Effect of Combined MgO Expansive Agent and Rice Husk Ash on Deformation and Strength of Post-Cast Concrete

Abstract

1. Introduction

2. Materials and Experimental Methods

2.1. Raw Materials and Mix Proportions

2.2. Experimental Methods

2.2.1. Laboratory Tests

- (1)

- Autogenous Deformation Test

- (2)

- Compressive Strength Test

2.2.2. On-Site In Situ Tests

- (1)

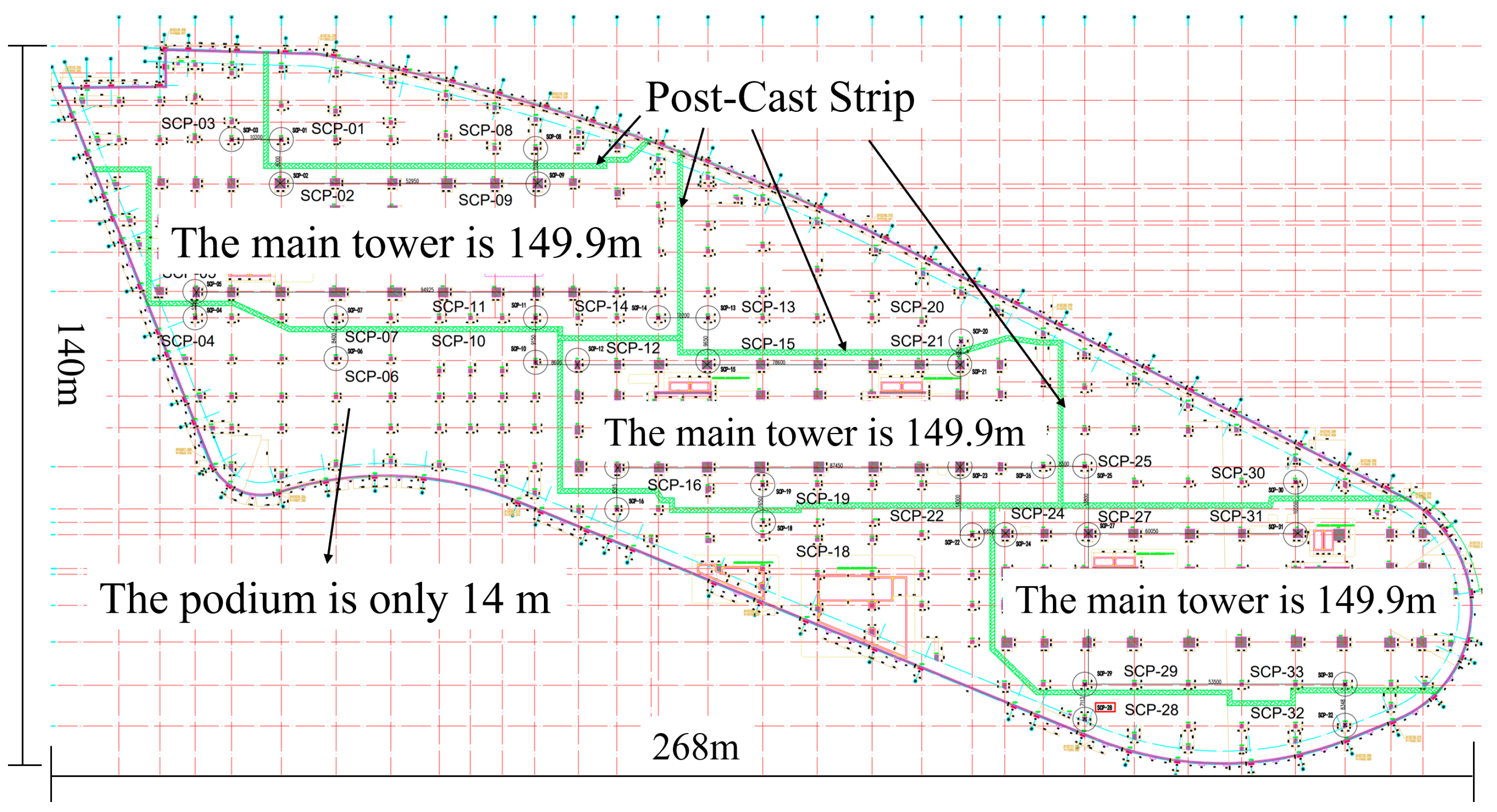

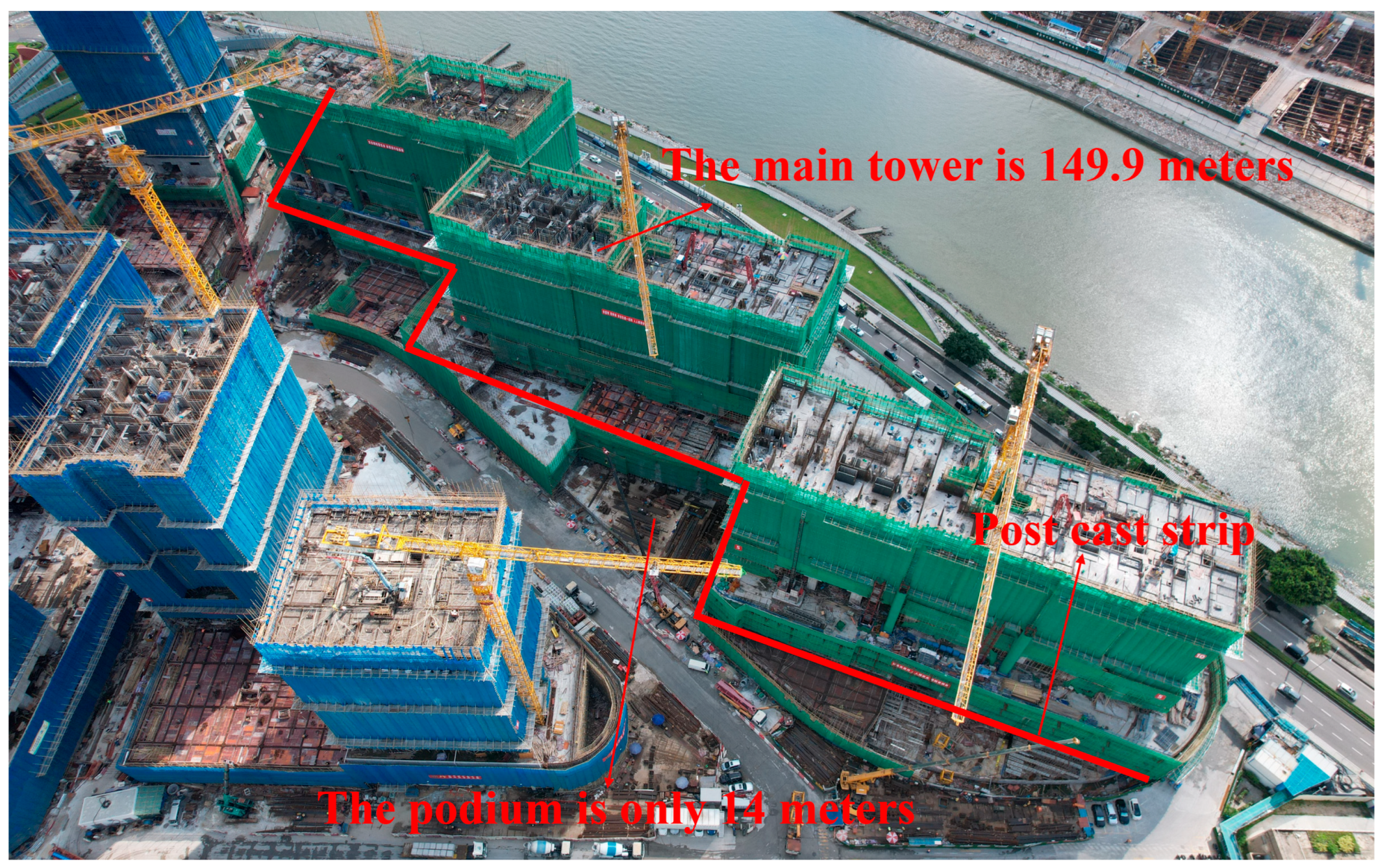

- Project Overview

- (2)

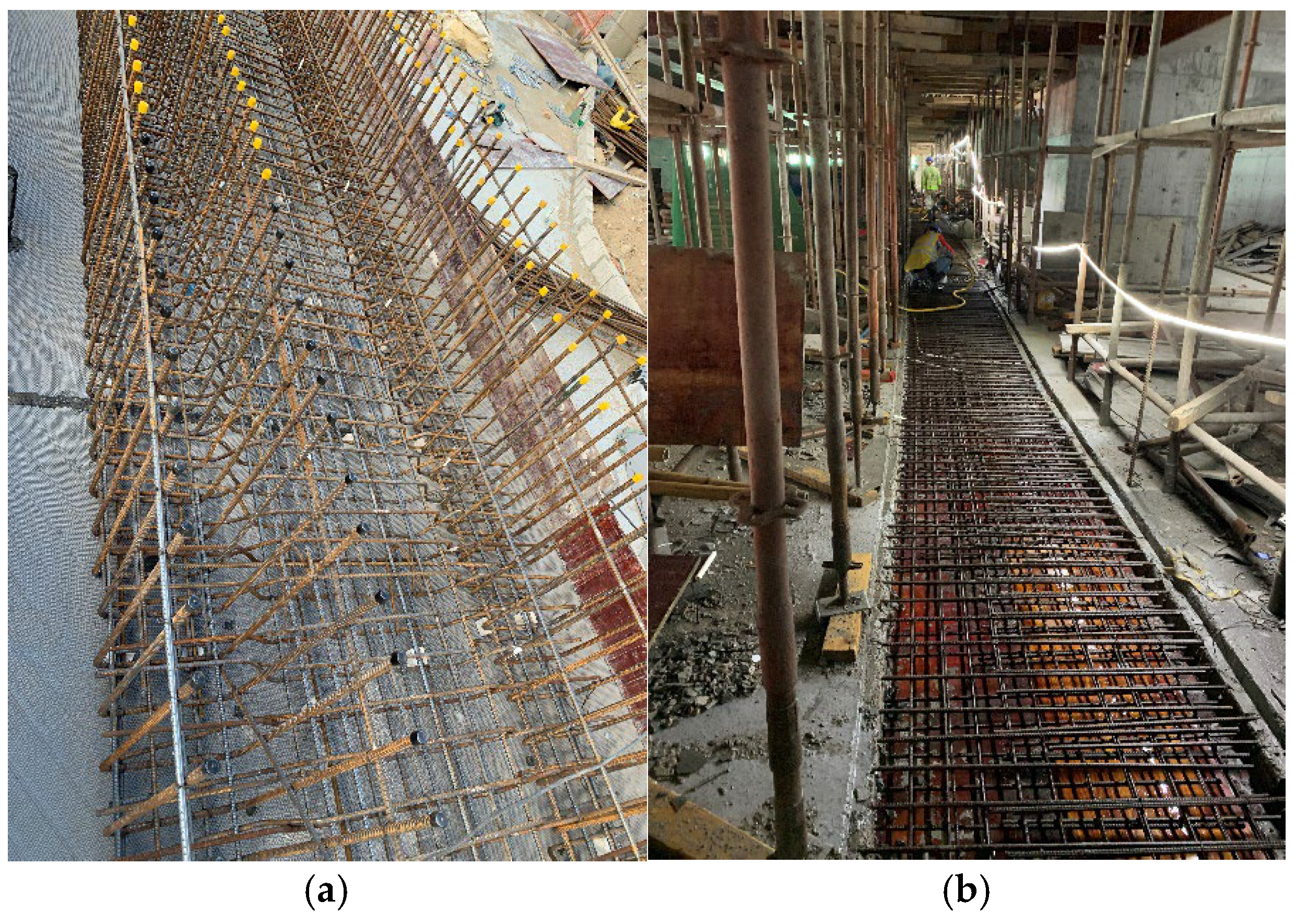

- Concrete Pouring

- (3)

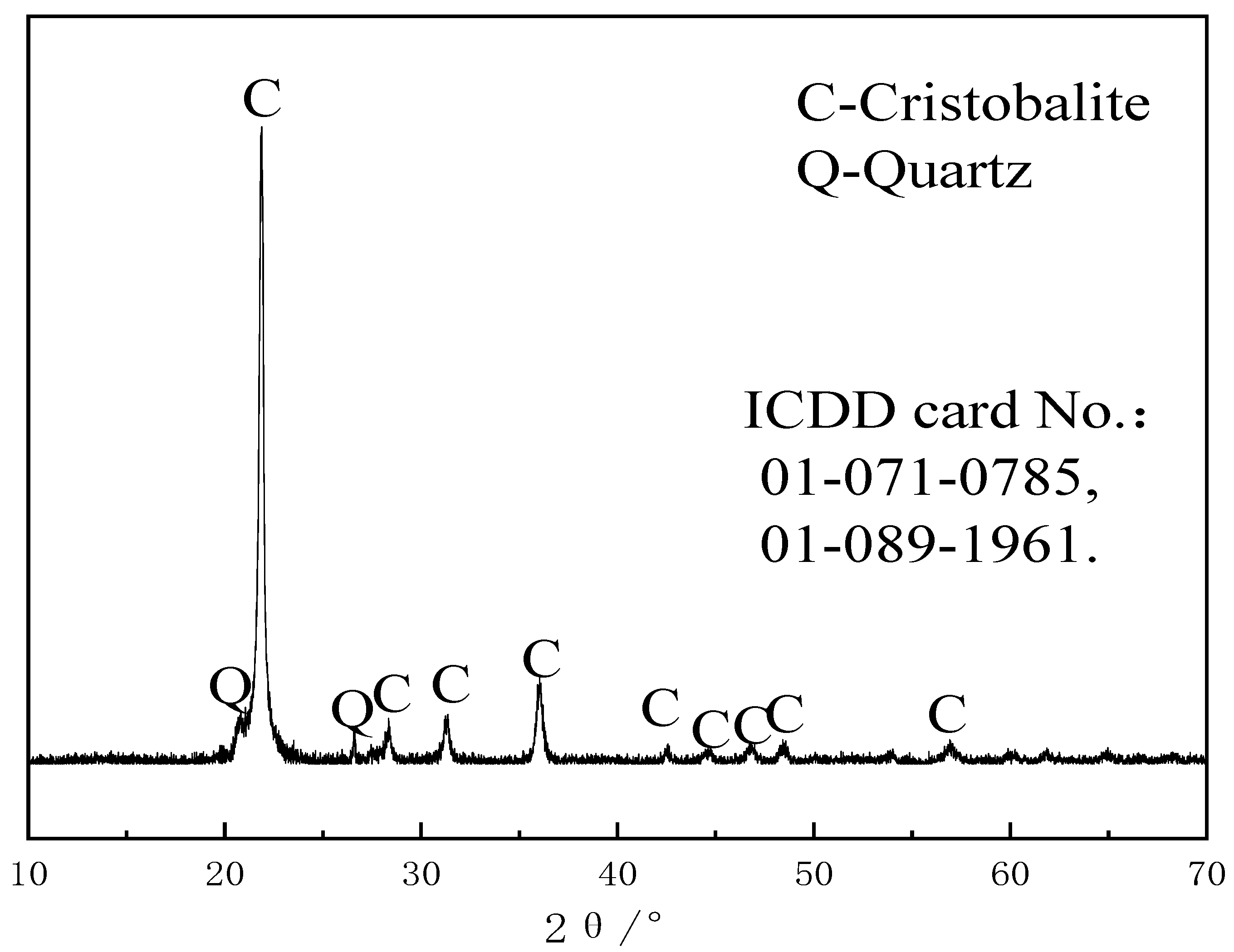

- Evaluation of the Hydration Degree of MEA

- (4)

- On-Site Strength Testing

- (5)

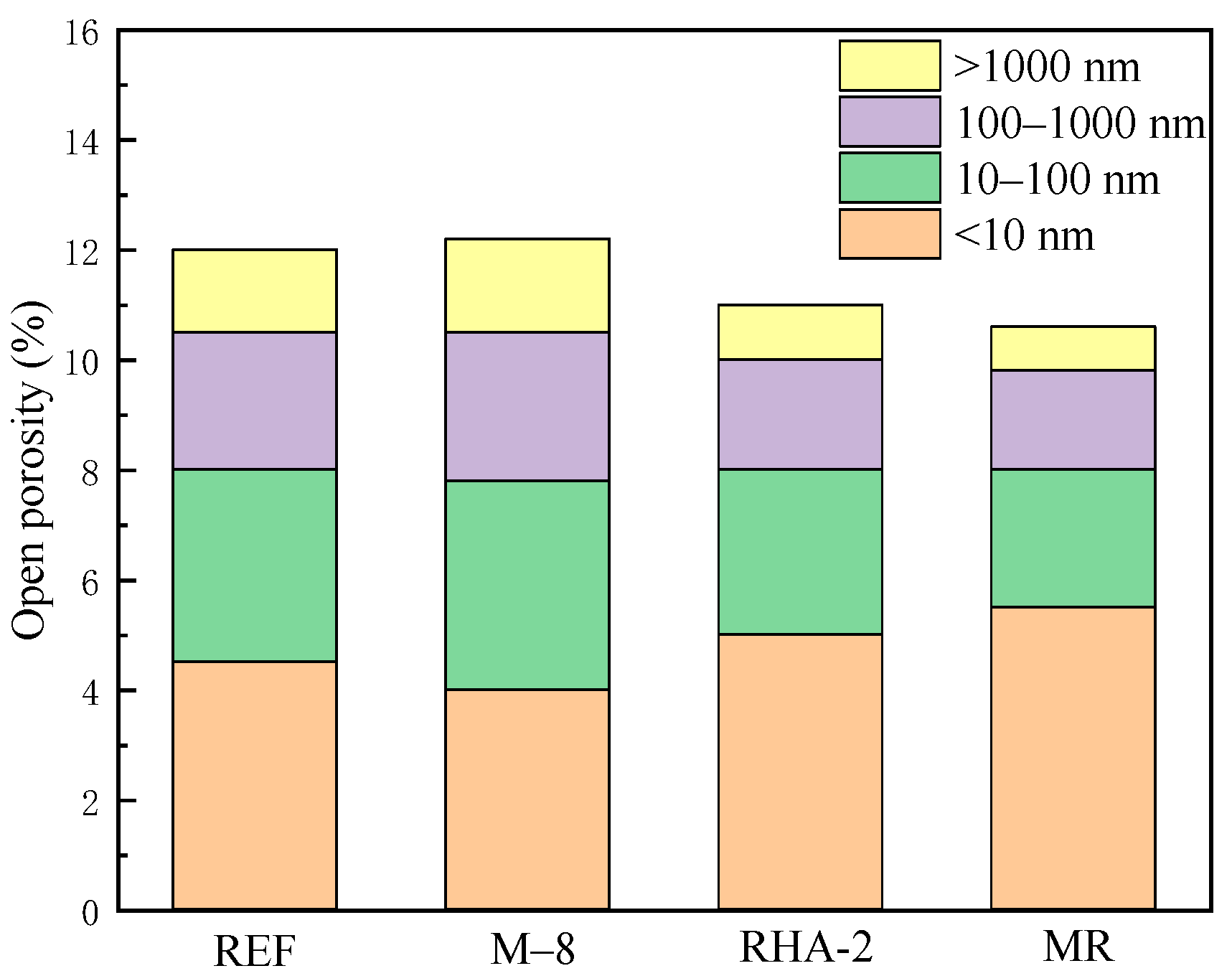

- Pore Structure

3. Results and Discussion

3.1. Workability of Concrete

3.2. Deformation Performance of Concrete

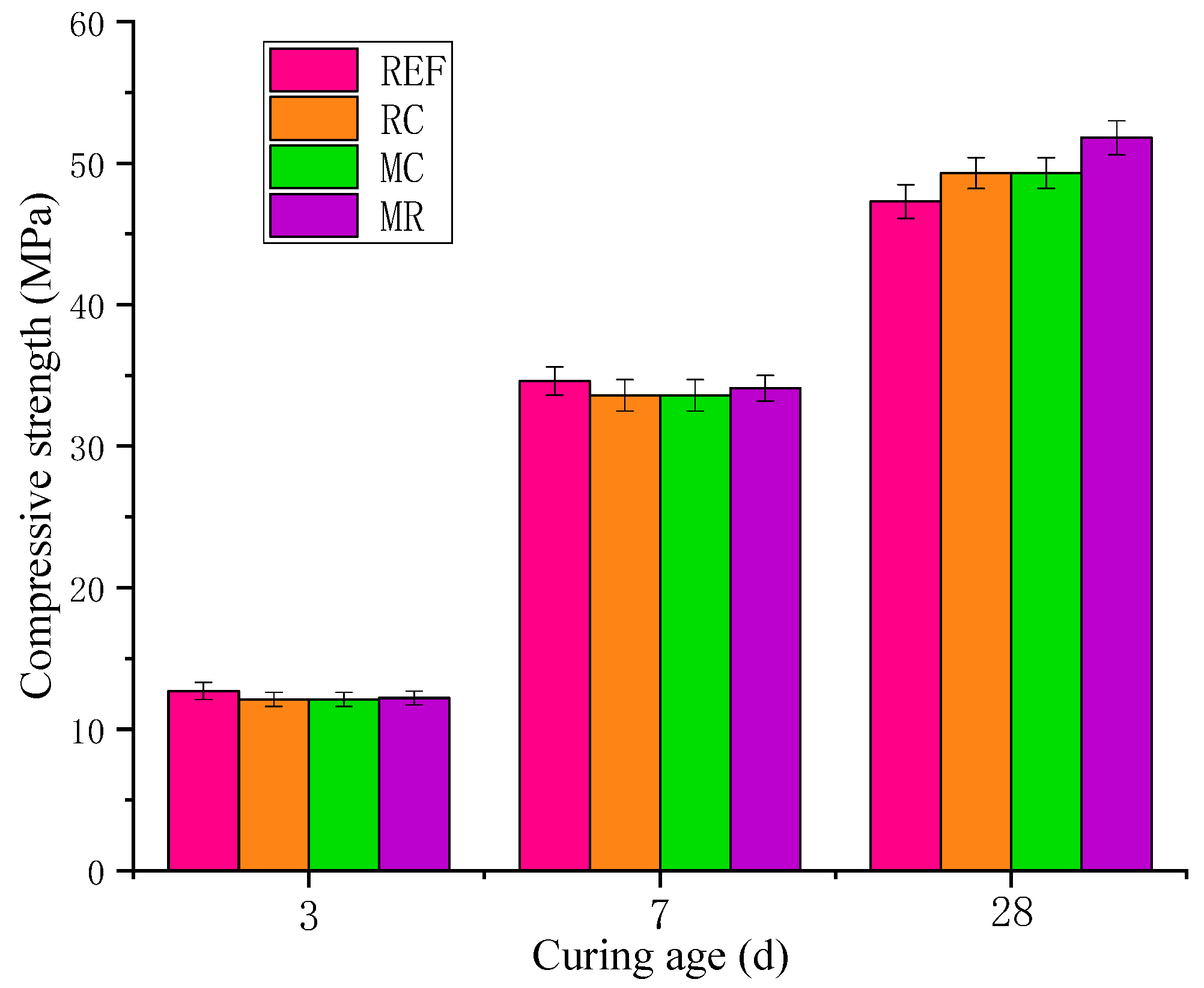

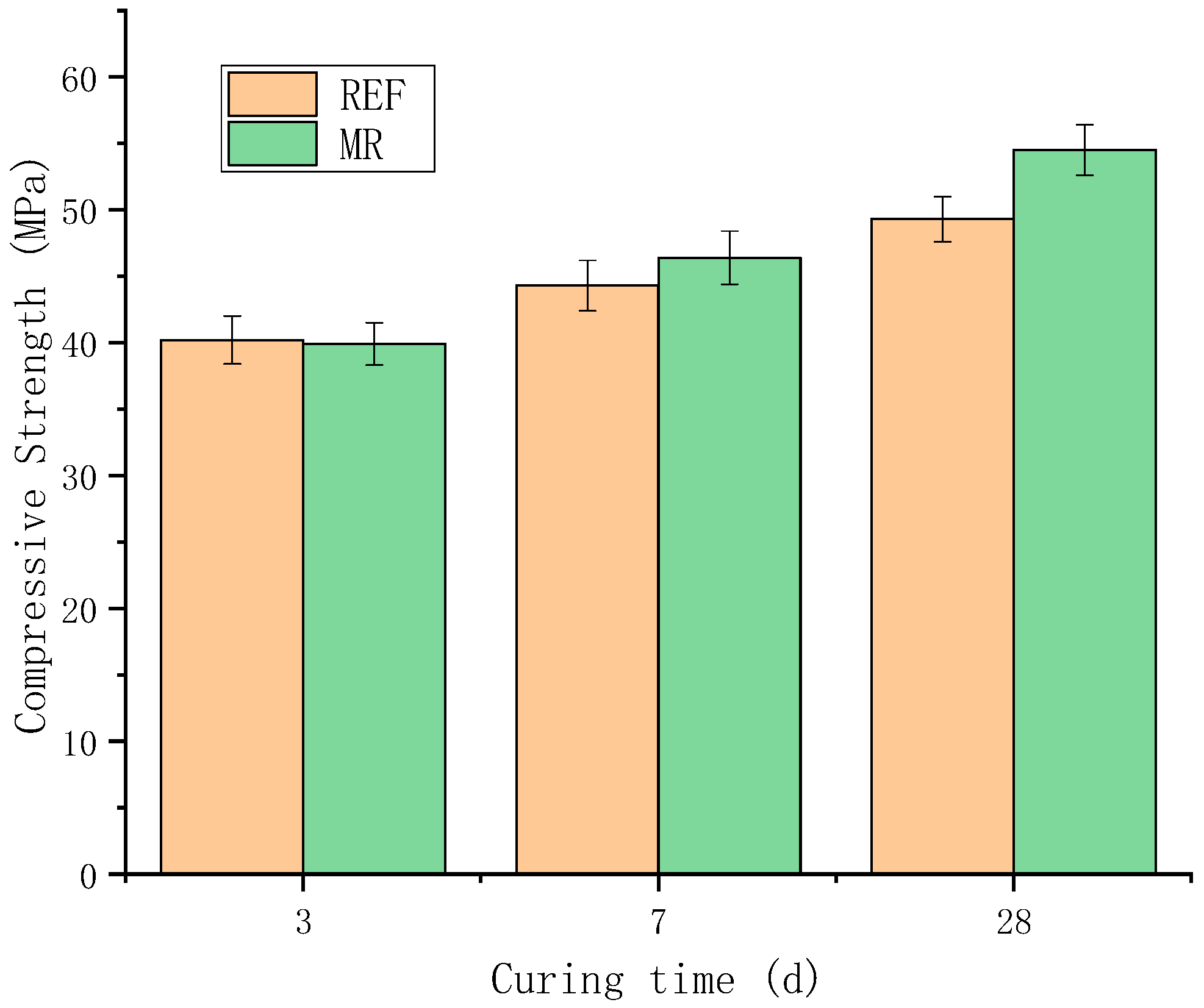

3.3. Mechanical Properties of Concrete

3.4. Field Test Results and Analysis

- (1)

- Engineering Challenges of Post-Cast Concrete in Tall buildings

- (2)

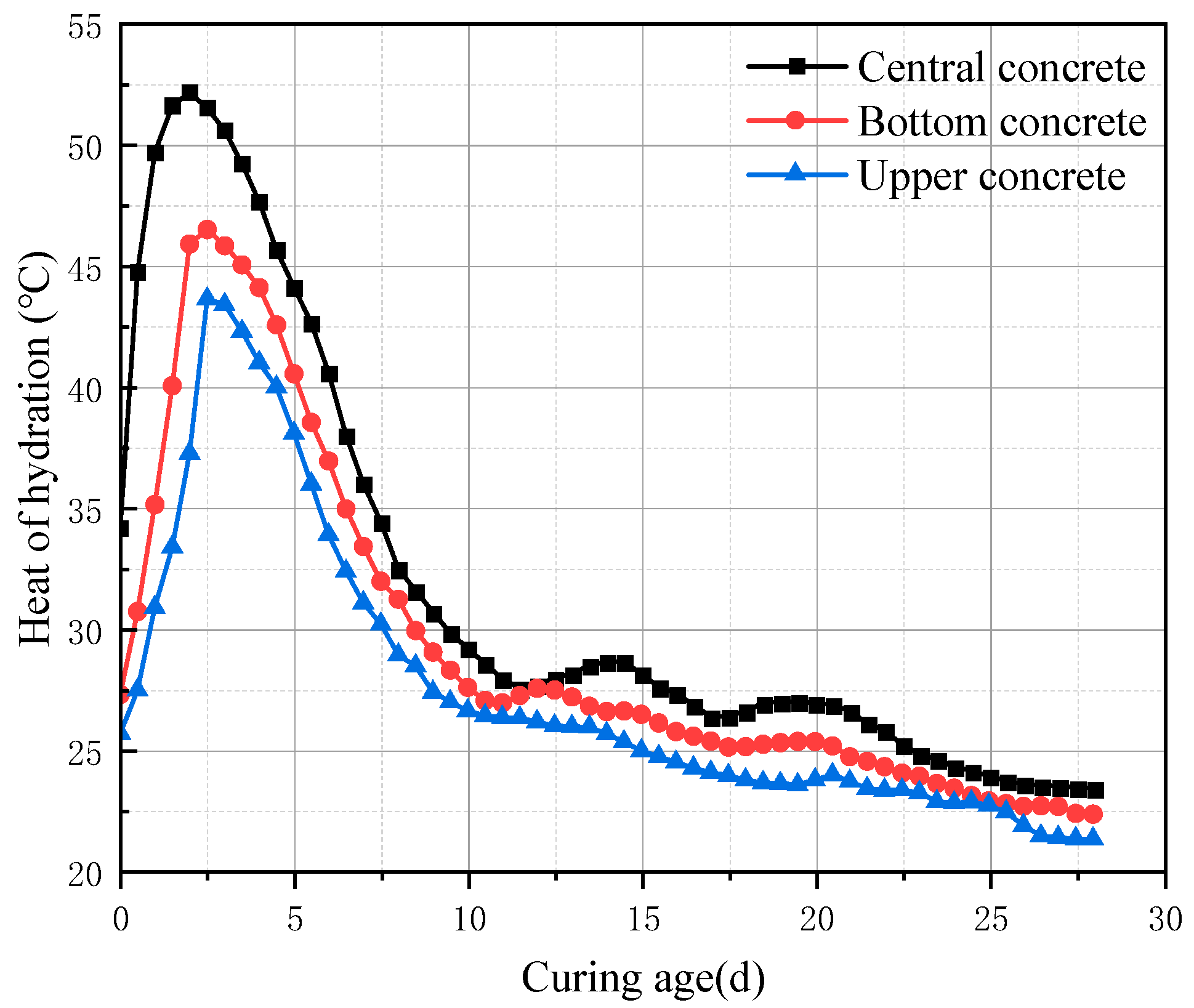

- Measured Temperature of Concrete Slab

- (3)

- Measured Deformation of the Concrete Slab

- (4)

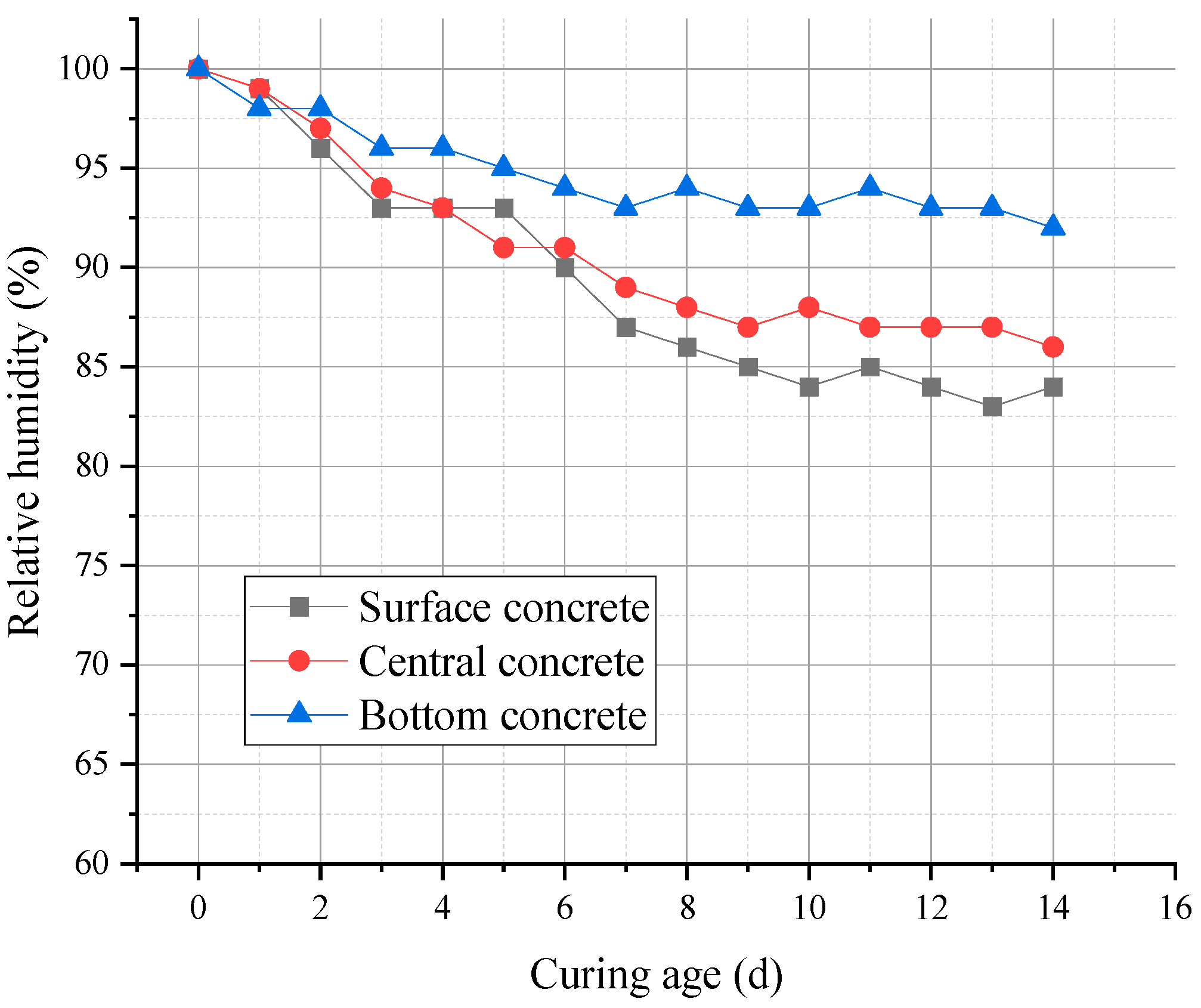

- Relative Humidity Inside Concrete at Different Positions

- (5)

- Degree of MEA Hydration

- (6)

- Measured Compressive Strength of Post-pour Concrete

4. Conclusions

- (1)

- The combined incorporation of MgO expansive agent (MEA) and rice husk ash (RHA) has demonstrated a synergistic effect on improving the crack resistance and durability of post-cast concrete used in tall building foundations. Their interaction effectively addresses both early-age shrinkage and long-term strength development.

- (2)

- MEA provided expansion to counteract shrinkage; however, its hydration was limited in low-humidity, highly restrained environments. RHA, serving as an internal curing agent, improved internal moisture conditions, promoted the continuous hydration of MEA, and participated in pozzolanic reactions, forming additional C-S-H and M-S-H gels. This dual mechanism optimized the pore structure, enhanced matrix densification, and significantly reduced cracking risks.

- (3)

- The composite mix showed reduced early-age workability due to the water absorption and ion exchange of MEA and the thickening effect of RHA. Slump loss was accelerated, and it is recommended that concrete be placed within 120 min of mixing to ensure good workability.

- (4)

- Compared to conventional concrete, the composite concrete exhibited 10.5% higher 28 d compressive strength, while maintaining excellent shrinkage control. Field application demonstrated its suitability for high-strength, densely reinforced post-cast strips in tall buildings, offering a practical and effective approach to mitigating shrinkage-induced cracking in large-volume structural elements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kvocka, D.; Sustersic, J.; Pranjic, A.M.; Mladenovic, A. Mass Concrete with EAF Steel Slag Aggregate: Workability, Strength, Temperature Rise, and Environmental Performance. Sustainability 2022, 14, 15502. [Google Scholar] [CrossRef]

- Mao, Y.G.; Liu, J.H.; Shi, C.J. Autogenous shrinkage and drying shrinkage of recycled aggregate concrete: A review. J. Clean. Prod. 2021, 295, 126435. [Google Scholar] [CrossRef]

- Dhahir, M.K.; Marx, S. Shrinkage behaviour of high-strength concrete plates reinforced with carbon textile reinforcement. Structures 2024, 69, 107504. [Google Scholar] [CrossRef]

- Stindt, J.; Forman, P.; Mark, P. Influence of Rapid Heat Treatment on the Shrinkage and Strength of High-Performance Concrete. Materials 2021, 14, 4102. [Google Scholar] [CrossRef] [PubMed]

- Won, J.P.; Kim, S.H.; Lee, S.J.; Choi, S.J. Shrinkage and durability characteristics of eco-friendly fireproof high-strength concrete. Constr. Build. Mater. 2013, 40, 753–762. [Google Scholar] [CrossRef]

- Pan, Z.F.; Meng, S.P. Three-level experimental approach for creep and shrinkage of high-strength high-performance concrete. Eng. Struct. 2016, 120, 23–36. [Google Scholar] [CrossRef]

- Li, P.J.; Chen, M.J.; Sun, W.H. Numerical Simulation Analysis of the Full-Section Immersed Tube with the Post-Pouring Belt under Hydration Reaction. Buildings 2023, 13, 2377. [Google Scholar] [CrossRef]

- Xu, F.; Yang, Z.; Liu, W.; Wang, S.; Zhang, H. Experimental investigation on the effect of sulfate attack on chloride diffusivity of cracked concrete subjected to composite solution. Constr. Build. Mater. 2020, 237, 117643. [Google Scholar] [CrossRef]

- Ying, J.; Yan, H.; Huang, J.; Li, Z.A.; Chen, B. Simulation of concrete cracking and chloride diffusion under uniaxial compression. J. Build. Eng. 2024, 96, 110329. [Google Scholar] [CrossRef]

- Neves, R.; Vicente, C.; Castela, A.; Montemor, M.F. Durability performance of concrete incorporating spent fluid cracking catalyst. Cem. Concr. Compos. 2015, 55, 308–314. [Google Scholar] [CrossRef]

- Li, K.F.; Li, L. Crack-altered durability properties and performance of structural concretes. Cem. Concr. Res. 2019, 124, 105811. [Google Scholar] [CrossRef]

- Mo, L.W.; Deng, M.; Tang, M.S.; Al-Tabbaa, A. MgO expansive cement and concrete in China: Past, present and future. Cem. Concr. Res. 2014, 57, 1–12. [Google Scholar] [CrossRef]

- Kabir, H.; Hooton, R.D. Evaluating soundness of concrete containing shrinkage-compensating MgO admixtures. Constr. Build. Mater. 2020, 253, 119141. [Google Scholar] [CrossRef]

- Tian, C.J.; Wang, Y.Z.; Qiu, K.; Yang, Q.L. Effects of submicron-MgO and nano-MgO on the expansion and microscopic properties of high-performance concrete. J. Cent. South Univ. 2022, 29, 3186–3200. [Google Scholar] [CrossRef]

- Guo, J.J.; Zhang, S.W.; Guo, T.; Zhang, P. Effects of UEA and MgO expansive agents on fracture properties of concrete. Constr. Build. Mater. 2020, 263, 120245. [Google Scholar] [CrossRef]

- Wang, A.G.; Sun, D.S.; Deng, M.; Chen, X.M.; Zhang, F.J. Influence of Restraint on Pore Structures and Air Permeability of Concrete Containing MgO-Type Expansive Agent. Asian J. Chem. 2013, 25, 5532–5534. [Google Scholar] [CrossRef]

- Wang, L.; Song, X.; Yang, H.; Wang, L.; Tang, S.; Wu, B.; Mao, W. Pore Structural and Fractal Analysis of the Effects of MgO Reactivity and Dosage on Permeability and F–T Resistance of Concrete. Fractal Fract. 2022, 6, 113. [Google Scholar] [CrossRef]

- Liu, K.; Cui, Y.; Yu, X. Analysis of the influence of MgO expansion agent on the expansion performance of cement mortar under constant humidity and variable humidity curing conditions. Mater. Introd. 2025, 39, 80–86. (In Chinese) [Google Scholar]

- Wang, J.L.; Jiang, F.F.; Wang, R. Study on the interaction between limestone filler and rice husk ash on the rheological properties of cement composite pastes. Constr. Build. Mater. 2024, 456, 139247. [Google Scholar] [CrossRef]

- Jiang, F.; Liu, R.; Mao, Z.; Deng, M. The combined effect of steel fiber and MgO on the deformation and mechanical properties of high-strength concrete. J. Mater. Res. Technol.-JMRT 2023, 26, 4296–4309. [Google Scholar] [CrossRef]

- GB/T 50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2002.

- Mo, L.; Fang, J.; Huang, B.; Wang, A.; Deng, M. Combined effects of biochar and MgO expansive additive on the autogenous shrinkage, internal relative humidity and compressive strength of cement pastes. Constr. Build. Mater. 2019, 229, 116877. [Google Scholar] [CrossRef]

- JGJ/T23-2011; Technical Specification for Inspection of Concrete Compressive Strength by Rebound Method. China Architecture & Building Press: Beijing, China, 2011.

- GBT50107-2013; Standard for Test Methods of Concrete Strength. Standards Press of China: Beijing, China, 2013.

- Li, S.K.; Mo, L.W.; Deng, M.; Cheng, S.K. Mitigation on the autogenous shrinkage of ultra-high performance concrete via using MgO expansive agent. Constr. Build. Mater. 2021, 312, 125422. [Google Scholar] [CrossRef]

- Zhang, R.X.; Panesar, D.K. New approach to calculate water film thickness and the correlation to the rheology of mortar and concrete containing reactive MgO. Constr. Build. Mater. 2017, 150, 892–902. [Google Scholar] [CrossRef]

- Wang, K.; Moon, J.; Du, H.J.; Xia, X.; Zhu, D.; Zhang, P.; Guo, J.J. Early-age shrinkage and hydration of concrete incorporating a mutually reinforcing systems of super absorbent polymers and MgO expansive agent under low humidity conditions. Constr. Build. Mater. 2024, 417, 135350. [Google Scholar] [CrossRef]

- Jeon, I.K.; Woo, B.H.; Yoo, D.H.; Ryou, J.S.; Kim, H.G. Evaluation of the Hydration Characteristics and Anti-Washout Resistance of Non-Dispersible Underwater Concrete with Nano-SiO2 and MgO. Materials 2021, 14, 1328. [Google Scholar] [CrossRef]

- Liu, J.P.; Tian, Q.; Wang, Y.J.; Li, H.; Xu, W. Evaluation Method and Mitigation Strategies for Shrinkage Cracking of Modern Concrete. Engineering 2021, 7, 348–357. [Google Scholar] [CrossRef]

- Endale, S.A.; Taffese, W.Z.; Vo, D.H.; Yehualaw, M.D. Rice Husk Ash in Concrete. Sustainability 2023, 15, 137. [Google Scholar] [CrossRef]

- Mo, L.W.; Deng, M.; Tang, M.S. Effects of calcination condition on expansion property of MgO-type expansive agent used in cement-based materials. Cem. Concr. Res. 2010, 40, 437–446. [Google Scholar] [CrossRef]

- Bandara, D.H.M.S. Development of blended cement utilizing the pozzolanic amorphous silica component of rice husk ash. J. Natl. Sci. Counc. Sri Lanka 1994, 22, 189–199. [Google Scholar] [CrossRef]

- Rattanachu, P.; Toolkasikorn, P.; Tangchirapat, W.; Chindaprasirt, P.; Jaturapitakkul, C. Performance of recycled aggregate concrete with rice husk ash as cement binder. Cem. Concr. Compos. 2020, 108, 103533. [Google Scholar] [CrossRef]

- Abellán-García, J. Effect of rice husk ash as partial replacement of ordinary Portland cement in ultra-high-performance glass concrete. Eur. J. Environ. Civ. Eng. 2024, 28, 661–683. [Google Scholar] [CrossRef]

- He, P.P.; Poon, C.S.; Tsang, D. Comparison of glass powder and pulverized fuel ash for improving the water resistance of magnesium oxychloride cement. Cem. Concr. Compos. 2018, 86, 98–109. [Google Scholar] [CrossRef]

- Yang, Y.; Yao, J.; Liu, J.; Kong, D.; Gu, C.; Wang, L. Evaluation of the thermal and shrinkage stresses in restrained concrete: New method of investigation. Constr. Build. Mater. 2024, 411, 134493. [Google Scholar] [CrossRef]

- Chen, S.; Zhao, H.; Chen, Y.; Huang, D.; Chen, Y.; Chen, X. Experimental study on interior relative humidity development in early-age concrete mixed with shrinkage-reducing and expansive admixtures. Constr. Build. Mater. 2020, 232, 117204. [Google Scholar] [CrossRef]

- Li, H.; Tian, Q.; Zhao, H.T.; Lu, A.Q.; Liu, J. Temperature sensitivity of MgO expansive agent and its application in temperature crack mitigation in shiplock mass concrete. Constr. Build. Mater. 2018, 170, 613–618. [Google Scholar] [CrossRef]

| Chemicals | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | K2O | Cl | LOI |

|---|---|---|---|---|---|---|---|---|---|---|

| RHA | 78.25 | 0.33 | 0.28 | 0.933 | 0.395 | 0.143 | 0.053 | 0.052 | 0.016 | 19.548 |

| No. | Cement | Coarse Aggregate | Fine Aggregate | Water | Water Reducer | MEA | RHA |

|---|---|---|---|---|---|---|---|

| REF | 450 | 980 | 740 | 172 | 5.7 | ||

| MC | 414 | 980 | 740 | 172 | 5.7 | 36 | |

| RC | 441 | 980 | 740 | 172 | 5.7 | 9 | |

| MR | 405 | 980 | 740 | 172 | 5.7 | 36 | 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, F.; Xing, Y.; Deng, W.; Wang, Q.; Wang, J.; Mao, Z. Effect of Combined MgO Expansive Agent and Rice Husk Ash on Deformation and Strength of Post-Cast Concrete. Materials 2025, 18, 2815. https://doi.org/10.3390/ma18122815

Jiang F, Xing Y, Deng W, Wang Q, Wang J, Mao Z. Effect of Combined MgO Expansive Agent and Rice Husk Ash on Deformation and Strength of Post-Cast Concrete. Materials. 2025; 18(12):2815. https://doi.org/10.3390/ma18122815

Chicago/Turabian StyleJiang, Feifei, Yijiang Xing, Wencong Deng, Qi Wang, Jialei Wang, and Zhongyang Mao. 2025. "Effect of Combined MgO Expansive Agent and Rice Husk Ash on Deformation and Strength of Post-Cast Concrete" Materials 18, no. 12: 2815. https://doi.org/10.3390/ma18122815

APA StyleJiang, F., Xing, Y., Deng, W., Wang, Q., Wang, J., & Mao, Z. (2025). Effect of Combined MgO Expansive Agent and Rice Husk Ash on Deformation and Strength of Post-Cast Concrete. Materials, 18(12), 2815. https://doi.org/10.3390/ma18122815