Effect of a Recycled Phosphogypsum Modifier on the Performance of High-Content Phosphogypsum Cementing Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Specimen Preparation

2.2.1. Preparation of the Modifiers

2.2.2. Characterization of the Modifiers

2.2.3. Sample Preparation

2.3. Test Methods

2.3.1. Workability Testing

2.3.2. Mechanical Performance Testing

2.3.3. Hydration Heat

2.3.4. Characterization of the Hydration Products

2.3.5. Microstructure Testing

3. Characterization of Modifiers

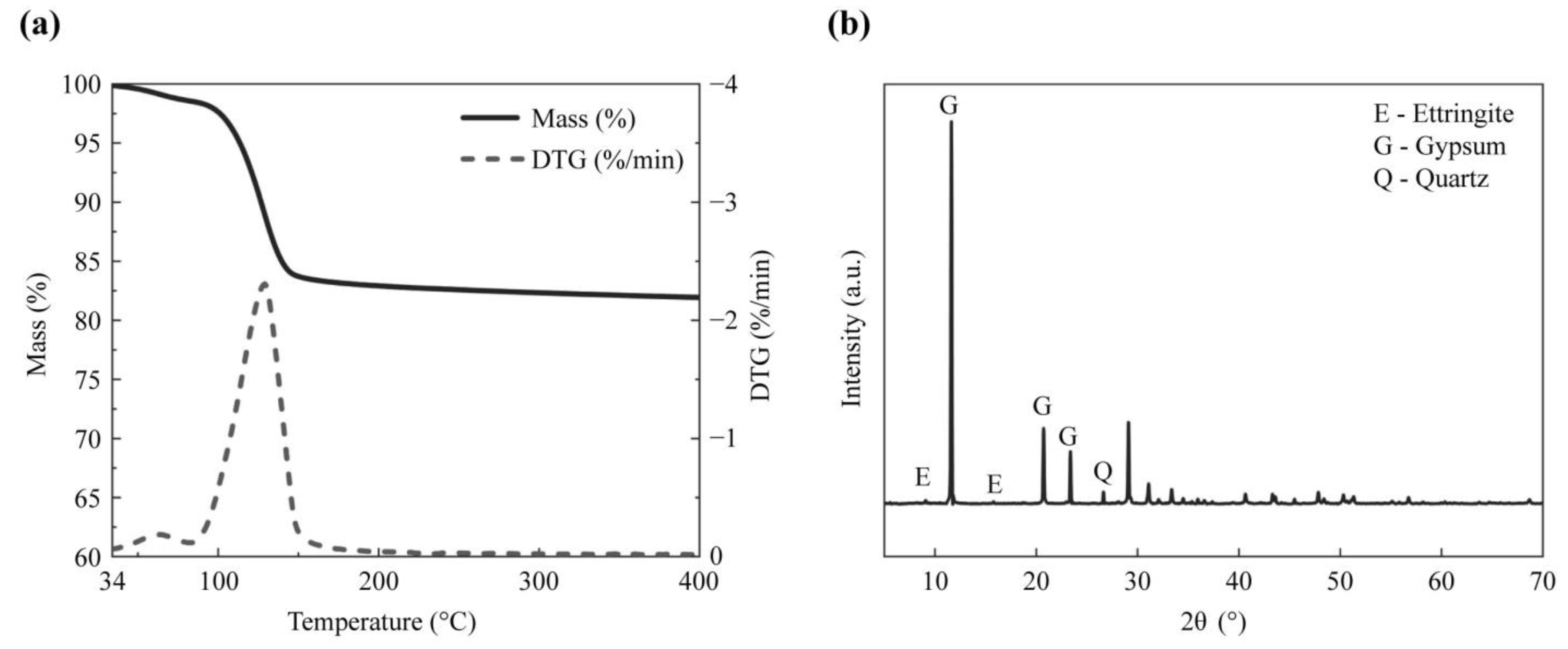

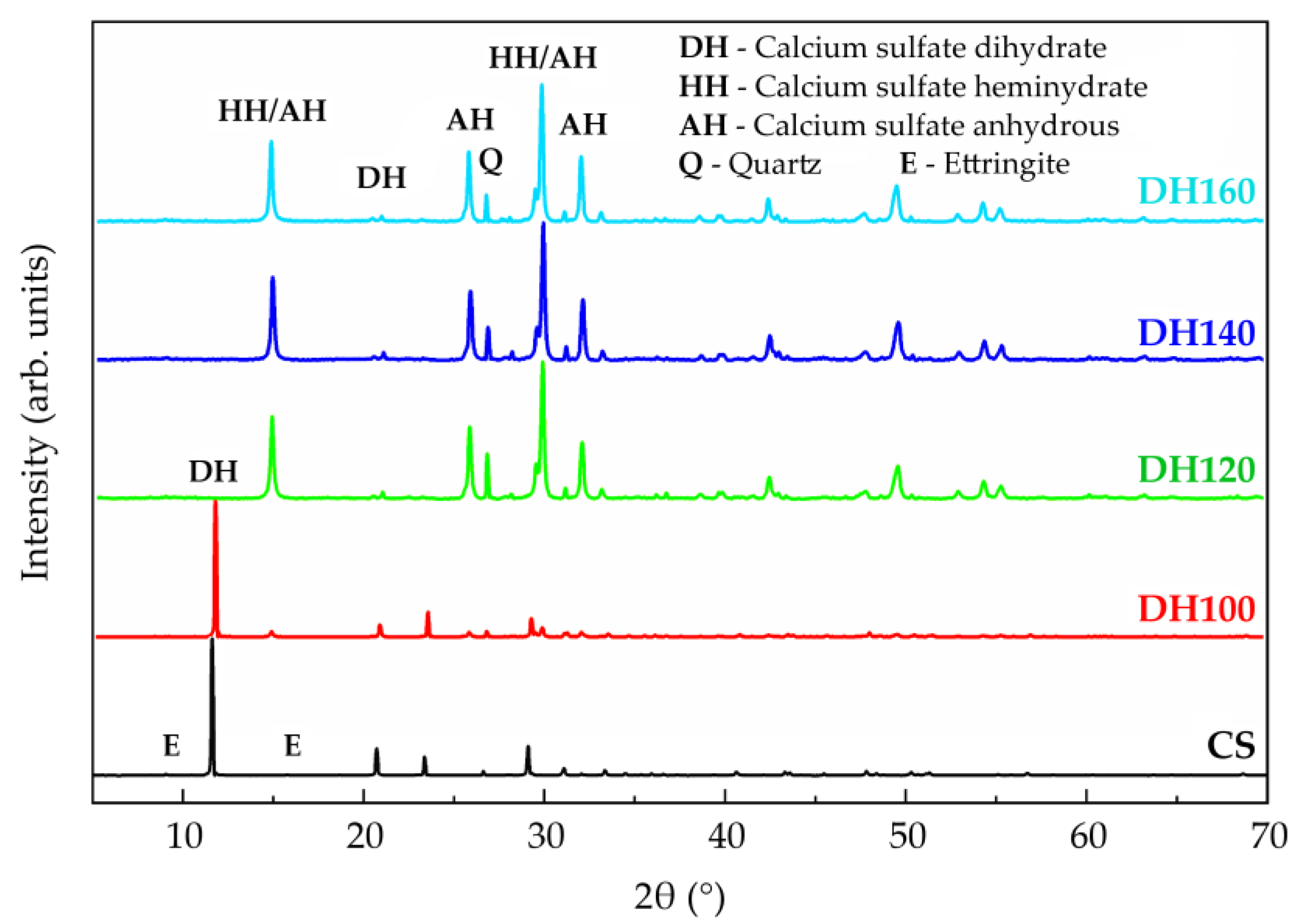

3.1. Phase Composition

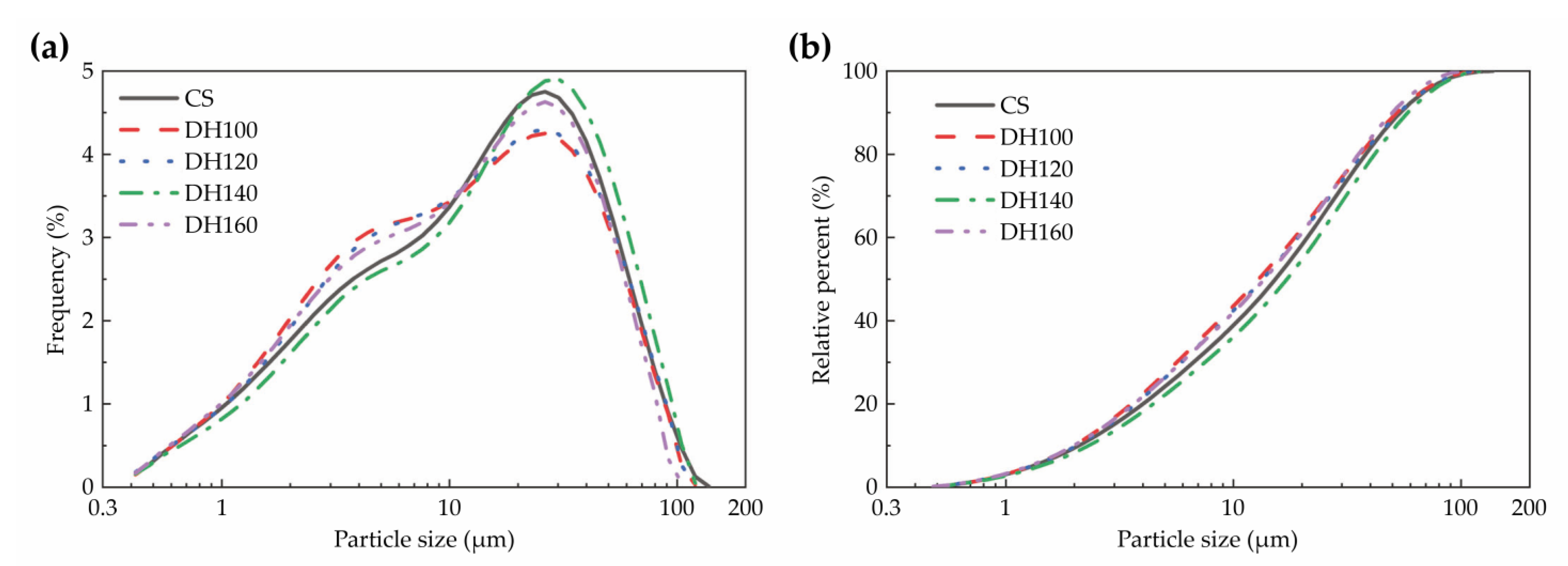

3.2. Particle Size Distribution

4. Results and Discussion

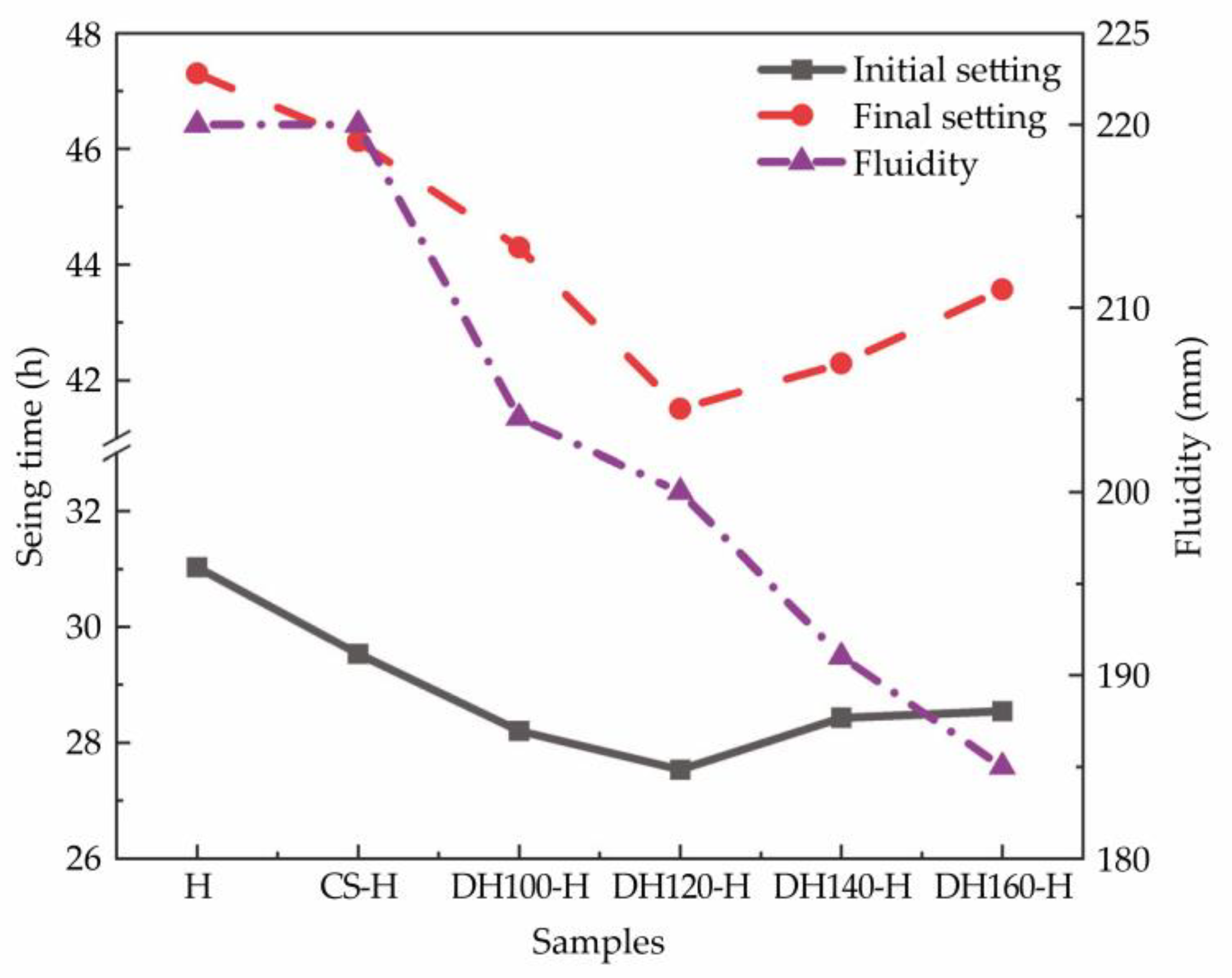

4.1. Workability

4.2. Mechanical Performance

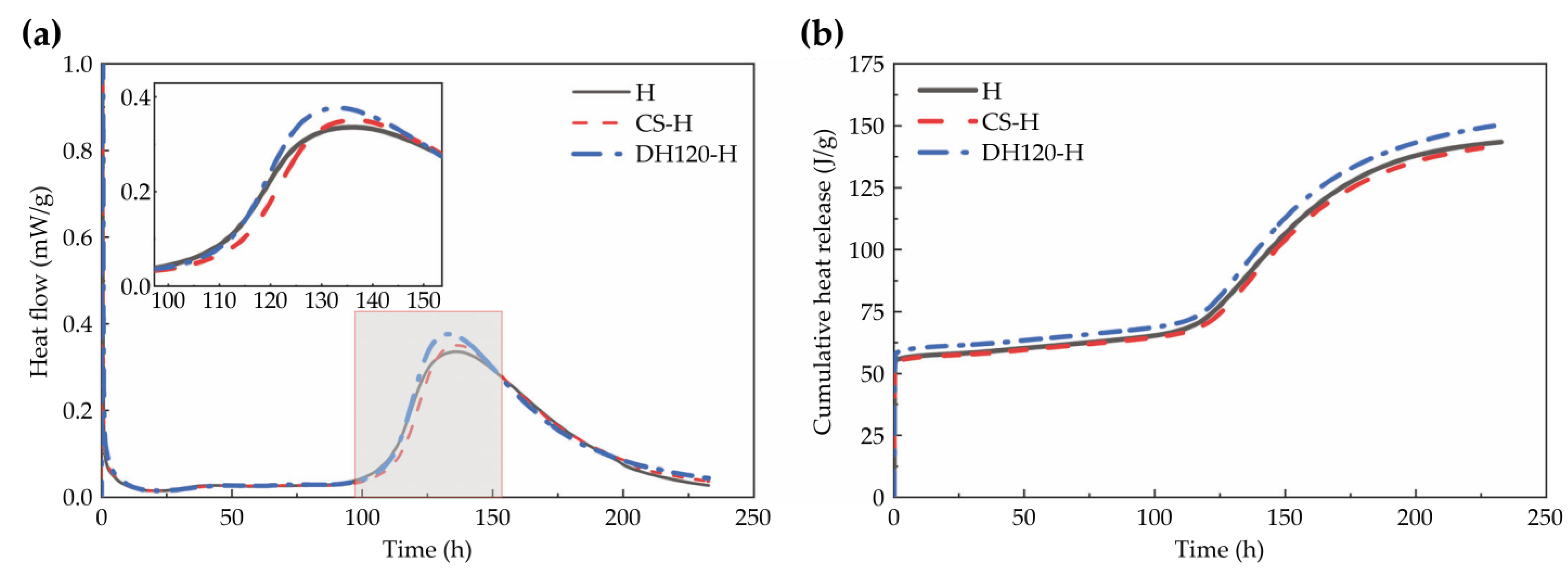

4.3. Hydration Process

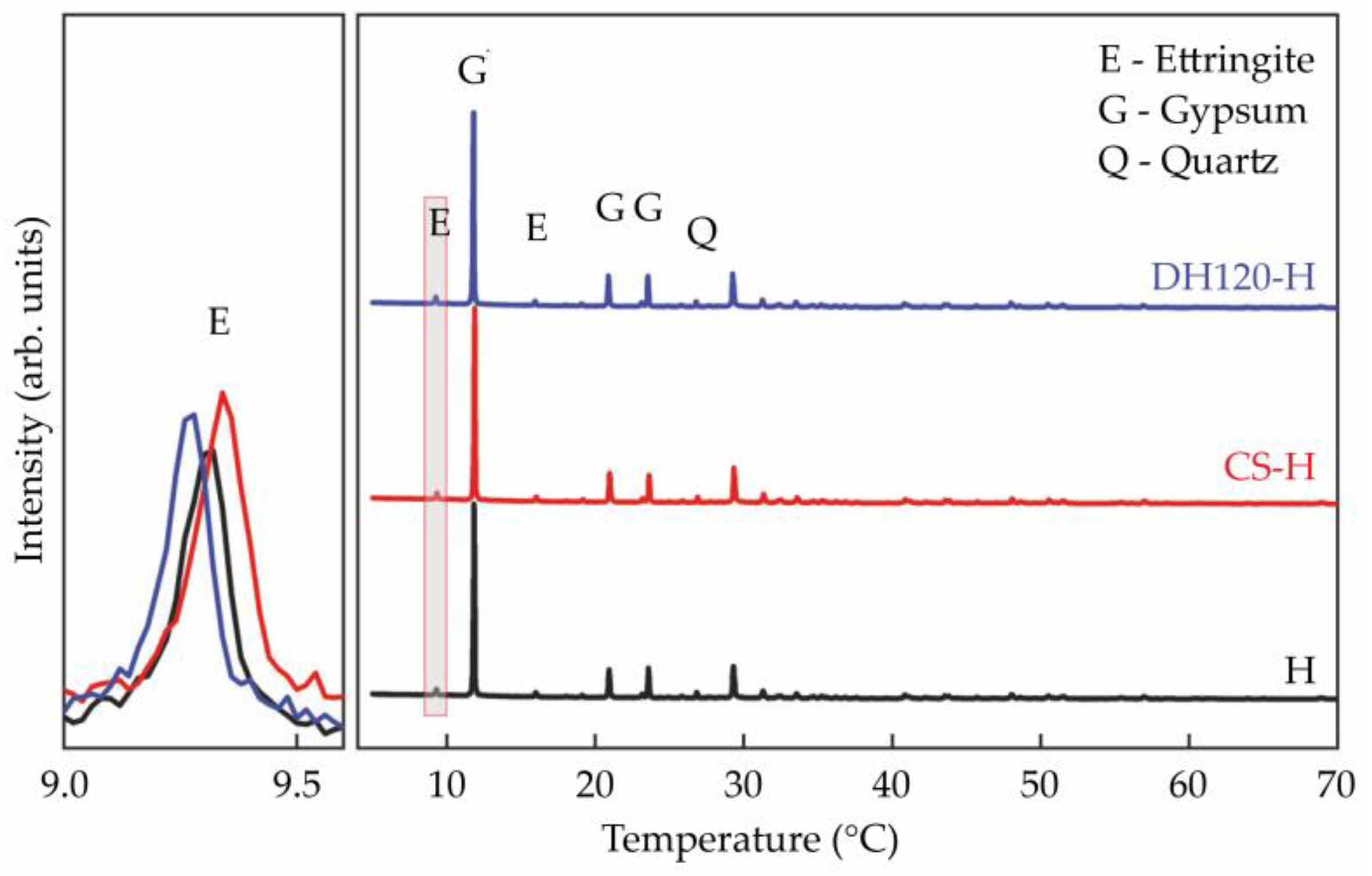

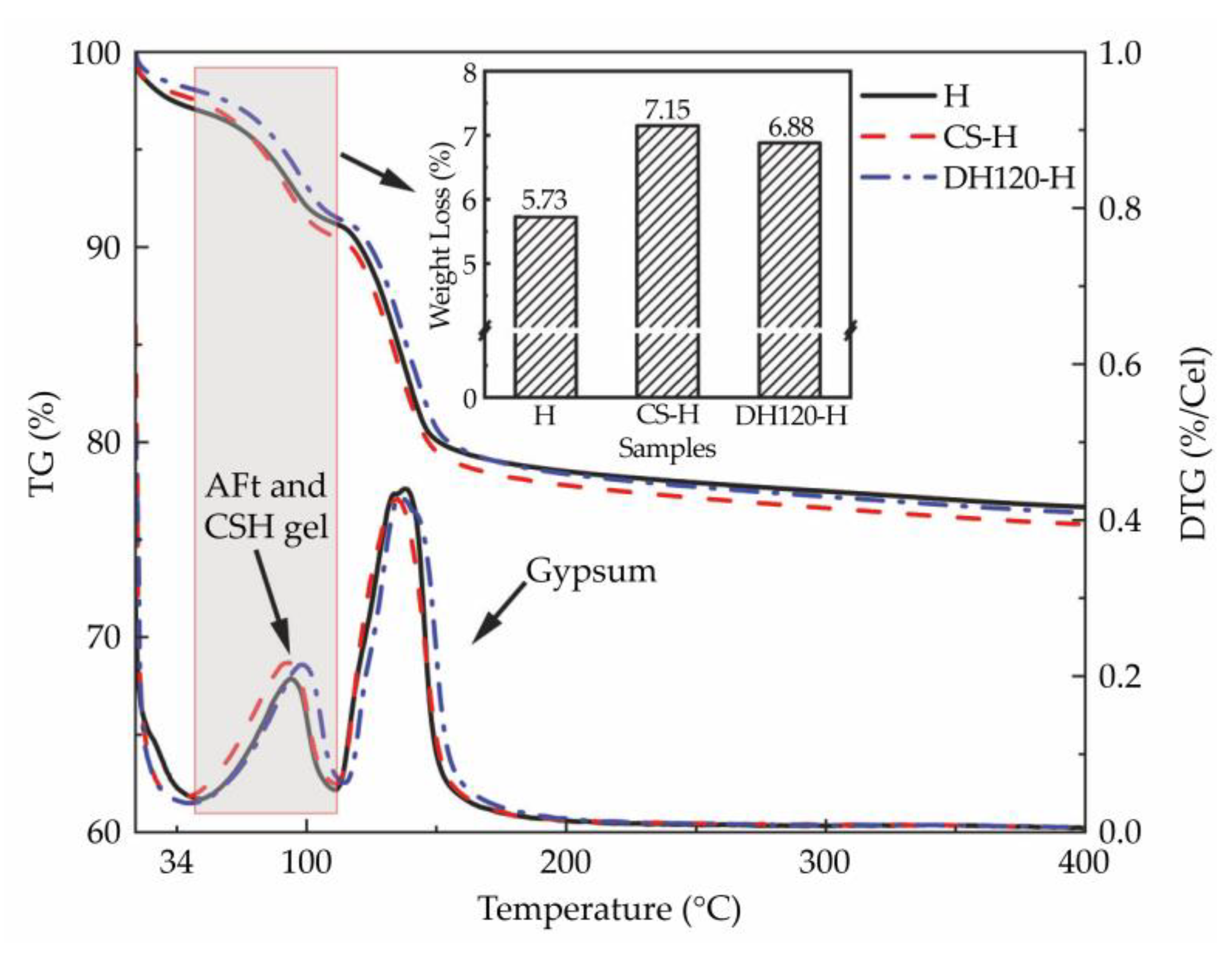

4.4. Phase Analysis of the Hydration Products

4.5. Microstructure Study

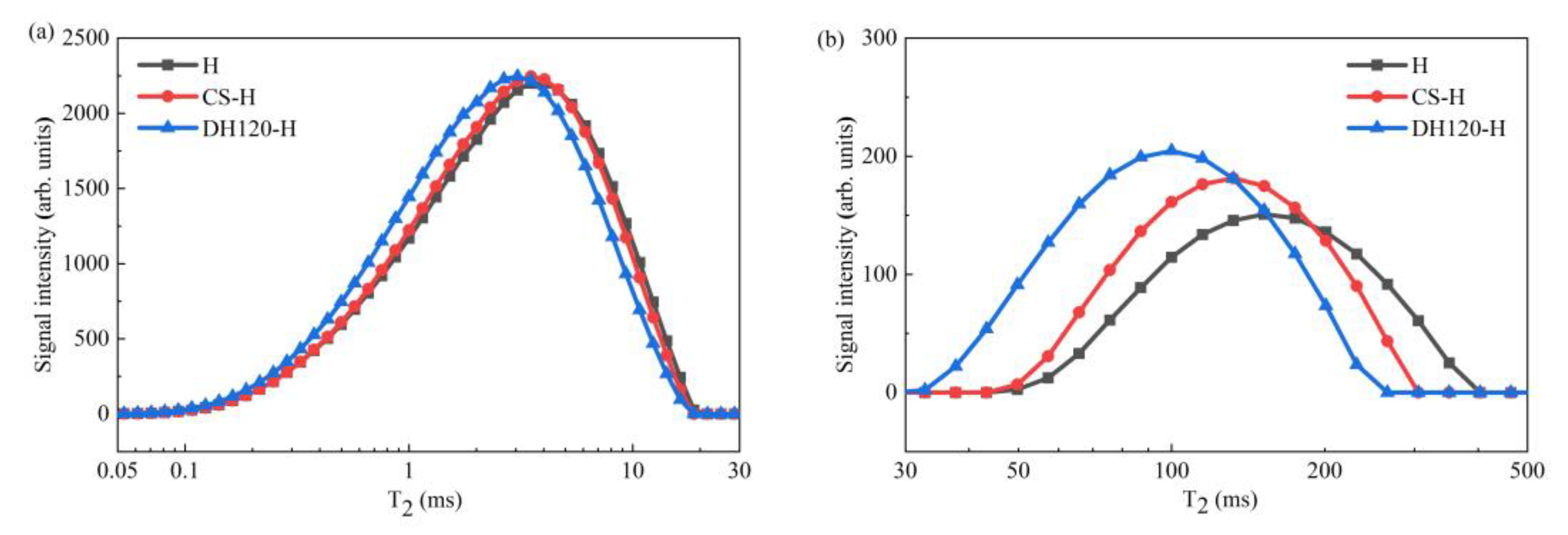

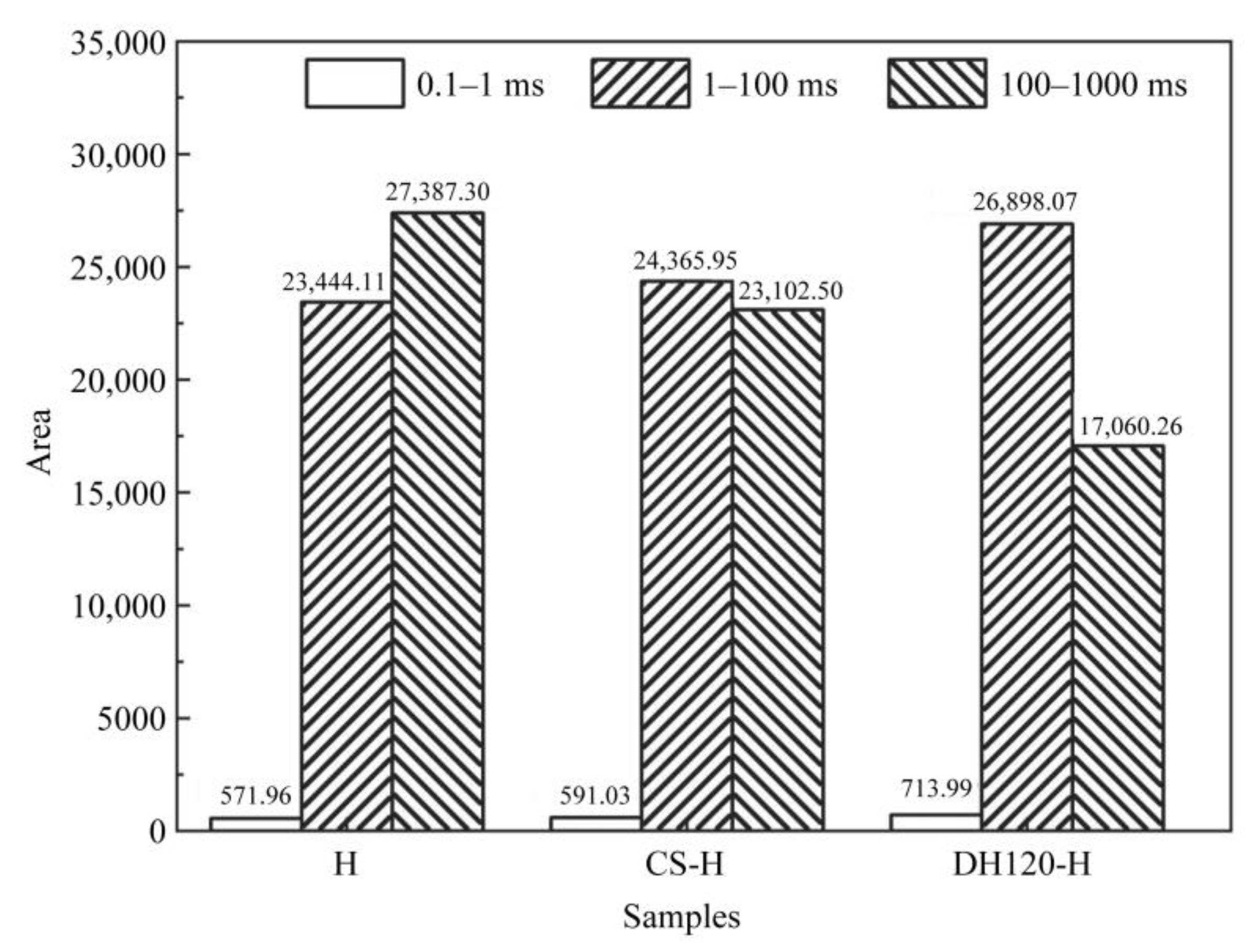

4.5.1. LF-NMR

4.5.2. SEM

5. Conclusions

- (1)

- The particle size of the DH modifier is smaller than that of the CS modifier. The phase composition of the DH modifier (primarily dehydrated gypsum and ettringite) is significantly influenced by the heat treatment temperature, with the hemihydrate gypsum content increasing as the temperature rises. Experimental optimization results indicate that 120 °C is the most effective heat treatment temperature, under which the generated components exhibit a well-balanced composition and demonstrate optimal mechanical performance.

- (2)

- Both modifiers led to notable improvements in the compressive strength across all curing periods, with the most significant gains observed at 14 d. More specifically, the crystal seed-modified samples exhibited a 12.24% increase in strength, while the sample modified with the dehydration phase synthesized in the 120 °C group (DH120-H) achieved a more substantial 35.71% improvement, highlighting the superior performance of the dehydration phase modifier.

- (3)

- The dehydration phase modifier demonstrated significant catalytic effects in terms of the hydration kinetics, with isothermal calorimetry revealing a 12.12% increase in the hydration heat release rate and a 4.9% elevation in the cumulative heat evolution. This acceleration reduced the initial setting time by 11.3% (i.e., from 31.0 to 27.5 h) and promoted the formation of hydration products, further enhancing the material performance.

- (4)

- Both modifiers effectively refined the pore structure by increasing the proportion of gel pores (by 24.83%) and capillary pores (by 14.73%) while decreasing the mesopore and macropore areas (by 37.71%). This optimization resulted in a denser microstructure and improved the overall properties of the phosphogypsum cementitious material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guan, Q.; Wang, Z.; Zhou, F.; Yu, W.; Yin, Z.; Zhang, Z.; Chi, R.; Zhou, J. The impurity removal and comprehensive utilization of phosphogypsum: A review. Materials 2024, 17, 2067. [Google Scholar] [CrossRef] [PubMed]

- Lv, Z.J.; Lin, Z.S.; Wang, H.J. Effect of phosphogypsum on the properties of over-sulfur phosphogypsum-ground granulate blast-furnace slag cement. Appl. Mechan. Mater. 2014, 638–640, 1453–1459. [Google Scholar] [CrossRef]

- Wu, M.; Shen, W.; Xiong, X.; Zhao, L.; Yu, Z.; Sun, H.; Xu, G.; Zhao, Q.; Wang, G.; Zhang, W. Effects of the Phosphogypsum on the Hydration and Microstructure of Alkali Activated Slag Pastes. Constr. Build. Mater. 2023, 368, 130391. [Google Scholar] [CrossRef]

- Doussang, L.; Samson, G.; Deby, F.; Huet, B.; Guillon, E.; Cyr, M. Durability Parameters of Three Low-Carbon Concretes (Low Clinker, Alkali-Activated Slag and Supersulfated Cement). Constr. Build. Mater. 2023, 407, 133511. [Google Scholar] [CrossRef]

- Zhang, J.; Li, C.; Lv, T.; Zhao, Q.; Dong, B. Microstructure Regulation and Performance Enhancement of Waste Gypsum-Based Supersulfated Cement with Sintered Sludge Ash. Constr. Build. Mater. 2025, 477, 141358. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, X.; Zhou, Q.; Cheng, F.; Guo, W. Solid Waste Binder Cemented Dihydrate Phosphogypsum Aggregate to Prepare Backfill Material. Miner. Eng. 2025, 226, 109249. [Google Scholar] [CrossRef]

- Wu, H.; Han, C.; Tang, Y. Research progress on reutilization of phosphogypsum in China. Mod. Chem. Ind. 2023, 43, 18–21. [Google Scholar]

- Yu, J.C.; Qian, J.S.; Tang, J.Y.; Ji, Z.; Fan, Y. Effect of ettringite seed crystals on the properties of calcium sulphoaluminate cement. Constr. Build. Mater. 2019, 207, 249–257. [Google Scholar] [CrossRef]

- Li, X.R.; Bizzozero, J.; Hesse, C. Impact of C-S-H seeding on hydration and strength of slag blended cement. Cem. Concr. Res. 2022, 161, 106935. [Google Scholar] [CrossRef]

- Gu, X.; Tan, H.; He, X.; Zhang, J.; Li, M.; Su, Y.; Yang, J. Nano C-S-H Seeds Prepared from Ground Granulated Blast-Furnace Slag-Carbide Slag and Its Application in Portland Cement. Constr. Build. Mater. 2022, 329, 127204. [Google Scholar] [CrossRef]

- Zhan, P.; Wang, J.; Zhao, H.; Li, W.; Shah, S.P.; Xu, J. Impact of Synthetic C-S-H Seeds on Early Hydration and Pore Structure Evolution of Cement Pastes: A Study by 1H Low-Field NMR and Path Analysis. Cem. Concr. Res. 2024, 175, 107376. [Google Scholar] [CrossRef]

- Li, M.G.; Deng, X.F.; Jian, S.W.; Huang, J.; He, X.; Yang, J.; Tan, H. Effects of ettringite seed on the hydration and properties of supersulphated phosphogypsum-slag cement. J. Clean. Prod. 2024, 452, 106935. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Fan, M.X.; Zhou, Y.X.; Ji, D.; Li, J.; Yu, R. Development of a Sustainable Alkali Activated Ultra-High Performance Concrete (A-UHPC) Incorporating Recycled Concrete Fines. J. Build. Eng. 2023, 67, 105986. [Google Scholar] [CrossRef]

- Zhai, W.; Sun, R.; Xie, Y.; Ding, H.; Su, Y.; He, Z. Thermal-Activated Recycled Cement Powder Synergized with Fly Ash as Supplementary Cementitious in Portland Cement: Strength, Microstructure and Environmental Benefits. Constr. Build. Mater. 2025, 474, 141018. [Google Scholar] [CrossRef]

- Sun, T.; Hu, T.; Shui, Z.H.; Wang, G.M.; Gai, K.Y.; Xie, Y.F.; Wang, Z.Y.; Ding, C. A Phosphogypsum Slag Cement Early Strength Promoter Based on Modified Composite Dewatering Phase: CN110104984A; Wuhan University of Technology: Wuhan, China, 2019. [Google Scholar]

- Kaufmann, J.; Winnefeld, F.; Lothenbach, B. Stability of ettringite in CSA cement at elevated temperatures. Adv. Cem. Res. 2015, 28, 251–261. [Google Scholar] [CrossRef]

- Li, Y.X.; Qiao, X.C. Review on influences of external factors on crystal structure and morphology of ettringite. Bull. Chin. Ceram. Soc. 2023, 42, 31–47. [Google Scholar]

- Chen, W.H.; Xu, J.Z. Study of the dehydration phase of gypsum and its hydration. J. Chin. Ceram. Soc. 1983, 4, 414–421. [Google Scholar]

- Huang, J.; Huang, J.; Min, J.; Lv, R.; Kuang, H.; Hu, H.; Yang, R.; Tang, P.; Zhao, Q.; Jian, S. Hydration Mechanism of a Sodium-Doped Phosphogypsum-Based Hemihydrate Whisker (Omongwaite) in Supersulfated Cement System. Constr. Build. Mater. 2024, 427, 136236. [Google Scholar] [CrossRef]

- GB/T 17671–1999; Test Method for Strength of Cement Mortar (ISO Method). State Bureau of Quality and Technical Supervision: Beijing, China, 1999.

- GB/T 1346–2011; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of Cement. China Standards Press: Beijing, China, 2011.

- Li, X.; Zhang, Q. Dehydration Behaviour and Impurity Change of Phosphogypsum during Calcination. Constr. Build. Mater. 2021, 311, 125328. [Google Scholar] [CrossRef]

- Bazaldúa-Medellín, M.E.; Fuentes, A.F.; Gorokhovsky, A.; Escalante-García, J.I. Early and late hydration of supersulphated cements of blast furnace slag with fluorgypsum. Mater. De Constr. 2015, 65, e053. [Google Scholar] [CrossRef]

- Yuan, J.F.; Liu, B.; Dong, X.J. Early hydration properties of phosphogypsum-based cement. Concrete 2014, 8, 92–94+97. [Google Scholar]

- Liao, Y.S.; Wang, K.; Li, H. Hydration process and long-term strength of gypsum slag cement with high content of phosphogypsum. Bull. Chin. Ceram. Soc. 2023, 42, 4408–4415. [Google Scholar]

- Xia, Y.; Tang, L.; He, Z.; Tang, J.; Yu, J.; Cao, D.; Wei, D. Study on Mechanical Properties, Hydration Mechanism and Carbon Emission of Phosphogypsum-Based Sustainable Cementitious Materials. Sustain. Chem. Pharm. 2025, 45, 102016. [Google Scholar] [CrossRef]

- Yang, J.; Zeng, J.Y.; He, X.Y.; Zhang, Y.; Su, Y.; Tan, H. Sustainable clinker-free solid waste binder produced from wet-ground granulated blast-furnace slag, phosphogypsum and carbide slag. Constr. Build. Mater. 2022, 330, 127218. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Sun, T.; Ouyang, G.S.; Li, Z.; Chen, M.; Li, H.; Wang, K.; Guo, Y. Simultaneous enhanced phosphorus removal and hydration reaction: Utilisation of polyaluminium chloride and polyaluminium ferric chloride to modify phosphogypsum-based excess-sulphate slag cement. J. Clean. Prod. 2024, 476, 143712. [Google Scholar] [CrossRef]

- Liu, S.; Ouyang, J.; Ren, J. Mechanism of Calcination Modification of Phosphogypsum and Its Effect on the Hydration Properties of Phosphogypsum-Based Supersulfated Cement. Constr. Build. Mater. 2020, 243, 118226. [Google Scholar] [CrossRef]

- Gui, Y.; Pu, L.; Lu, S.; Xie, M.; Pei, L.; Tian, Y. Physical, Mechanical, Compaction, and Leaching Properties of Phosphogypsum-Based Semi-Rigid Aggregated Geomaterial. J. Clean. Prod. 2025, 513, 145664. [Google Scholar] [CrossRef]

- Wang, X.; Yu, Y.; Zou, F.; Luo, H.; Zhou, Z.; Zhu, J.; Guo, G.; Zhong, Y. High performance C-A-S-H seeds from fly ash-carbide slag for activating lithium slag towards a low carbon binder. J. Environ. Manag. 2023, 345, 118658. [Google Scholar] [CrossRef]

- Ouyang, G.S.; Sun, T.; Yu, Z.C.; Xu, F.; Bai, J.; Xu, D. Investigation on macroscopic properties, leachability and microstructures of surface reinforced phosphogypsum-based cold-bonded aggregates. J. Build. Eng. 2023, 69, 106305. [Google Scholar] [CrossRef]

| Sample | Al2O3 | SiO2 | CaO | P2O5 | SO3 | Na2O | MgO | K2O | TiO2 | Fe2O3 | F | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Phosphogypsum | 0.795 | 6.714 | 28.785 | 0.837 | 38.747 | 0.174 | 0.849 | 0.32 | 0.10 | 0.467 | 0.969 | 21.171 |

| OPC | 5.126 | 22.24 | 61.189 | 0.20 | 2.612 | 0.20 | 1.913 | 0.883 | 0.239 | 3.078 | —— | 1.992 |

| GGBFS | 16.132 | 33.952 | 34.91 | 0.061 | 2.913 | 0.96 | 6.865 | 0.458 | 0.942 | 1.152 | —— | 0.885 |

| RCMP | 2.142 | 9.495 | 34.695 | 1.003 | 38.954 | 0.216 | 0.888 | 0.61 | 0.26 | 0.933 | 0.587 | 9.774 |

| Group | Heat Treatment Temperature/°C |

|---|---|

| DH100 | 100 |

| DH120 | 120 |

| DH140 | 140 |

| DH160 | 160 |

| Group | Modifier (wt%) | Phosphogypsum Cementitious Material (wt%) | |||

|---|---|---|---|---|---|

| Crystal Seed Modifier | Dehydrated Phase Modifier | Phosphogypsum | Slag | Cement | |

| H | - | - | 80 | 14 | 6 |

| CS-H | 5 | - | 80 | 14 | 6 |

| DH100-H | - | 5 | 80 | 14 | 6 |

| DH120-H | - | 5 | 80 | 14 | 6 |

| DH140-H | - | 5 | 80 | 14 | 6 |

| DH160-H | - | 5 | 80 | 14 | 6 |

| Sample | D0.1/μm | D0.5/μm | D0.9/μm | D [4.3]/μm | D [3.2]/μm |

|---|---|---|---|---|---|

| CS | 2.096 | 15.296 | 54.054 | 22.533 | 5.534 |

| DH100 | 1.99 | 12.924 | 52.226 | 20.883 | 5.164 |

| DH120 | 2.047 | 13.453 | 53.347 | 21.39 | 5.265 |

| DH160 | 1.989 | 13.675 | 49.852 | 20.482 | 5.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lian, J.; Wu, C.; Shui, Z.; Lyu, W. Effect of a Recycled Phosphogypsum Modifier on the Performance of High-Content Phosphogypsum Cementing Materials. Materials 2025, 18, 2807. https://doi.org/10.3390/ma18122807

Lian J, Wu C, Shui Z, Lyu W. Effect of a Recycled Phosphogypsum Modifier on the Performance of High-Content Phosphogypsum Cementing Materials. Materials. 2025; 18(12):2807. https://doi.org/10.3390/ma18122807

Chicago/Turabian StyleLian, Jiuyang, Chiqiu Wu, Zhonghe Shui, and Wei Lyu. 2025. "Effect of a Recycled Phosphogypsum Modifier on the Performance of High-Content Phosphogypsum Cementing Materials" Materials 18, no. 12: 2807. https://doi.org/10.3390/ma18122807

APA StyleLian, J., Wu, C., Shui, Z., & Lyu, W. (2025). Effect of a Recycled Phosphogypsum Modifier on the Performance of High-Content Phosphogypsum Cementing Materials. Materials, 18(12), 2807. https://doi.org/10.3390/ma18122807