Life Cycle Assessment and Performance Evaluation of Self-Compacting Concrete Incorporating Waste Marble Powder and Aggregates

Highlights

- 5% waste marble powder enhances SCC compressive strength.

- Optimal fine-aggregate substitution at 30% waste marble aggregate.

- Marble waste significantly improves SCC acid resistance.

- Life-cycle assessment shows 20% lower carbon footprint.

- 10% marble powder mix offers best eco-mechanical performance.

Abstract

1. Introduction

2. Research Significance

3. Materials and Mix Design

3.1. Materials Characteristics

3.1.1. Binder

3.1.2. Aggregates

3.1.3. Chemical Admixture

3.1.4. Water

3.2. Mix Proportions

3.3. Test Program

3.3.1. Compressive Strength Test

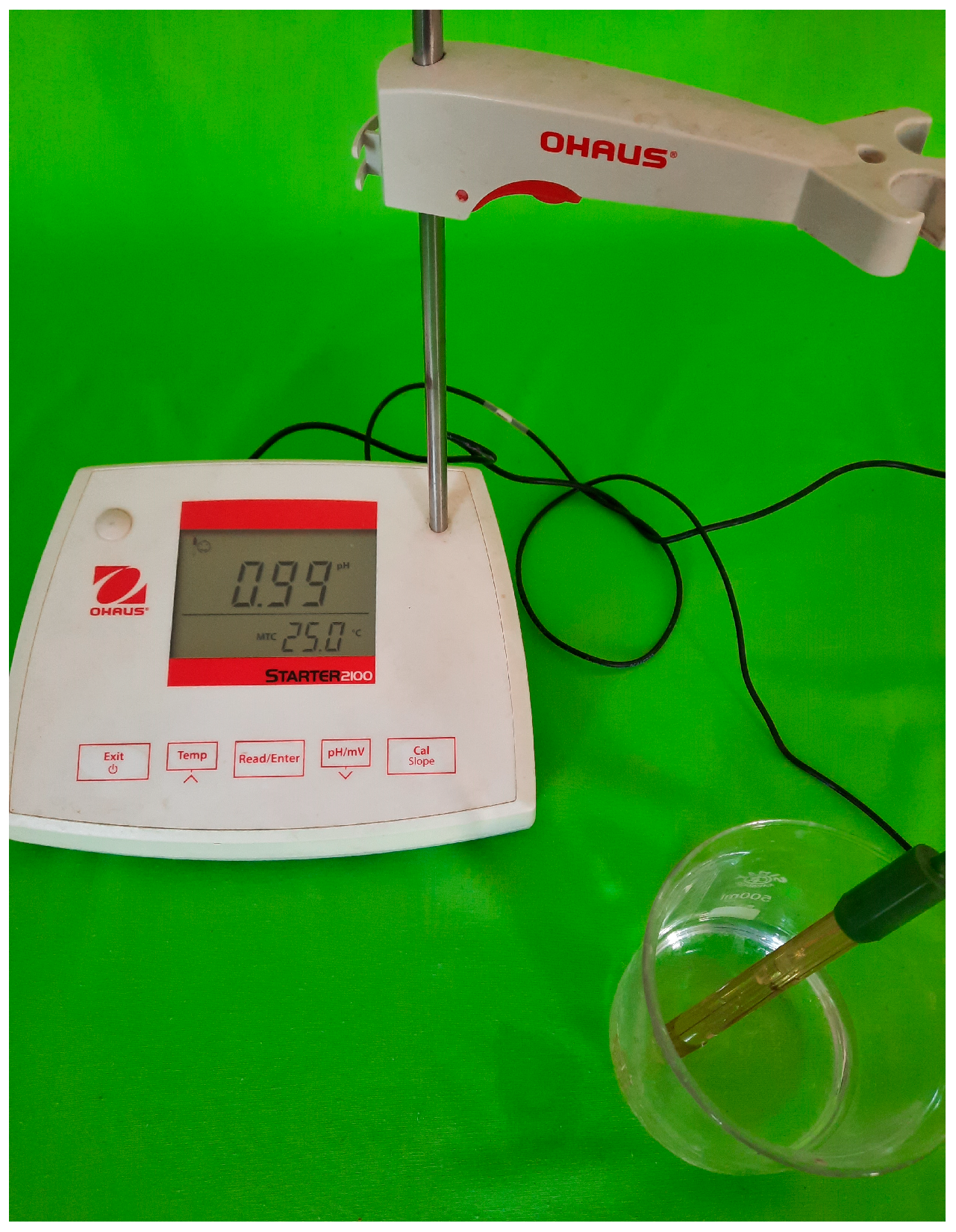

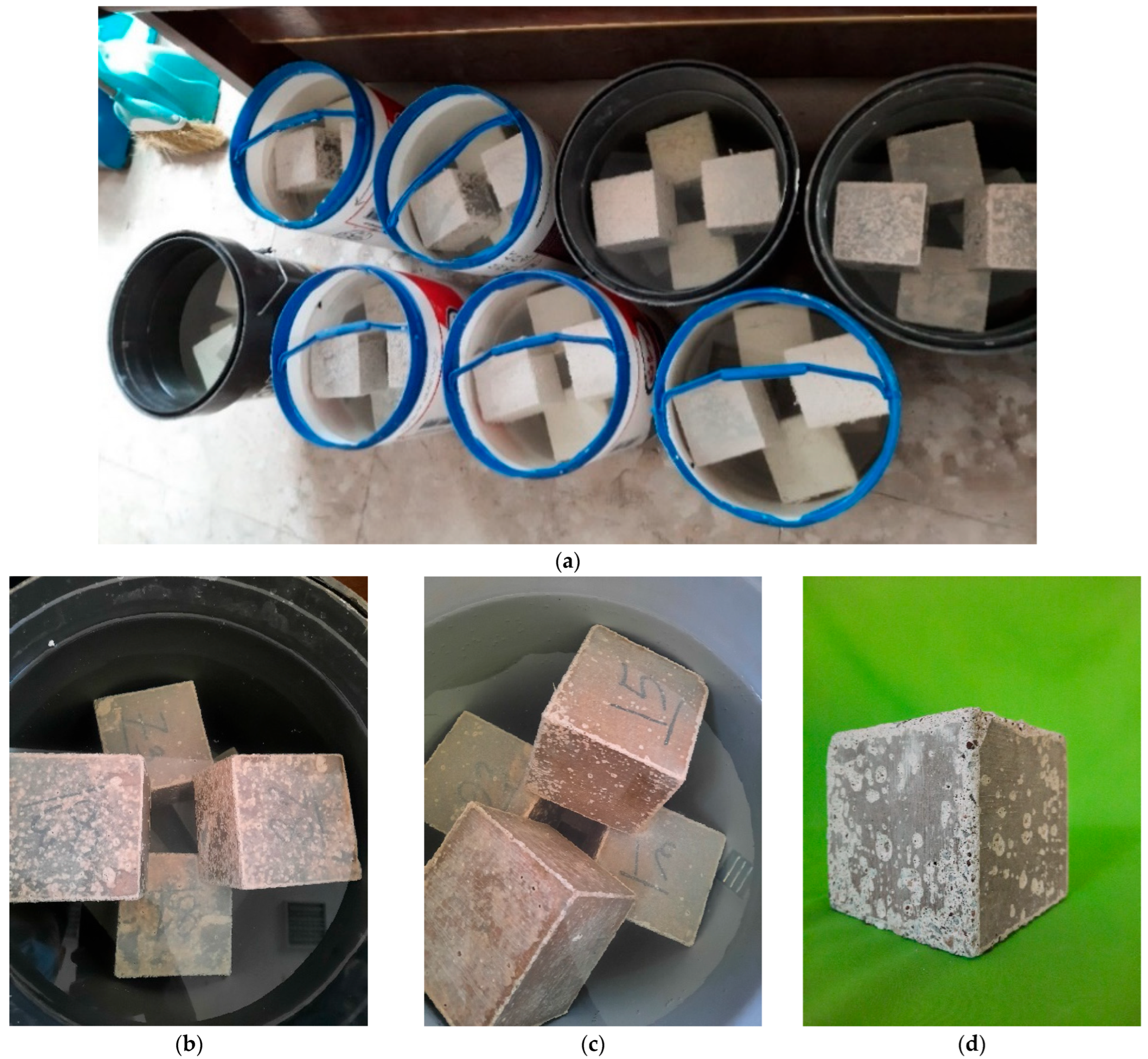

3.3.2. Sulfuric Acid Attack Test

4. Results and Discussion

4.1. Mechanical and Durability Properties

4.1.1. Compressive Strength

Effect of WMP as OPC Replacement

Effect of WMA as Fine Aggregate Replacement

4.1.2. Resistance to Sulfuric Acid Attack

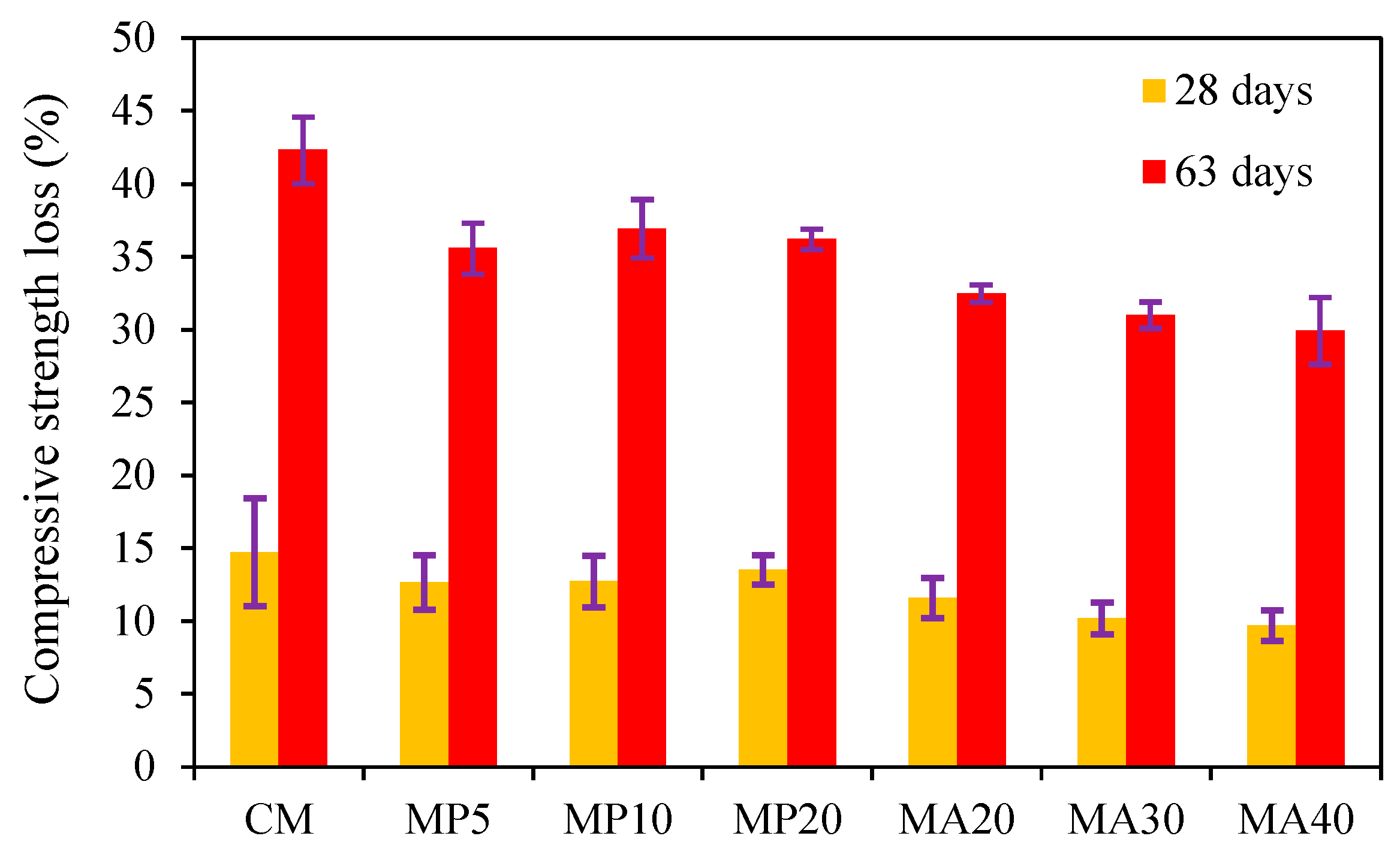

Compressive Strength Loss

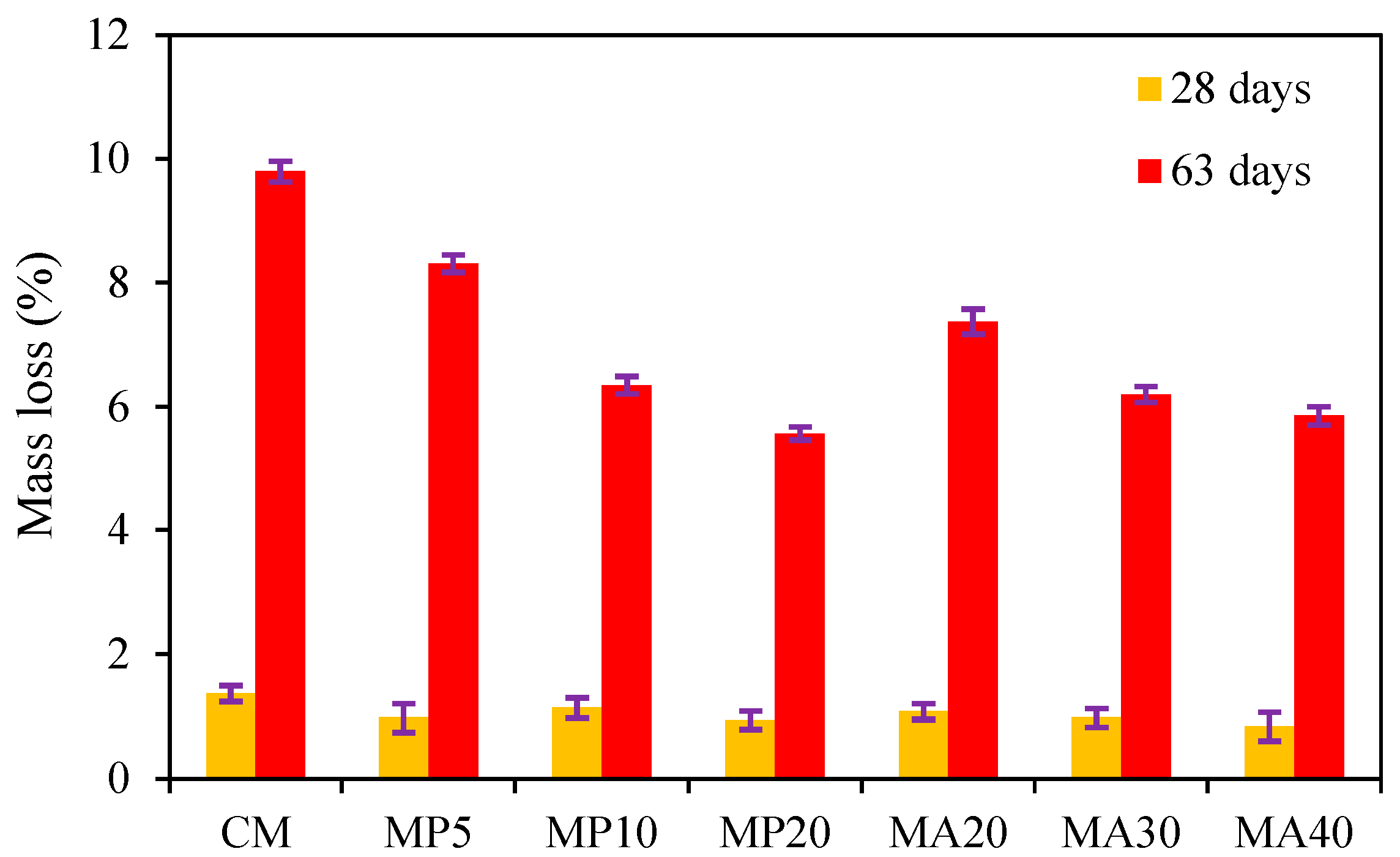

Mass Loss

4.2. Life Cycle Assessment

4.2.1. Environmental Indicators

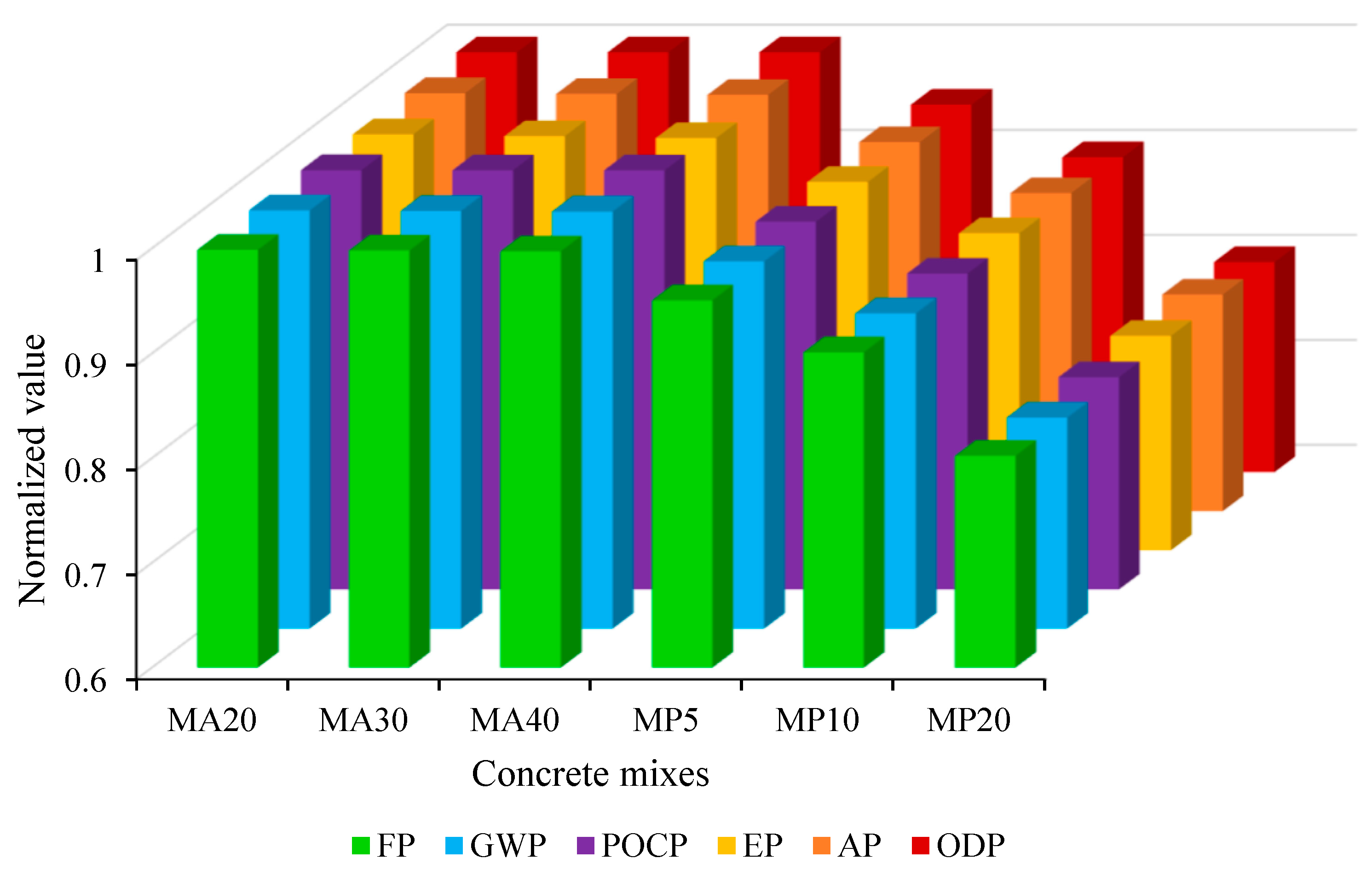

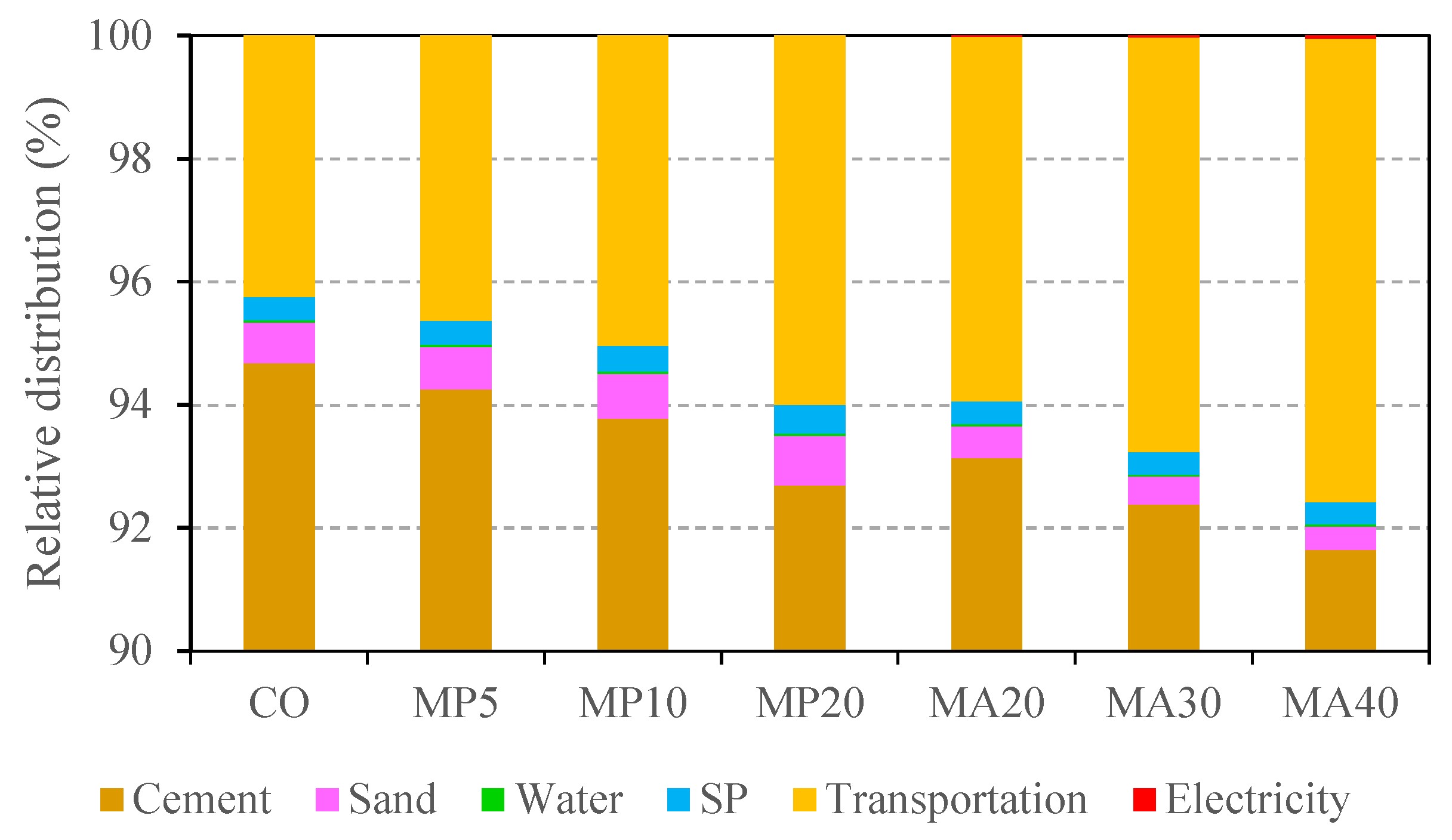

Overview of Results

| Indicator | ODP | AP | EP | POCP | GWP | FP |

|---|---|---|---|---|---|---|

| Unit | kg R11/kg | kg SO2/kg | kg PO4/kg | kg C2H4/kg | kg CO2/kg | MJ/kg |

| Cement | 7.22 × 10−9 | 1.72 × 10−3 | 2.10 × 10−4 | 1.70 × 10−4 | 0.7634 | 4.727 |

| Water | 3.01 × 10−11 | 1.31 × 10−4 | 7.28 × 10−7 | 5.88 × 10−8 | 0.0025 | 0.00574 |

| Natural fine agg. | 0.00 | 9.58 × 10−6 | 2.49 × 10−6 | 1.25 × 10−7 | 0.0028 | 0.022 |

| Superplasticizer | 2.30 × 10−10 | 2.92 × 10−3 | 1.03 × 10−3 | 2.12 × 10−3 | 0.7670 | 18.3 |

| Sources | [60] | [60] | [60] | [60] | [53,58] | [61] |

| Mix ID | ODP (kg R11/kg) | AP (kg SO2/kg) | EP (kg PO4/kg) | POCP (kg C2H4/kg) | GWP (kg CO2/kg) | FP (MJ/kg) |

|---|---|---|---|---|---|---|

| CO | 0.000006796 | 1.6725158 | 0.2021187 | 0.1620291 | 707.63364 | 4397.725856 |

| MP5 | 0.000006457 | 1.5916758 | 0.1922487 | 0.1540391 | 672.51724 | 4180.283856 |

| MP10 | 0.000006117 | 1.5108358 | 0.1823787 | 0.1460491 | 637.40084 | 3962.841856 |

| MP20 | 0.000005439 | 1.3491558 | 0.1626387 | 0.1300691 | 567.16804 | 3527.957856 |

| MA20 | 0.000006796 | 1.6698142 | 0.2014165 | 0.1619939 | 706.86084 | 4391.653856 |

| MA30 | 0.000006796 | 1.6684635 | 0.2010654 | 0.1619763 | 706.47444 | 4388.617856 |

| MA40 | 0.000006796 | 1.6671127 | 0.2007143 | 0.1619586 | 706.08804 | 4385.581856 |

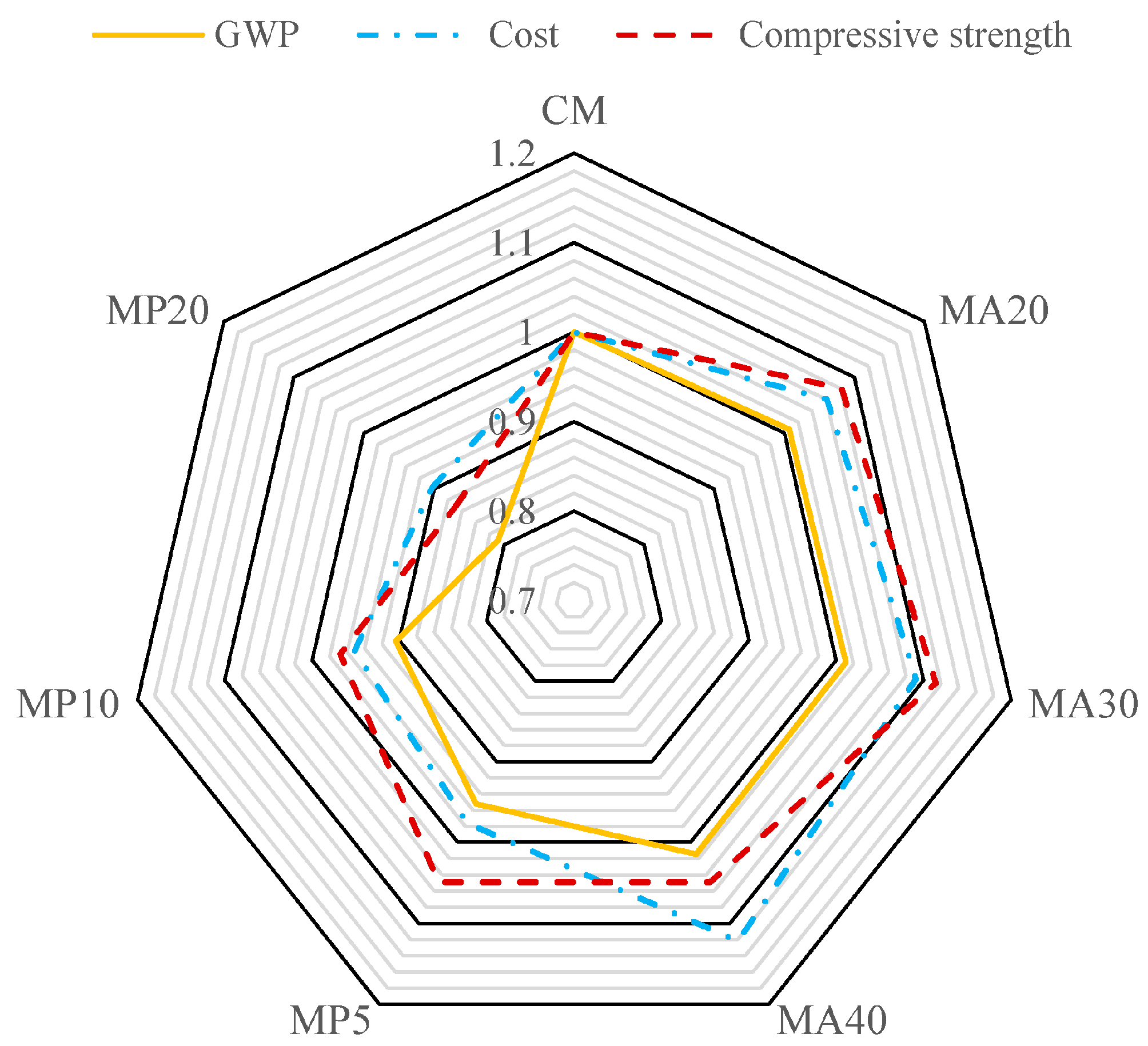

4.2.2. Eco-Cost-Mechanical Assessment

4.2.3. Optimization of Triple Indicators

5. Conclusions

- Mechanical performance: the optimal mechanical performance was achieved with 5% cement replacement by WMP, where improved matrix densification and particle packing enhanced compressive strength. However, higher WMP levels (10–20%) led to strength reductions due to dilution of reactive binders. In contrast, replacing natural sand with WMA at 20–40% consistently improved strength—peaking at 30% with an 11.5% increase—driven by superior particle grading, enhanced packing density, and improved interfacial transition zone characteristics.

- Durability in acidic environments: all SCC mixtures incorporating marble waste exhibited enhanced resistance to sulfuric acid exposure relative to the control. The MP20 and MA40 mixes showed the least mass and strength losses after 63 days, indicating superior chemical durability. This improvement is attributed to the formation of a temporary protective gypsum layer from the reaction between calcium carbonate and sulfuric acid, which helped slow surface degradation and maintain structural integrity.

- Environmental and economic benefits: The results demonstrated that replacing cement with WMP significantly reduced the GWP by 5% to 20% for substitution levels of 5% to 20%, highlighting the dominant role of cement in concrete’s environmental footprint. In contrast, the use of WMA as a partial sand replacement had minimal effect on GWP. From an economic standpoint, WMP substitution also proved more beneficial, reducing production costs by up to 10%, whereas mixes with WMA showed increased costs of up to 12% compared to the control. These findings confirm the environmental and economic advantages of WMP over WMA in sustainable SCC design.

- Integrated sustainability optimization: multi-criteria optimization using desirability functions identified MP10 (10% WMP) as the most balanced and sustainable mix, effectively integrating strength, durability, environmental, and economic performance. Although MP20 offered the highest environmental gain, its compromised mechanical strength limited its structural applicability.

- Explore combined replacement strategies involving both WMP and WMA (e.g., MP5MA20, MP10MA30) to assess potential synergistic enhancements in mechanical, durability, and environmental performance;

- Investigate the integration of marble waste with supplementary industrial materials such as fly ash, ground granulated blast furnace slag, or ceramic waste to optimize binder efficiency and sustainability;

- Assess the long-term performance and durability of marble waste-incorporated SCC under realistic environmental exposures, including variable temperature, humidity, and aggressive chemical conditions;

- Extend the application of marble waste into advanced cementitious systems, including high-performance concrete, ultra-high-performance concrete, and alkali-activated/geopolymer matrices;

- Employ advanced microstructural characterization techniques (e.g., SEM, XRD, MIP, FTIR) to elucidate the underlying mechanisms governing strength development, durability enhancement, and chemical resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nouhoun, I.S.; Nshimiyimana, P.; Hema, C.; Messan, A. Development of a Life Cycle Inventory Database for Environmental Impact Assessment of Construction Materials in Burkina Faso. Sustainability 2025, 17, 471. [Google Scholar] [CrossRef]

- Khataei, B.; Ahmadi, M.; Kioumarsi, M. Environmental Assessment of Fiber-Reinforced Self-Compacting Concrete Containing Class-F Fly Ash. In The International Conference on Net-Zero Civil Infrastructures: Innovations in Materials, Structures, and Management Practices (NTZR); Springer: Berlin/Heidelberg, Germany, 2025; pp. 377–388. [Google Scholar]

- Kontoni, D.-P.N.; Ahmadi, M. Practical Prediction of Ultimate Axial Strain and Peak Axial Stress of FRP-Confined Concrete Using Hybrid ANFIS-PSO Models. In Artificial Intelligence Applications for Sustainable Construction; Elsevier: Amsterdam, The Netherlands, 2024; pp. 225–255. [Google Scholar]

- Herki, B.M.A. Strength and Absorption Study on Eco-Efficient Concrete Using Recycled Powders as Mineral Admixtures under Various Curing Conditions. Recycling 2024, 9, 99. [Google Scholar] [CrossRef]

- Luo, H.; Aguiar, J.; Wan, X.; Wang, Y.; Cunha, S.; Jia, Z. Application of Aggregates from Construction and Demolition Wastes in Concrete: Review. Sustainability 2024, 16, 4277. [Google Scholar] [CrossRef]

- Lu, L. Optimal Replacement Ratio of Recycled Concrete Aggregate Balancing Mechanical Performance with Sustainability: A Review. Buildings 2024, 14, 2204. [Google Scholar] [CrossRef]

- Zamani, A.A.; Ahmadi, M.; Dalvand, A.; Aslani, F. Effect of Single and Hybrid Fibers on Mechanical Properties of High-Strength Self-Compacting Concrete Incorporating 100% Waste Aggregate. J. Mater. Civ. Eng. 2023, 35, 04022365. [Google Scholar] [CrossRef]

- Ige, O.E.; Von Kallon, D.V.; Desai, D. Carbon Emissions Mitigation Methods for Cement Industry Using a Systems Dynamics Model. Clean Technol. Environ. Policy 2024, 26, 579–597. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z.; Deifalla, A.F. Self-Compacting Concrete with Partially Substitution of Waste Marble: A Review. Int. J. Concr. Struct. Mater. 2023, 17, 25. [Google Scholar] [CrossRef]

- Kuoribo, E.; Mahmoud, H. Utilisation of Waste Marble Dust in Concrete Production: A Scientometric Review and Future Research Directions. J. Clean. Prod. 2022, 374, 133872. [Google Scholar] [CrossRef]

- Song, W.; Wang, Q.; Qu, L.; Li, X.; Xu, S. Study of Water Absorption and Corrosion Resistance of the Mortar with Waste Marble Powder. Constr. Build. Mater. 2022, 345, 128235. [Google Scholar] [CrossRef]

- Mangi, S.A.; Raza, M.S.; Khahro, S.H.; Qureshi, A.S.; Kumar, R. Recycling of Ceramic Tiles Waste and Marble Waste in Sustainable Production of Concrete: A Review. Environ. Sci. Pollut. Res. 2022, 29, 18311–18332. [Google Scholar] [CrossRef]

- Ince, C.; Hamza, A.; Derogar, S.; Ball, R.J. Utilisation of Waste Marble Dust for Improved Durability and Cost Efficiency of Pozzolanic Concrete. J. Clean. Prod. 2020, 270, 122213. [Google Scholar] [CrossRef]

- Ashish, D.K. Concrete Made with Waste Marble Powder and Supplementary Cementitious Material for Sustainable Development. J. Clean. Prod. 2019, 211, 716–729. [Google Scholar] [CrossRef]

- Şahan Arel, H. Recyclability of Waste Marble in Concrete Production. J. Clean. Prod. 2016, 131, 179–188. [Google Scholar] [CrossRef]

- Simão, L.; Souza, M.T.; Ribeiro, M.J.; Klegues Montedo, O.R.; Hotza, D.; Novais, R.M.; Raupp-Pereira, F. Assessment of the Recycling Potential of Stone Processing Plant Wastes Based on Physicochemical Features and Market Opportunities. J. Clean. Prod. 2021, 319, 128678. [Google Scholar] [CrossRef]

- Demirel, B.; Alyamaç, K.E. Waste Marble Powder/Dust. In Waste and Supplementary Cementitious Materials in Concrete: Characterisation, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 181–197. ISBN 9780081021569. [Google Scholar]

- Tressmann, D.M.G.A.; Pedroti, L.G.; de Carvalho, A.F.; Ribeiro, J.C.L.; de Paula Cardoso, F.; Lopes, M.M.S.; de Oliveira, A.F.; Ferreira, S.O. Research into the Use of Marble Waste as Mineral Filler in Soil Pigment-Based Paints and as an Active Pigment in Waterborne Paints. Constr. Build. Mater. 2020, 241, 117976. [Google Scholar] [CrossRef]

- Ahmadi, M.; Abdollahzadeh, E.; Kioumarsi, M. Using Marble Waste as a Partial Aggregate Replacement in the Development of Sustainable Self-Compacting Concrete. Mater. Today Proc. 2023, in press. [CrossRef]

- Tugrul Tunc, E. Recycling of Marble Waste: A Review Based on Strength of Concrete Containing Marble Waste. J. Environ. Manage. 2019, 231, 86–97. [Google Scholar] [CrossRef]

- Rana, A.; Kalla, P.; Verma, H.K.; Mohnot, J.K. Recycling of Dimensional Stone Waste in Concrete: A Review. J. Clean. Prod. 2016, 135, 312–331. [Google Scholar] [CrossRef]

- Silva, L.S.; Amario, M.; Stolz, C.M.; Figueiredo, K.V.; Haddad, A.N. A Comprehensive Review of Stone Dust in Concrete: Mechanical Behavior, Durability, and Environmental Performance. Buildings 2023, 13, 1856. [Google Scholar] [CrossRef]

- Binici, H.; Shah, T.; Aksogan, O.; Kaplan, H. Durability of Concrete Made with Granite and Marble as Recycle Aggregates. J. Mater. Process. Technol. 2008, 208, 299–308. [Google Scholar] [CrossRef]

- Hebhoub, H.; Aoun, H.; Belachia, M.; Houari, H.; Ghorbel, E. Use of Waste Marble Aggregates in Concrete. Constr. Build. Mater. 2011, 25, 1167–1171. [Google Scholar] [CrossRef]

- Silva, D.; Gameiro, F.; de Brito, J. Mechanical Properties of Structural Concrete Containing Fine Aggregates from Waste Generated by the Marble Quarrying Industry. J. Mater. Civ. Eng. 2014, 26, 4014008. [Google Scholar] [CrossRef]

- Uygunoğlu, T.; Topçu, İ.B.; Çelik, A.G. Use of Waste Marble and Recycled Aggregates in Self-Compacting Concrete for Environmental Sustainability. J. Clean. Prod. 2014, 84, 691–700. [Google Scholar] [CrossRef]

- Vardhan, K.; Siddique, R.; Goyal, S. Influence of Marble Waste as Partial Replacement of Fine Aggregates on Strength and Drying Shrinkage of Concrete. Constr. Build. Mater. 2019, 228, 116730. [Google Scholar] [CrossRef]

- Benjeddou, O.; Ravindran, G.; Abdelzaher, M.A. Thermal and Acoustic Features of Lightweight Concrete Based on Marble Wastes and Expanded Perlite Aggregate. Buildings 2023, 13, 992. [Google Scholar] [CrossRef]

- Alyamaç, K.E.; Ince, R. A Preliminary Concrete Mix Design for SCC with Marble Powders. Constr. Build. Mater. 2009, 23, 1201–1210. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Auda, E.M. Re-Use of Waste Marble Dust in the Production of Cement and Concrete. Constr. Build. Mater. 2014, 50, 28–41. [Google Scholar] [CrossRef]

- Singh, M.; Srivastava, A.; Bhunia, D. Long Term Strength and Durability Parameters of Hardened Concrete on Partially Replacing Cement by Dried Waste Marble Powder Slurry. Constr. Build. Mater. 2019, 198, 553–569. [Google Scholar] [CrossRef]

- Lezzerini, M.; Luti, L.; Aquino, A.; Gallello, G.; Pagnotta, S. Effect of Marble Waste Powder as a Binder Replacement on the Mechanical Resistance of Cement Mortars. Appl. Sci. 2022, 12, 4481. [Google Scholar] [CrossRef]

- Jia, F.; Chen, L.; Zhang, J.; Hu, Q.; Wang, Y. Effect of Sodium Stearate Modified Waste Marble Powder on the Properties and Hydration of Cement Mortar. Constr. Build. Mater. 2025, 465, 140213. [Google Scholar] [CrossRef]

- Rana, A.; Kalla, P.; Csetenyi, L.J. Sustainable Use of Marble Slurry in Concrete. J. Clean. Prod. 2015, 94, 304–311. [Google Scholar] [CrossRef]

- De Maio, U.; Gaetano, D.; Greco, F.; Luciano, R.; Pranno, A. Degradation Analysis of Dynamic Properties for Plain Concrete Structures under Mixed-Mode Fracture Conditions via an Improved Cohesive Crack Approach. Fract. Struct. Integr. 2024, 18, 422–439. [Google Scholar] [CrossRef]

- Turcry, P.; Loukili, A.; Haidar, K.; Pijaudier-Cabot, G.; Belarbi, A. Cracking Tendency of Self-Compacting Concrete Subjected to Restrained Shrinkage: Experimental Study and Modeling. J. Mater. Civ. Eng. 2006, 18, 46–54. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Bilir, T.; Uygunoğlu, T. Effect of Waste Marble Dust Content as Filler on Properties of Self-Compacting Concrete. Constr. Build. Mater. 2009, 23, 1947–1953. [Google Scholar] [CrossRef]

- Alyamac, K.E.; Ghafari, E.; Ince, R. Development of Eco-Efficient Self-Compacting Concrete with Waste Marble Powder Using the Response Surface Method. J. Clean. Prod. 2017, 144, 192–202. [Google Scholar] [CrossRef]

- Danish, P.; Mohan Ganesh, G. Study on Influence of Metakaolin and Waste Marble Powder on Self-Compacting Concrete—A State of the Art Review. Mater. Today Proc. 2021, 44, 1428–1436. [Google Scholar] [CrossRef]

- Sadek, D.M.; El-Attar, M.M.; Ali, H.A. Reusing of Marble and Granite Powders in Self-Compacting Concrete for Sustainable Development. J. Clean. Prod. 2016, 121, 19–32. [Google Scholar] [CrossRef]

- Ergün, A. Effects of the Usage of Diatomite and Waste Marble Powder as Partial Replacement of Cement on the Mechanical Properties of Concrete. Constr. Build. Mater. 2011, 25, 806–812. [Google Scholar] [CrossRef]

- ASTM C150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C136; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM C494; Standard Specification for Chemical Admixtures for Concrete. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C1602; Standard Specification for Mixing Water Used in the Production of Hydraulic Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2022.

- BS EN 12390-3; Testing Hardened Concrete–Part 3: Compressive Strength of Test Specimens. BSI Knowledge: London, UK, 2009.

- ASTM C267; Standard Test Methods for Chemical Resistance of Mortars, Grouts, and Monolithic Surfacings and Polymer Concretes. ASTM International: West Conshohocken, PA, USA, 2012.

- Khodabakhshian, A.; Ghalehnovi, M.; de Brito, J.; Asadi Shamsabadi, E. Durability Performance of Structural Concrete Containing Silica Fume and Marble Industry Waste Powder. J. Clean. Prod. 2018, 170, 42–60. [Google Scholar] [CrossRef]

- Selim, F.A.; Hashem, F.S.; Amin, M.S. Mechanical, Microstructural and Acid Resistance Aspects of Improved Hardened Portland Cement Pastes Incorporating Marble Dust and Fine Kaolinite Sand. Constr. Build. Mater. 2020, 251, 118992. [Google Scholar] [CrossRef]

- Xiao, J.; Qu, W.; Li, W.; Zhu, P. Investigation on Effect of Aggregate on Three Non-Destructive Testing Properties of Concrete Subjected to Sulfuric Acid Attack. Constr. Build. Mater. 2016, 115, 486–495. [Google Scholar] [CrossRef]

- Xiao, J.; Long, X.; Li, L.; Jiang, H.; Zhang, Y.; Qu, W. Study on the Influence of Three Factors on Mass Loss and Surface Fractal Dimension of Concrete in Sulfuric Acid Environments. Fractal Fract. 2021, 5, 146. [Google Scholar] [CrossRef]

- Tennich, M.; Ben Ouezdou, M.; Kallel, A. Behavior of Self-Compacting Concrete Made with Marble and Tile Wastes Exposed to External Sulfate Attack. Constr. Build. Mater. 2017, 135, 335–342. [Google Scholar] [CrossRef]

- Khodabakhshian, A.; De Brito, J.; Ghalehnovi, M.; Shamsabadi, E.A. Mechanical, Environmental and Economic Performance of Structural Concrete Containing Silica Fume and Marble Industry Waste Powder. Constr. Build. Mater. 2018, 169, 237–251. [Google Scholar] [CrossRef]

- Khattab, M.; Jaradat, O.; Hachemi, S.; Suleiman, H.; Benzetta, H. Mechanical, Physical and Environmental Performance of Sustainable Concrete Containing Marble Wastes. Secur. Manag. Mod. Civ. Eng 2023, 2, 1–10. [Google Scholar]

- Ghanbari, M.; Abbasi, A.M.; Ravanshadnia, M. Production of Natural and Recycled Aggregates: The Environmental Impacts of Energy Consumption and CO2 Emissions. J. Mater. Cycles Waste Manag. 2018, 20, 810–822. [Google Scholar] [CrossRef]

- Coelho, A.; de Brito, J. Environmental Analysis of a Construction and Demolition Waste Recycling Plant in Portugal–Part I: Energy Consumption and CO2 Emissions. Waste Manag. 2013, 33, 1258–1267. [Google Scholar] [CrossRef]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative Environmental Assessment of Natural and Recycled Aggregate Concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef]

- Bennett, B.; Visintin, P.; Xie, T. Global Warming Potential of Recycled Aggregate Concrete with Supplementary Cementitious Materials. J. Build. Eng. 2022, 52, 104394. [Google Scholar] [CrossRef]

- Belaidi, A.S.E.; Azzouz, L.; Kadri, E.; Kenai, S. Effect of Natural Pozzolana and Marble Powder on the Properties of Self-Compacting Concrete. Constr. Build. Mater. 2012, 31, 251–257. [Google Scholar] [CrossRef]

- Gholami, E.; Afshin, H.; Basim, M.C.; Sharghi, M. Ultra-High Performance Recycled Steel Fiber Reinforced Concrete Segments under the Thrust Force of TBM Jacks and Their Environmental Potentialities. Structures 2023, 47, 2465–2484. [Google Scholar] [CrossRef]

- Long, G.; Gao, Y.; Xie, Y. Designing More Sustainable and Greener Self-Compacting Concrete. Constr. Build. Mater. 2015, 84, 301–306. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.R.; Abdollahnejad, Z.; Illikainen, M. Characterization and Optimization of Hardened Properties of Self-Consolidating Concrete Incorporating Recycled Steel, Industrial Steel, Polypropylene and Hybrid Fibers. Compos. Part B Eng. 2018, 151, 186–200. [Google Scholar] [CrossRef]

- Brandt, A.M.; Marks, M. Examples of the Multicriteria Optimization of Cement-Based Composites. Compos. Struct. 1993, 25, 51–60. [Google Scholar] [CrossRef]

- Sengul, O.; Tasdemir, M.A. Compressive Strength and Rapid Chloride Permeability of Concretes with Ground Fly Ash and Slag. J. Mater. Civ. Eng. 2009, 21, 494–501. [Google Scholar] [CrossRef]

- Bayramov, F.; Taşdemir, C.; Taşdemir, M.A. Optimisation of Steel Fibre Reinforced Concretes by Means of Statistical Response Surface Method. Cem. Concr. Compos. 2004, 26, 665–675. [Google Scholar] [CrossRef]

| Chemical Compound (%) | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | SO3 | Loss of Ignition |

|---|---|---|---|---|---|---|---|---|

| OPC | 20.97 | 4.37 | 3.74 | 63.21 | 1.77 | 0.38 | 2.05 | 1.1 |

| WM | 0.46 | 0.05 | 0.32 | 53.49 | 0.12 | 0.01 | 0.015 | 43.26 * |

| Specimen | Designation of Mixes | Binder | Fine Aggregate | ||

|---|---|---|---|---|---|

| OPC (%) | WMP (%) | WMA (%) | Sand (%) | ||

| Control | CM | 100 | 0 | 0 | 100 |

| Series-I | MP5 | 95 | 5 | 0 | 100 |

| MP10 | 90 | 10 | 0 | 100 | |

| MP20 | 80 | 20 | 0 | 100 | |

| Series-II | MA20 | 100 | 0 | 20 | 80 |

| MA30 | 100 | 0 | 30 | 70 | |

| MA40 | 100 | 0 | 40 | 60 | |

| Material | Cement | Aggregate | SP | Water | WMA | WMP |

|---|---|---|---|---|---|---|

| Cost (Euro/kg) | 0.021 | 0.053 | 0.10 | 0.82 | 0.02 | 0.10 |

| Sources | [62] | [62] | [62] | [62] | * | * |

| Mix ID | Individual Desirability Function | Overall Desirability Function (D) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d1 | d2 | d3 | d4 | d5 | d6 | d7 | d8 | d9 | d10 | d11 | ||

| AP | EP | POCP | GWP | Energy | Cost | CS | CS-28 | CS-63 | Mass-28 | Mass-63 | ||

| CM | 0.000 | 0.000 | 0.000 | 0.071 | 0.157 | 0.556 | 0.588 | 0.368 | 0.064 | 0.000 | 0.000 | 0.000 |

| MP5 | 0.252 | 0.250 | 0.250 | 0.303 | 0.367 | 0.667 | 0.765 | 0.639 | 0.544 | 0.736 | 0.352 | 0.422 |

| MP10 | 0.504 | 0.500 | 0.500 | 0.536 | 0.578 | 0.778 | 0.471 | 0.333 | 0.224 | 0.434 | 0.816 | 0.476 |

| MP20 | 1.008 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.000 | 0.000 | 0.000 | 0.811 | 1.000 | 0.000 |

| MA20 | 0.008 | 0.018 | 0.001 | 0.036 | 0.078 | 0.278 | 0.882 | 0.806 | 0.816 | 0.547 | 0.572 | 0.107 |

| MA30 | 0.013 | 0.027 | 0.002 | 0.018 | 0.039 | 0.139 | 1.000 | 1.000 | 1.000 | 0.736 | 0.851 | 0.111 |

| MA40 | 0.017 | 0.036 | 0.002 | 0.000 | 0.000 | 0.000 | 0.765 | 0.771 | 0.832 | 1.000 | 0.931 | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmadi, M.; Abdollahzadeh, E.; Kashfi, M.; Khataei, B.; Razavi, M. Life Cycle Assessment and Performance Evaluation of Self-Compacting Concrete Incorporating Waste Marble Powder and Aggregates. Materials 2025, 18, 2982. https://doi.org/10.3390/ma18132982

Ahmadi M, Abdollahzadeh E, Kashfi M, Khataei B, Razavi M. Life Cycle Assessment and Performance Evaluation of Self-Compacting Concrete Incorporating Waste Marble Powder and Aggregates. Materials. 2025; 18(13):2982. https://doi.org/10.3390/ma18132982

Chicago/Turabian StyleAhmadi, Masoud, Erfan Abdollahzadeh, Mohammad Kashfi, Behnoosh Khataei, and Marzie Razavi. 2025. "Life Cycle Assessment and Performance Evaluation of Self-Compacting Concrete Incorporating Waste Marble Powder and Aggregates" Materials 18, no. 13: 2982. https://doi.org/10.3390/ma18132982

APA StyleAhmadi, M., Abdollahzadeh, E., Kashfi, M., Khataei, B., & Razavi, M. (2025). Life Cycle Assessment and Performance Evaluation of Self-Compacting Concrete Incorporating Waste Marble Powder and Aggregates. Materials, 18(13), 2982. https://doi.org/10.3390/ma18132982