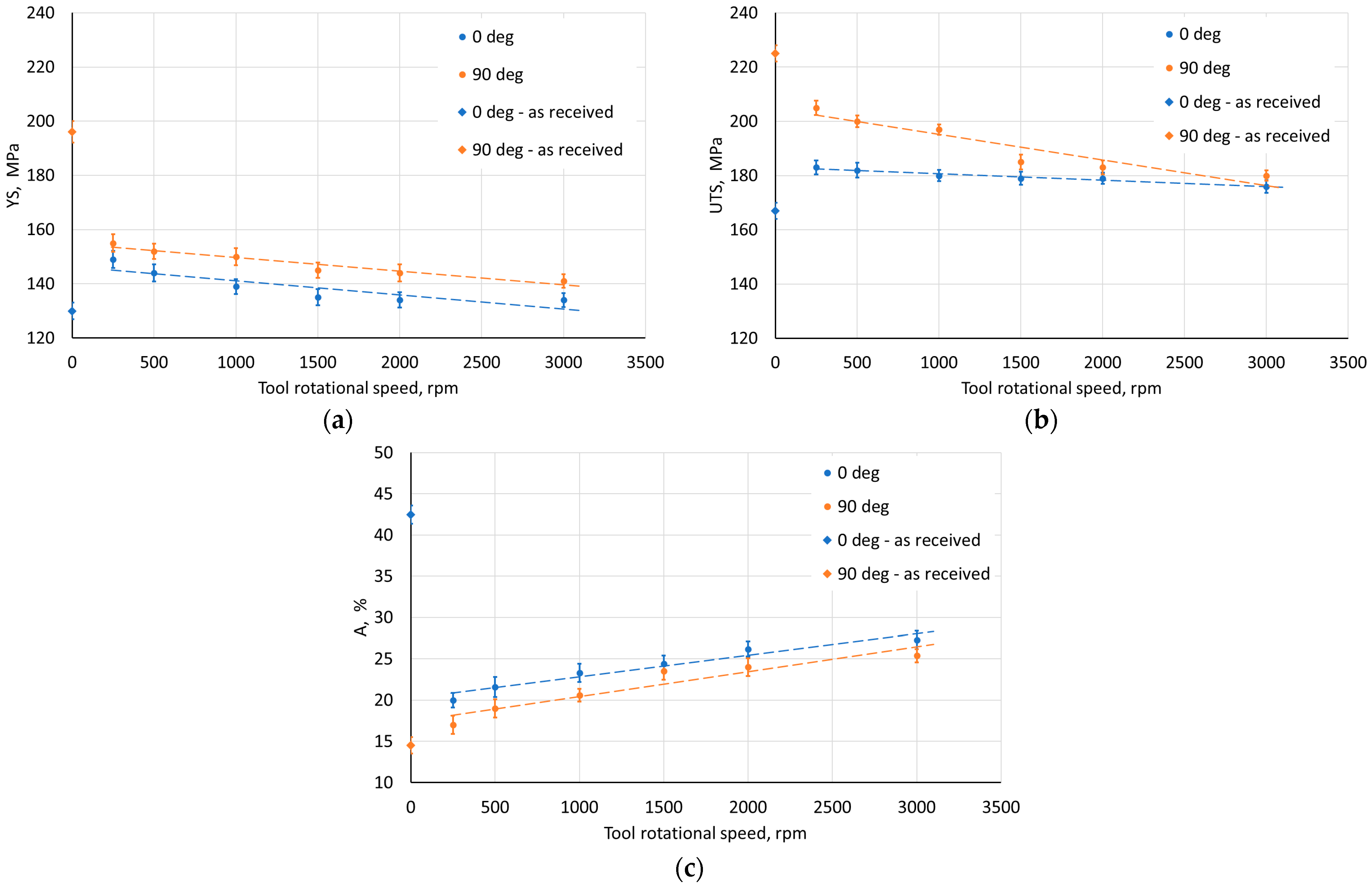

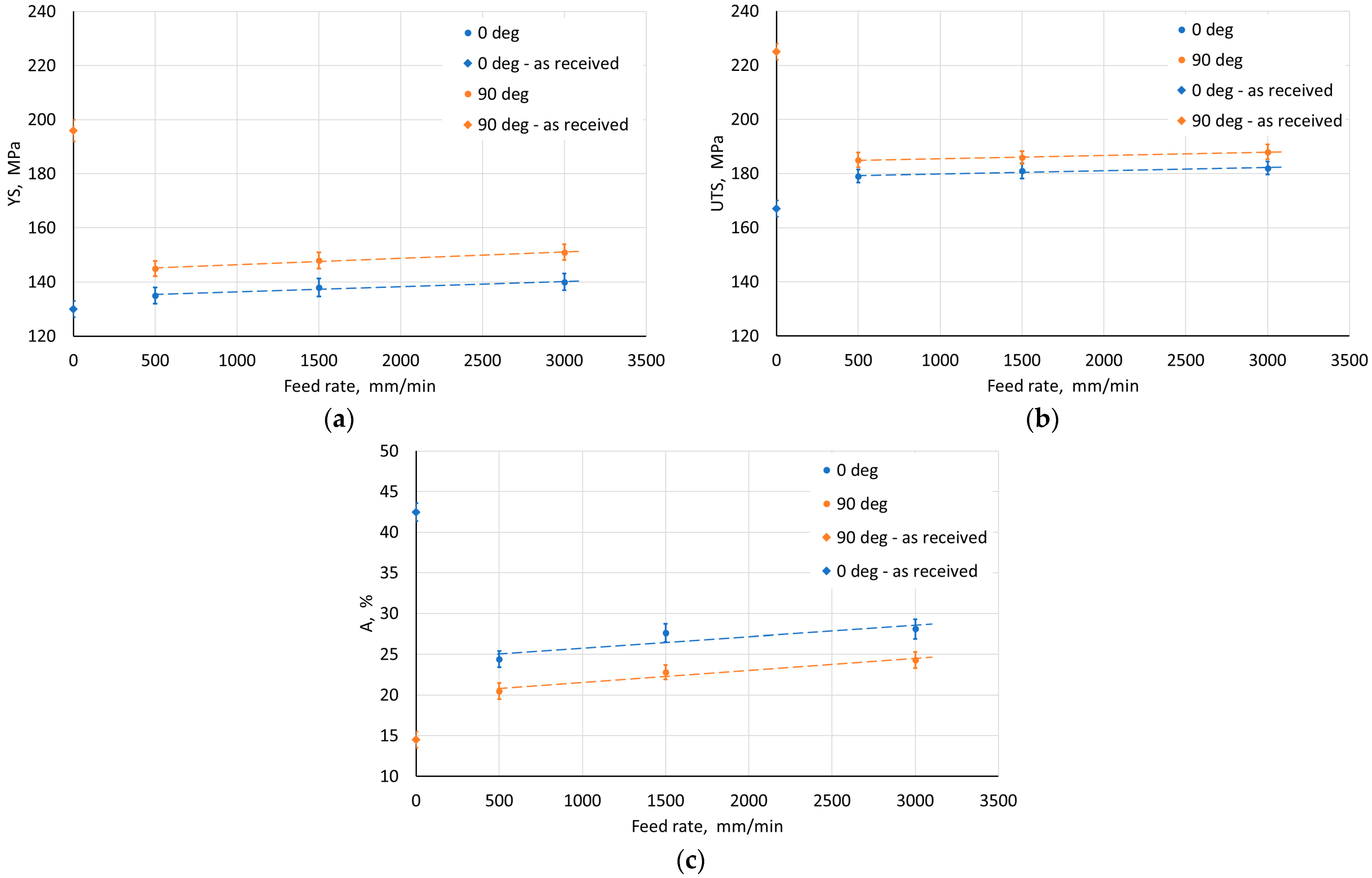

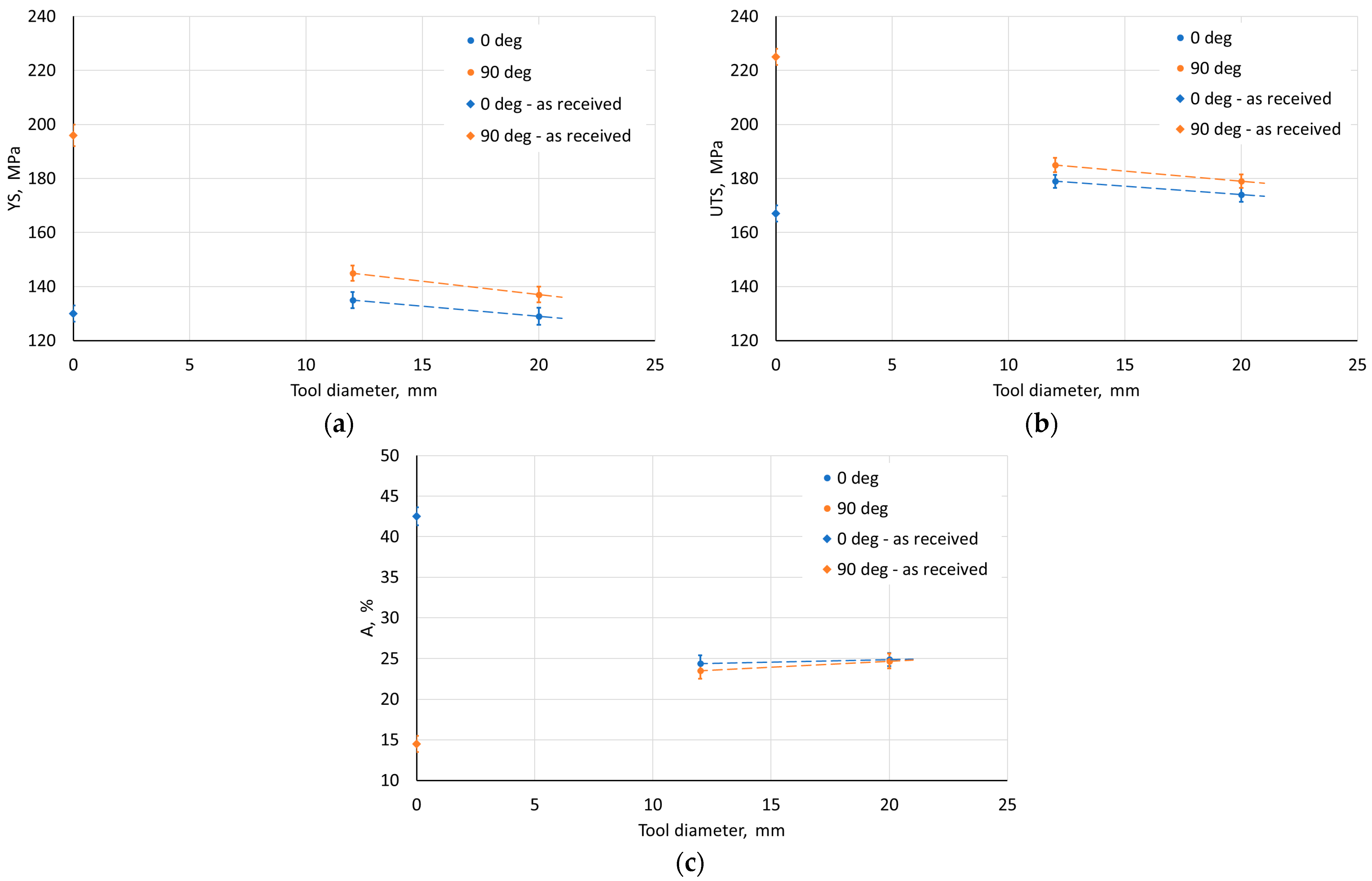

3.2.4. SPIF-Induced Mechanical Properties of the Drawpieces

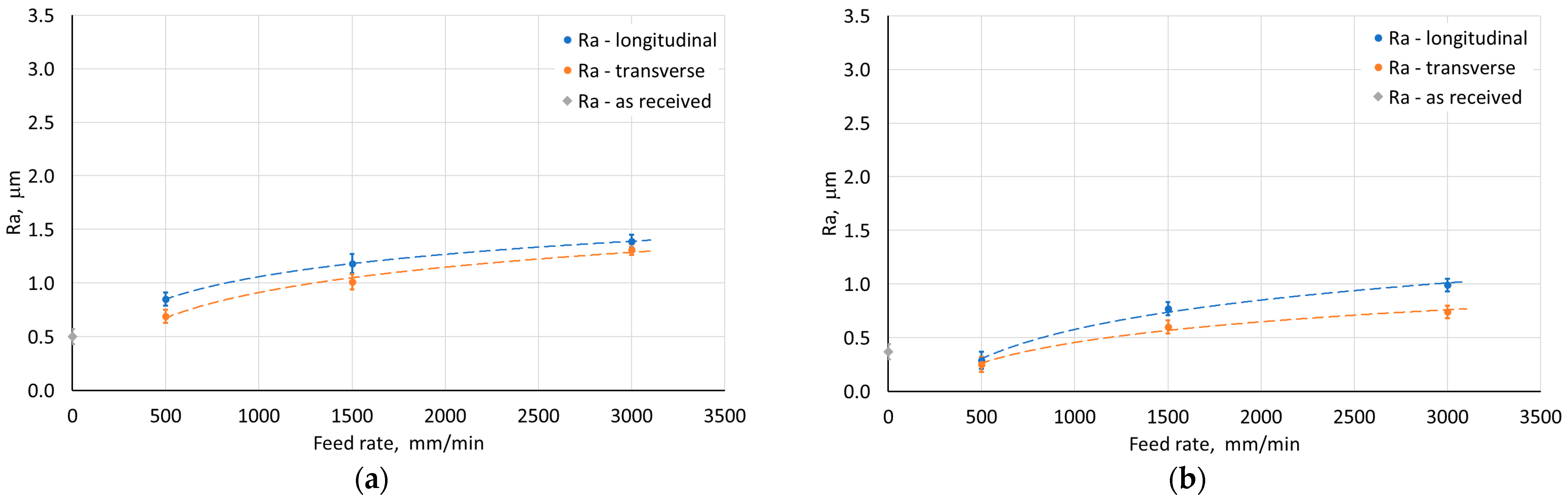

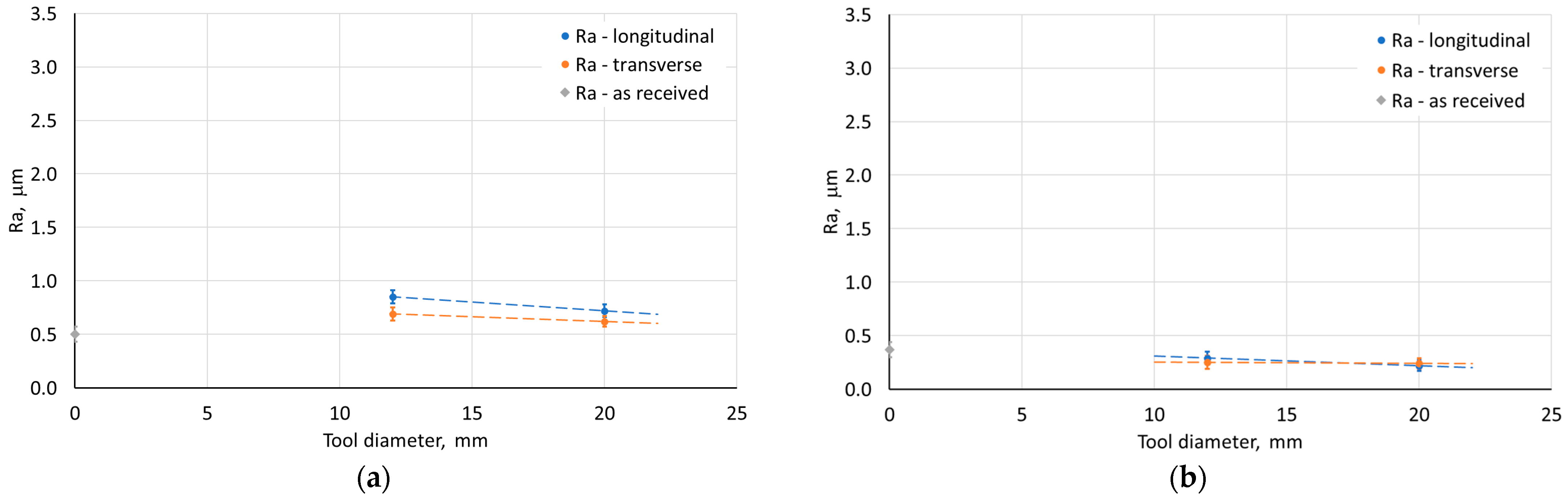

3.2.5. Surface Roughness

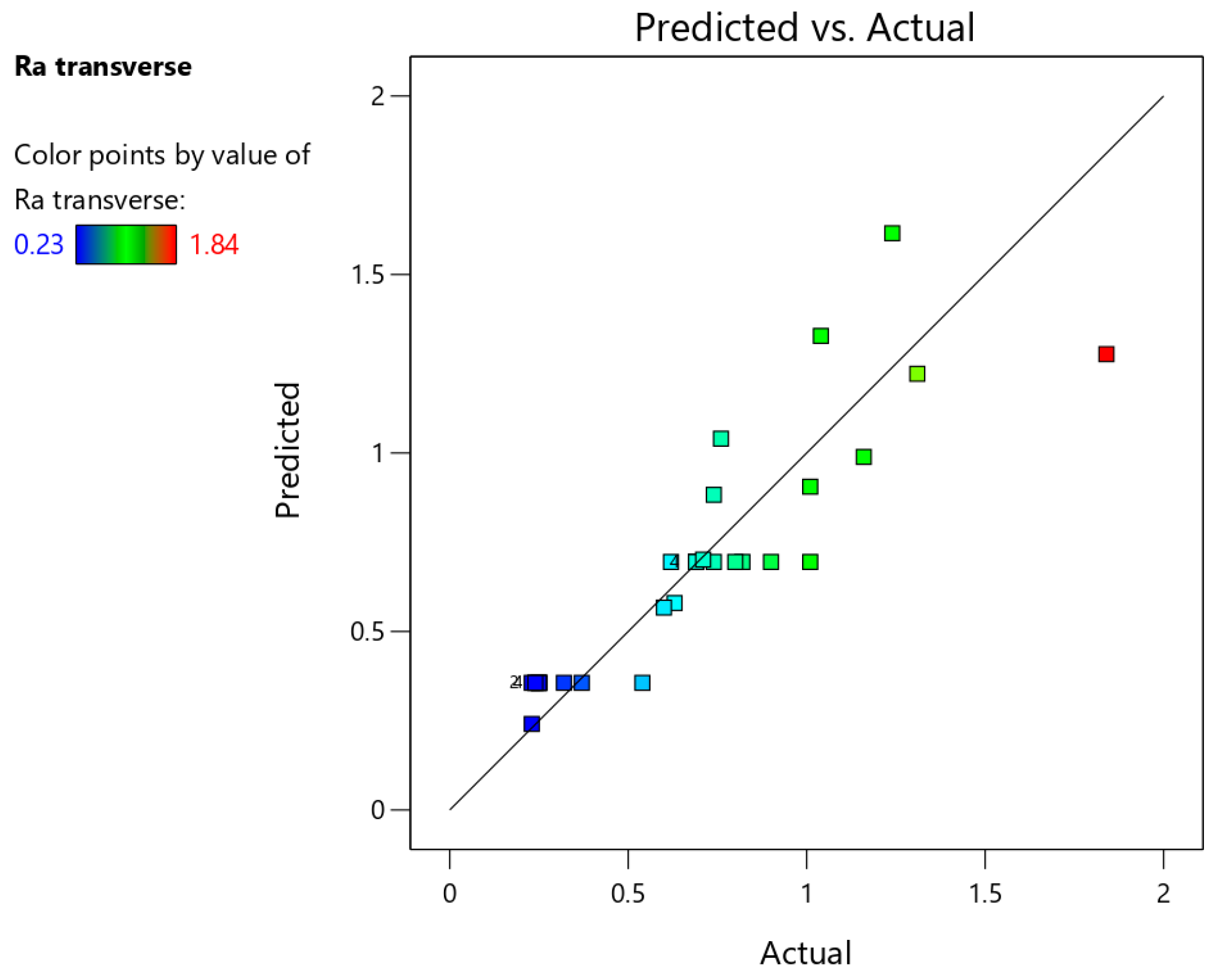

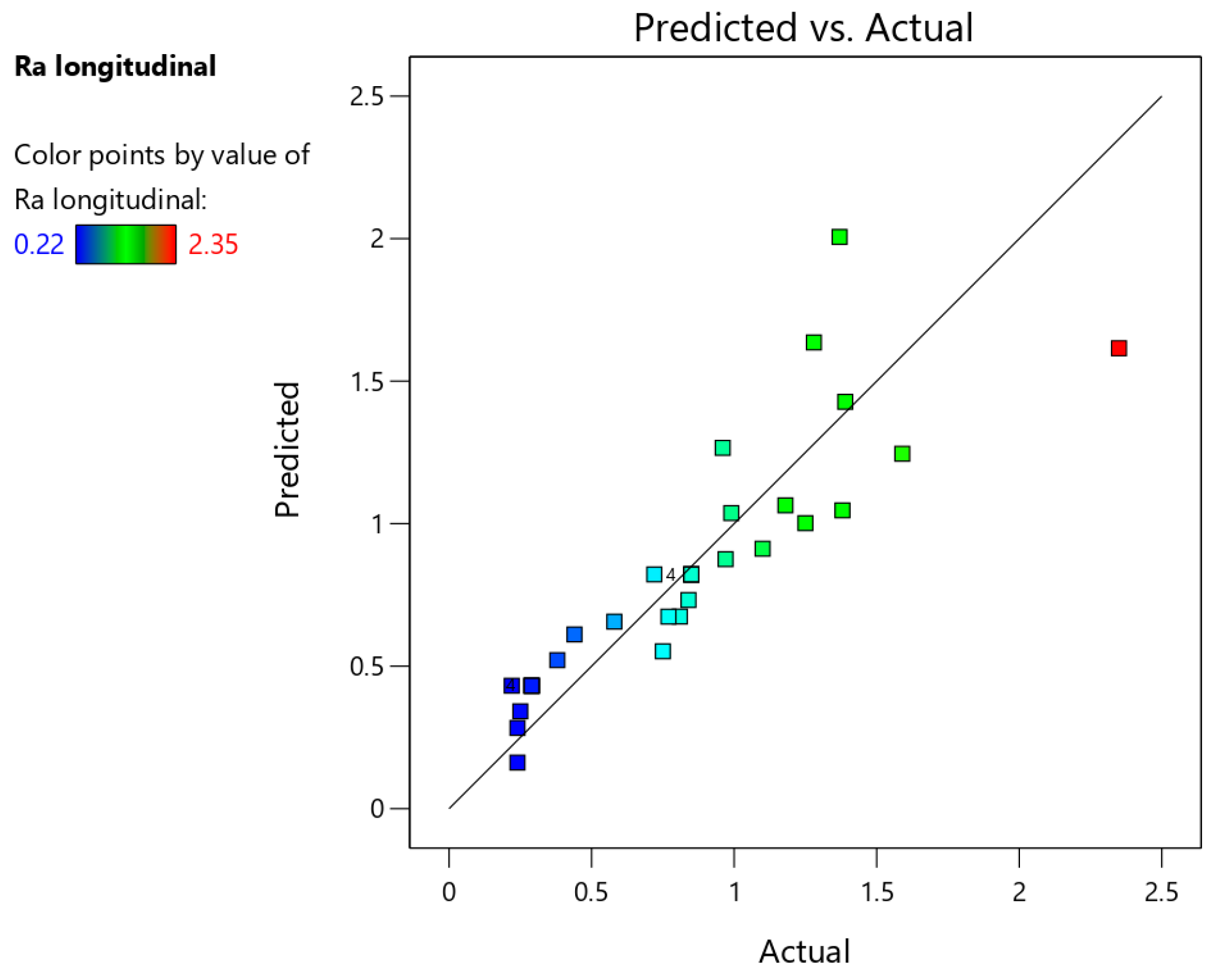

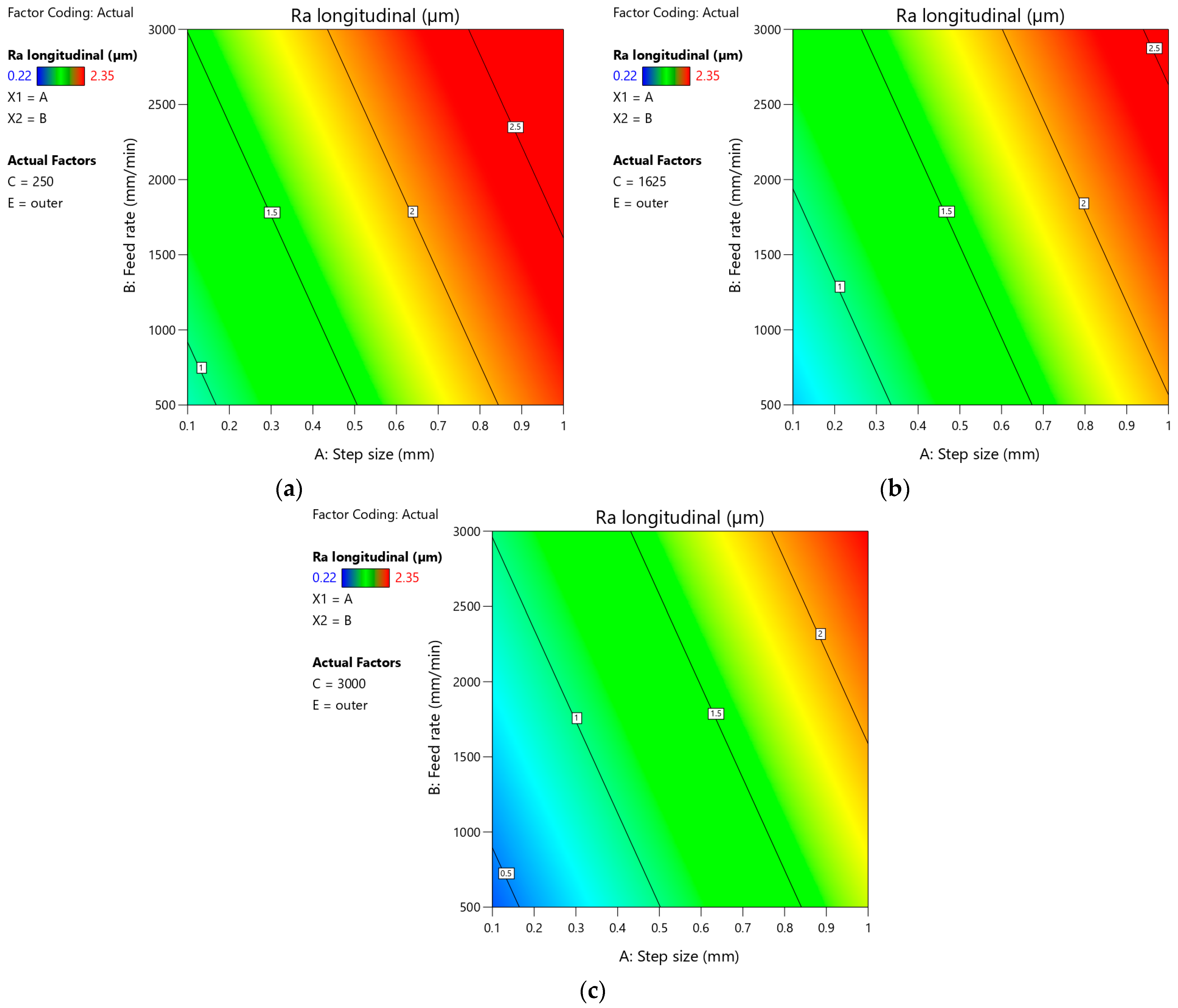

Experimental Analysis

Analysis of Variance

4. Conclusions

- Zn-Cu-Ti alloy sheet is characterized by high anisotropy of mechanical properties and plastic anisotropy (determined by the Lankford coefficient). This feature significantly affects the behavior of the material during SPIF, contributing to a lower wall angle for the 0° orientation of the sample in relation to the 45° orientation.

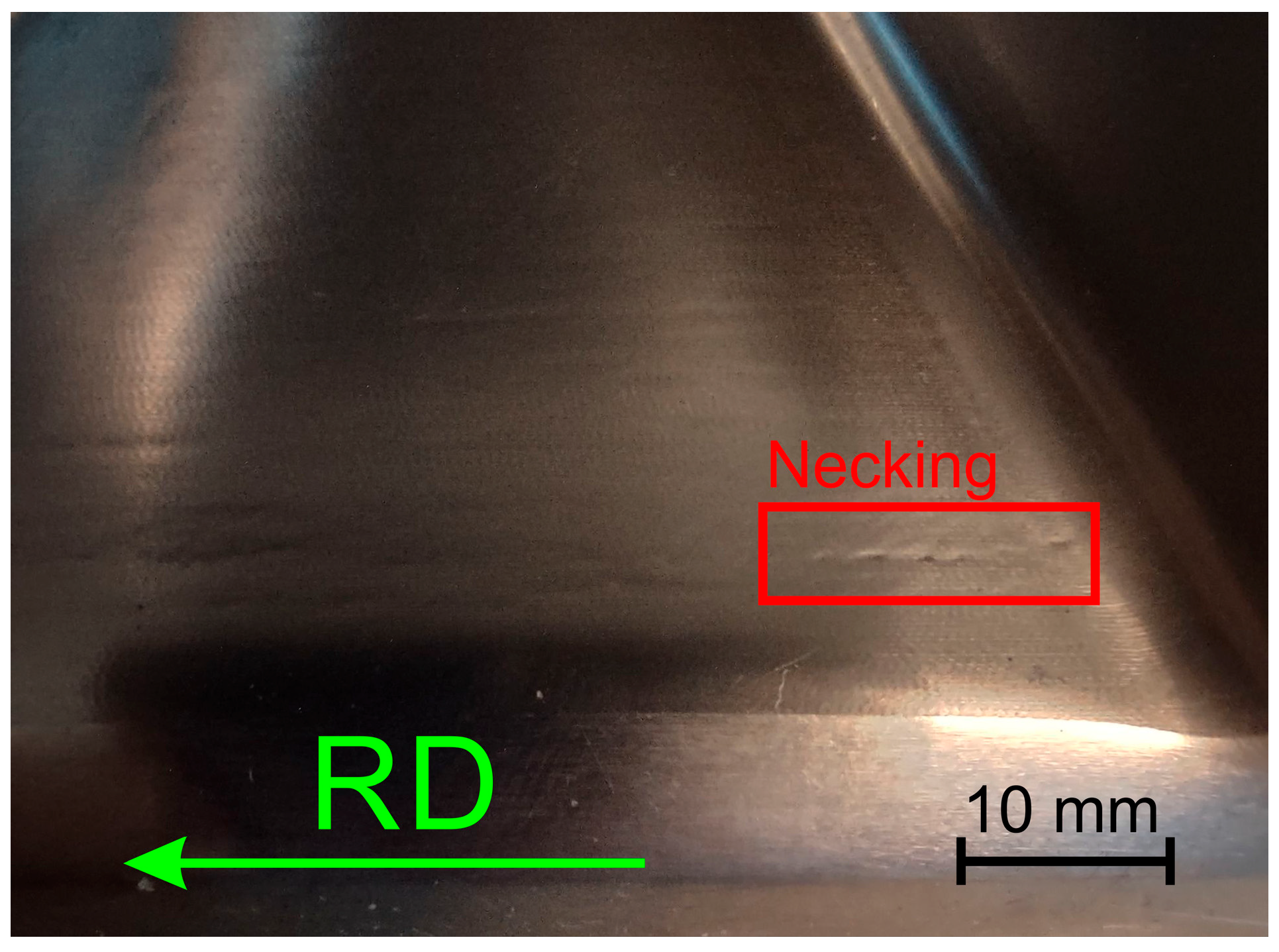

- The large difference in the properties of the workpiece material between the orientations 0° and 90° relative to the RD causes the creation of transverse grooves during SPIF only on the drawpiece walls perpendicular to the sheet RD, which are the sources of material cracking. For the orientation 45°, transverse grooves also appear, but at higher values of the drawpiece wall angle.

- The SPIF process parameters had a different effect on the mechanical properties of the drawpieces. Regardless of the SPIF process conditions, however, there was a significant difference in the basic mechanical properties measured in the walls oriented parallel and perpendicular to the RD. The drawpieces were characterized by higher values of strength parameters being found for the walls with an orientation of 90° in relation to the RD. Higher elongation after rupture was observed for the walls with an axis parallel to the RD.

- All the factors analyzed had an impact on the value of the limit-forming angle of the drawpiece wall. The greatest impact was found in the case of the step size, where the increase in its value was accompanied by a decrease in the value of the limit-forming angle. For the remaining parameters, their influence on the limit-forming angle was moderate, although not insignificant.

- Both the step size and the tool rotational speed contribute to the increase of the maximum wall profile deviation. However, the use of higher feed rates and a larger tool diameter caused its reduction. At the same time, the increase in feed rate caused a smaller reproduction of the rounding of the side edge of the drawpiece. At a feed rate of 3000 mm/min, the value of rounding was about two times larger than the tool radius.

- The surface roughness of the surface of the drawpiece walls varied depending on the SPIF process parameters. Higher values of arithmetic mean surface roughness Ra were found for the outer surface of drawpieces. One of the important parameters influencing the Ra value was the step size. High values of this parameter contributed to the formation of clear forming marks. On the other hand, the use of a smaller step size with a larger tool diameter caused the individual forming marks to overlap and reduced the surface roughness of the drawpiece wall.

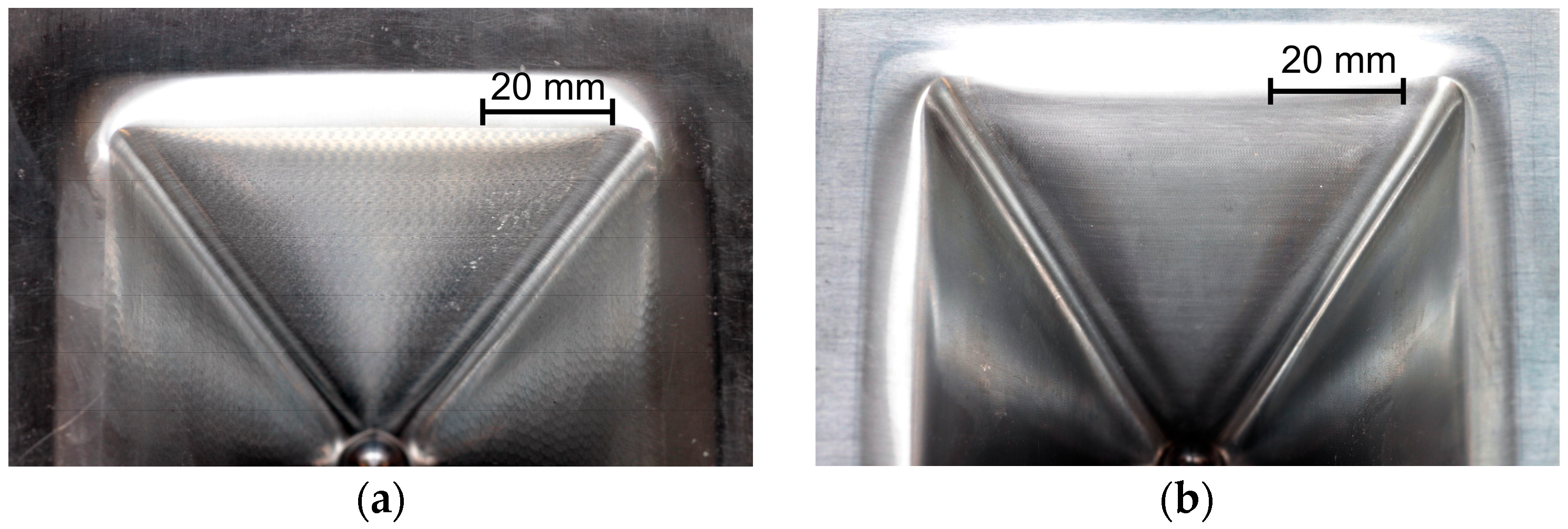

- The use of low tool rotational speeds at constant feed rate contributed to the formation of distinct topography in the form of ‘fish scale” marks on the inner wall surface. Similar effects were observed at high feed rates, with a constant value of the tool rotational speed. It was found that at a ratio of tool rotational speed to feed rate (n/f ≥ 2), visible forming marks no longer appeared on the inner surface of the drawpiece.

- Based on the analysis of variance, it was found that the value of the arithmetic mean surface roughness Ra measured in the transverse direction significantly depends only on the step size, feed rate, and measurement side (inner, outer) on the drawpiece. For the longitudinal direction, the tool rotational speed also significantly determines the Ra value. For both measurement directions, it was found that with the increase of the step size and feed rate, the value of the Ra parameter increases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ullah, S.; Xu, P.; Li, X.; Li, Y.; Han, K.; Li, D. A review on part geometric precision improvement strategies in double-sided incremental forming. Metals 2022, 12, 103. [Google Scholar] [CrossRef]

- Meier, H.; Smukala, V.; Dewald, O.; Zhang, J. Two-point incremental forming with two moving forming tools. Key Eng. Mater. 2007, 344, 599–605. [Google Scholar] [CrossRef]

- Resende, T.P.; Carmo, G.P.; Afonso, D.G.; de Sousa, R.J.A. Development of a compact incremental forming machine. Machines 2024, 12, 86. [Google Scholar] [CrossRef]

- Almadani, M.; Guner, A.; Hassanin, H.; Essa, K. Hot-air contactless single-point incremental forming. J. Manuf. Mater. Process. 2023, 7, 179. [Google Scholar] [CrossRef]

- Popp, G.P.; Racz, S.G.; Breaz, R.E.; Oleksik, V.Ș.; Popp, M.O.; Morar, D.-E.; Chicea, A.L.; Popp, I.O. State of the art in incremental forming: Process variants, tooling, industrial applications for complex part manufacturing and sustainability of the process. Materials 2024, 17, 5811. [Google Scholar] [CrossRef] [PubMed]

- Rusu, G.P.; Oleksik, V.Ş.; Breaz, R.E.; Dobrotă, D.; Popp, O. Analysis of the metal sheets formability at single point incremental forming process. MATEC Web Conf. 2022, 368, 01006. [Google Scholar] [CrossRef]

- Coman, C.C.; Mazurchevici, S.-N.; Carausu, C.; Nedelcu, D. Analysis of incremental sheet forming of aluminum alloy. Materials 2023, 16, 6371. [Google Scholar] [CrossRef]

- Behera, A.K.; de Sousa, R.A.; Ingarao, G.; Oleksik, V. Single point incremental forming: An assessment of the progress and technology trends from 2005 to 2015. J. Manuf. Process. 2017, 27, 37–62. [Google Scholar] [CrossRef]

- Żaba, K.; Trzepieciński, T.; Puchlerska, S.; Noga, P.; Balcerzak, M. Coupled thermomechanical response measurement of deformation of nickel-based superalloys using full-field digital image correlation and infrared thermography. Materials 2021, 14, 2163. [Google Scholar] [CrossRef]

- Shankar, M.R.; Verma, R.; Rao, B.C.; Chandrasekar, S.; Compton, W.D.; King, A.H.; Trumble, K.P. Severe plastic deformation of difficult-to-deform materials at near-ambient temperatures. Metall. Mater. Trans. A 2007, 38, 1899–1905. [Google Scholar] [CrossRef]

- Wen, X.; Huang, H.; Wu, H.; Zhou, M.; Bu, Y.; Yuan, X.; Jiang, S.; Wang, H.; Liu, X.; Wang, H.; et al. Enhanced plastic deformation capacity in hexagonal-close-packed medium entropy alloys via facilitating cross slip. J. Mater. Sci. Technol. 2023, 134, 1–10. [Google Scholar] [CrossRef]

- Milesi, M.; Logé, R.; Jansen, Y. Anisotropic mechanical behavior and formability criterion for zinc sheets. J. Mater. Process. Technol. 2014, 214, 2869–2876. [Google Scholar] [CrossRef]

- Alister, F.; Celentano, D.; Signorelli, J.; Bouchard, P.O.; Pino, D.; Cruchaga, M. Characterization of the elastoplastic response of low Zn-Cu-Ti alloy sheets using the CPB-06 criterion. Materials 2019, 12, 3072. [Google Scholar] [CrossRef] [PubMed]

- Philippe, M.J.; Fundenberger, J.J.; Galledou, Y.; Humbert, M.; Wegria, J.; Esling, C. Influence of texture on low temperature bendability of Zn alloys. Textures Stress Microstruct. 1991, 14, 471–476. [Google Scholar] [CrossRef]

- Szpunar, M.; Trzepieciński, T.; Żaba, K.; Ostrowski, R.; Zwolak, M. Effect of lubricant type on the friction behaviours and surface topography in metal forming of Ti-6Al-4V titanium alloy sheets. Materials 2021, 14, 3721. [Google Scholar] [CrossRef]

- Formisano, A.; Boccarusso, L.; De Fazio, D.; Durante, M. Experimental evidence on incremental formed polymer sheets using a stair toolpath strategy. J. Manuf. Mater. Process. 2024, 8, 105. [Google Scholar] [CrossRef]

- Kuczek, Ł.; Żaba, K.; Trzepieciński, T.; Wąsikowski, M.; Balcerzak, M.; Sitek, R. Influence of heat treatment on properties and microstructure of EN AW-6082 aluminium alloy drawpieces after single-point incremental sheet forming. Appl. Sci. 2025, 15, 783. [Google Scholar] [CrossRef]

- Żaba, K.; Puchlerska, S.; Kuczek, Ł.; Trzepieciński, T.; Maj, P. Effect of step size on the formability of Al/Cu bimetallic sheets in single point incremental sheet forming. Materials 2023, 16, 367. [Google Scholar] [CrossRef]

- de Sousa, R.J.A.; Ferreira, J.A.F.; Sá de Farias, J.B.; Torrão, J.N.D.; Afonso, D.G.; Martins, M.A.B.E. SPIF-A: On the development of a new concept of forming machine. Struct. Eng. Mech. 2014, 49, 645–660. [Google Scholar] [CrossRef]

- Maqbool, F.; Bambach, M. Dominant deformation mechanisms in single point incremental forming (SPIF) and their effect on geometrical accuracy. Int. J. Mech. Sci. 2018, 136, 279–292. [Google Scholar] [CrossRef]

- Silva, M.B.; Nielsen, P.S.; Bay, N.; Martins, P.A.F. Failure mechanisms in single-point incremental forming of metals. Int. J. Adv. Manuf. Technol. 2011, 56, 893–903. [Google Scholar] [CrossRef]

- Ragab, A.E. Analyzing SPIF product characteristics using full factorial design-integrated PCA approach. Processes 2023, 11, 1254. [Google Scholar] [CrossRef]

- Popp, M.O.; Racz, A.G.; Oleksik, M.; Girjob, C.; Biriş, C. Analysis of forming forces at SPIF using Taguchi method. MATEC Web Conf. 2022, 368, 01007. [Google Scholar] [CrossRef]

- Karthik, T.; Srinivasan, N.; Rajenthirakumar, D.; Sridhar, R. Multi-response optimization of single point incremental forming of Al 6061 sheet through grey-based response surface methodology. Stroj. Vestn.-J. Mech. Eng. 2024, 70, 507–514. [Google Scholar] [CrossRef]

- Najm, S.M.; Paniti, I. Investigation and machine learning-based prediction of parametric effects of single point incremental forming on pillow effect and wall profile of AlMn1Mg1 aluminum alloy sheets. J. Intell. Manuf. 2022, 34, 331–367. [Google Scholar] [CrossRef]

- Najm, S.M.; Paniti, I. Artificial neural network for modeling and investigating the effects of forming tool characteristics on the accuracy and formability of thin aluminum alloy blanks when using SPIF. Int. J. Adv. Manuf. Technol. 2021, 114, 2591–2615. [Google Scholar] [CrossRef]

- Sevšek, L.; Pepelnjak, T. Optimisation of flexible forming processes using multilayer perceptron artificial neural networks and genetic algorithms: A generalised approach for advanced high-strength steels. Materials 2024, 17, 5459. [Google Scholar] [CrossRef]

- Szpunar, M.; Ostrowski, R.; Dzierwa, A. Effect of single-point incremental forming process parameters on roughness of the outer surface of conical drawpieces from cp titanium sheets. Adv. Mech. Mater. Eng. 2024, 41, 221–231. [Google Scholar] [CrossRef]

- Szpunar, M.; Szawara, P.; Myśliwiec, P.; Ostrowski, R. Influence of input parameters on the coefficient of friction during incremental sheet forming of grade 5 titanium alloy sheets. Adv. Mech. Mater. Eng. 2023, 40, 113–123. [Google Scholar] [CrossRef]

- Zhang, Q.; Guo, H.; Xiao, F.; Gao, L.; Bondarev, A.B.; Han, W. Influence of anisotropy of the magnesium alloy AZ31 sheets on warm negative incremental forming. J. Mater. Process. Technol. 2009, 209, 5514–5520. [Google Scholar] [CrossRef]

- An, Z.G.; Yan, D.; Qie, J.J.; Lu, Z.L.; Gao, Z.Y. Effect of process parameters on formability of a AZ31 magnesium alloy thin-walled cylindrical part formed by multistage warm single-point incremental forming. Frontiers 2020, 7, 151. [Google Scholar] [CrossRef]

- Rai, D.; Saini, M.; Saw, A.; Shinde, P.; Barve, S.; Kharche, A. Experimental investigations on Inconel 625 using single point incremental forming. Mater. Today Proc. 2024, 103, 336–341. [Google Scholar] [CrossRef]

- Araújo, R.; Teixeira, P.; Montanari, L.; Reis, A.; Silva, M.B.; Martins, P.A.F. Single point incremental forming of a facial implant. Prosthet. Orthot. Int. 2013, 38, 369–378. [Google Scholar] [CrossRef] [PubMed]

- Embury, J.D.; Duncan, J.L. Formability maps. Annu. Rev. Mater. Sci. 1981, 11, 505–521. [Google Scholar] [CrossRef]

- Kumar, N.; Mahala, M.; Agrawal, A. Experimental and numerical investigation of heat assisted incremental sheet forming process of magnesium alloy. In Proceedings of the ASME 2022 17th International Manufacturing Science and Engineering Conference, West Lafayette, IN, USA, 27 June–1 July 2022. Paper no. MSEC2022-85205. [Google Scholar] [CrossRef]

- Liu, Y.; Zeng, Z.; Gong, H.; Zhu, D.; Qin, W.; Lin, W.; Zhan, Y. Work Softening Behavior and Microstructure Evolution of Zn-0.12Cu-0.08Ti Alloy during Cold Rolling. J. Alloys Compd. 2025, 1032, 180998. [Google Scholar] [CrossRef]

- Roatta, A.; Leonard, M.; Nicoletti, E.; Signorelli, J.W. Modeling Texture Evolution during Monotonic Loading of Zn-Cu-Ti Alloy Sheet Using the Viscoplastic Self-Consistent Polycrystal Model. J. Alloys Compd. 2021, 860, 158425. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Oleksik, V.; Pepelnjak, T.; Najm, S.M.; Paniti, I.; Maji, K. Emerging Trends in Single Point Incremental Sheet Forming of Lightweight Metals. Metals 2021, 11, 1188. [Google Scholar] [CrossRef]

- EN ISO 6892-1; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2019.

- EN ISO 10113; Metallic Materials—Sheet and Strip—Determination of Plastic Strain Ratio. ISO: Geneva, Switzerland, 2020.

- EN ISO 20482; Metallic Materials—Sheet and Strip—Erichsen Cupping Test. ISO: Geneva, Switzerland, 2013.

- JIS Z 2249; Method of Conical Cup Test. Japanese Industrial Standard: Tokyo, Japan, 2022.

- Cauvin, L.; Raghavan, B.; Jin, J.; Bouvier, S.; Wang, X.; Meraghni, F.; Alves, J.L. Investigating the plastic anisotropy and hardening behavior of a commercial Zn–Cu–Ti alloy: Experimental & modeling approach. Mech. Mater. 2022, 164, 104103. [Google Scholar] [CrossRef]

- Muzykiewicz, W.; Rękas, A.; Kosmalski, G. Validation tests for the 6082-grade sheet in the "0" state with an account of its application for deep drawing processes. Rudy I Met. Nieżelazne 2006, 51, 422–427. [Google Scholar]

- Fang, Y.; Lu, B.; Chen, J.; Xu, D.K.; Ou, H. Analytical and experimental investigations on deformation mechanism and fracture behavior in single point incremental forming. J. Mater. Process. Technol. 2014, 214, 1503–1515. [Google Scholar] [CrossRef]

- Ham, M.; Jeswiet, J. Single point incremental forming and the forming criteria for AA3003. CIRP Ann. 2006, 55, 241–244. [Google Scholar] [CrossRef]

- Kumar, A.; Gulati, V.; Kumar, P.; Singh, V.; Kumar, B.; Singh, H. Parametric effects on formability of AA2024-O aluminum alloy sheets in single point incremental forming. J. Mater. Res. Technol. 2019, 8, 1461–1469. [Google Scholar] [CrossRef]

- Centeno, G.; Bagudanch, I.; Martínez-Donaire, A.J.; García-Romeu, M.L.; Vallellano, C. Critical analysis of necking and fracture limit strains and forming forces in single-point incremental forming. Mater. Des. 2014, 63, 20–29. [Google Scholar] [CrossRef]

- Madeira, T.; Silva, C.M.A.; Silva, M.B.; Martins, P.A.F. Failure in single point incremental forming. Int. J. Adv. Manuf. Technol. 2015, 80, 1471–1479. [Google Scholar] [CrossRef]

- Basak, S.; Prasad, K.S.; Sidpara, A.M.; Panda, S.K. Single point incremental forming of AA6061 thin sheet: Calibration of ductile fracture models incorporating anisotropy and post forming analyses. Int. J. Mater. Form. 2019, 12, 623–642. [Google Scholar] [CrossRef]

- Pohlak, M.; Küttner, R.; Majak, J.; Karjust, K.; Sutt, A. Experimental study of incremental forming of sheet metal product. In Proceedings of the 4th International DAAAM Conference “Industrial Engineering—Innovation As Competitive Edge for SME”, Tallinn, Estonia, 29–30 April 2004; pp. 139–142. [Google Scholar]

- Lu, B.; Fang, Y.; Xu, D.K.; Chen, J.; Ou, H.; Moser, N.H.; Cao, J. Mechanism investigation of friction-related effects in single point incremental forming using a developed oblique roller-ball tool. Int. J. Mach. Tools Manuf. 2014, 85, 14–29. [Google Scholar] [CrossRef]

- Ilyas, M.; Hussain, G.; Rashid, H.; Alkahtani, M. Influence of forming parameters on the mechanical behavior of a thin aluminum sheet processed through single point incremental forming. Metals 2020, 10, 1461. [Google Scholar] [CrossRef]

- Al-Ghandi, Hussain, Threshold tool-radius condition maximizing the formability in SPIF considering a variety of materials: Experimental and FE investigations. Int. J. Mach. Tools Manuf. 2015, 88, 82–94. [CrossRef]

- Kumar, S.P.; Elangovan, S. Optimization in single point incremental forming of Inconel 718 through response surface methodology. Trans. Can. Soc. Mech. Eng. 2020, 44, 148–160. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Szpunar, M.; Dzierwa, A.; Żaba, K. Investigation of surface roughness in incremental sheet forming of conical drawpieces from pure titanium sheets. Materials 2022, 15, 4278. [Google Scholar] [CrossRef]

| Zn | Cu | Ti |

|---|---|---|

| 98.9 | 0.95 | 0.15 |

| Sample Orientation (Relative to RD), ° | Feed Rate f, mm/min | Tool Rotational Speed n, rpm | Tool Diameter D, mm | Step Size in Z-Direction Δz, mm |

|---|---|---|---|---|

| 0, 45 | 500, 1000, 1500, 2000, 3000 | 250, 500, 1000, 1500, 3000 | 12, 20 | 0.1, 0.2, 0.5, 0.75, 1.0, 1.2 |

| Sample Orientation, ° | YS, MPa | UTS, MPa | A, % | r-Value | Δr | ||||

|---|---|---|---|---|---|---|---|---|---|

| Mean Value | 95% CI | Mean Value | 95% CI | Mean Value | 95% CI | Mean Value | 95% CI | ||

| 0 | 130 ± 1.5 | 127–133 | 167 ± 1.1 | 164– 170 | 42.5 ± 1.56 | 41.4–43.6 | 0.163 ± 0.0021 | 0.158–0.168 | −1.5 |

| 45 | 181 ± 2.1 | 178–184 | 204 ± 1.2 | 201–207 | 26.1 ± 0.95 | 24.8–27.6 | 0.180 ± 0.0012 | 0.177–0.183 | |

| 90 | 196 ± 3.6 | 192–200 | 225 ± 1.1 | 222–228 | 14.5 ± 0.67 | 13.5–15.5 | 0.194 ± 0.0015 | 0.190–0.198 | |

| Average value | 172 | - | 200 | - | 27.3 | - | 0.179 | - | |

| Erichsen Number IE, mm | Fukui Coefficient ηF |

|---|---|

| 9.6 ± 0.15 | 0.818 ± 0.0061 |

| Tool Diameter D, mm | Step Size Δz, mm | Feed Rate f, mm/min | Tool Rotational Speed n, rpm | Sample Orientation According to the RD, ° | Limit-Forming Angle θcM, ° | Limit-Forming Angle (Based on the 3D Scanning) θcS, ° |

|---|---|---|---|---|---|---|

| 12 | 0.1 | 500 | 1500 | 0 | 69 | 59.5 ± 0.29 |

| 12 | 0.2 | 500 | 1500 | 0 | 69 | 59.2 ± 0.32 |

| 12 | 0.5 | 500 | 1500 | 0 | 67 | 57.3 ± 0.29 |

| 12 | 0.75 | 500 | 1500 | 0 | 65 | 55.4 ± 0.26 |

| 12 | 1.0 | 500 | 1500 | 0 | 64 | 54.2 ± 0.31 |

| 12 | 0.2 | 500 | 250 | 0 | 68 | 58.5 ± 0.32 |

| 12 | 0.2 | 500 | 500 | 0 | 69 | 59.3 ± 0.25 |

| 12 | 0.2 | 500 | 1000 | 0 | 69 | 59.5 ± 0.27 |

| 12 | 0.2 | 500 | 2000 | 0 | 70 | 60.2 ± 0.30 |

| 12 | 0.2 | 500 | 3000 | 0 | 70 | 60.4 ± 0.28 |

| 12 | 0.2 | 1500 | 1500 | 0 | 69 | 59.1 ± 0.32 |

| 12 | 0.2 | 3000 | 1500 | 0 | 69 | 59.3 ± 0.26 |

| 12 | 0.2 | 500 | 1500 | 45 | 71 | 61.4 ± 0.28 |

| 20 | 0.2 | 500 | 1500 | 0 | 68 | 58.4 ± 0.27 |

| Source | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value | Model Evaluation |

|---|---|---|---|---|---|---|

| Model | 3.529716 | 3 | 1.176572 | 33.25087 | 2.28 × 10−9 | significant |

| A—Step size | 2.317558 | 1 | 2.317558 | 65.49605 | 8.22 × 10−9 | |

| B—Feed rate | 0.564782 | 1 | 0.564782 | 15.96119 | 0.000426 | |

| E—side (inner, outer) | 0.918013 | 1 | 0.918013 | 25.94377 | 2.15 × 10−5 | |

| Residual | 0.990772 | 28 | 0.035385 | |||

| Lack of fit | 0.990772 | 22 | 0.045035 | |||

| Pure error | 0 | 6 | 0 | |||

| Correlation total | 4.520488 | 31 |

| Source | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value | Model Evaluation |

|---|---|---|---|---|---|---|

| Model | 5.63898 | 4 | 1.409745 | 21.08243 | 5.55 × 10−8 | significant |

| A—Step size | 3.825182 | 1 | 3.825182 | 57.20477 | 3.9 × 10−8 | |

| B—Feed rate | 0.745074 | 1 | 0.745074 | 11.14242 | 0.002471 | |

| C—Tool rotational speed | 0.340258 | 1 | 0.340258 | 5.088483 | 0.032393 | |

| E—side (inner, outer) | 1.220703 | 1 | 1.220703 | 18.25535 | 0.000214 | |

| Residual | 1.805442 | 27 | 0.066868 | |||

| Lack of fit | 1.805442 | 21 | 0.085973 | |||

| Pure error | 0 | 6 | 0 | |||

| Correlation total | 7.444422 | 31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuczek, Ł.; Żaba, K.; Trzepieciński, T.; Balcerzak, M.; Novák, V. Characterization of Hexagonal Close-Packed Zn-Cu-Ti Alloy Pyramid Drawpieces in Single-Point Incremental Sheet Forming Process. Materials 2025, 18, 3078. https://doi.org/10.3390/ma18133078

Kuczek Ł, Żaba K, Trzepieciński T, Balcerzak M, Novák V. Characterization of Hexagonal Close-Packed Zn-Cu-Ti Alloy Pyramid Drawpieces in Single-Point Incremental Sheet Forming Process. Materials. 2025; 18(13):3078. https://doi.org/10.3390/ma18133078

Chicago/Turabian StyleKuczek, Łukasz, Krzysztof Żaba, Tomasz Trzepieciński, Maciej Balcerzak, and Vít Novák. 2025. "Characterization of Hexagonal Close-Packed Zn-Cu-Ti Alloy Pyramid Drawpieces in Single-Point Incremental Sheet Forming Process" Materials 18, no. 13: 3078. https://doi.org/10.3390/ma18133078

APA StyleKuczek, Ł., Żaba, K., Trzepieciński, T., Balcerzak, M., & Novák, V. (2025). Characterization of Hexagonal Close-Packed Zn-Cu-Ti Alloy Pyramid Drawpieces in Single-Point Incremental Sheet Forming Process. Materials, 18(13), 3078. https://doi.org/10.3390/ma18133078