Evolutions in Microstructure and Mechanical Properties of Ultra-Thin Oligocrystalline Invar Alloy Strip During Cold Rolling

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Materials

2.2. Characterizations

2.3. Mechanical Properties Tests

3. Results and Discussion

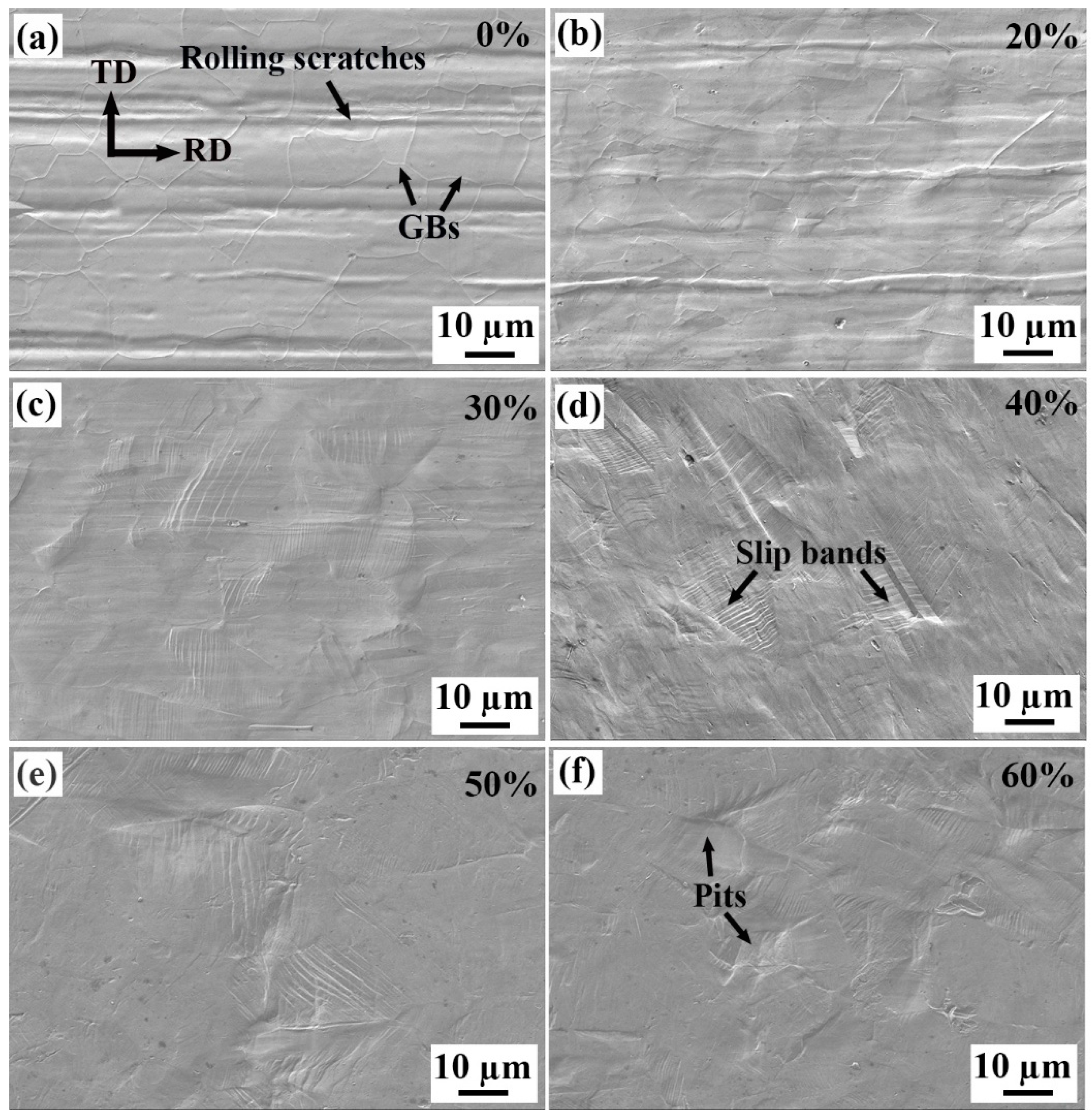

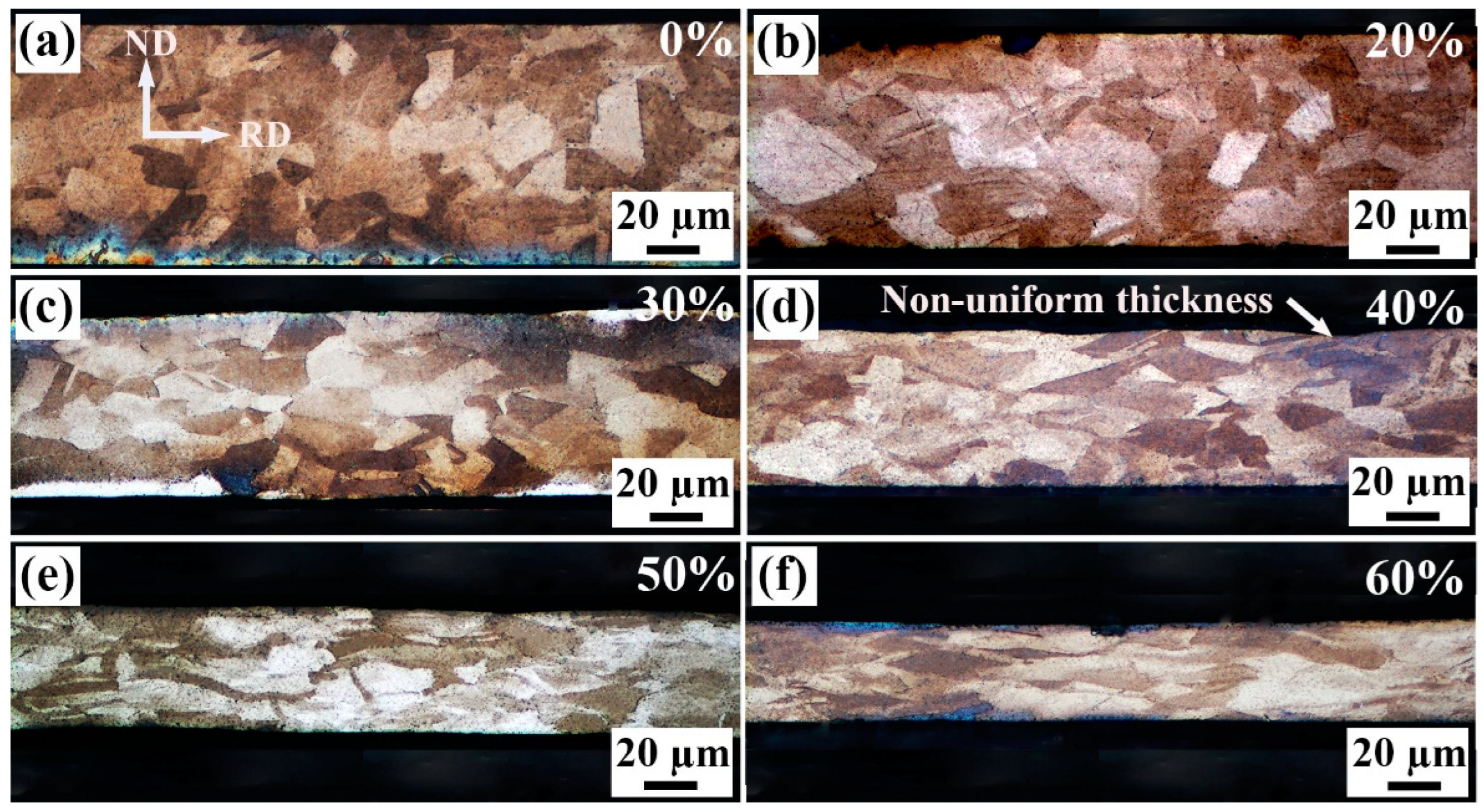

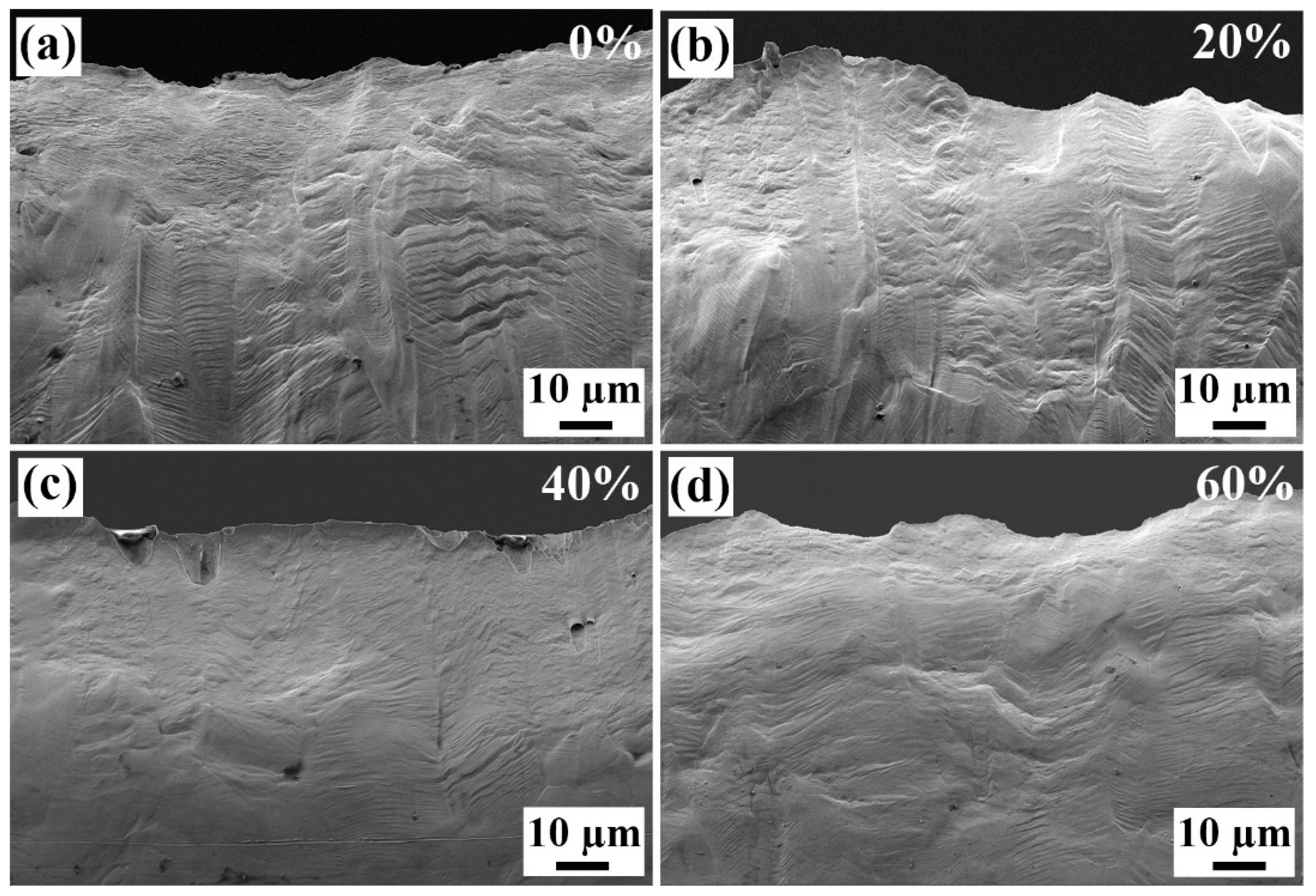

3.1. Evolution in Surface Morphology

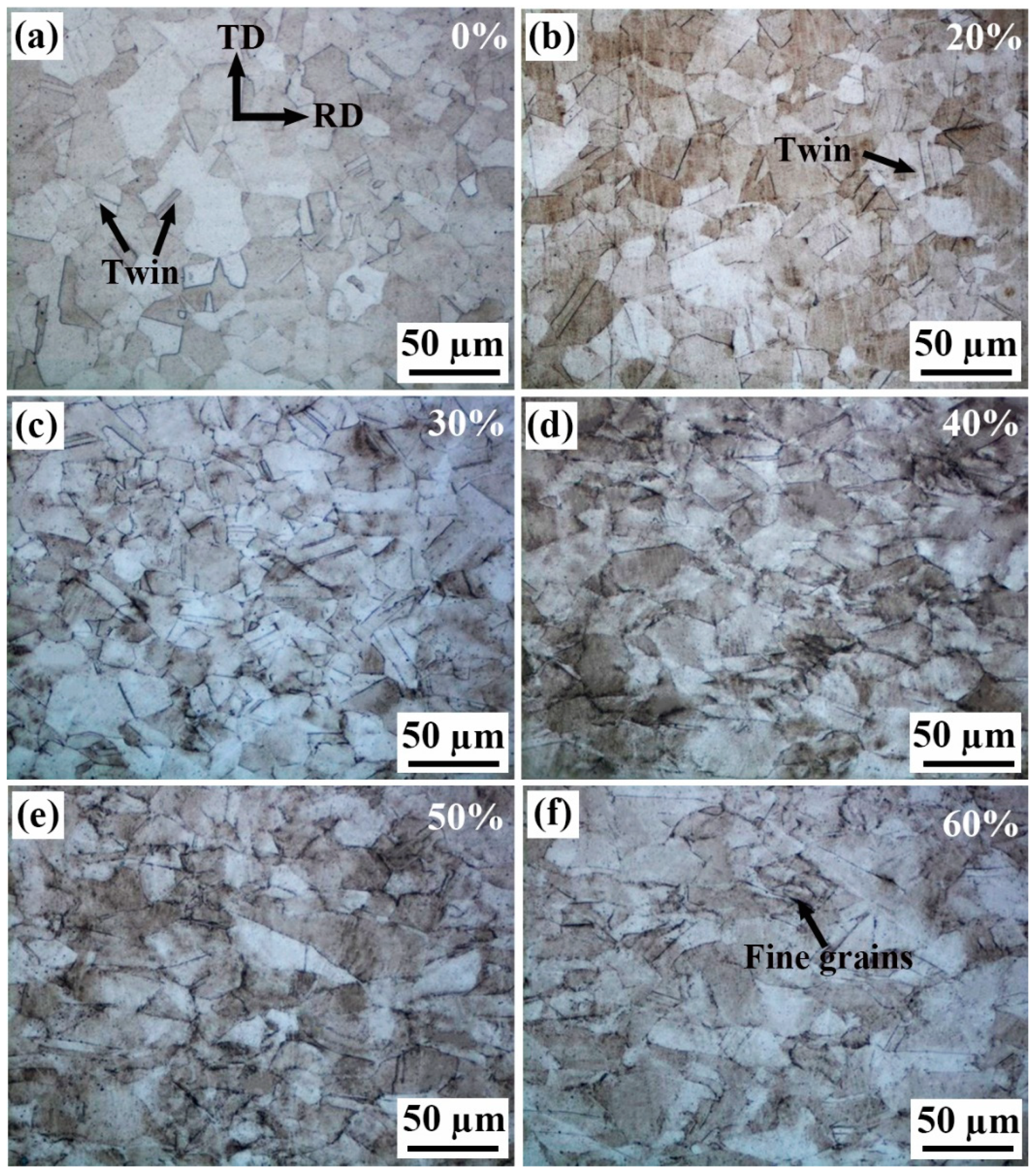

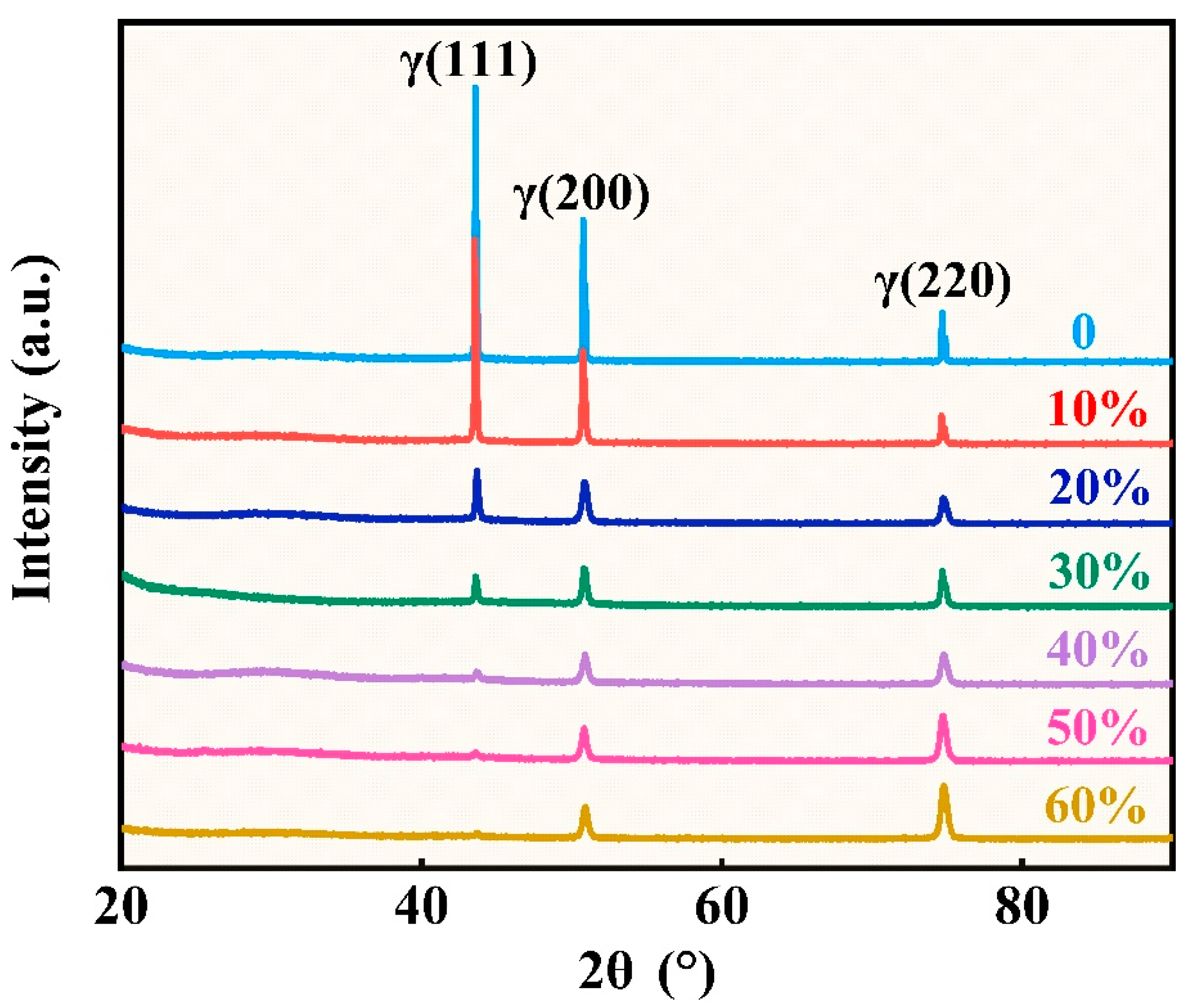

3.2. Evolutions of Grains and Intracrystalline Microstructure

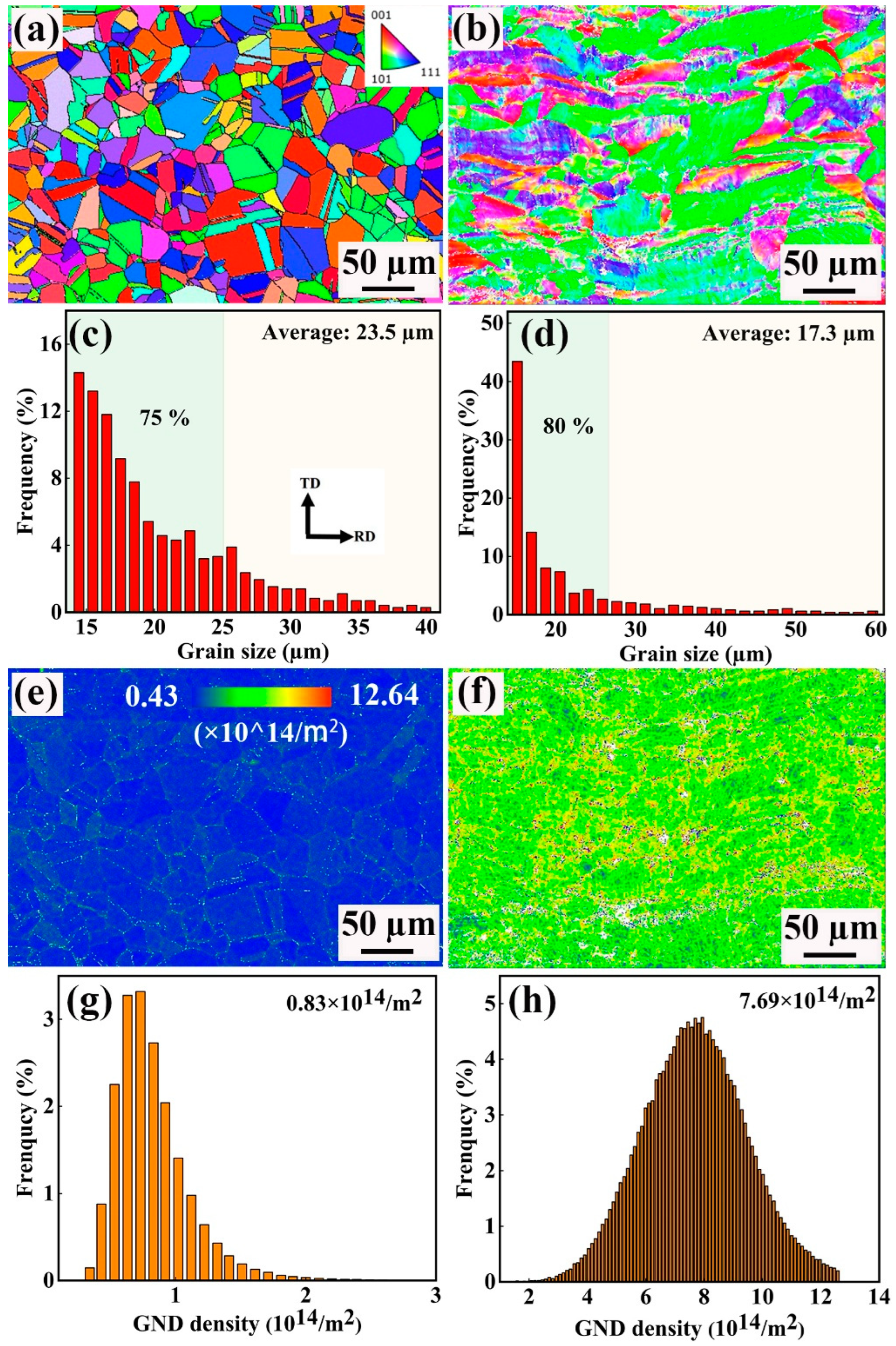

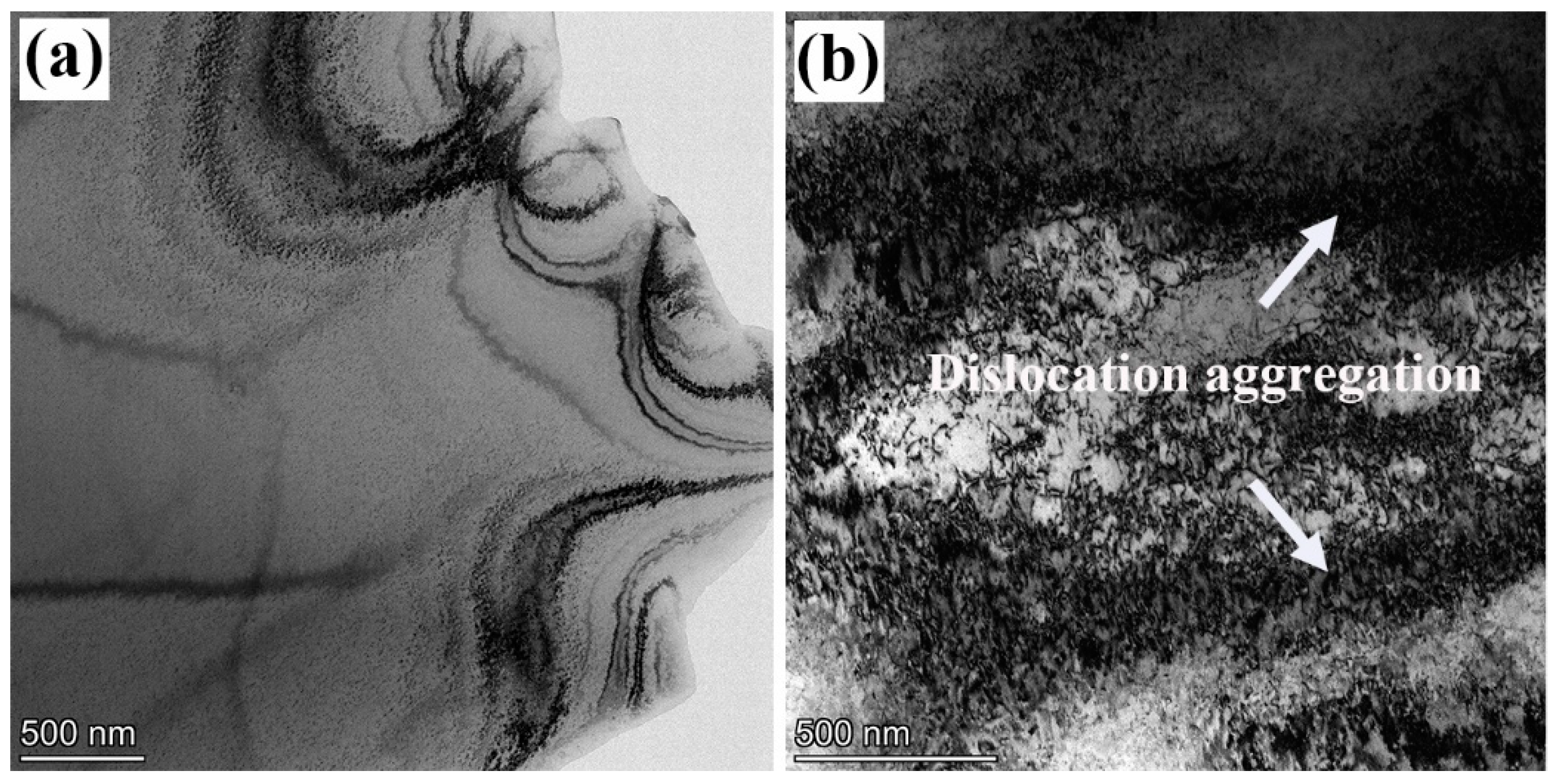

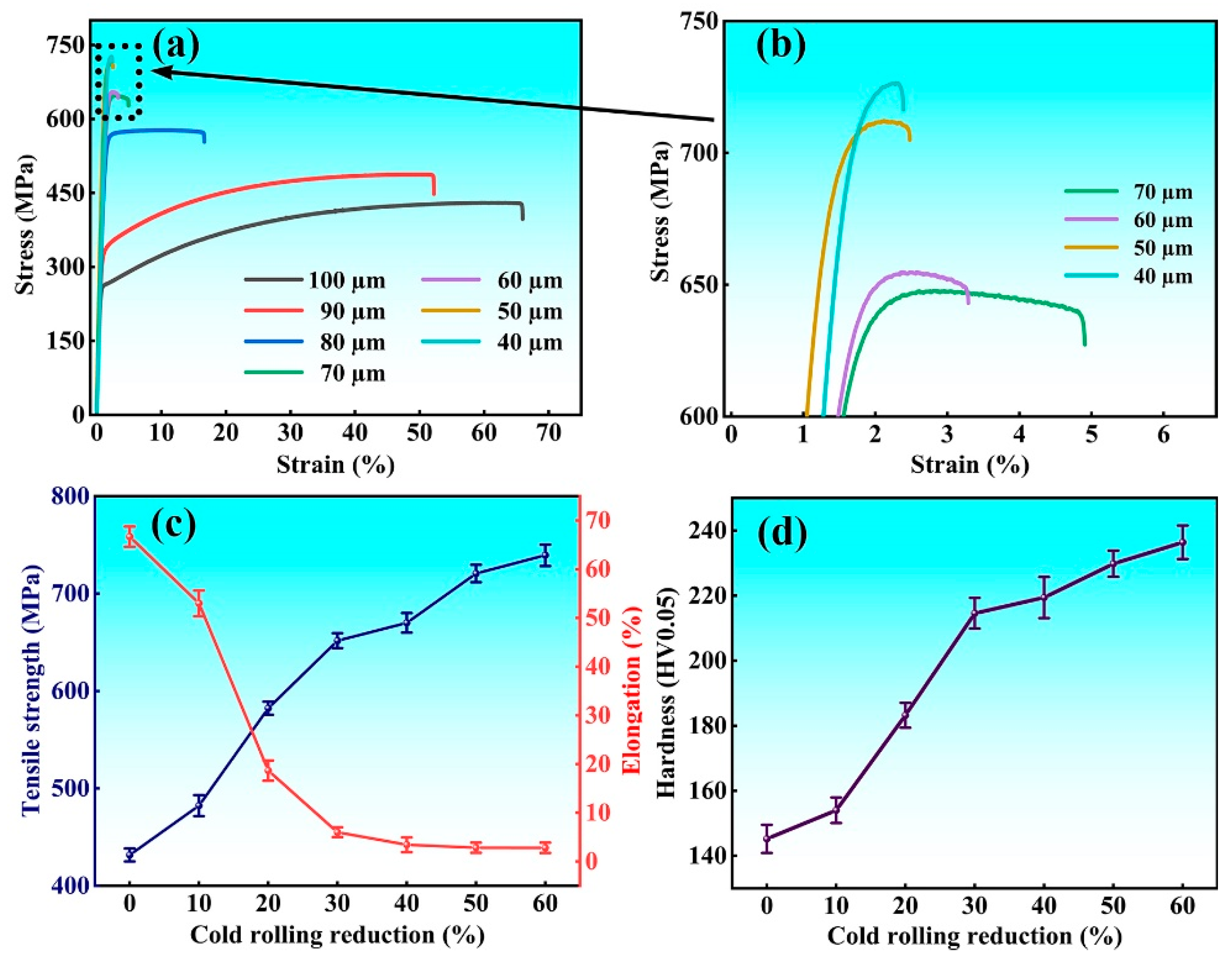

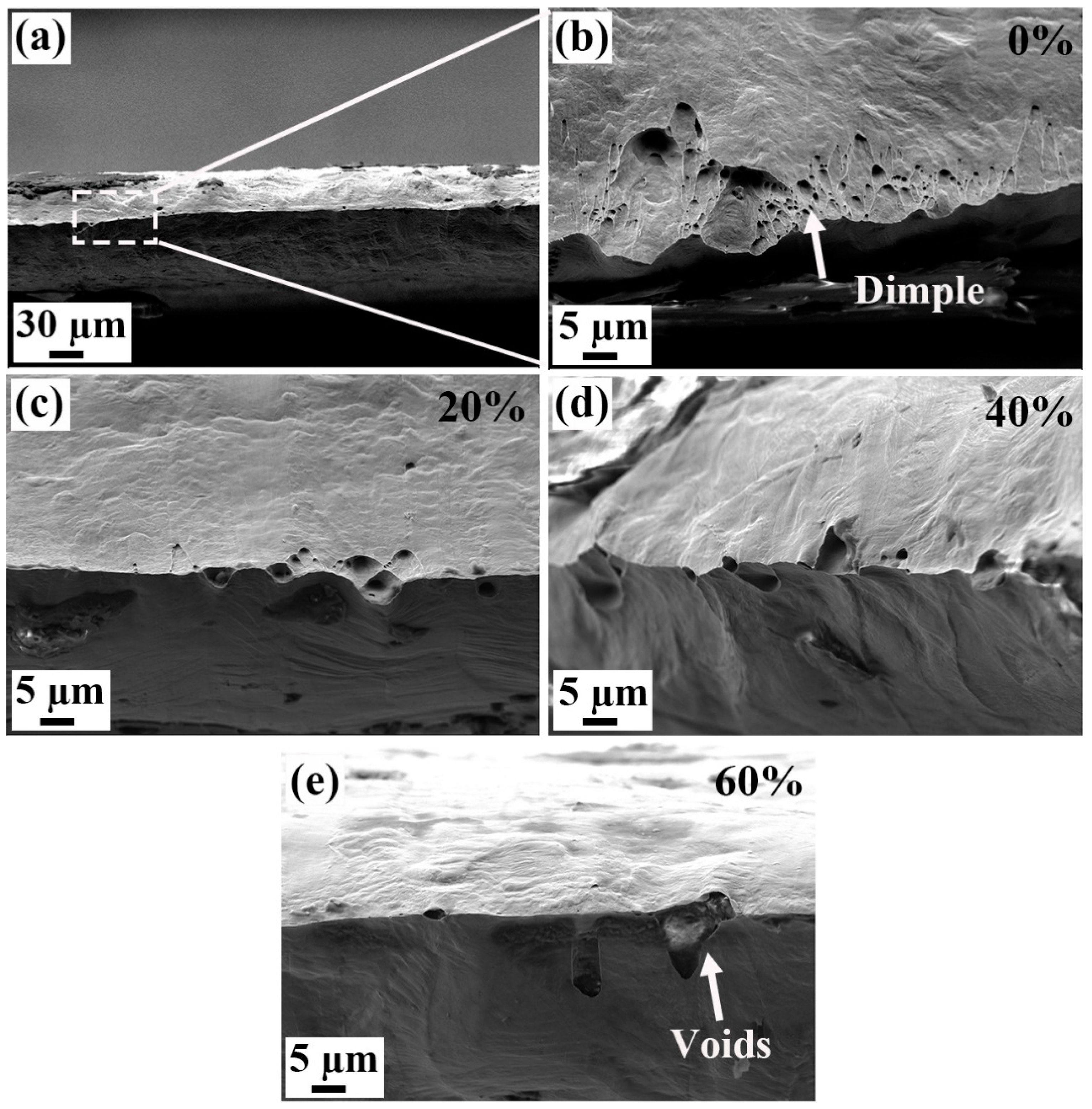

3.3. Mechanical Properties and Fracture Behavior

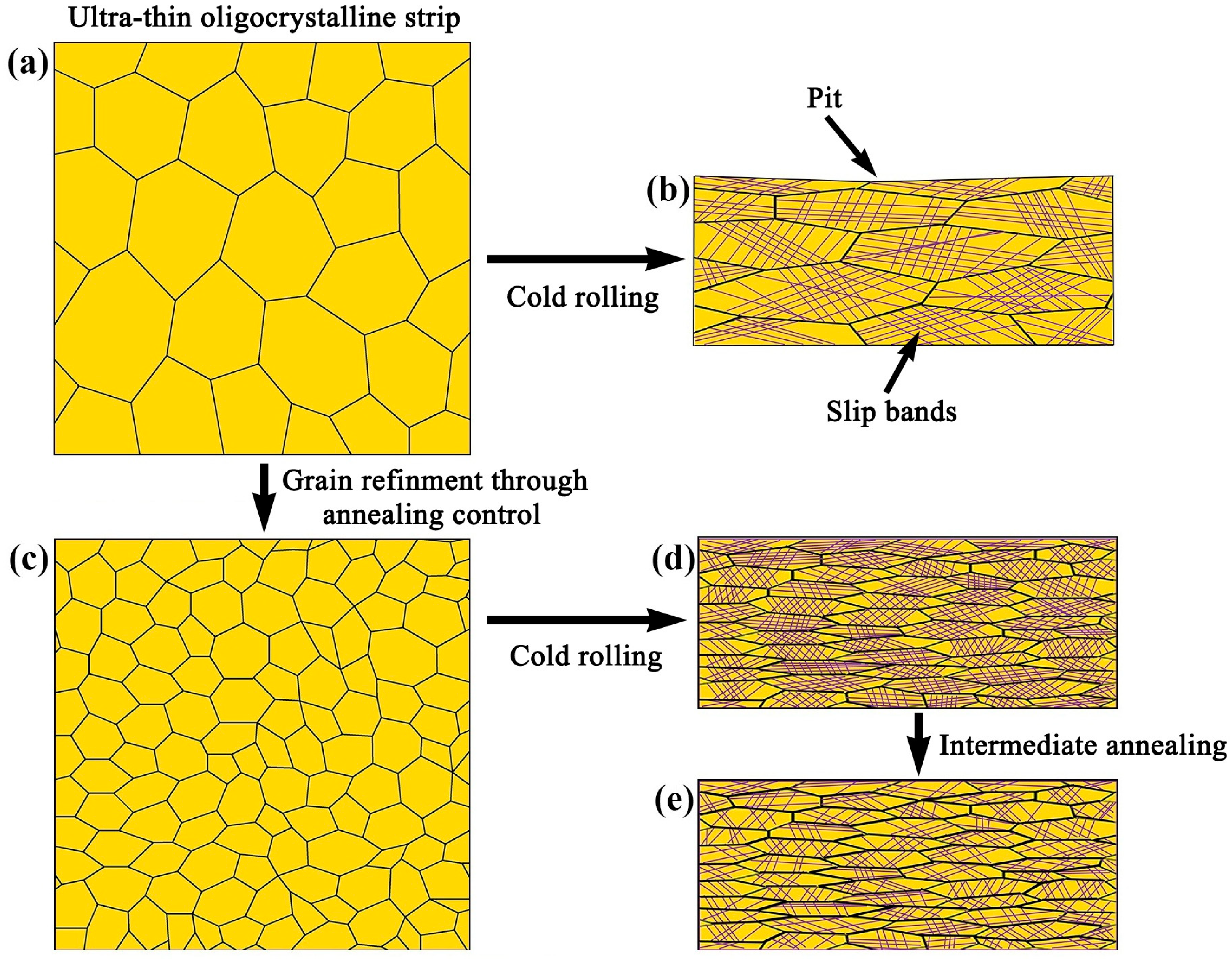

3.4. Discussion

4. Conclusions

- (1)

- Plastic deformation at different locations of the strip during the cold rolling is quite non-uniform, depending on the orientation and deformation resistance of the grains in each area, forming different slip band appearances, uneven thickness and increase in surface roughness. Grain rotation and rolling texture develop with increasing cold rolling reduction.

- (2)

- The grains are elongated during the cold rolling, and fragmentation occurs only in grains with severe plastic deformation. The dislocation density in the 60% cold-rolled strip is almost decuple that of the original strip, forming dislocations tangles, but this is not uniform in different grains.

- (3)

- The tensile strength increases from 430 MPa of the annealed strip to 738 MPa of the 60% cold-rolled strip, but the elongation decreases sharply from 65.4% to 2.8%. The total plastic deformation of cold rolling and tensile processes has a certain limit. Grain refining and proper intermediate annealing are proposed to optimize the thickness uniformity, evenness and surface roughness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Q.; Dong, Y.; Jiang, Z.; Yin, Z. Unveiling the influence of zirconium on the corrosion behavior of Fe-36Ni Invar alloy. Intermetallics 2024, 175, 108519. [Google Scholar] [CrossRef]

- Huang, G.; Peng, X.; Yang, L.; He, Y.; Liu, C.; Zhu, J.; Huang, K.; Liu, Y. Microstructure evolution and corrosion behavior of Invar 36 alloy additively manufactured via laser powder bed fusion. Mater. Charact. 2024, 217, 114422. [Google Scholar] [CrossRef]

- Dong, L.; Yang, F.; Xu, M.; Hu, X.; Fang, F. Effect of Cold-Drawn Deformation on Microstructure and Properties of Invar Alloy Wires. Mate. Eng. Perform. 2024. [Google Scholar] [CrossRef]

- Chen, C.C.; Wang, X.J.; Yu, F.; Song, Z.X.; Yang, L.F.; Zhang, Z.S.; Cui, J.Z. Evolution of microstructure, mechanical properties, and corrosion behavior of Al-xMg-Mn alloy plates by rolling treatment. Mater. Today Commun. 2024, 39, 108624. [Google Scholar] [CrossRef]

- Jiao, G.; Fang, X.; Li, X.; Zhang, M.; Zhang, Z.; Li, H.; Huang, K. High performance ultrasonic vibration assisted Wire-arc directed energy deposition of Invar alloy. J. Mater. Process. 2024, 332, 118534. [Google Scholar] [CrossRef]

- Wegener, T.; Pramanik, S.; Niendorf, T.; Günther, J. On the cyclic deformation behavior of wire-based directed energy deposited Fe-Ni Invar alloy. Mater. Sci. Eng. A 2024, 918, 147403. [Google Scholar] [CrossRef]

- Jin, D.S.; Chun, K.H.; Lee, E.S. Analysis of the current density characteristics in through-mask electrochemical micromachining (TMEMM) for fabrication of micro-hole arrays on invar alloy film. Chin. J. Aeronaut. 2017, 30, 1231–1241. [Google Scholar] [CrossRef]

- Wei, R.; Xi, L.; Guo, L.; Guo, Z.C. Fabrication of low thermal expansion coefficient electrodeposited Invar alloy films by hydrogen annealing for OLED fine metal masks. J. Mater. Chem. C 2024, 29, 10910–10918. [Google Scholar] [CrossRef]

- Tirsatine, K.; Azzeddine, H.; Baudin, T.; Helbert, A.L.; Brisset, F.; Bradai, D. Microstructure and Microtexture Evolution of Invar Alloy after Cross Accumulative Roll Bonding (CARB) Compared to ARB. Mater. Sci. Forum. 2017, 879, 744–749. [Google Scholar] [CrossRef]

- Zhang, D.; Du, X.; Song, Y.; Sun, H.; Zheng, Y.; Sun, Z.; She, Y.; Wang, B. Oxidation mechanism and microstructure evolution of invar alloy with high temperature annealing process. J. Mater. Res. Technol. 2024, 32, 185–195. [Google Scholar] [CrossRef]

- Xu, J.; Guan, B.; Fu, R.; Wu, Y.; Hu, Q.; Zou, J.; Huang, G.; Yan, C. Tailoring the microstructure and mechanical properties of Cu-Fe alloy by varying the rolling path and rolling temperature. J. Mater. Res. Technol. 2023, 27, 182–193. [Google Scholar] [CrossRef]

- Song, H.Y.; Wang, G.D.; Liu, H.T. Effect of cold rolling on microstructure and texture evolution in strip casting Fe-36%Ni invar alloy foil. J. Alloys. Compd. 2021, 888, 161519. [Google Scholar] [CrossRef]

- Yao, Y.; Zhao, Q.; Zhang, C.; He, J.; Wu, Y.; Meng, G.; Chen, C.; Sun, Z.; Peng, H. Effect of warm rolling on microstructures and properties of the high strength invar alloy. J. Mater. Res. Technol. 2022, 19, 3046–3058. [Google Scholar] [CrossRef]

- Jiao, G.; Fang, X.; Chen, X.; Xi, N.; Zhang, M.; Liu, Y.; Wu, H.; Huang, K. The origin of low thermal expansion coefficient and enhanced tensile properties of Invar alloy fabricated by directed energy deposition. J. Mater. Process. Technol. 2023, 317, 117994. [Google Scholar] [CrossRef]

- Zheng, J.; Li, C.; He, S.; Ma, B.; Song, Y. Deformation twin and martensite in the Fe–36%Ni alloy during cryorolling. Mater. Sci. Technol. 2017, 33, 1681–1687. [Google Scholar] [CrossRef]

- Zhao, X.; Jin, T.; Ding, L.; Wan, B.; Lei, X.; Xu, C.; Zhang, C.; Jia, Z.; Liu, Q. The effect of combined cold rolling and homogenization on the microstructures and mechanical properties of twin-roll casted 8021 aluminum alloy. J. Alloys. Compd. 2023, 937, 168385. [Google Scholar] [CrossRef]

- Lu, C.; Li, J.; Fang, Z. Effects of asymmetric rolling process on ridging resistance of ultra-purified 17%Cr ferritic stainless steel. Int. J. Min. Met. Mater. 2018, 25, 216–225. [Google Scholar] [CrossRef]

- Kundu, A.; Field, D.P.; Chandra, C.P. Influence of strain amplitude on the development of dislocation structure during cyclic plastic deformation of 304 LN austenitic stainless steel. Mater. Sci. Eng. A 2019, 762, 138090. [Google Scholar] [CrossRef]

- Witzen, W.A.; Polonsky, A.T.; Pollock, T.M.; Beyerlein, I.J. Three-dimensional maps of geometrically necessary dislocation densities in additively manufactured Ni-based superalloy IN718. Int. J. Plast. 2020, 131, 102709. [Google Scholar] [CrossRef]

- Wang, X.L.; Zhang, W.N.; Hao, Y.S.; Jiang, Q.W.; Li, D.G.; Li, Y.H. Refinement of coarse AlN by the shear effect of dislocation slip during cold rolling in low-temperature grain-oriented silicon steel. Intermetallics 2021, 132, 107136. [Google Scholar] [CrossRef]

- Yu, Z.; Yan, S.; Liang, T.; Tang, R.; Li, Y.; Liu, X. Architectured heterogeneous microstructure of medium-Mn steel through cold rolling and intercritical annealing to improve deformation behavior. Mater. Charact. 2025, 221, 114746. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, L.; Zhang, Y.Q.; Zhao, X.; Wang, E.G. Evolution of microstructure and property alterations in Cu-Ag-Cr alloy under rolling deformation. Mater. Sci. Eng. A 2025, 924, 147768. [Google Scholar] [CrossRef]

- Li, H.F.; Wang, S.G.; Zhang, P.; Qu, R.T.; Zhang, Z.F. Crack propagation mechanisms of AISI 4340 steels with different strength and toughness. Mater. Sci. Eng. A 2018, 729, 130–140. [Google Scholar] [CrossRef]

- Jafarlou, D.M.; Walde, C.; Champagne, V.K.; Krishnamurty, S.; Grosse, I.R. Influence of cold sprayed Cr3C2-Ni coating on fracture characteristics of additively manufactured 15Cr-5Ni stainless steel. Mater. Design. 2018, 155, 134–147. [Google Scholar] [CrossRef]

- Li, J.Q.; Li, X.H.; Xu, T.Y.; Yan, H.; Mao, Y.Z.; Chen, R.S. Regulating the grain refinement and rolling properties of coarse-crystalline Mg-Zn-Gd-Ca-Mn alloy through multi-pass cold rolling and annealing. Mater. Sci. Eng. A 2024, 911, 146940. [Google Scholar] [CrossRef]

- Kapoor, G.; Kvackaj, T.; Heczel, A.; Bidulská, J.; Fogarassy, Z.; Simcak, D.; Gubicza, J.; Kočiško, R. The Influence of Severe Plastic Deformation and Subsequent Annealing on the Microstructure and Hardness of a Cu-Cr-Zr Alloy. Mater. Design. 2020, 13, 2241. [Google Scholar] [CrossRef]

- Wu, Z.L.; Cai, B.Z.; Bai, Y.H.; Quan, S.W.; Li, X.F.; Li, C.; Gong, Y.L.; Pan, H.J.; Zhu, X.K. Regulating strength and ductility of gradient-structured Cu-Al-Zn via SMAT and annealing. J. Mater. Res. Technol. 2025, 34, 703–715. [Google Scholar] [CrossRef]

| Elements | Ni | Mn | Si | Cu | S | Fe |

|---|---|---|---|---|---|---|

| Content (wt%) | 36.2 | 0.331 | 0.239 | 0.11 | 0.09 | Bal |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Xia, Y.; Zhang, Q.; Chen, G.; Xu, C.; Song, Z.; Chen, J. Evolutions in Microstructure and Mechanical Properties of Ultra-Thin Oligocrystalline Invar Alloy Strip During Cold Rolling. Materials 2025, 18, 2026. https://doi.org/10.3390/ma18092026

Yang J, Xia Y, Zhang Q, Chen G, Xu C, Song Z, Chen J. Evolutions in Microstructure and Mechanical Properties of Ultra-Thin Oligocrystalline Invar Alloy Strip During Cold Rolling. Materials. 2025; 18(9):2026. https://doi.org/10.3390/ma18092026

Chicago/Turabian StyleYang, Jianguo, Yajin Xia, Qingke Zhang, Genbao Chen, Cheng Xu, Zhenlun Song, and Jiqiang Chen. 2025. "Evolutions in Microstructure and Mechanical Properties of Ultra-Thin Oligocrystalline Invar Alloy Strip During Cold Rolling" Materials 18, no. 9: 2026. https://doi.org/10.3390/ma18092026

APA StyleYang, J., Xia, Y., Zhang, Q., Chen, G., Xu, C., Song, Z., & Chen, J. (2025). Evolutions in Microstructure and Mechanical Properties of Ultra-Thin Oligocrystalline Invar Alloy Strip During Cold Rolling. Materials, 18(9), 2026. https://doi.org/10.3390/ma18092026