Effect of Hybrid Fiber Compositions on Mechanical Properties and Durability of Ultra-High-Performance Concrete: A Comprehensive Review

Abstract

1. Introduction

2. Methodology of Literature Review

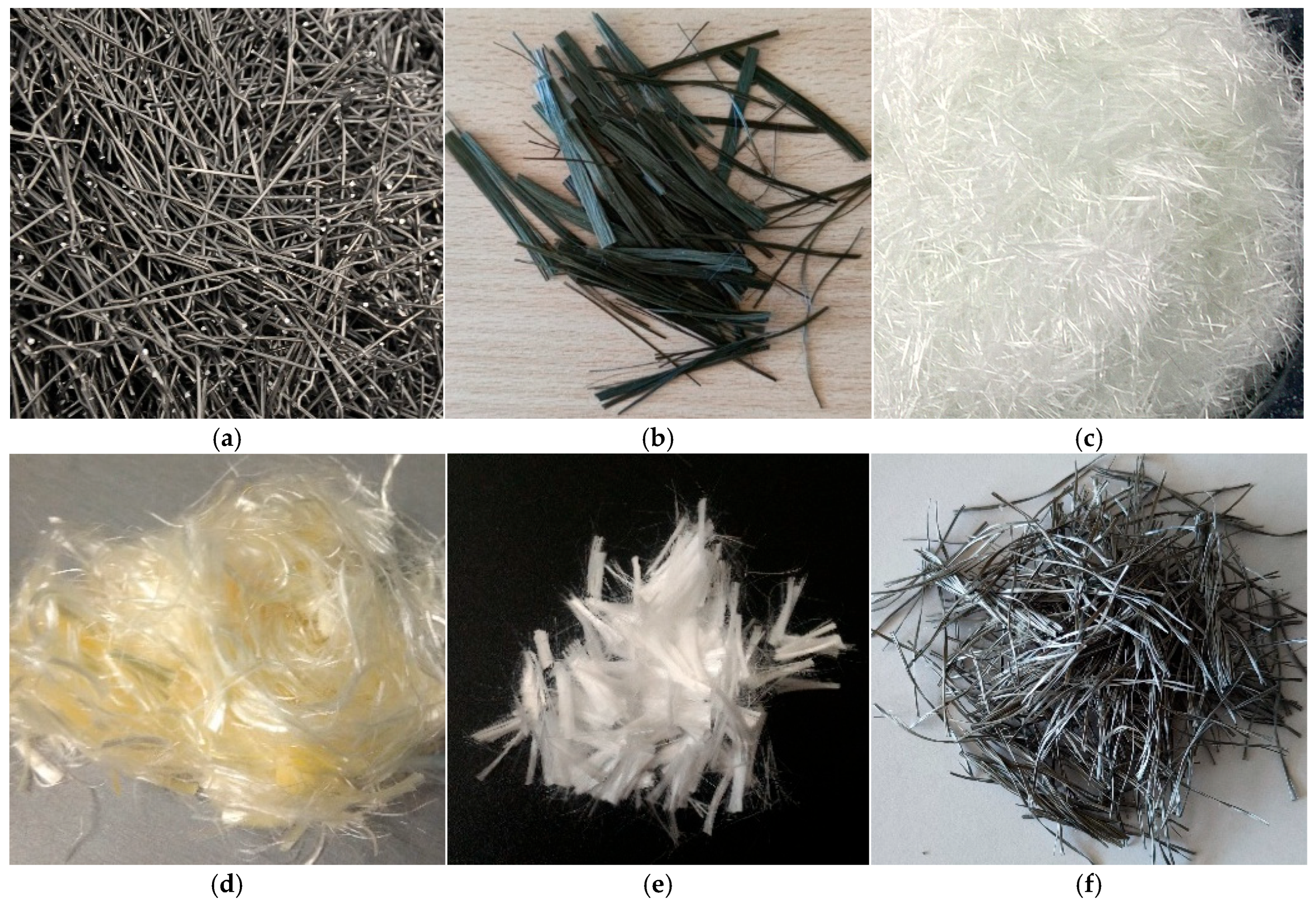

3. Characteristics of Fiber

3.1. Non-Synthetic Fibers

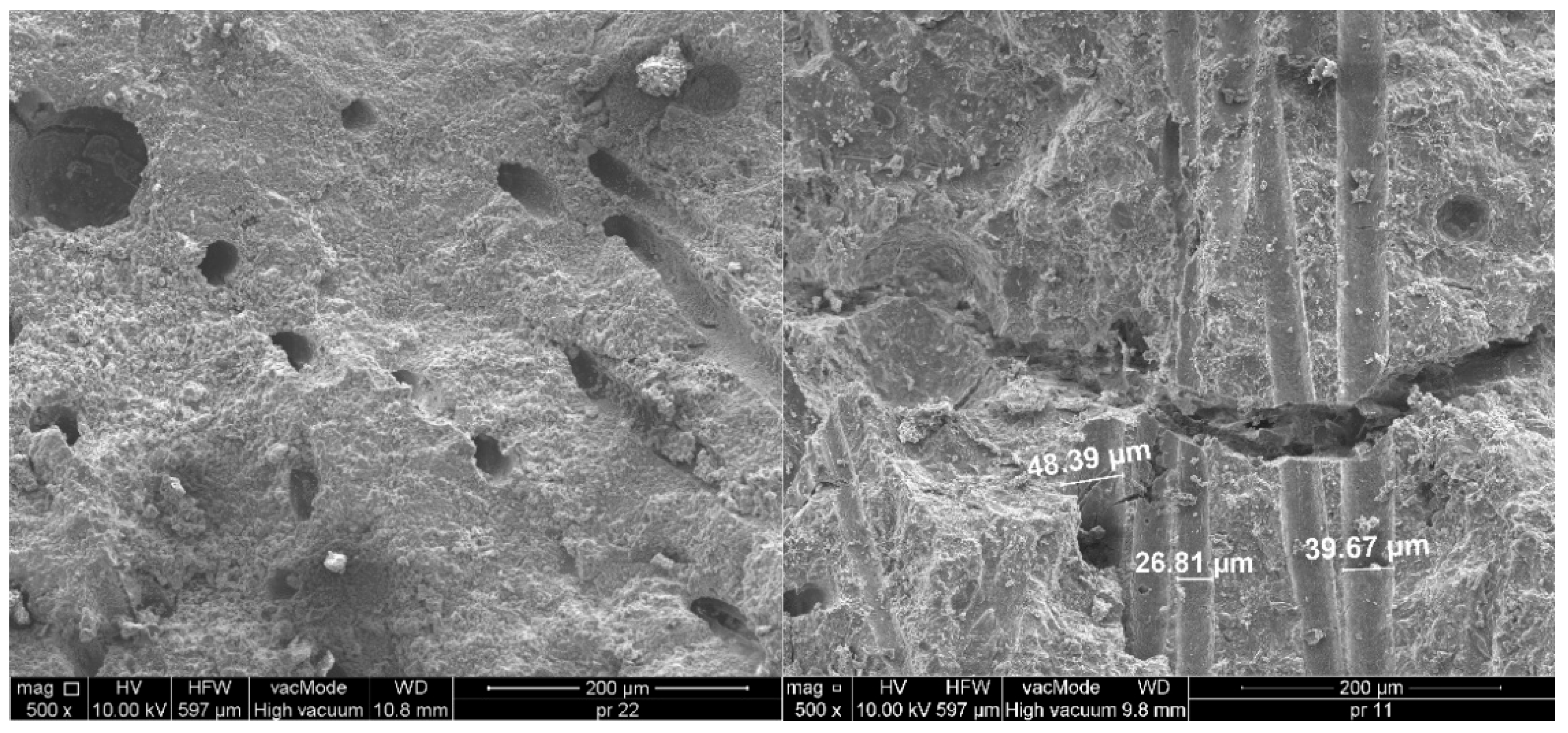

3.1.1. Steel Fibers

3.1.2. Basalt Fiber

3.1.3. Glass Fiber

3.1.4. Carbon Fiber

3.2. Synthetic Fibers

3.3. Influence of Fiber Orientation and Casting Methods on UHPC Properties

3.4. Fiber Hybridization

4. The Influence of Hybrid Fibers on the Mechanical Properties of UHPC

4.1. Steel Fiber Combinations

4.2. Combinations of Steel and Synthetic Fibers

4.3. Combinations of Basalt and Synthetic Fibers

4.4. Summary of Mechanical Property Test Results

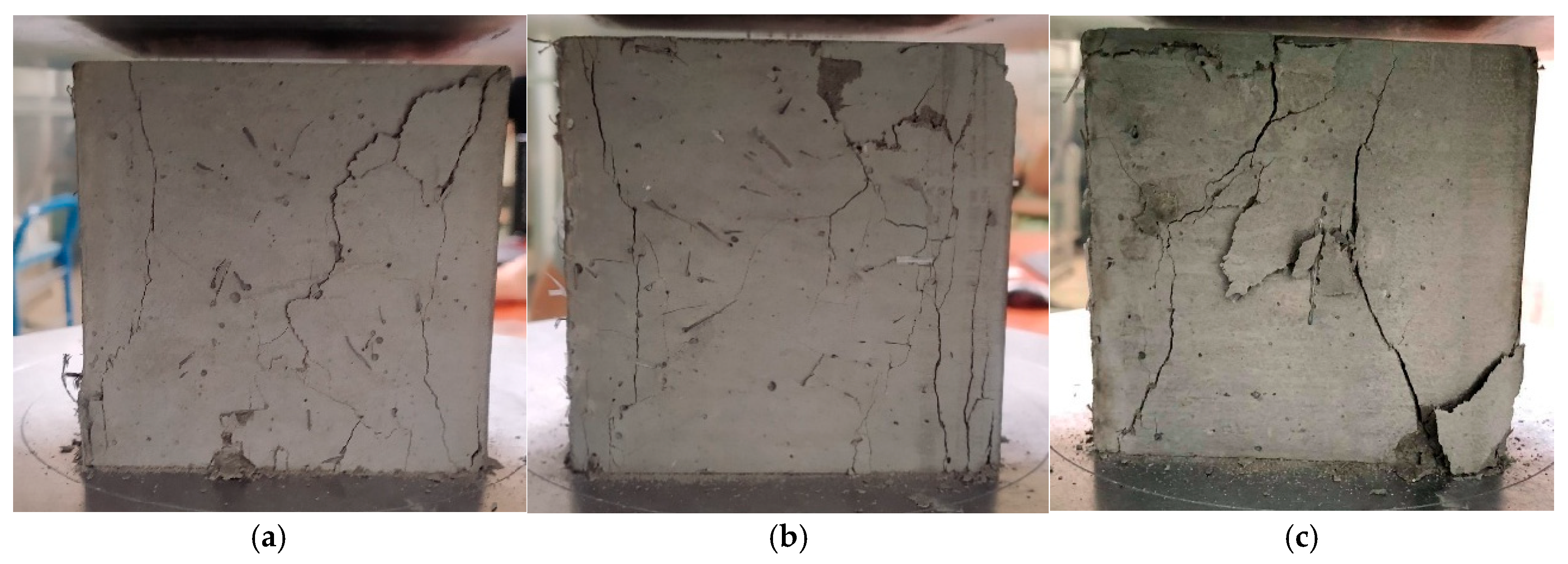

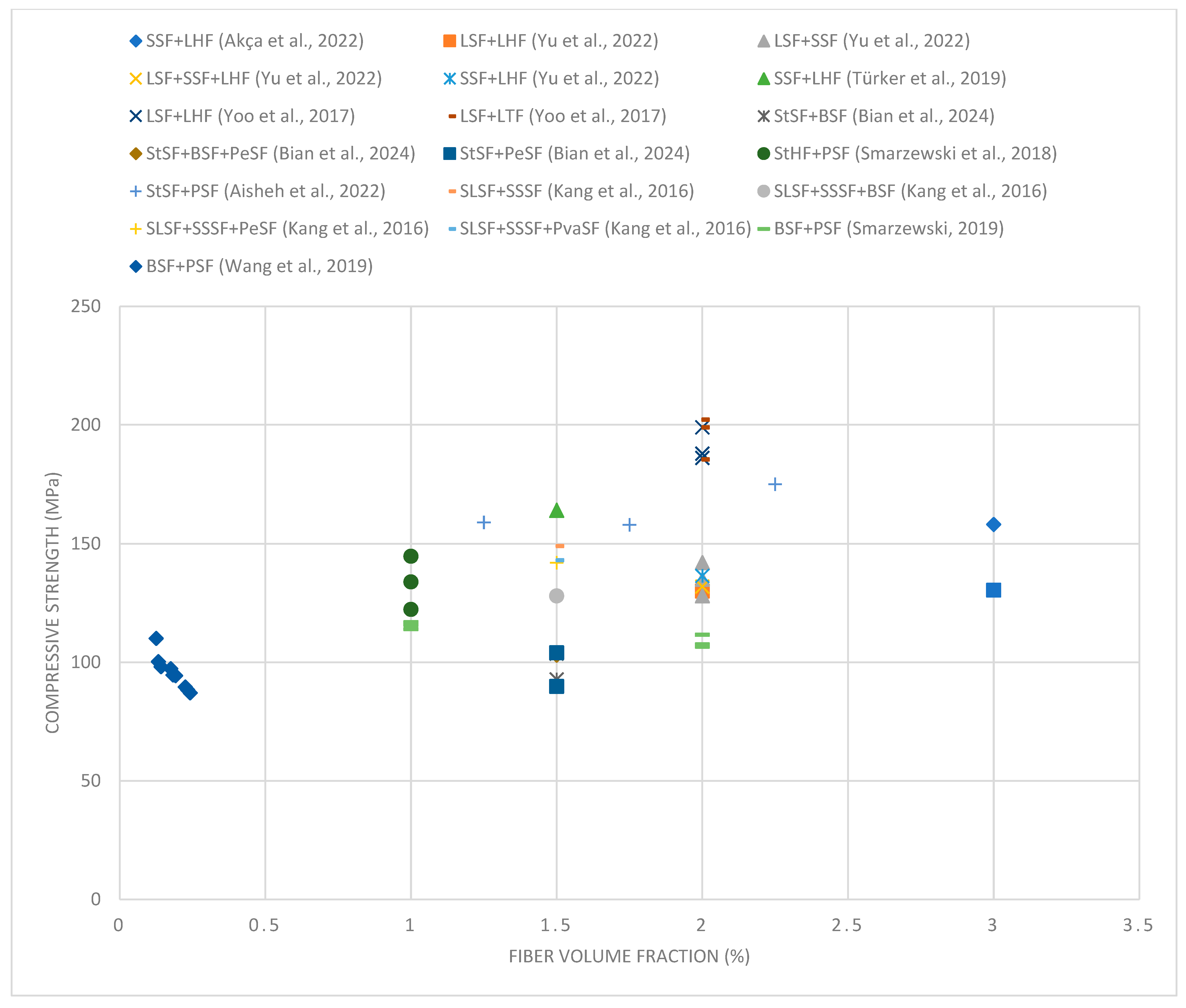

4.4.1. Compressive Strength

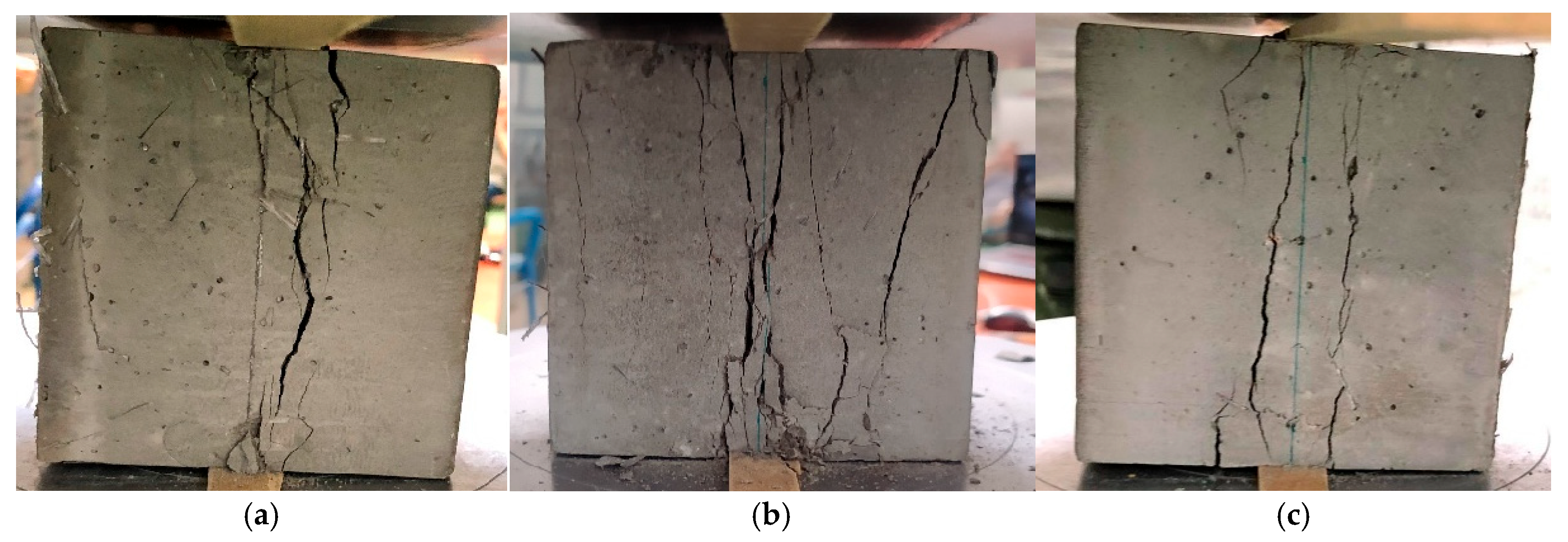

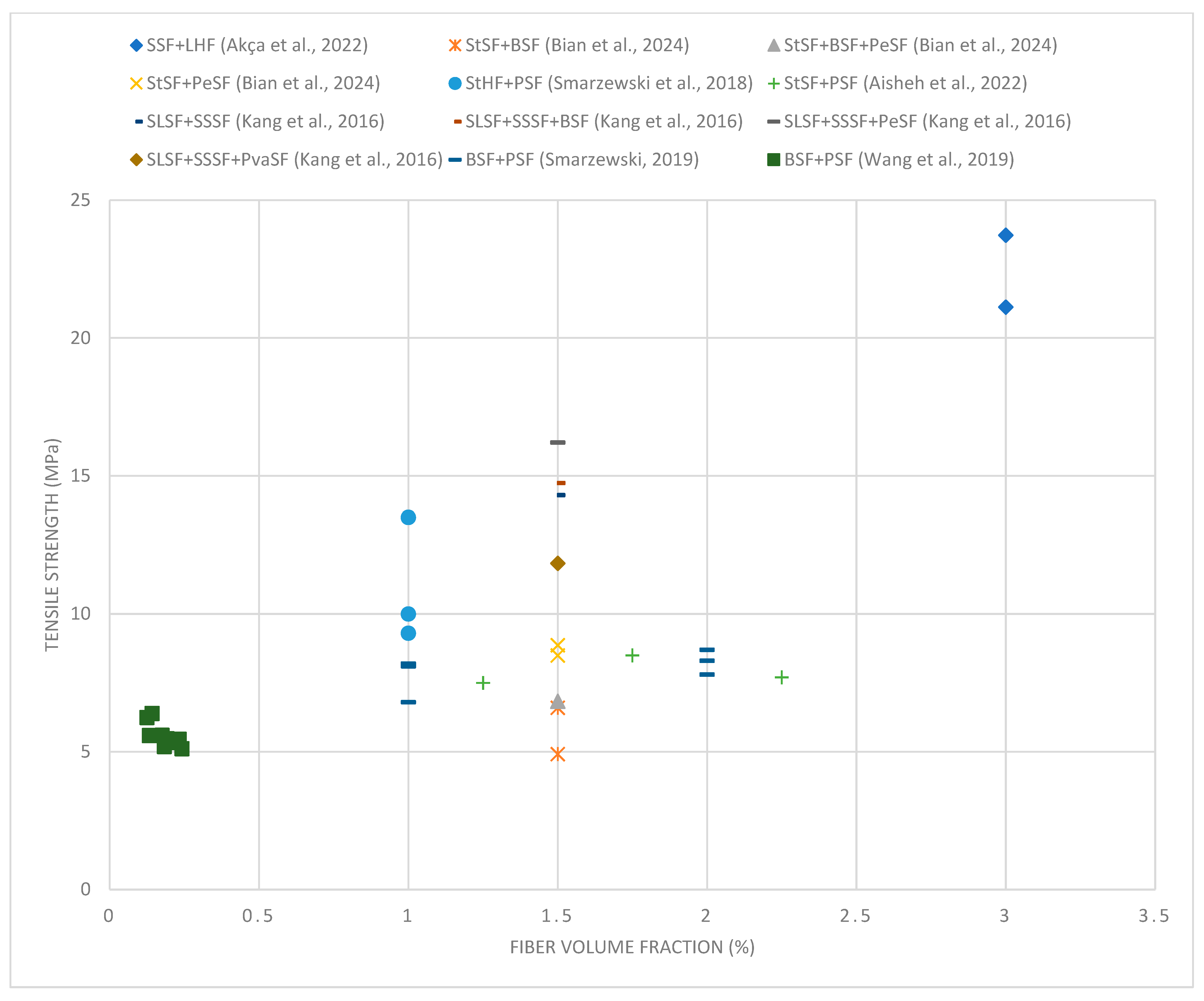

4.4.2. Tensile Strength

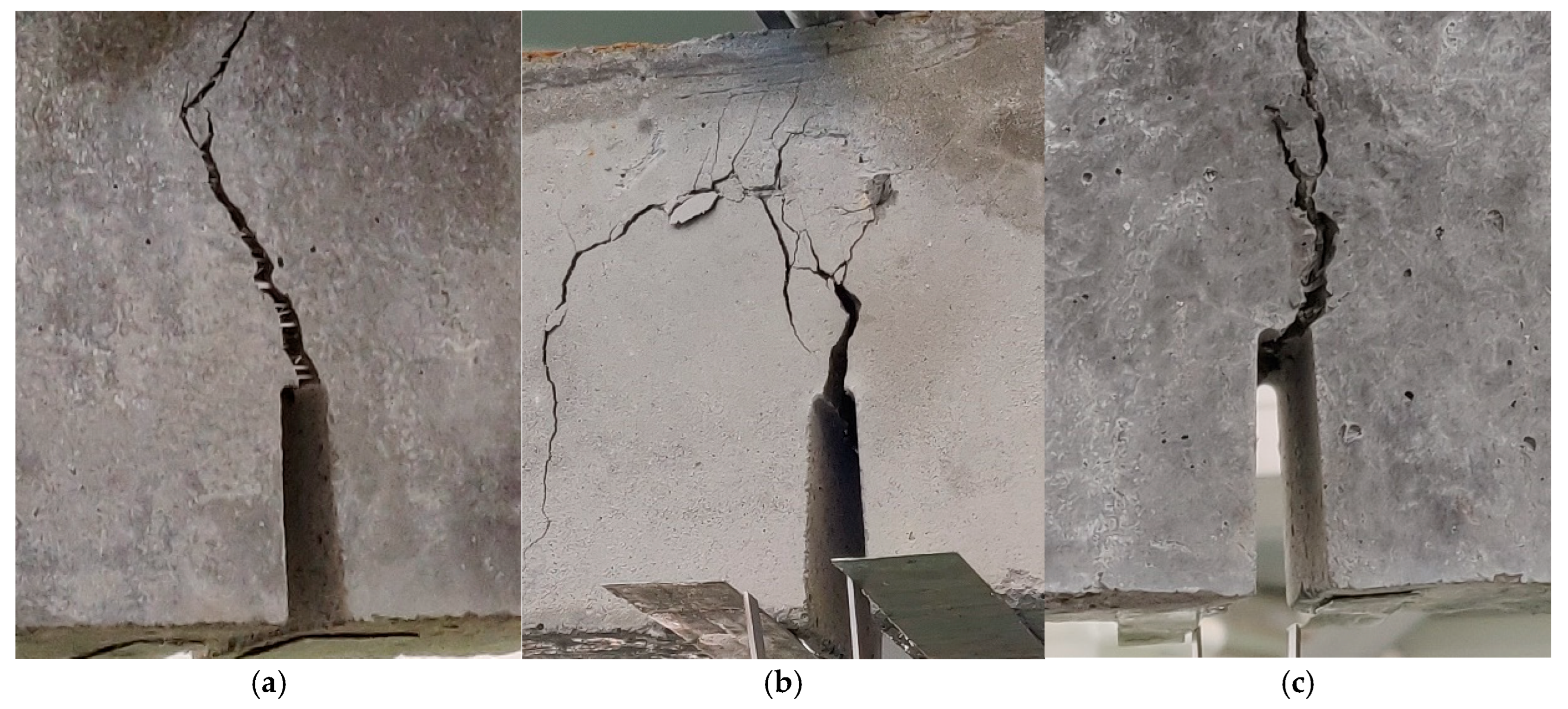

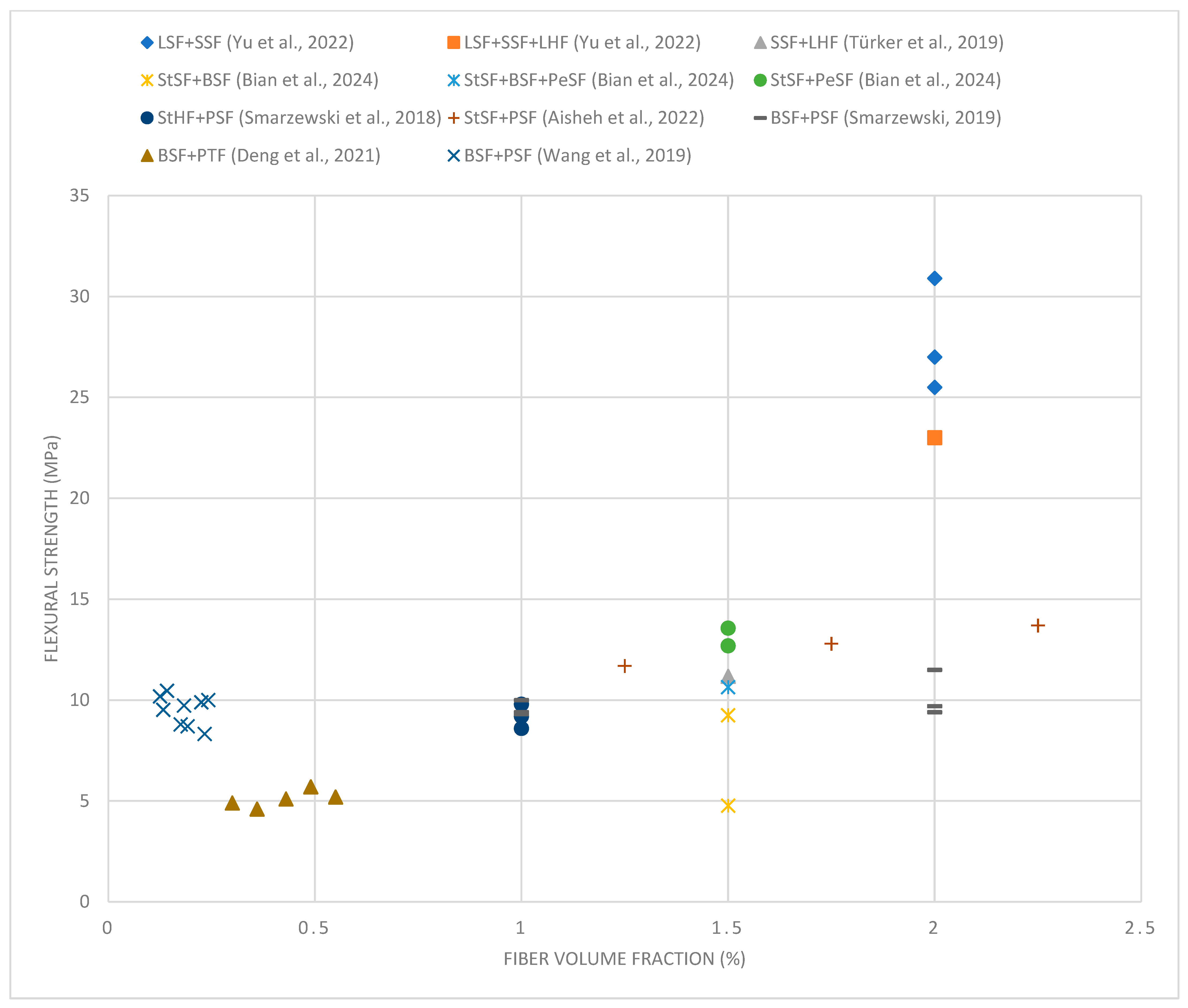

4.4.3. Flexural Strength

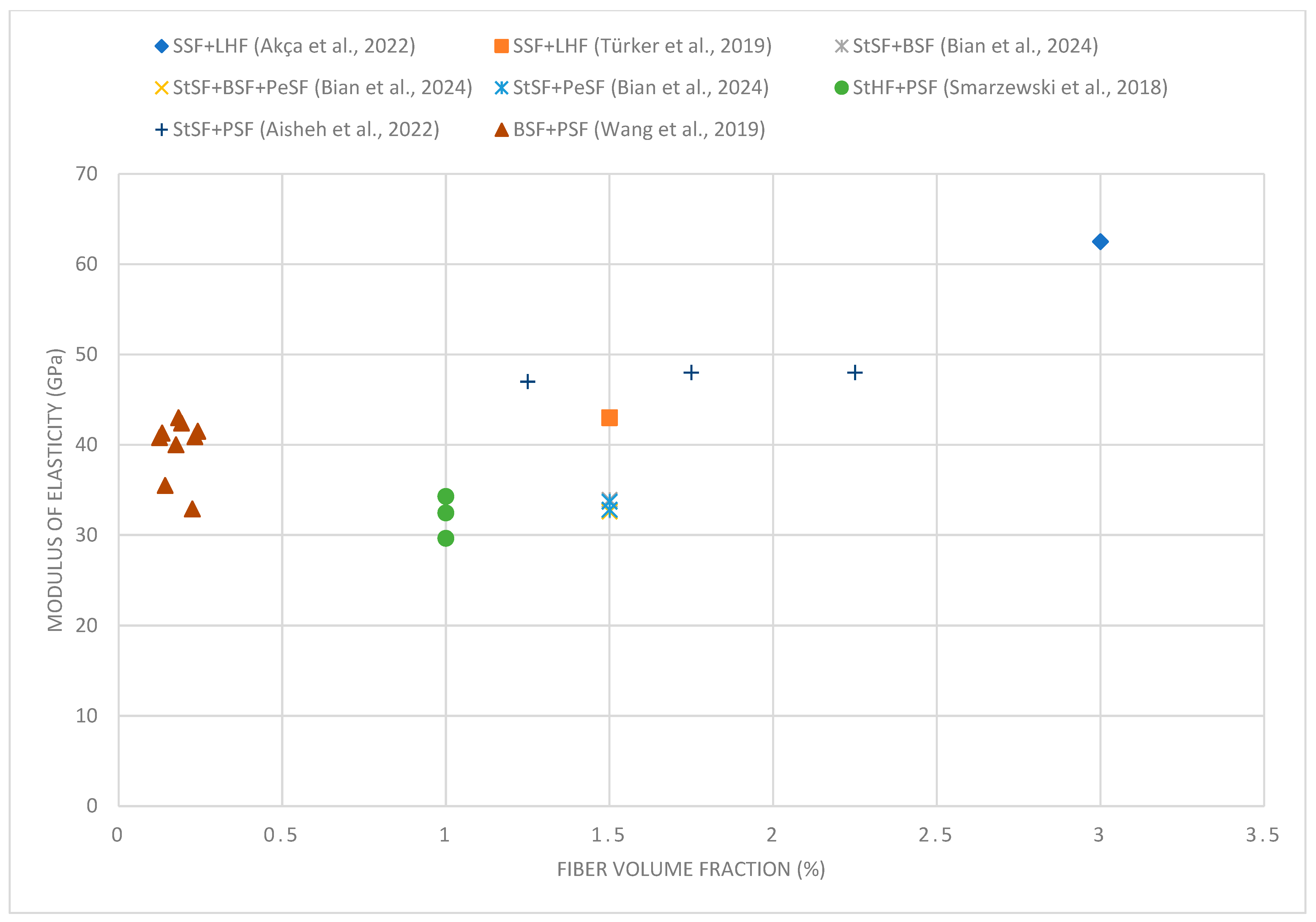

4.4.4. Elastic Modulus

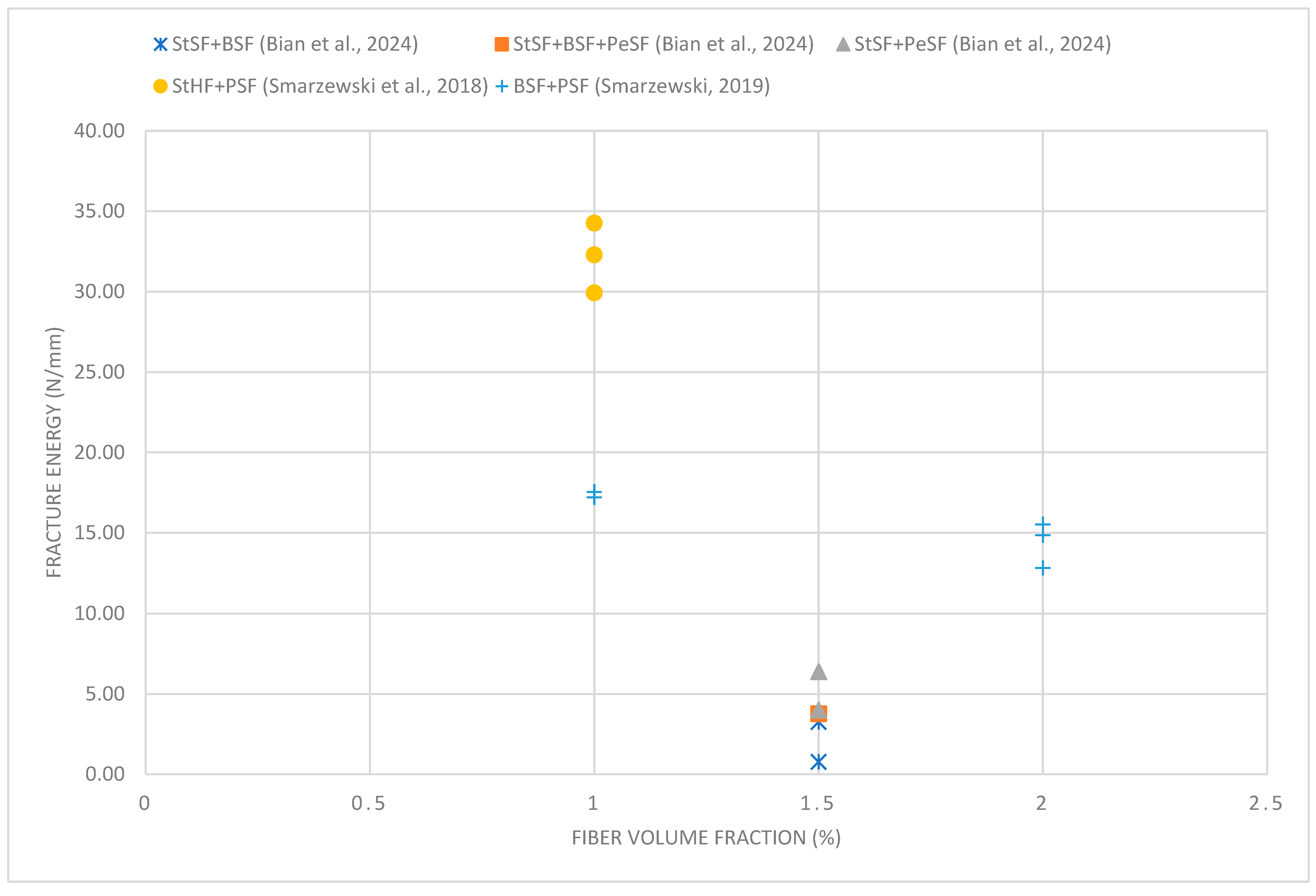

4.4.5. Fracture Energy

4.5. Summary of Key Findings from the Mechanical Parameter Review

5. Durability of UHPC with Hybrid Fibers

- -

- Frost resistance test, consisting of cyclic freezing and thawing of samples in a water or salt solution and then assessing their strength.

- -

- Carbonation test, i.e., the process of carbon dioxide penetrating the material’s structure, which leads to a decrease in pH and may result in corrosion of the reinforcement.

- -

- Chloride resistance test, consisting of exposing a concrete sample to a chloride solution and then analyzing the degree of penetration and diffusion coefficient.

- -

- Fire resistance test, e.g., by subjecting the sample to controlled heating according to standard temperature curves and then analyzing its residual strength and degree of degradation.

5.1. Corrosion Resistance

5.1.1. Permeability Test

5.1.2. Resistance to Chloride and Salt Penetration

5.1.3. Carbonation Resistance

5.2. Resistance to Freeze–Thaw Cycles

5.3. Fire Resistance

6. Costs and Environmental Impact of Using Fibers in UHPC

6.1. Economic Aspects of Using Hybrid Fibers in UHPC

- Reducing the dosage of steel fibers without compromising mechanical properties by combining them with cheaper, locally available synthetic or natural fibers.

- Incorporating coarse aggregates to reduce the share of the expensive powder part of the mix.

- Eliminating heat treatment and other energy-intensive processes, such as high-pressure compaction.

- Designing mixes based on locally available materials, for example, fly ash, metakaolin, or lime powder, that can replace up to 50% of Portland cement without significant loss of mechanical properties.

6.2. Environmental Aspects of Using Fibers in UHPC

7. Summary and Conclusions

7.1. Conclusions of the Review

- (1)

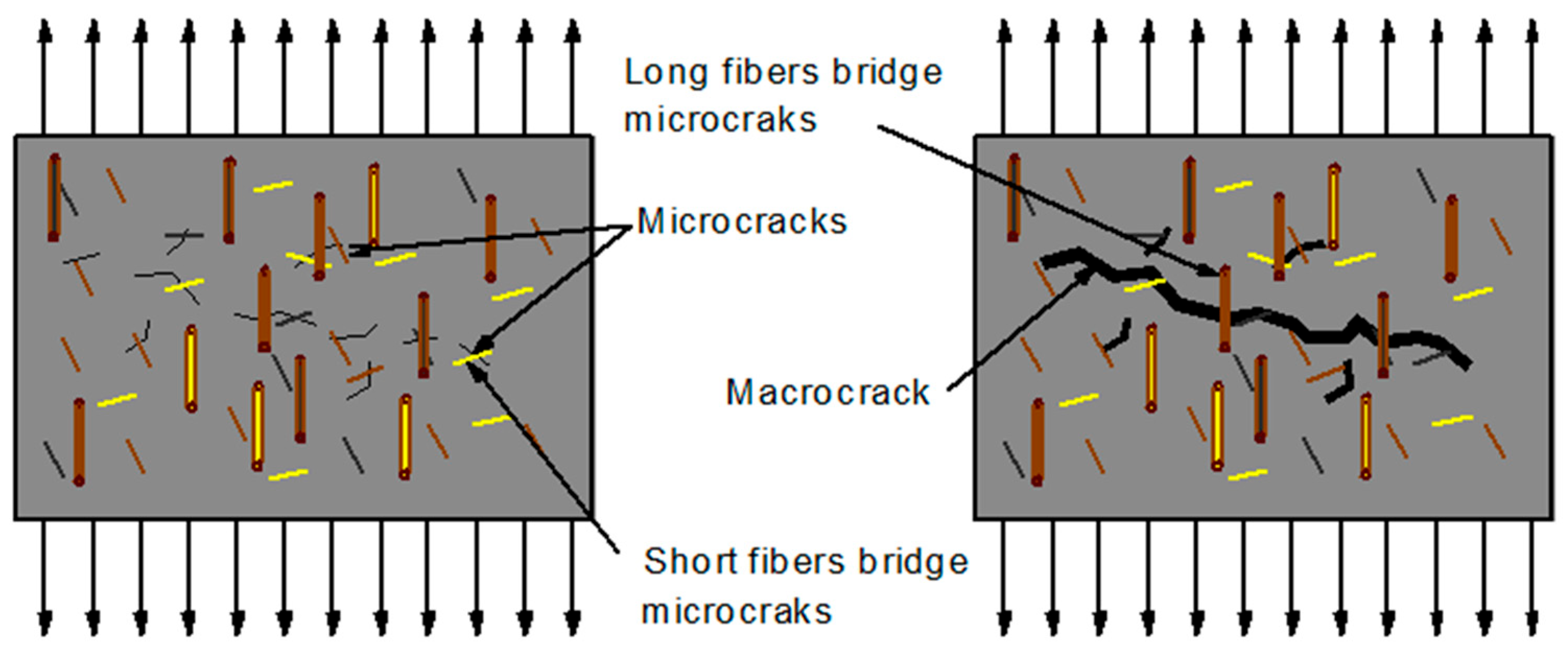

- The use of hybrid steel fibers in ultra-high-performance concrete (UHPC) significantly improves its mechanical properties, especially compressive, tensile, and bending strength, due to the synergy of short fibers that bridge microcracks and long fibers that limit the development of macrocracks. The appropriate selection of the proportions and types of fibers allows for an increase in the modulus of elasticity and an improvement in the ductility and ability of the concrete to crack multiple times, making it more resistant to dynamic loads and long-term use.

- (2)

- Hybrid steel–synthetic fibers effectively improve the mechanical properties of concrete, combining the high strength of steel fibers with the flexibility and ability to bridge microcracks of synthetic fibers. The use of such combinations increases the tensile strength, fracture energy, and ductility of concrete while reducing the brittleness of the material. However, an excessive amount of synthetic fibers can lead to a decrease in compressive strength and the modulus of elasticity, which is why it is crucial to properly select the proportions of both types of fibers in the mixture.

- (3)

- Short basalt–polypropylene hybrid fibers, despite reducing the compressive strength of high-performance concrete, significantly improve its tensile strength and crack resistance, indicating their beneficial effect in applications requiring increased durability and resistance to microcracks.

- (4)

- Hybrid fibers can improve or worsen the permeability of concrete depending on their quantity and environmental conditions—in optimal proportions (0.05–0.1%), they reduce microcracks and improve water tightness, but their excess (>0.2%) increases porosity and can weaken the structure, especially at high temperatures, where they promote the formation of microchannels facilitating water flow.

- (5)

- The use of hybrid fibers in UHPC can also increase its resistance to chloride ion penetration by reducing porosity and limiting the formation of microcracks, leading to a lower chloride diffusion coefficient and increased durability of concrete structures.

- (6)

- Hybrid fibers, by increasing the structural density of concrete and reducing microcracks, can also improve the resistance of concrete to carbonation, limiting CO2 penetration and thus minimizing the impact of this process on the durability of the structure.

- (7)

- The introduction of hybrid fibers into concrete effectively increases its resistance to freeze–thaw cycles by reducing cracks due to the bridging effect, improving the cohesion of the structure and optimizing the pore system, which limits the negative impact of frost and increases the durability of the material.

- (8)

- The use of hybrid fibers, which combine steel and polypropylene fibers, significantly improves the fire resistance of UHPC, reducing the risk of spalling and loss of strength by reducing thermal stresses and creating pores that facilitate the release of water vapor.

7.2. Future Research Directions

7.3. Practical Recommendations for Engineering Applications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, J.; Yuan, H.; Zhang, J.; Zhang, P. Enhancing Concrete Performance: A Comprehensive Review of Hybrid Fiber Reinforced Concrete. Structures 2024, 64, 106560. [Google Scholar] [CrossRef]

- Singh, N.K.; Rai, B. A Review of Fiber Synergy in Hybrid Fiber Reinforced Concrete. J. Appl. Eng. Sci. 2018, 8, 41–50. [Google Scholar] [CrossRef]

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-High-Performance Fiber-Reinforced Concrete. Part I: Developments, Principles, Raw Materials. Case Stud. Constr. Mater. 2022, 17, e01290. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.H.; Megat Johari, M.A.; Voo, Y.L. Mechanical and Permeability Properties of the Interface between Normal Concrete Substrate and Ultra High Performance Fiber Concrete Overlay. Constr. Build. Mater. 2012, 36, 538–548. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.H.; Megat Johari, M.A. Characterization of the Interfacial Bond between Old Concrete Substrate and Ultra High Performance Fiber Concrete Repair Composite. Mater. Struct. 2013, 46, 743–753. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Bakar, B.H.A.; Johari, M.A.M.; Ratnam, M.M. The Relationship between Substrate Roughness Parameters and Bond Strength of Ultra High-Performance Fiber Concrete. J. Adhes. Sci. Technol. 2013, 27, 1790–1810. [Google Scholar] [CrossRef]

- Xu, Q.; Jiang, X.; Lv, H.; Xu, C. Experimental Investigation on Bond-Slip Performance and Damage Evolution Mechanism of Deformed Reinforcing Bar Embedded in Steel Polyvinyl-Alcohol Hybrid Fiber High Performance Concrete after High Temperature. Constr. Build. Mater. 2024, 436, 136951. [Google Scholar] [CrossRef]

- Dushimimana, A.; Niyonsenga, A.A.; Nzamurambaho, F. A Review on Strength Development of High Performance Concrete. Constr. Build. Mater. 2021, 307, 124865. [Google Scholar] [CrossRef]

- Hiew, S.Y.; Teoh, K.B.; Raman, S.N.; Kong, D.; Hafezolghorani, M. A Generalised Predictive Model for the Mechanical Properties of Mono/Hybrid Fibre-Reinforced Ultra-High-Performance Concrete. Constr. Build. Mater. 2024, 426, 136154. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Banthia, N. Mechanical Properties of Ultra-High-Performance Fiber-Reinforced Concrete: A Review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Gong, J.; Ma, Y.; Fu, J.; Hu, J.; Ouyang, X.; Zhang, Z.; Wang, H. Utilization of Fibers in Ultra-High Performance Concrete: A Review. Compos. Part B Eng. 2022, 241, 109995. [Google Scholar] [CrossRef]

- Wang, Y.; Qiao, P.; Sun, J.; Chen, A. Influence of Fibers on Tensile Behavior of Ultra-High Performance Concrete: A Review. Constr. Build. Mater. 2024, 430, 136432. [Google Scholar] [CrossRef]

- Muhyaddin, G.F. Mechanical and Fracture Characteristics of Ultra-High Performance Concretes Reinforced with Hybridization of Steel and Glass Fibers. Heliyon 2023, 9, e17926. [Google Scholar] [CrossRef]

- Li, S.; Zheng, W.; Zhou, W.; Wang, Y. Local Compression Capacity of Ultra-High Performance Concrete Containing Coarse Aggregate: Testing and Calculation Method. J. Build. Eng. 2023, 76, 107411. [Google Scholar] [CrossRef]

- Saleh, S.; Mahmood, A.H.; Zhao, X.-L.; Hamed, E. Durability Assessment of Industrial By-Product and Marine Resource-Based Ultra-High-Performance Concrete. Mater. Today Proc. 2023, S2214785323041391. [Google Scholar] [CrossRef]

- Esmaeili, J.; Romouzi, V.; Kasaei, J.; Andalibi, K. An Investigation of Durability and the Mechanical Properties of Ultra-High Performance Concrete (UHPC) Modified with Economical Graphene Oxide Nano-Sheets. J. Build. Eng. 2023, 80, 107908. [Google Scholar] [CrossRef]

- Wei, X.; Zhu, H.; Chen, Q.; Ju, J.W.; Cai, W.; Yan, Z.; Shen, Y. Microstructure-Based Prediction of UHPC’s Tensile Behavior Considering the Effects of Interface Bonding, Matrix Spalling and Fiber Distribution. Cem. Concr. Compos. 2023, 139, 105015. [Google Scholar] [CrossRef]

- Teng, L.; Huang, H.; Khayat, K.H.; Gao, X. Simplified Analytical Model to Assess Key Factors Influenced by Fiber Alignment and Their Effect on Tensile Performance of UHPC. Cem. Concr. Compos. 2022, 127, 104395. [Google Scholar] [CrossRef]

- Isa, M.N.; Pilakoutas, K.; Guadagnini, M. Determination of Tensile Characteristics and Design of Eco-Efficient UHPC. Structures 2021, 32, 2174–2194. [Google Scholar] [CrossRef]

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Exploring Mechanical and Durability Properties of Ultra-High Performance Concrete Incorporating Various Steel Fiber Lengths and Dosages. Constr. Build. Mater. 2015, 75, 429–441. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, P.; Wang, J.; Hu, S. Influence of Fibers on the Mechanical Properties and Durability of Ultra-High-Performance Concrete: A Review. J. Build. Eng. 2022, 52, 104370. [Google Scholar] [CrossRef]

- Kang, S.-T.; Lee, Y.; Park, Y.-D.; Kim, J.-K. Tensile Fracture Properties of an Ultra High Performance Fiber Reinforced Concrete (UHPFRC) with Steel Fiber. Compos. Struct. 2010, 92, 61–71. [Google Scholar] [CrossRef]

- Alkaysi, M.; El-Tawil, S.; Liu, Z.; Hansen, W. Effects of Silica Powder and Cement Type on Durability of Ultra High Performance Concrete (UHPC). Cem. Concr. Compos. 2016, 66, 47–56. [Google Scholar] [CrossRef]

- Amin, M.; Agwa, I.S.; Mashaan, N.; Mahmood, S.; Abd-Elrahman, M.H. Investigation of the Physical Mechanical Properties and Durability of Sustainable Ultra-High Performance Concrete with Recycled Waste Glass. Sustainability 2023, 15, 3085. [Google Scholar] [CrossRef]

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Emad, W.; Faraj, R.H.; Mohammed, A.S.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-High-Performance Fiber-Reinforced Concrete. Part III: Fresh and Hardened Properties. Case Stud. Constr. Mater. 2022, 17, e01265. [Google Scholar] [CrossRef]

- Esmaeili, J.; Oudah AL-Mwanes, A. Production of Eco-Friendly UHPC with High Durability and Resistance to Harsh Environmental Conditions Using Copper Mine Tailings. J. Build. Eng. 2023, 76, 107297. [Google Scholar] [CrossRef]

- Li, J.; Wang, X.; Chen, D.; Wu, D.; Han, Z.; Hou, D.; Zhen, Z.; Peng, C.; Ding, Q.; Yin, B. Design and Application of UHPC with High Abrasion Resistance. Constr. Build. Mater. 2021, 309, 125141. [Google Scholar] [CrossRef]

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-High-Performance Fiber-Reinforced Concrete. Part IV: Durability Properties, Cost Assessment, Applications, and Challenges. Case Stud. Constr. Mater. 2022, 17, e01271. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.-S.; Onaizi, A.M.; Makul, N.; Abdelgader, H.S.; Ozbakkaloglu, T. Recent Trends in Ultra-High Performance Concrete (UHPC): Current Status, Challenges, and Future Prospects. Constr. Build. Mater. 2022, 352, 129029. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Chen, F.X.; Dai, X.Q.; Tan, Y.Z.; Duan, L.Q.; Zhang, Z.W.; Leng, Y.; Wang, S.Y.; Yin, T.Y.; Yu, R. Development of a Novel Ultra-High Performance Concrete (UHPC) Suitable for Underwater Operation: Design and Performance Evaluation. J. Build. Eng. 2023, 75, 107030. [Google Scholar] [CrossRef]

- Xue, J.; Briseghella, B.; Huang, F.; Nuti, C.; Tabatabai, H.; Chen, B. Review of Ultra-High Performance Concrete and Its Application in Bridge Engineering. Constr. Build. Mater. 2020, 260, 119844. [Google Scholar] [CrossRef]

- Abdal, S.; Mansour, W.; Agwa, I.; Nasr, M.; Abadel, A.; Onuralp Özkılıç, Y.; Akeed, M.H. Application of Ultra-High-Performance Concrete in Bridge Engineering: Current Status, Limitations, Challenges, and Future Prospects. Buildings 2023, 13, 185. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, Z.; Zhang, Z.; Zou, Y.; Jiang, J.; Zeng, X. Experimental and Numerical Studies on Shear Behavior of Prefabricated Bridge Deck Slabs with Compact UHPC Wet Joint. Case Stud. Constr. Mater. 2023, 19, e02362. [Google Scholar] [CrossRef]

- Mash, J.A.; Harries, K.A.; Rogers, C. Repair of Corroded Steel Bridge Girder End Regions Using Steel, Concrete, UHPC and GFRP Repair Systems. J. Constr. Steel Res. 2023, 207, 107975. [Google Scholar] [CrossRef]

- Ono, T. Application of Ultra-High-Strength Fiber-Reinforced Concrete for Irrigation Channel Repair Works. In Designing and Building with UHPFRC; 2011; pp. 541–552. ISBN 978-1-118-55783-9. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Nikoo, M.R.; Hosseini, S.A. Determination of Optimized Mix Design and Curing Conditions of Reactive Powder Concrete (RPC). Constr. Build. Mater. 2016, 123, 754–767. [Google Scholar] [CrossRef]

- Faraj, R.H.; Ahmed, H.U.; Rafiq, S.; Sor, N.H.; Ibrahim, D.F.; Qaidi, S.M.A. Performance of Self-Compacting Mortars Modified with Nanoparticles: A Systematic Review and Modeling. Clean. Mater. 2022, 4, 100086. [Google Scholar] [CrossRef]

- Almeshal, I.; Al-Tayeb, M.M.; Qaidi, S.M.A.; Bakar, B.H.A.; Tayeh, B.A. Mechanical Properties of Eco-Friendly Cements-Based Glass Powder in Aggressive Medium. Mater. Today Proc. 2022, 58, 1582–1587. [Google Scholar] [CrossRef]

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-High-Performance Fiber-Reinforced Concrete. Part II: Hydration and Microstructure. Case Stud. Constr. Mater. 2022, 17, e01289. [Google Scholar] [CrossRef]

- Aisheh, Y.I.A.; Atrushi, D.S.; Akeed, M.H.; Qaidi, S.; Tayeh, B.A. Influence of Steel Fibers and Microsilica on the Mechanical Properties of Ultra-High-Performance Geopolymer Concrete (UHP-GPC). Case Stud. Constr. Mater. 2022, 17, e01245. [Google Scholar] [CrossRef]

- Aisheh, Y.I.A.; Atrushi, D.S.; Akeed, M.H.; Qaidi, S.; Tayeh, B.A. Influence of Polypropylene and Steel Fibers on the Mechanical Properties of Ultra-High-Performance Fiber-Reinforced Geopolymer Concrete. Case Stud. Constr. Mater. 2022, 17, e01234. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Mohammed, A.S.; Ahmed, H.U.; Faraj, R.H.; Emad, W.; Tayeh, B.A.; Althoey, F.; Zaid, O.; Sor, N.H. Rubberized Geopolymer Composites: A Comprehensive Review. Ceram. Int. 2022, 48, 24234–24259. [Google Scholar] [CrossRef]

- Guo, H.; Wang, H.; Li, H.; Wei, L.; Li, Y. Effect of Whisker Toughening on the Dynamic Properties of Hybrid Fiber Concrete. Case Stud. Constr. Mater. 2023, 19, e02517. [Google Scholar] [CrossRef]

- Gorji Azandariani, M.; Vajdian, M.; Asghari, K.; Mehrabi, S. Mechanical Properties of Polyolefin and Polypropylene Fibers-Reinforced Concrete–An Experimental Study. Compos. Part C Open Access 2023, 12, 100410. [Google Scholar] [CrossRef]

- Ekta; Kumar, R.; Babu, T.S.R.; Venkatesan, G.; Padhi, S.N.; Parida, J.L.; Kumar, V.R. Investigation of Fiber Reinforced Concrete—Energy Absorption Capacity with Steel and Polymeric Fibers. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Du, W.; Qian, C. Atomic-Level Insights into the Mechanism by Which Synthetic Organic Fibers Enhance the Tensile Strength of Concrete. J. Build. Eng. 2023, 75, 106891. [Google Scholar] [CrossRef]

- Sadighi, A.; Maghami, E.; Khaneghahi, M.H.; Kamireddi, D.; Rahmaninezhad, S.A.; Farnam, Y.; Sales, C.M.; Schauer, C.L.; Najafi, A.R. Fracture Analysis of Multifunctional Fiber-Reinforced Concrete Using Phase-Field Method. Int. J. Solids Struct. 2023, 283, 112493. [Google Scholar] [CrossRef]

- Kushzhanova, A.; Raiymbek, M.; Ogwumeh, C.M.; Bakhbergen, U.; Shon, C.-S.; Zhang, D.; Kim, J.R. Freeze-Thaw Resistance and Mechanical Properties of UHPC Reinforced with a Lower Amount of Hybrid Fibers. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Hybrid Fiber Reinforced Concrete (HyFRC): Fiber Synergy in High Strength Matrices. Mater. Struct. 2004, 37, 707–716. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wang, D. Static and Dynamic Compressive Properties of Ultra-High Performance Concrete (UHPC) with Hybrid Steel Fiber Reinforcements. Cem. Concr. Compos. 2017, 79, 148–157. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Kim, M.J.; Kim, S.-W.; Park, J.-J. Development of Cost Effective Ultra-High-Performance Fiber-Reinforced Concrete Using Single and Hybrid Steel Fibers. Constr. Build. Mater. 2017, 150, 383–394. [Google Scholar] [CrossRef]

- Kim, D.J.; Park, S.H.; Ryu, G.S.; Koh, K.T. Comparative Flexural Behavior of Hybrid Ultra High Performance Fiber Reinforced Concrete with Different Macro Fibers. Constr. Build. Mater. 2011, 25, 4144–4155. [Google Scholar] [CrossRef]

- Niu, Y.; Wei, J.; Jiao, C. Crack Propagation Behavior of Ultra-High-Performance Concrete (UHPC) Reinforced with Hybrid Steel Fibers under Flexural Loading. Constr. Build. Mater. 2021, 294, 123510. [Google Scholar] [CrossRef]

- Jiao, C.; Ta, J.; Niu, Y.; Meng, S.; Chen, X.-F.; He, S.; Ma, R. Analysis of the Flexural Properties of Ultra-High-Performance Concrete Consisting of Hybrid Straight Steel Fibers. Case Stud. Constr. Mater. 2022, 17, e01153. [Google Scholar] [CrossRef]

- Ma, R.; Guo, L.; Ye, S.; Sun, W.; Liu, J. Influence of Hybrid Fiber Reinforcement on Mechanical Properties and Autogenous Shrinkage of an Ecological UHPFRCC. J. Mater. Civ. Eng. 2019, 31, 04019032. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, D.J.; Ryu, G.S.; Koh, K.T. Tensile Behavior of Ultra High Performance Hybrid Fiber Reinforced Concrete. Cem. Concr. Compos. 2012, 34, 172–184. [Google Scholar] [CrossRef]

- Kang, S.-T.; Choi, J.-I.; Koh, K.-T.; Lee, K.S.; Lee, B.Y. Hybrid Effects of Steel Fiber and Microfiber on the Tensile Behavior of Ultra-High Performance Concrete. Compos. Struct. 2016, 145, 37–42. [Google Scholar] [CrossRef]

- Smarzewski, P.; Barnat-Hunek, D. Property Assessment of Hybrid Fiber-Reinforced Ultra-High-Performance Concrete. Int. J. Civ. Eng. 2018, 16, 593–606. [Google Scholar] [CrossRef]

- Smarzewski, P. Influence of Basalt-Polypropylene Fibres on Fracture Properties of High Performance Concrete. Compos. Struct. 2019, 209, 23–33. [Google Scholar] [CrossRef]

- Turker, K.; Hasgul, U.; Birol, T.; Yavas, A.; Yazici, H. Hybrid Fiber Use on Flexural Behavior of Ultra High Performance Fiber Reinforced Concrete Beams. Compos. Struct. 2019, 229, 111400. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical Properties of High Performance Concrete Reinforced with Basalt Fiber and Polypropylene Fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Deng, Z.; Liu, X.; Liang, N. Flexural Performance of a New Hybrid Basalt-Polypropylene Fiber-Reinforced Concrete Oriented to Concrete Pipelines. Fibers 2021, 9, 43. [Google Scholar] [CrossRef]

- Akça, K.R.; İpek, M. Effect of Different Fiber Combinations and Optimisation of an Ultra-High Performance Concrete (UHPC) Mix Applicable in Structural Elements. Constr. Build. Mater. 2022, 315, 125777. [Google Scholar] [CrossRef]

- Elsayed, M.; Althoey, F.; Tayeh, B.A.; Ahmed, N.; El-Azim, A.A. Behavior of Eccentrically Loaded Hybrid Fiber-Reinforced High Strength Concrete Columns Exposed to Elevated Temperature. J. Mater. Res. Technol. 2022, 19, 1003–1020. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Development of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC): Towards an Efficient Utilization of Binders and Fibres. Constr. Build. Mater. 2015, 79, 273–282. [Google Scholar] [CrossRef]

- Bian, Z.; Zhang, L.; Peng, C.; Zhou, Z.; Shen, H. Experimental Study on Hybrid Fiber Reinforced High Performance Concrete Properties: Investigatingcomprehensive Energy Consumption Capacity. Constr. Build. Mater. 2024, 443, 137682. [Google Scholar] [CrossRef]

- Li, S.; Qian, H. Crack Resistance and Permeability of Hybrid Fiber Reinforced Concrete Application in Understructure Work. Appl. Mech. Mater. 2013, 438–439, 257–261. [Google Scholar] [CrossRef]

- Xu, H.; Wang, Z.; Shao, Z.; Cai, L.; Jin, H.; Zhang, Z.; Qiu, Z.; Rui, X.; Chen, T. Experimental Study on Durability of Fiber Reinforced Concrete: Effect of Cellulose Fiber, Polyvinyl Alcohol Fiber and Polyolefin Fiber. Constr. Build. Mater. 2021, 306, 124867. [Google Scholar] [CrossRef]

- Huang, C.-K.; Che, Y.; Wang, B.-X. Mechanical Properties and Impermeability of Hybrid Fiber Reinforced Concrete. J. Build. Mater. 2008, 11, 89–93. [Google Scholar]

- Liu, D. Study on the Properties of Basalt and Polypropylene Mixed Fiber Concrete. Ph.D. Thesis, Chongqing Jiaotong University, Chongqing, China, 2018. [Google Scholar]

- Hung, C.-C.; Yulianti, E.; Agrawal, S. Microstructures, Durability, and Mechanical Behavior of Hybrid Steel and PP Fiber Reinforced UHPC at Elevated Temperatures. Constr. Build. Mater. 2024, 447, 138208. [Google Scholar] [CrossRef]

- Ghafari, E.; Arezoumandi, M.; Costa, H.; Júlio, E. Influence of Nano-Silica Addition on Durability of UHPC. Constr. Build. Mater. 2015, 94, 181–188. [Google Scholar] [CrossRef]

- Long, G.; Xie, Y.; Wang, P.; Jiang, Z. Properties and Micro/Mecrostructure of Reactive Powder Concrete. Kuei Suan Jen Hsueh Pao J. Chin. Ceram. Soc. 2005, 33, 456–461. [Google Scholar]

- Guler, S.; Akbulut, Z.F. Workability, Physical & Mechanical Properties of the Cement Mortars Strengthened with Metakaolin and Steel/Basalt Fibers Exposed to Freezing-Thawing Periods. Constr. Build. Mater. 2023, 394, 132100. [Google Scholar] [CrossRef]

- Guler, S.; Akbulut, Z.F. Workability & Mechanical Properties of the Single and Hybrid Basalt Fiber Reinforced Volcanic Ash-Based Cement Mortars after Freeze–Thaw Cycles. Structures 2023, 48, 1537–1547. [Google Scholar] [CrossRef]

- Tai, Y.-S.; Pan, H.-H.; Kung, Y.-N. Mechanical Properties of Steel Fiber Reinforced Reactive Powder Concrete Following Exposure to High Temperature Reaching 800°C. Nucl. Eng. Des. 2011, 241, 2416–2424. [Google Scholar] [CrossRef]

- Zheng, W.; Luo, B.; Wang, Y. Compressive and Tensile Properties of Reactive Powder Concrete with Steel Fibres at Elevated Temperatures. Constr. Build. Mater. 2013, 41, 844–851. [Google Scholar] [CrossRef]

- 78. Heinz, D.; Dehn, F.; Urbonas, L. Fire resistance of ultra high performance concrete (UHPC)-Testing of laboratory samples and columns under load, International symposium on ultra high performance concrete. Kassel University Press: Kassel, Germany, 2004; pp. 703–715. [Google Scholar]

- Peng, G.-F.; Kang, Y.-R.; Huang, Y.-Z.; Liu, X.-P.; Chen, Q. Experimental Research on Fire Resistance of Reactive Powder Concrete. Adv. Mater. Sci. Eng. 2012, 2012, 860303. [Google Scholar] [CrossRef]

- Shafei, B.; Kazemian, M.; Dopko, M.; Najimi, M. State-of-the-Art Review of Capabilities and Limitations of Polymer and Glass Fibers Used for Fiber-Reinforced Concrete. Materials 2021, 14, 409. [Google Scholar] [CrossRef]

- Trinh-Duc, D.; Piotrowski, A.; Ajdukiewicz, C.; Woyciechowski, P.; Gajewski, M. Estimation of Post-Cracking Dissipation Capabilities of Fiber Reinforced Concretes in Three Point Bending Test Monitored with Application of Digital Image Correlation System. Materials 2021, 14, 5088. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Akeed, M.H.; Qaidi, S.; Bakar, B.H.A. Ultra-High-Performance Concrete: Impacts of Steel Fibre Shape and Content on Flowability, Compressive Strength and Modulus of Rupture. Case Stud. Constr. Mater. 2022, 17, e01615. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of Steel Fiber Content and Shape on Mechanical Properties of Ultra High Performance Concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Rezakhani, R.; Scott, D.A.; Bousikhane, F.; Pathirage, M.; Moser, R.D.; Green, B.H.; Cusatis, G. Influence of Steel Fiber Size, Shape, and Strength on the Quasi-Static Properties of Ultra-High Performance Concrete: Experimental Investigation and Numerical Modeling. Constr. Build. Mater. 2021, 296, 123532. [Google Scholar] [CrossRef]

- Frazão, C.; Camões, A.; Barros, J.; Gonçalves, D. Durability of Steel Fiber Reinforced Self-Compacting Concrete. Constr. Build. Mater. 2015, 80, 155–166. [Google Scholar] [CrossRef]

- Granju, J.-L.; Balouch, S.U. Corrosion of Steel Fibre Reinforced Concrete from the Cracks. Cem. Concr. Res. 2005, 35, 572–577. [Google Scholar] [CrossRef]

- Lin, J.-X.; Su, J.-Y.; Pan, H.-S.; Peng, Y.-Q.; Guo, Y.-C.; Chen, W.-S.; Sun, X.-L.; Yuan, B.-X.; Liu, G.-T.; Lan, X.-W. Dynamic Compression Behavior of Ultra-High Performance Concrete with Hybrid Polyoxymethylene Fiber and Steel Fiber. J. Mater. Res. Technol. 2022, 20, 4473–4486. [Google Scholar] [CrossRef]

- Jang, Y.S.; Oh, T.; Banthia, N.; Yoo, D.-Y. Effects of Nano-SiO2 Coating and Induced Corrosion of Steel Fiber on the Interfacial Bond and Tensile Properties of Ultra-High-Performance Concrete (UHPC). J. Build. Eng. 2022, 54, 104637. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Kim, M.-J. High Energy Absorbent Ultra-High-Performance Concrete with Hybrid Steel and Polyethylene Fibers. Constr. Build. Mater. 2019, 209, 354–363. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Hakeem, I.Y.; Amin, M.; Tayeh, B.A.; Agwa, I.S. Effect of Aggregate and Fibre Types on Ultra-High-Performance Concrete Designed for Radiation Shielding. J. Build. Eng. 2022, 58, 104960. [Google Scholar] [CrossRef]

- Kim, S.; Jang, Y.S.; Oh, T.; Lee, S.K.; Yoo, D.-Y. Effect of Crack Width on Electromagnetic Interference Shielding Effectiveness of High-Performance Cementitious Composites Containing Steel and Carbon Fibers. J. Mater. Res. Technol. 2022, 20, 359–372. [Google Scholar] [CrossRef]

- Kamjou, A.S.; Khaloo, A.; Hassanpour, S. Experimental and Numerical Investigation of Minimum Required Fiber Content in Bending Characteristics of 100 MPa UHPC-Formulated Concrete. Case Stud. Constr. Mater. 2022, 16, e01066. [Google Scholar] [CrossRef]

- Michal, Ž.; Tomáš, V.; Řepka, J.; Pavlů, T. Segregation of Steel Fibres of UHPFRC. Solid State Phenom. 2018, 272, 166–171. [Google Scholar] [CrossRef]

- Yang, Z.J.; Qsymah, A.; Peng, Y.Z.; Margetts, L.; Sharma, R. 4D Characterisation of Damage and Fracture Mechanisms of Ultra High Performance Fibre Reinforced Concrete by In-Situ Micro X-Ray Computed Tomography Tests. Cem. Concr. Compos. 2020, 106, 103473. [Google Scholar] [CrossRef]

- Tue, N.V.; Henze, S.; Küchler, M.; Schenck, G.; Wille, K. Ein Optoanalytisches Verfahren Zur Bestimmung Der Faserverteilung Und -Orientierung in Stahlfaserverstärktem UHFB. Beton Stahlbetonbau 2007, 102, 674–680. [Google Scholar] [CrossRef]

- Prem, P.R.; Ramachandra Murthy, A.; Bharatkumar, B.H. Influence of Curing Regime and Steel Fibres on the Mechanical Properties of UHPC. Mag. Concr. Res. 2015, 67, 988–1002. [Google Scholar] [CrossRef]

- Mishra, S.; Sharma, H.K. Influence of Fibre Volume on the Structural Behaviour of Ultra-High-Performance Fibrous Concrete. Int. J. Microstruct. Mater. Prop. 2021, 15, 457–474. [Google Scholar] [CrossRef]

- Maryamh, K.; Hauch, K.; Redenbach, C.; Schnell, J. Influence of Specimen Size on the Fibre Geometry and Tensile Strength of Ultra-High-Performance Fibre-Reinforced Concrete. Struct. Concr. 2022, 23, 1239–1252. [Google Scholar] [CrossRef]

- Makita, T.; Brühwiler, E. Tensile Fatigue Behaviour of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Mater. Struct. 2014, 47, 475–491. [Google Scholar] [CrossRef]

- Lanwer, J.-P.; Empelmann, M. Performance-Based Fibre Design for Ultra-High Performance Concrete (UHPC). Appl. Sci. 2022, 12, 8559. [Google Scholar] [CrossRef]

- Lande, I.; Thorstensen, R.T. Locally Produced UHPC: The Influence of Type and Content of Steel Fibres. Nord. Concr. Res. 2021, 64, 31–52. [Google Scholar] [CrossRef]

- Hu, A.; Liang, X.; Yu, J.; Shi, Q. Tensile Characteristics of Ultra-High-Performance Concrete. Mag. Concr. Res. 2018, 70, 314–324. [Google Scholar] [CrossRef]

- Gietz, L.; Kowalsky, U.; Dinkler, D. A Phenomenological Model to Describe Cracking and Fibre Pull-out in Ultra High-Performance Fibre Reinforced Concrete. PAMM 2023, 22, e202200321. [Google Scholar] [CrossRef]

- Bashar, I.I.; Sturm, A.B.; Visintin, P.; Sheikh, A.H. Pull-out Creep of Hooked-End Fibre Embedded in Ultra-High-Performance Concrete. Constr. Build. Mater. 2023, 366, 130189. [Google Scholar] [CrossRef]

- Abrishambaf, A.; Pimentel, M.; Nunes, S. Influence of Fibre Orientation on the Tensile Behaviour of Ultra-High Performance Fibre Reinforced Cementitious Composites. Cem. Concr. Res. 2017, 97, 28–40. [Google Scholar] [CrossRef]

- Abdolpour, H.; Niewiadomski, P.; Sadowski, Ł.; Kwiecień, A. Engineering of Ultra-High Performance Self-Compacting Mortar with Recycled Steel Fibres Extracted from Waste Tires. Arch. Civ. Mech. Eng. 2022, 22, 175. [Google Scholar] [CrossRef]

- Ahmad, W.; Khan, M.; Smarzewski, P. Effect of Short Fiber Reinforcements on Fracture Performance of Cement-Based Materials: A Systematic Review Approach. Materials 2021, 14, 1745. [Google Scholar] [CrossRef] [PubMed]

- Bjegovic, D.; Baricevic, A.; Lakusic, S.; Damjanovic, D.; Duvnjak, I. POSITIVE INTERACTION OF INDUSTRIAL AND RECYCLED STEEL FIBRES IN FIBRE REINFORCED CONCRETE. J. Civ. Eng. Manag. 2014, 19, S50–S60. [Google Scholar] [CrossRef]

- Jabbar, A.; Hamood, M.; Mohammed, D. The Effect of Using Basalt Fibers Compared to Steel Fibers On the Shear Behavior of Ultra-High Performance Concrete T-Beam. Case Stud. Constr. Mater. 2021, 15, e00702. [Google Scholar] [CrossRef]

- Liew, K.M.; Akbar, A. The Recent Progress of Recycled Steel Fiber Reinforced Concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Balouch, S.U.; Forth, J.P.; Granju, J.-L. Surface Corrosion of Steel Fibre Reinforced Concrete. Cem. Concr. Res. 2010, 40, 410–414. [Google Scholar] [CrossRef]

- Li, J.; Wu, C.; Liu, Z.-X. Comparative Evaluation of Steel Wire Mesh, Steel Fibre and High Performance Polyethylene Fibre Reinforced Concrete Slabs in Blast Tests. Thin Walled Struct. 2018, 126, 117–126. [Google Scholar] [CrossRef]

- Chen, E.; Berrocal, C.G.; Löfgren, I.; Lundgren, K. Comparison of the Service Life, Life-Cycle Costs and Assessment of Hybrid and Traditional Reinforced Concrete through a Case Study of Bridge Edge Beams in Sweden. Struct. Infrastruct. Eng. 2023, 19, 39–57. [Google Scholar] [CrossRef]

- Hosking, N.C.; Ström, M.A.; Shipway, P.H.; Rudd, C.D. Corrosion Resistance of Zinc–Magnesium Coated Steel. Corros. Sci. 2007, 49, 3669–3695. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.-J.; Hui, D. A Short Review on Basalt Fiber Reinforced Polymer Composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Yan, P.; Chen, B.; Afgan, S.; Haque, M.A.; Wu, M.; Han, J. Experimental Research on Ductility Enhancement of Ultra-High Performance Concrete Incorporation with Basalt Fibre, Polypropylene Fibre and Glass Fibre. Constr. Build. Mater. 2021, 279, 122489. [Google Scholar] [CrossRef]

- Li, J.; Deng, Z. Tensile Behavior of Ultra-High Performance Concrete Reinforced with Different Hybrid Fibers. Struct. Concr. 2023, 24, 1415–1435. [Google Scholar] [CrossRef]

- Li, J.; Deng, Z. Tensile Behavior of Hybrid Fiber-Reinforced Ultra-High-Performance Concrete. Front. Mater. 2021, 8, 769579. [Google Scholar] [CrossRef]

- Ye, J.; Cui, C.; Yu, J.; Yu, K.; Dong, F. Effect of Polyethylene Fiber Content on Workability and Mechanical-Anisotropic Properties of 3D Printed Ultra-High Ductile Concrete. Constr. Build. Mater. 2021, 281, 122586. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Tensile Behavior Contrast of Basalt and Glass Fibers after Chemical Treatment. Mater. Des. 2010, 31, 4244–4250. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, X.; Ding, L.; Jiang, K.; Su, C.; Liu, J.; Wu, Z. Mechanical Properties of a Novel UHPC Reinforced with Macro Basalt Fibers. Constr. Build. Mater. 2023, 377, 131107. [Google Scholar] [CrossRef]

- Dong, C.; Ma, X. Experimental Research on Mechanical Properties of Basalt Fiber Reinforced Reactive Powder Concrete. Adv. Mater. Res. 2014, 893, 610–613. [Google Scholar] [CrossRef]

- Militký, J.; Kovačič, V.; Rubnerová, J. Influence of Thermal Treatment on Tensile Failure of Basalt Fibers. Eng. Fract. Mech. 2002, 69, 1025–1033. [Google Scholar] [CrossRef]

- Ali, B.; Ahmed, H.; Hafez, H.; Brahmia, A.; Ouni, M.H.E.; Raza, A. Life Cycle Impact Assessment (Cradle-to-Gate) of Fiber-Reinforced Concrete Application for Pavement Use: A Case Study of Islamabad City. Int. J. Pavement Res. Technol. 2023, 16, 247–263. [Google Scholar] [CrossRef]

- Tassew, S.T.; Lubell, A.S. Mechanical Properties of Glass Fiber Reinforced Ceramic Concrete. Constr. Build. Mater. 2014, 51, 215–224. [Google Scholar] [CrossRef]

- Zhou, C.; Shi, S.Q.; Chen, Z.; Cai, L.; Smith, L. Comparative Environmental Life Cycle Assessment of Fiber Reinforced Cement Panel between Kenaf and Glass Fibers. J. Clean. Prod. 2018, 200, 196–204. [Google Scholar] [CrossRef]

- Backes, J.G.; Traverso, M.; Horvath, A. Environmental Assessment of a Disruptive Innovation: Comparative Cradle-to-Gate Life Cycle Assessments of Carbon-Reinforced Concrete Building Component. Int. J. Life Cycle Assess. 2023, 28, 16–37. [Google Scholar] [CrossRef]

- Chand, S. Review Carbon Fibers for Composites. J. Mater. Sci. 2000, 35, 1303–1313. [Google Scholar] [CrossRef]

- Chung, D. Carbon Composites: Composites with Carbon Fibers, Nanofibers, and Nanotubes, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2016. [Google Scholar]

- Bhatt, P.; Goe, A. Carbon Fibres: Production, Properties and Potential Use. Mater. Sci. Res. India 2017, 14, 52–57. [Google Scholar] [CrossRef]

- Bunsell, A.R.; Somer, A.M. The Tensile and Fatigue Behaviour of Carbon Fibres. Plast. Rubber Compos. Process. Appl. 1992, 18, 263–267. [Google Scholar]

- Dorey, G. Carbon Fibres and Their Applications. J. Phys. D Appl. Phys. 1987, 20, 245. [Google Scholar] [CrossRef]

- Bunsell, A.R. 1—Introduction to Fibre Tensile Properties and Failure. In Handbook of Tensile Properties of Textile and Technical Fibres; Bunsell, A.R., Ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2009; pp. 1–17. ISBN 978-1-84569-387-9. [Google Scholar]

- Bompa, D.V.; Xu, B.; Elghazouli, A.Y. Constitutive Modelling and Mechanical Properties of Cementitious Composites Incorporating Recycled Vinyl Banner Plastics. Constr. Build. Mater. 2021, 275, 122159. [Google Scholar] [CrossRef]

- Xu, B.; Bompa, D.V.; Elghazouli, A.Y.; Ruiz-Teran, A.M.; Stafford, P.J. Behaviour of Rubberised Concrete Members in Asymmetric Shear Tests. Constr. Build. Mater. 2018, 159, 361–375. [Google Scholar] [CrossRef]

- Zollo, R.F. Fiber-Reinforced Concrete: An Overview after 30 Years of Development. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Liu, X.; Sun, Q.; Yuan, Y.; Taerwe, L. Comparison of the Structural Behavior of Reinforced Concrete Tunnel Segments with Steel Fiber and Synthetic Fiber Addition. Tunn. Undergr. Space Technol. 2020, 103, 103506. [Google Scholar] [CrossRef]

- Ko, Y.-H.; Ahart, M.; Ko, J.-H.; Song, J. Investigation of Polymorphism for Amorphous and Semi-Crystalline Poly (-Ethylene Terephthalate-) Using High-Pressure Brillouin Spectroscopy. J. Korean Phys. Soc. 2017, 70, 382–388. [Google Scholar] [CrossRef]

- Mehrali, M.; Bagherifard, S.; Akbari, M.; Thakur, A.; Mirani, B.; Mehrali, M.; Hasany, M.; Orive, G.; Das, P.; Emneus, J.; et al. Blending Electronics with the Human Body: A Pathway toward a Cybernetic Future. Adv. Sci. 2018, 5, 1700931. [Google Scholar] [CrossRef]

- Larena, A.; Pinto, G. The Effect of Surface Roughness and Crystallinity on the Light Scattering of Polyethylene Tubular Blown Films. Polym. Eng. Sci. 1993, 33, 742–747. [Google Scholar] [CrossRef]

- Hajiesmaeili, A.; Denarié, E. Next Generation UHPFRC for Sustainable Structural Applications. Aci Mater. J. 2018, 326, 58.1–58.10. [Google Scholar]

- Signorini, C.; Marinelli, S.; Volpini, V.; Nobili, A.; Radi, E.; Rimini, B. Performance of Concrete Reinforced with Synthetic Fibres Obtained from Recycling End-of-Life Sport Pitches. J. Build. Eng. 2022, 53, 104522. [Google Scholar] [CrossRef]

- Acosta-Calderon, S.; Gordillo-Silva, P.; García-Troncoso, N.; Bompa, D.V.; Flores-Rada, J. Comparative Evaluation of Sisal and Polypropylene Fiber Reinforced Concrete Properties. Fibers 2022, 10, 31. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of Recycled Plastic in Concrete: A Review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef]

- Islam, G.M.S.; Gupta, S.D. Evaluating Plastic Shrinkage and Permeability of Polypropylene Fiber Reinforced Concrete. Int. J. Sustain. Built Environ. 2016, 5, 345–354. [Google Scholar] [CrossRef]

- Ryu, G.S.; Lee, Y.B.; Koh, K.T.; Chung, Y.S. The Mechanical Properties of Fly Ash-Based Geopolymer Concrete with Alkaline Activators. Constr. Build. Mater. 2013, 47, 409–418. [Google Scholar] [CrossRef]

- Mu, B.; Meyer, C.; Shimanovich, S. Improving the Interface Bond between Fiber Mesh and Cementitious Matrix. Cem. Concr. Res. 2002, 32, 783–787. [Google Scholar] [CrossRef]

- Richardson, A.E. Compressive Strength of Concrete with Polypropylene Fibre Additions. Struct. Surv. 2006, 24, 138–153. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Influence of Polypropylene Fiber Geometry on Plastic Shrinkage Cracking in Concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Redon, C.; Li, V.C.; Wu, C.; Hoshiro, H.; Saito, T.; Ogawa, A. Measuring and Modifying Interface Properties of PVA Fibers in ECC Matrix. J. Mater. Civ. Eng. 2001, 13, 399–406. [Google Scholar] [CrossRef]

- Li, V.; Wu, C.; Wang, S.; Ogawa, A.; Saito, T. Interface Tailoring for Strain-Hardening Polyvinyl Alcohol-Engineered Cementitious Composite (PVA-ECC). ACI Mater. J. 2002, 99, 463–472. [Google Scholar]

- Estefen, S.; Lourenço, M.I.; Feng, J.; Paz, C.; Lima, D. Sandwich Pipe for Long Distance Pipelines: Flow Assurance and Costs. In Proceedings of the ASME 2016 35th International Conference on Ocean, Offshore and Arctic Engineering. Volume 5: Pipelines, Risers, and Subsea Systems, Busan, Republic of Korea, 19–24 June 2016; p. V005T04A025. [Google Scholar]

- Kanda, T.; Li, V.C. Interface Property and Apparent Strength of High-Strength Hydrophilic Fiber in Cement Matrix. J. Mater. Civ. Eng. 1998, 10, 5–13. [Google Scholar] [CrossRef]

- Nematollahi, B.; Qiu, J.; Yang, E.-H.; Sanjayan, J. Micromechanics Constitutive Modelling and Optimization of Strain Hardening Geopolymer Composite. Ceram. Int. 2017, 43, 5999–6007. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Qiu, J.; Yang, E.-H. High Ductile Behavior of a Polyethylene Fiber-Reinforced One-Part Geopolymer Composite: A Micromechanics-Based Investigation. Arch. Civ. Mech. Eng. 2017, 17, 555–563. [Google Scholar] [CrossRef]

- Choi, J.-I.; Lee, B.Y.; Ranade, R.; Li, V.C.; Lee, Y. Ultra-High-Ductile Behavior of a Polyethylene Fiber-Reinforced Alkali-Activated Slag-Based Composite. Cem. Concr. Compos. 2016, 70, 153–158. [Google Scholar] [CrossRef]

- Lu, W.; Fu, X.; Chung, D.D.L. A Comparative Study of the Wettability of Steel, Carbon, and Polyethylene Fibers by Water. Cem. Concr. Res. 1998, 28, 783–786. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, X.; Wang, H.; Wei, F.; Zhang, Y. Experimental and Numerical Analysis of Interfacial Bonding Strength of Polyoxymethylene Reinforced Cement Composites. Constr. Build. Mater. 2019, 207, 1–9. [Google Scholar] [CrossRef]

- Curosu, I.; Liebscher, M.; Mechtcherine, V.; Bellmann, C.; Michel, S. Tensile Behavior of High-Strength Strain-Hardening Cement-Based Composites (HS-SHCC) Made with High-Performance Polyethylene, Aramid and PBO Fibers. Cem. Concr. Res. 2017, 98, 71–81. [Google Scholar] [CrossRef]

- Huang, B.-T.; Zhu, J.-X.; Weng, K.-F.; Li, V.C.; Dai, J.-G. Ultra-High-Strength Engineered/Strain-Hardening Cementitious Composites (ECC/SHCC): Material Design and Effect of Fiber Hybridization. Cem. Concr. Compos. 2022, 129, 104464. [Google Scholar] [CrossRef]

- He, S.; Qiu, J.; Li, J.; Yang, E.-H. Strain Hardening Ultra-High Performance Concrete (SHUHPC) Incorporating CNF-Coated Polyethylene Fibers. Cem. Concr. Res. 2017, 98, 50–60. [Google Scholar] [CrossRef]

- Shen, Y.; Dai, M.; Pu, W.; Xiang, Z. Effects of Content and Length/Diameter Ratio of PP Fiber on Explosive Spalling Resistance of Hybrid Fiber-Reinforced Ultra-High-Performance Concrete. J. Build. Eng. 2022, 58, 105071. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Si, R.; Guo, S. Investigation of Properties and Performances of Polyvinyl Alcohol (PVA) Fiber-Reinforced Rubber Concrete. Constr. Build. Mater. 2018, 193, 631–642. [Google Scholar] [CrossRef]

- Ren, G.; Wang, J.; Wen, X.; Gao, X. Using Sol-Gel Deposition of Nanosilica to Enhance Interface Bonding between Sisal Fiber and Ultra-High Performance Concrete. Cem. Concr. Compos. 2022, 133, 104705. [Google Scholar] [CrossRef]

- Mohammed, B.H.; Sherwani, A.F.H.; Faraj, R.H.; Qadir, H.H.; Younis, K.H. Mechanical Properties and Ductility Behavior of Ultra-High Performance Fiber Reinforced Concretes: Effect of Low Water-to-Binder Ratios and Micro Glass Fibers. Ain Shams Eng. J. 2021, 12, 1557–1567. [Google Scholar] [CrossRef]

- Dehghanpour, H.; Subasi, S.; Guntepe, S.; Emiroglu, M.; Marasli, M. Investigation of Fracture Mechanics, Physical and Dynamic Properties of UHPCs Containing PVA, Glass and Steel Fibers. Constr. Build. Mater. 2022, 328, 127079. [Google Scholar] [CrossRef]

- Zheng, Z.; Feldman, D. Synthetic Fibre-Reinforced Concrete. Prog. Polym. Sci. 1995, 20, 185–210. [Google Scholar] [CrossRef]

- Cao, Y.Y.Y.; Yu, Q.L. Effect of Inclination Angle on Hooked End Steel Fiber Pullout Behavior in Ultra-High Performance Concrete. Compos. Struct. 2018, 201, 151–160. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Lee, J.-H.; Yoon, Y.-S. Effect of Fiber Content on Mechanical and Fracture Properties of Ultra High Performance Fiber Reinforced Cementitious Composites. Compos. Struct. 2013, 106, 742–753. [Google Scholar] [CrossRef]

- Dupont, D.; Vandewalle, L. Distribution of Steel Fibres in Rectangular Sections. Cem. Concr. Compos. 2005, 27, 391–398. [Google Scholar] [CrossRef]

- Laranjeira, F.; Aguado, A.; Molins, C.; Grünewald, S.; Walraven, J.; Cavalaro, S. Framework to Predict the Orientation of Fibers in FRC: A Novel Philosophy. Cem. Concr. Res. 2012, 42, 752–768. [Google Scholar] [CrossRef]

- Yang, I.H.; Joh, C.; Kim, B.-S. Structural Behavior of Ultra High Performance Concrete Beams Subjected to Bending. Eng. Struct. 2010, 32, 3478–3487. [Google Scholar] [CrossRef]

- Chen, L.; Sun, W.; Chen, B.; Shi, Z.; Lai, J.; Feng, J. Multiscale Study of Fibre Orientation Effect on Pullout and Tensile Behavior of Steel Fibre Reinforced Concrete. Constr. Build. Mater. 2021, 283, 122506. [Google Scholar] [CrossRef]

- Song, Q.; Yu, R.; Shui, Z.; Wang, X.; Rao, S.; Lin, Z. Optimization of Fibre Orientation and Distribution for a Sustainable Ultra-High Performance Fibre Reinforced Concrete (UHPFRC): Experiments and Mechanism Analysis. Constr. Build. Mater. 2018, 169, 8–19. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, Y.; Qu, S.; Kumar, A.; Shao, X. Improvement of Flexural and Tensile Strength of Layered-Casting UHPC with Aligned Steel Fibers. Constr. Build. Mater. 2020, 251, 118893. [Google Scholar] [CrossRef]

- Mu, R.; Chen, J.; Chen, X.; Diao, C.; Wang, X.; Qing, L. Effect of the Orientation of Steel Fiber on the Strength of Ultra-High-Performance Concrete (UHPC). Constr. Build. Mater. 2023, 406, 133431. [Google Scholar] [CrossRef]

- Carrera, K.; Künzel, K.; Konrád, P.; Mára, M.; Kheml, P.; Papež, V.; Sovják, R. The Effect of Magnetic Field Parameters on Fibre Orientation in High-Performance Fibre-Reinforced Concrete. Mech. Mater. 2023, 177, 104534. [Google Scholar] [CrossRef]

- Hajforoush, M.; Kheyroddin, A.; Rezaifar, O. Investigation of Engineering Properties of Steel Fiber Reinforced Concrete Exposed to Homogeneous Magnetic Field. Constr. Build. Mater. 2020, 252, 119064. [Google Scholar] [CrossRef]

- Zhang, X.; He, F.; Chen, J.; Yang, C.; Xu, F. Orientation of Steel Fibers in Concrete Attracted by Magnetized Rebar and Its Effects on Bond Behavior. Cem. Concr. Compos. 2023, 138, 104977. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Li, L.; Wang, H. Improvement Effect of Steel Fiber Orientation Control on Mechanical Performance of UHPC. Constr. Build. Mater. 2018, 188, 709–721. [Google Scholar] [CrossRef]

- Roy, M.; Hollmann, C.; Wille, K. Influence of Volume Fraction and Orientation of Fibers on the Pullout Behavior of Reinforcement Bar Embedded in Ultra High Performance Concrete. Constr. Build. Mater. 2017, 146, 582–593. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Teng, L. Fiber Alignment and Its Effect on Mechanical Properties of UHPC: An Overview. Constr. Build. Mater. 2021, 296, 123741. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, W.; Sun, G.; Xiu, Y.; Zhang, Z.; Li, C.; Zhang, Y. A New Orientational Molding Method for Ultra-High Performance Concrete with High Content of Steel Fiber and Investigation on Its Flexure and Axial Tensile Properties. Constr. Build. Mater. 2023, 400, 132755. [Google Scholar] [CrossRef]

- Huang, H.; Su, A.; Gao, X.; Yang, Y. Influence of Formwork Wall Effect on Fiber Orientation of UHPC with Two Casting Methods. Constr. Build. Mater. 2019, 215, 310–320. [Google Scholar] [CrossRef]

- Song, Q.; Yu, R.; Shui, Z.; Wang, X.; Rao, S.; Lin, Z.; Wang, Z. Key Parameters in Optimizing Fibres Orientation and Distribution for Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Constr. Build. Mater. 2018, 188, 17–27. [Google Scholar] [CrossRef]

- Islam, S.U.; Waseem, S.A. An Experimental Study on Mechanical and Fracture Characteristics of Hybrid Fibre Reinforced Concrete. Structures 2024, 68, 107053. [Google Scholar] [CrossRef]

- Qian, C.; Stroeven, P. Fracture Properties of Concrete Reinforced with Steel–Polypropylene Hybrid Fibres. Cem. Concr. Compos. 2000, 22, 343–351. [Google Scholar] [CrossRef]

- Lawler, J.S.; Wilhelm, T.; Zampini, D.; Shah, S.P. Fracture Processes of Hybrid Fiber-Reinforced Mortar. Mater. Struct. 2003, 36, 197–208. [Google Scholar] [CrossRef]

- Pichler, C.; Lackner, R.; Mang, H.A. Multiscale Model for Creep of Shotcrete—From Logarithmic-Type Viscous Behavior of CSH at the μm-Scale to Macroscopic Tunnel Analysis. J. Adv. Concr. Technol. 2008, 6, 91–110. [Google Scholar] [CrossRef]

- Pourjahanshahi, A.; Madani, H. Chloride Diffusivity and Mechanical Performance of UHPC with Hybrid Fibers under Heat Treatment Regime. Mater. Today Commun. 2021, 26, 102146. [Google Scholar] [CrossRef]

- Deng, F.; Xu, L.; Chi, Y.; Wu, F.; Chen, Q. Effect of Steel-Polypropylene Hybrid Fiber and Coarse Aggregate Inclusion on the Stress–Strain Behavior of Ultra-High Performance Concrete under Uniaxial Compression. Compos. Struct. 2020, 252, 112685. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-Performance Fiber-Reinforced Concrete: A Review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef]

- Han, B.; Dong, S.; Ou, J.; Zhang, C.; Wang, Y.; Yu, X.; Ding, S. Microstructure Related Mechanical Behaviors of Short-Cut Super-Fine Stainless Wire Reinforced Reactive Powder Concrete. Mater. Des. 2016, 96, 16–26. [Google Scholar] [CrossRef]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Yousef, R.A.; Abduljabbar, H.A.; Sufian, M. Effect of Coconut Fiber Length and Content on Properties of High Strength Concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef]

- Köksal, F.; Şahin, Y.; Gencel, O.; Yiğit, İ. Fracture Energy-Based Optimisation of Steel Fibre Reinforced Concretes. Eng. Fract. Mech. 2013, 107, 29–37. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Latifi, M.; Jamshidi, M. Hybrid Short Fiber Reinforcement System in Concrete: A Review. Constr. Build. Mater. 2017, 142, 280–294. [Google Scholar] [CrossRef]

- Markovic, I. High-Performance Hybrid-Fibre Concrete: Development and Utilisation; IOS Press: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Romain Njimou, J.; Tamwa Sieugaing, M.; Péguy Nanseu-Njiki, C.; Ngameni, E. Bio-based Nanomaterial in Carefully Designed Carbon Paste Electrode for the Detection of Methyl Orange. Electroanalysis 2024, 36, e202300364. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Compressive Strength, Chloride Diffusivity and Pore Structure of High Performance Metakaolin and Silica Fume Concrete. Constr. Build. Mater. 2006, 20, 858–865. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014; ISBN 978-0-07-179787-0. [Google Scholar]

- Ghafari, E.; Costa, H.; Júlio, E.; Portugal, A.; Durães, L. Enhanced Durability of Ultra High Performance Concrete by Incorporating Supplementary Cementitious Materials. In Proceedings of the The 2nd international conference microdurability Delft, Amsterdam, The Netherland, 11–13 April 2012. [Google Scholar]

- Baharuddin, N.K.; Nazri, F.M.; Bakar, B.H.A.; Beddu, S.; Tayeh, B.A. Potential Use of Ultra High-Performance Fibre-Reinforced Concrete as a Repair Material for Fire-Damaged Concrete in Terms of Bond Strength. Int. J. Integr. Eng. 2020, 12, 87–95. [Google Scholar] [CrossRef]

- Al-Attar, A.; Abdulrahman, M.; Hamada, H.; Bassam, T. Investigating the Behaviour of Hybrid Fibre-Reinforced Reactive Powder Concrete Beams after Exposure to Elevated Temperatures. J. Mater. Res. Technol. 2019, 9, 1966–1977. [Google Scholar] [CrossRef]

- Abdul-Rahman, M.; Al-Attar, A.A.; Hamada, H.M.; Tayeh, B. Microstructure and Structural Analysis of Polypropylene Fibre Reinforced Reactive Powder Concrete Beams Exposed to Elevated Temperature. J. Build. Eng. 2020, 29, 101167. [Google Scholar] [CrossRef]

- Faried, A.S.; Mostafa, S.A.; Tayeh, B.A.; Tawfik, T.A. The Effect of Using Nano Rice Husk Ash of Different Burning Degrees on Ultra-High-Performance Concrete Properties. Constr. Build. Mater. 2021, 290, 123279. [Google Scholar] [CrossRef]

- Faried, A.S.; Mostafa, S.A.; Tayeh, B.A.; Tawfik, T.A. Mechanical and Durability Properties of Ultra-High Performance Concrete Incorporated with Various Nano Waste Materials under Different Curing Conditions. J. Build. Eng. 2021, 43, 102569. [Google Scholar] [CrossRef]

- Tam, C.M.; Tam, V.W.Y.; Ng, K.M. Assessing Drying Shrinkage and Water Permeability of Reactive Powder Concrete Produced in Hong Kong. Constr. Build. Mater. 2012, 26, 79–89. [Google Scholar] [CrossRef]

- He, X.; Yuhua, Z.; Qaidi, S.; Isleem, H.F.; Zaid, O.; Althoey, F.; Ahmad, J. Mine Tailings-Based Geopolymers: A Comprehensive Review. Ceram. Int. 2022, 48, 24192–24212. [Google Scholar] [CrossRef]

- Qaidi, S.; Tayeh, B.; Zeyad, A.; Azevedo, A.; Ahmed, H.; Mahmood, W. Recycling of Mine Tailings for the Geopolymers Production: A Systematic Review. Case Stud. Constr. Mater. 2022, 16, e00933. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Dinkha, Y.Z.; Haido, J.H.; Ali, M.H.; Tayeh, B.A. Engineering Properties of Sustainable Green Concrete Incorporating Eco-Friendly Aggregate of Crumb Rubber: A Review. J. Clean. Prod. 2021, 324, 129251. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Al-Kamaki, Y.S.S. State-of-the-Art Review: Concrete Made of Recycled Waste Pet As Fine Aggregate. Duhok Univ. 2020, 23, 412–429. [Google Scholar] [CrossRef]

- Aslam, F.; Zaid, O.; Althoey, F.; Alyami, S.; Qaidi, S.; de Prado Gil, J.; Martínez García, R. Evaluating the Influence of Fly Ash and Waste Glass on the Characteristics of Coconut Fibers Reinforced Concrete. Struct. Concr. 2022, 24, 2440–2459. [Google Scholar] [CrossRef]

- Yuan, Q.; Shi, C.; Schutter, G.D.; Audenaert, K.; Deng, D. Chloride Binding of Cement-Based Materials Subjected to External Chloride Environment—A Review. Constr. Build. Mater. 2009, 23, 1–13. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, R.; Wang, X.; Chen, J.; Shui, Z. Evaluation and Optimization of Ultra-High Performance Concrete (UHPC) Subjected to Harsh Ocean Environment: Towards an Application of Layered Double Hydroxides (LDHs). Constr. Build. Mater. 2018, 177, 51–62. [Google Scholar] [CrossRef]

- Poupard, O.; Aı̈t-Mokhtar, A.; Dumargue, P. Corrosion by Chlorides in Reinforced Concrete: Determination of Chloride Concentration Threshold by Impedance Spectroscopy. Cem. Concr. Res. 2004, 34, 991–1000. [Google Scholar] [CrossRef]

- Roux, N.; Andrade, C.; Sanjuán, M. Experimental Study of Durability of Reactive Powder Concretes. J. Mater. Civ. Eng. 1996, 8, 1–6. [Google Scholar] [CrossRef]

- Liu, J.; Song, S.; Wang, L. Durability and Micro-Structure of Reactive Powder Concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2009, 24, 506–509. [Google Scholar] [CrossRef]

- Chuang, M.L.; Huang, W.H. Durability Analysis Testing on Reactive Powder Concrete. Adv. Mater. Res. 2013, 811, 244–248. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.A.; Rafiq, S.; Mohammed, A.S.; Mosavi, A.; Sor, N.H.; Qaidi, S.M.A. Compressive Strength of Sustainable Geopolymer Concrete Composites: A State-of-the-Art Review. Sustainability 2021, 13, 13502. [Google Scholar] [CrossRef]

- Bertos, M.F.; Simons, S.J.R.; Hills, C.D.; Carey, P.J. A Review of Accelerated Carbonation Technology in the Treatment of Cement-Based Materials and Sequestration of CO2. J. Hazard. Mater. 2004, 112, 193–205. [Google Scholar] [CrossRef]

- Liu, S.; Sun, W.; Lin, W.; Lai, J. Preparation and Durability of a High Performance Concrete with Natural Ultra-Fine Particles. Guisuanyan Xuebao J. Chin. Ceram. Soc. 2003, 31, 1080–1085. [Google Scholar]

- Mehta, P.K. Durability of Concrete—Fifty Years of Progress? ACI Symp. Publ. 1991, 126, 1–32. [Google Scholar] [CrossRef]

- Yao, Z.; Fang, Y.; Zhang, P.; Huang, X. Experimental Study on Durability of Hybrid Fiber-Reinforced Concrete in Deep Alluvium Frozen Shaft Lining. Crystals 2021, 11, 725. [Google Scholar] [CrossRef]

- Li, J.; Qiao, H.; Zhu, F. Reliability Analysis of Freezethaw Damage of Fiber Concrete Based on Miner Theory. Emerg. Mater. Res. 2019, 8, 508–515. [Google Scholar] [CrossRef]

- Cwirzen, A.; Penttala, V. Effects of Increased Aggregate Size on the Mechanical and Rheological Properties of RPC. In Proceedings of the Second International Symposium on Advances in Concrete through Science and Engineering, Quebec City, QC, Canada, 11–13 September 2006. [Google Scholar]

- Smarzewski, P.; Barnat-Hunek, D. Effect of Fiber Hybridization on Durability Related Properties of Ultra-High Performance Concrete. Int. J. Concr. Struct. Mater. 2017, 11, 315–325. [Google Scholar] [CrossRef]

- Liu, C.-T.; Huang, J.-S. Fire Performance of Highly Flowable Reactive Powder Concrete. Constr. Build. Mater. 2009, 23, 2072–2079. [Google Scholar] [CrossRef]

- Rabehi, B.; Ghernouti, Y.; Boumchedda, K.; Li, A.; Drir, A. Durability and Thermal Stability of Ultra High-Performance Fibre-Reinforced Concrete (UHPFRC) Incorporating Calcined Clay. Eur. J. Environ. Civ. Eng. 2017, 21, 594–611. [Google Scholar] [CrossRef]

- Sanchayan, S.; Foster, S.J. High Temperature Behaviour of Hybrid Steel–PVA Fibre Reinforced Reactive Powder Concrete. Mater. Struct. 2016, 49, 769–782. [Google Scholar] [CrossRef]

- Li, Y.; Tan, K.H.; Yang, E.-H. Synergistic Effects of Hybrid Polypropylene and Steel Fibers on Explosive Spalling Prevention of Ultra-High Performance Concrete at Elevated Temperature. Cem. Concr. Compos. 2019, 96, 174–181. [Google Scholar] [CrossRef]

- Zheng, W.; Li, H.; Wang, Y. Compressive Behaviour of Hybrid Fiber-Reinforced Reactive Powder Concrete after High Temperature. Mater. Des. 2012, 41, 403–409. [Google Scholar] [CrossRef]

- Li, H.; Liu, G. Tensile Properties of Hybrid Fiber-Reinforced Reactive Powder Concrete After Exposure to Elevated Temperatures. Int. J. Concr. Struct. Mater. 2016, 10, 29–37. [Google Scholar] [CrossRef]

- Zheng, W.; Li, H.; Wang, Y. Compressive Stress–Strain Relationship of Steel Fiber-Reinforced Reactive Powder Concrete after Exposure to Elevated Temperatures. Constr. Build. Mater. 2012, 35, 931–940. [Google Scholar] [CrossRef]

- Khoury, G.A. Effect of Fire on Concrete and Concrete Structures. Prog. Struct. Eng. Mater. 2000, 2, 429–447. [Google Scholar] [CrossRef]

- Soliman, N.A.; Tagnit-Hamou, A. Development of Ultra-High-Performance Concrete Using Glass Powder—Towards Ecofriendly Concrete. Constr. Build. Mater. 2016, 125, 600–612. [Google Scholar] [CrossRef]

- Tafraoui, A.; Escadeillas, G.; Vidal, T. Durability of the Ultra High Performances Concrete Containing Metakaolin. Constr. Build. Mater. 2016, 112, 980–987. [Google Scholar] [CrossRef]

- Graybeal, B.A. Development of Non-Proprietary Ultra-High Performance Concrete for Use in the Highway Bridge Sector: TechBrief; Federal Highway Administration: Washington, DC, USA, 2013. [Google Scholar]

- Arora, A.; Almujaddidi, A.; Kianmofrad, F.; Mobasher, B.; Neithalath, N. Material Design of Economical Ultra-High Performance Concrete (UHPC) and Evaluation of Their Properties. Cem. Concr. Compos. 2019, 104, 103346. [Google Scholar] [CrossRef]

- Njimou, J.R.; Mallet Tcheulo Njike, R.; Marie Kepdieu, J.; Njiomou Djangang, C.; Talla, A.; George Elambo, N.; Fritsky, J.W.; Andrada Maicaneanu, S.; Rosso, D. Eco-Friendly Chitin-MnO2-Alginate Nanobiocomposite Spheres for Enhanced Heavy Metal Removal from Wastewater. Inorg. Chem. Commun. 2025, 172, 113719. [Google Scholar] [CrossRef]

- Njimou, J.R.; Godwin, J.; Pahimi, H.; Maicaneanu, S.A.; Kouatchie-Njeutcha, F.; Tripathy, B.C.; Talla, A.; Watanabe, T.; Elambo, N.G. Biocomposite Spheres Based on Aluminum Oxide Dispersed with Orange-Peel Powder for Adsorption of Phenol from Batch Membrane Fraction of Olive Mill Wastewater. Colloid. Interface Sci. Commun. 2021, 42, 100402. [Google Scholar] [CrossRef]

- Xing, W.; Tam, V.W.; Le, K.N.; Hao, J.L.; Wang, J. Life Cycle Assessment of Sustainable Concrete with Recycled Aggregate and Supplementary Cementitious Materials. Resour. Conserv. Recycl. 2023, 193, 106947. [Google Scholar] [CrossRef]

- Manso-Morato, J.; Hurtado-Alonso, N.; Revilla-Cuesta, V.; Skaf, M.; Ortega-López, V. Fiber-Reinforced Concrete and Its Life Cycle Assessment: A Systematic Review. J. Build. Eng. 2024, 94, 110062. [Google Scholar] [CrossRef]

- Hamada, H.M.; Shi, J.; Jawahery, M.S.A.; Majdi, A.; Yousif, S.T.; Kaplan, G. Application of Natural Fibres in Cement Concrete: A Critical Review. Mater. Today Commun. 2023, 35, 105833. [Google Scholar] [CrossRef]

- Marvila, M.T.; Rocha, H.A.; de Azevedo, A.R.G.; Colorado, H.A.; Zapata, J.F.; Vieira, C.M.F. Use of Natural Vegetable Fibers in Cementitious Composites: Concepts and Applications. Innov. Infrastruct. Solut. 2021, 6, 180. [Google Scholar] [CrossRef]

- Martinelli, F.R.B.; Ribeiro, F.R.C.; Marvila, M.T.; Monteiro, S.N.; Filho, F.D.C.G.; Azevedo, A.R.G.D. A Review of the Use of Coconut Fiber in Cement Composites. Polymers 2023, 15, 1309. [Google Scholar] [CrossRef]

- Kumarasamy, K.; Shyamala, G.; Gebreyowhanse, H. Kumarasamy. Strength Properties of Bamboo Fiber Reinforced Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2020, 981, 032063. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z.; Deifalla, A.F. Structural Properties of Concrete Reinforced with Bamboo Fibers: A Review. J. Mater. Res. Technol. 2023, 24, 844–865. [Google Scholar] [CrossRef]

- Zia, A.; Pu, Z.; Holly, I.; Umar, T.; Tariq, M.A.U.R.; Sufian, M. A Comprehensive Review of Incorporating Steel Fibers of Waste Tires in Cement Composites and Its Applications. Materials 2022, 15, 7420. [Google Scholar] [CrossRef]

- Martínez-Barrera, G.; del Coz-Díaz, J.J.; Martínez-Cruz, E.; Martínez-López, M.; Ribeiro, M.C.S.; Velasco-Santos, C.; Lobland, H.E.H.; Brostow, W. Modified Recycled Tire Fibers by Gamma Radiation and Their Use on the Improvement of Polymer Concrete. Constr. Build. Mater. 2019, 204, 327–334. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Bank, L.C.; Rieder, K.-A.; Tian, Y.; Chen, C. Concrete with Discrete Slender Elements from Mechanically Recycled Wind Turbine Blades. Resour. Conserv. Recycl. 2018, 128, 11–21. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A Review on Recycling and Reuse Methods for Carbon Fiber/Glass Fiber Composites Waste from Wind Turbine Blades. Compos. Part B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Hossain, F.M.Z.; Pal, A.; Ahmed, K.S.; Bediwy, A.; Alam, M.S. Shear Behavior of Polypropylene Fiber-Reinforced Concrete Beams Containing Recycled Aggregate and Crumb Rubber. J. Clean. Prod. 2023, 412, 137370. [Google Scholar] [CrossRef]

- Ortega-López, V.; Revilla-Cuesta, V.; Santamaría, A.; Orbe, A.; Skaf, M. Microstructure and Dimensional Stability of Slag-Based High-Workability Concrete with Steelmaking Slag Aggregate and Fibers. J. Mater. Civ. Eng. 2022, 34, 04022224. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Abdelgader, H.S.; Murali, G.; Ozbakkaloglu, T.; Lee, Y.H.; Lee, Y.Y. Fiber-Reinforced Alkali-Activated Concrete: A Review. J. Build. Eng. 2022, 45, 103638. [Google Scholar] [CrossRef]

- Nagle, A.J.; Delaney, E.L.; Bank, L.C.; Leahy, P.G. A Comparative Life Cycle Assessment between Landfilling and Co-Processing of Waste from Decommissioned Irish Wind Turbine Blades. J. Clean. Prod. 2020, 277, 123321. [Google Scholar] [CrossRef]

| Author | Types of Fibers | Total Volume Fractions [%] | Test Methods |

|---|---|---|---|

| Park et al. (2012) [56] | steel–steel | 1.5 ÷ 2.5 | tensile strength |

| Kang et al. (2016) [57] | steel–synthetic | 1.5 | compressive strength, tensile strength |

| Yoo et al. (2017) [51] | steel–steel | 2 | compressive strength |

| Smarzewski and Barnat-Hunek (2018) [58] | steel–synthetic | 1 | compressive strength, tensile strength, flexural strength, modulus of elasticity, energy cracking |

| Smarzewski (2019) [59] | basalt–synthetic | 1 ÷ 2 | compressive strength, tensile strength, flexural strength, energy cracking |

| Türker et al. (2019) [60] | steel–steel | 1.5 | compressive strength, flexural strength, modulus of elasticity |

| Wang et al. (2019) [61] | basalt–synthetic | 0.125 ÷ 0.242 | compressive strength, tensile strength, flexural strength, modulus of elasticity |

| Deng et al. (2021) [62] | basalt–synthetic | 0.3 ÷ 0.55 | flexural strength |

| Aisheh et al. (2022) [41] | steel–synthetic | 1.25 + 2.25 | compressive strength, tensile strength, flexural strength, modulus of elasticity |

| Akça and İpek (2022) [63] | steel–steel | 3 | compressive strength, tensile strength, modulus of elasticity |

| Elsayed et al. (2022) [64] | steel–synthetic | - | compressive strength, tensile strength, flexural strength |

| Yu et al. (2022) [65] | steel–steel | 2 | compressive strength, flexural strength |

| Bian et al. (2024) [66] | steel–synthetic | 1.5 | compressive strength, tensile strength, flexural strength, modulus of elasticity, energy cracking |

| Author | Research Area | Type of Research |

|---|---|---|

| Li et al. [67] Xu et al. [68] Yang et al. [69] Liu [70] | permeability | permeability tests with hybrid fibers |

| Hung [71] | permeability test at elevated temperature | |

| Ghafari et al. [72] | resistance to chloride and salt penetration | corrosion test |

| Long et al. [73] | carbonation resistance | CO2 penetration |

| Guler et al. [74] Yao et al. [75] Smarzewski and Barnat-Hunek [58] | resistance to freeze–thaw cycles | freeze–thaw cycle test |

| Tai et al. [76] Zheng et al. [77] Heinz et al. [78] Peng et al. [79] | fire resistance | high-temperature resistance test |

| Ref. | Fiber Types | Fibers Volume Fraction [%] | ln/dn [mm] | fc [MPa] | ft [MPa] | fl [MPa] | Ec [GPa] |

|---|---|---|---|---|---|---|---|

| [63] | SSF + LHF | 2 + 1 | 6/0.20; 35/0.75 | 158.11 | 23.73 | 62.5 | |

| SSF + LHF | 2 + 1 | 6/0.20; 35/0.75 | 130.41 | 21.12 | |||

| [65] | LSF + SSF | 1.5 + 0.5 | 13/20; 6/0.16 | 142 | 30.9 | ||

| SSF + LHF | 0.5 + 1.5 | 6/0.16; 35/0.55 | 136.5 | ||||

| LSF + SSF | 1 + 1 | 13/20; 6/0.16 | 135 | 27 | |||

| LSF + SSF + LHF | 0.125 + 0.375 + 1.5 | 13/20; 6/0.16; 35/0.55 | 132 | 23 | |||

| LSF + LHF | 0.5 + 1.5 | 13/20; 35/0.55 | 130 | ||||

| LSF + SSF | 0.5 + 1.5 | 13/20; 6/0.16 | 128 | 25.50 | |||

| [60] | SSF + LHF | 1.0 + 0.5 | 13/0.16; 60/0.75 | 164 | 11.18 | 43 | |

| [51] | LSF + LTF | 1.5 + 0.5 | 19.5/0.2; 30/0.30 | 202.2 | |||

| LSF + LHF | 1.5 + 0.5 | 19.5/0.2; 30/0.38 | 199 | ||||

| LSF + LTF | 1.0 + 1.0 | 19.5/0.2; 30/0.30 | 198.9 | ||||

| LSF + LHF | 1.0 + 1.0 | 19.5/0.2; 30/0.38 | 187.9 | ||||

| LSF + LHF | 0.5 + 1.5 | 19.5/0.2; 30/0.38 | 186.1 | ||||

| LSF + LTF | 0.5 + 1.5 | 19.5/0.2; 30/0.30 | 185.4 | ||||

| [56] | LTF + SSF | 1.0 + 1.5 | 30/0.3; 13/0.2 | 18.56 | |||

| LTF + SSF | 1.0 + 1.0 | 30/0.3; 13/0.2 | 14.77 | ||||

| SHF + SSF | 1.0 + 1.5 | 30/0.375; 13/0.2 | 13.84 | ||||

| LTF + SSF | 1.0 + 0.5 | 30/0.3; 13/0.2 | 13.50 | ||||

| LSF + SSF | 1.0 + 1.0 | 30/0.3; 13/0.2 | 13.31 | ||||

| LSF + SSF | 1.0 + 1.5 | 30/0.3; 13/0.2 | 13.22 | ||||

| SHF + SSF | 1.0 + 1.0 | 30/0.375; 13/0.2 | 12.25 | ||||

| LHF + SSF | 1.0 + 1.5 | 62/0.775; 13/0.2 | 12.01 | ||||

| LSF + SSF | 1.0 + 0.5 | 30/0.3; 13/0.2 | 11.42 | ||||

| LHF + SSF | 1.0 + 1.0 | 62/0.775; 13/0.2 | 11.33 | ||||

| SHF + SSF | 1.0 + 0.5 | 30/0.375; 13/0.2 | 10.90 | ||||

| LHF + SSF | 1.0 + 0.5 | 62/0.775; 13/0.2 | 10.31 |

| Ref. | Fiber Types | Fiber Volume Fraction [%] | ln/dn [mm] | fc [MPa] | ft [MPa] | fl [MPa] | Ec [GPa] | Gf [N/mm] |

|---|---|---|---|---|---|---|---|---|

| [66] | StSF + PeSF | 1.0 + 0.5 | 13/0.2; 18/0.025 | 104 | 8.87 | 12.69 | 33.7 | 4 |

| StSF + BSF | 1.0 + 0.5 | 13/0.2; 18/0.024 | 103.7 | 6.60 | 9.25 | 33.9 | 0.77 | |

| StSF + BSF + PeSF | 0.5 + 0.5 + 0.5 | 13/0.2; 18/0.024; 18/0.025 | 103 | 6.83 | 10.65 | 32.6 | 3.77 | |

| StSF + BSF | 0.5 + 1.0 | 13/0.2; 18/0.024 | 92.8 | 4.92 | 4.77 | 32.7 | 3.26 | |

| StSF + PeSF | 0.5 + 1.0 | 13/0.2; 18/0.025 | 89.8 | 8.50 | 13.57 | 32.8 | 6.38 | |

| [58] | StHF + PSF | 0.75 + 0.25 | 50/1; 12/0.025 | 144.7 | 13.50 | 9.80 | 34.27 | 34.26 |

| StHF + PSF | 0.5 + 0.5 | 50/1; 12/0.025 | 133.9 | 10 | 9.20 | 32.45 | 32.29 | |

| StHF + PSF | 0.25 + 0.75 | 50/1; 12/0.025 | 122.3 | 9.30 | 8.60 | 29.63 | 29.93 | |

| [41] | StSF + PSF | 2.0 + 0.25 | 15/0.12; 8/0.033 | 175 | 7.70 | 13.70 | 48 | |

| StSF + PSF | 1.0 + 0.25 | 15/0.12; 8/0.033 | 159 | 7.50 | 11.70 | 47 | ||

| StSF + PSF | 1.5 + 0.25 | 15/0.12; 8/0.033 | 158 | 8.50 | 12.80 | 48 | ||

| [64] | StHF + PSF | 50/0.1; 12/0.018 | 64.2 | 7.10 | 15.20 | |||

| StHF + GSF | 50/0.1; 12/0.013 | 60.3 | 7.60 | 14.90 | ||||

| GSF + PSF | 12/0.013; 12/0.018 | 56.9 | 5.20 | 14.10 | ||||

| StHF + PSF | 50/0.1; 12/0.018 | 44.7 | 5.10 | 9.80 | ||||

| StHF + GSF | 50/0.1; 12/0.013 | 40.3 | 5.70 | 10.60 | ||||

| GSF + PSF | 12/0.013; 12/0.018 | 39.3 | 2.70 | 6.90 | ||||

| [57] | SLSF + SSSF | 1.0 + 0.5 | 19.5/0.2; 16.3/0.2 | 149 | 14.30 | |||

| SLSF + SSSF + PvaSF | 0.67 + 0.33 + 0.5 | 19.5/0.2; 16.3/0.2; 12/0.040 | 143 | 11.84 | ||||

| SLSF + SSSF + PeSF | 0.67 + 0.33 + 0.5 | 19.5/0.2; 16.3/0.2; 18/0.012 | 142 | 16.21 | ||||

| SLSF + SSSF + BSF | 0.67 + 0.33 + 0.5 | 19.5/0.2; 16.3/0.2; 12/0.012 | 128 | 14.74 |

| Ref. | Fiber Types | Fiber Volume Fraction [%] | ln/dn [mm] | fc [MPa] | ft [MPa] | fl [MPa] | Ec [GPa] | Gf [N/mm] |

|---|---|---|---|---|---|---|---|---|

| [59] | BSF + PSF | 0.75 + 0.25 | 12/0.013; 12/0.025 | 114 | 6.8 | 10 | 17.55 | |

| BSF + PSF | 0.25 + 0.75 | 12/0.013; 12/0.025 | 116.9 | 8.2 | 9.3 | 17.21 | ||

| BSF + PSF | 0.5 + 0.5 | 12/0.013; 12/0.025 | 115.7 | 8.1 | 9.4 | 17.21 | ||

| BSF + PSF | 0.5 + 1.5 | 12/0.013; 12/0.025 | 111.6 | 8.7 | 9.4 | 15.53 | ||

| BSF + PSF | 1.5 + 0.5 | 12/0.013; 12/0.025 | 107.5 | 7.8 | 11.5 | 14.85 | ||

| BSF + PSF | 1.0 + 1.0 | 12/0.013; 12/0.025 | 106.6 | 8.3 | 9.7 | 12.83 | ||

| [62] | BSF + PTF | 0.07 + 0.42 | 19/0.0013; 50/0.8 | 5.70 | ||||

| BSF + PTF | 0.04 + 0.51 | 19/0.0013; 50/0.8 | 5.20 | |||||

| BSF + PTF | 0.11 + 0.32 | 19/0.0013; 50/0.8 | 5.10 | |||||

| BSF + PTF | 0.17 + 0.13 | 19/0.0013; 50/0.8 | 4.90 | |||||

| BSF + PTF | 0.15 + 0.21 | 19/0.0013; 50/0.8 | 4.60 | |||||

| [61] | BSF + PSF | 0.15 + 0.033 | 12/0.012; 12/0.02 | 110.07 | 6.24 | 10.19 | 40.8 | |

| BSF + PSF | 0.15 + 0.042 | 12/0.012; 12/0.02 | 100.3 | 5.59 | 9.53 | 41.3 | ||

| BSF + PSF | 0.15 + 0.025 | 12/0.012; 12/0.02 | 98.13 | 6.39 | 10.47 | 35.5 | ||

| BSF + PSF | 0.2 + 0.025 | 12/0.012; 12/0.02 | 97.33 | 5.6 | 8.80 | 40 | ||

| BSF + PSF | 0.1 + 0.025 | 12/0.012; 12/0.02 | 94.67 | 5.19 | 9.74 | 43 | ||

| BSF + PSF | 0.2 + 0.033 | 12/0.012; 12/0.02 | 94.37 | 5.47 | 8.71 | 42.4 | ||

| BSF + PSF | 0.1 + 0.033 | 12/0.012; 12/0.02 | 89.57 | 5.33 | 9.90 | 32.9 | ||

| BSF + PSF | 0.2 + 0.042 | 12/0.012; 12/0.02 | 88.47 | 5.45 | 8.33 | 40.9 | ||

| BSF + PSF | 0.1 + 0.042 | 12/0.012; 12/0.02 | 87.13 | 5.11 | 10.01 | 41.5 |

| Hybrid Fibers | Ref. | Fiber Types | Fiber Volume Fraction [%] | ln/dn [mm] | fc [MPa] | ft [MPa] | fl [MPa] | Ec [GPa] |

|---|---|---|---|---|---|---|---|---|

| steel–steel | [64] | SSF + LHF | 2 + 1 | 6/0.20; 35/0.75 | 23.73 | 62.5 | ||

| [66] | LSF + SSF | 1.5 + 0.5 | 13/20; 6/0.16 | 30.9 | ||||

| [52] | LSF + LTF | 1.5 + 0.5 | 19.5/0.2; 30/0.30 | 202.2 | ||||

| steel–synthetic | [41] | StSF + PSF | 2.0 + 0.25 | 15/0.12; 8/0.033 | 175 | |||

| [58] | SLSF + SSSF + PeSF | 0.67 + 0.33 + 0.5 | 19.5/0.2; 16.3/0.2; 18/0.012 | 16.21 | ||||

| [65] | StHF + PSF | 50/0.1; 12/0.018 | 15.20 | |||||

| [41] | StSF + PSF | 1.5 + 0.25 | 15/0.12; 8/0.033 | 48 | ||||

| basalt–synthetic | [60] | BSF + PSF | 0.25 + 0.75 | 12/0.013; 12/0.025 | 116.9 | |||

| [60] | BSF + PSF | 0.5 + 1.5 | 12/0.013; 12/0.025 | 8.7 | ||||

| [62] | BSF + PSF | 0.15 + 0.025 | 12/0.012; 12/0.02 | 10.47 | ||||

| [62] | BSF + PSF | 0.1 + 0.025 | 12/0.012; 12/0.02 | 43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dziomdziora, P.; Smarzewski, P. Effect of Hybrid Fiber Compositions on Mechanical Properties and Durability of Ultra-High-Performance Concrete: A Comprehensive Review. Materials 2025, 18, 2426. https://doi.org/10.3390/ma18112426

Dziomdziora P, Smarzewski P. Effect of Hybrid Fiber Compositions on Mechanical Properties and Durability of Ultra-High-Performance Concrete: A Comprehensive Review. Materials. 2025; 18(11):2426. https://doi.org/10.3390/ma18112426

Chicago/Turabian StyleDziomdziora, Paulina, and Piotr Smarzewski. 2025. "Effect of Hybrid Fiber Compositions on Mechanical Properties and Durability of Ultra-High-Performance Concrete: A Comprehensive Review" Materials 18, no. 11: 2426. https://doi.org/10.3390/ma18112426

APA StyleDziomdziora, P., & Smarzewski, P. (2025). Effect of Hybrid Fiber Compositions on Mechanical Properties and Durability of Ultra-High-Performance Concrete: A Comprehensive Review. Materials, 18(11), 2426. https://doi.org/10.3390/ma18112426