A Comprehensive Experimental, Simulation, and Characterization Mechanical Analysis of Ecoflex and Its Formulation Under Uniaxial Testing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

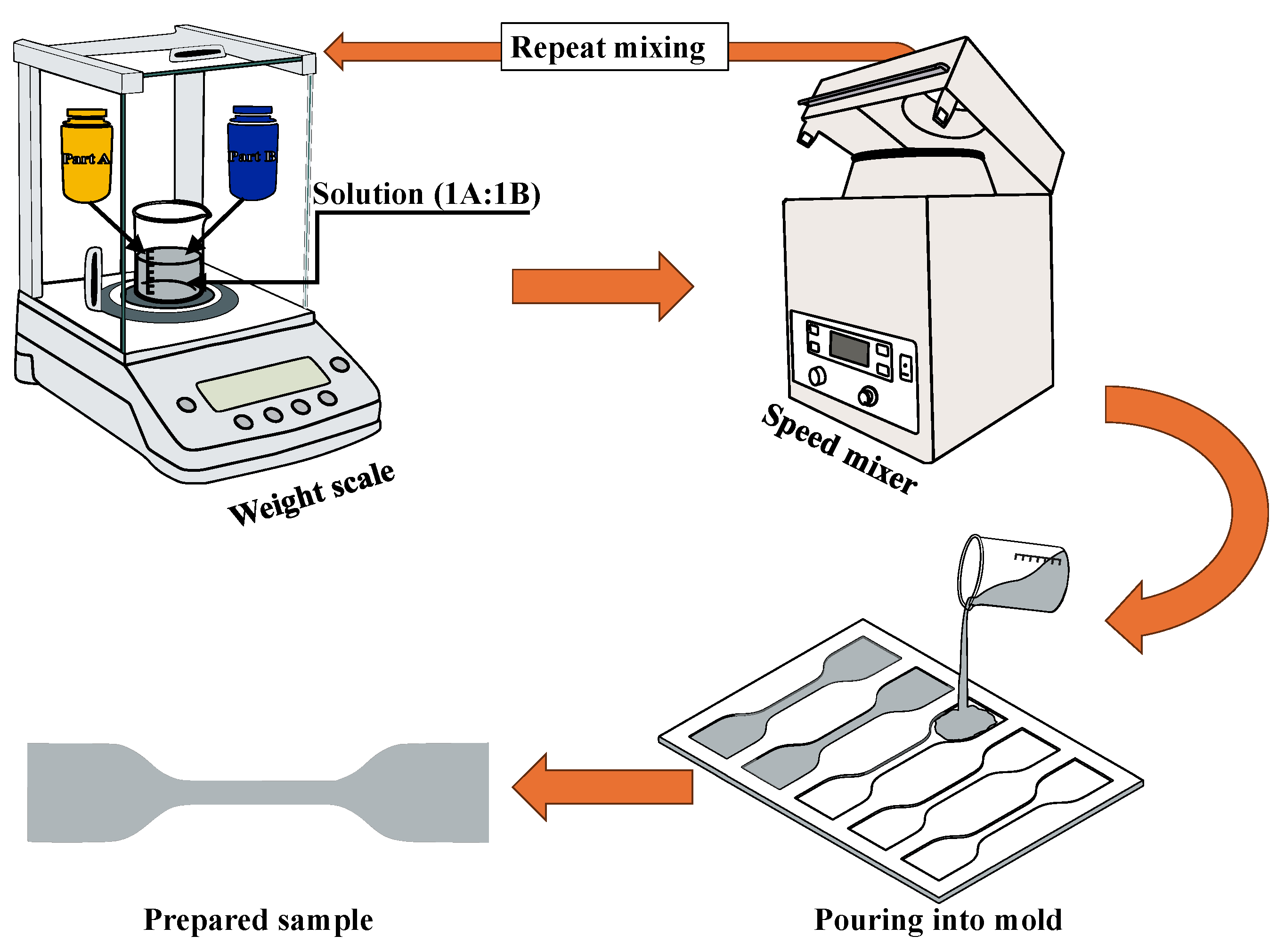

2.2. Sample Preparation

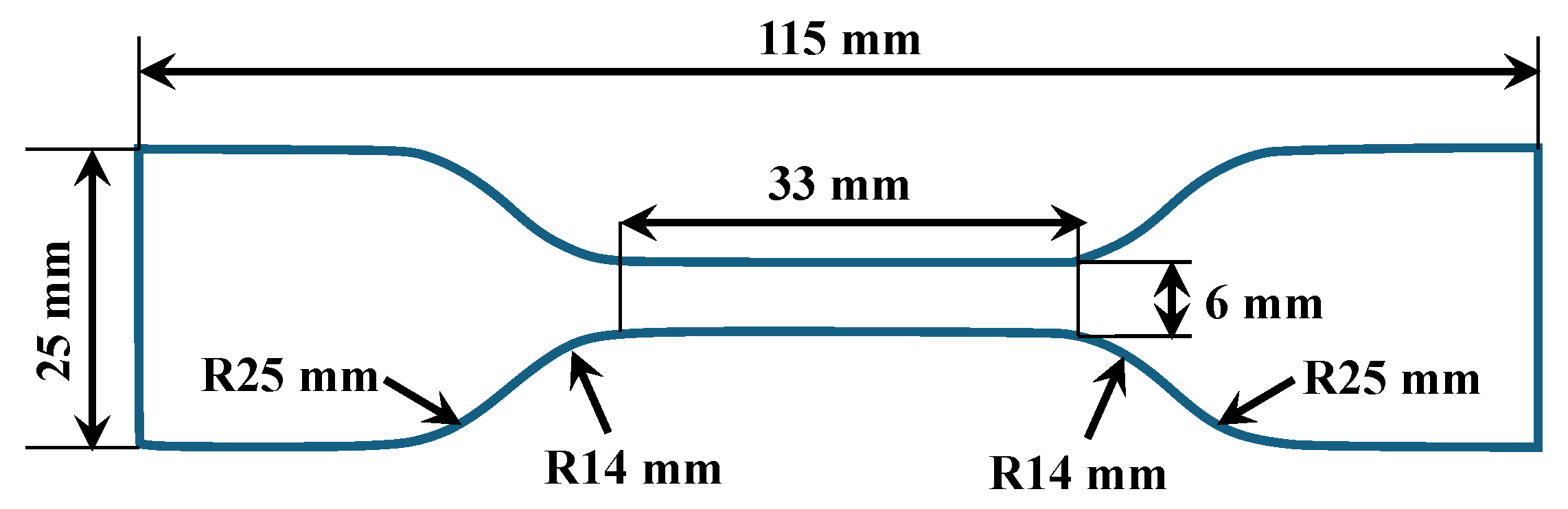

2.3. Experimental Setup and Characterization

3. Results and Discussion

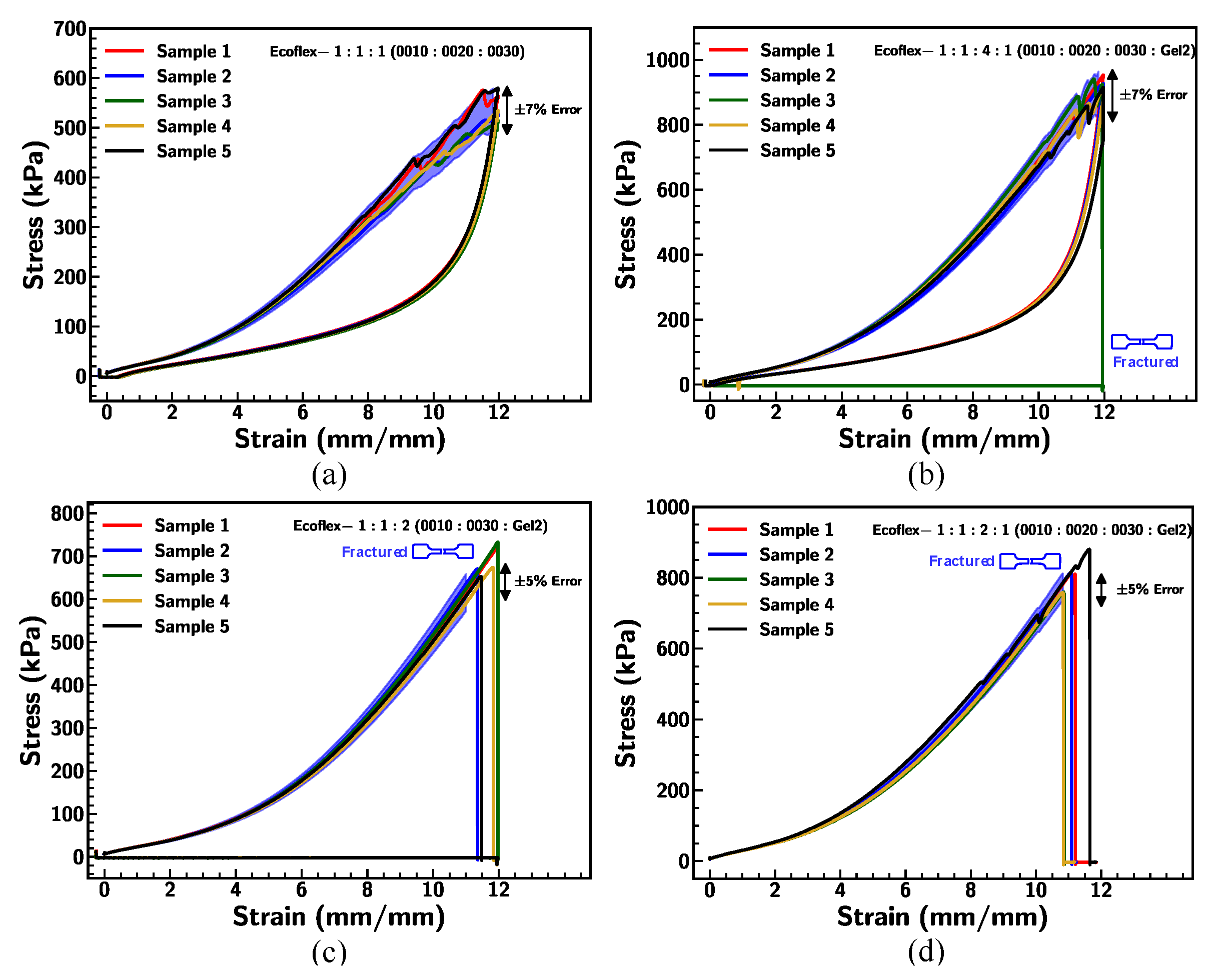

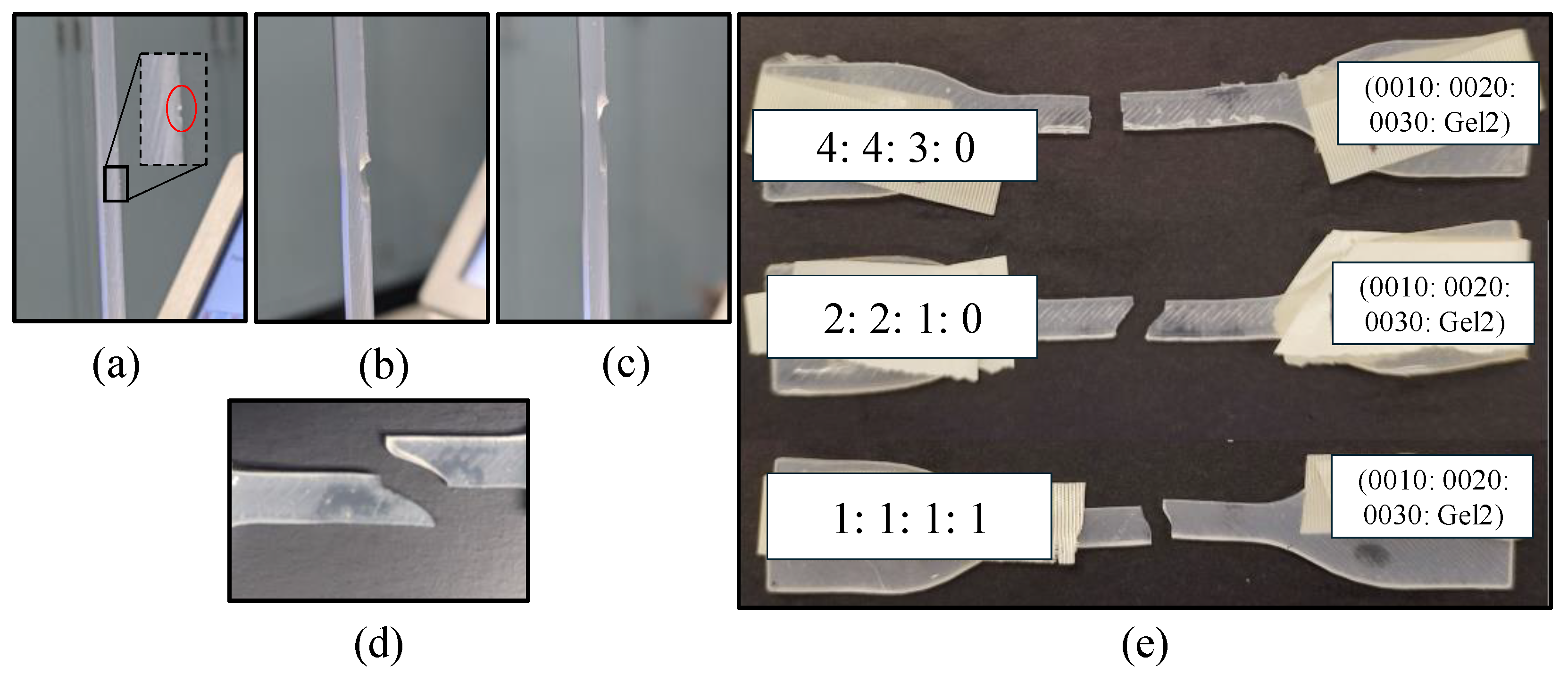

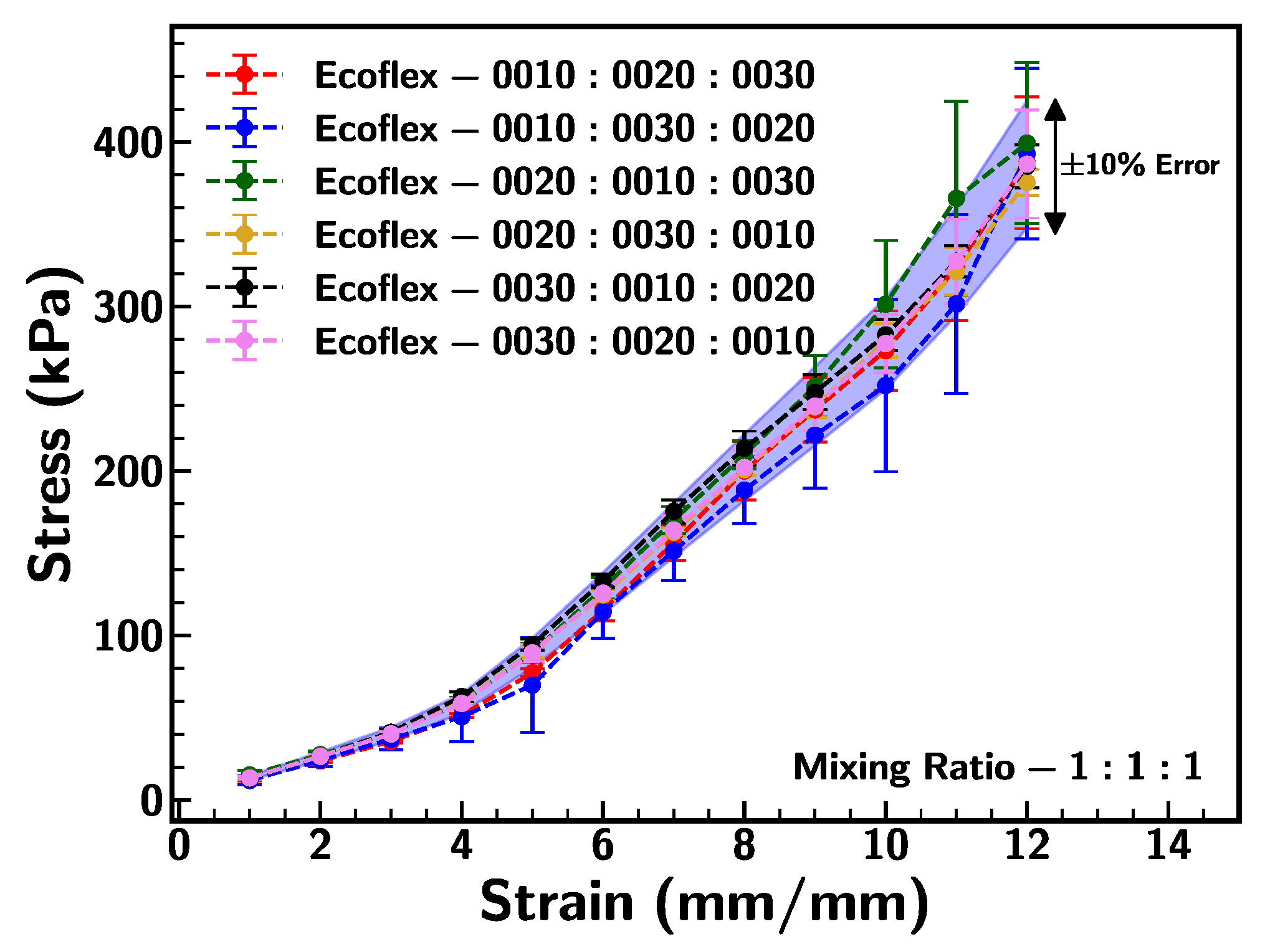

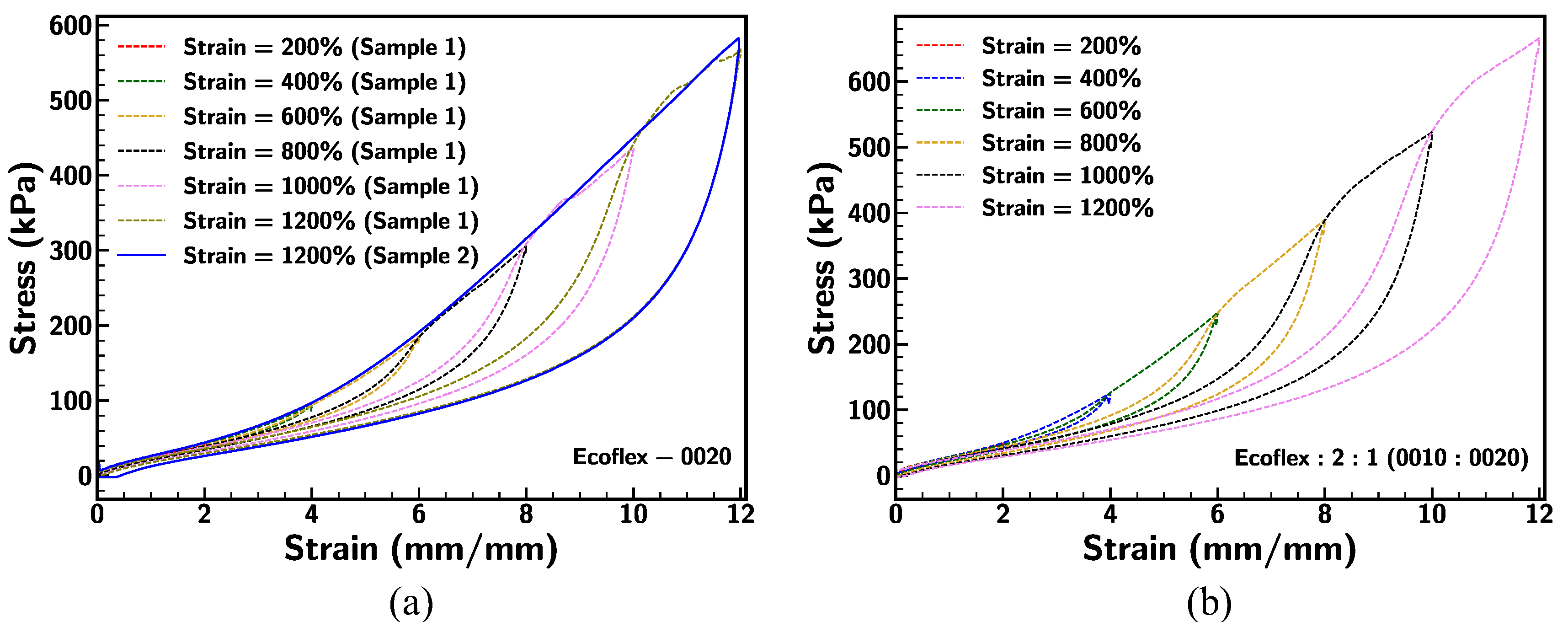

3.1. Reproducibility

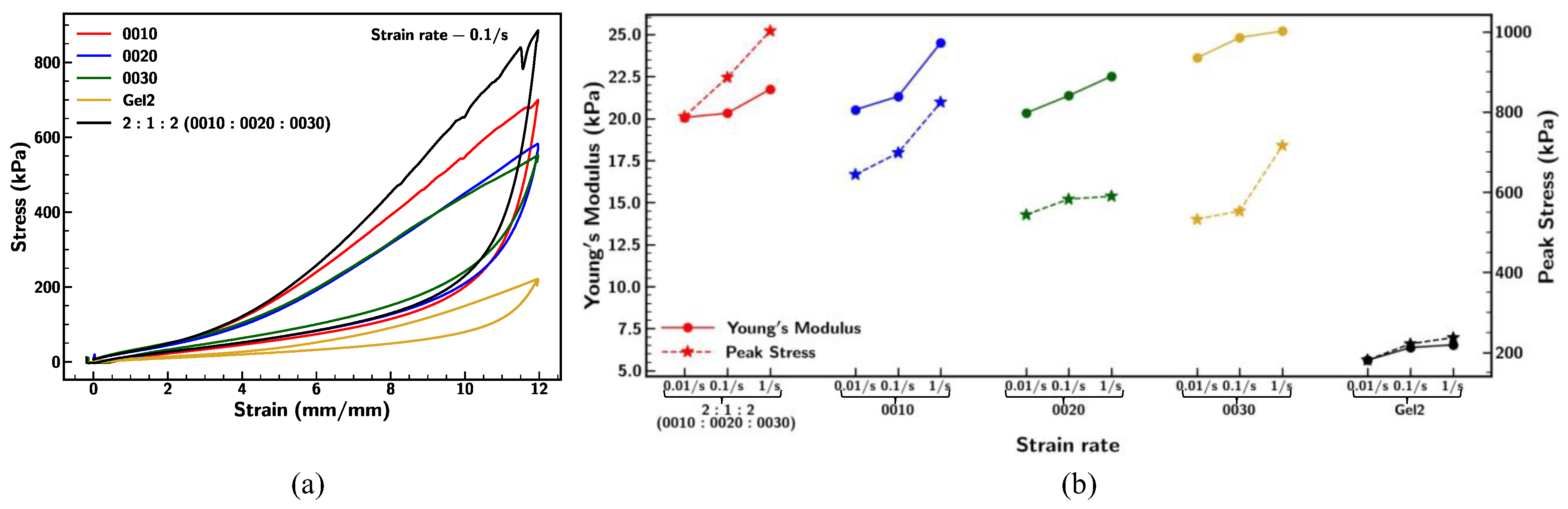

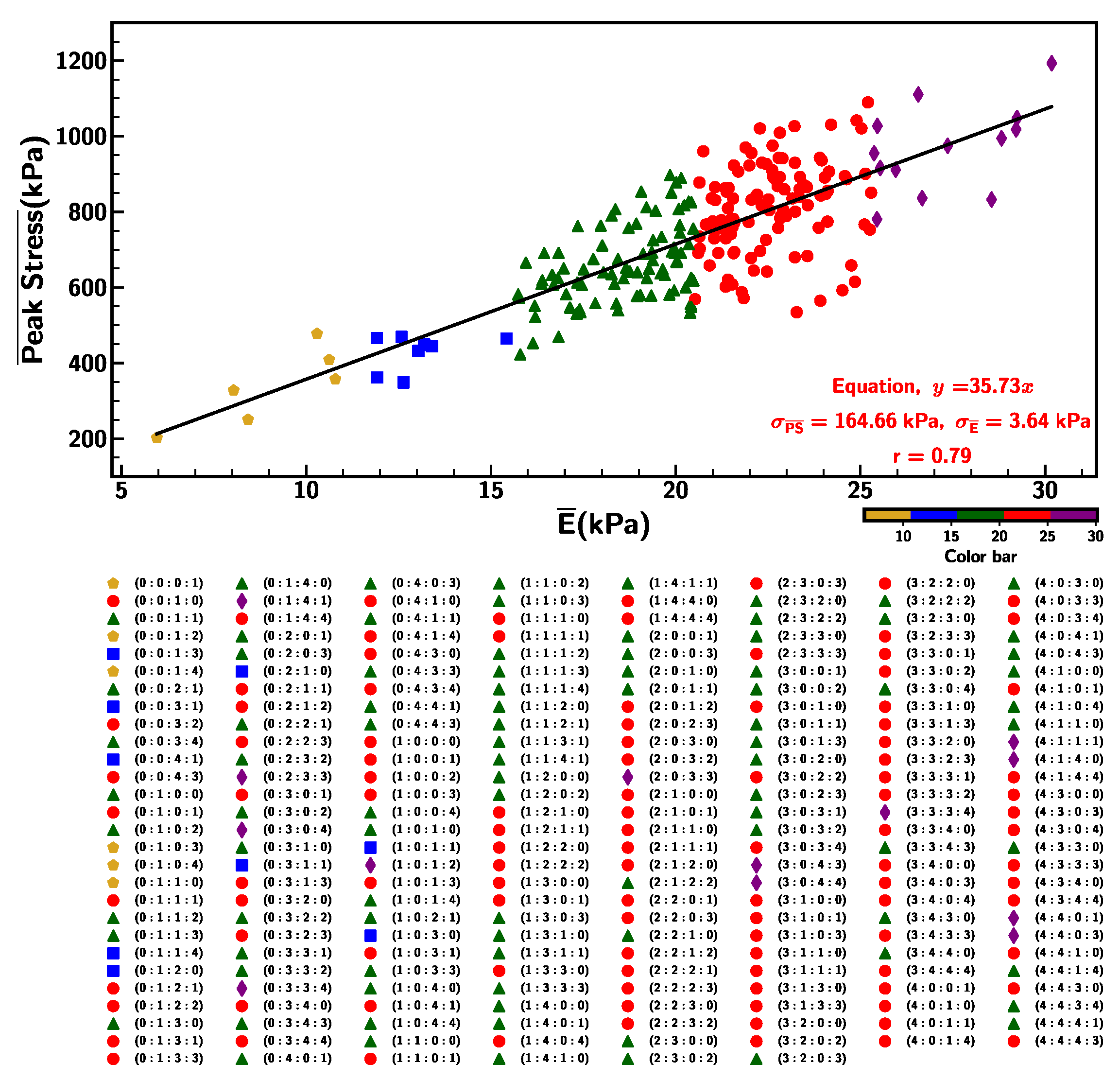

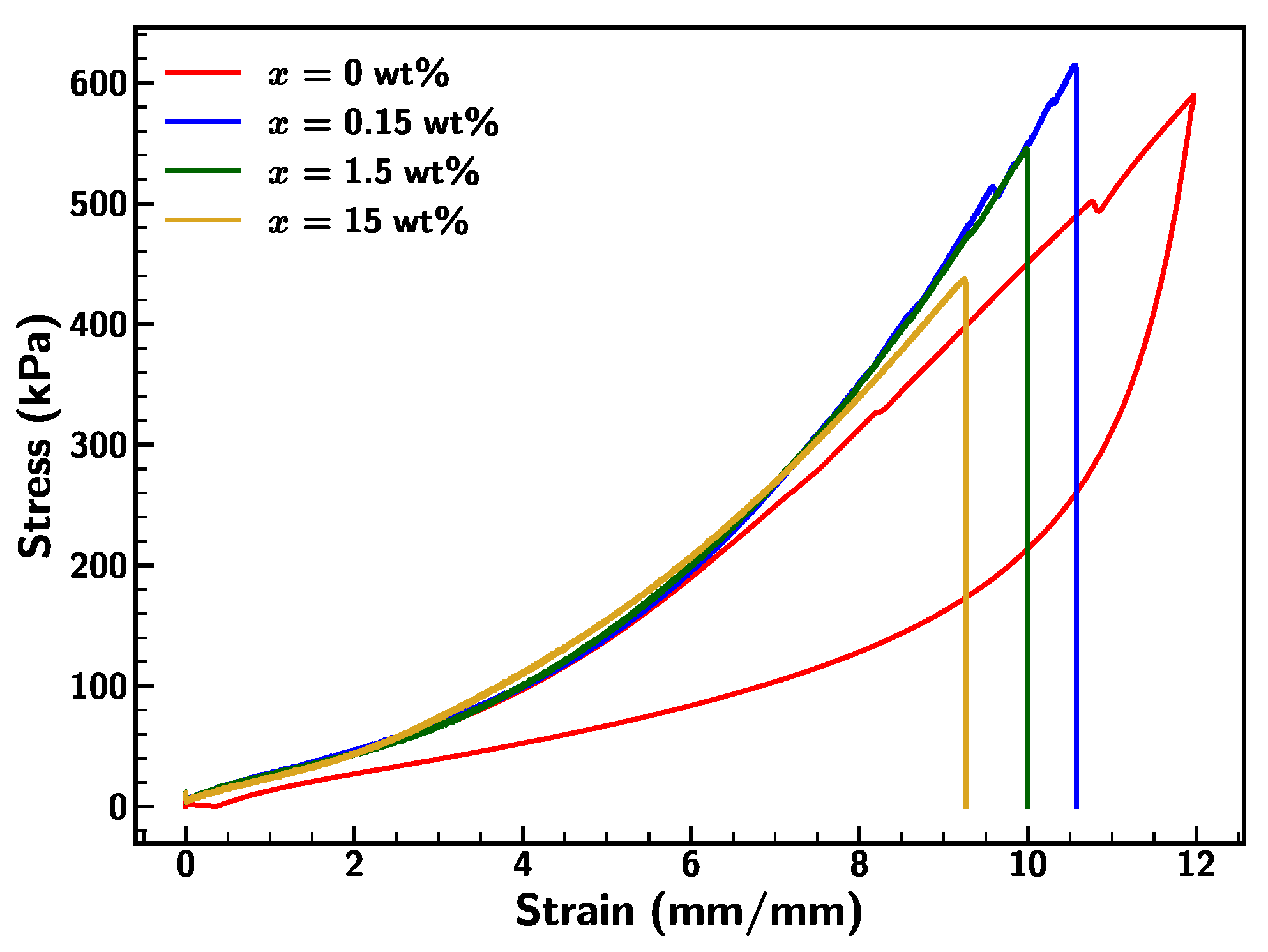

3.2. Young’s Modulus and Peak Stress

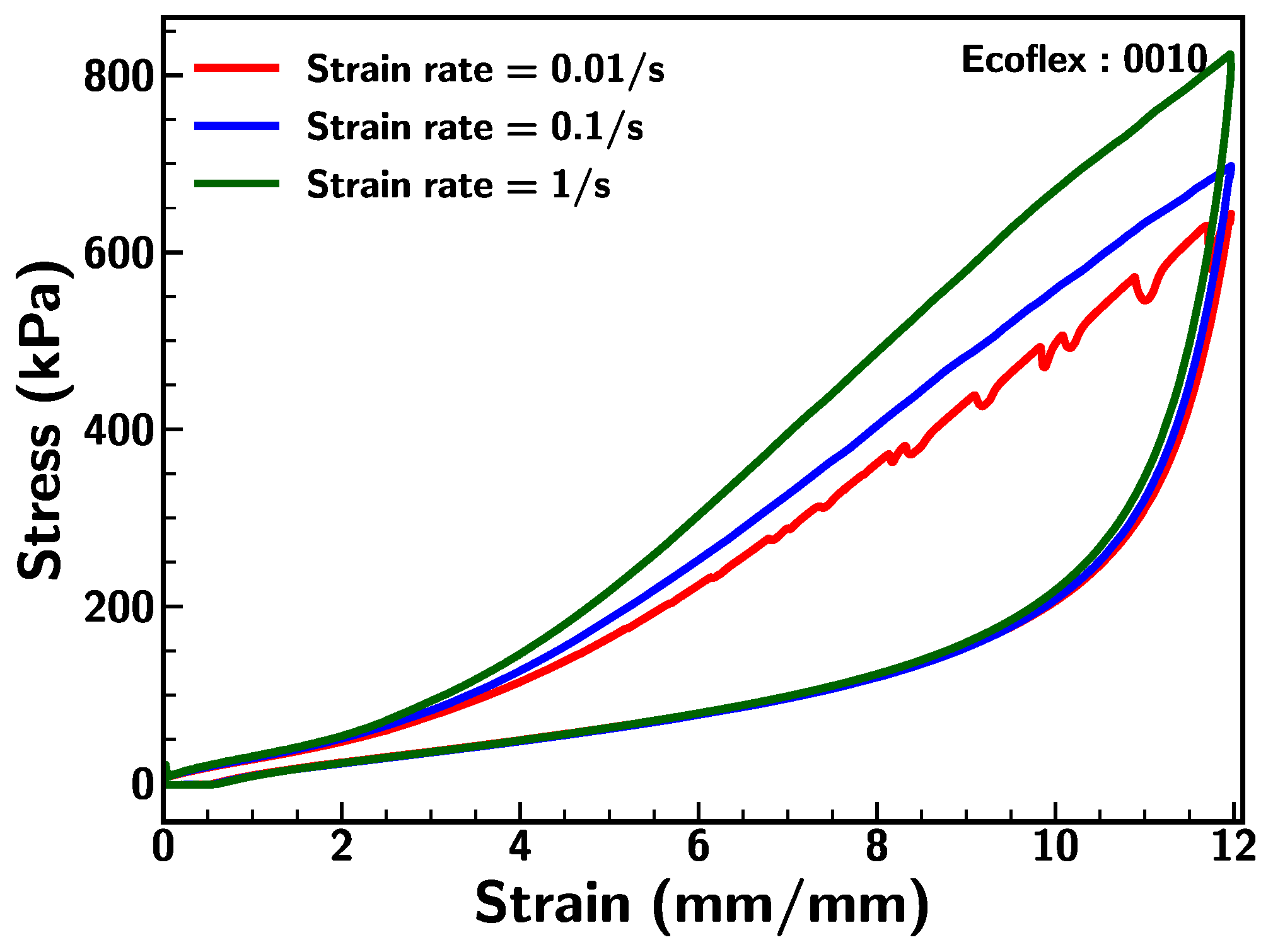

3.3. Strain Rate

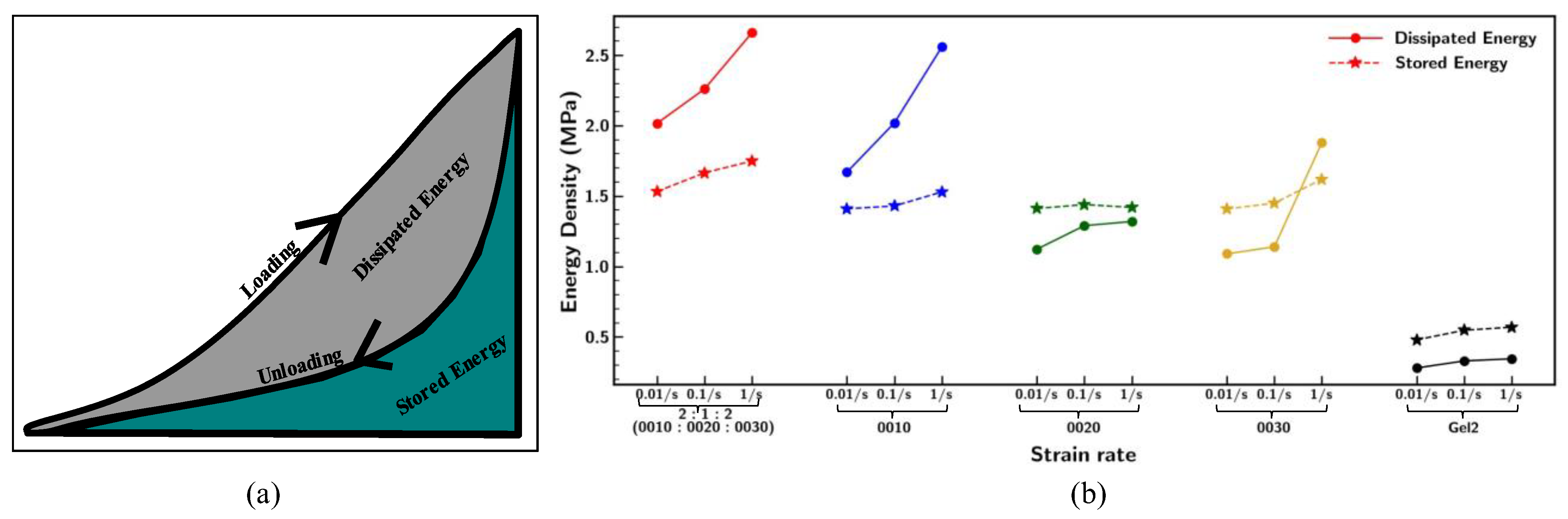

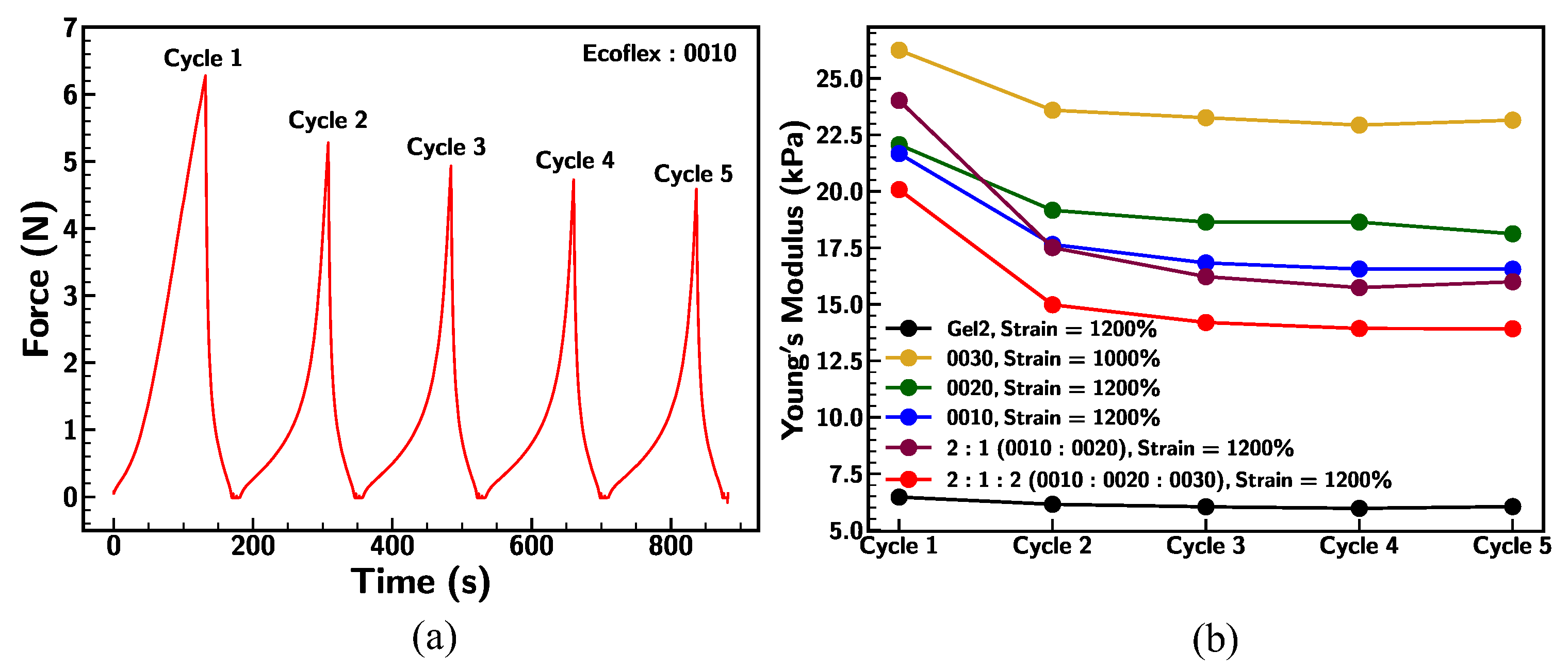

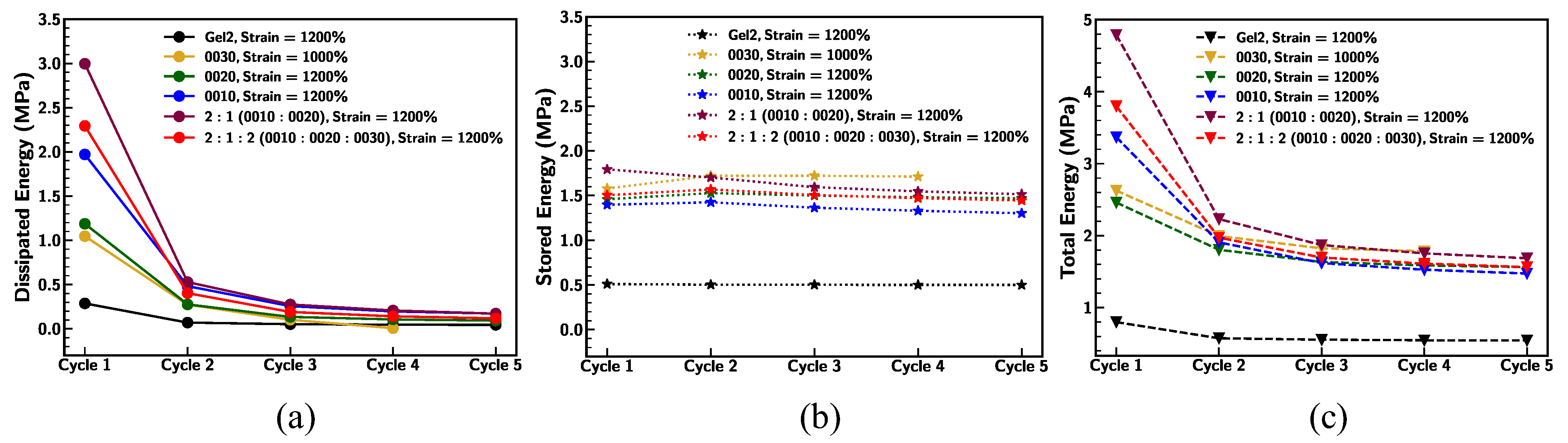

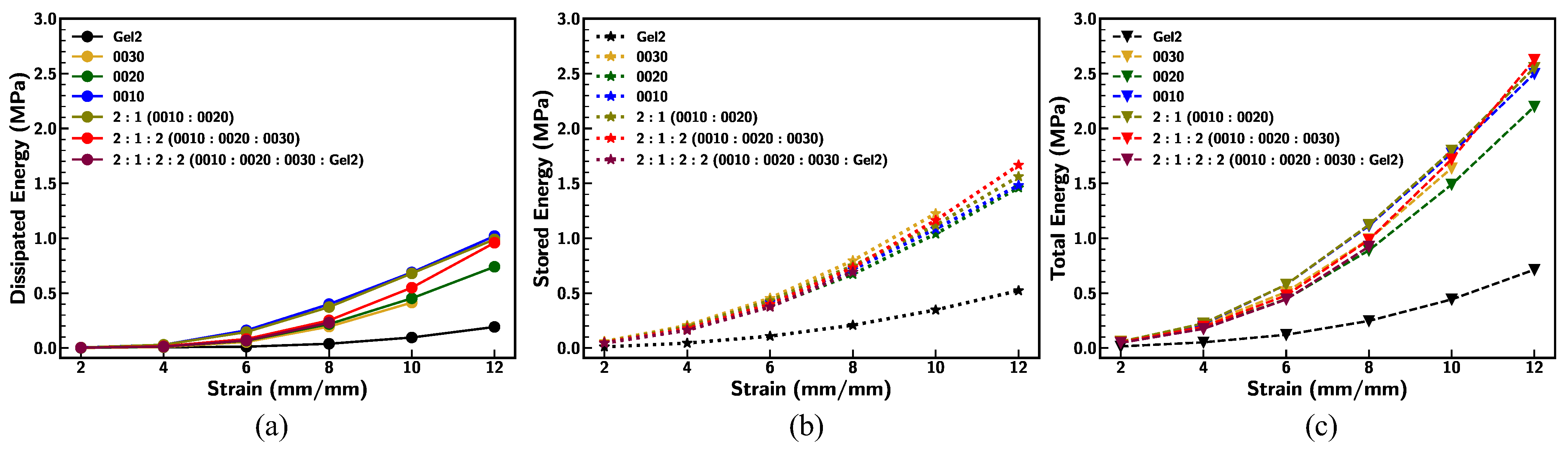

3.4. Cyclic Loading

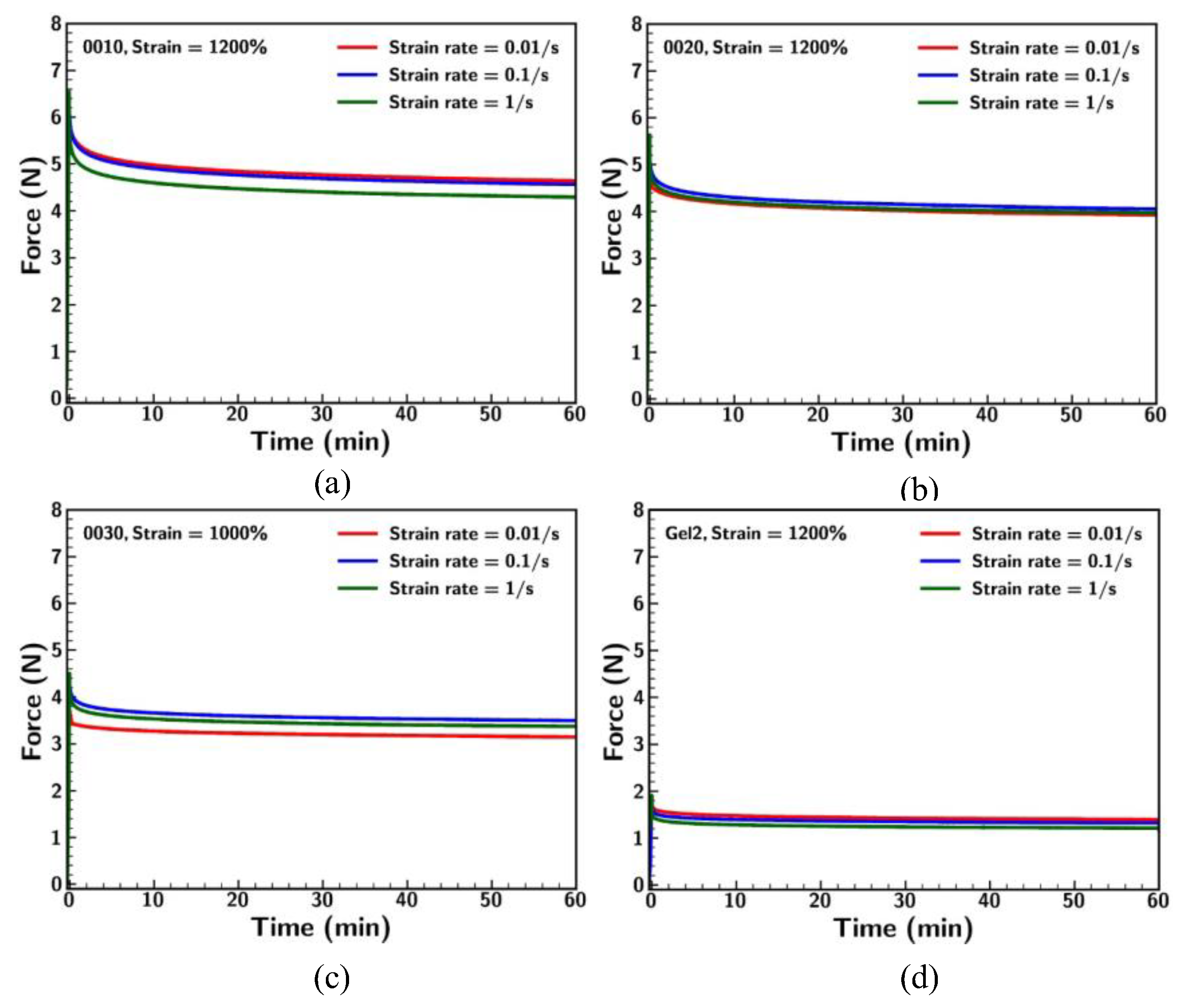

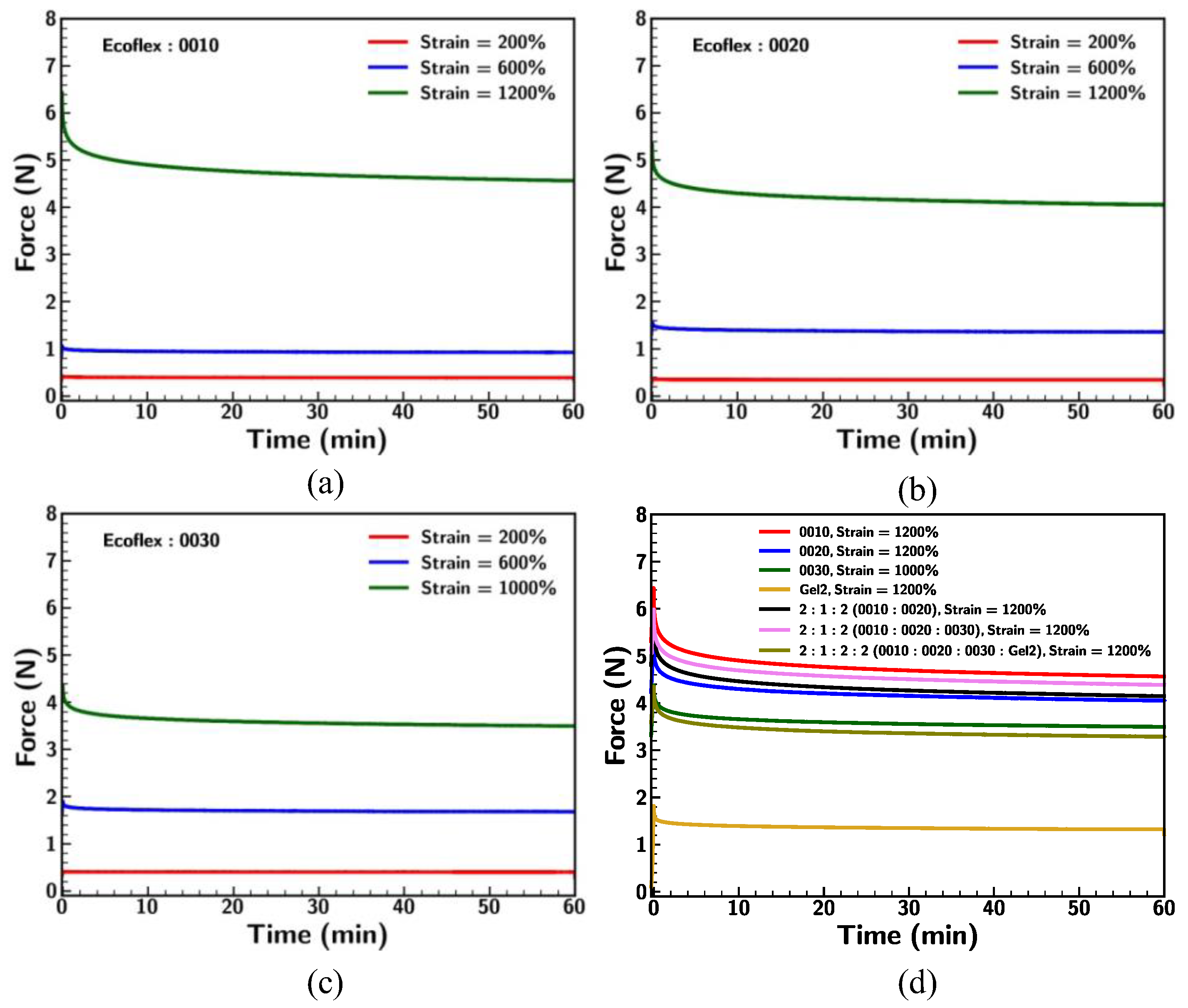

3.5. Stress Relaxation

3.6. Mullin Effect

3.7. Shore Hardness

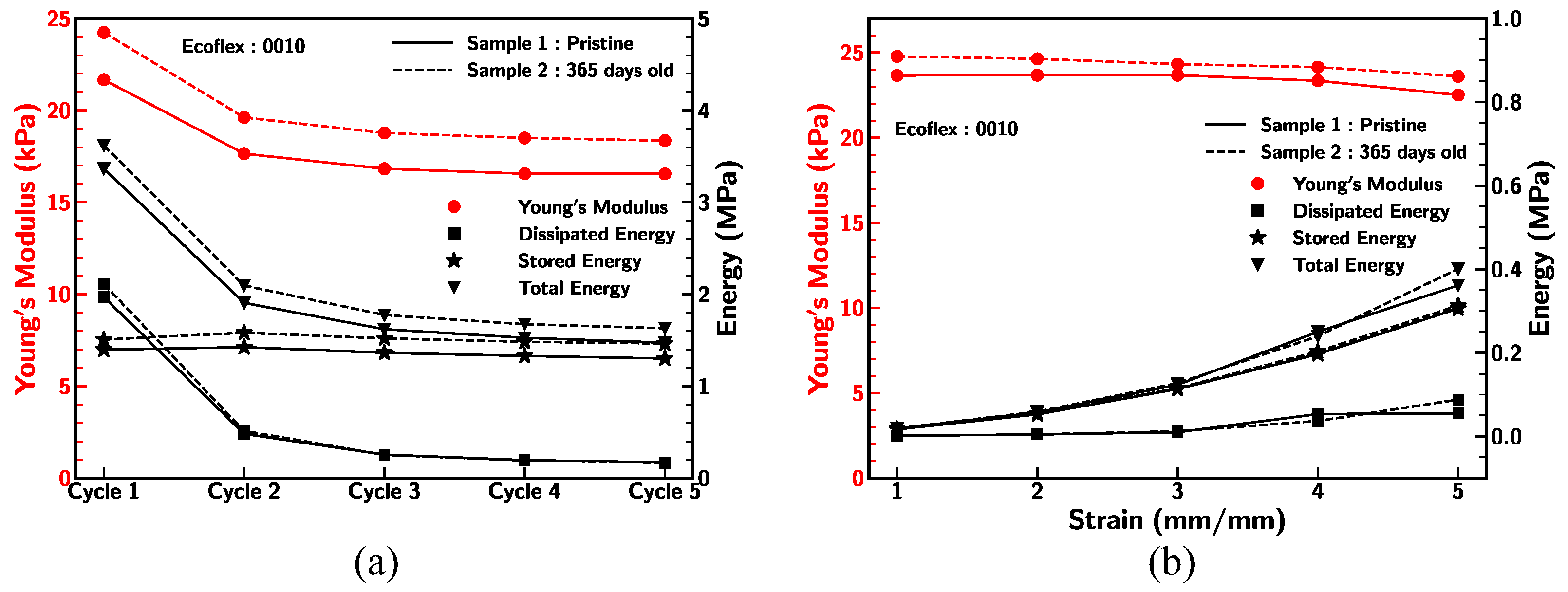

3.8. Aging

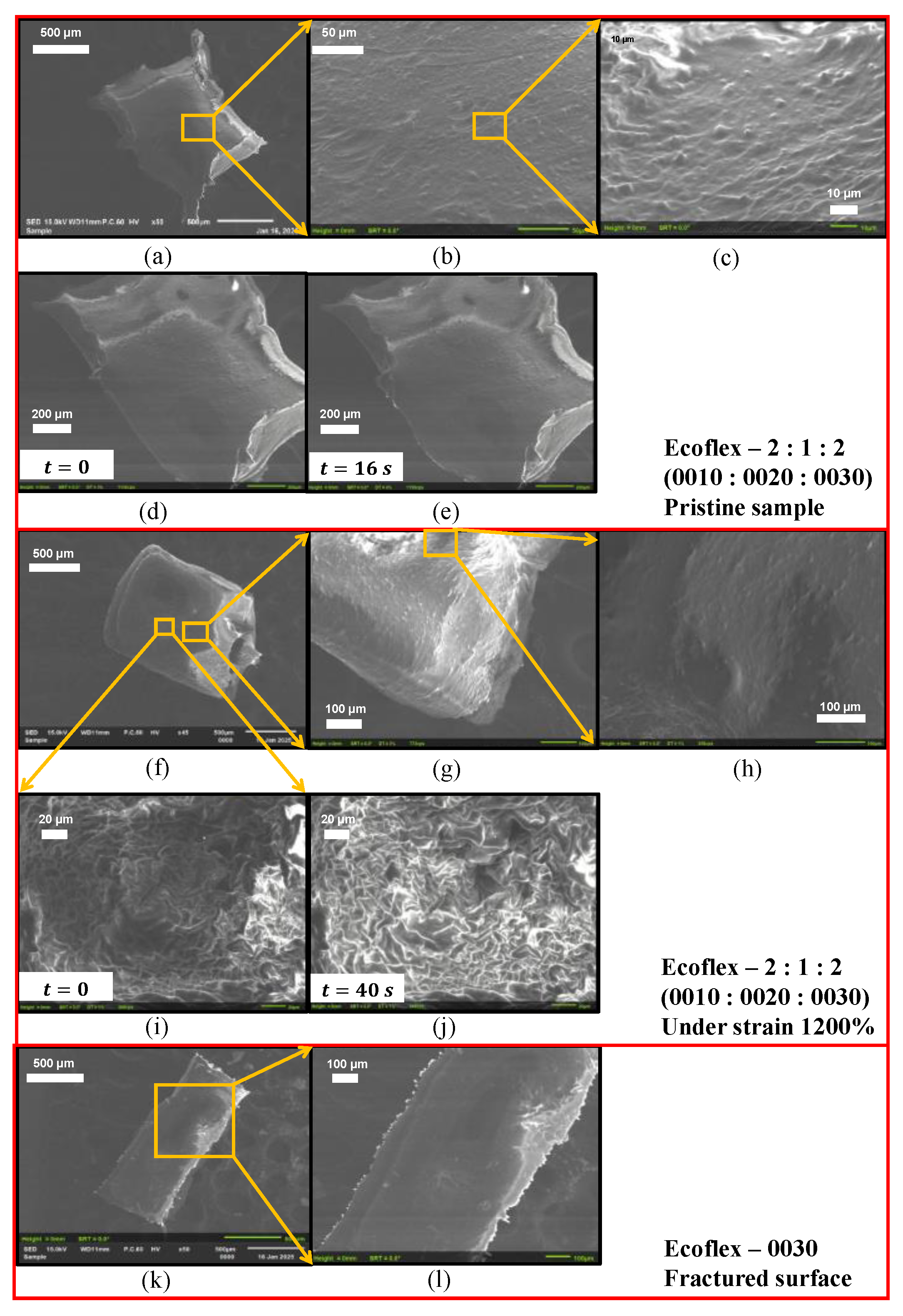

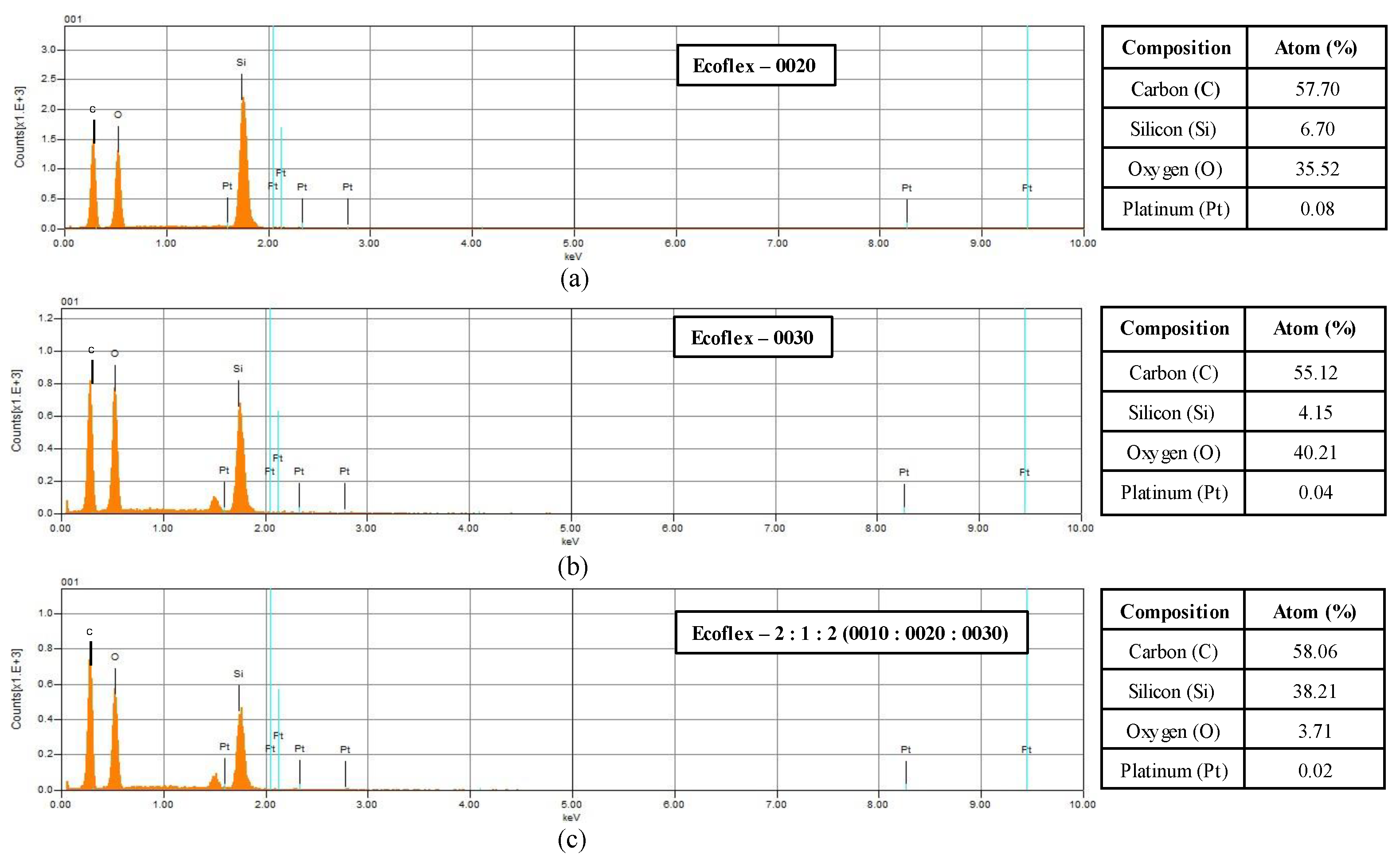

3.9. Surface Morphology

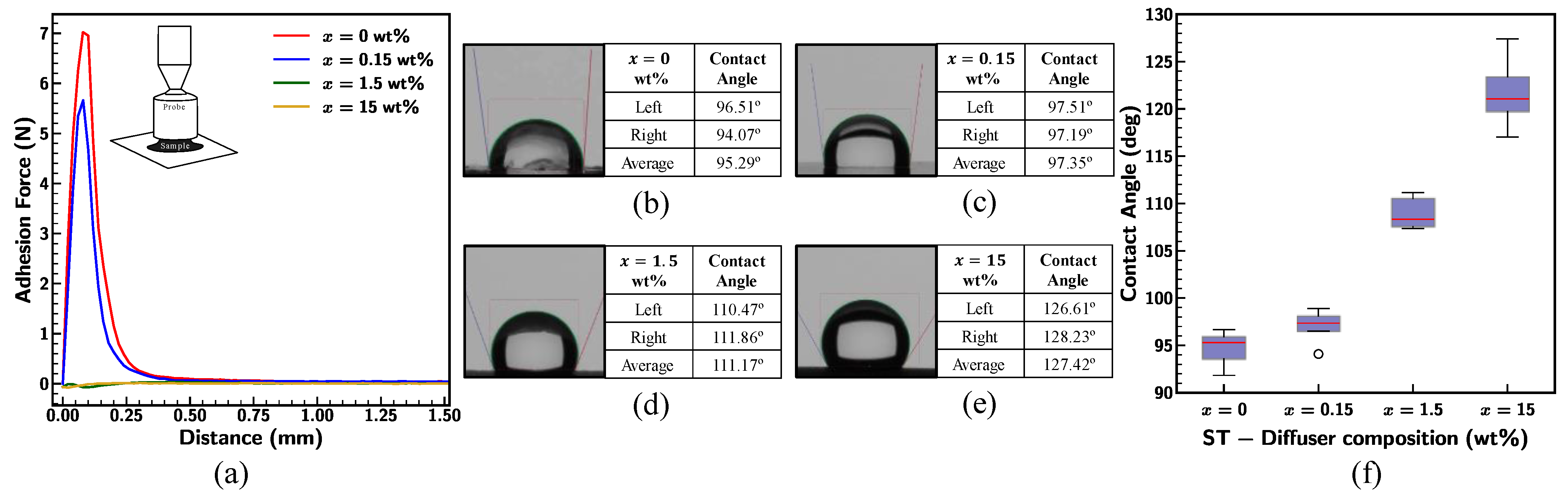

3.10. Hydrophobicity

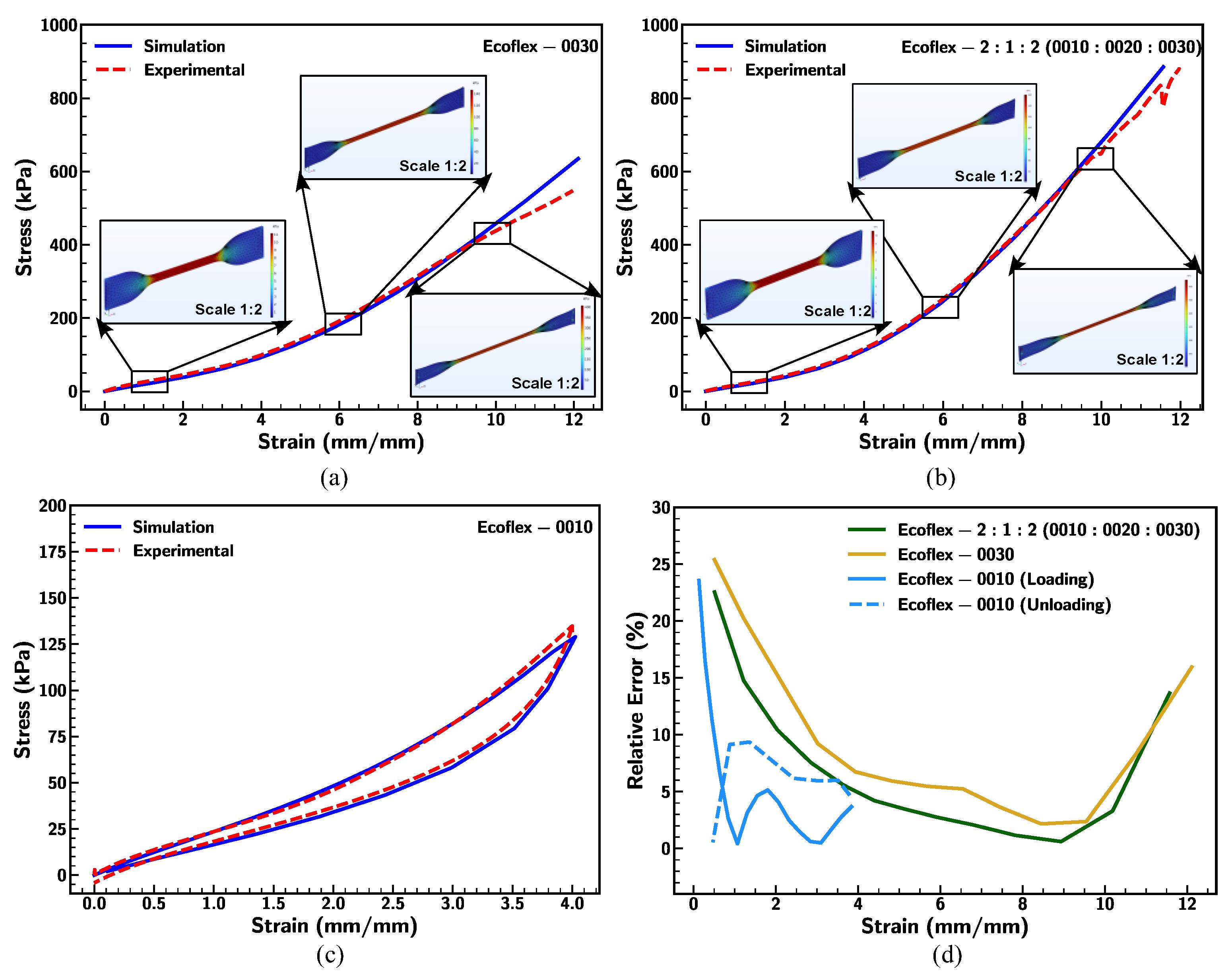

3.11. Simulation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brown, X.Q.; Ookawa, K.; Wong, J.Y. Evaluation of Polydimethylsiloxane Scaffolds with Physiologically-Relevant Elastic Moduli: Interplay of Substrate Mechanics and Surface Chemistry Effects on Vascular Smooth Muscle Cell Response. Biomaterials 2005, 26, 3123–3129. [Google Scholar] [CrossRef] [PubMed]

- Del Bosque, A.; Sánchez-Romate, X.F.; Gómez, A.; Sánchez, M.; Ureña, A. Highly Stretchable Strain Sensors Based on Graphene Nanoplatelet-Doped Ecoflex for Biomedical Purposes. Sens. Actuators A Phys. 2023, 353, 114249. [Google Scholar] [CrossRef]

- Fujii, T. PDMS-Based Microfluidic Devices for Biomedical Applications. Microelectron. Eng. 2002, 61–62, 907–914. [Google Scholar] [CrossRef]

- Potrich, C.; Lunelli, L.; Cocuzza, M.; Marasso, S.L.; Pirri, C.F.; Pederzolli, C. Simple PDMS Microdevice for Biomedical Applications. Talanta 2019, 193, 44–50. [Google Scholar] [CrossRef]

- Ahmad, D.; Ajaj, R.M.; Amoozgar, M. Elastomer-Based Skins for Morphing Aircraft Applications: Effect of Biaxial Strain Rates and Prestretch. Polym. Test. 2022, 113, 107655. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, L.; Wang, W.; Kota, A.K.; Hu, H. An Experimental Study on Soft PDMS Materials for Aircraft Icing Mitigation. Appl. Surf. Sci. 2018, 447, 599–609. [Google Scholar] [CrossRef]

- Gray, D.S.; Tien, J.; Chen, C.S. High-Conductivity Elastomeric Electronics. Adv. Mater. 2004, 16, 393–397. [Google Scholar] [CrossRef]

- Larmagnac, A.; Eggenberger, S.; Janossy, H.; Vörös, J. Stretchable Electronics Based on Ag-PDMS Composites. Sci. Rep. 2014, 4, 7254. [Google Scholar] [CrossRef]

- Qi, D.; Zhang, K.; Tian, G.; Jiang, B.; Huang, Y. Stretchable Electronics Based on PDMS Substrates. Adv. Mater. 2021, 33, 2003155. [Google Scholar] [CrossRef]

- Cheng, W.; Kai, D.; Loh, X.J.; He, C.; Li, Z. Silicone Copolymers for Healthcare and Personal Care Applications. In Silicon Containing Hybrid Copolymers; He, C., Li, Z., Eds.; Wiley: New York, NY, USA, 2020; pp. 145–166. ISBN 978-3-527-34664-6. [Google Scholar]

- Ivanova, E.V.; Minyaylo, E.O.; Temnikov, M.N.; Mukhtorov, L.G.; Atroshchenko, Y.M. Silicones in Cosmetics. Polym. Sci. Ser. B 2023, 65, 578–594. [Google Scholar] [CrossRef]

- Moon, J.; Huh, Y.; Park, J.; Kim, H.W.; Choe, Y.; Huh, J.; Bang, J. Adhesion Behavior of Catechol-Incorporated Silicone Elastomer on Metal Surface. ACS Appl. Polym. Mater. 2020, 2, 2444–2451. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Z.; Li, X.; Zhang, J.; Lou, H.; Shi, X.; Cheng, X.; Peng, H. A Smart, Stretchable Resistive Heater Textile. J. Mater. Chem. C 2017, 5, 41–46. [Google Scholar] [CrossRef]

- Yamashita, T.; Takamatsu, S.; Miyake, K.; Itoh, T. Fabrication and Evaluation of a Conductive Polymer Coated Elastomer Contact Structure for Woven Electronic Textile. Sens. Actuators A Phys. 2013, 195, 213–218. [Google Scholar] [CrossRef]

- Darby, D.R.; Cai, Z.; Mason, C.R.; Pham, J.T. Modulus and Adhesion of Sylgard 184, Solaris, and Ecoflex 00-30 Silicone Elastomers with Varied Mixing Ratios. J. Appl. Polym. Sci. 2022, 139, e52412. [Google Scholar] [CrossRef]

- Guler, Z.; Jackson, N. Mechanical Properties of Stretchable Multifunctional Ecoflex Composites for E-Skin Applications. In Proceedings of the Volume 12: Micro- and Nano-Systems Engineering and Packaging; American Society of Mechanical Engineers: New Orleans, LA, USA, 2023; p. V012T13A020. [Google Scholar]

- Lavazza, J. A Study on the Mechanical Behaviour of Ecoflex 00-50 Silicone Elastomer. Available online: https://www.politesi.polimi.it/bitstream/10589/187294/5/Executive_Summary_Lavazza.pdf (accessed on 23 June 2025).

- Lavazza, J.; Contino, M.; Marano, C. Strain Rate, Temperature and Deformation State Effect on Ecoflex 00-50 Silicone Mechanical Behaviour. Mech. Mater. 2023, 178, 104560. [Google Scholar] [CrossRef]

- Liao, Z.; Hossain, M.; Yao, X.; Navaratne, R.; Chagnon, G. A Comprehensive Thermo-Viscoelastic Experimental Investigation of Ecoflex Polymer. Polym. Test. 2020, 86, 106478. [Google Scholar] [CrossRef]

- Yoda, R. Elastomers for Biomedical Applications. J. Biomater. Sci. Polym. Ed. 1998, 9, 561–626. [Google Scholar] [CrossRef] [PubMed]

- Suo, G.; Yu, Y.; Zhang, Z.; Wang, S.; Zhao, P.; Li, J.; Wang, X. Piezoelectric and Triboelectric Dual Effects in Mechanical-Energy Harvesting Using BaTiO3/Polydimethylsiloxane Composite Film. ACS Appl. Mater. Interfaces 2016, 8, 34335–34341. [Google Scholar] [CrossRef]

- Said, M.M.; Yunas, J.; Pawinanto, R.E.; Majlis, B.Y.; Bais, B. PDMS Based Electromagnetic Actuator Membrane with Embedded Magnetic Particles in Polymer Composite. Sens. Actuators A Phys. 2016, 245, 85–96. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, J.; Ladani, R.B.; Ravindran, A.R.; Mouritz, A.P.; Kinloch, A.J.; Wang, C.H. Novel Electrically Conductive Porous PDMS/Carbon Nanofiber Composites for Deformable Strain Sensors and Conductors. ACS Appl. Mater. Interfaces 2017, 9, 14207–14215. [Google Scholar] [CrossRef]

- Vazquez, I.R.; Guler, Z.; Jackson, N. Enhancing Manufacturability of SU-8 Piezoelectric Composite Films for Microsystem Applications. Micromachines 2024, 15, 397. [Google Scholar] [CrossRef] [PubMed]

- Guler, Z.; Vazquez, I.R.; Jackson, N. Multi-Functional 0–3 Composite Polyimide Films for Microsystem Applications. Smart Mater. Struct. 2023, 32, 075015. [Google Scholar] [CrossRef]

- Babu, I.; De With, G. Highly Flexible Piezoelectric 0–3 PZT–PDMS Composites with High Filler Content. Compos. Sci. Technol. 2014, 91, 91–97. [Google Scholar] [CrossRef]

- Demidenko, N.A.; Kuksin, A.V.; Molodykh, V.V.; Pyankov, E.S.; Ichkitidze, L.P.; Zaborova, V.A.; Tsymbal, A.A.; Tkachenko, S.A.; Shafaei, H.; Diachkova, E.; et al. Flexible Strain-Sensitive Silicone-CNT Sensor for Human Motion Detection. Bioengineering 2022, 9, 36. [Google Scholar] [CrossRef]

- Someya, T.; Kato, Y.; Sekitani, T.; Iba, S.; Noguchi, Y.; Murase, Y.; Kawaguchi, H.; Sakurai, T. Conformable, Flexible, Large-Area Networks of Pressure and Thermal Sensors with Organic Transistor Active Matrixes. Proc. Natl. Acad. Sci. USA 2005, 102, 12321–12325. [Google Scholar] [CrossRef]

- Silipigni, L.; Salvato, G.; Torrisi, A.; Cutroneo, M.; Slepicka, P.; Fajstavr, D.; Torrisi, L. Pressure Sensor Based on Porous Polydimethylsiloxane with Embedded Gold Nanoparticles. J. Mater. Sci. Mater. Electron. 2021, 32, 8703–8715. [Google Scholar] [CrossRef]

- Ye, Z.; Faisal, M.S.S.; Asmatulu, R.; Chen, Z. Artificial Muscles of Dielectric Elastomers Attached to Artificial Tendons of Functionalized Carbon Fibers. In Proceedings of Volume 9056: Electroactive Polymer Actuators and Devices (EAPAD); SPIE: San Diego, CA, USA, 2014. [Google Scholar]

- Park, Y.-L.; Chen, B.-R.; Wood, R.J. Design and Fabrication of Soft Artificial Skin Using Embedded Microchannels and Liquid Conductors. IEEE Sens. J. 2012, 12, 2711–2718. [Google Scholar] [CrossRef]

- Victor, A.; Ribeiro, J.E.; Araújo, F.F. Study of PDMS Characterization and Its Applications in Biomedicine: A Review. J. Mech. Eng. Biomech. 2019, 4, 1–9. [Google Scholar] [CrossRef]

- Nachman, M.; Franklin, S.E. Artificial Skin Model Simulating Dry and Moist in Vivo Human Skin Friction and Deformation Behaviour. Tribol. Int. 2016, 97, 431–439. [Google Scholar] [CrossRef]

- Liao, Z.; Hossain, M.; Yao, X. Ecoflex Polymer of Different Shore Hardnesses: Experimental Investigations and Constitutive Modelling. Mech. Mater. 2020, 144, 103366. [Google Scholar] [CrossRef]

- Hensley, D.; Christodoulou, C.; Jackson, N. A Stretchable Liquid Metal Antenna Array. In Proceedings of the 2021 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting (APS/URSI), Singapore, 4 December 2021; pp. 1777–1778. [Google Scholar]

- Hensley, D.M.; Christodoulou, C.G.; Jackson, N. A Stretchable Liquid Metal Coaxial Phase Shifter. IEEE Open J. Antennas Propag. 2021, 2, 370–374. [Google Scholar] [CrossRef]

- Jackson, N.; Buckley, J.; Clarke, C.; Stam, F. Manufacturing Methods of Stretchable Liquid Metal-Based Antenna. Microsyst. Technol. 2019, 25, 3175–3184. [Google Scholar] [CrossRef]

- Fassler, A.; Majidi, C. Liquid-Phase Metal Inclusions for a Conductive Polymer Composite. Adv. Mater. 2015, 27, 1928–1932. [Google Scholar] [CrossRef]

- Jeong, C.K.; Lee, J.; Han, S.; Ryu, J.; Hwang, G.; Park, D.Y.; Park, J.H.; Lee, S.S.; Byun, M.; Ko, S.H.; et al. A Hyper-Stretchable Elastic-Composite Energy Harvester. Adv. Mater. 2015, 27, 2866–2875. [Google Scholar] [CrossRef] [PubMed]

- Noh, J.S. Conductive Elastomers for Stretchable Electronics, Sensors and Energy Harvesters. Polymers 2016, 8, 123. [Google Scholar] [CrossRef]

- Zhou, Z.; Tang, H.; Sodano, H.A. Scalable Synthesis of Morphotropic Phase Boundary Lead Zirconium Titanate Nanowires for Energy Harvesting. Adv. Mater. 2014, 26, 7547–7554. [Google Scholar] [CrossRef]

- Amjadi, M.; Yoon, Y.J.; Park, I. Ultra-Stretchable and Skin-Mountable Strain Sensors Using Carbon Nanotubes–Ecoflex Nanocomposites. Nanotechnology 2015, 26, 375501. [Google Scholar] [CrossRef]

- Boland, C.S.; Khan, U.; Backes, C.; O’Neill, A.; McCauley, J.; Duane, S.; Shanker, R.; Liu, Y.; Jurewicz, I.; Dalton, A.B.; et al. Sensitive, High-Strain, High-Rate Bodily Motion Sensors Based on Graphene–Rubber Composites. ACS Nano 2014, 8, 8819–8830. [Google Scholar] [CrossRef]

- Tang, Y.; Zhao, Z.; Hu, H.; Liu, Y.; Wang, X.; Zhou, S.; Qiu, J. Highly Stretchable and Ultrasensitive Strain Sensor Based on Reduced Graphene Oxide Microtubes–Elastomer Composite. ACS Appl. Mater. Interfaces 2015, 7, 27432–27439. [Google Scholar] [CrossRef]

- Mariello, M.; Fachechi, L.; Guido, F.; De Vittorio, M. Multifunctional Sub-100 μm Thickness Flexible Piezo/Triboelectric Hybrid Water Energy Harvester Based on Biocompatible AlN and Soft Parylene C-PDMS-EcoflexTM. Nano Energy 2021, 83, 105811. [Google Scholar] [CrossRef]

- Daly, C.H. Biomechanical Properties of Dermis. J. Investig. Dermatol. 1982, 79, 17–20. [Google Scholar] [CrossRef]

- Kalra, A.; Lowe, A. An Overview of Factors Affecting the Skins Youngs Modulus. J. Aging Sci. 2016, 4, 1000156. [Google Scholar] [CrossRef]

- Janardhana, R.; Guler, Z.; Akram, F.; Jackson, N. Comparison of Mechanical Behavior of Macro and Micro-Sized Ecoflex 0030 and 0031. In Proceedings of the Volume 10: Mechanics of Solids, Structures, and Fluids; Micro- and Nano-Systems Engineering and Packaging; American Society of Mechanical Engineers: Portland, OR, USA, 2024; p. 010. [Google Scholar]

- Krpovic, S.; Dam-Johansen, K.; Skov, A.L. Importance of Mullins Effect in Commercial Silicone Elastomer Formulations for Soft Robotics. J. Appl. Polym. Sci. 2021, 138, 50380. [Google Scholar] [CrossRef]

- Vaicekauskaite, J.; Mazurek, P.; Vudayagiri, S.; Skov, A.L. Mapping the Mechanical and Electrical Properties of Commercial Silicone Elastomer Formulations for Stretchable Transducers. J. Mater. Chem. C 2020, 8, 1273–1279. [Google Scholar] [CrossRef]

- Blanchard, B.; Derail, C.; Nardin, C. Measurement of Human Skin Mechanical Properties: Variations According to the Effect of Different Stresses. In Mesure Des Propriétés Mécaniques de La Peau Humaine: Variations Sous l’effet de Différents Stress; Université de Pau et des Pays de l’Adour: Pau, France, 2023. [Google Scholar]

- Weigel, E.; Janardhana, R.; Jackson, N. Mechanical Characterization of Stretchable Ecoflex Thin Films for Microengineering Applications (Manuscript Accepted). In Proceedings of the ASME International Mechanical Engineering Congress and Expositio, Memphis, TN, USA, 16–20 November 2025. Unpublished results. [Google Scholar]

- ASTM-D412; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers. ASTM: West Conshohocken, PA, USA, 2012.

- Modulus of Elasticity. Available online: https://www.instron.com/en/resources/glossary/modulus-of-elasticity (accessed on 20 January 2025).

- Zhao, Z.; Mu, X.; Du, F. Modeling and Verification of a New Hyperelastic Model for Rubber-Like Materials. Math. Probl. Eng. 2019, 2019, 2832059. [Google Scholar] [CrossRef]

- Meng, F.; Pritchard, R.H.; Terentjev, E.M. Stress Relaxation, Dynamics, and Plasticity of Transient Polymer Networks. Macromolecules 2016, 49, 2843–2852. [Google Scholar] [CrossRef]

- Guo, S.; Wang, L.; Shao, G.; Shao, H.; Jiang, J.; Chen, N. Mechanical Behavior and Energy Dissipation of Woven and Warp-Knitted Pvc Membrane Materials under Multistage Cyclic Loading. Polymers 2022, 14, 1666. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Li, J.; Deng, H.; Xu, X. Study on the Mechanical Properties of Unloading Damaged Sandstone under Cyclic Loading and Unloading. Sci. Rep. 2023, 13, 7370. [Google Scholar] [CrossRef] [PubMed]

- Houwink, R. Slipping of Molecules during the Deformation of Reinforced Rubber. Rubber Chem. Technol. 1956, 29, 888–893. [Google Scholar] [CrossRef]

- Liao, Z.; Yang, J.; Hossain, M.; Chagnon, G.; Yao, X. The Time and Temperature Dependences of the Stress Recovery of Ecoflex Polymer. Int. J. Non-Linear Mech. 2023, 149, 104338. [Google Scholar] [CrossRef]

- Luis, E.; Pan, H.M.; Bastola, A.K.; Bajpai, R.; Sing, S.L.; Song, J.; Yeong, W.Y. 3D Printed Silicone Meniscus Implants: Influence of the 3D Printing Process on Properties of Silicone Implants. Polymers 2020, 12, 2136. [Google Scholar] [CrossRef] [PubMed]

- Abadi, M.; Serag, M.F.; Habuchi, S. Entangled Polymer Dynamics beyond Reptation. Nat. Commun. 2018, 9, 5098. [Google Scholar] [CrossRef] [PubMed]

- Diani, J.; Fayolle, B.; Gilormini, P. A Review on the Mullins Effect. Eur. Polym. J. 2009, 45, 601–612. [Google Scholar] [CrossRef]

- COMSOL Multiphysicss® v. 6.1. COMSOL, Inc. Available online: https://www.comsol.com (accessed on 10 May 2025).

- Janardhana, R.D.; Jackson, N. A Simulated Investigation of Lithium Niobate Orientation Effects on Standing Acoustic Waves. Sensors 2023, 23, 8317. [Google Scholar] [CrossRef] [PubMed]

| Ecoflex | Relaxation Ratio (%) | |||

|---|---|---|---|---|

| Strain | 200% | 600% | 1000% | 1200% |

| 0010 | 3.8 | 12.7 | 29.1 | |

| 0020 | 3.7 | 13.7 | 24.1 | |

| 0030 | 2.8 | 11.7 | 20.1 | |

| Gel2 | 407 | 7.4 | 24.7 | |

| 2:1 (0010:0020) | 28.9 | |||

| 2:1:2 (0010:0020:0030) | 26 | |||

| 2:1:2:2 (0010:0020:0030:Gel2) | 24.4 | |||

| Ecoflex | |

|---|---|

| 0010 | 11.5 |

| 0020 | 19.85 |

| 0030 | 25 |

| Gel2 | 5.05 |

| 2:1 (0010:0020) | 18.4 |

| 2:1:2 (0010:0020:0030) | 16.2 |

| 2:1:2:2 (0010:0020:0030:Gel2) | 17.55 |

| Yeoh Material Model | Ecoflex 0030 | Ecoflex 2:1:2 (0010:0020:0030) |

| (MPa) | 0.0033 | 0.0031 |

| (MPa) | 0 | 0 |

| (MPa) | ||

| (MPa) | 0.78 | 1.13 |

| 0.4 | 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janardhana, R.; Akram, F.; Guler, Z.; Adaval, A.; Jackson, N. A Comprehensive Experimental, Simulation, and Characterization Mechanical Analysis of Ecoflex and Its Formulation Under Uniaxial Testing. Materials 2025, 18, 3037. https://doi.org/10.3390/ma18133037

Janardhana R, Akram F, Guler Z, Adaval A, Jackson N. A Comprehensive Experimental, Simulation, and Characterization Mechanical Analysis of Ecoflex and Its Formulation Under Uniaxial Testing. Materials. 2025; 18(13):3037. https://doi.org/10.3390/ma18133037

Chicago/Turabian StyleJanardhana, Ranjith, Fazli Akram, Zeynel Guler, Akanksha Adaval, and Nathan Jackson. 2025. "A Comprehensive Experimental, Simulation, and Characterization Mechanical Analysis of Ecoflex and Its Formulation Under Uniaxial Testing" Materials 18, no. 13: 3037. https://doi.org/10.3390/ma18133037

APA StyleJanardhana, R., Akram, F., Guler, Z., Adaval, A., & Jackson, N. (2025). A Comprehensive Experimental, Simulation, and Characterization Mechanical Analysis of Ecoflex and Its Formulation Under Uniaxial Testing. Materials, 18(13), 3037. https://doi.org/10.3390/ma18133037