1. Introduction

In 2024, China’s total coal consumption was 5.96 billion tons, accounting for 53.2% of the country’s total energy consumption [

1]. Chinese coal-fired power plants generate approximately 600–700 million tons of solid industrial residues annually, primarily comprising fly ash (about 80–90%) and coal-fired slag (about 10–20%). Fly ash comprises fine particulate matter collected from flue gases, whereas coal-fired slag refers to the coarser residues accumulated at the bottom of the furnace (also referred to as bottom ash or cinder) [

2].

Fly ash has been widely adopted in industrial applications, particularly as a cementitious additive in concrete and construction materials, owing to its favorable pozzolanic properties and consistent particle morphology [

3,

4]. However, the potential application of cinder is fundamentally limited by its unstable structure and poor compaction characteristics, which seriously affect its functionality [

5,

6]. Therefore, only a limited fraction of cinder is utilized in subbase fill and brick manufacturing [

7,

8,

9]. Over 85% of the cinder generated by coal-fired power plants is either stockpiled in open-air storage or disposed of in landfills, which has a significant impact on the surrounding air and soil [

4,

10,

11]. Recent studies have confirmed the potential of cinder for use in construction applications. However, in China, its value-added utilization remains limited and is primarily restricted to brick production and road construction. Zhang et al. [

12] prepared three different types of sintered bricks using lakebed mud, cinder, and sludge as the primary raw materials. Moreno Nabarro et al. [

13], Fedorova and Shaforost [

14], and other researchers have found that using cinder as a substitute for traditional road construction materials in road construction and maintenance applications can yield some economic benefits. In addition, cinder can be used to produce concrete [

5,

15]. Coarse aggregates can partially replace the stone, while fine aggregates can replace some of the sand and cement [

16,

17,

18,

19]. In recent years, much research has focused on using cinder to prepare concrete mixtures. However, bricks containing cinder are prone to cracking, and using cinder as a road base or fine aggregate fails to utilize its chemical properties, leading to resource waste. It is urgent to reasonably and fully develop and utilize cinder.

Cinder contains significant amounts of reactive components such as SiO2 and Al2O3, which enable its use as a supplementary cementitious material. This application can help reduce cement consumption and enhance its added value in construction materials. However, its low early-age reactivity limits the incorporation ratio, hindering large-scale application. Existing technologies improve its reactivity through superfine grinding, but this results in high energy consumption and costs. Therefore, finding ways to increase the cinder content while reducing costs and improving cement strength has become a key challenge.

Cement-based materials are among the most widely used structural materials in modern construction projects, and their mechanical properties have a significant impact on both the engineering quality and durability. As core components, cement clinker and cinder not only influence the process of the hydration reaction but also directly determine the microstructure of the paste and its mechanical properties.

Composite cement is typically produced by blending Portland cement with supplementary cementitious materials (SCMs), including ground granulated blast-furnace slag, fly ash, or steel slag. Currently, the content of high-activity waste residues (such as slag and fly ash) in composite cement can reach 20–30%, while the content of low-activity waste residues (such as cinder and steel slag) is usually below 10% [

20,

21,

22,

23]. This preparation method is relatively simple, but the utilization of SCMs is low. When the content of these materials is higher, the early strength and other properties of the blended cement are poor, which limits the amount of SCMs that can be incorporated into the blended cement.

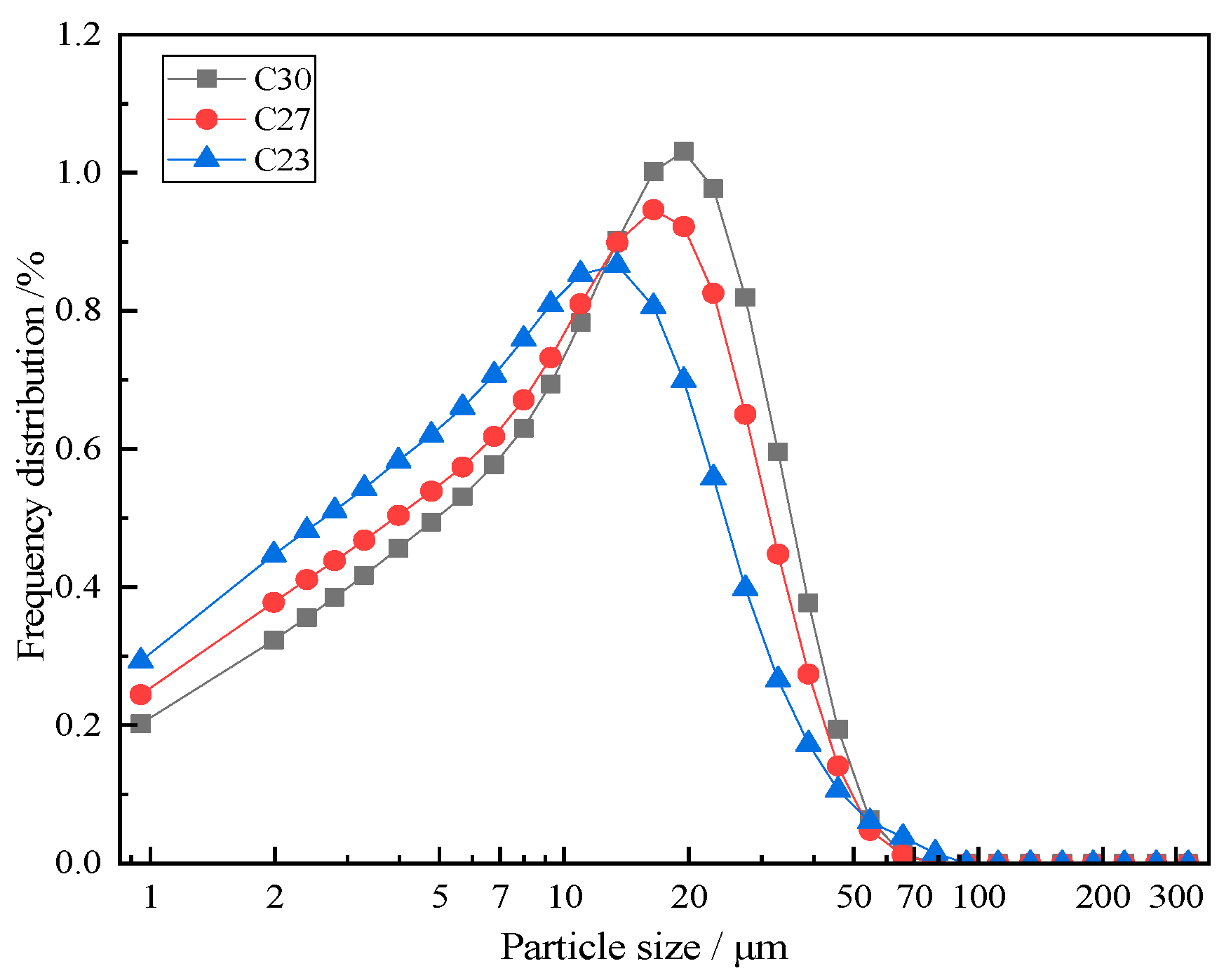

In addition, analyzing the particle size distribution of cement using the Rosin–Rammler–Bennet (RRB) distribution and the Fuller ideal packing curve [

24,

25] reveals that an insufficient amount of fine cement particles makes it difficult for the grinding system to achieve the ideal packing curve in a single process. Even when energy consumption is not considered, achieving the Fuller ideal packing curve through particle selection and blending would still lead to increased water demand, reduced early strength, poorer workability, and shrinkage cracking issues. This is evidently impractical and unsuitable for guiding production. Therefore, researchers recommend using a graded grinding process, where SCMs replace some of the fine cement particles. This approach not only optimizes the particle packing density but also mitigates the adverse effects of excessively fine cement particles [

26,

27].

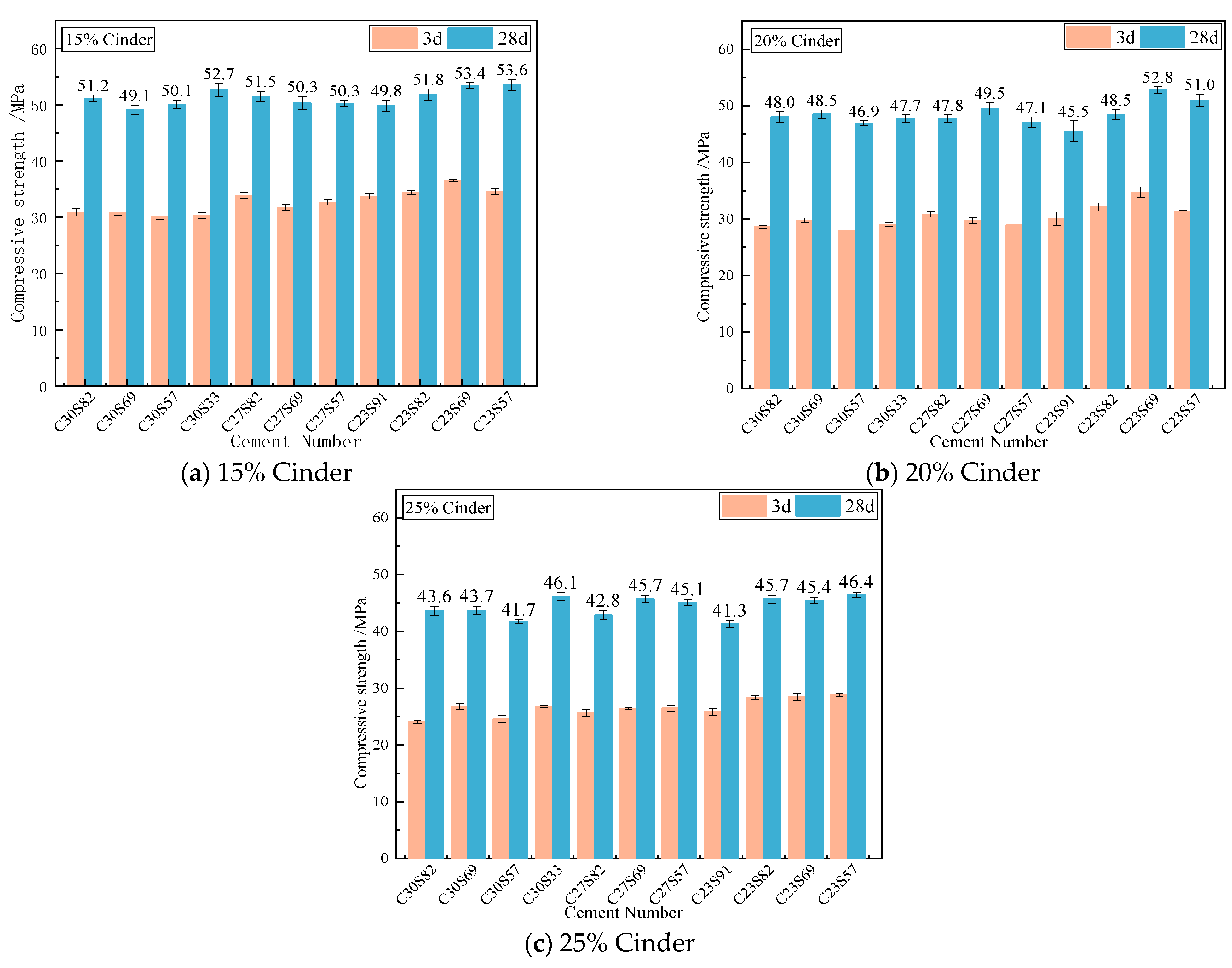

In recent years, a large number of scholars have focused on the ultrafine grinding of low-grade SCMs, solid waste, or industrial by-products, and their subsequent blending with cement clinker. Kupwade-Patil et al. replaced Portland cement with finer volcanic ash components obtained through grinding and found that the finer volcanic ash components produced a more compact pore structure in the paste, thereby achieving higher compressive strength [

28]. Carvalho et al. conducted experiments and found that replacing 25% of Portland cement with fine recycled powder in cement mortar resulted in almost the same compressive strength as the control group mortar [

29]. Other researchers have found that, when the replacement rate of fine steel slag does not exceed 20%, its effect on the strength and drying shrinkage of ordinary concrete can be considered negligible [

30]. Bui et al. found that, compared to the combination with fine cement, the composite of rice husk ash with coarse cement resulted in a higher increase in the relative strength of the paste [

31]. Pormmoon et al. [

32] found that micronized high-calcium and low-calcium coal bottom ash (D50 ≈ 4 μm) significantly improved the 28-day compressive strength of high-performance concrete while reducing chloride permeability and water adsorption. This was attributed to the filler effect of fine particles and pore refinement via pozzolanic reactions. Liew et al. [

33] systematically studied the synergistic gradation effects of low-calcium coal bottom ash (LCBA) and ground granulated blast-furnace slag (GGBS). When 15% cement was replaced by LCBA combined with GGBS, the ternary blend achieved 58.1 MPa compressive strength (52.5 N grade) with 45% lower CO

2 emissions. These studies confirm that particle gradation optimization is critical for enhancing cement’s mechanical properties and durability. They also propose a sustainable strategy: balancing performance and environmental benefits by tailoring fineness and calcium content [

32,

33]. Thus, integrating coal-based waste with clinker and slag, guided by particle design, could optimize cement performance while reducing environmental impact.

Despite extensive research on the use of cinder in cementitious materials, several critical gaps remain. First, most studies focus on ultrafine grinding of cinder to enhance reactivity, which incurs high energy costs without proportional strength gains. Second, the synergistic effects of particle gradation between clinker and cinder on hydration kinetics and pore structure evolution are poorly understood. Third, existing work rarely addresses the trade-off between water demand and mechanical properties when optimizing particle size distributions. This study fills these gaps by (1) proposing a cost-effective strategy combining fine clinker with coarse cinder to balance reactivity and water requirements, (2) systematically linking particle gradation to microstructure development through hydration heat and pore analysis, and (3) establishing an optimal fineness ratio (clinker: 498 m2/kg; cinder: 210 m2/kg) that outperforms conventional blends in terms of both strength and workability. These contributions advance the sustainable utilization of cinder while reducing grinding energy consumption.