Investigating the Efficacy of Established Chemical Wood Modifications on Large-Diameter Pine: Durability Against Basidiomycetes

Abstract

1. Introduction

2. Materials and Methods

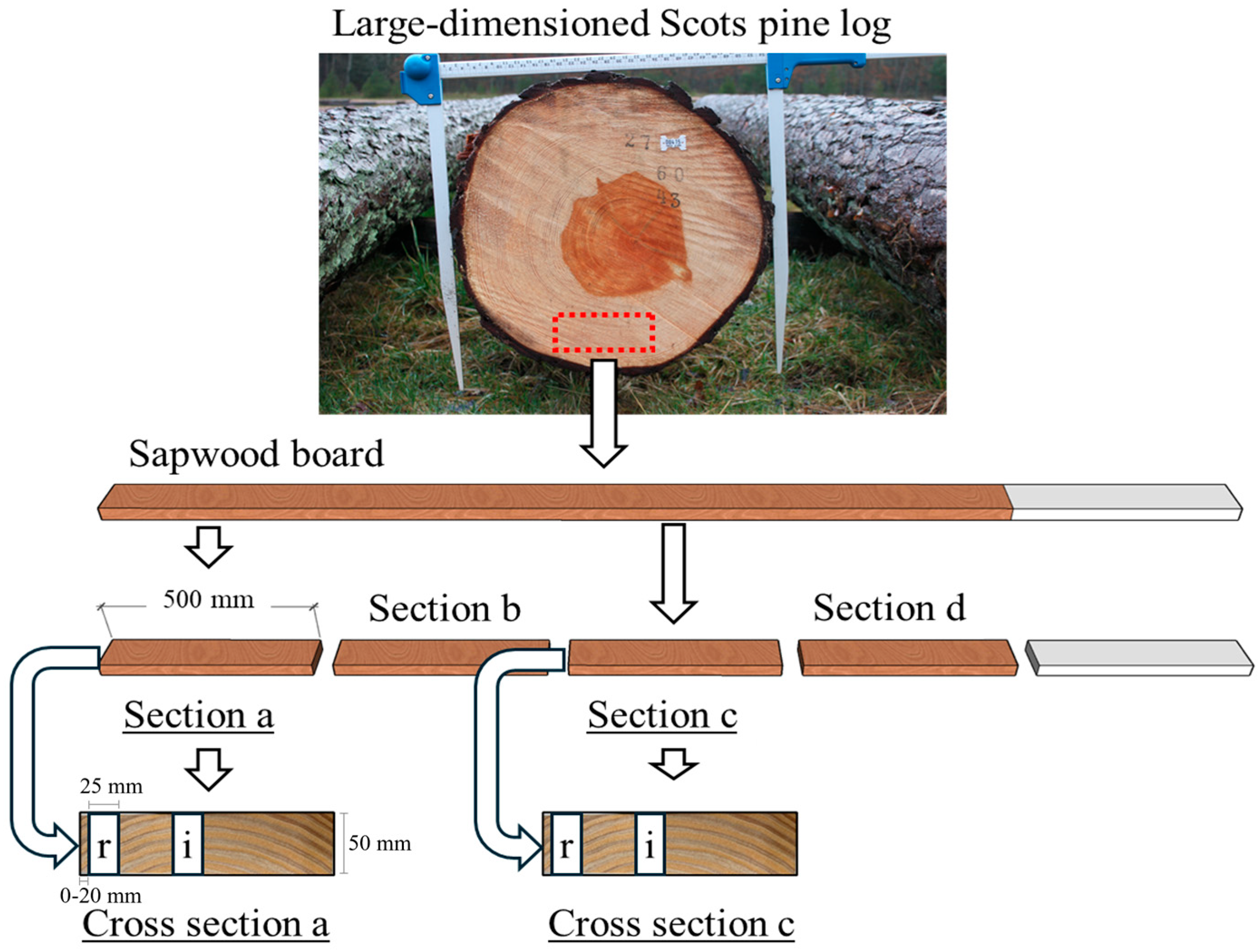

2.1. Test Material and Treatment

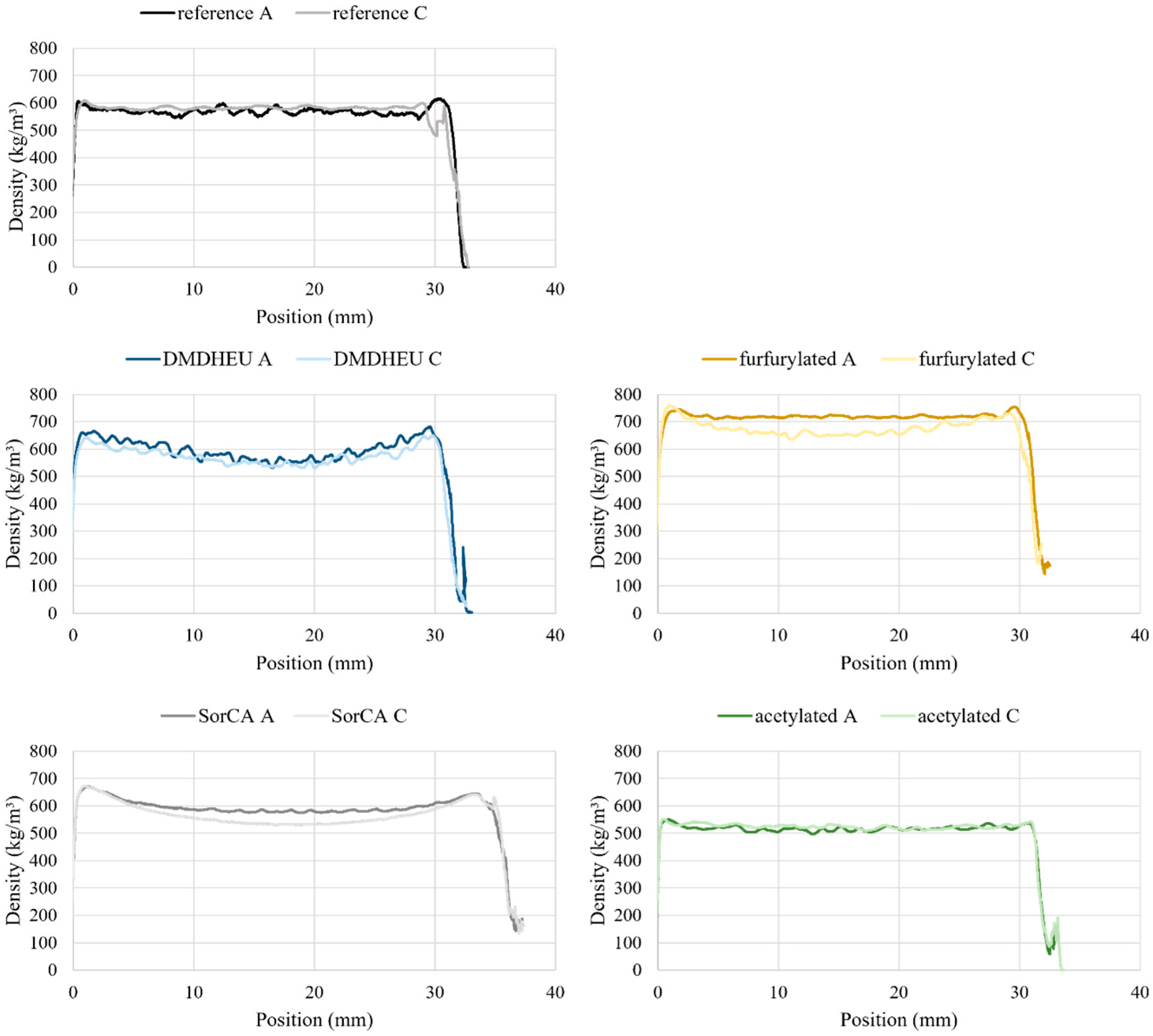

2.2. Density Profile

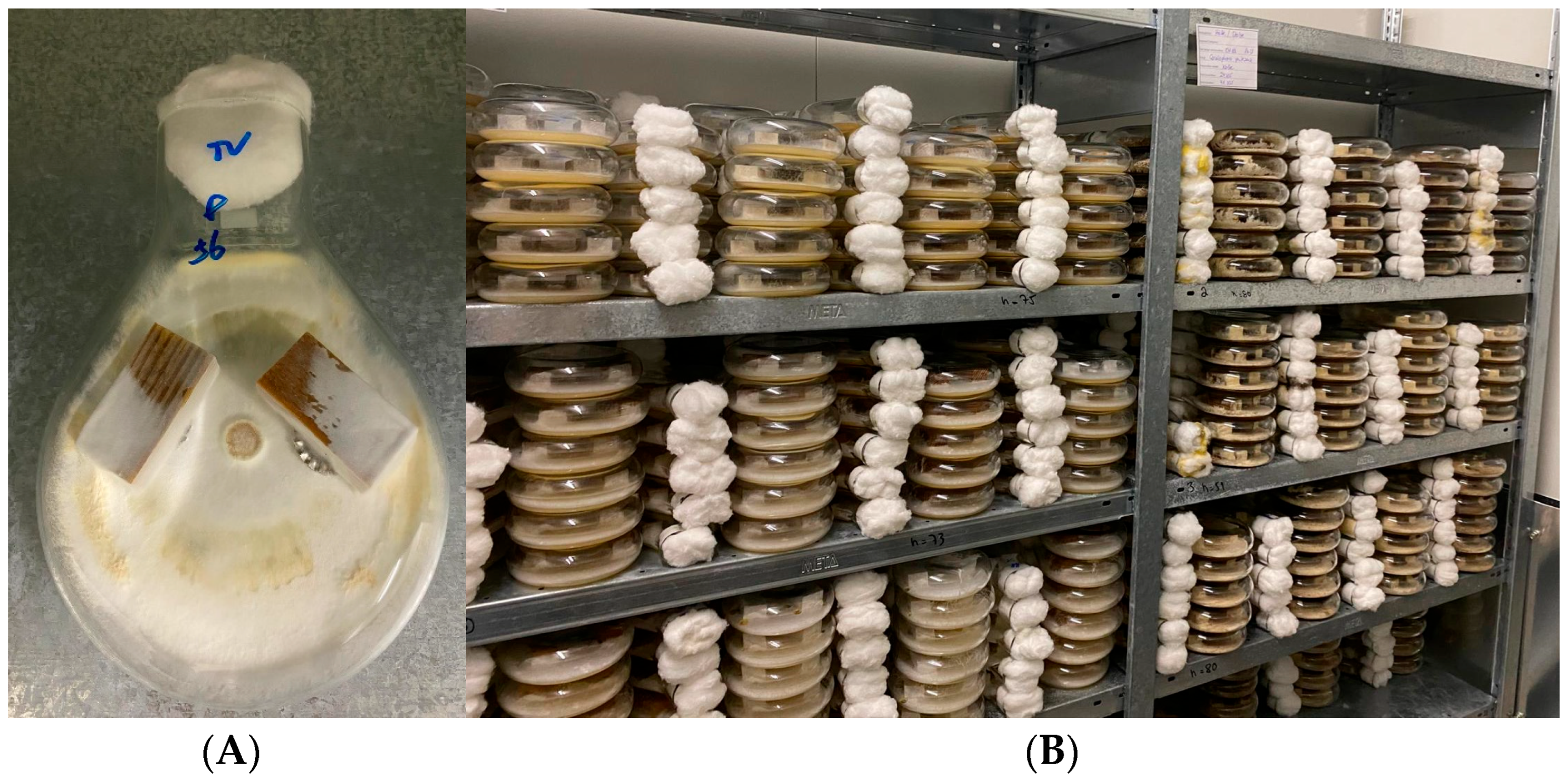

2.3. Fungal Durability Test

3. Results

3.1. Density Profiles

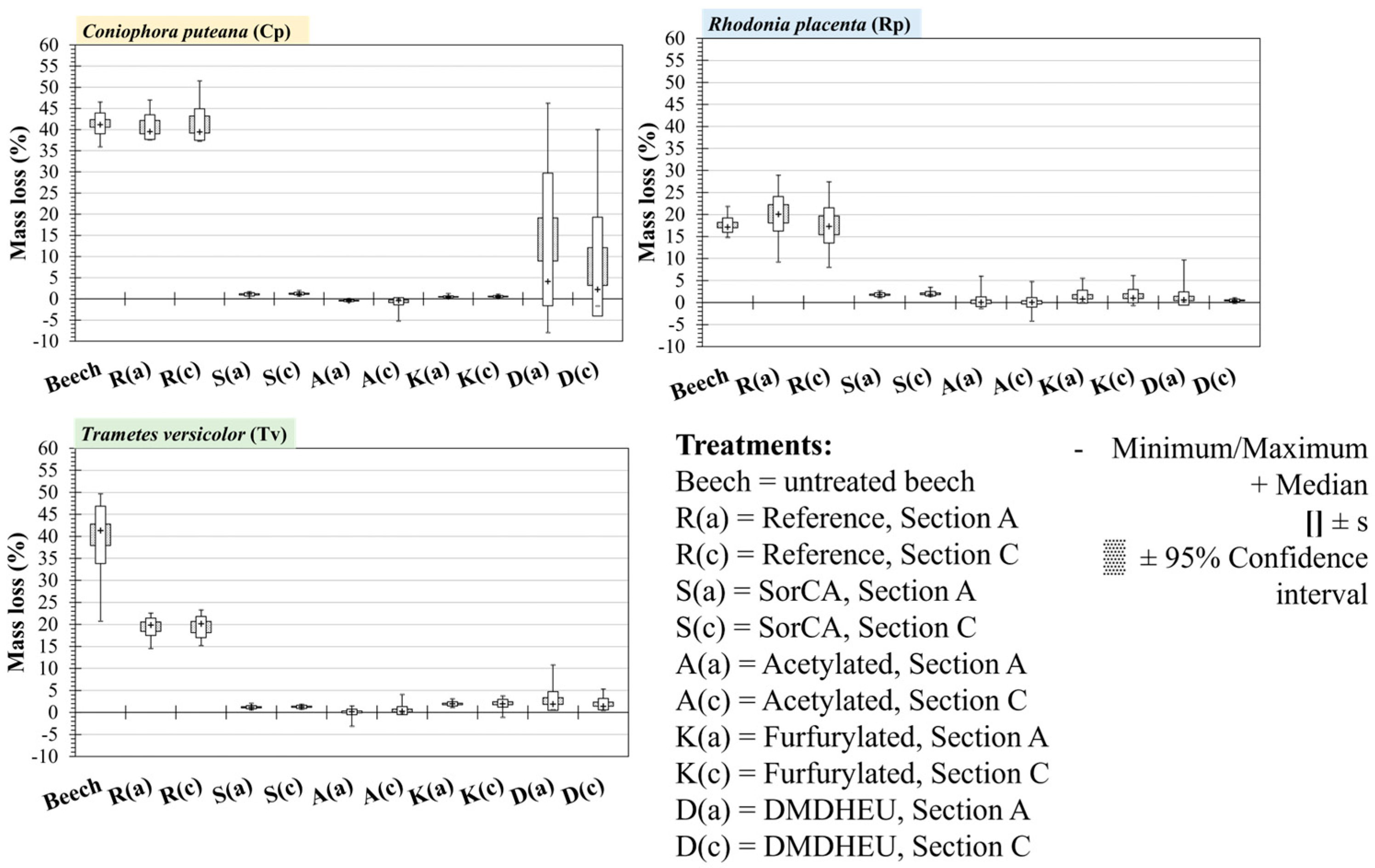

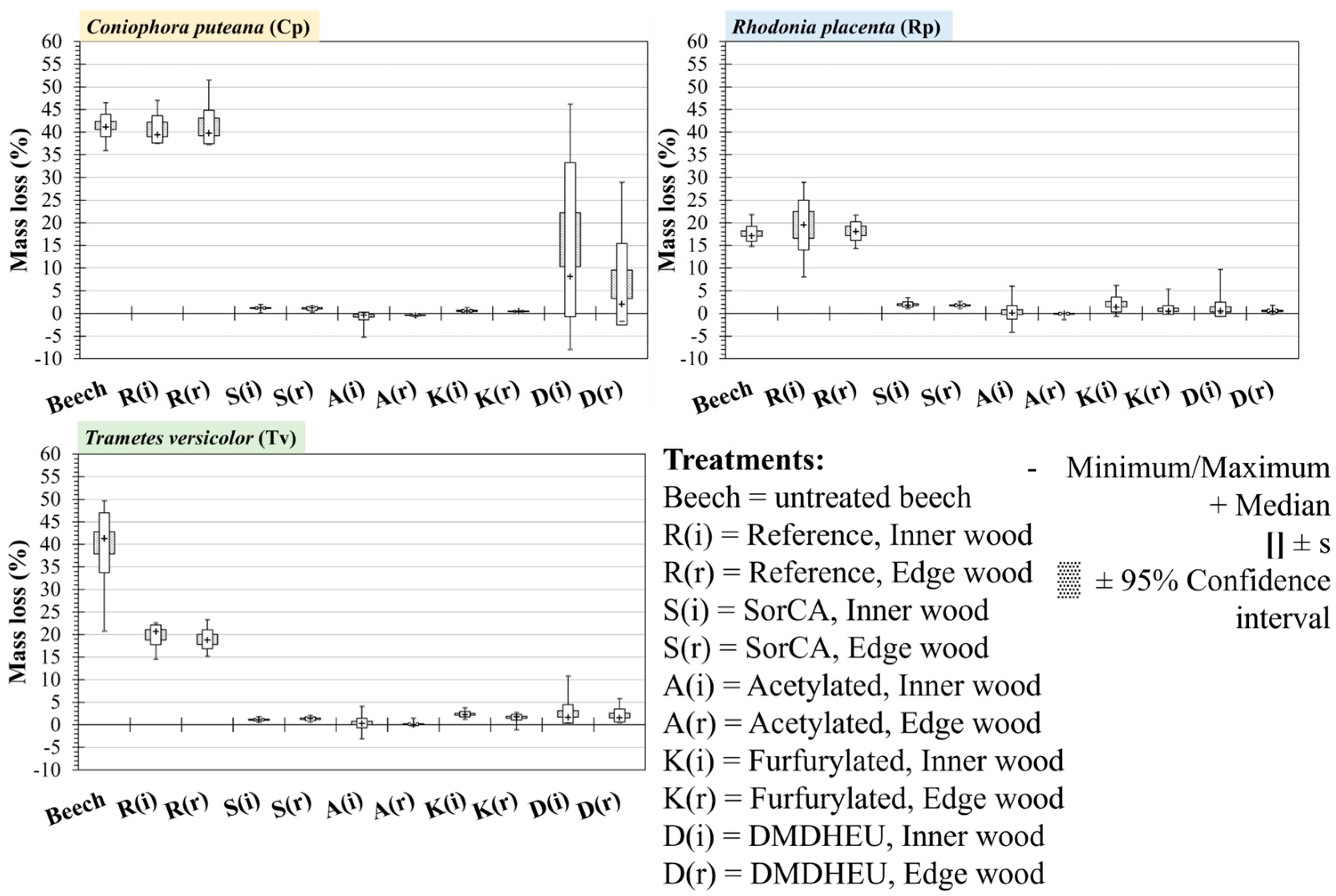

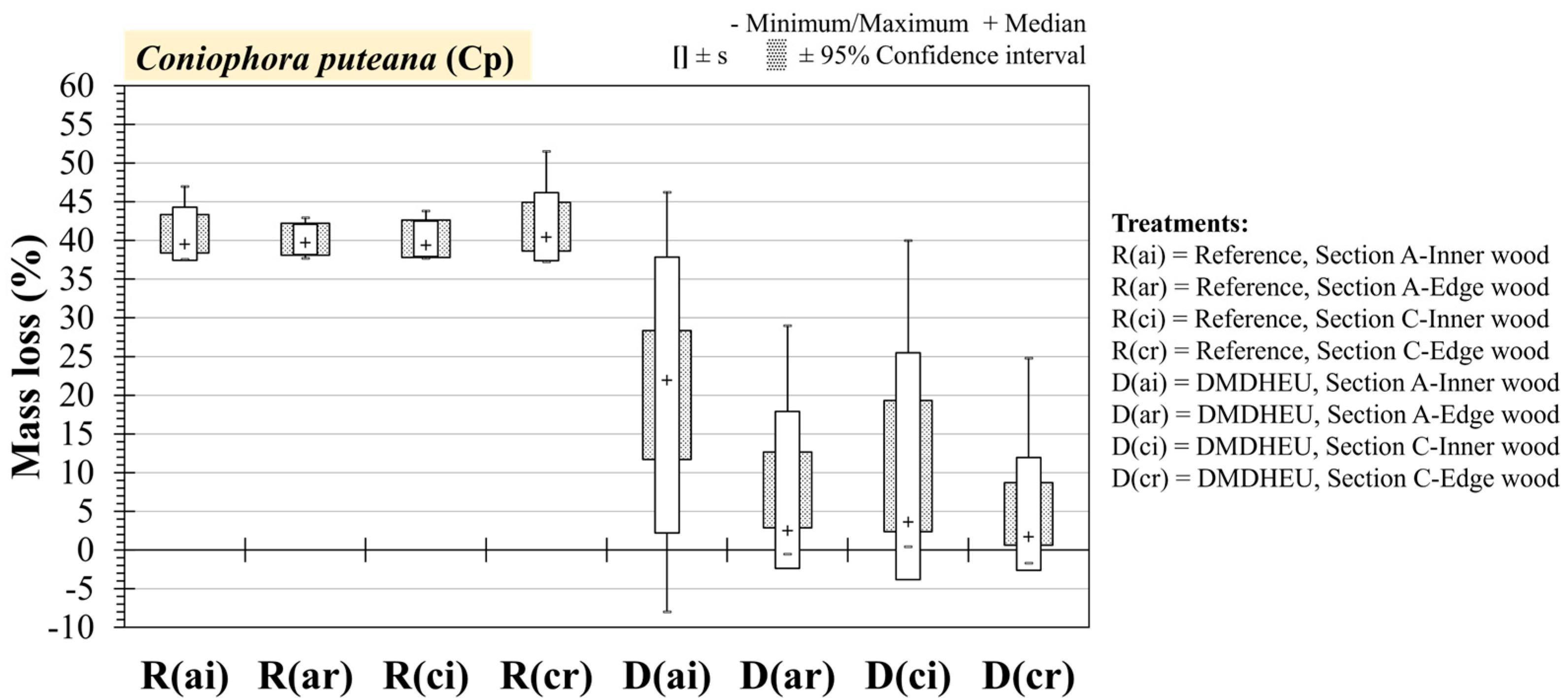

3.2. Fungi Test Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ax. | Axial |

| Cp | Coniophora puteana |

| DBH | Diameter at breast height |

| DMDHEU | 1.3-dimethylol-4.5-dihydroxyethyleneurea |

| long. | Longitudinal |

| MC | Moisture content |

| ML | Mass loss |

| RH | Relative humidity |

| Rp | Rhodonia placenta |

| SorCA | Sorbitol and citric acid |

| Tv | Trametes versicolor |

Appendix A

| Fungus | Treatment | Mean MC (%) | Median ML (%) | Mean ML (%) | SD ML (%) | DC | Mean DC |

|---|---|---|---|---|---|---|---|

| Cp | S | 54.62 | 1.18 | 1.14 | 0.37 | 1 | 1.00 |

| A | 50.92 | −0.42 | −0.49 | 0.61 | 1 | 1.00 | |

| K | 50.20 | 0.52 | 0.53 | 0.22 | 1 | 1.00 | |

| D | 70.55 | 3.15 | 11.32 | 14.27 | 1 | 2.22 | |

| R | 73.34 | 39.44 | 40.90 | 3.26 | 5 | 5.00 | |

| B | 69.05 | 41.15 | 41.47 | 2.40 | 5 | 5.00 | |

| Rp | S | 29.61 | 1.84 | 1.88 | 0.47 | 1 | 1.00 |

| A | 17.86 | 0.05 | 0.11 | 1.09 | 1 | 1.01 | |

| K | 31.74 | 0.92 | 1.40 | 1.47 | 1 | 1.06 | |

| D | 41.50 | 0.49 | 0.73 | 1.15 | 1 | 1.01 | |

| R | 91.14 | 19.08 | 18.85 | 4.05 | 4 | 3.81 | |

| B | 92.31 | 17.14 | 17.60 | 1.60 | 4 | 3.97 | |

| Tv | S | 52.07 | 1.20 | 1.24 | 0.35 | 1 | 1.00 |

| A | 23.83 | 0.23 | 0.27 | 0.78 | 1 | 1.00 | |

| K | 55.72 | 1.98 | 2.01 | 0.69 | 1 | 1.00 | |

| D | 79.63 | 1.62 | 2.24 | 1.77 | 1 | 1.07 | |

| R | 57.08 | 19.95 | 19.45 | 2.13 | 4 | 3.97 | |

| B | 60.23 | 41.32 | 40.36 | 6.51 | 5 | 4.93 |

| Fungus | Treatment | Mean MC (%) | Median ML (%) | Mean ML (%) | SD ML (%) | DC | Mean DC |

|---|---|---|---|---|---|---|---|

| Cp | S(A) | 54.69 | 1.14 | 1.07 | 0.39 | 1 | 1.00 |

| S(C) | 54.53 | 1.20 | 1.23 | 0.31 | 1 | 1.00 | |

| A(A) | 50.88 | −0.44 | −0.41 | 0.21 | 1 | 1.00 | |

| A(C) | 50.96 | −0.40 | −0.57 | 0.85 | 1 | 1.00 | |

| K(A) | 50.79 | 0.49 | 0.49 | 0.21 | 1 | 1.00 | |

| K(C) | 49.54 | 0.54 | 0.56 | 0.22 | 1 | 1.00 | |

| D(A) | 69.67 | 4.13 | 14.06 | 15.49 | 1 | 2.56 | |

| D(C) | 71.73 | 2.25 | 7.64 | 11.48 | 1 | 1.76 | |

| R(A) | 72.55 | 39.52 | 40.59 | 2.83 | 5 | 5.00 | |

| R(C) | 74.14 | 39.43 | 41.20 | 3.62 | 5 | 5.00 | |

| B | 69.05 | 41.15 | 41.47 | 2.40 | 5 | 5.00 | |

| Rp | S(A) | 29.07 | 1.74 | 1.78 | 0.42 | 1 | 1.00 |

| S(C) | 30.26 | 1.86 | 2.00 | 0.49 | 1 | 1.00 | |

| A(A) | 17.35 | 0.06 | 0.19 | 1.10 | 1 | 1.03 | |

| A(C) | 18.32 | 0.03 | 0.03 | 1.07 | 1 | 1.00 | |

| K(A) | 31.77 | 0.82 | 1.33 | 1.45 | 1 | 1.06 | |

| K(C) | 31.71 | 1.03 | 1.48 | 1.48 | 1 | 1.06 | |

| D(A) | 42.61 | 0.57 | 0.92 | 1.49 | 1 | 1.03 | |

| D(C) | 40.09 | 0.46 | 0.50 | 0.28 | 1 | 1.00 | |

| R(A) | 90.59 | 20.04 | 20.16 | 3.79 | 4 | 3.88 | |

| R(C) | 91.69 | 17.29 | 17.54 | 3.87 | 4 | 3.75 | |

| B | 92.31 | 17.14 | 17.60 | 1.60 | 4 | 3.97 | |

| Tv | S(A) | 50.62 | 1.17 | 1.19 | 0.34 | 1 | 1.00 |

| S(C) | 53.71 | 1.28 | 1.29 | 0.35 | 1 | 1.00 | |

| A(A) | 24.14 | 0.19 | 0.14 | 0.61 | 1 | 1.00 | |

| A(C) | 23.46 | 0.25 | 0.42 | 0.91 | 1 | 1.00 | |

| K(A) | 56.79 | 1.97 | 1.94 | 0.48 | 1 | 1.00 | |

| K(C) | 54.44 | 1.99 | 2.09 | 0.86 | 1 | 1.00 | |

| D(A) | 82.31 | 1.91 | 2.60 | 2.09 | 1 | 1.12 | |

| D(C) | 76.96 | 1.37 | 1.88 | 1.27 | 1 | 1.03 | |

| R(A) | 57.93 | 19.86 | 19.49 | 1.90 | 4 | 3.94 | |

| R(C) | 56.23 | 20.15 | 19.40 | 2.33 | 4 | 4.00 | |

| B | 60.23 | 41.32 | 40.36 | 6.51 | 5 | 4.93 |

| Fungus | Treatment | Mean MC (%) | Median ML (%) | Mean ML (%) | SD ML (%) | DC | Mean DC |

|---|---|---|---|---|---|---|---|

| Cp | S(i) | 51.76 | 1.17 | 1.17 | 0.28 | 1 | 1.00 |

| S(r) | 57.48 | 1.23 | 1.12 | 0.44 | 1 | 1.00 | |

| A(i) | 52.75 | −0.40 | −0.54 | 0.84 | 1 | 1.00 | |

| A(r) | 49.09 | −0.44 | −0.43 | 0.18 | 1 | 1.00 | |

| K(i) | 50.46 | 0.54 | 0.58 | 0.27 | 1 | 1.00 | |

| K(r) | 49.94 | 0.50 | 0.48 | 0.14 | 1 | 1.00 | |

| D(i) | 73.23 | 8.13 | 16.24 | 16.75 | 2 | 2.76 | |

| D(r) | 67.87 | 2.05 | 6.40 | 8.87 | 1 | 1.68 | |

| R(i) | 73.88 | 39.44 | 40.62 | 2.90 | 5 | 5.00 | |

| R(r) | 72.81 | 39.76 | 41.17 | 3.57 | 5 | 5.00 | |

| B | 69.05 | 41.15 | 41.47 | 2.40 | 5 | 5.00 | |

| Rp | S(i) | 29.34 | 1.85 | 1.95 | 0.57 | 1 | 1.00 |

| S(r) | 29.89 | 1.83 | 1.81 | 0.32 | 1 | 1.00 | |

| A(i) | 17.69 | 0.11 | 0.27 | 1.49 | 1 | 1.03 | |

| A(r) | 18.04 | 0.00 | −0.06 | 0.31 | 1 | 1.00 | |

| K(i) | 32.68 | 1.38 | 2.00 | 1.64 | 1 | 1.09 | |

| K(r) | 30.81 | 0.51 | 0.80 | 0.94 | 1 | 1.03 | |

| D(i) | 42.31 | 0.53 | 0.90 | 1.57 | 1 | 1.03 | |

| D(r) | 40.69 | 0.48 | 0.57 | 0.36 | 1 | 1.00 | |

| R(i) | 92.44 | 19.57 | 19.51 | 5.30 | 4 | 3.69 | |

| R(r) | 89.84 | 18.11 | 18.20 | 1.96 | 4 | 3.94 | |

| B | 92.31 | 17.14 | 17.60 | 1.60 | 4 | 3.97 | |

| Tv | S(i) | 48.31 | 1.12 | 1.13 | 0.28 | 1 | 1.00 |

| S(r) | 55.83 | 1.44 | 1.35 | 0.38 | 1 | 1.00 | |

| A(i) | 22.07 | 0.31 | 0.40 | 1.05 | 1 | 1.00 | |

| A(r) | 25.58 | 0.08 | 0.13 | 0.28 | 1 | 1.00 | |

| K(i) | 56.65 | 2.23 | 2.35 | 0.59 | 1 | 1.00 | |

| K(r) | 54.78 | 1.78 | 1.66 | 0.60 | 1 | 1.00 | |

| D(i) | 80.62 | 1.66 | 2.42 | 2.03 | 1 | 1.09 | |

| D(r) | 78.65 | 1.59 | 2.06 | 1.44 | 1 | 1.06 | |

| R(i) | 57.08 | 20.68 | 19.95 | 2.10 | 4 | 3.94 | |

| R(r) | 57.08 | 18.81 | 18.95 | 2.04 | 4 | 4.00 | |

| B | 60.23 | 41.32 | 40.36 | 6.51 | 5 | 4.93 |

| Fungus | Treatment | Mean MC (%) | Median ML (%) | Mean ML (%) | SD ML (%) | DC | Mean DC |

|---|---|---|---|---|---|---|---|

| Cp | R(Ai) | 74.01 | 39.52 | 40.86 | 3.27 | 5 | 5.00 |

| R(Ar) | 70.12 | 39.70 | 40.15 | 1.79 | 5 | 5.00 | |

| R(Ci) | 73.65 | 39.38 | 40.21 | 2.10 | 5 | 5.00 | |

| R(Cr) | 74.43 | 40.45 | 41.79 | 4.17 | 5 | 5.00 | |

| D(Ai) | 70.19 | 20.25 | 19.26 | 17.49 | 4 | 3.16 | |

| D(Ar) | 69.18 | 2.49 | 7.77 | 9.86 | 1 | 1.84 | |

| D(Ci) | 77.64 | 3.63 | 10.83 | 14.14 | 1 | 2.07 | |

| D(Cr) | 66.22 | 1.73 | 4.67 | 7.05 | 1 | 1.47 |

References

- Schrader, L.; Brischke, C.; Trautner, J.; Tebbe, C.C. Microbial Decay of Wooden Structures: Actors, Activities and Means of Protection. Appl. Microbiol. Biotechnol. 2025, 109, 59. [Google Scholar] [CrossRef] [PubMed]

- Sandberg, D.; Kutnar, A.; Karlsson, O.; Jones, D. Wood Modification Technologies: Principles, Sustainability, and the Need for Innovation, 1st ed.; CRC Press: Boca Raton, FL, USA, 2021; ISBN 978-1-138-49177-9. [Google Scholar]

- Hill, C. Wood Modification: An Update. BioResources 2011, 6, 918–919. [Google Scholar] [CrossRef]

- Emmerich, L.; Bollmus, S.; Militz, H. Wood Modification with DMDHEU (1.3-Dimethylol-4.5-Dihydroxyethyleneurea)—State of the Art, Recent Research Activities and Future Perspectives. Wood Mater. Sci. Eng. 2019, 14, 3–18. [Google Scholar] [CrossRef]

- Kurkowiak, K.; Emmerich, L.; Militz, H. Wood Chemical Modification Based on Bio-Based Polycarboxylic Acid and Polyols—Status Quo and Future Perspectives. Wood Mater. Sci. Eng. 2022, 17, 1040–1054. [Google Scholar] [CrossRef]

- Zelinka, S.L.; Altgen, M.; Emmerich, L.; Guigo, N.; Keplinger, T.; Kymäläinen, M.; Thybring, E.E.; Thygesen, L.G. Review of Wood Modification and Wood Functionalization Technologies. Forests 2022, 13, 1004. [Google Scholar] [CrossRef]

- Zhou, T.; Liu, H. Research Progress of Wood Cell Wall Modification and Functional Improvement: A Review. Materials 2022, 15, 1598. [Google Scholar] [CrossRef] [PubMed]

- Mantanis, G. Chemical Modification of Wood by Acetylation or Furfurylation: A Review of the Present Scaled-up Technologies. BioResources 2017, 12, 4478–4489. [Google Scholar] [CrossRef]

- Tarmian, A.; Zahedi Tajrishi, I.; Oladi, R.; Efhamisisi, D. Treatability of Wood for Pressure Treatment Processes: A Literature Review. Eur. J. Wood Wood Prod. 2020, 78, 635–660. [Google Scholar] [CrossRef]

- Wang, J.; DeGroot, R. Treatability and Durability of Heartwood; Forest Products Laboratory: Madison, WI, USA, 1996. [Google Scholar]

- EN 350:2016; Durability of Wood and Wood-Based Products—Testing and Classification of the Durability to Biological Agents of Wood and Wood-Based Materials. International Organization for Standardization: Geneva, Switzerland, 2016.

- Lande, S.; Høibø, O.; Larnøy, E. Variation in Treatability of Scots Pine (Pinus sylvestris) by the Chemical Modification Agent Furfuryl Alcohol Dissolved in Water. Wood Sci. Technol. 2010, 44, 105–118. [Google Scholar] [CrossRef]

- Zimmer, K.P.; Høibø, O.A.; Vestøl, G.I.; Larnøy, E. Variation in Treatability of Scots Pine Sapwood: A Survey of 25 Different Northern European Locations. Wood Sci. Technol. 2014, 48, 1049–1068. [Google Scholar] [CrossRef]

- Riedel, T.; Bender, S.; Hennig, P.; Kroiher, F.; Schnell, S.; Schwitzgebel, F.; Stauber, T.; Stahlmann, J.K.; Kühling, M. Der Wald in Deutschland: Ausgewählte Ergebnisse der Vierten Bundeswaldinventur; BMEL: Bonn, Germany, 2024. [Google Scholar]

- Spathelf, P.; Ammer, C. Forest Management of Scots Pine (Pinus sylvestris L.) in Northern Germany—A Brief Review of the History and Current Trends. Forstarchiv 2015, 86, 59–66. [Google Scholar] [CrossRef]

- Knocke, H.C.; Axer, M.; Hamkens, H.F.; Fischer, C.; Hansen, J.H.; Nagel, R.-V.; Albert, M. Quo Vadis Scots Pine Forestry in Northern Germany: How Do Silvicultural Management and Climate Change Determine an Uncertain Future? Eur. J. For. Res. 2024, 143, 1477–1497. [Google Scholar] [CrossRef]

- EN 113-2:2020; Durability of Wood and Wood-Based Products—Test Method against Wood Destroying Basidiomycetes—Part 2: Assessment of Inherent or Enhanced Durability. International Organization for Standardization: Geneva, Switzerland, 2020.

- Kurkowiak, K.; Mayer, A.K.; Emmerich, L.; Militz, H. Investigations of the Chemical Distribution in Sorbitol and Citric Acid (SorCA) Treated Wood—Development of a Quality Control Method on the Basis of Electromagnetic Radiation. Forests 2022, 13, 151. [Google Scholar] [CrossRef]

- Klüppel, A.; Mai, C. The influence of curing conditions on the chemical distribution in wood modified with thermosetting resins. Wood Sci. Technol. 2013, 47, 643–658. [Google Scholar] [CrossRef]

- Emmerich, L.; Militz, H.; Brischke, C. Long-Term Performance of DMDHEU-Treated Wood Installed in Different Test Set-Ups in Ground, above Ground and in the Marine Environment. Int. Wood Prod. J. 2020, 11, 27–37. [Google Scholar] [CrossRef]

- Emmerich, L. Wood Modification with Cyclic N-methylol and N-methyl Compounds: Studies on the Mode of Action. Ph.D. Thesis, Georg-August-University Göttingen, Göttingen, Germany, 2021. [Google Scholar]

- Schaffert, S. Steuerung und Optimierung von Holzvernetzungsprozessen. Ph.D. Thesis, University of Goettingen, Göttingen, Germany, 2006. [Google Scholar]

- Krause, A. Holzmodifizierung mit N-Methylolvernetzern; Sierke: Göttingen, Germany, 2006. [Google Scholar]

- Houston Durrant, T.; de Rigo, D.; Caudullo, G. Pinus sylvestris in Europe: Distribution, Habitat, Usage and Threats. In European Atlas of Forest Tree Species; Publication Office EU: Luxembourg, 2016. [Google Scholar]

| Abbreviation | Modification | Institution | Board Dimensions [mm] | Concentration/ WPG (%) |

|---|---|---|---|---|

| S | Sorbitol/citric acid (SorCA) | University of Göttingen, Göttingen, Germany | 35 × 85 × 1700 (long) | 30/19.5 |

| A | Acetylation | Accsys, Arnhem, The Netherlands | 32 × 75 × 2500 (long) or 32 × 100 × 2500 (long) | -/22.8 |

| K | Furfurylation | Kebony, Skien, Norway | 32 × 75 × 2500 (long) or 32 × 100 × 2500 (long) | -/57.6 |

| D | DMDHEU | University of Göttingen, Göttingen, Germany | 30 × 145 × 1400 (long) | 25/32.3 |

| R | None (reference) | University of Göttingen, Göttingen, Germany | / | / |

| B | None (untreated beech) | University of Göttingen, Göttingen, Germany | / | / |

| Durability Class | Description | Median Mass Loss (%) |

|---|---|---|

| DC1 | Highly durable | ≤5 |

| DC2 | Durable | >5 to ≤10 |

| DC3 | Moderately durable | >10 to ≤15 |

| DC4 | Slightly durable | >15 to ≤30 |

| DC5 | Not durable | >30 |

| Treatment | % | |

|---|---|---|

| DMDHEU | A | 77.71 |

| C | 82.43 | |

| Acetylated | A | 93.27 |

| C | 93.30 | |

| Furfurylated | A | 95.35 |

| C | 85.11 | |

| SorCA | A | 86.12 |

| C | 79.10 | |

| Reference | A | 93.34 |

| C | 95.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martin, L.S.; Stolze, H.; Hötte, C.; Militz, H. Investigating the Efficacy of Established Chemical Wood Modifications on Large-Diameter Pine: Durability Against Basidiomycetes. Materials 2025, 18, 2985. https://doi.org/10.3390/ma18132985

Martin LS, Stolze H, Hötte C, Militz H. Investigating the Efficacy of Established Chemical Wood Modifications on Large-Diameter Pine: Durability Against Basidiomycetes. Materials. 2025; 18(13):2985. https://doi.org/10.3390/ma18132985

Chicago/Turabian StyleMartin, Lucy S., Hannes Stolze, Christoph Hötte, and Holger Militz. 2025. "Investigating the Efficacy of Established Chemical Wood Modifications on Large-Diameter Pine: Durability Against Basidiomycetes" Materials 18, no. 13: 2985. https://doi.org/10.3390/ma18132985

APA StyleMartin, L. S., Stolze, H., Hötte, C., & Militz, H. (2025). Investigating the Efficacy of Established Chemical Wood Modifications on Large-Diameter Pine: Durability Against Basidiomycetes. Materials, 18(13), 2985. https://doi.org/10.3390/ma18132985