Effect of Changing Climatic Conditions on Properties of Wood Textile Composites

Abstract

1. Introduction

2. Materials and Methods

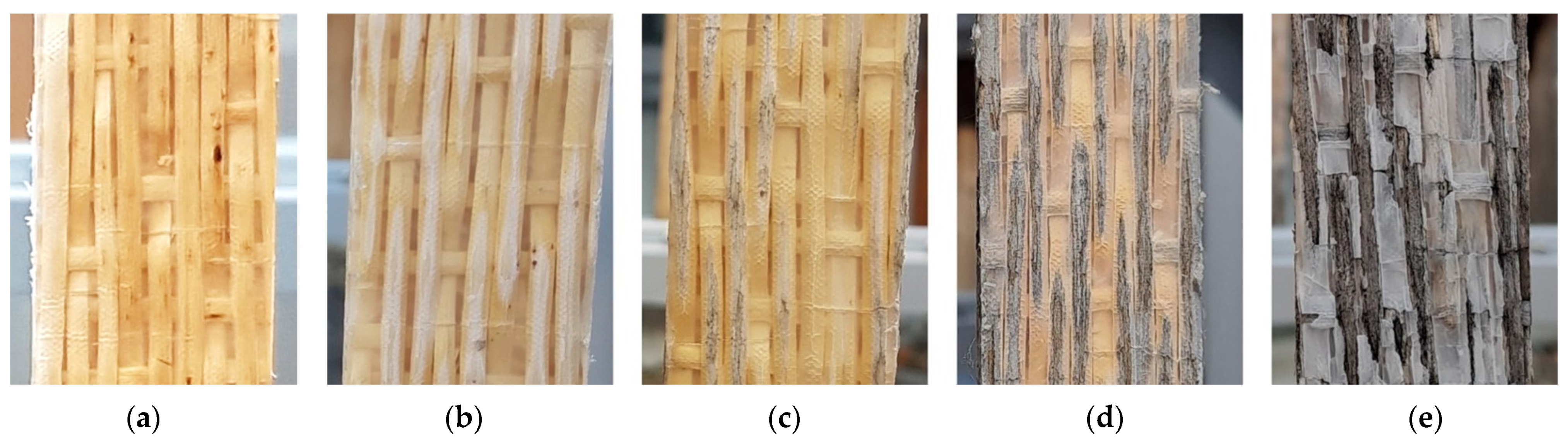

2.1. Basic Materials and Manufacturing

2.2. Aging of Specimens

2.3. Thermal Expansion

2.4. Swelling and Shrinking

2.5. μ-CT Measurements

2.6. Color Measurements

2.7. FTIR

2.8. Mechanical Testing

3. Results and Discussion

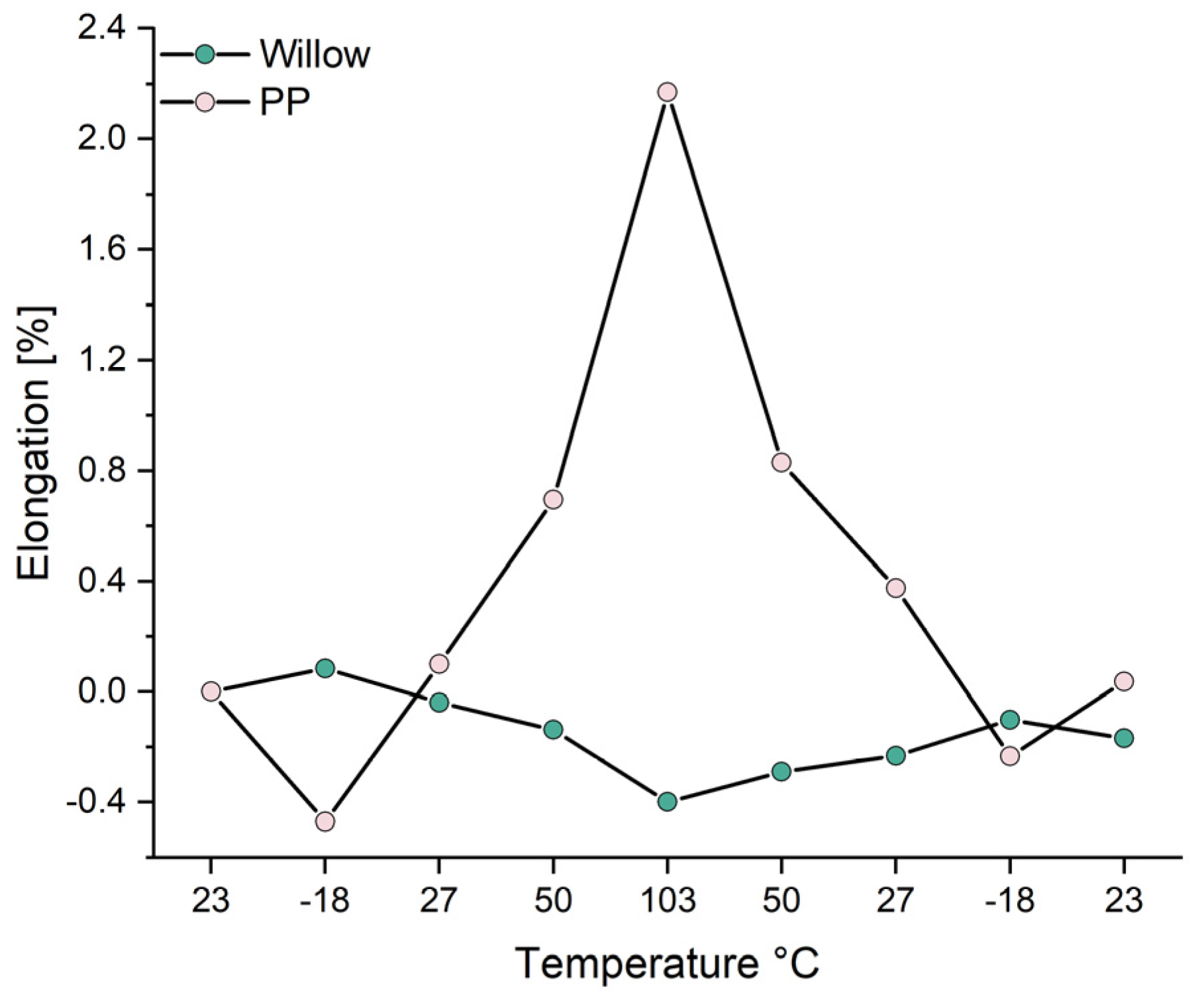

3.1. Thermal Expansion of the Basic Materials

3.2. Thermo-Hygroscopic Effects on Basic Material and Composite

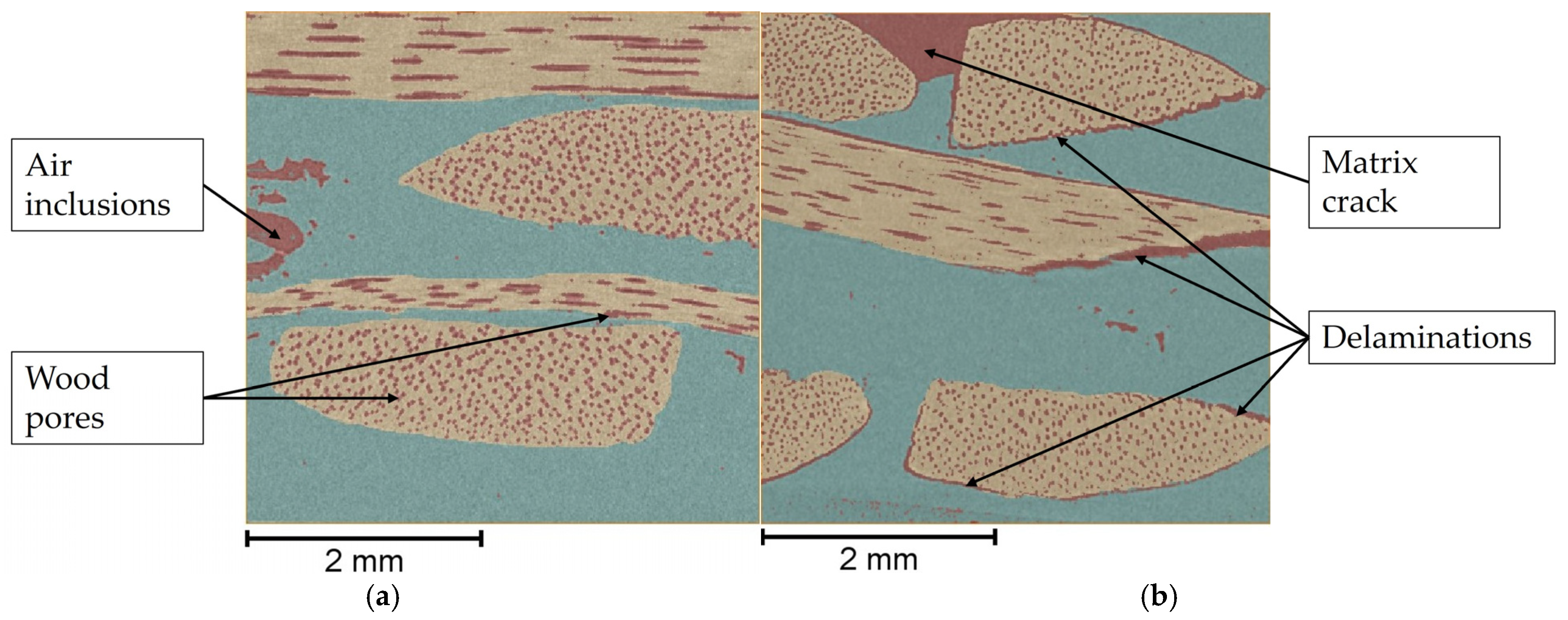

3.3. Results of the μ-CT Measurements

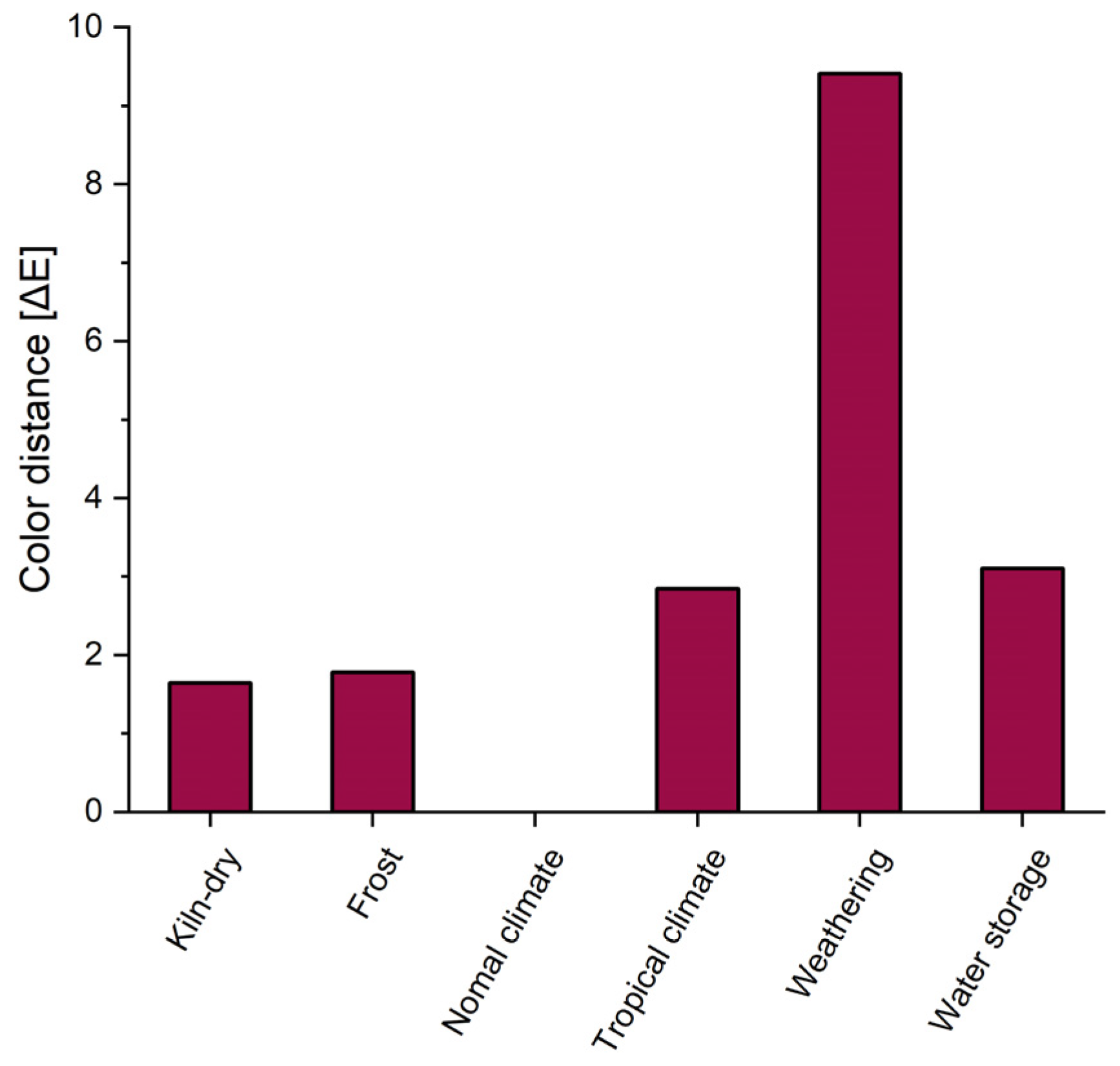

3.4. Results of the Color Measurements

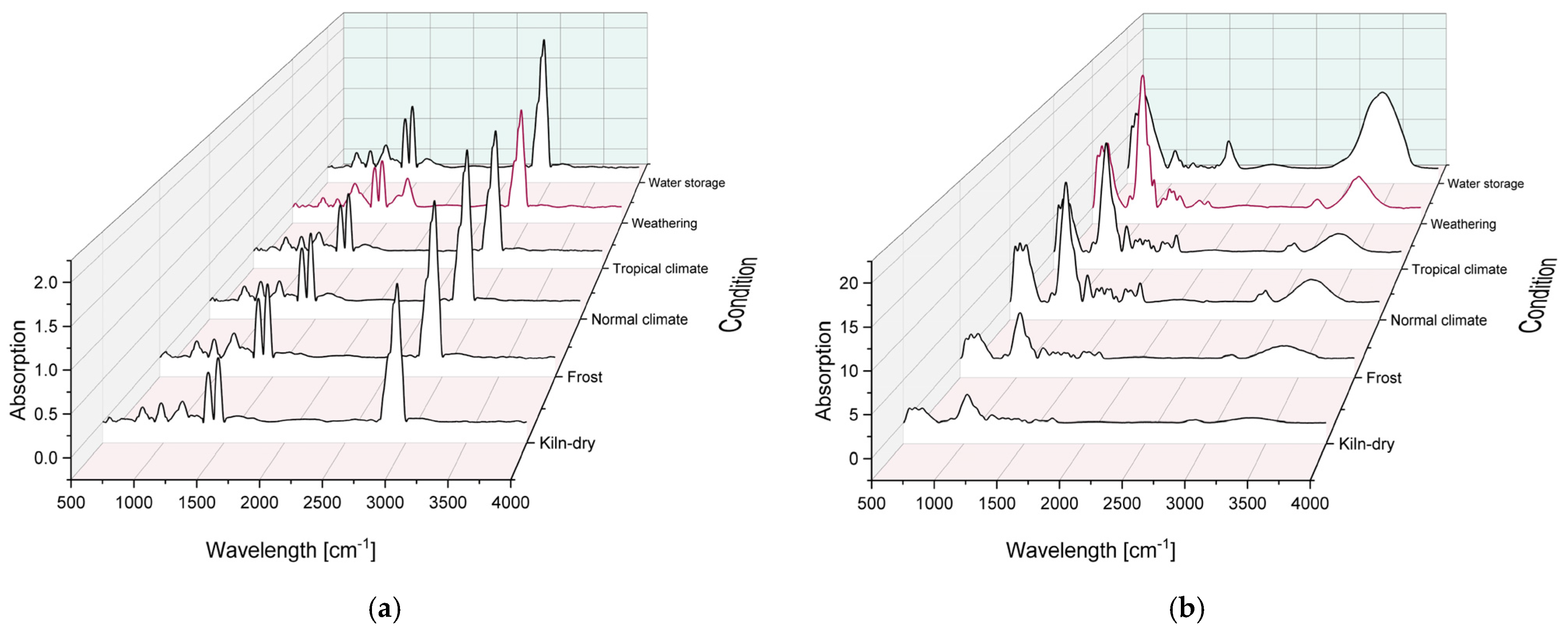

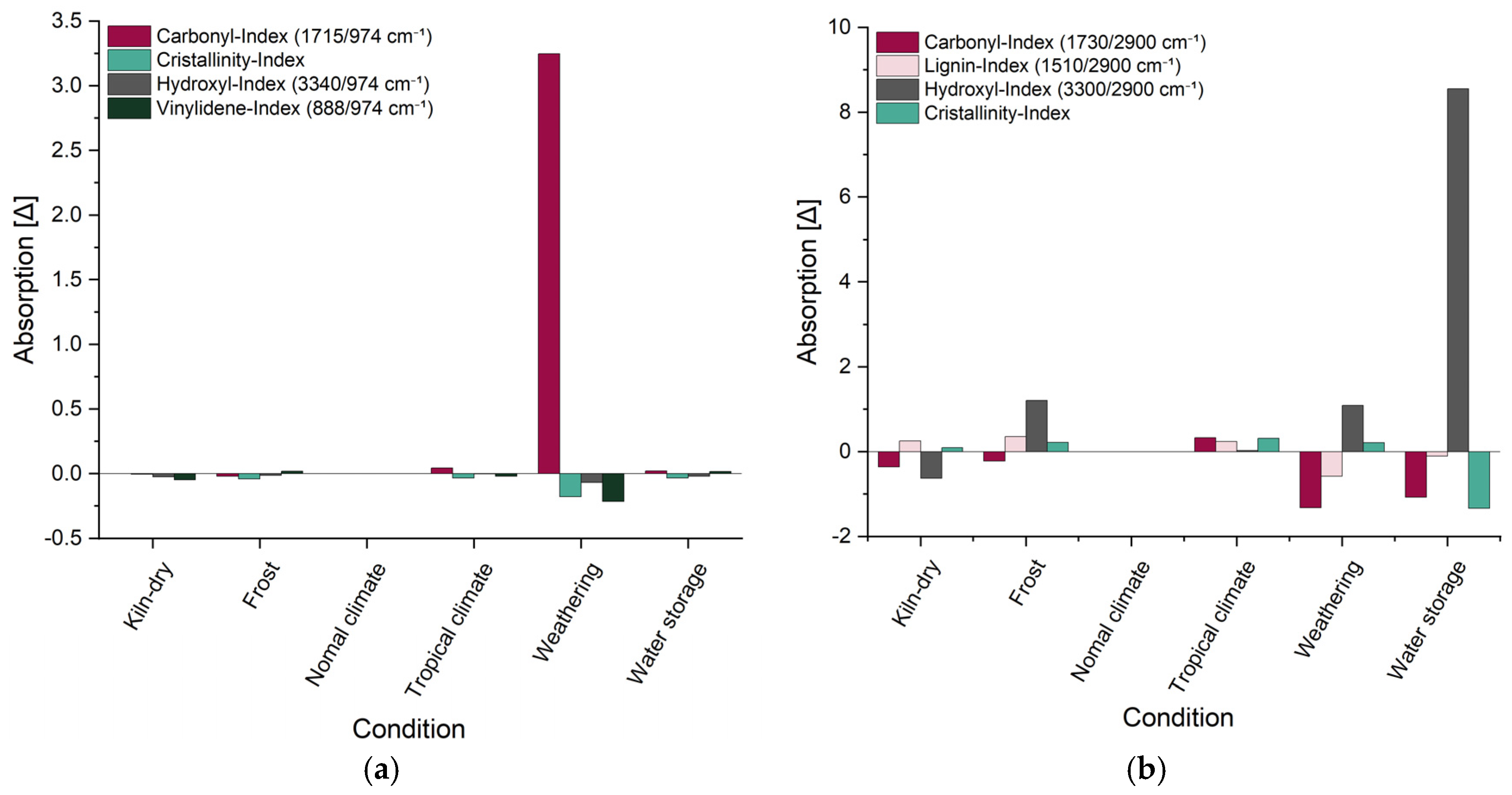

3.5. Results of FTIR Measurements

3.6. Results of the Tensile Test

3.7. Results of the Impact Bending Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WTC | Wood–Textile Composites |

| UV | Ultraviolet |

| μ-CT | Micro Computer Tomograph |

| FTIR | Fourier Transform Infrared Spectroscopy |

| PP | Polypropylene |

| WPC | Wood–Plastic Composites |

| CV | Coefficient of Variation |

| MC | Moisture Content |

References

- Lienhard, J.; Eversmann, P. New hybrids—from textile logics towards tailored material behaviour. Archit. Eng. Des. Manag. 2021, 17, 169–174. [Google Scholar] [CrossRef]

- Eversmann, P.; Ochs, J.; Heise, J.; Akbar, Z.; Böhm, S. Additive Timber Manufacturing: A Novel, Wood-Based Filament and Its Additive Robotic Fabrication Techniques for Large-Scale, Material-Efficient Construction. 3D Print. Addit. Manuf. 2021, 5, 71. [Google Scholar] [CrossRef] [PubMed]

- Dawod, M.; Deetman, A.; Akbar, Z.; Heise, J.; Böhm, S.; Klussmann, H.; Eversmann, P. Continuous Timber Fibre Placement: Towards the Design and Robotic Fabrication of High-Resolution Timber Structures. In Impact: Design With All Senses; Springer International Publishing: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- von Boyneburgk, C.L.; Zarges, J.-C.; Kuhl, D.; Heim, H.-P. Mechanical Characterization and Simulation of Wood Textile Composites (WTC) supported by Digital Image Correlation (DIC). Compos. Part C Open Access 2023, 11, 100370. [Google Scholar] [CrossRef]

- Silbermann, S.; Heise, J.; Kohl, D.; Böhm, S.; Akbar, Z.; Eversmann, P.; Klussmann, H. Textile Architecture for Wood Construction. In Research Culture in Architecture: Cross-Disciplinary Collaboration; Leopold, C., Robeller, C., Weber, U., Eds.; Birkhäuser: Basel, Switzerland, 2020; pp. 113–122. [Google Scholar]

- Ehrenstein, G.W. Faserverbund-Kunststoffe: Werkstoffe-Verarbeitung-Eigenschaften, 2nd ed.; Carl Hanser Verlag: München, Germany; Wien, Austria, 2006. [Google Scholar]

- Cherif, C. (Ed.) Textile Materials for Lightweight Constructions: Technologies-Methods-Materials-Properties; Springer: Berlin/Heidelberg, Germany, 2016; Available online: http://ebooks.ciando.com/book/index.cfm/bok_id/1898532 (accessed on 2 May 2024).

- Wagenführ, A.; Scholz, F. Taschenbuch der Holztechnik; Carl Hanser Verlag GmbH Co KG: Munich, Germany, 2012. [Google Scholar]

- Haghdan, S.; Tannert, T.; Smith, G.D. Effects of reinforcement configuration and densification on impact strength of wood veneer/polyester composites. J. Compos. Mater. 2015, 49, 1161–1170. [Google Scholar] [CrossRef]

- von Boyneburgk, C.; Silbermann, S.; Schweiger, L.; Zarges, J.-C.; Klussmann, H.; Heim, H.-P. Holzdesign trifft Kunststofftechnik. Kunststoffe 2022, 6, 82–85. [Google Scholar]

- von Boyneburgk, C.L.; Zarges, J.-C.; Seim, W.; Heim, H.-P. Investigation of Dynamic-Cyclic, Dynamic-Impact, and Timber-Construction-Relevant Characteristics of Wood–Textile Composites. J. Compos. Sci. 2024, 8, 454. [Google Scholar] [CrossRef]

- von Boyneburgk, C.L.; Oikonomou, D.; Seim, W.; Heim, H.-P. Mechanical Analysis and Simulation of Wood Textile Composites. J. Compos. Sci. 2024, 8, 190. [Google Scholar] [CrossRef]

- Matuana, L.M.; Kamdem, D.P. Accelerated ultraviolet weathering of PVC/wood-flour composites. Polym. Eng. Sci. 2002, 42, 1657–1666. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M. Surface chemistry changes of weathered HDPE/wood-flour composites studied by XPS and FTIR spectroscopy. Polym. Degrad. Stab. 2004, 86, 1–9. [Google Scholar] [CrossRef]

- Davis, A.; Sims, D. Weathering of Polymers; Applied Science Publ: London, UK, 1983. [Google Scholar]

- Yousif, E.; Haddad, R. Photodegradation and photostabilization of polymers, especially polystyrene: Review. SpringerPlus 2013, 2, 398. [Google Scholar] [CrossRef]

- Muasher, M.; Sain, M. The efficacy of photostabilizers on the color change of wood filled plastic composites. Polym. Degrad. Stab. 2006, 91, 1156–1165. [Google Scholar] [CrossRef]

- Adhikary, K.B.; Pang, S.; Staiger, M.P. Effects of the accelerated freeze-thaw cycling on physical and mechanical properties of wood flour-recycled thermoplastic composites. Polym. Compos. 2010, 31, 185–194. [Google Scholar] [CrossRef]

- Karmaker, A.C.; Hoffmann, A.; Hinrichsen, G. Influence of water uptake on the mechanical properties of jute fiber-reinforced polypropylene. J. Appl. Polym. Sci. 1994, 54, 1803–1807. [Google Scholar] [CrossRef]

- Andrady, A.L.; Hamid, H.; Torikai, A. Effects of solar UV and climate change on materials. Photochem. Photobiol. Sci. 2011, 10, 292–300. [Google Scholar] [CrossRef]

- Mehta, G.; Mohanty, A.K.; Drzal, L.T.; Kamdem, D.P.; Misra, M. Effect of Accelerated Weathering on Biocomposites Processed by SMC and Compression Molding. J. Polym. Environ. 2006, 14, 359–368. [Google Scholar] [CrossRef]

- Mankowski, M.; Morrell, J.J. Patterns of fungal attack in wood-plastic composites following exposure in a soil block test. Wood Fiber Sci. 2000, 32, 340–345. [Google Scholar]

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Friedrich, D. Effects from natural weathering on long-term structural performance of wood-polymer composite cladding in the building envelope. J. Build. Eng. 2019, 23, 68–76. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Faruk, O. Creep and impact properties of wood fibre–polypropylene composites: Influence of temperature and moisture content. Compos. Sci. Technol. 2004, 64, 693–700. [Google Scholar] [CrossRef]

- EN ISO 291; Plastics—Standard Atmospheres for Conditioning and Testing. EN ISO: Geneva, Switzerland, May 2008.

- EN ISO 62; Plastics—Determination of Water Absorption. EN ISO: Berlin, Germany, August 1999.

- EN ISO 16474-3; Paints and Varnishes—Methods of Exposure to Laboratory Light Sources—Part 3: Fluorescent UV Lamps. EN ISO: Geneva, Switzerland, April 2021.

- EN ISO 13183-1; Moisture Content of a Piece of Sawn Timber; Part 1: Determination by oven dry method; EN ISO: Geneva, Switzerland, July 2002.

- Lohmann, U. Holzlexikon, 4th ed.; DRW-Verlag: Leinfelden-Echterdingen, Germany, 2003. [Google Scholar]

- Michaeli, W. Einführung in Die Kunststoffverarbeitung, 6th ed.; Carl Hanser Verlag: München, Germany, 2010. [Google Scholar]

- Rajakumar, K.; Sarasvathy, V.; Chelvan, A.T.; Chitra, R.; Vijayakumar, C.T. Natural Weathering Studies of Polypropylene. J. Polym. Environ. 2009, 17, 191–202. [Google Scholar] [CrossRef]

- Windeisen, E.; Strobel, C.; Wegener, G. Chemical changes during the production of thermo-treated beech wood. Wood Sci. Technol. 2007, 41, 523–536. [Google Scholar] [CrossRef]

- Mellor, D.C.; Moir, A.B.; Scott, G. The effect of processing conditions on the u.v. stability of polyolefins. Eur. Polym. J. 1973, 9, 219–225. [Google Scholar] [CrossRef]

- Carlsson, D.J.; Wiles, D.M. The Photooxidative Degradation of Polypropylene. Part I. Photooxidation and Photoinitiation Processes. J. Macromol. Sci. Part C 1976, 14, 65–106. [Google Scholar] [CrossRef]

- Rouillon, C.; Bussiere, P.-O.; Desnoux, E.; Collin, S.; Vial, C.; Therias, S.; Gardette, J.-L. Is carbonyl index a quantitative probe to monitor polypropylene photodegradation? Polym. Degrad. Stab. 2016, 128, 200–208. [Google Scholar] [CrossRef]

- Mendes, L.C.; Rufino, E.S.; de Paula, F.O.; Torres, A.C., Jr. Mechanical, thermal and microstructure evaluation of HDPE after weathering in Rio de Janeiro City. Polym. Degrad. Stab. 2003, 79, 371–383. [Google Scholar] [CrossRef]

- Arráez, F.J.; Arnal, M.L.; Müller, A.J. Thermal and UV degradation of polypropylene with pro-oxidant. Abiotic characterization. J. Appl. Polym. Sci. 2018, 135, 46088. [Google Scholar] [CrossRef]

- Grause, G.; Chien, M.-F.; Inoue, C. Changes during the weathering of polyolefins. Polym. Degrad. Stab. 2020, 181, 109364. [Google Scholar] [CrossRef]

- Grillo, C.C.; Saron, C. Accelerated aging of polymer composite from Pennisetum purpureum fibers with recycled low-density polyethylene. J. Compos. Mater. 2023, 57, 3231–3242. [Google Scholar] [CrossRef]

- Teacă, C.-A.; Bodîrlău, R.; Spiridon, I. Maleic anhydride treatment of softwood-effect on wood structure and properties. Cellul. Chem. Technol. 2014, 48, 863–868. [Google Scholar]

- Evans, P.D.; Thay, P.D.; Schmalzl, K.J. Degradation of wood surfaces during natural weathering. Effects on lignin and cellulose and on the adhesion of acrylic latex primers. Wood Sci. Technol. 1996, 30, 411–422. [Google Scholar] [CrossRef]

- Cavallaro, G.; Gallitto, A.A.; Lisuzzo, L.; Lazzara, G. Comparative study of historical woods from XIX century by thermogravimetry coupled with FTIR spectroscopy. Cellulose 2019, 26, 8853–8865. [Google Scholar] [CrossRef]

- Colom, X.; Carrillo, F.; Nogués, F.; Garriga, P. Structural analysis of photodegraded wood by means of FTIR spectroscopy. Polym. Degrad. Stab. 2003, 80, 543–549. [Google Scholar] [CrossRef]

- Nasır, N. Effect of Oak Wood Modification on FTIR Crystallinity In-dexes. GreenTech 2023, 1, 7–12. [Google Scholar] [CrossRef]

- Teacă, C.-A. Crystalline structure of cellulose in wood after chemical modification using cyclic acid anhydrides (maleic and succinic). BioResources 2023, 18, 2535–2550. [Google Scholar] [CrossRef]

- Pandey, K.K.; Theagarajan, K.S. Analysis of wood surfaces and ground wood by diffuse reflectance (DRIFT) and photoacoustic (PAS) Fourier transform infrared spectroscopic techniques. Eur. J. Wood Prod. 1997, 55, 383–390. [Google Scholar] [CrossRef]

- EN ISO 527-4; Plastics—Determination of Tensile Properties: Part 4: Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites. EN ISO: Geneva, Switzerland, July 2023.

- EN ISO 179-2; Plastics—Determination of Charpy Impact Properties: Part 2: Instrumented Impact Test. EN ISO: Geneva, Switzerland, May 2020.

- EN ISO 179-1; Plastics—Determination of Charpy Impact Properties: Part 1: Non-Instrumented Impact Test. EN ISO: Geneva, Switzerland, June 2023.

- Eckelmann, C.A. The shrinking and swelling of wood and its effect on furniture. In Forestry & Natural Resources; Purdue University: West Lafayette, IN, USA, 1998; Volume 163, Available online: https://extension.purdue.edu/extmedia/fnr/fnr-163.pdf (accessed on 25 April 2025).

- Srubar, W.V. An analytical model for predicting the freeze–thaw durability of wood–fiber composites. Compos. Part B Eng. 2015, 69, 435–442. [Google Scholar] [CrossRef]

- El Hachem, Z.; Célino, A.; Challita, G.; Moya, M.-J.; Fréour, S. Hygroscopic multi-scale behavior of polypropylene matrix reinforced with flax fibers. Ind. Crops Prod. 2019, 140, 111634. [Google Scholar] [CrossRef]

- Robertson, N.-L.M.; Nychka, J.A.; Alemaskin, K.; Wolodko, J.D. Mechanical performance and moisture absorption of various natural fiber reinforced thermoplastic composites. J. Appl. Polym. Sci. 2013, 130, 969–980. [Google Scholar] [CrossRef]

- Jeschke, D.; Stuart, H.A. Diffusion und Permeation von Gasen in Hochpolymeren in Abhängigkeit vom Kritallisationsgrad und von der Temperatur. Z. Für Naturforschung A 1961, 16, 37–50. [Google Scholar] [CrossRef]

- Lohmann, U. Holz Handbuch, 7th ed.; DRW-Verlag: Karlsruhe, Germany, 2010. [Google Scholar]

- Ehrenstein, G.W.; Riedel, G.; Trawiel, P. Praxis der Thermischen Analyse von Kunststoffen, 2nd ed.; Hanser: München, Germany, 2003. [Google Scholar]

- Ono, M.; Washiyama, J.; Nakajima, K.; Nishi, T. Anisotropy in Thermal Expansion in Rubber Toughened Polypropylene—Injection Molded System. Polym. J. 2004, 36, 563–566. [Google Scholar] [CrossRef][Green Version]

- Wagenführ, R. Holzatlas, 6th ed.; Fachbuchverlag Leipzig im Carl Hanser Verlag: München, Germany, 2007. [Google Scholar]

- Agbossou, A.; Pastor, J. Thermal stresses and thermal expansion coefficients ofn-layered fiber-reinforced composites. Compos. Sci. Technol. 1997, 57, 249–260. [Google Scholar] [CrossRef]

- Sit, M.; Ling, J.; Jiang, C.; Zhang, Z.; Khalfallah, M.; Ioos, F.; Grossmann, E.; Dhakal, H.N. Influence of accelerated weathering on the properties of flax reinforced PLA biocomposites. Results Mater. 2022, 16, 100333. [Google Scholar] [CrossRef]

- Baar, J.; Paschová, Z.; Čermák, P.; Wimmer, R. Color Changes of Various Wood Species in Response to Moisture. Wood Fiber Sci. 2019, 51, 119–131. [Google Scholar] [CrossRef]

- Klement, I.; Marko, P. Colour changes of beech wood (Fagus sylvatica L.) during high temperature drying process. Wood Res. 2009, 54, 45–54. [Google Scholar]

- Kuka, E.; Andersons, B.; Cirule, D.; Andersone, I.; Kajaks, J.; Militz, H.; Bicke, S. Weathering properties of wood-plastic composites based on heat-treated wood and polypropylene. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106102. [Google Scholar] [CrossRef]

- Petrillo, M.; Sandak, J.; Grossi, P.; Sandak, A. Chemical and appearance changes of wood due to artificial weathering—Dose–response model. J. Near Infrared Spectrosc. 2019, 27, 26–37. [Google Scholar] [CrossRef]

- Fabiyi, J.S.; McDonald, A.G. Effect of wood species on property and weathering performance of wood plastic composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1434–1440. [Google Scholar] [CrossRef]

- Fabiyi, J.S.; McDonald, A.G.; Wolcott, M.P.; Griffiths, P.R. Wood plastic composites weathering: Visual appearance and chemical changes. Polym. Degrad. Stab. 2008, 93, 1405–1414. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M. Ultraviolet weathering of photostabilized wood-flour-filled high-density polyethylene composites. J. Appl. Polym. Sci. 2003, 90, 2609–2617. [Google Scholar] [CrossRef]

- Rodolfo, C.; Livio, T.; Ottaviano, A. White Beech: A Tricky Problem in the Drying Process: International Scientific Conference on Hardwood Processing; ISCHP: Quebec City, QC, Canada, 2007; Available online: https://www.researchgate.net/profile/timothy-young-11/publication/259284977_real-time_statistical_process_control_and_components_of_variance_systems_for_reducing_lumber_thickness_variation_in_hardwood_sawmills/links/54e4f02a0cf29865c3359513/real-time-statistical-process-control-and-components-of-variance-systems-for-reducing-lumber-thickness-variation-in-hardwood-sawmills.pdf#page=143 (accessed on 25 April 2025).

- Hamid, S.H.; Prichard, W.H. Application of Infrared Spectroscopy in Polymer Degradation. Polym.-Plast. Technol. Eng. 1988, 27, 303–334. [Google Scholar] [CrossRef]

- Cui, Y.H.; Lee, S.; Noruziaan, B.; Cheung, M.; Tao, J. Fabrication and interfacial modification of wood/recycled plastic composite materials. Compos. Part A Appl. Sci. Manuf. 2008, 39, 655–661. [Google Scholar] [CrossRef]

- Müller, U.; Rätzsch, M.; Schwanninger, M.; Steiner, M.; Zöbl, H. Yellowing and IR-changes of spruce wood as result of UV-irradiation. J. Photochem. Photobiol. B Biol. 2003, 69, 97–105. [Google Scholar] [CrossRef] [PubMed]

- John, R.; Schreiter, K.; Trommler, K.; Siegel, C.; Wagenführ, A.; Spange, S. Maleic anhydride copolymers as adhesion-promoting reagent in wood veneer/biopolyethlyene composite materials. Polym. Compos. 2019, 40, 1979–1988. [Google Scholar] [CrossRef]

- Evans, P.D.; Michell, A.J.; Schmalzl, K.J. Studies of the degradation and protection of wood surfaces. Wood Sci. Technol. 1992, 26, 151–163. [Google Scholar] [CrossRef]

- Hoekstra, H.D.; Spoormaker, J.L.; Breen, J. Mechanical and morphological properties of stabilized and non-stabilized HDPE films versus exposure time. Angew. Makromol. Chem. 1997, 247, 91–110. [Google Scholar] [CrossRef]

- Torikai, A.; Shirakawa, H.; Nagaya, S.; Fueki, K. Photodegradation of polyethylene: Factors affecting photostability. J. Appl. Polym. Sci. 1990, 40, 1637–1646. [Google Scholar] [CrossRef]

- Carlsson, D.J.; Wiles, D.M. The Photodegradation of Polypropylene Films. III. Photolysis of Polypropylene Hydroperoxides. Macromolecules 1969, 2, 597–606. [Google Scholar] [CrossRef]

- Dahlmann, R.; Haberstroh, E.; Menges, G. Menges Werkstoffkunde Kunststoffe, 7th ed.; Carl Hanser Verlag: München, Germany, 2022. [Google Scholar]

- Kaiser, W. Kunststoffchemie Für Ingenieure, 3rd ed.; Carl Hanser Verlag: München, Germany, 2011. [Google Scholar]

- SABIC—Saudi Basic Industries Corperation. SABIC PP 520P: PP Homopolymer for Cast Film; Datasheet: Houston, TX, USA.

- Niemz, P.; Sonderegger, W.U. Holzphysik: Eigenschaften, Prüfung, und Kennwerte, 2nd ed.; Carl Hanser Verlag: München, Germany, 2021. [Google Scholar]

- Badji, C.; Beigbeder, J.; Garay, H.; Bergeret, A.; Bénézet, J.-C.; Desauziers, V. Exterior and under glass natural weathering of hemp fibers reinforced polypropylene biocomposites: Impact on mechanical, chemical, microstructural and visual aspect properties. Polym. Degrad. Stab. 2018, 148, 104–116. [Google Scholar] [CrossRef]

- Mohammed, M.; Rozyanty, A.R.; Adam, T.; Betar, B.O. Study of the weathering effect in a natural environment on the hybrid kenaf bast/glass fibre-filled unsaturated polyester composite. AIP Conf. Proc. 2017, 1885, 20201. [Google Scholar] [CrossRef]

- Brischke, C.; Emmerich, L. Impact of Wood Moisture Content on Structural Integrity of Wood Under Dynamic Loads. Drv. Ind. 2023, 74, 243–250. [Google Scholar] [CrossRef]

- Kallakas, H.; Poltimäe, T.; Süld, T.-M.; Kers, J.; Krumme, A. The influence of accelerated weathering on the mechanical and physical properties of wood-plastic composites. Proc. Estonian Acad. Sci. 2015, 64, 94. [Google Scholar] [CrossRef]

- Kohl, D.; von Boyneburgk, C.; Feldmann, M.; Heim, H.-P.; Böhm, S. Characterization of wood-based multi-material systems under dynamic impact stress. Wood Mater. Sci. Eng. 2018, 56, 130–139. [Google Scholar] [CrossRef]

| Aging Conditions | Parameters | Time | Reference |

|---|---|---|---|

| Kiln-drying | 103 °C | 24 h | [29] |

| Frost | −18 °C | 24 h | - |

| Standard climate | 23 °C/50% r. h. | 168 h | [26] |

| Tropical climate | 27 °C/65% r. h. | 168 h | [26] |

| Weathering | 50 °C + UV (5 h) 23 °C + Rain (1 h) | 504 h | [28] |

| Water-storage | 23 °C | 24 h | [27] |

| Material | Index | Wavelength | References |

|---|---|---|---|

| PP (reference wavelength: 974 cm−1) | Carbonyl Index | 1715 cm−1 | [32,34,35] |

| Crystallinity Index | 998 cm−1 | [32,36] | |

| Vinylidene Index | 888 cm−1 | [32,37] | |

| Hydroxyl Index | 3340 cm−1 | [32,38,39] | |

| Willow (reference wavelength: 2900 cm−1) | Carbonyl Index | 1730 cm−1 | [40,41] |

| Lignin Index | 1510 cm−1 | [42,43,44] | |

| Crystallinity Index | 1375 cm−1 | [45,46] | |

| Hydroxyl Index | 3300 cm−1 | [41,47] |

| Aging Conditions | Red–Green | Yellow–Blue | Light–Dark | |||

|---|---|---|---|---|---|---|

| a* | CV (%) | b* | CV (%) | L* | CV [%] | |

| Kiln-drying | 9.19 | 3 | 25.08 | 3 | 67.20 | 2 |

| Frost | 8.23 | 4 | 24.00 | 5 | 68.50 | 1 |

| Standard climate | 8.98 | 9 | 25.60 | 7 | 68.75 | 1 |

| Tropical climate | 10.16 | 1 | 28.18 | 1 | 68.87 | 0 |

| Weathering | 7.64 | 50 | 16.36 | 43 | 69.91 | 9 |

| Water storage | 10.17 | 3 | 25.57 | 5 | 65.89 | 1 |

| Magnitude of ΔE | Classification |

|---|---|

| 0.2 > ΔE | No color difference |

| 0.2 < ΔE < 2 | Slight color difference |

| 2 < ΔE < 6 | Moderate color difference |

| 6 < ΔE < 12 | Significant color difference |

| 12 < ΔE | Different colors |

| Aging Conditions | Tensile Strength [MPa] | CV (%) | Elongation at Break [%] | CV (%) | Young’s Modulus [MPa] | CV (%) |

|---|---|---|---|---|---|---|

| Kiln-dry | 38.08 | 11 | 0.87 | 18 | 4420.83 | 16 |

| Frost | 43.81 | 4 | 0.98 | 10 | 4893.78 | 13 |

| Standard climate | 44.81 | 5 | 1.02 | 9 | 5215.44 | 12 |

| Tropical climate | 42.76 | 11 | 0.95 | 9 | 5301.60 | 3 |

| Weathering | 32.05 | 4 | 1.34 | 14 | 2665.34 | 10 |

| Water storage | 43.73 | 7 | 1.92 | 9 | 2894.42 | 12 |

| Aging Conditions | Impact Bending Strength (kJ/m²) | CV (%) |

|---|---|---|

| Kiln-dry | 12.77 | 27 |

| Frost | 18.59 | 28 |

| Standard climate | 16.70 | 26 |

| Tropical climate | 17.72 | 27 |

| Weathering | 12.40 | 22 |

| Water storage | 29.25 | 23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

von Boyneburgk, C.L.; Heim, H.-P. Effect of Changing Climatic Conditions on Properties of Wood Textile Composites. Materials 2025, 18, 2764. https://doi.org/10.3390/ma18122764

von Boyneburgk CL, Heim H-P. Effect of Changing Climatic Conditions on Properties of Wood Textile Composites. Materials. 2025; 18(12):2764. https://doi.org/10.3390/ma18122764

Chicago/Turabian Stylevon Boyneburgk, Claudia L., and Hans-Peter Heim. 2025. "Effect of Changing Climatic Conditions on Properties of Wood Textile Composites" Materials 18, no. 12: 2764. https://doi.org/10.3390/ma18122764

APA Stylevon Boyneburgk, C. L., & Heim, H.-P. (2025). Effect of Changing Climatic Conditions on Properties of Wood Textile Composites. Materials, 18(12), 2764. https://doi.org/10.3390/ma18122764