Comparison of Microstructure and Mechanical Properties of Ultra-Narrow Gap-Welded and Submerged Arc-Welded Q355E HSLA Steel

Abstract

1. Introduction

2. Experimental Section

2.1. Welding Processes

2.2. Microstructure Characterization

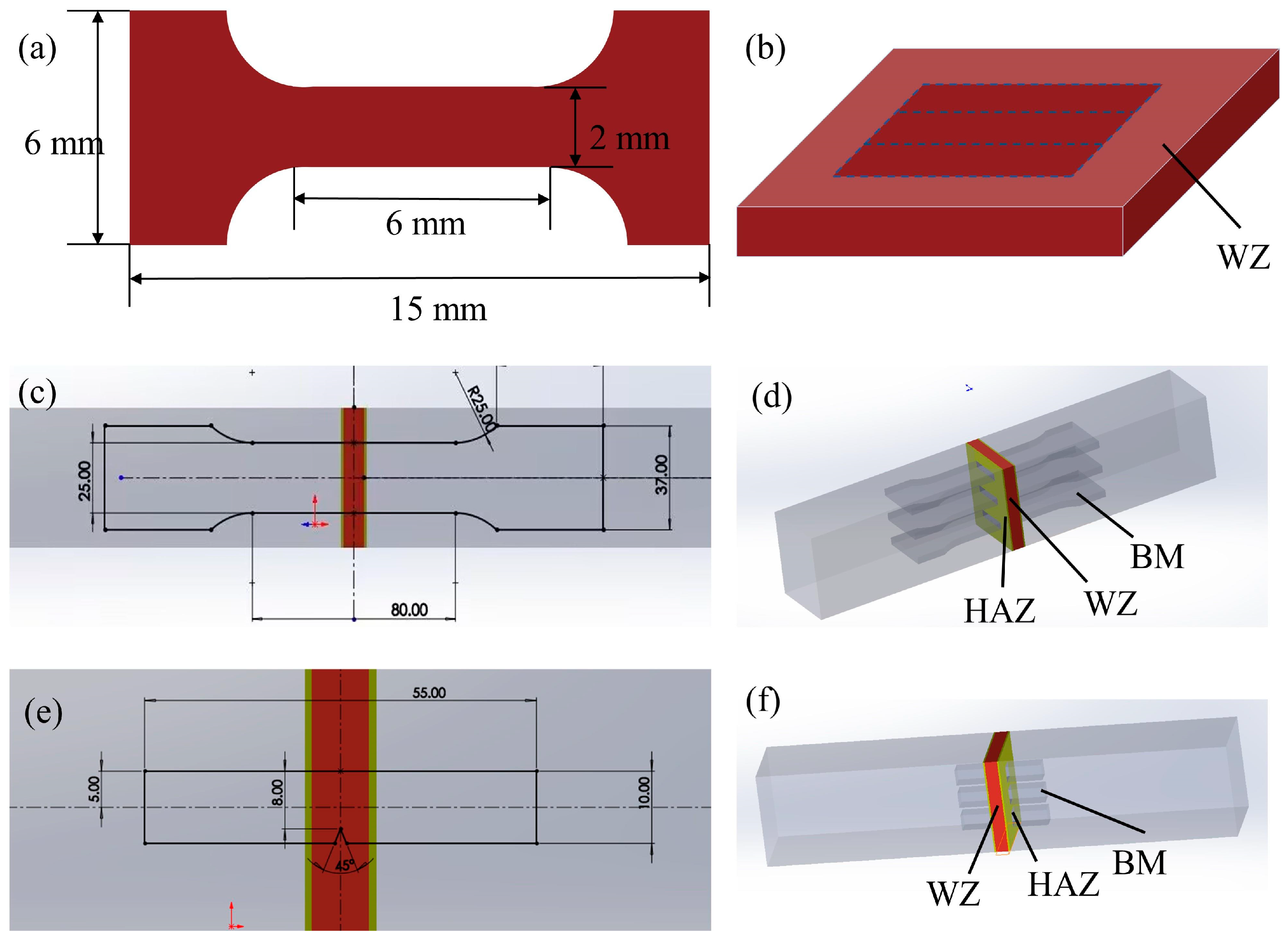

2.3. Mechanical Properties Testing

3. Results

3.1. Microstructure

3.2. Mechanical Properties

4. Discussion

4.1. Strengthening and Toughening Mechanisms

4.2. AF Introduced in UNGW

5. Conclusions

- (1)

- The UNGW joint exhibited narrower weld and heat-affected zones. Both UNGW and SAW joints showed distinct columnar grain and equiaxed grain zones in the weld zone, while the microstructures of these two zones differ between the two welded joints. In UNGW joints, abundant acicular ferrite was found within the grains in both columnar and equiaxed zones, and network proeutectoid ferrite precipitated along prior austenite grain boundaries. In contrast, the SAW columnar zone showed similar characteristics to UNGW but with less acicular ferrite and more blocky ferrite, while its equiaxed zone mainly consisted of pearlite and blocky ferrite. Additionally, the heat-affected zone of the UNGW joint experienced quenching effects, being divided into a quenched zone, an incomplete quenched zone, and a transition zone, in which lath martensite with good performance was identified. However, the SAW heat-affected zone showed no quenching effects and consisted of overheated, complete recrystallization and incomplete recrystallization zones.

- (2)

- The UNGW welded joint exhibits superior comprehensive mechanical properties compared to the SAW welded joint. Specifically, the microhardness of the weld and heat-affected zones in the UNGW joint reached 290 HV0.5 and 250 HV0.5, respectively. The room-temperature tensile strength of the weld zone reached 664 MPa, which is 124 MPa higher than that for the base material and 80 MPa higher than that for the SAW weld zone, while maintaining a comparable fracture elongation of 43.1%. Additionally, the impact toughness of the weld and heat-affected zones at −40 °C was 55 J and 48 J, respectively, significantly exceeding the 17 J and 15 J of the SAW specimens.

- (3)

- The outstanding mechanical properties of the UNGW welded joint primarily result from the formation of a large amount of acicular ferrite in the welded joint, which contributes to notable grain boundary strengthening, dislocation strengthening, and phase transformation strengthening. The formation of acicular ferrite is closely related to the cooling rate during welding and the size of precipitated inclusions in the joint structure. These factors are particularly attributed to the lower heat input and faster cooling rate characteristic of the UNGW process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| HSLA | high-strength low-alloy | PF | proeutectoid ferrite |

| UNGW | ultra-narrow gap welding | BF | blocky ferrite |

| SAW | submerged arc welding | P | pearlite |

| HAZ | heat-affected zone | QZ | quenched zone |

| AF | acicular ferrite | IQZ | incomplete quenched zone |

| WZ | weld zone | TZ | transition zone |

| BM | base material | LM | lath martensite |

| OM | optical microscopy | OHZ | overheated zone |

| SEM | scanning electron microscopy | CRZ | complete recrystallization zone |

| EDS | energy dispersive spectrometer | IRZ | incomplete recrystallization zone |

| EBSD | electron backscatter diffraction | LAGBs | low-angle grain boundaries |

References

- Geng, H.; Sun, X.; Zhao, Y.; Yin, X.; Du, Z. Assessing the microstructure, mechanical properties, and deformation mechanism of high-strength low-alloy steel prepared via powder metallurgy. J. Mater. Res. Technol. 2025, 35, 3620–3633. [Google Scholar] [CrossRef]

- Vervynckt, S.; Verbeken, K.; Lopez, B.; Jonas, J.J. Modern HSLA steels and role of non-recrystallisation temperature. Int. Mater. Rev. 2013, 57, 187–207. [Google Scholar] [CrossRef]

- Kamikawa, N.; Abe, Y.; Miyamoto, G.; Funakawa, Y.; Furuhara, T. Tensile Behavior of Ti,Mo-added Low Carbon Steels with Interphase Precipitation. ISIJ Int. 2014, 54, 212–221. [Google Scholar] [CrossRef]

- Karmakar, A.; Biswas, S.; Mukherjee, S.; Chakrabarti, D.; Kumar, V. Effect of composition and thermo-mechanical processing schedule on the microstructure, precipitation and strengthening of Nb-microalloyed steel. Mater. Sci. Eng. A 2017, 690, 158–169. [Google Scholar] [CrossRef]

- Wen, Y.R.; Li, Y.P.; Hirata, A.; Zhang, Y.; Fujita, T.; Furuhara, T.; Liu, C.T.; Chiba, A.; Chen, M.W. Synergistic alloying effect on microstructural evolution and mechanical properties of Cu precipitation-strengthened ferritic alloys. Acta Mater. 2013, 61, 7726–7740. [Google Scholar] [CrossRef]

- Wen, Y.R.; Hirata, A.; Zhang, Z.W.; Fujita, T.; Liu, C.T.; Jiang, J.H.; Chen, M.W. Microstructure characterization of Cu-rich nanoprecipitates in a Fe–2.5 Cu–1.5 Mn–4.0 Ni–1.0 Al multicomponent ferritic alloy. Acta Mater. 2013, 61, 2133–2147. [Google Scholar] [CrossRef]

- Jia, Z.; Misra, R.D.K.; O’Malley, R.; Jansto, S.J. Fine-scale precipitation and mechanical properties of thin slab processed titanium–niobium bearing high strength steels. Mater. Sci. Eng. A 2011, 528, 7077–7083. [Google Scholar] [CrossRef]

- Kim, Y.M.; Kim, S.K.; Kim, N.J. Simple method for tailoring the optimum microstructures of high-strength low-alloyed steels by the use of constitutive equation. Mater. Sci. Eng. A 2019, 743, 138–147. [Google Scholar] [CrossRef]

- Duan, Y.; Zhu, W.; Liu, W.; Ma, Y.; Cai, Q.; Cai, Y. A novel strategy for preparing high-performance powder metallurgical low alloy ultrahigh strength steel. Mater. Sci. Eng. A 2023, 864, 144585. [Google Scholar] [CrossRef]

- Ledermueller, C.; Pratiwi, H.I.; Webster, R.F.; Eizadjou, M.; Ringer, S.P.; Primig, S. Microalloying effects of Mo versus Cr in HSLA steels with ultrafine-grained ferrite microstructures. Mater. Des. 2020, 185, 108278. [Google Scholar] [CrossRef]

- Tkachev, E.; Borisov, S.; Belyakov, A.; Kniaziuk, T.; Vagina, O.; Gaidar, S.; Kaibyshev, R. Effect of quenching and tempering on structure and mechanical properties of a low-alloy 0.25C steel. Mater. Sci. Eng. A 2023, 868, 144757. [Google Scholar] [CrossRef]

- Moon, J.; Kim, S.-J.; Lee, C. Effect of thermo-mechanical cycling on the microstructure and strength of lath martensite in the weld CGHAZ of HSLA steel. Mater. Sci. Eng. A 2011, 528, 7658–7662. [Google Scholar] [CrossRef]

- Bunaziv, I.; Akselsen, O.M.; Frostevarg, J.; Kaplan, A.F.H. Laser-arc hybrid welding of thick HSLA steel. J. Mater. Process. Technol. 2018, 259, 75–87. [Google Scholar] [CrossRef]

- Kiran, D.V.; Basu, B.; Shah, A.K.; Mishra, S.; De, A. Probing influence of welding current on weld quality in two wire tandem submerged arc welding of HSLA steel. Sci. Technol. Weld. Join. 2010, 15, 111–116. [Google Scholar] [CrossRef]

- Zhang, G.; Yu, F. Ultra-Narrow Gap Fiber Laser Conduction Welding Technology for 304 Stainless Steel Thick Plates and the Mechanical Properties of Welding Joints. Coatings 2022, 12, 59. [Google Scholar] [CrossRef]

- Guo, W.; Li, L.; Dong, S.; Crowther, D.; Thompson, A. Comparison of microstructure and mechanical properties of ultra-narrow gap laser and gas-metal-arc welded S960 high strength steel. Opt. Lasers Eng. 2017, 91, 1–15. [Google Scholar] [CrossRef]

- Dai, K.; He, P.; Zhu, L.; Zhang, F.; Chen, F.; Zhai, X.; Xiao, W. Effect of solution treatment on microstructure and cryogenic toughness of 316LN austenite stainless steel weld metal welded by NG-MAG arc welding. Fusion Eng. Des. 2017, 125, 178–188. [Google Scholar] [CrossRef]

- Bajic, D.; Kuzmenko, G.V.; Samardžić, I. Welding of rails with new technology of arc welding. Metalurgija 2013, 52, 399–402. [Google Scholar]

- Li, W.; Gao, K.; Wu, J.; Wang, J.; Ji, Y. Groove sidewall penetration modeling for rotating arc narrow gap MAG welding. Int. J. Adv. Manuf. Technol. 2014, 78, 573–581. [Google Scholar] [CrossRef]

- Cai, X.Y.; Lin, S.B.; Fan, C.L.; Yang, C.L.; Zhang, W.; Wang, Y.W. Molten pool behaviour and weld forming mechanism of tandem narrow gap vertical GMAW. Sci. Technol. Weld. Join. 2016, 21, 124–130. [Google Scholar] [CrossRef]

- Wang, Y.; Kannan, R.; Zhang, L.; Li, L. Microstructural Analysis of the As-Welded Heat-Affected Zone of a Grade 91 Steel Heavy Section Weldment. Weld. J. 2017, 96, 203–219. [Google Scholar]

- Lu, X.; Cen, Y.; Wang, H.; Wu, M. Structure and mechanical properties on DH40 ship building steel joints by multi-layer and multi-pass welding technology. Trans. China Weld. Inst. 2013, 34, 79–83. [Google Scholar]

- Shao, Y.; Liu, C.; Yan, Z.; Li, H.; Liu, Y. Formation mechanism and control methods of acicular ferrite in HSLA steels: A review. J. Mater. Sci. Technol. 2018, 34, 737–744. [Google Scholar] [CrossRef]

- Lv, S.; Wu, H.-H.; Wang, K.; Wang, S.; Wu, G.; Gao, J.; Yang, X.-S.; Zhu, J.; Mao, X. The microstructure evolution and influence factors of acicular ferrite in low alloy steels. Comput. Mater. Sci 2023, 218, 111989. [Google Scholar] [CrossRef]

- Zhang, X.; Li, G.; Zhao, H.; Gao, J.; Wu, H.; Zhang, C.; Huang, Y.; Wu, G.; Wang, S.; Mao, X. Evolution of microstructure and mechanical properties along the thickness direction of 500 MPa HSLA steel heavy plates. Mater. Sci. Eng. A 2024, 913, 147097. [Google Scholar] [CrossRef]

- Xiao, F.-R.; Liao, B.; Shan, Y.-Y.; Qiao, G.-Y.; Zhong, Y.; Zhang, C.; Yang, K. Challenge of mechanical properties of an acicular ferrite pipeline steel. Mater. Sci. Eng. A 2006, 431, 41–52. [Google Scholar] [CrossRef]

- Wang, W.; Yan, W.; Zhu, L.; Hu, P.; Shan, Y.; Yang, K. Relation among rolling parameters, microstructures and mechanical properties in an acicular ferrite pipeline steel. Mater. Des. 2009, 30, 3436–3443. [Google Scholar] [CrossRef]

- Shi, L.; Yan, Z.; Liu, Y.; Yang, X.; Qiao, Z.; Ning, B.; Li, H. Development of ferrite/bainite bands and study of bainite transformation retardation in HSLA steel during continuous cooling. Met. Mater. Int. 2014, 20, 19–25. [Google Scholar] [CrossRef]

- Hui, W.; Zhang, Y.; Shao, C.; Chen, S.; Zhao, X.; Dong, H. Effect of Cooling Rate and Vanadium Content on the Microstructure and Hardness of Medium Carbon Forging Steel. J. Mater. Sci. Technol. 2016, 32, 545–551. [Google Scholar] [CrossRef]

- Wu, S.; Xiao, W.; Gong, L.; Zhang, F. Comparison of Microstructure and Mechanical Properties of Ultra-Narrow Gap Metal Active Gas Arc Welded and Narrow Gap Submerged Arc Welded Q235A Low Carbon Steel. Materials 2023, 16, 6601. [Google Scholar] [CrossRef]

- GB/T 2651-2023; Destructive Tests on Welds in Metallic Materials—Transverse Tensile Test. National Technical Committee on Welding of Standardization Administration of China: Beijing, China, 2023.

- GB/T 2650-2022; Destructive Tests on Welds in Metallic Materials—Impact Test. National Technical Committee on Welding of Standardization Administration of China: Beijing, China, 2022.

- Cheng, L.; Wu, K.M. New insights into intragranular ferrite in a low-carbon low-alloy steel. Acta Mater. 2009, 57, 3754–3762. [Google Scholar] [CrossRef]

- Hsu, C.J.; Chang, C.Y.; Kao, P.W.; Ho, N.J.; Chang, C.P. Al–Al3Ti nanocomposites produced in situ by friction stir processing. Acta Mater. 2006, 54, 5241–5249. [Google Scholar] [CrossRef]

- Liu, G.; Guo, H.; Wang, S.; Wu, H.; Ruan, X.; Huang, Y.; Li, X.; Mao, X. Unveiling the kinetics of interphase and random quaternary Nb Ti precipitations, and strengthening mechanism of HSLA steel. Mater. Charact. 2024, 215, 114238. [Google Scholar] [CrossRef]

- DAVIS, C.L.; KING, J.E. Cleavage Initiation in the Intercritically Reheated Coarse-Grained Heat-Affected Zone: Part I. Fractographic Evidence. Metall. Mater. Trans. A 1994, 25, 563–573. [Google Scholar] [CrossRef]

- Zhao, H.; Gao, J.; Wu, G.; Wu, H.; Zhang, C.; Huang, Y.; Luo, Y.; Yang, X.; Wang, S. Crystallographic characteristics of acicular ferrite nucleated on inclusions in a HSLA steel. J. Mater. Res. Technol. 2024, 28, 1957–1966. [Google Scholar] [CrossRef]

- Wang, T.; Yang, S.; Li, J.; Guo, H.; Chen, Z. Effect of in situ observation of cooling rates on acicular ferrite nucleation. High Temp. Mater. Process. 2022, 41, 181–190. [Google Scholar] [CrossRef]

| Element [wt.%] | C | Mn | Si | S | P | Cr | Ni | Ti | Cu | Mo | V | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q355E | ≤0.15 | ≤0.15 | ≤0.5 | ≤0.02 | ≤0.025 | / | ≤0.5 | ≤0.2 | / | / | ≤0.15 | Bal. |

| UNGW | 0.06–0.15 | 1.40–1.95 | 0.80–1.15 | ≤0.025 | ≤0.025 | ≤0.15 | ≤0.15 | / | ≤0.50 | ≤0.15 | ≤0.03 | Bal. |

| SAW | ≤0.12 | ≤0.07 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.20 | ≤0.30 | / | ≤0.35 | / | / | Bal. |

| Process | Welding Current [A] | Welding Voltage [V] | Welding Speed [mm/s] |

|---|---|---|---|

| UNGW | 260–270 | 28–30 | 4.0–4.5 |

| SAW | 650–750 | 32–34 | 5.6–10 |

| Testing | Process | Yield Strength [σYS, MPa] | Ultimate Tensile Strength [σUTS, MPa] | Elongation [δ, %] |

|---|---|---|---|---|

| large-scale tensile | UNGW | 299.7 ± 6.5 | 497.4 ± 7.8 | 28.1 ± 0.9 |

| SAW | 326.5 ± 35.9 | 488.5 ± 16.6 | 24.1 ± 3.4 | |

| small-scale tensile | BM | 330.8 ± 15.5 | 537.7 ± 3.0 | 42.8 ± 2.2 |

| UNGW | 570.8 ± 24.4 | 680.8 ± 14.6 | 38.2 ± 4.4 | |

| SAW | 445.4 ± 21.4 | 553.3 ± 26.9 | 39.1 ± 1.4 |

| Element [wt.%] | C | O | Mn | Si | Ti | Al | Fe |

|---|---|---|---|---|---|---|---|

| 1 | 1.76 | 16.66 | 9.06 | 7.20 | 0.32 | 5.46 | Bal. |

| 2 | 1.60 | 8.95 | 7.50 | 4.55 | 0.19 | 2.57 | Bal. |

| 3 | 6.52 | / | 1.26 | 0.71 | / | / | Bal. |

| 4 | 2.80 | / | 1.28 | 0.58 | / | / | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Li, R.; Wen, Q.; Xiao, W.; Wu, S.; Zhai, X.; Zhang, F. Comparison of Microstructure and Mechanical Properties of Ultra-Narrow Gap-Welded and Submerged Arc-Welded Q355E HSLA Steel. Materials 2025, 18, 2805. https://doi.org/10.3390/ma18122805

Wang Y, Li R, Wen Q, Xiao W, Wu S, Zhai X, Zhang F. Comparison of Microstructure and Mechanical Properties of Ultra-Narrow Gap-Welded and Submerged Arc-Welded Q355E HSLA Steel. Materials. 2025; 18(12):2805. https://doi.org/10.3390/ma18122805

Chicago/Turabian StyleWang, Youqi, Renge Li, Qingnian Wen, Wenkai Xiao, Shang Wu, Xian Zhai, and Fuju Zhang. 2025. "Comparison of Microstructure and Mechanical Properties of Ultra-Narrow Gap-Welded and Submerged Arc-Welded Q355E HSLA Steel" Materials 18, no. 12: 2805. https://doi.org/10.3390/ma18122805

APA StyleWang, Y., Li, R., Wen, Q., Xiao, W., Wu, S., Zhai, X., & Zhang, F. (2025). Comparison of Microstructure and Mechanical Properties of Ultra-Narrow Gap-Welded and Submerged Arc-Welded Q355E HSLA Steel. Materials, 18(12), 2805. https://doi.org/10.3390/ma18122805