Crack Failure Analysis of Hot-Stamping Die Insert for Manufacturing an Automobile A-Pillar

Abstract

1. Introduction

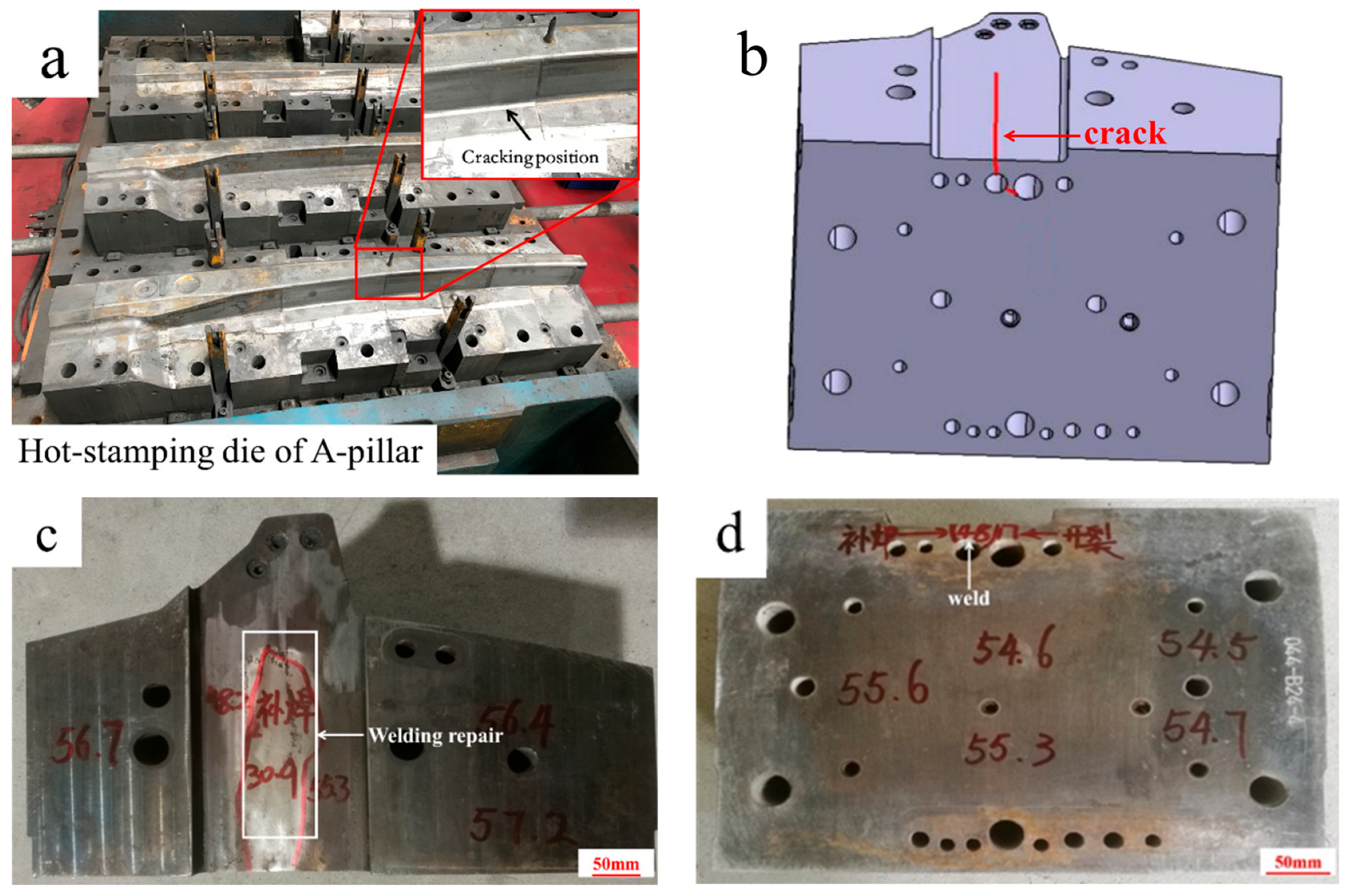

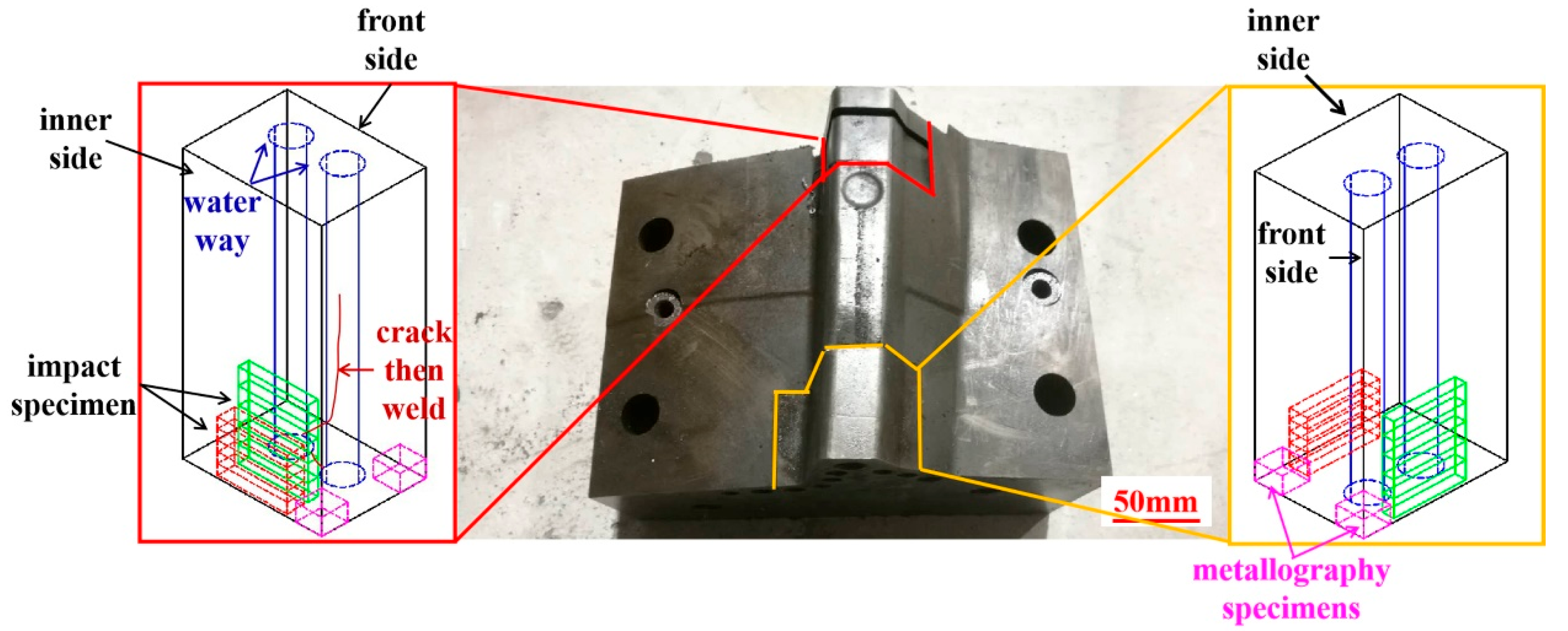

2. Background and Experimental Information

3. Results

3.1. Chemical Composition

3.2. Surface Hardness

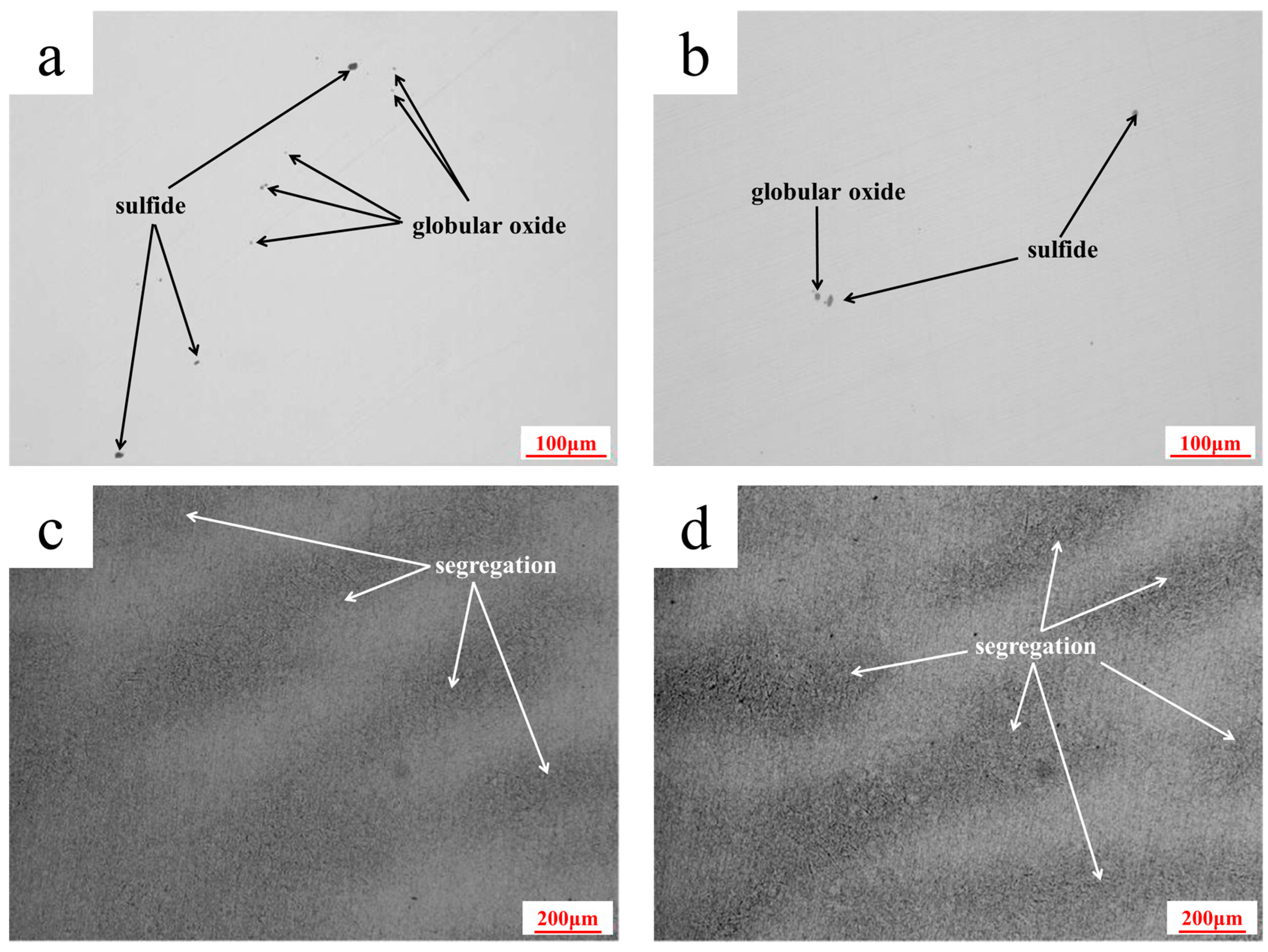

3.3. Non-Metallic Inclusion

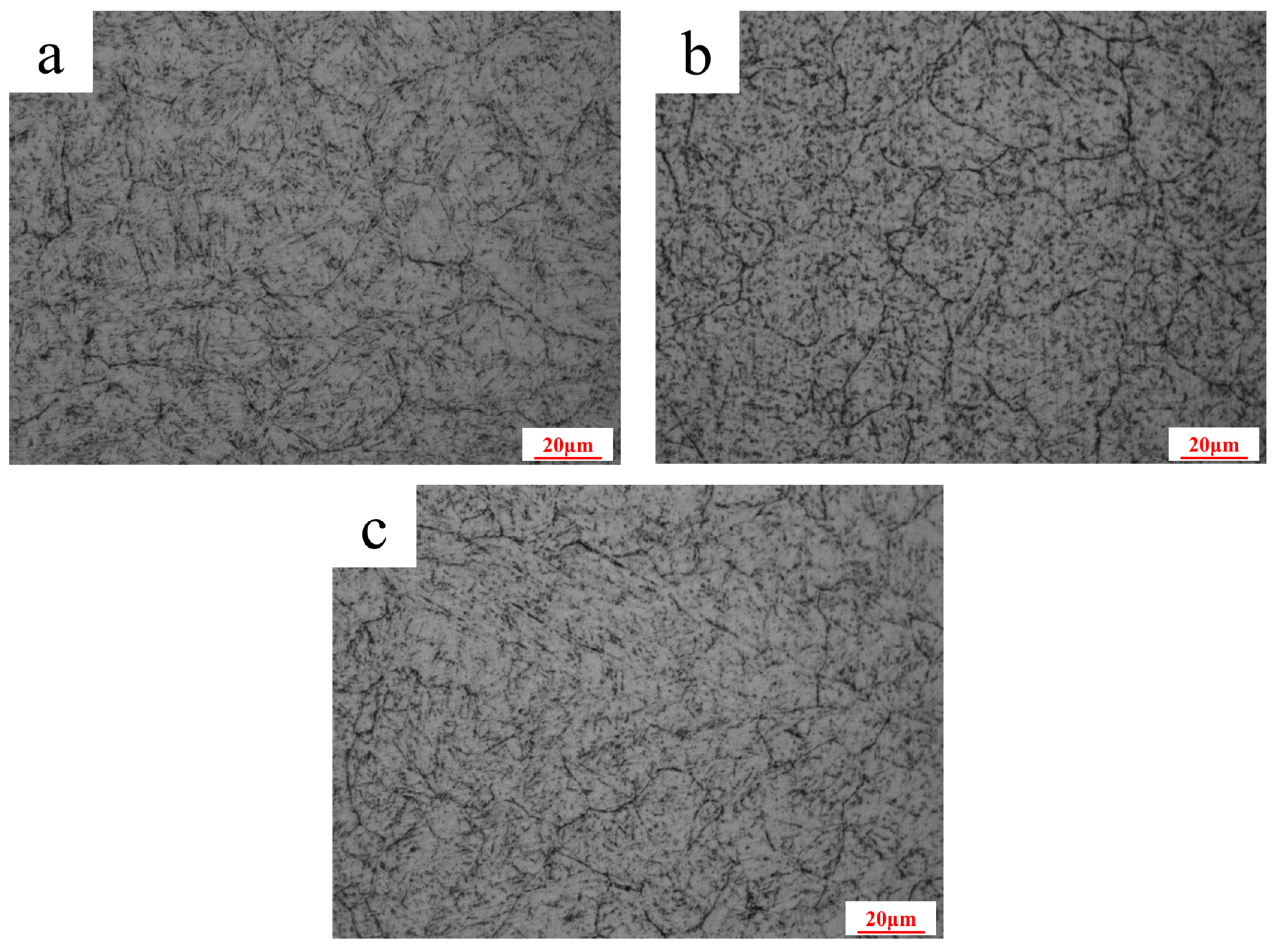

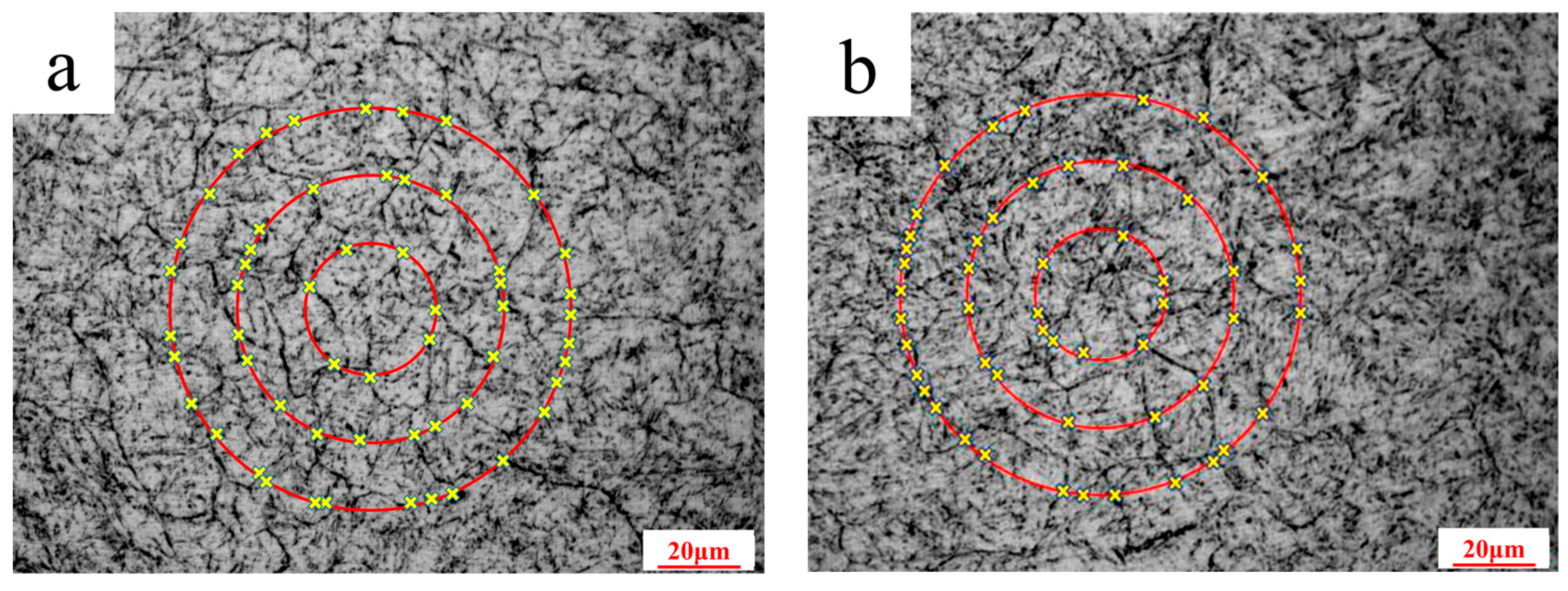

3.4. Microstructure Characterization

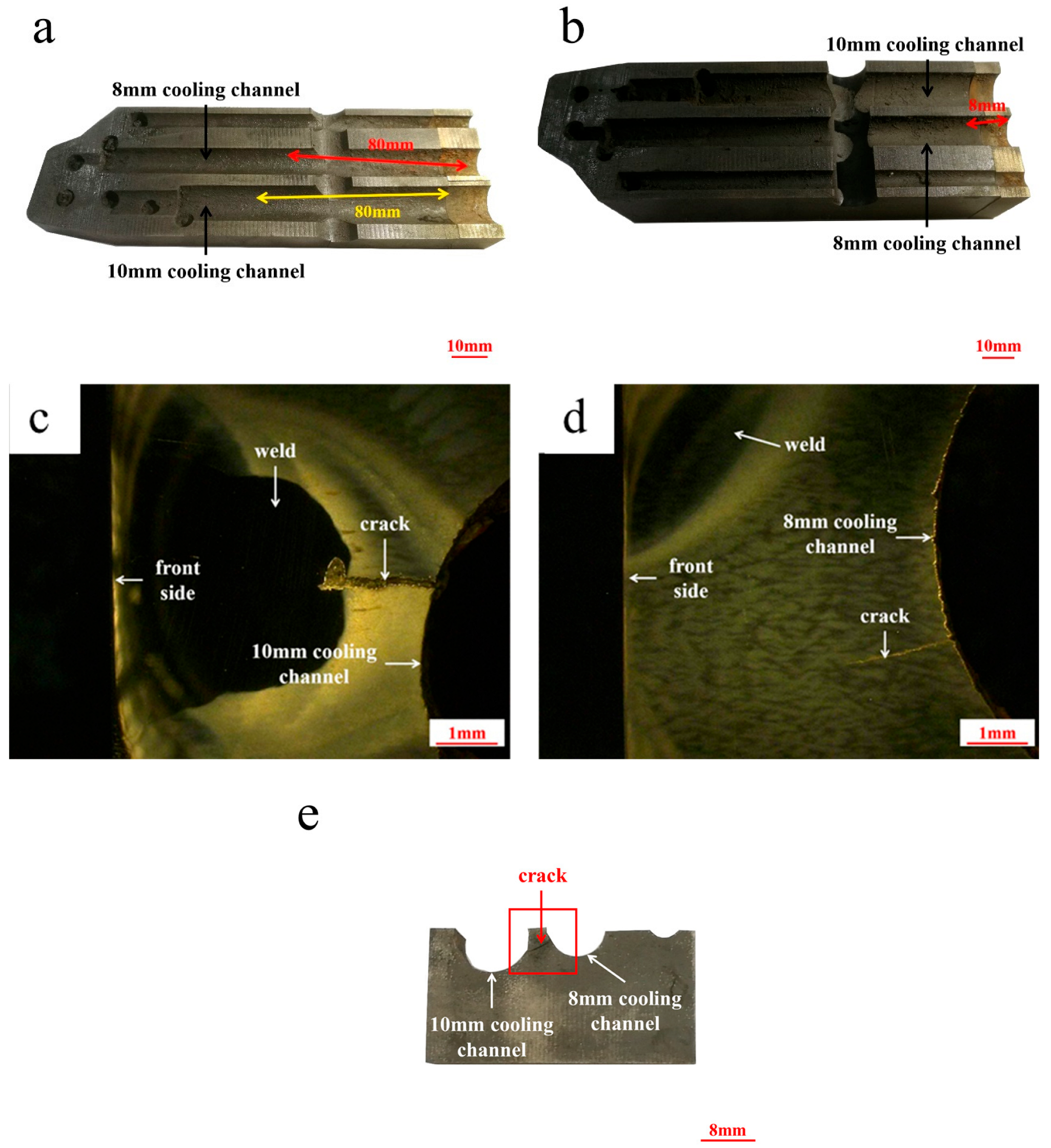

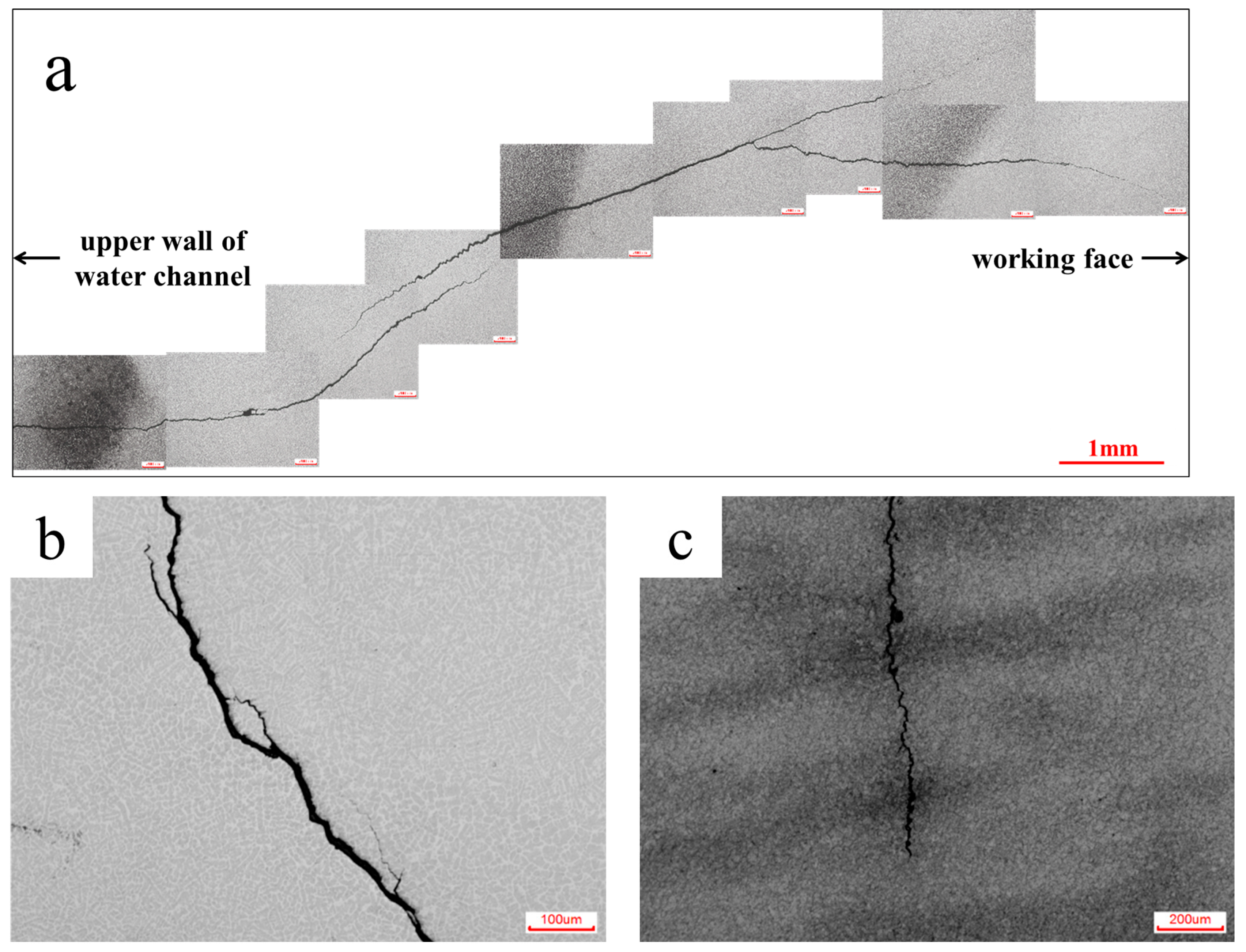

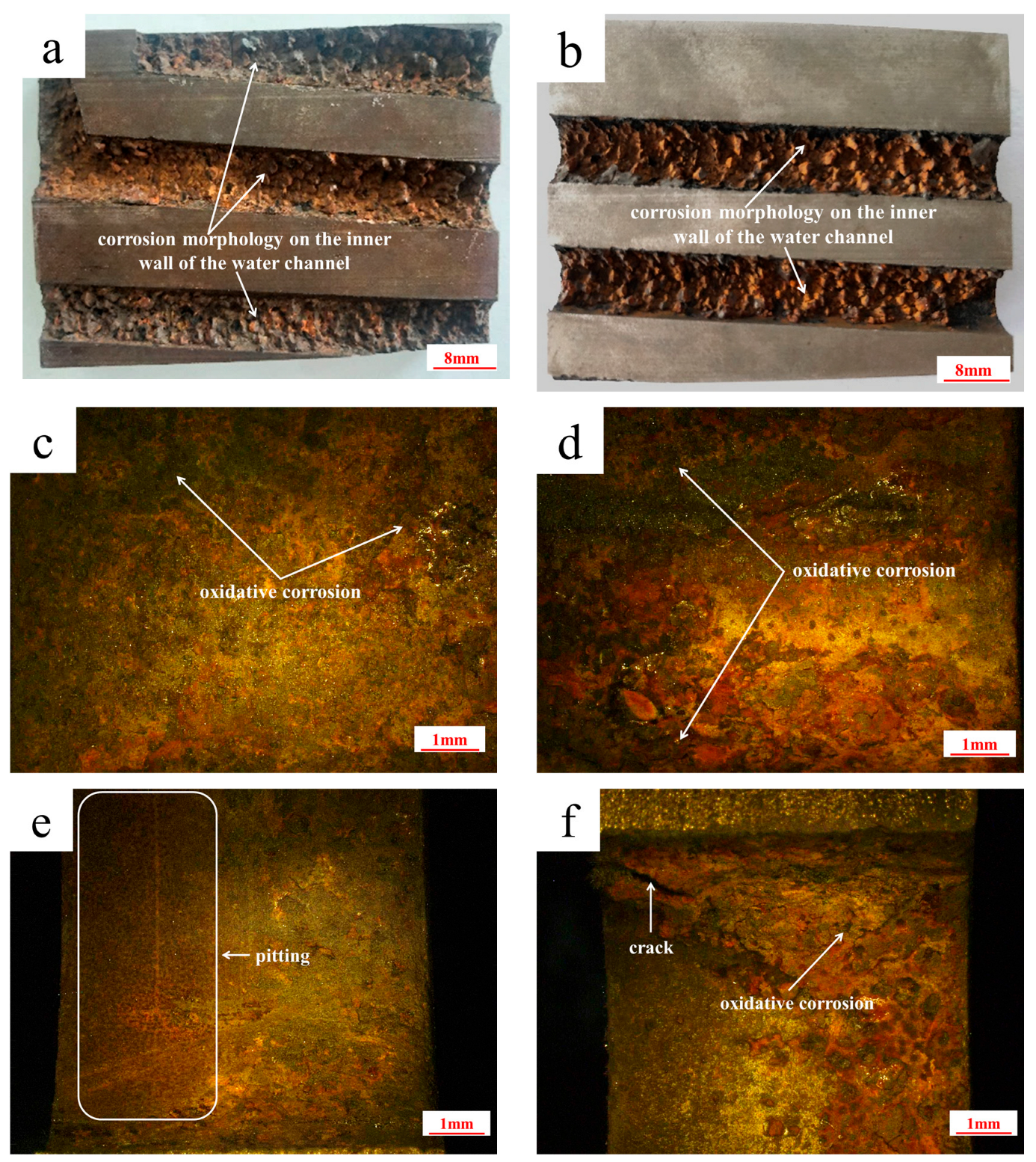

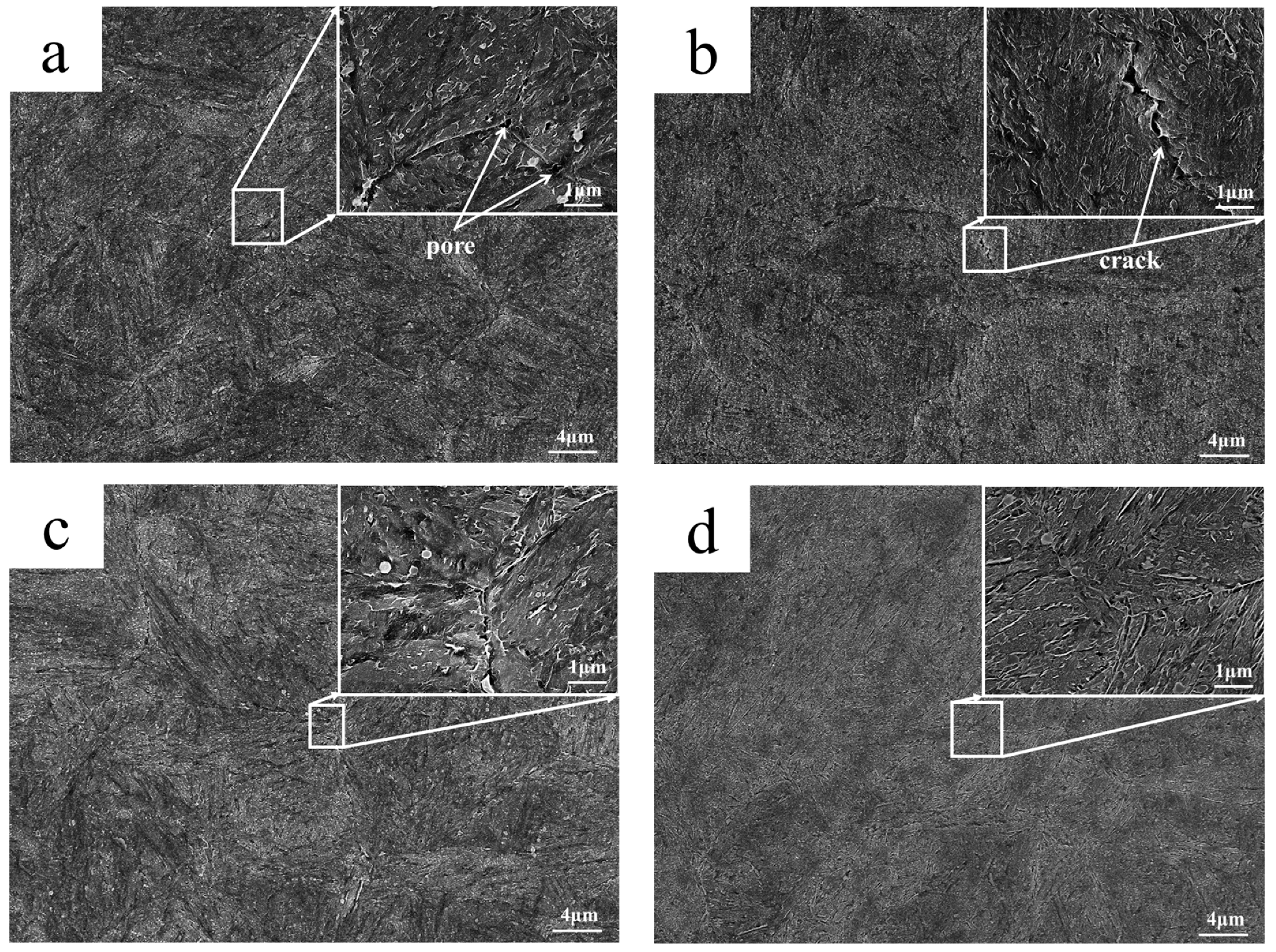

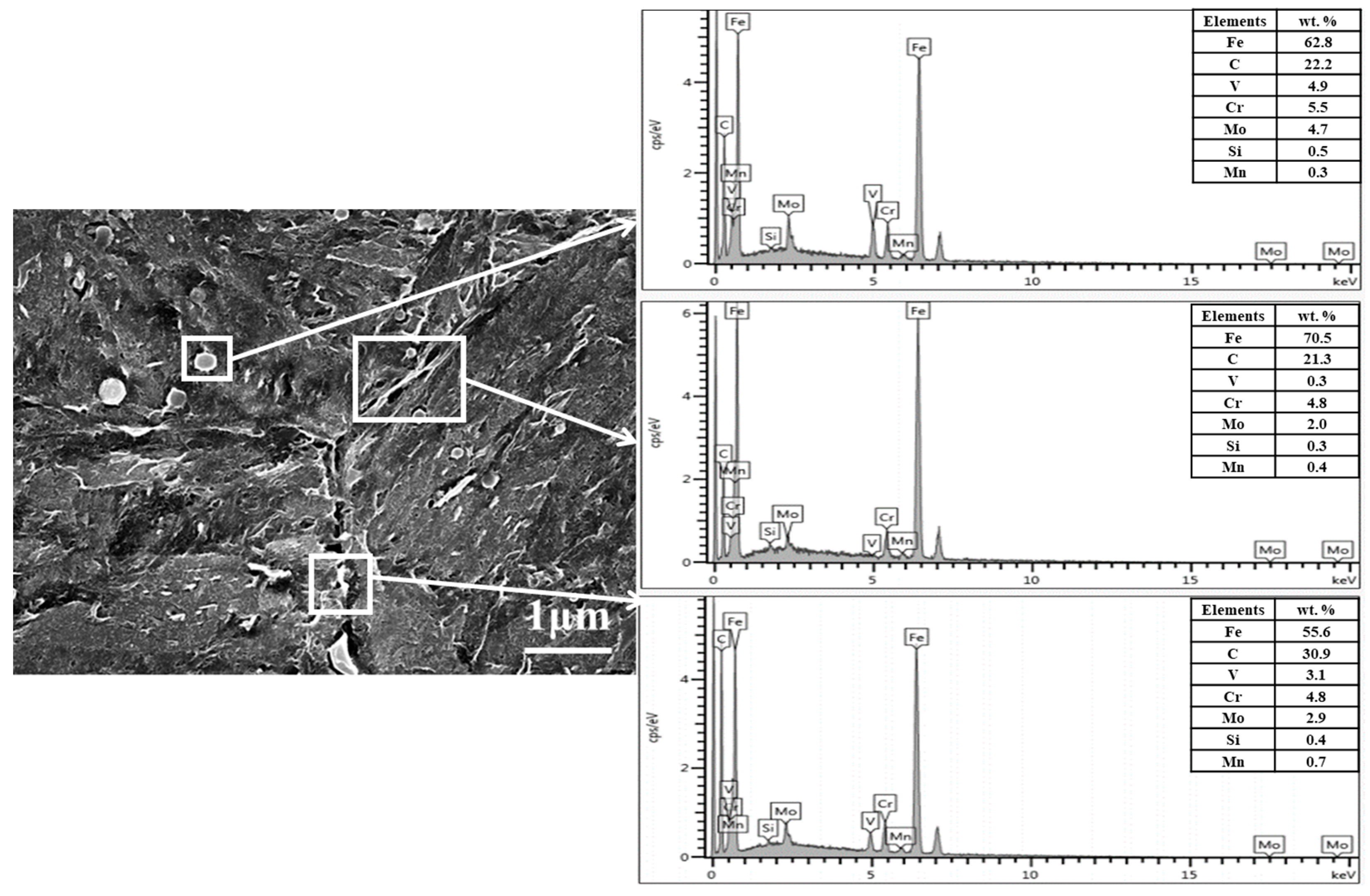

3.5. Crack Observation

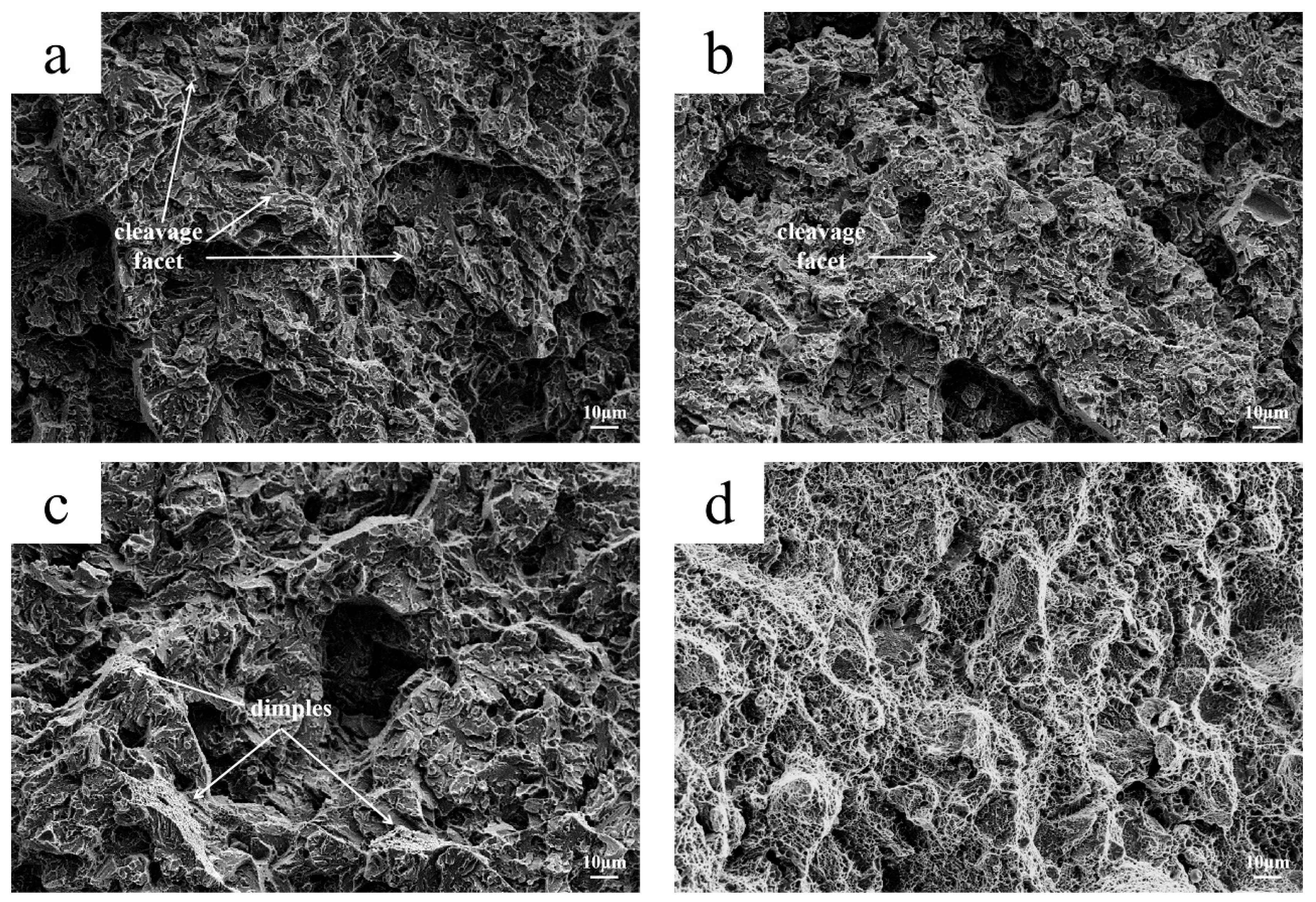

3.6. Impact Toughness

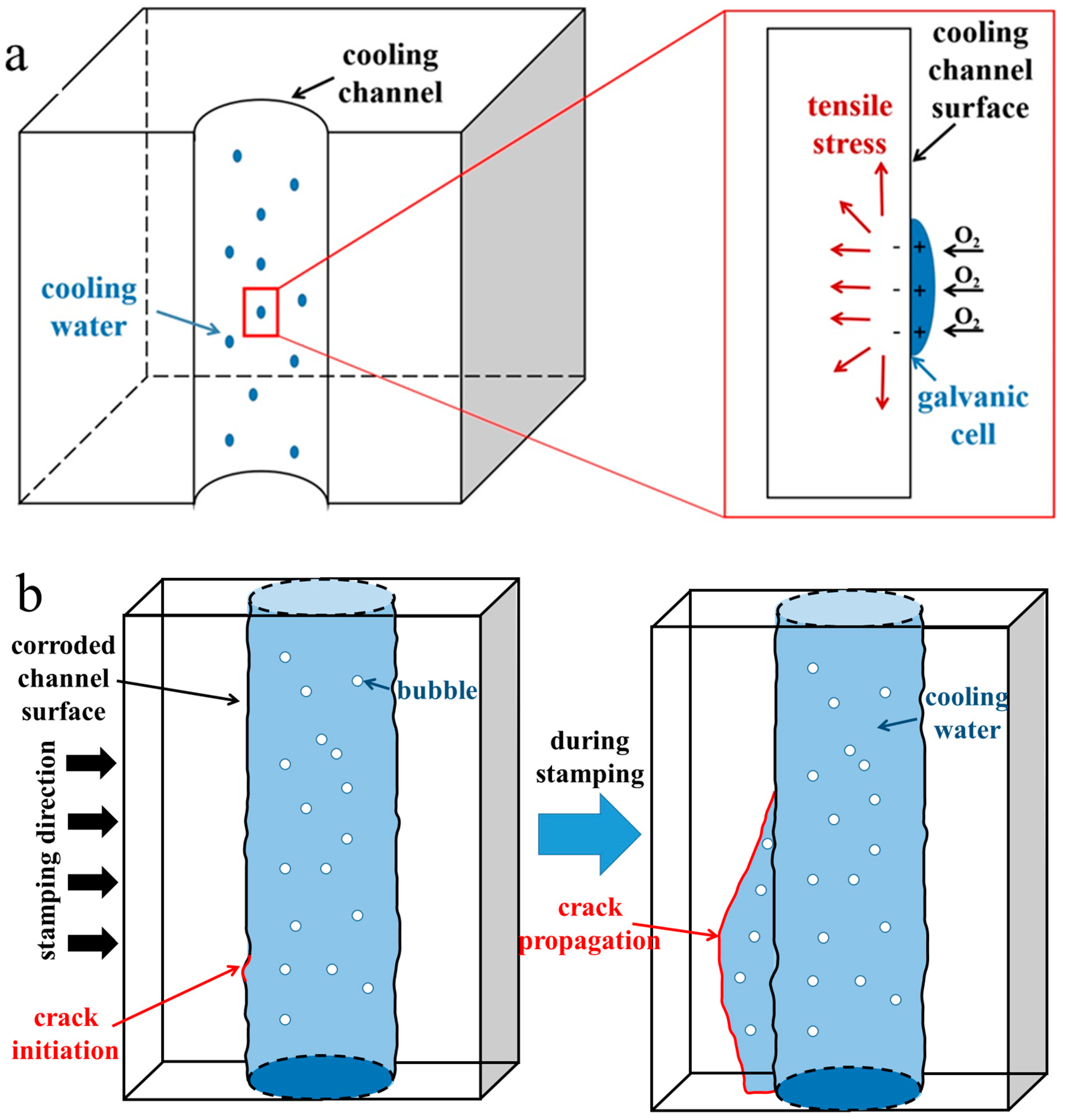

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jin, X.; Gong, Y.; Han, X.; Du, H.; Ding, W.; Zhang, Y.; Feng, Y.; Ma, M.; Liang, B.; Zhao, Y.; et al. A review of current state and prospect of the manufacturing and application of advanced hot stamping automobile steels. Acta Metall. Sin. 2020, 56, 411–428. [Google Scholar] [CrossRef]

- Costa, L.D.L.; Brito, A.M.G.; Rosiak, A.; Schaeffer, L. Study of the applicability of 22MnB5 sheet metal as protective masks to improve tool life in hot forging process. Int. J. Adv. Manufact. Technol. 2020, 107, 39–47. [Google Scholar] [CrossRef]

- Jiang, B.; Li, X.; Zuo, P.; Wu, X. Study on isothermal fatigue life prediction model of a new type hot stamping die steel 4Cr2Mo2V. Eng. Fail. Anal. 2020, 136, 106211. [Google Scholar] [CrossRef]

- Escher, C.; Wilzer, J. Tool steels for hot-stamping of high strength automotive body parts. Int. Conf. Stone Concr. Mach. (ICSCM) 2015, 3, 219–228. [Google Scholar] [CrossRef]

- Tisza, M.; Imre, C. Comparative study of the application of steels and aluminum in lightweight production of automotive parts. Int. J. Lightweight Mater. Manuf. 2018, 1, 229–238. [Google Scholar] [CrossRef]

- Abdullah, N.A.Z.; Sani, M.S.M.; Salwani, M.S.; Husain, N.A. A review on crashworthiness studies of crash box structure. Thin-Walled Struct. 2020, 153, 106795. [Google Scholar] [CrossRef]

- Shi, D.; Watanabe, K.; Naito, J.; Funada, K.; Yasui, K. Design optimization and application of hot-stamped B pillar with local patchwork blanks. Thin-Walled Struct. 2022, 170, 108523. [Google Scholar] [CrossRef]

- Lu, R.; Gao, W.; Hu, X.; Liu, W.; Li, Y.; Liu, X. Crushing analysis and crashworthiness optimization of tailor rolled tubes with variation of thickness and material properties. Int. J. Mech. Sci. 2018, 136, 67–84. [Google Scholar] [CrossRef]

- Li, S.; Wu, X.; Li, X.; Li, J.; He, X. Wear characteristics of Mo-W-type hot-work steel at high temperature. Tribol. Lett. 2016, 64, 32. [Google Scholar] [CrossRef]

- Barrau, O.; Boher, C.; Gras, R.; Rezai-Aria, F. Analysis of the friction and wear behaviour of hot work tool steel for forging. Wear 2003, 255, 1444–1454. [Google Scholar] [CrossRef]

- Song, X.; Zhan, P. Study on temperature field of hot-stamping dies for b pillar of vehicles. CFHI Technol. 2017, 6, 7–11. [Google Scholar] [CrossRef]

- Bernhart, G.; Moulinier, G.; Brucelle, O.; Delagnes, D. High temperature low cycle fatigue behaviour of a martensitic forging tool steel. Int. J. Fatigue 1999, 21, 179–186. [Google Scholar] [CrossRef]

- Jung, I.; Lubich, V.; Wieland, H.-J. Tool failure–causes and prevention. In Proceedings of the 6th International Tooling Conference, Karlstad, Sweden, 10–13 September 2002; pp. 1343–1362. [Google Scholar]

- Wang, W.; Wu, X. Analyses on cracking reasons of a hot-stamping B-pillar die insertges. Die Mould Manuf. 2017, 17, 93–96. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Z.; Shi, C. Intergranular fatigue cracking mechanisms. J. Grad. Sch. Chin. Acad. Sci. 2004, 21, 270–275. [Google Scholar] [CrossRef]

- Alkan, A.; Gümüş, S.; Atapek, Ş.H.; Polat, Ş. A case study of a stress corrosion cracking failure in an AA5083 mold material used for curing rubber compounds. Prot. Met. Phys. Chem. Surf. 2016, 52, 1100–1105. [Google Scholar] [CrossRef]

- Valls, I.; Casas, B.; Rodríguez, N.; Paar, U. Benefits from using high thermal conductivity tool steels in the hot forming of steels. La Metall. Ital. 2010, 102, 23–28. [Google Scholar] [CrossRef]

- GB/T 229-2020; Metallic Materials—Charpy Pendulum Impact Test Method. The State Bureau of Quality and Technical Supervision: Beijing, China, 2000.

- NADCA #207-2016; Special Quality Die Steel & Heat Yreatment Acceptance Criteria For Die Casting Dies. North American Die Casting Association: Arlington Heights, IL, USA, 2016.

- NADCA #207-90; Premium Quality H13 Steel Acceptance Criteria For Pressure Die Casting Dies. North American Die Casting Association: Arlington Heights, IL, USA, 1990.

- Hofinger, M.; Seisenbacher, B.; Ognianov, M.; Leitner, H.; Turk, C.; Kapp, M.; Schnitzer, R. Thermomechanical fatigue testing of dual hardening tool steels. Steel Res. Int. 2020, 91, 1900423. [Google Scholar] [CrossRef]

- Mori, K.I.; Bariani, P.F.; Behrens, B.A.; Brosius, A.; Bruschi, S.; Maeno, T.; Merklein, M.; Yanagimoto, J.J.C.A. Hot stamping of ultra-high strength steel parts. CIRP Ann. 2017, 66, 755–777. [Google Scholar] [CrossRef]

- Elboujdaini, M.; Revie, R. Metallurgical factors in stress corrosion cracking (SCC) and hydrogen-induced cracking (HIC). J. Solid State Electr. 2009, 13, 1091–1099. [Google Scholar] [CrossRef]

- Parkins, R.N.; O′Dell, C.S.; Fessler, R.R. Factors affecting the potential of galvanostatically polarised pipeline steel in relation to scc in co2-3-hco-3 solutions. Corros. Sci. 1984, 24, 343–374. [Google Scholar] [CrossRef]

- Wang, L.; Xin, J.; Cheng, L.; Zhao, K.; Sum, B.; Li, J.; Wang, X.; Cui, Z. Influence of inclusions on initiation of pitting corrosion and stress corrosion cracking of X70 steel in near-neutral pH environment. Corros. Sci. 2019, 147, 108–127. [Google Scholar] [CrossRef]

- Turnbull, A.; Wright, L.; Crocker, L. New insight into the pit-to-crack transition from finite element analysis of the stress and strain distribution around a corrosion pit. Corros. Sci. 2010, 52, 1492–1498. [Google Scholar] [CrossRef]

- Peng, Q.; Li, G.; Shoji, T. The crack tip solution chemistry in sensitized stainless steel in simulated boiling water reactor water studied using a microsampling technique. J. Nucl. Sci. Technol. 2003, 40, 397–404. [Google Scholar] [CrossRef]

- Valiev, R. Nanostructuring of metals by severe plastic deformation for advanced properties. Nat. Mater. 2004, 8, 511–516. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | V | Mo | Cr | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Content | 0.39 | 0.22 | 0.43 | 0.63 | 2.34 | 5.00 | 0.010 | 0.002 | Bal. |

| Inclusion Type | Grade A | Grade B | Grade C | Grade D | ||||

|---|---|---|---|---|---|---|---|---|

| Fine | Heavy | Fine | Heavy | Fine | Heavy | Fine | Heavy | |

| Levels in NADCA#207-2016 | 0.5 | 0.5 | 1.0 | 1.0 | 0.5 | 0.5 | 1.0 | 1.0 |

| Near the weld | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 1.0 | 0.5 |

| Non-welded | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 1.0 | 0.5 |

| Position | Impact Energy, J | |||||

|---|---|---|---|---|---|---|

| No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | Average Value | |

| Near the weld area (impact direction parallel to the cooling channel) | 45 | 43 | 37 | 20 | 40 | 37 |

| Near the weld area (impact direction perpendicular to the cooling channel) | 84 | 106 | 85 | 104 | 100 | 96 |

| Non-welded area (impact direction parallel to cooling channel) | 71 | 45 | 43 | 89 | 64 | 62 |

| Non-welded area (impact direction is perpendicular to the cooling channel) | 265 | 325 | 167 | 270 | 200 | 245 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Dou, Z.; Yin, Y.; Zhao, H.; Wang, Y.; Zuo, P.; Min, N.; Jin, S. Crack Failure Analysis of Hot-Stamping Die Insert for Manufacturing an Automobile A-Pillar. Materials 2025, 18, 3052. https://doi.org/10.3390/ma18133052

Wang S, Dou Z, Yin Y, Zhao H, Wang Y, Zuo P, Min N, Jin S. Crack Failure Analysis of Hot-Stamping Die Insert for Manufacturing an Automobile A-Pillar. Materials. 2025; 18(13):3052. https://doi.org/10.3390/ma18133052

Chicago/Turabian StyleWang, Shuo, Zhiyang Dou, Yixiu Yin, Hanqi Zhao, Yaocheng Wang, Pengpeng Zuo, Na Min, and Senlin Jin. 2025. "Crack Failure Analysis of Hot-Stamping Die Insert for Manufacturing an Automobile A-Pillar" Materials 18, no. 13: 3052. https://doi.org/10.3390/ma18133052

APA StyleWang, S., Dou, Z., Yin, Y., Zhao, H., Wang, Y., Zuo, P., Min, N., & Jin, S. (2025). Crack Failure Analysis of Hot-Stamping Die Insert for Manufacturing an Automobile A-Pillar. Materials, 18(13), 3052. https://doi.org/10.3390/ma18133052