Cushioning Performance of Specialized Running Socks for Enhanced Shock Absorption and Reduced Plantar Pressure

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Experimental Procedure

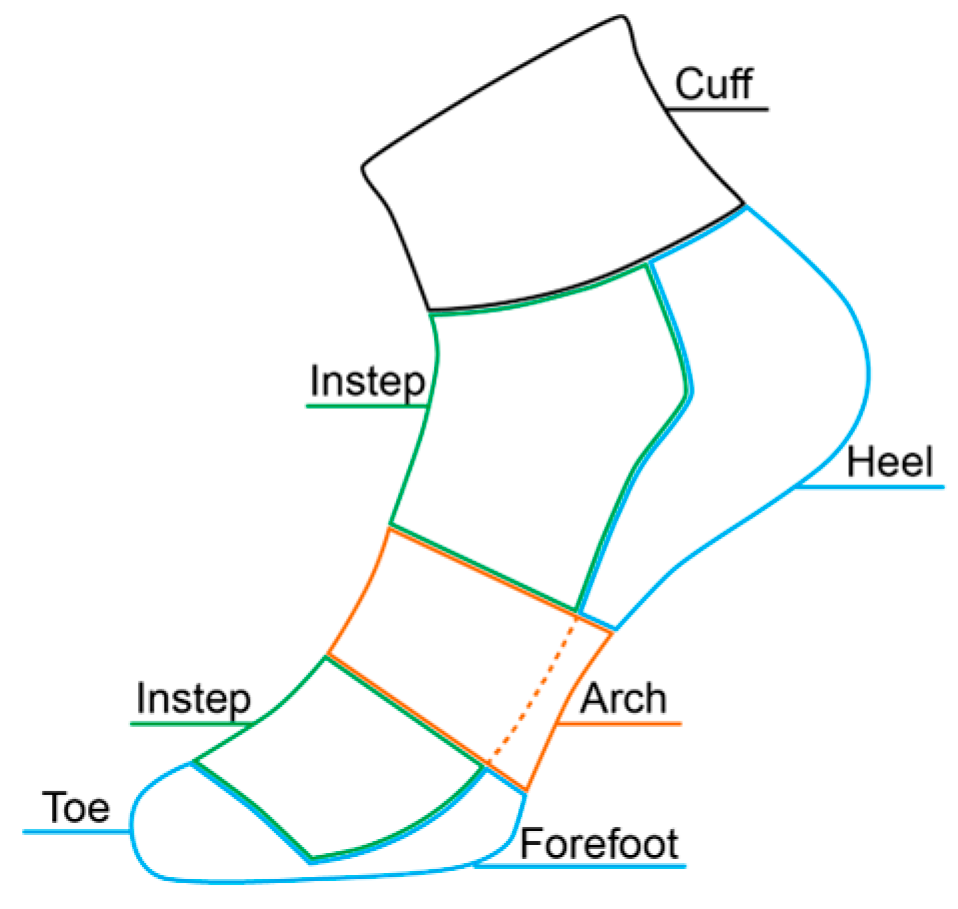

2.2.1. Material Tests of Sock Sole Regions

2.2.2. Wear Test

2.3. Data Analysis

3. Results and Discussion

3.1. Material Properties of Sock Sole Regions

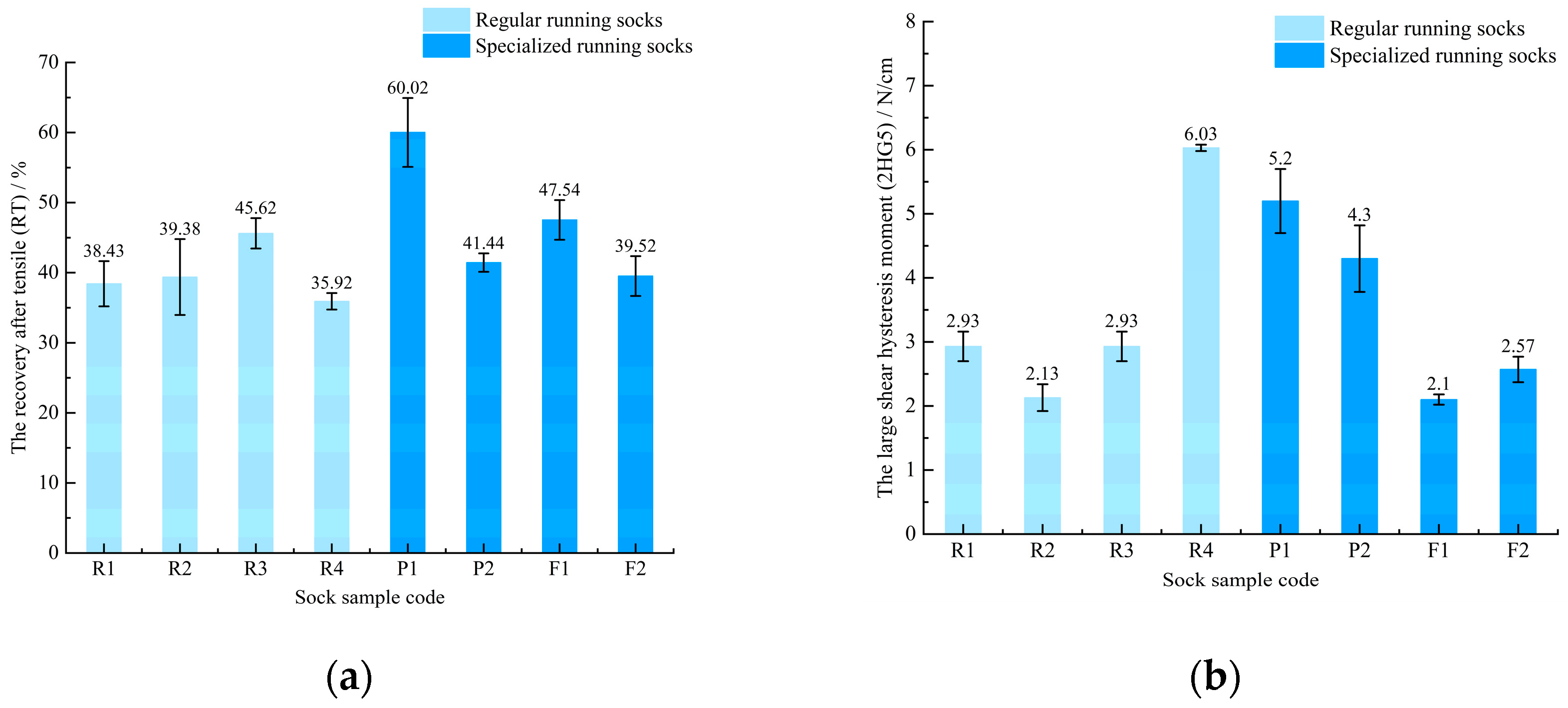

3.1.1. Tensile and Shear Properties of Sock Sole Regions

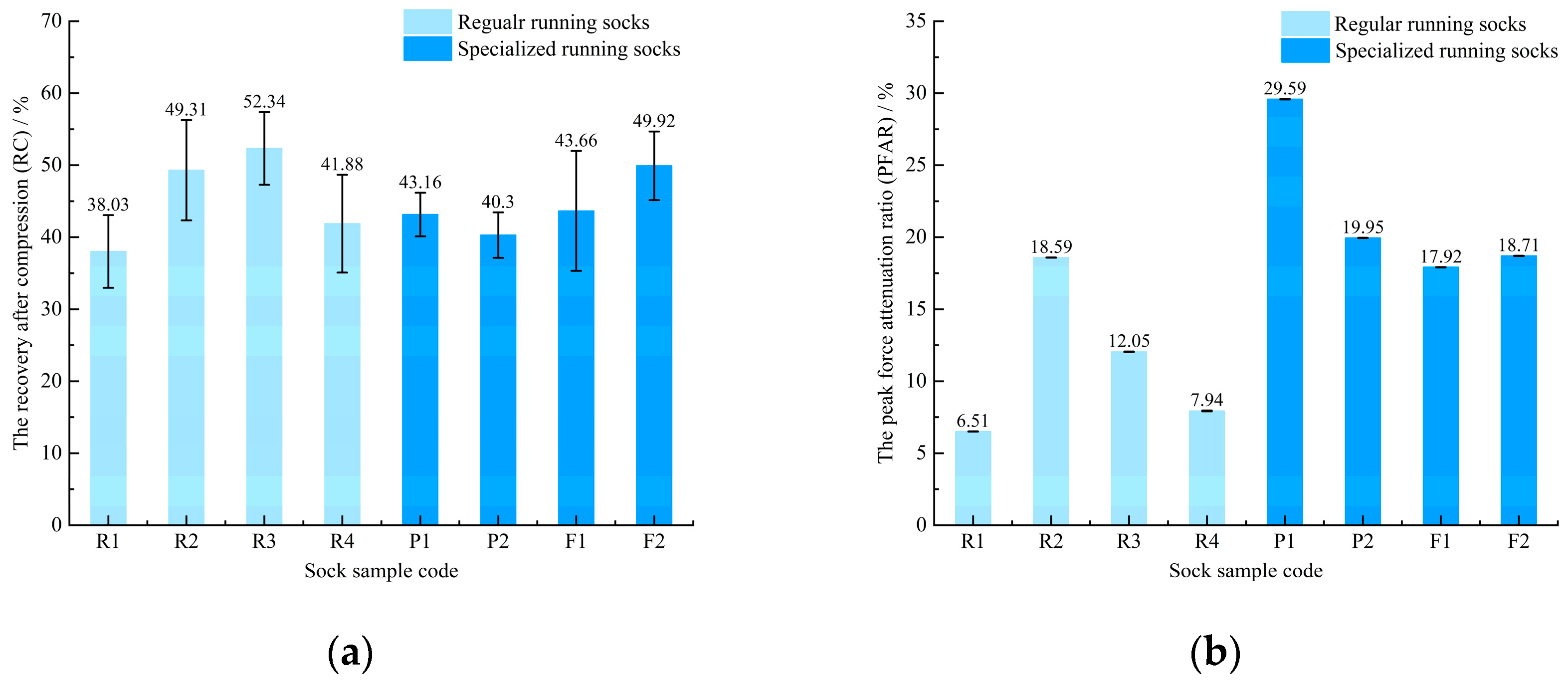

3.1.2. Compression Properties of Sock Sole Regions

3.1.3. Impact Force Reduction Properties of Sock Sole Regions

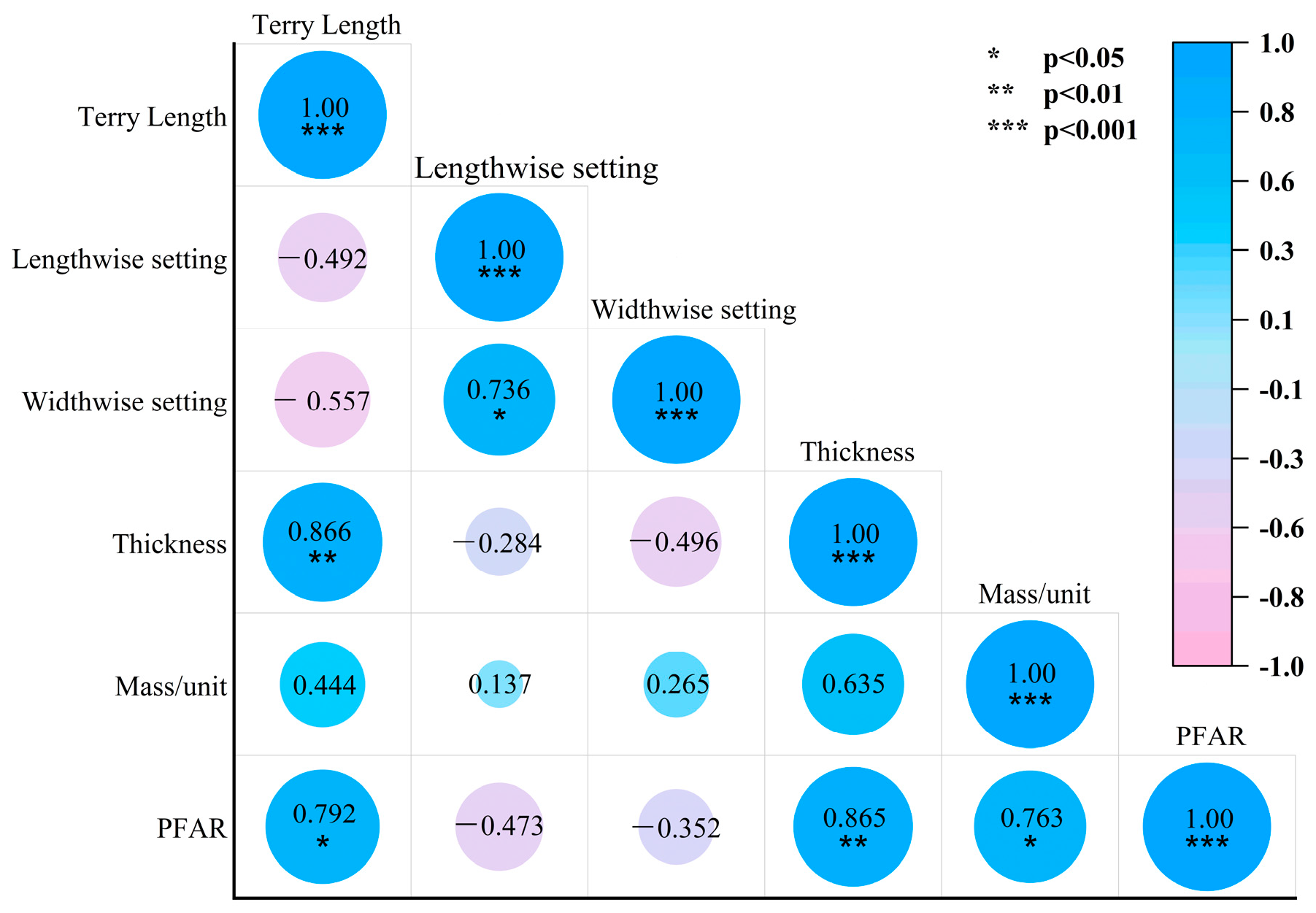

3.1.4. Relationship Between Sockwear Structural Parameters and Material Properties

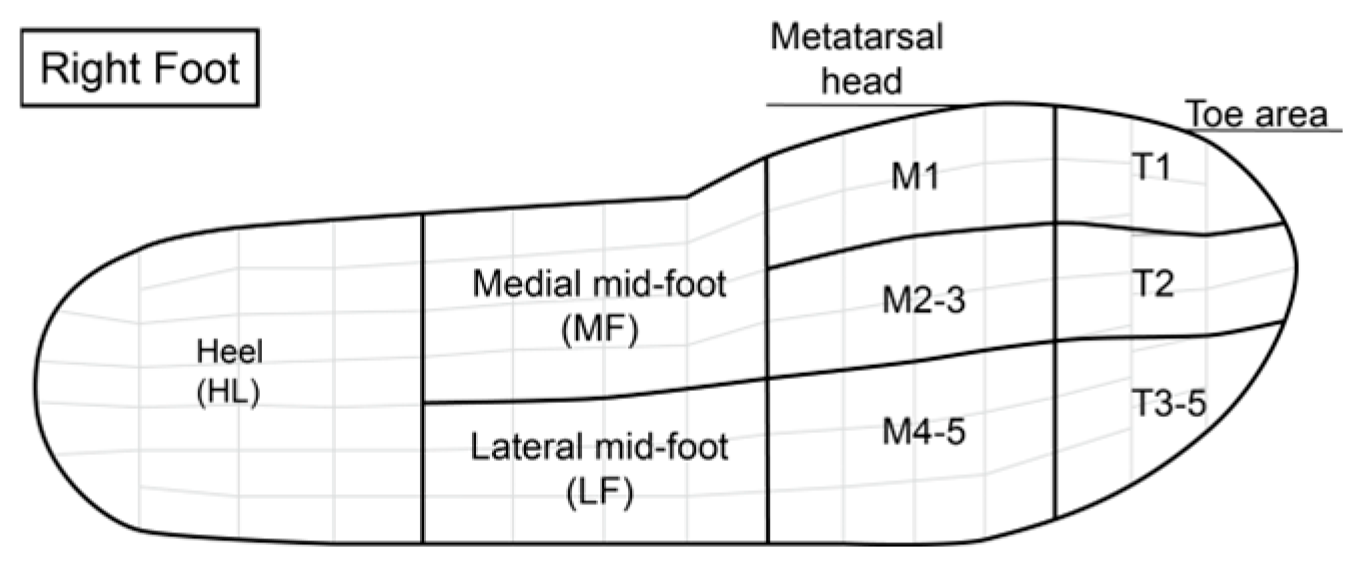

3.2. Wear Test on Plantar Pressure Distribution

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Popov, S.; Sokić, J.; Stupar, D. Relations between motivation for long-distance running and emotional well-being. Psihologija 2019, 52, 139–154. [Google Scholar] [CrossRef]

- Kusy, K.; Zielinski, J. Sprinters versus Long-distance Runners: How to Grow Old Healthy. Exerc. Sport Sci. Rev. 2015, 43, 57–64. [Google Scholar] [CrossRef] [PubMed]

- Chang, W.-L.; Shih, Y.-F.; Chen, W.-Y. Running injuries and associated factors in participants of ING Taipei Marathon. Phys. Ther. Sport 2012, 13, 170–174. [Google Scholar] [CrossRef] [PubMed]

- Junior, L.C.H.; Costa, L.O.P.; Lopes, A.D. Previous injuries and some training characteristics predict running-related injuries in recreational runners: A prospective cohort study. J. Physiother. 2013, 59, 263–269. [Google Scholar] [CrossRef] [PubMed]

- Schache, A.G.; Blanch, P.D.; Dorn, T.W.; Brown, N.A.; Rosemond, D.; Pandy, M.G. Effect of running speed on lower limb joint kinetics. Med. Sci. Sports Exerc. 2011, 43, 1260–1271. [Google Scholar] [CrossRef]

- Nielsen, R.Ø.; Parner, E.T.; Nohr, E.A.; Sørensen, H.; Lind, M.; Rasmussen, S. Excessive progression in weekly running distance and risk of running-related injuries: An association which varies according to type of injury. J. Orthop. Sports Phys. Ther. 2014, 44, 739–747. [Google Scholar] [CrossRef]

- Tasron, D.; Maiti, R.; Hemming, M.; Lewis, R.; Carré, M. Frictional interaction between running sock fabrics and plantar aspect of first metatarsal head in different moisture conditions. Procedia Eng. 2016, 147, 753–758. [Google Scholar] [CrossRef][Green Version]

- Soltanzadeh, Z.; Najar, S.S.; Haghpanahi, M.; Mohajeri-Tehrani, M.R. Plantar static pressure distribution in Normal feet using cotton socks with different structures. J. Am. Podiatr. Med. Assoc. 2017, 107, 30–38. [Google Scholar] [CrossRef]

- Howarth, S.; Rome, K. A short-term study of shock-attenuation in different sock types. Foot 1996, 6, 5–9. [Google Scholar] [CrossRef]

- Blackmore, T.; Ball, N.; Scurr, J. The effect of socks on vertical and anteroposterior ground reaction forces in walking and running. Foot 2011, 21, 1–5. [Google Scholar] [CrossRef]

- Martínez Nova, A.; Marcos-Tejedor, F.; Gómez Martín, B.; Sánchez-Rodríguez, R.; Escamilla-Martínez, E. Bioceramic-fiber socks have more benefits than cotton-made socks in controlling bacterial load and the increase of sweat in runners. Text. Res. J. 2018, 88, 696–703. [Google Scholar] [CrossRef]

- Escamilla-Martínez, E.; Gómez-Martín, B.; Sánchez-Rodríguez, R.; Fernández-Seguín, L.M.; Pérez-Soriano, P.; Martínez-Nova, A. Running thermoregulation effects using bioceramics versus polyester fibres socks. J. Ind. Text. 2022, 51, 1236–1249. [Google Scholar] [CrossRef]

- Kim, H.A. Water/moisture vapor permeabilities and thermal wear comfort of the Coolmax®/bamboo/tencel included PET and PP composite yarns and their woven fabrics. J. Text. Inst. 2021, 112, 1940–1953. [Google Scholar] [CrossRef]

- Jiménez-Cano, V.; Martínez-Nova, A.; Caracuel-López, J.M.; Escamilla-Martínez, E.; Gómez-Martín, B.; Sánchez-Roríguez, R. Socks with an U-shaped 3D discharge element are capable to reduce dynamic plantar pressures under the central forefoot. J. Tissue Viability 2022, 31, 309–314. [Google Scholar] [CrossRef]

- Rushton, R.; Richie, D. Friction Blisters of the Feet: A Critical Assessment of Current Prevention Strategies. J. Athl. Train. 2024, 59, 8–21. [Google Scholar] [CrossRef]

- Tedeschi, R. What are the benefits of five-toed socks? A scoping review. Reabil. Moksl.Slauga Kineziter.Ergoter. 2023, 1, 21–34. [Google Scholar] [CrossRef]

- Smith, B.S.; Burton, B.; Johnson, D.; Kendrick, S.; Meyer, E.; Yuan, W. Effects of wearing athletic shoes, five-toed shoes, and standing barefoot on balance performance in young adults. Int. J. Sports Phys. Ther. 2015, 10, 69. [Google Scholar]

- Shinohara, J.; Gribble, P.A. Five-Toed Socks with Grippers on the Foot Sole Improve Dynamic Postural Control in Healthy Individuals: 2066: Board# 195 June 3 9: 00 AM-10: 30 AM. Med. Sci. Sports Exerc. 2010, 42, 496. [Google Scholar]

- Baussan, E.; Bueno, M.-A.; Rossi, R.; Derler, S. Analysis of current running sock structures with regard to blister prevention. Text. Res. J. 2013, 83, 836–848. [Google Scholar] [CrossRef]

- Van Amber, R.R.; Lowe, B.J.; Niven, B.E.; Laing, R.M.; Wilson, C.A. Sock fabrics: Relevance of fiber type, yarn, fabric structure and moisture on cyclic compression. Text. Res. J. 2015, 85, 26–35. [Google Scholar] [CrossRef]

- Soltanzadeh, Z.; Shaikhzadeh Najar, S.; Haghpanahi, M.; Mohajeri-Tehrani, M. Effect of socks structures on plantar dynamic pressure distribution. Proc. Inst. Mech. Eng.Part H J. Eng. Med. 2016, 230, 1043–1050. [Google Scholar] [CrossRef] [PubMed]

- González, M.N.; Sánchez-Rodríguez, R.; Escamilla-Martínez, E.; Gómez-Martín, B.; Nova, A.M.; Cortés, J.F.M. Plantar pressues in two sock models with different three-dimensional wave separation. Rev. Esp. Pod 2022, 33, 88–95. [Google Scholar]

- Zhang, L.-Y.; Liu, Q.-L.; Yick, K.-L.; Yip, J.; Ng, S.-P. Analysis of diabetic foot deformation and plantar pressure distribution of women at different walking speeds. Int. J. Environ. Res. Public Health 2023, 20, 3688. [Google Scholar] [CrossRef]

- Lo, W.T.; Yick, K.L.; Ng, S.P.; Yip, J. New methods for evaluating physical and thermal comfort properties of orthotic materials used in insoles for patients with diabetes. J. Rehabil. Res. Dev. 2014, 51, 311–324. [Google Scholar] [CrossRef]

- Cüreklibatır Encan, B.; Marmaralı, A. A New Preventive Sock for People with Diabetes. J. Test. Eval. 2023, 51, 383–397. [Google Scholar] [CrossRef]

- Asayesh, A.; Mirgoli, F.; Gholamhosseini, A. An investigation into the effect of fabric structure on the compressional properties of woven fabrics. J. Text. Inst. 2018, 109, 32–38. [Google Scholar] [CrossRef]

- Veves, A.; Masson, E.A.; Fernando, D.J.; Boulton, A.J. Use of experimental padded hosiery to reduce abnormal foot pressures in diabetic neuropathy. Diabetes Care 1989, 12, 653–655. [Google Scholar] [CrossRef]

- Veves, A.; Masson, E.; Fernandox, D.; Boulton, A. Studies of experimental hosiery in diabetic neuropathic patients with high foot pressures. Diabet. Med. 1990, 7, 324–326. [Google Scholar] [CrossRef]

- Veves, A.; Boulton, A.; Hay, E. The use of specially padded hosiery in the painful rheumatoid foot. Foot 1992, 1, 175–177. [Google Scholar] [CrossRef]

- Blackmore, T.; Jessop, D.; Bruce-Low, S.; Scurr, J. The cushioning properties of athletic socks: An impact testing perspective. Clin. Biomech. 2013, 28, 825–830. [Google Scholar] [CrossRef]

- Babay, A.; Helali, H.a.; Msahli, S. Study of the mechanical behaviour of the elastic-core-spun yarns. J. Text. Inst. 2014, 105, 701–710. [Google Scholar] [CrossRef]

- Hong, Y.; Wang, L.; Li, J.X.; Zhou, J.H. Comparison of plantar loads during treadmill and overground running. J. Sci. Med. Sport 2012, 15, 554–560. [Google Scholar] [CrossRef] [PubMed]

| Code | Fiber Content | Pattern Structure | Wearing Features (By Producer) | Picture |

|---|---|---|---|---|

| Regular plain running socks | ||||

| R1 | 67.9% Cotton, 27.7% Polyester, 4.4% Elastane | Welt: double-sided ribbing; Instep: single jersey; Arch part: single jersey with inlaid rubber thread; Heel and toe: terry knitted | Stretchy and comfortable |  |

| R2 | 52.1% Wool, 30.7% Polyamide, 13.2% Polyester, 4% Elastane | Welt: double-sided ribbing; Instep: single jersey; Arch part: terry knitted with inlaid rubber thread (3:1); Heel and toe: terry knitted | Soft, good resilience |  |

| R3 | 89% Polyester, 11% Elastane | Welt: double-sided ribbing; Instep: single jersey; Arch part: terry knitted with inlaid rubber thread (2:1); Heel and toe: terry knitted | Anti-bacterial, anti-odor, breathable |  |

| R4 | 94% Nylon, 6% Spandex | Welt: double-sided ribbing; Instep: single jersey; Arch part: single jersey with inlaid rubber thread (2:1); Heel and toe: terry knitted | Moisture wicking, anti-odor |  |

| Specialized running socks (Two plain running socks and two five-toed running socks) | ||||

| P1 | 28% Drynamix®, 27% Mohair 43% Nylon, 2% Elastane | Welt: double-sided ribbing; Instep: single jersey; Arch part: terry knitted with inlaid rubber thread (2:1); Heel and toe: terry knitted | Anatomically shaped for L/R, V-Tech arch support design |  |

| P2 | 52% Drymax® Olefin, 32% Polyester, 11% Elastane, 5% Nylon | Welt: double-sided ribbing; Instep: single jersey; Arch part: terry knitted with inlaid rubber thread (3:1); Heel and toe: terry knitted | With Drymax dual-layer active wicking material |  |

| F1 | 39% Coolmax®, 58% Nylon, 3%Lycra® | Welt: double-sided ribbing; Instep: single jersey; Arch part: terry knitted with inlaid rubber thread (2:1); Heel: terry knitted; Toe: single jersey | Five-toe design prevents blisters and redness |  |

| F2 | 43% NüWoolTM, 43% Acrylic 12% Nylon, 2% Lycra® | Welt: double-sided ribbing; Instep: single jersey; Arch part: terry knitted with inlaid rubber thread (2:1); Heel: terry knitted; Toe: single jersey | Five-toe design, moisture management |  |

| Code | Terry Length (mm) | Thickness (mm) | Lengthwise Setting (cm−1) | Widthwise Setting (cm−1) | Mass/Unit (g/m2) | Front Organization | Terry Structure | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | S.D. | Mean | S.D. | Mean | S.D. | Mean | S.D. | Mean | S.D. | |||

| R1 | 0.85 | 0.05 | 1.95 | 0.04 | 13.83 | 0.14 | 11.14 | 0.13 | 371.29 | 19.67 |  |  |

| R2 | 2.27 | 0.07 | 3.98 | 0.02 | 12.25 | 0.21 | 8.94 | 0.10 | 630.45 | 4.14 |  |  |

| R3 | 1.24 | 0.07 | 2.70 | 0.07 | 14.68 | 0.14 | 8.32 | 0.07 | 419.07 | 23.69 |  |  |

| R4 | 1.50 | 0.08 | 2.74 | 0.13 | 13.35 | 0.24 | 11.70 | 0.06 | 747.17 | 10.57 |  |  |

| P1 | 2.35 | 0.07 | 4.76 | 0.09 | 14.50 | 0.18 | 10.48 | 0.12 | 1322.09 | 28.48 |  |  |

| P2 | 2.92 | 0.08 | 3.36 | 0.10 | 7.77 | 0.08 | 7.43 | 0.22 | 535.75 | 14.16 |  |  |

| F1 | 2.02 | 0.10 | 3.61 | 0.14 | 13.15 | 0.12 | 9.50 | 0.26 | 724.83 | 31.70 |  |  |

| F2 | 2.04 | 0.10 | 3.80 | 0.04 | 11.63 | 0.19 | 8.94 | 0.06 | 841.35 | 0.17 |  |  |

| Dependent Variable | Mean (S.D.) | t | p | |

|---|---|---|---|---|

| Regular Running Sock | Specialized Running Sock | |||

| PFAR (%) | 11.27 (5.51) | 21.54 (5.43) | −2.684 | 0.036 * |

| RC (%) | 45.39 (6.59) | 46.01 (7.43) | −0.125 | 0.904 |

| RT (%) | 42.46 (2.87) | 47.00 (8.91) | −0.969 | 0.370 |

| 2HG5 (N/cm) | 2.59 (0.37) | 3.47 (1.43) | −1.198 | 0.276 |

| Variable | Mean (Standard Deviation) | |||

|---|---|---|---|---|

| Regular Plain Running Sock (R2) | Specialized Five-Toed Running Sock (P2) | Specialized Plain Running Sock (F1) | p | |

| Maximum peak pressure (kPa) | ||||

| T1 | 222.3 (55.1) | 198 (53.5) | 199.6 (56.1) | 0.009 * |

| T2 | 150.1 (23.7) | 153.9 (31.1) | 153 (25.4) | 0.854 |

| T3–5 | 116.2 (22.6) | 109.4 (26.1) | 113.9 (26.4) | 0.426 |

| M1 | 377.2 (88.7) | 349.5 (93.9) | 349.2 (98.1) | 0.014 * |

| M2–3 | 282.8 (43.6) | 280.7 (53.1) | 279.9 (55.4) | 0.822 |

| M4–5 | 200.7 (28.5) | 206.9 (35.0) | 200.7 (27.5) | 0.501 |

| MF | 83.8 (20.3) | 88.6 (18.6) | 88.2 (15.8) | 0.059 |

| LF | 104.5 (19.4) | 105.9 (18.3) | 103.9 (14.6) | 0.725 |

| HL | 213.4 (75.2) | 205.1 (58.1) | 210.9 (45.9) | 0.717 |

| Total | 385.8 (77.4) | 358.2 (79.5) | 355.3 (91.9) | 0.011 * |

| Pressure time integral (kPa∗s) | ||||

| T1 | 28.1 (5.2) | 25 (6.2) | 26.2 (6.1) | 0.017 * |

| T2 | 21.3 (4.3) | 21.3 (4.9) | 21.7 (4.0) | 0.878 |

| T3–5 | 18.1 (4.5) | 16.1 (4.6) | 17.4 (4.8) | 0.039 * |

| M1 | 47.8 (11.3) | 45.4 (12.5) | 45.5 (12.6) | 0.103 |

| M2–3 | 38.4 (6.7) | 38.2 (8.2) | 38.4 (8.4) | 0.945 |

| M4–5 | 29.2 (6.0) | 30 (7.1) | 29.3 (6.2) | 0.636 |

| MF | 8.3 (2.5) | 8.8 (2.4) | 8.6 (2.3) | 0.059 |

| LF | 13 (3.3) | 13.1 (3.0) | 12.9 (2.5) | 0.856 |

| HL | 18.1 (5.7) | 20.3 (7.5) | 20.4 (10.5) | 0.520 |

| Total | 57.7 (9.2) | 55.5 (9.7) | 55.5 (11.6) | 0.085 |

| Ground contact stance (ms) | ||||

| T1 | 214.2 (12.8) | 197.2 (14.4) | 200.2 (13.6) | 0.000 * |

| T2 | 214.5 (18.4) | 204 (19.8) | 203.6 (14.8) | 0.012 * |

| T3–5 | 220.8 (20.1) | 205.4 (18.4) | 205.6 (18.1) | 0.000 * |

| M1 | 223.9 (18.7) | 211.4 (21.7) | 208.2 (18.4) | 0.002 * |

| M2–3 | 226.6 (15.6) | 215.6 (18.4) | 213 (15.6) | 0.002 * |

| M4–5 | 239 (18.8) | 225 (18.2) | 224.6 (17.3) | 0.014 * |

| MF | 132.4 (14.1) | 130.4 (16) | 131.1 (16.6) | 0.689 |

| LF | 189.1 (37.4) | 170.2 (28.7) | 171.6 (21.4) | 0.051 |

| HL | 158.8 (36.9) | 161.4 (43.5) | 159 (43.9) | 0.961 |

| Total | 247.5 (12.2) | 233.2 (15.7) | 235.4 (13.4) | 0.000 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Li, P.-L.; Yick, K.-L.; Yu, A. Cushioning Performance of Specialized Running Socks for Enhanced Shock Absorption and Reduced Plantar Pressure. Materials 2025, 18, 2941. https://doi.org/10.3390/ma18132941

Zhou X, Li P-L, Yick K-L, Yu A. Cushioning Performance of Specialized Running Socks for Enhanced Shock Absorption and Reduced Plantar Pressure. Materials. 2025; 18(13):2941. https://doi.org/10.3390/ma18132941

Chicago/Turabian StyleZhou, Xia, Pui-Ling Li, Kit-Lun Yick, and Annie Yu. 2025. "Cushioning Performance of Specialized Running Socks for Enhanced Shock Absorption and Reduced Plantar Pressure" Materials 18, no. 13: 2941. https://doi.org/10.3390/ma18132941

APA StyleZhou, X., Li, P.-L., Yick, K.-L., & Yu, A. (2025). Cushioning Performance of Specialized Running Socks for Enhanced Shock Absorption and Reduced Plantar Pressure. Materials, 18(13), 2941. https://doi.org/10.3390/ma18132941