Assessment of the Feasibility of Using Additive Manufacturing from Metal Powder to Produce Compact Heat Exchangers

Abstract

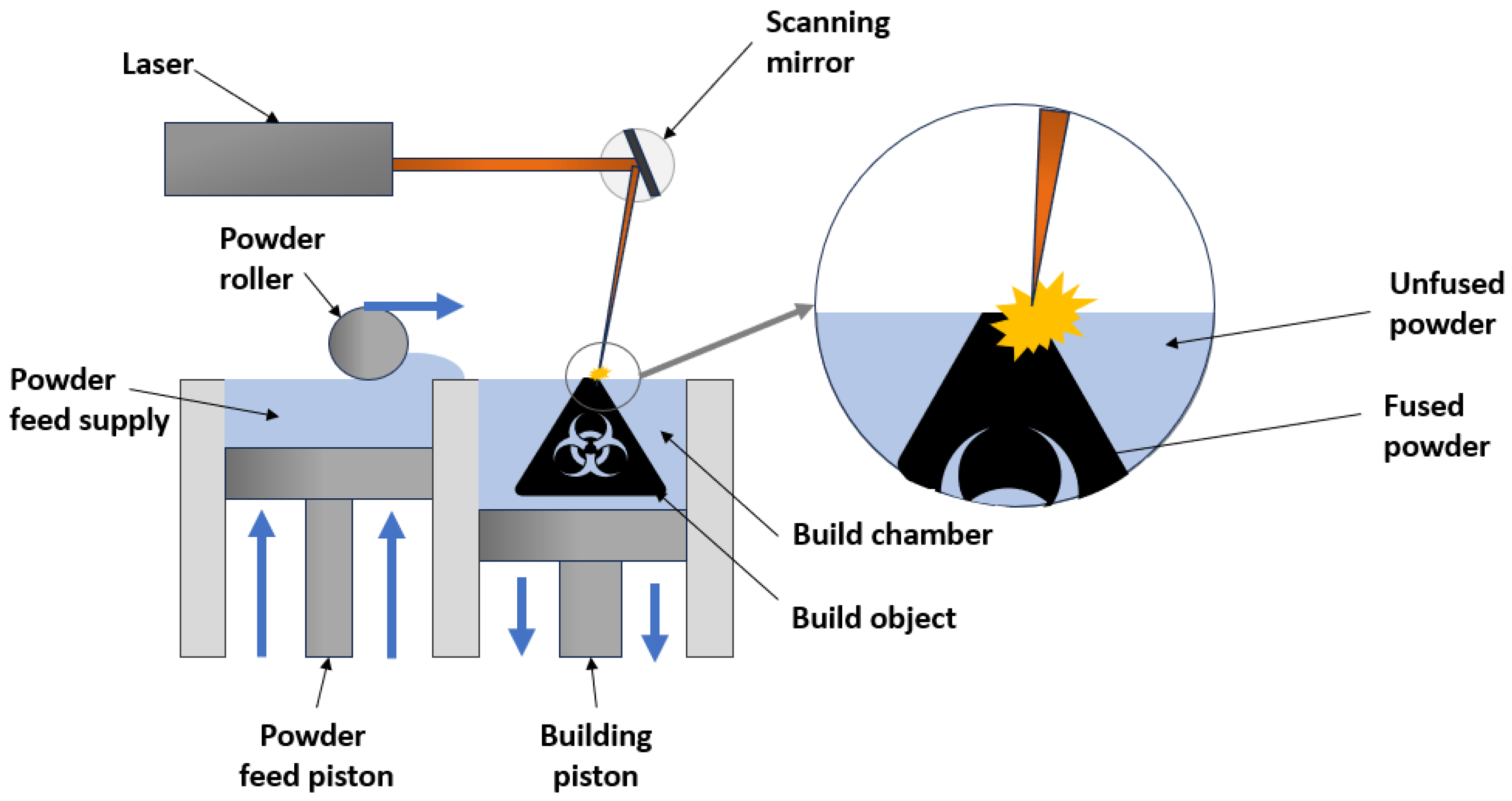

1. Introduction

2. Materials and Methods

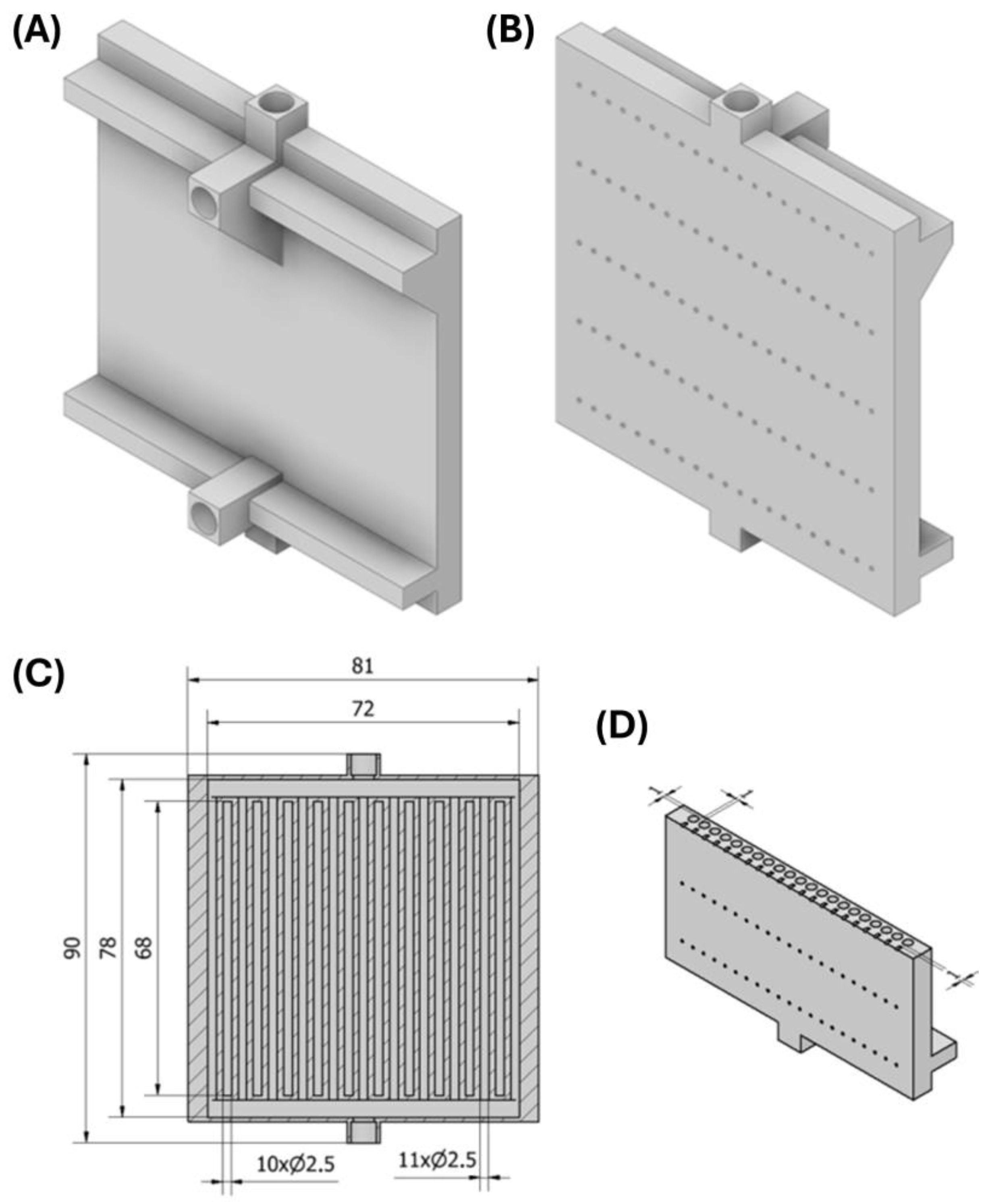

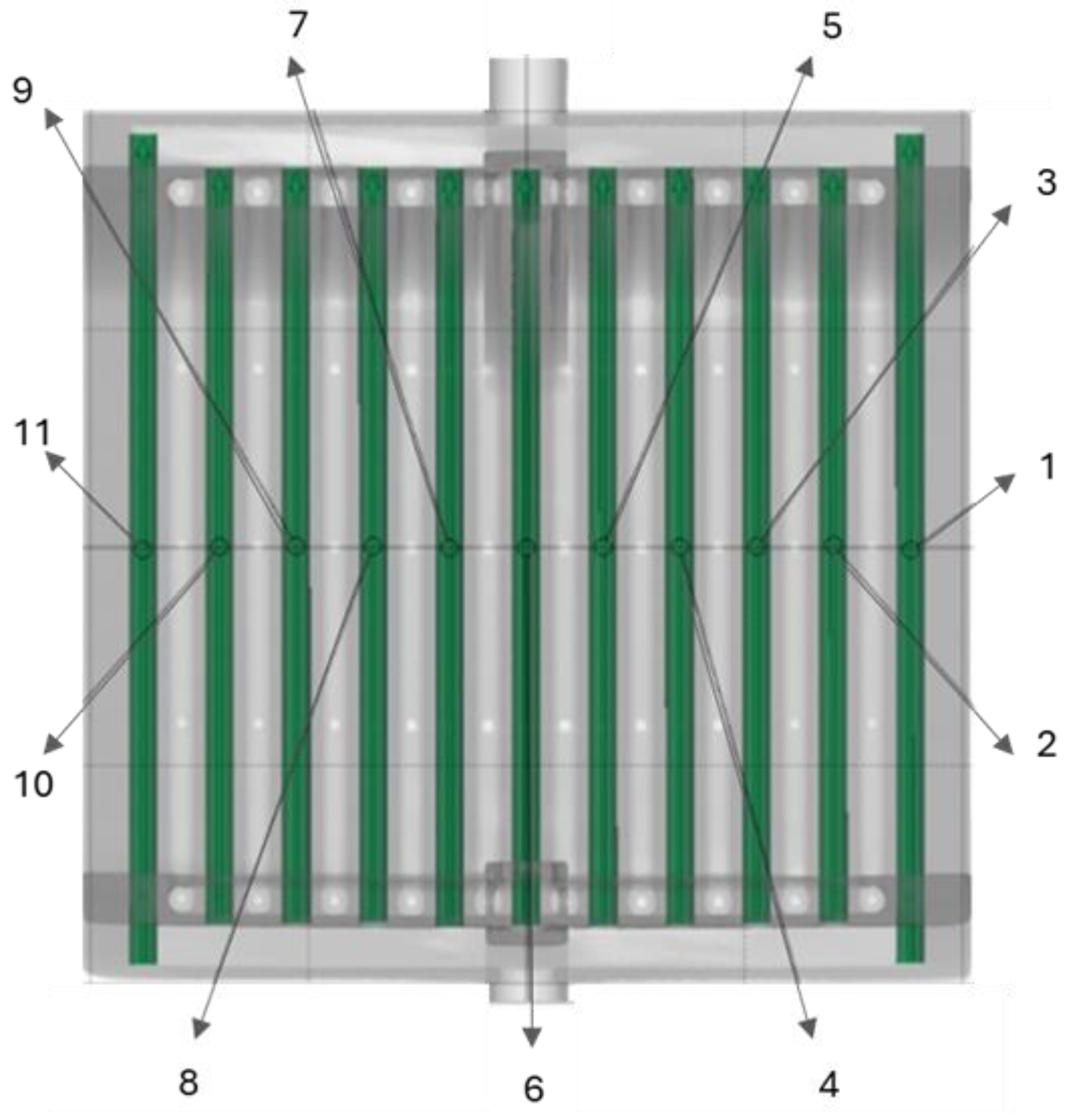

2.1. Compact Heat Exchangers Design

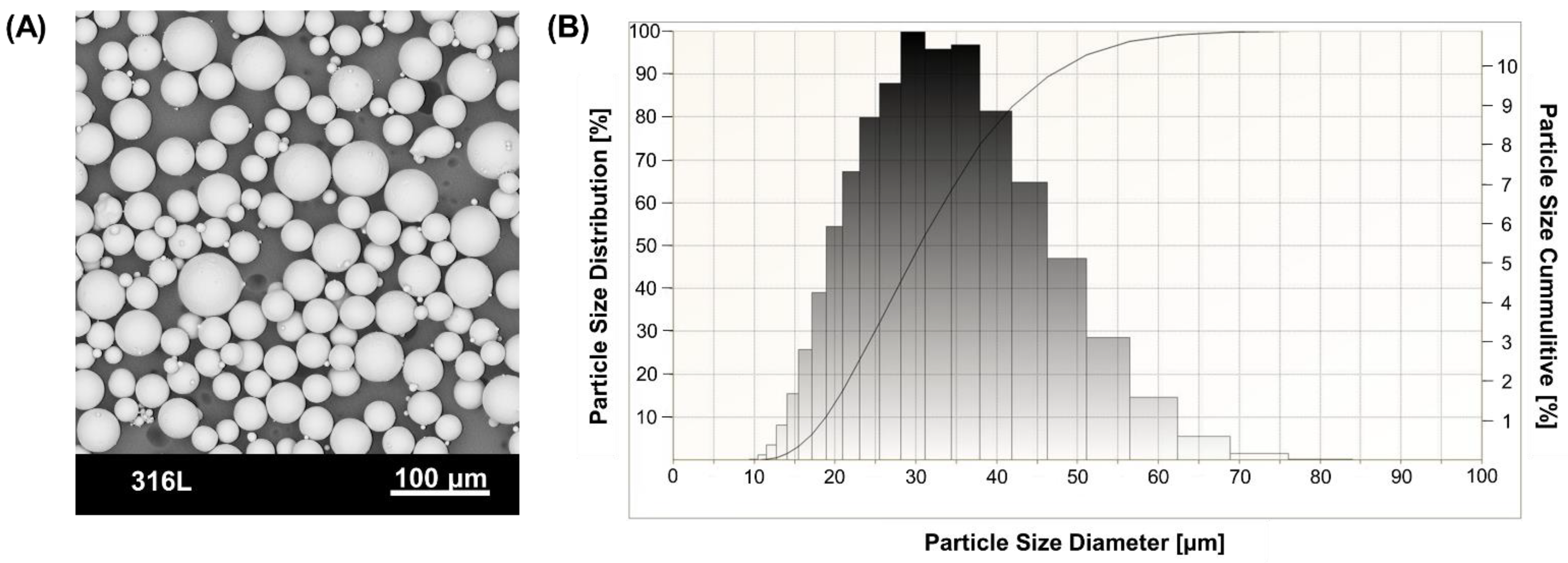

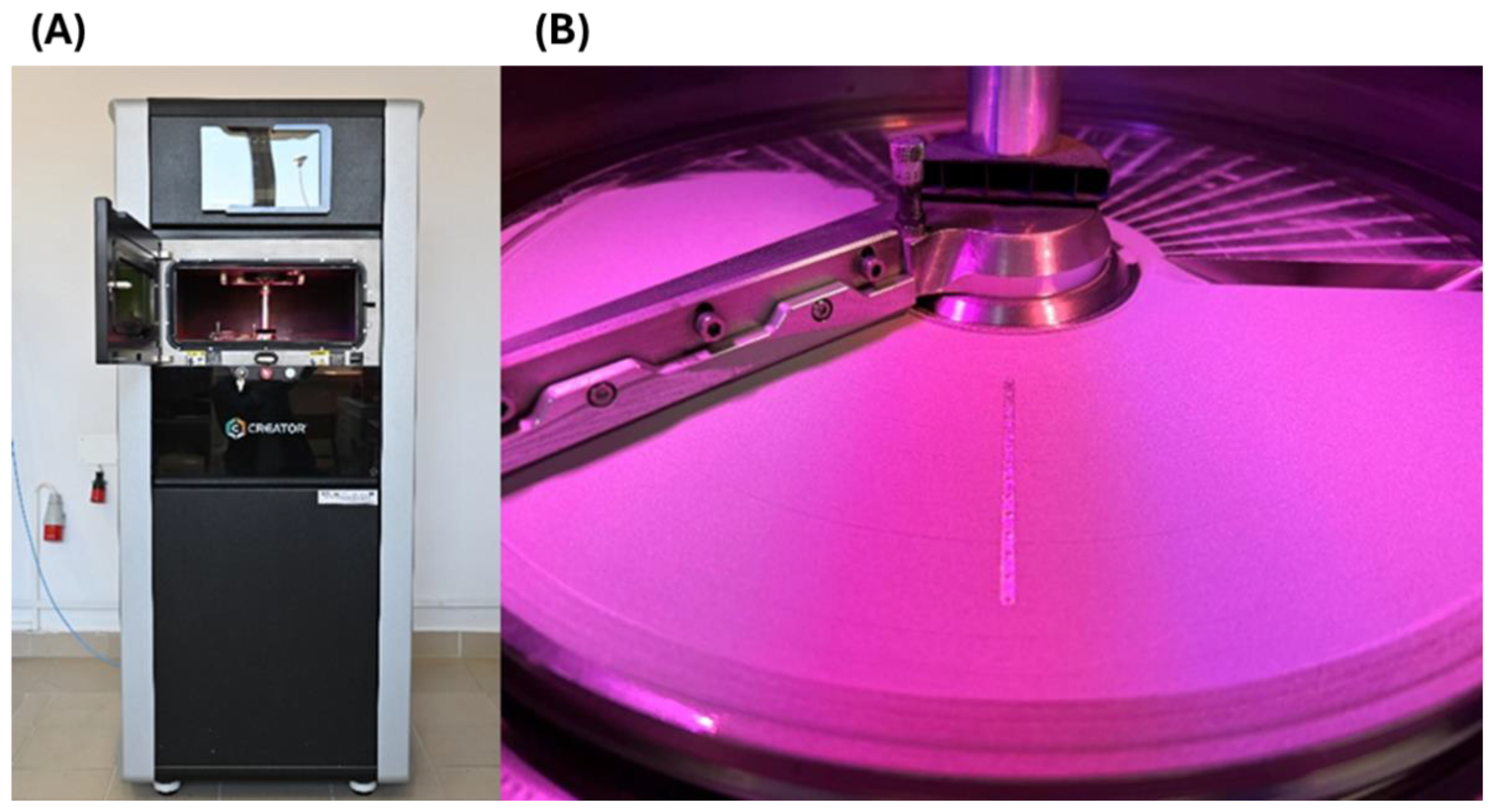

2.2. Compact Heat Exchanger Fabrication and Powder Characterization

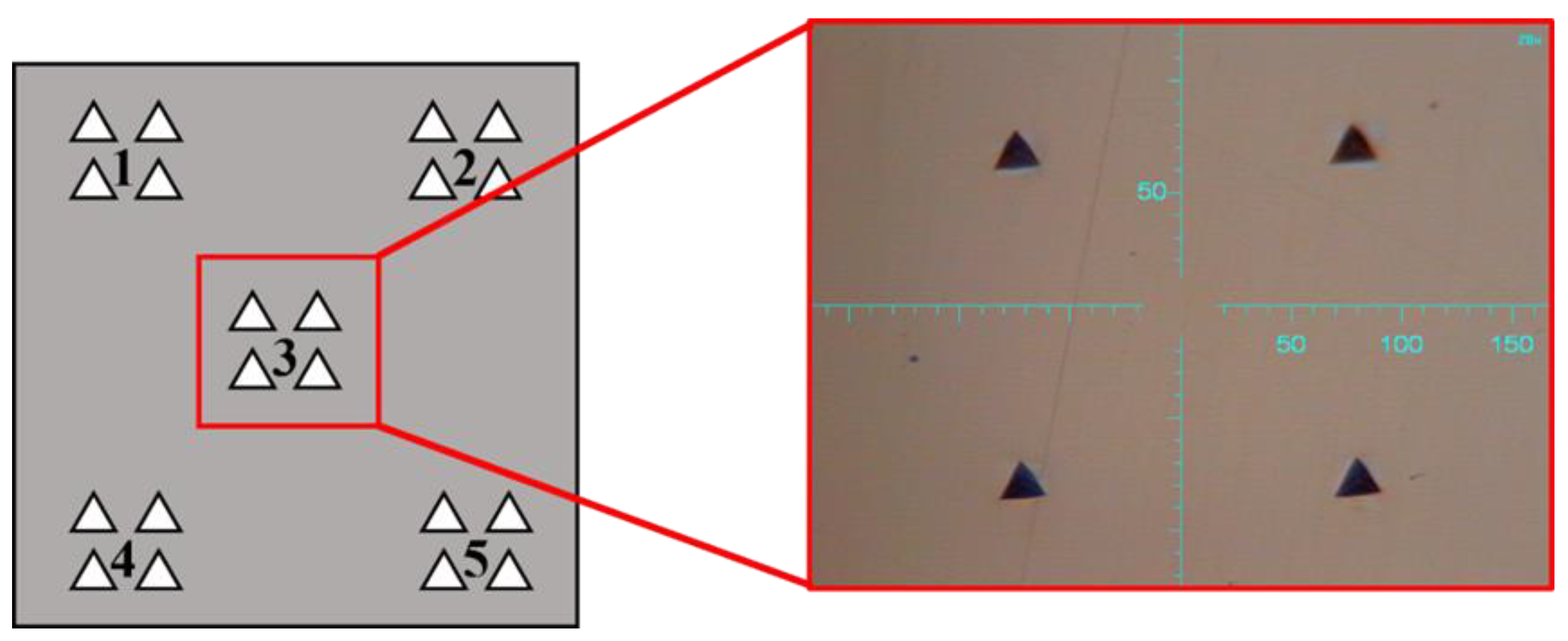

2.3. Material Characterization

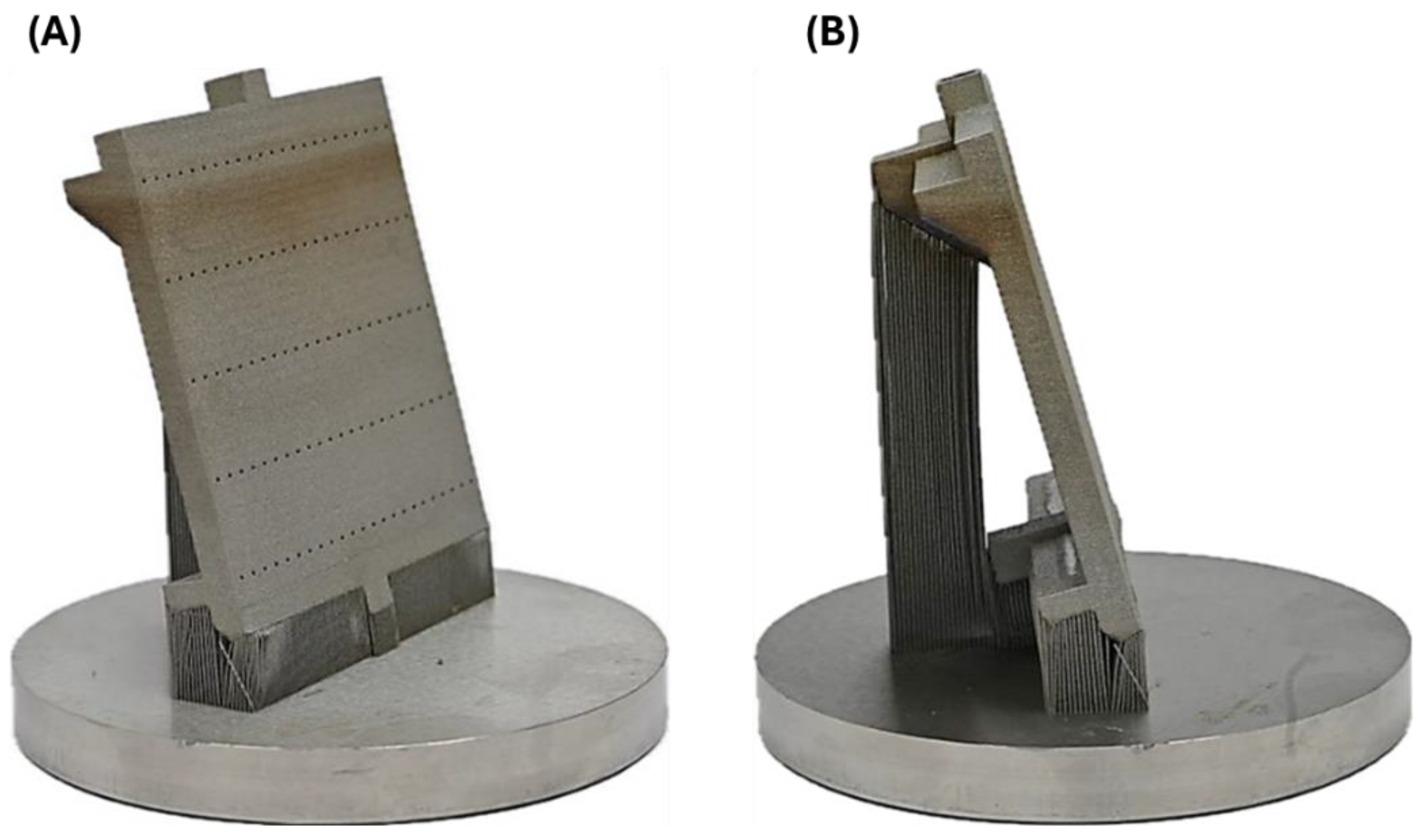

2.4. Workspace Orientation and Support Structures

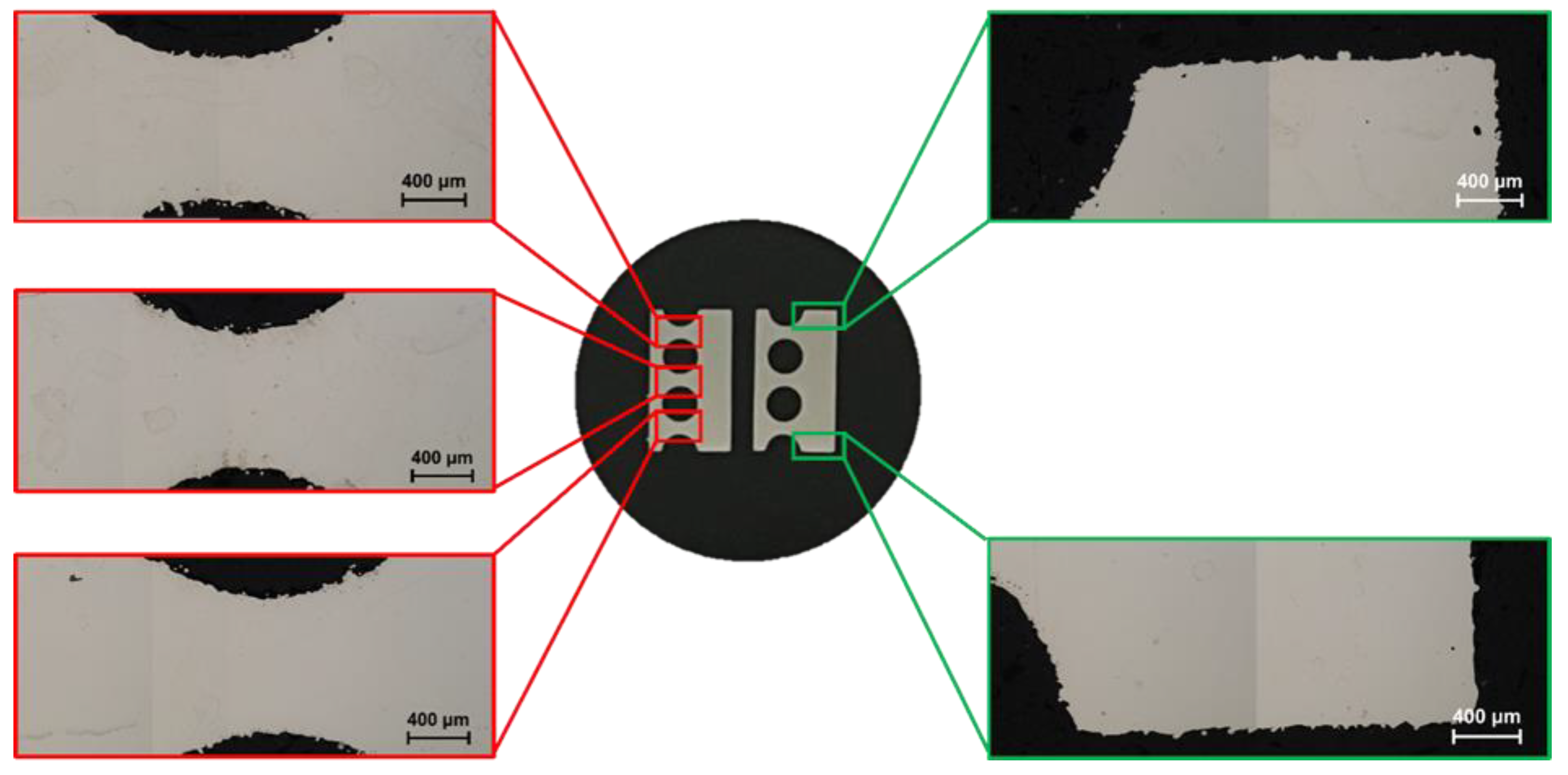

2.5. Optical Microscopy

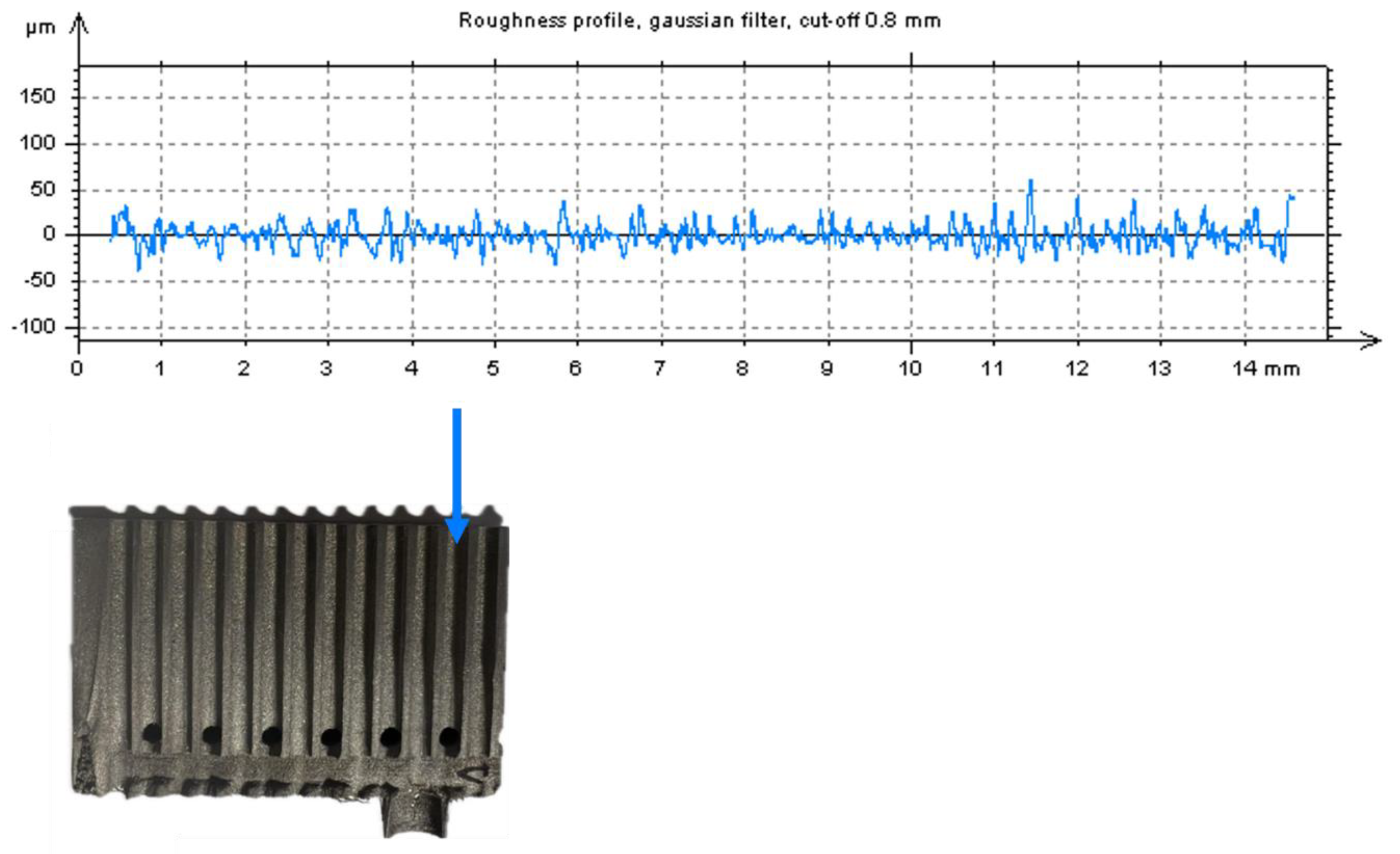

2.6. Contact Profilometry

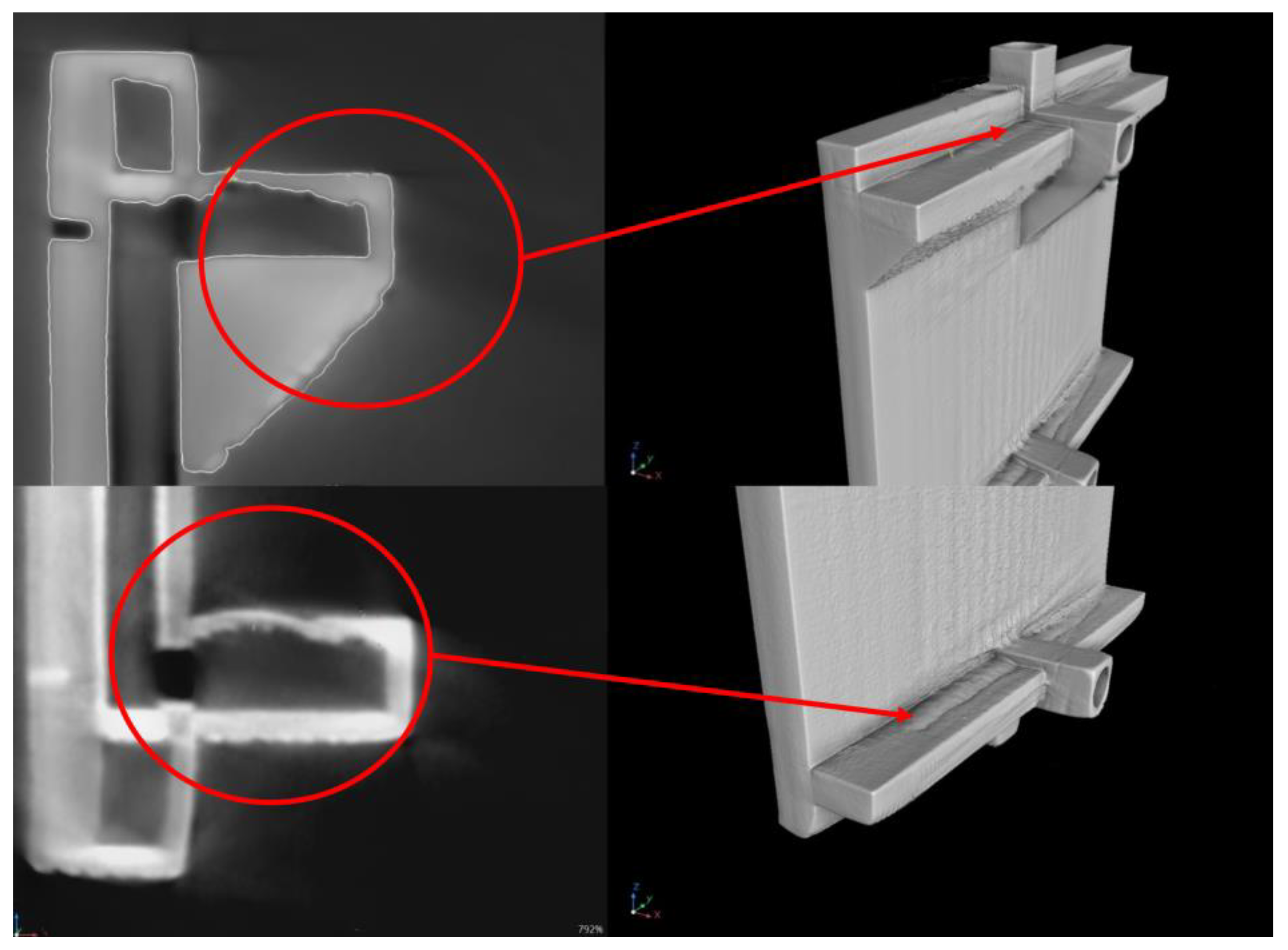

2.7. Computed Tomography

3. Results and Discussion

3.1. Material Characterization

3.2. Structural Defects Analysis

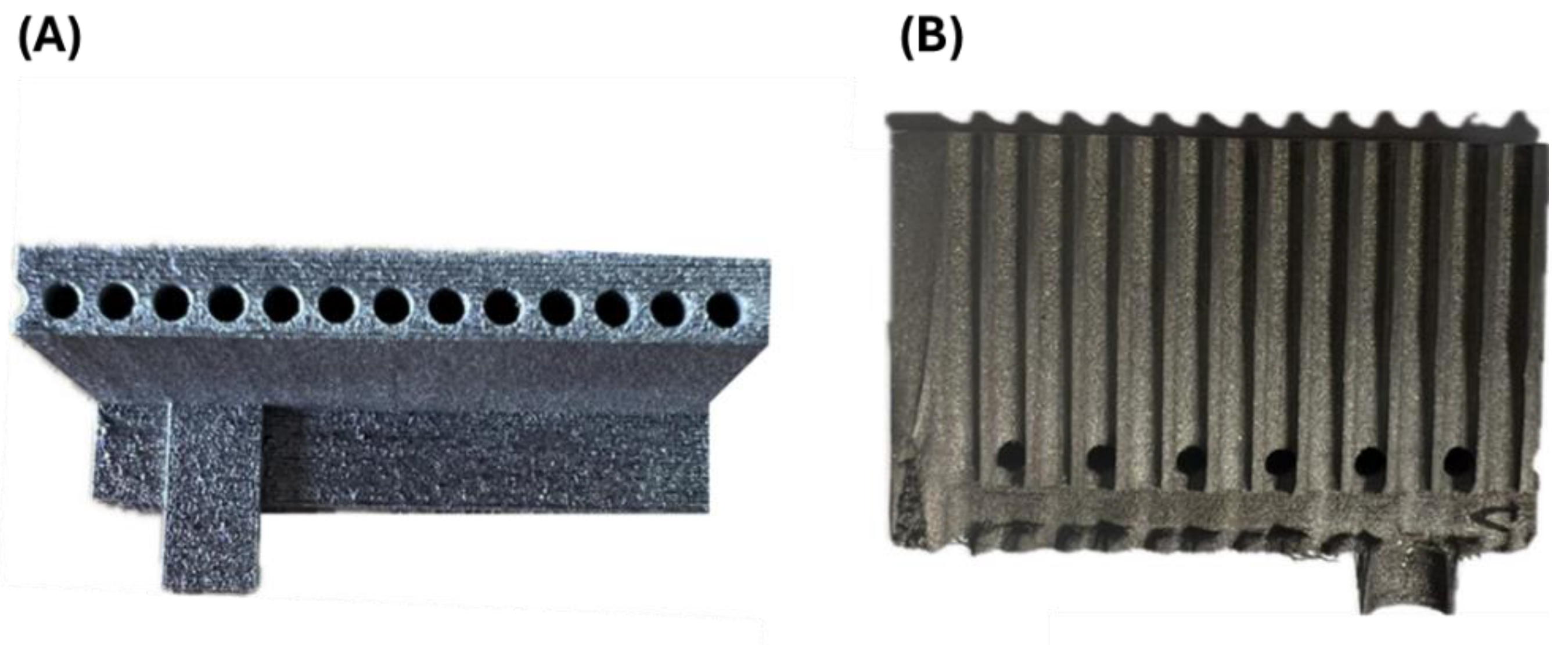

3.3. Surface Roughness of Internal Channels

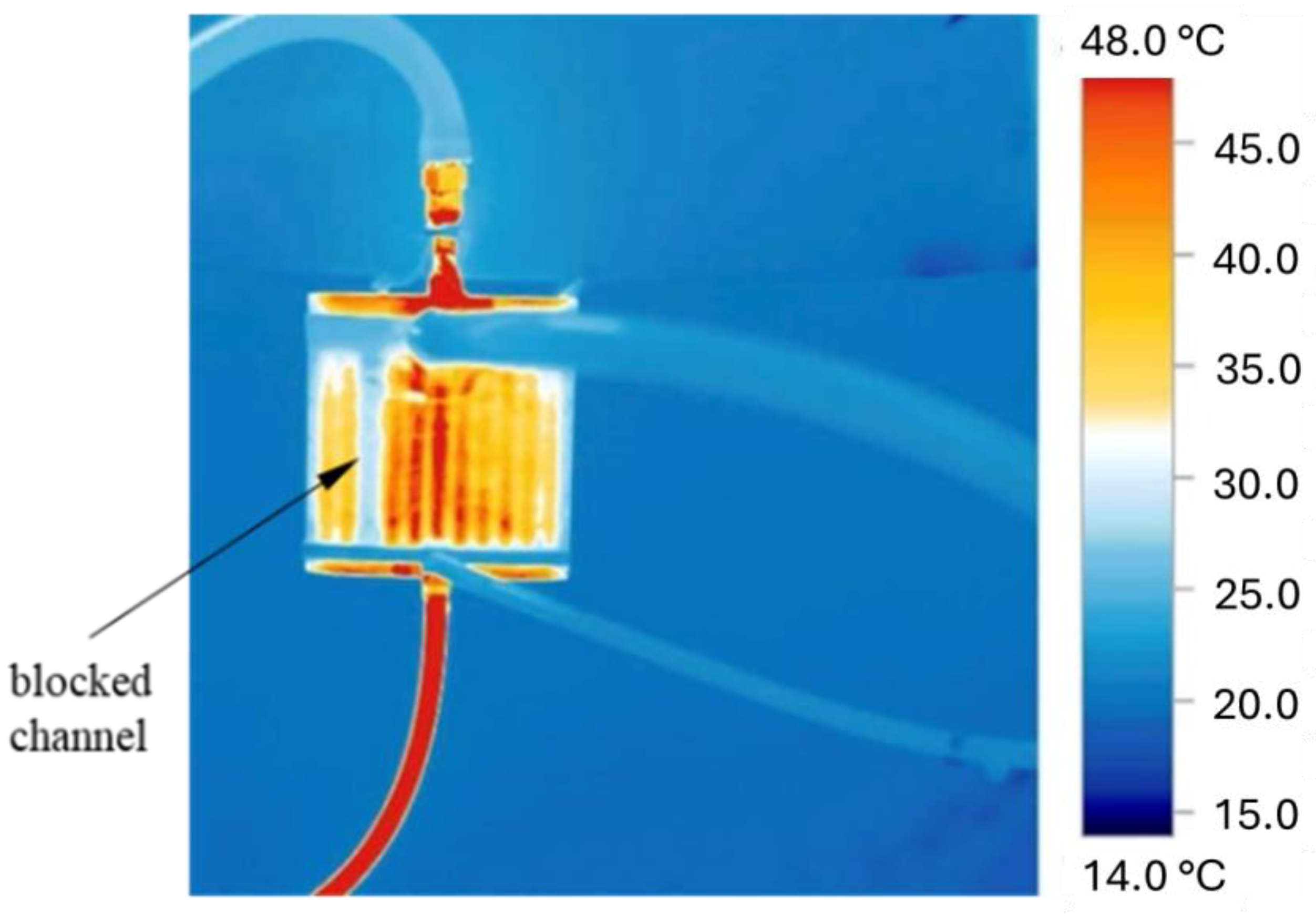

3.4. Analysis of the Accuracy of Execution and Patency of Internal Channels

4. Conclusions

- Diameter of the minichannels (to prevent clogging due to powder adhesion),

- Minimum wall thickness (the smaller the wall thickness, the greater the possibility of structural defects and wall discontinuities, which will cause the exchanger to leak),

- Construction angles that will be possible with this technology.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Doubek, M.; Vacek, V. Universal Heat Exchanger for Air and Evaporative Cooling of Electronics. Therm. Sci. Eng. Progress 2021, 23, 100865. [Google Scholar] [CrossRef]

- Parizad Benam, B.; Sadaghiani, A.K.; Yağcı, V.; Parlak, M.; Sefiane, K.; Koşar, A. Review on High Heat Flux Flow Boiling of Refrigerants and Water for Electronics Cooling. Int. J. Heat Mass Transf. 2021, 180, 121787. [Google Scholar] [CrossRef]

- İpek, O.; Kılıç, B.; Gürel, B. Experimental Investigation of Exergy Loss Analysis in Newly Designed Compact Heat Exchangers. Energy 2017, 124, 330–335. [Google Scholar] [CrossRef]

- Liang, Y.Y.; Liu, C.C.; Li, C.Z.; Chen, J.P. Experimental and Simulation Study on the Air Side Thermal Hydraulic Performance of Automotive Heat Exchangers. Appl. Therm. Eng. 2015, 87, 305–315. [Google Scholar] [CrossRef]

- Oh, S.-H.; An, C.-H.; Seo, B.; Kim, J.; Park, C.Y.; Park, K. Functional Morphology Change of TPMS Structures for Design and Additive Manufacturing of Compact Heat Exchangers. Addit. Manuf. 2023, 76, 103778. [Google Scholar] [CrossRef]

- Fawaz, A.; Hua, Y.; Le Corre, S.; Fan, Y.; Luo, L. Topology Optimization of Heat Exchangers: A Review. Energy 2022, 252, 124053. [Google Scholar] [CrossRef]

- Kuczyński, W.; Chliszcz, K. Experimental Investigations into the Condensation Process of New Environmentally Friendly F-Gas Substitutes in Mini-Channels. Energy 2024, 295, 130883. [Google Scholar] [CrossRef]

- Awais, M.; Bhuiyan, A.A. Heat and Mass Transfer for Compact Heat Exchanger (CHXs) Design: A State-of-the-Art Review. Int. J. Heat Mass Transf. 2018, 127, 359–380. [Google Scholar] [CrossRef]

- Shah, S.M.; Kabe, D.G. An Upper Bound for the Number of Treatments Common to Any Set of Blocks of Certain PBIB Designs. Biom. J. 1981, 23, 9–16. [Google Scholar] [CrossRef]

- Li, Q.; Flamant, G.; Yuan, X.; Neveu, P.; Luo, L. Compact Heat Exchangers: A Review and Future Applications for a New Generation of High Temperature Solar Receivers. Renew. Sustain. Energy Rev. 2011, 15, 4855–4875. [Google Scholar] [CrossRef]

- Kelly, J.P.; Finkenauer, L.R.; Roy, P.; Stolaroff, J.K.; Nguyen, D.T.; Ross, M.S.; Hoff, A.T.; Haslam, J.J. Binder Jet Additive Manufacturing of Ceramic Heat Exchangers for Concentrating Solar Power Applications with Thermal Energy Storage in Molten Chlorides. Addit. Manuf. 2022, 56, 102937. [Google Scholar] [CrossRef]

- Salmon, F.; Ghadim, H.B.; Godin, A.; Haillot, D.; Veillere, A.; Lacanette, D.; Duquesne, M. Optimizing Performance for Cooling Electronic Components Using Innovative Heterogeneous Materials. Appl. Energy 2024, 362, 122983. [Google Scholar] [CrossRef]

- Santa-aho, S.; Kiviluoma, M.; Jokiaho, T.; Gundgire, T.; Honkanen, M.; Lindgren, M.; Vippola, M. Additive Manufactured 316L Stainless-Steel Samples: Microstructure, Residual Stress and Corrosion Characteristics after Post-Processing. Metals 2021, 11, 182. [Google Scholar] [CrossRef]

- Alfaify, A.; Saleh, M.; Abdullah, F.M.; Al-Ahmari, A.M. Design for Additive Manufacturing: A Systematic Review. Sustainability 2020, 12, 7936. [Google Scholar] [CrossRef]

- Stimpson, C.K.; Snyder, J.C.; Thole, K.A.; Mongillo, D. Roughness Effects on Flow and Heat Transfer for Additively Manufactured Channels. J. Turbomach. 2016, 138, 051008. [Google Scholar] [CrossRef]

- Snyder, J.C.; Stimpson, C.K.; Thole, K.A.; Mongillo, D. Build Direction Effects on Additively Manufactured Channels. J. Turbomach. 2016, 138, 051006. [Google Scholar] [CrossRef]

- Sun, C.; Wang, Y.; McMurtrey, M.D.; Jerred, N.D.; Liou, F.; Li, J. Additive Manufacturing for Energy: A Review. Appl. Energy 2021, 282, 116041. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Smurov, I. Selective Laser Melting Technology: From the Single Laser Melted Track Stability to 3D Parts of Complex Shape. Phys. Procedia 2010, 5, 551–560. [Google Scholar] [CrossRef]

- Szatkiewicz, T.; Laskowska, D.; Bałasz, B.; Mitura, K. The Influence of the Structure Parameters on the Mechanical Properties of Cylindrically Mapped Gyroid TPMS Fabricated by Selective Laser Melting with 316L Stainless Steel Powder. Materials 2022, 15, 4352. [Google Scholar] [CrossRef]

- Zhou, C.; Wu, F.; Tang, D.; Zhang, Z.; Zhang, L.; Zheng, J. Effect of Subcritical-Temperature Heat Treatment on Corrosion of SLM SS316L with Different Process Parameters. Corros. Sci. 2023, 218, 111214. [Google Scholar] [CrossRef]

- Jiao, L.; Chua, Z.; Moon, S.; Song, J.; Bi, G.; Zheng, H. Femtosecond Laser Produced Hydrophobic Hierarchical Structures on Additive Manufacturing Parts. Nanomaterials 2018, 8, 601. [Google Scholar] [CrossRef] [PubMed]

- Ansari, P.; Rehman, A.U.; Pitir, F.; Veziroglu, S.; Mishra, Y.K.; Aktas, O.C.; Salamci, M.U. Selective Laser Melting of 316L Austenitic Stainless Steel: Detailed Process Understanding Using Multiphysics Simulation and Experimentation. Metals 2021, 11, 1076. [Google Scholar] [CrossRef]

- Zilio, G.; Teixeira, M.J.; Mortean, M.V.V.; Brandão, F.G.; Pontin, T.T.; Oliveira, J.L.G.; Paiva, K.V. Structural Analysis of Compact Heat Exchanger Samples Fabricated by Additive Manufacturing. Int. J. Press. Vessel. Pip. 2022, 199, 104714. [Google Scholar] [CrossRef]

- Kirsch, K.L.; Thole, K.A. Pressure Loss and Heat Transfer Performance for Additively and Conventionally Manufactured Pin Fin Arrays. Int. J. Heat Mass Transf. 2017, 108, 2502–2513. [Google Scholar] [CrossRef]

- Cormier, Y.; Dupuis, P.; Farjam, A.; Corbeil, A.; Jodoin, B. Additive Manufacturing of Pyramidal Pin Fins: Height and Fin Density Effects under Forced Convection. Int. J. Heat Mass Transf. 2014, 75, 235–244. [Google Scholar] [CrossRef]

- Schoen, A.H. Infinite Periodic Minimal Surfaces without Self-Intersections; NASA Technical Note, Report No. NASA-TN-D-5541; NASA: Washington, DC, USA, 1970. [Google Scholar]

- Dixit, T.; Al-Hajri, E.; Paul, M.C.; Nithiarasu, P.; Kumar, S. High Performance, Microarchitected, Compact Heat Exchanger Enabled by 3D Printing. Appl. Therm. Eng. 2022, 210, 118339. [Google Scholar] [CrossRef]

- Rastan, H.; Abdi, A.; Hamawandi, B.; Ignatowicz, M.; Meyer, J.P.; Palm, B. Heat Transfer Study of Enhanced Additively Manufactured Minichannel Heat Exchangers. Int. J. Heat Mass Transf. 2020, 161, 120271. [Google Scholar] [CrossRef]

- Pakkanen, J.; Calignano, F.; Trevisan, F.; Lorusso, M.; Ambrosio, E.P.; Manfredi, D.; Fino, P. Study of Internal Channel Surface Roughnesses Manufactured by Selective Laser Melting in Aluminum and Titanium Alloys. Metall. Mater. Trans. A 2016, 47, 3837–3844. [Google Scholar] [CrossRef]

- Jamshidinia, M.; Kovacevic, R. The Influence of Heat Accumulation on the Surface Roughness in Powder-Bed Additive Manufacturing. Surf. Topogr. 2015, 3, 014003. [Google Scholar] [CrossRef]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. Surface Roughness Analysis, Modelling and Prediction in Selective Laser Melting. J. Mater. Process Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Soontarapiromsook, J.; Mahian, O.; Dalkilic, A.S.; Wongwises, S. Effect of Surface Roughness on the Condensation of R-134a in Vertical Chevron Gasketed Plate Heat Exchangers. Exp. Therm. Fluid Sci. 2018, 91, 54–63. [Google Scholar] [CrossRef]

- Ventola, L.; Robotti, F.; Dialameh, M.; Calignano, F.; Manfredi, D.; Chiavazzo, E.; Asinari, P. Rough Surfaces with Enhanced Heat Transfer for Electronics Cooling by Direct Metal Laser Sintering. Int. J. Heat Mass Transf. 2014, 75, 58–74. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Easton, M. Powder Bed Fusion Processes. In Laser Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2017; pp. 55–77. [Google Scholar]

- Cooke, S.; Ahmadi, K.; Willerth, S.; Herring, R. Metal Additive Manufacturing: Technology, Metallurgy and Modelling. J. Manuf. Process 2020, 57, 978–1003. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Careri, F.; Khan, R.H.U.; Todd, C.; Attallah, M.M. Additive Manufacturing of Heat Exchangers in Aerospace Applications: A Review. Appl. Therm. Eng. 2023, 235, 121387. [Google Scholar] [CrossRef]

- Thompson, S.M.; Aspin, Z.S.; Shamsaei, N.; Elwany, A.; Bian, L. Additive Manufacturing of Heat Exchangers: A Case Study on a Multi-Layered Ti–6Al–4V Oscillating Heat Pipe. Addit. Manuf. 2015, 8, 163–174. [Google Scholar] [CrossRef]

- Singer, F.; Deisenroth, D.C.; Hymas, D.M.; Ohadi, M.M. Additively Manufactured Copper Components and Composite Structures for Thermal Management Applications. In Proceedings of the 2017 16th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 30 May–2 June 2017; pp. 174–183. [Google Scholar]

- Popovich, A.; Sufiiarov, V.; Polozov, I.; Borisov, E.; Masaylo, D.; Orlov, A. Microstructure and Mechanical Properties of Additive Manufactured Copper Alloy. Mater. Lett. 2016, 179, 38–41. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, P.; Yu, Z.; Shi, H.; Wu, D.; Yan, H.; Ye, X.; Lu, Q.; Tian, Y. A Review on Additive Manufacturing of Pure Copper. Coatings 2021, 11, 740. [Google Scholar] [CrossRef]

- Patalas-Maliszewska, J.; Topczak, M. Assessment of Energy Consumption in the Context of Implementing Additive Manufacturing Technologies: Evidence from Polish Small and Medium Sized Production Companies. Energy Sustain. Dev. 2023, 73, 355–364. [Google Scholar] [CrossRef]

- Wippermann, A.; Gutowski, T.G.; Denkena, B.; Dittrich, M.-A.; Wessarges, Y. Electrical Energy and Material Efficiency Analysis of Machining, Additive and Hybrid Manufacturing. J. Clean. Prod. 2020, 251, 119731. [Google Scholar] [CrossRef]

- Hunter, L.W.; Brackett, D.; Brierley, N.; Yang, J.; Attallah, M.M. Assessment of Trapped Powder Removal and Inspection Strategies for Powder Bed Fusion Techniques. Int. J. Adv. Manuf. Technol. 2020, 106, 4521–4532. [Google Scholar] [CrossRef]

- Wu, Z.; Narra, S.P.; Rollett, A. Exploring the Fabrication Limits of Thin-Wall Structures in a Laser Powder Bed Fusion Process. Int. J. Adv. Manuf. Technol. 2020, 110, 191–207. [Google Scholar] [CrossRef]

- Sabau, A.S.; Bejan, A.; Brownell, D.; Gluesenkamp, K.; Murphy, B.; List, F.; Carver, K.; Schaich, C.R.; Klett, J.W. Design, Additive Manufacturing, and Performance of Heat Exchanger with a Novel Flow-Path Architecture. Appl. Therm. Eng. 2020, 180, 115775. [Google Scholar] [CrossRef]

- Romei, F.; Grubišić, A.N.; Gibbon, D. Manufacturing of a High-Temperature Resistojet Heat Exchanger by Selective Laser Melting. Acta Astronaut. 2017, 138, 356–368. [Google Scholar] [CrossRef]

- Arie, M.A.; Shooshtari, A.H.; Ohadi, M.M. Experimental Characterization of an Additively Manufactured Heat Exchanger for Dry Cooling of Power Plants. Appl. Therm. Eng. 2018, 129, 187–198. [Google Scholar] [CrossRef]

- Zhang, X.; Tiwari, R.; Shooshtari, A.H.; Ohadi, M.M. An Additively Manufactured Metallic Manifold-Microchannel Heat Exchanger for High Temperature Applications. Appl. Therm. Eng. 2018, 143, 899–908. [Google Scholar] [CrossRef]

- Saltzman, D.; Bichnevicius, M.; Lynch, S.; Simpson, T.W.; Reutzel, E.W.; Dickman, C.; Martukanitz, R. Design and Evaluation of an Additively Manufactured Aircraft Heat Exchanger. Appl. Therm. Eng. 2018, 138, 254–263. [Google Scholar] [CrossRef]

- Chekurov, S.; Kajaste, J.; Saari, K.; Kauranne, H.; Pietola, M.; Partanen, J. Additively Manufactured High-Performance Counterflow Heat Exchanger. Prog. Addit. Manuf. 2019, 4, 55–61. [Google Scholar] [CrossRef]

- Material Product Data Sheet, Type 316L Austenic Stainless Steel Powders for Additive Manufacturing, MetcoAddTM 316L-A, Oerlicon Metco. Available online: https://www.oerlikon.com/ecoma/files/DSM-0272_AM_316L-AusteniticSteel.pdf?download=true (accessed on 23 June 2025).

- Pyka, G.; Kerckhofs, G.; Papantoniou, I.; Speirs, M.; Schrooten, J.; Wevers, M. Surface Roughness and Morphology Customization of Additive Manufactured Open Porous Ti6Al4V Structures. Materials 2013, 6, 4737–4757. [Google Scholar] [CrossRef]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Iuliano, L.; Fino, P. Influence of Process Parameters on Surface Roughness of Aluminum Parts Produced by DMLS. Int. J. Adv. Manuf. Technol. 2013, 67, 2743–2751. [Google Scholar] [CrossRef]

- Fang, Z.-C.; Wu, Z.-L.; Huang, C.-G.; Wu, C.-W. Review on Residual Stress in Selective Laser Melting Additive Manufacturing of Alloy Parts. Opt. Laser Technol. 2020, 129, 106283. [Google Scholar] [CrossRef]

- ISO 21920-3:2022; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 3: Specification Operators. ISO: Geneva, Switzerland, 2021.

- Lyczkowska-Widlak, E.; Lochynski, P.; Nawrat, G.; Chlebus, E. Comparison of Electropolished 316L Steel Samples Manufactured by SLM and Traditional Technology. Rapid Prototyp. J. 2019, 25, 566–580. [Google Scholar] [CrossRef]

- Rombouts, M.; Kruth, J.P.; Froyen, L.; Mercelis, P. Fundamentals of Selective Laser Melting of Alloyed Steel Powders. CIRP Ann. 2006, 55, 187–192. [Google Scholar] [CrossRef]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the Effect of Process Parameters on Microstructural and Physical Properties of 316L Stainless Steel Parts by Selective Laser Melting. Int. J. Adv. Manuf. Technol. 2015, 76, 869–879. [Google Scholar] [CrossRef]

- Dev Singh, D.; Mahender, T.; Raji Reddy, A. Powder Bed Fusion Process: A Brief Review. Mater. Today Proc. 2021, 46, 350–355. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of Keyhole-Mode Laser Melting in Laser Powder-Bed Fusion Additive Manufacturing. J. Mater. Process Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- da Silva, R.P.P.; Mortean, M.V.V.; de Paiva, K.V.; Beckedorff, L.E.; Oliveira, J.L.G.; Brandão, F.G.; Monteiro, A.S.; Carvalho, C.S.; Oliveira, H.R.; Borges, D.G.; et al. Thermal and Hydrodynamic Analysis of a Compact Heat Exchanger Produced by Additive Manufacturing. Appl. Therm. Eng. 2021, 193, 116973. [Google Scholar] [CrossRef]

- Davoodi, F.; Taghian, M.; Carbone, G.; Saboori, A.; Iuliano, L. An Overview of the Latest Progress in Internal Surface Finishing of the Additively Manufactured Metallic Components. Materials 2023, 16, 3867. [Google Scholar] [CrossRef]

- Alrbaey, K.; Wimpenny, D.I.; Al-Barzinjy, A.A.; Moroz, A. Electropolishing of Re-Melted SLM Stainless Steel 316L Parts Using Deep Eutectic Solvents: 3 × 3 Full Factorial Design. J. Mater. Eng. Perform. 2016, 25, 2836–2846. [Google Scholar] [CrossRef]

| Element | Fe | Cr | Ni | Mo | C | Other |

|---|---|---|---|---|---|---|

| Percentage by weight [%] | 65 | 18 | 12 | 2 | <0.03 | <1 |

| Laser Power [W] | Scanning Speed [mm s−1] | Layer Height [mm] | Hatch Distance [mm] | Protective Atmosphere |

|---|---|---|---|---|

| 250 | 900 | 0.025 | 0.06 | Argon |

| Element | Fe | Cr | Ni | Mo | C | Other |

|---|---|---|---|---|---|---|

| Percentage by weight [%] | 60 | 17 | 12 | 1.5 | <0.03 | <1 |

| Part | Measurement Number HV0.05 | Average HV0.05 | |||

|---|---|---|---|---|---|

| P1 | P2 | P3 | P4 | ||

| 1 | 251 | 264 | 260 | 274 | 262 ± 8 |

| 2 | 244 | 243 | 251 | 239 | 244 ± 5 |

| 3 | 259 | 241 | 255 | 263 | 255 ± 8 |

| 4 | 270 | 285 | 272 | 245 | 268 ± 14 |

| 5 | 244 | 240 | 234 | 236 | 238 ± 4 |

| Ra [μm] | 10.40 | 11.02 | 11.20 | 12.41 | 13.67 | 9.23 | 11.11 ± 1.63 |

| 12.77 | 9.88 | 8.89 | 8.70 | 12.40 | 12.83 | ||

| Rz [μm] | 63.42 | 79.68 | 74.90 | 82.80 | 86.61 | 65.09 | 74.98 ± 11.13 |

| 95.72 | 67.20 | 60.88 | 59.62 | 79.15 | 84.64 |

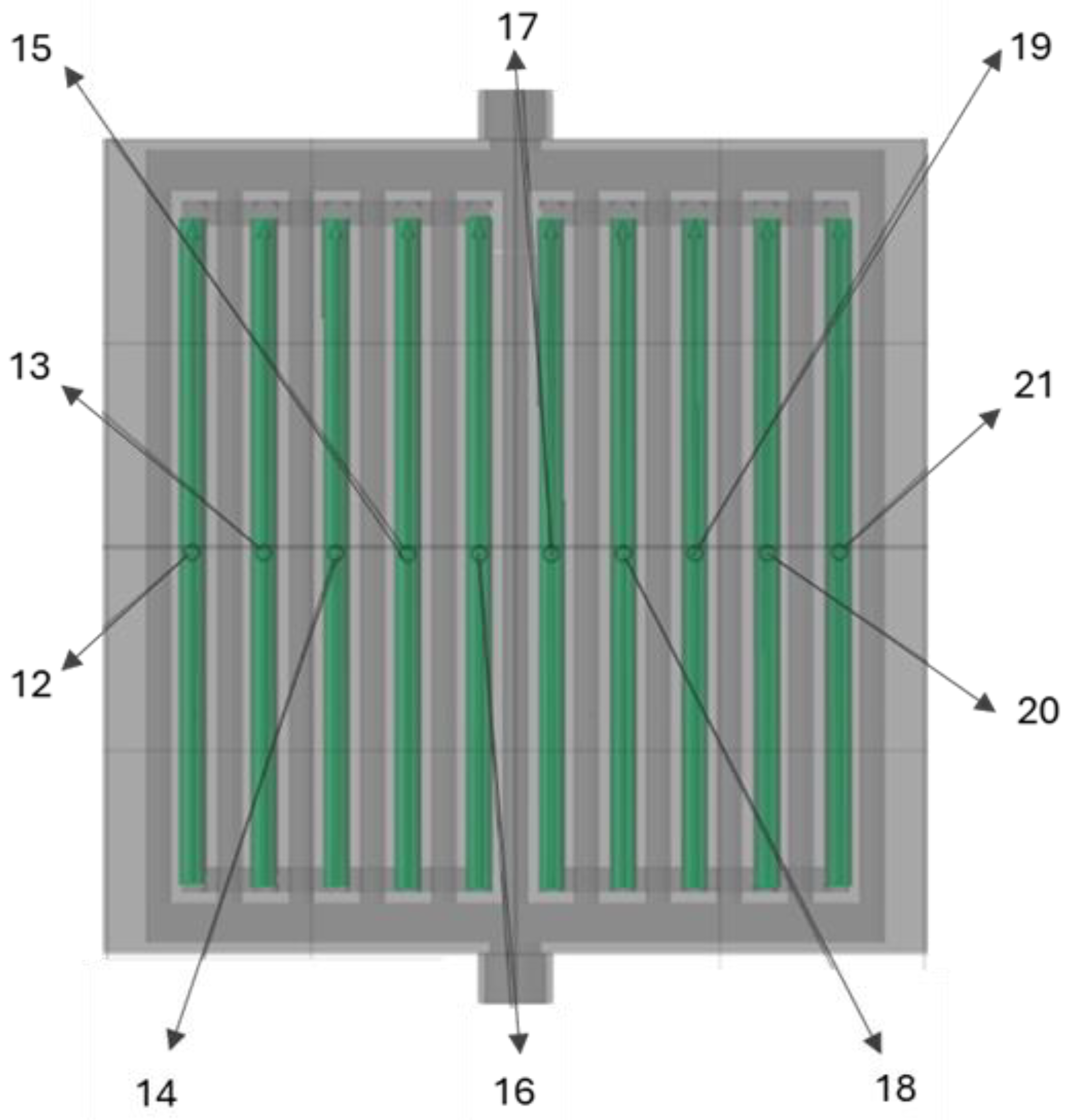

| Channel Number | Actual Diameter [mm] | Deviation [mm] | Channel Number | Actual Diameter [mm] | Deviation [mm] | Channel Number | Actual Diameter [mm] | Deviation [mm] |

|---|---|---|---|---|---|---|---|---|

| 1 | 2.6036 | 0.1036 | 8 | 2.5789 | 0.0789 | 15 | 2.5848 | 0.0848 |

| 2 | 2.6016 | 0.1016 | 9 | 2.5961 | 0.0961 | 16 | 2.5795 | 0.0795 |

| 3 | 2.5986 | 0.0986 | 10 | 2.5863 | 0.0863 | 17 | 2.5858 | 0.0858 |

| 4 | 2.5907 | 0.0907 | 11 | 2.5835 | 0.0835 | 18 | 2.5867 | 0.0867 |

| 5 | 2.5888 | 0.0888 | 12 | 2.5890 | 0.0890 | 19 | 2.5997 | 0.0997 |

| 6 | 2.5860 | 0.0860 | 13 | 2.5883 | 0.0883 | 20 | 2.6031 | 0.1031 |

| 7 | 2.5856 | 0.0856 | 14 | 2.5938 | 0.0938 | 21 | 2.6095 | 0.1095 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chliszcz, K.; Laskowska, D.; Kuczyński, W.; Bałasz, B.; Kasperowaicz, M.; Moj, K. Assessment of the Feasibility of Using Additive Manufacturing from Metal Powder to Produce Compact Heat Exchangers. Materials 2025, 18, 3035. https://doi.org/10.3390/ma18133035

Chliszcz K, Laskowska D, Kuczyński W, Bałasz B, Kasperowaicz M, Moj K. Assessment of the Feasibility of Using Additive Manufacturing from Metal Powder to Produce Compact Heat Exchangers. Materials. 2025; 18(13):3035. https://doi.org/10.3390/ma18133035

Chicago/Turabian StyleChliszcz, Katarzyna, Dorota Laskowska, Waldemar Kuczyński, Błażej Bałasz, Maciej Kasperowaicz, and Kevin Moj. 2025. "Assessment of the Feasibility of Using Additive Manufacturing from Metal Powder to Produce Compact Heat Exchangers" Materials 18, no. 13: 3035. https://doi.org/10.3390/ma18133035

APA StyleChliszcz, K., Laskowska, D., Kuczyński, W., Bałasz, B., Kasperowaicz, M., & Moj, K. (2025). Assessment of the Feasibility of Using Additive Manufacturing from Metal Powder to Produce Compact Heat Exchangers. Materials, 18(13), 3035. https://doi.org/10.3390/ma18133035