1. Introduction

Long-life asphalt pavement has become an important research topic in the field of road engineering. Numerous practical engineering studies have demonstrated that a thick asphalt layer or a full-thickness asphalt pavement structure is less prone to structural damage from the bottom to the top. Consequently, the service life of such pavements is generally longer [

1,

2,

3,

4]. The LSAM-50 pavement developed in the early stage of the research group is a full-thickness asphalt pavement, and its typical structure is 30~40 mm flexible base layer +6 mm joint layer +4 mm surface layer. LSAM-50 has the advantages of strength, rutting resistance, economy, etc., and can be used as the flexible base layer of LSAM-50 pavement [

5,

6,

7,

8], while SMA-13 and AC-20 can be used as the surface layer and joint layer of LSAM-50 pavement, respectively.

Asphalt mixtures are typical temperature-sensitive materials, and their performance characterization has significant temperature dependence. Qian et al. [

9] conducted direct tensile, uniaxial compression, and shear resistance tests on asphalt mixtures at various temperatures, and proposed a strength model that accounts for the effect of temperature based on the unified strength theory. The results showed that the strength prediction model, which incorporates temperature effects, demonstrated a high correlation with the actual. Pérez-Jiménez et al. [

10] investigated the effects of temperature and load coupling on the low-temperature cracking resistance of asphalt mixtures. The results showed that asphalt mixtures lose viscosity at −15 °C and exhibit significant rigidity. Boussabnia et al. [

11] found that the stiffness of mixtures increases at low temperatures and the fatigue life is shorter. Omran et al. [

12] found that when the temperature increases from 40 °C to 50 °C, the permanent deformation of asphalt mixtures will increase by 61% and creep modulus decreases by 34%. Jiang et al. [

13] carried out repeated loading tests at different temperatures with a variety of perimeter pressures and found that the higher the temperature, the greater the permanent deformation of the asphalt mixture and the stronger the load sensitivity.

The research conducted by the aforementioned scholars on the impact of temperature on the performance of asphalt mixtures has significantly advanced the quality of road construction and the prevention of pavement damage. A critical aspect of this research is how to integrate the temperature dependence of material performance with practical engineering considerations. The modulus value plays a pivotal role, as it serves as the foundation for pavement load response and structural design. Enhancing the reasonableness and accuracy of the modulus value is essential for optimizing the characteristics of road construction materials. This improvement can help mitigate issues, such as pavement rutting and cracking, which may occur prematurely within the design life of the pavement [

14,

15,

16].

The resilient modulus characterizes the ability of the specimen to resist vertical deformation and is defined as the relationship between the load strength and the resilient deformation of the specimen under the action of loading and unloading in the vertical direction step by step. However, the resilient modulus test typically employs fixed temperature and load conditions, which do not accurately represent the temperature and stress conditions of asphalt mixtures in actual pavements. As the research advances and pavement design methods evolve, the dynamic modulus—which more accurately reflects the true mechanical properties of pavement materials—has garnered increasing attention from researchers. The American Association of State Highway and Transportation Officials (AASHTO) pavement design guidelines incorporate the dynamic modulus as a key parameter in pavement design [

17]. AASHTO utilizes asphalt pavement core specimens to conduct repeated-loading indirect tensile tests, establishing the relationship between dynamic modulus and temperature. This relationship allows for the interpolation of the modulus value of the mixture under varying temperature conditions [

18,

19]. Christensen et al. [

20] established a dynamic modulus prediction model that can be utilized to predict the dynamic modulus of the mixture based on the mineral gap rate and asphalt saturation. Ali et al. [

21] investigated the effects of temperature, loading frequency, and mineral gap rate on the dynamic modulus of asphalt mixtures, establishing a nonlinear regression model that relates the dynamic modulus to these influencing factors.

To characterize the dynamic viscoelastic mechanical properties of asphalt mixtures and to obtain their dynamic properties across a broader range of temperatures and frequencies, some researchers have utilized the existing test data on dynamic modulus to construct a dynamic modulus master curve based on the principle of time–temperature equivalence. The sigmoidal model for fitting dynamic modulus master curves is proposed by the NCHRP Project A-37 [

22,

23]:

Zhao et al. [

24] proposed a horizontal shift factor model based on the sigmoidal model to simulate the effects of circumferential pressure and loading frequency:

Sakhaeifar et al. [

25] conducted function fitting using the least squares method. The dynamic modulus master curve is plotted, effectively capturing the dynamic viscoelastic properties of asphalt mixtures. Pablo et al. [

26] tested the dynamic modulus of asphalt mixtures at five various temperatures and loading frequencies, constructing dynamic modulus master curves based on various fitting models. Some scholars have also established dynamic modulus master curves for asphalt mixtures under varying humidity levels, degrees of aging, and wet/dry cycle conditions. These curves are used to evaluate the effects of humidity, aging, and the number of wet/dry cycles on the dynamic modulus of asphalt mixtures [

27,

28,

29]. In addition, constructing a dynamic modulus master curve is particularly relevant for studying the dynamic modulus of cold, recycled, asphalt mixtures [

30].

Most of the studies on modulus mentioned above have been conducted on asphalt mixtures with a nominal maximum particle size of D ≤ 37.5 mm. However, the study of the modulus temperature dependence of LSAM-50 has not been reported. Furthermore, compared to semi-rigid base asphalt pavements, LSAM-50 pavements feature a thicker asphalt mixture layer, leading to pavement load responses and structural design that exhibit stronger temperature dependence. In light of this, this paper examines three asphalt mixtures commonly used in the typical structure of LSAM-50 pavements: LSAM-50, AC-20, and SMA-13. This study investigates the effects of temperature and nominal maximum particle size on the resilient modulus and establishes a temperature-dependent model for the resilient modulus. Additionally, it explores the effects of temperature, loading frequency, and nominal maximum particle size on the dynamic modulus and constructs a master curve for the dynamic modulus. Furthermore, the correlation between the resilient modulus and dynamic modulus is analyzed, leading to the establishment of a multiple linear regression model based on dynamic modulus, resilient modulus, temperature, and loading frequency. The concept of the modulus from static is of significant importance in guiding the design of roads in solid engineering.

2. Materials and Methods

2.1. Materials

Zhejiang Ningbo Donghai brand 70# base asphalt is utilized in LSAM-50 and AC-20, while the same brand’s styrene–butadiene–styrene (SBS) modified asphalt is employed in SMA-13. The technical properties of both the 70# base asphalt and the SBS-modified asphalt are shown in

Table 1.

2.2. Mineral Grades

The mineral gradation of SMA-13, AC-20, and LSAM-50 is strong, embedded, skeleton, compact gradation, which is derived from the group’s previous research, as shown in

Table 2.

2.3. Test Program

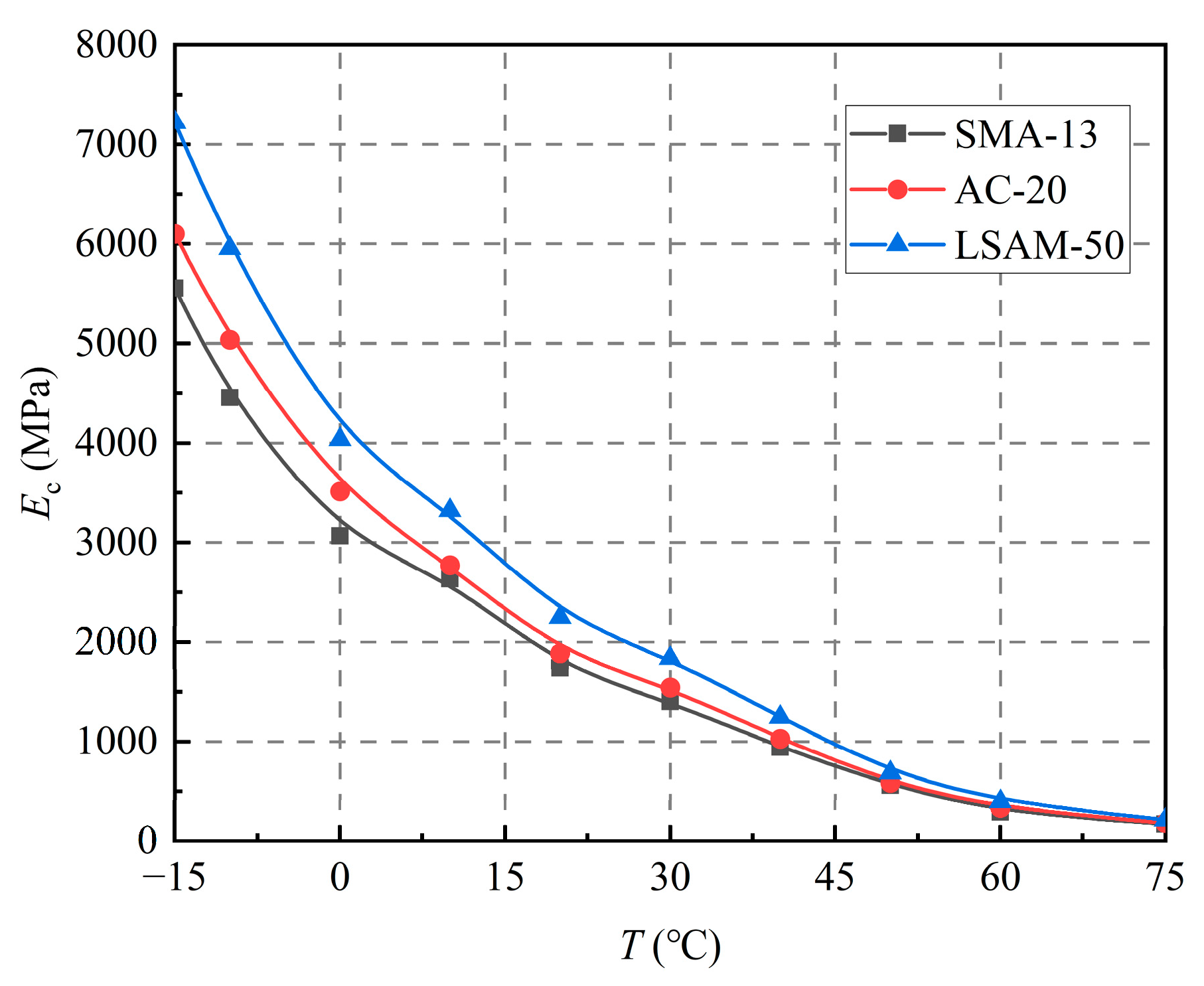

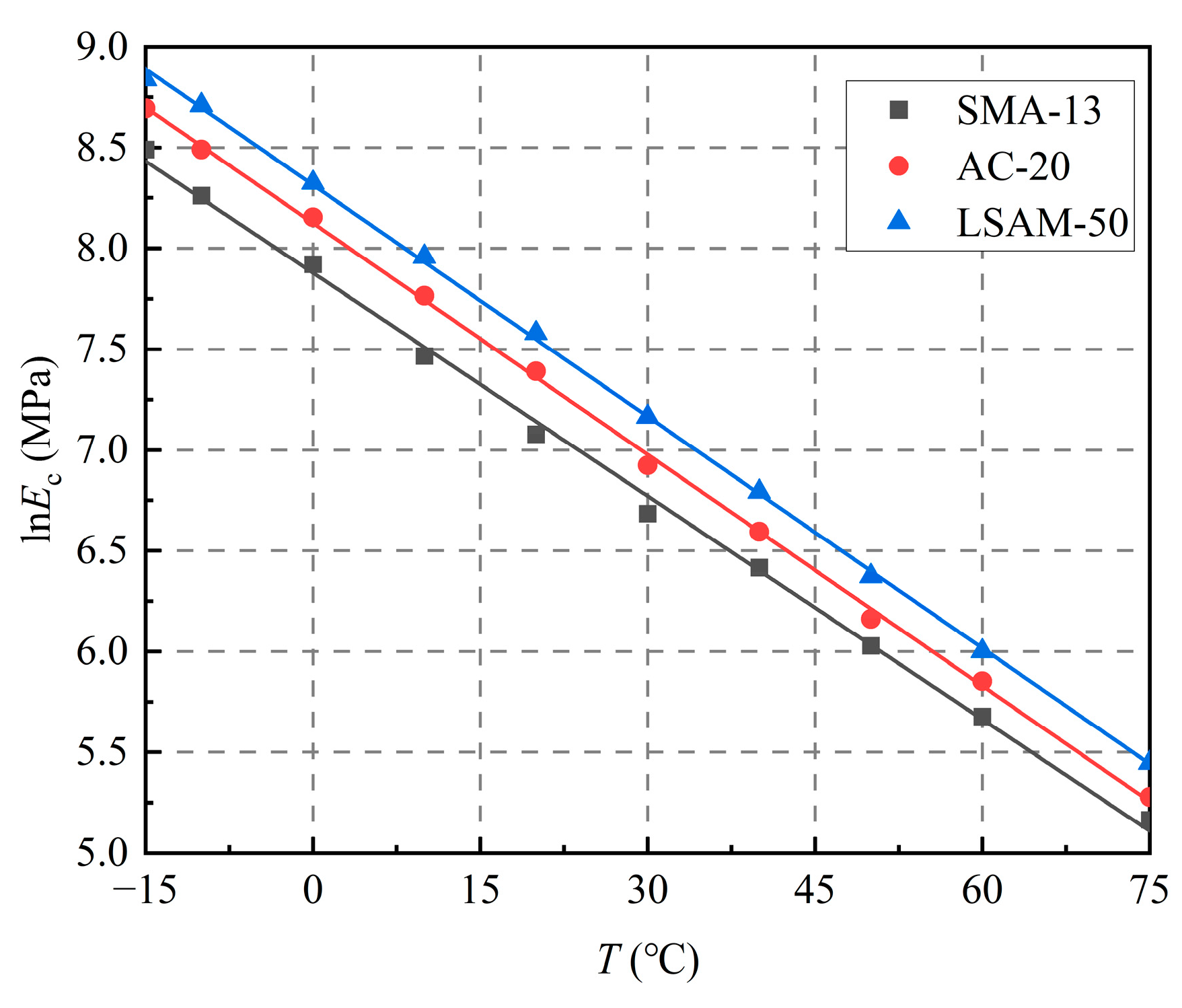

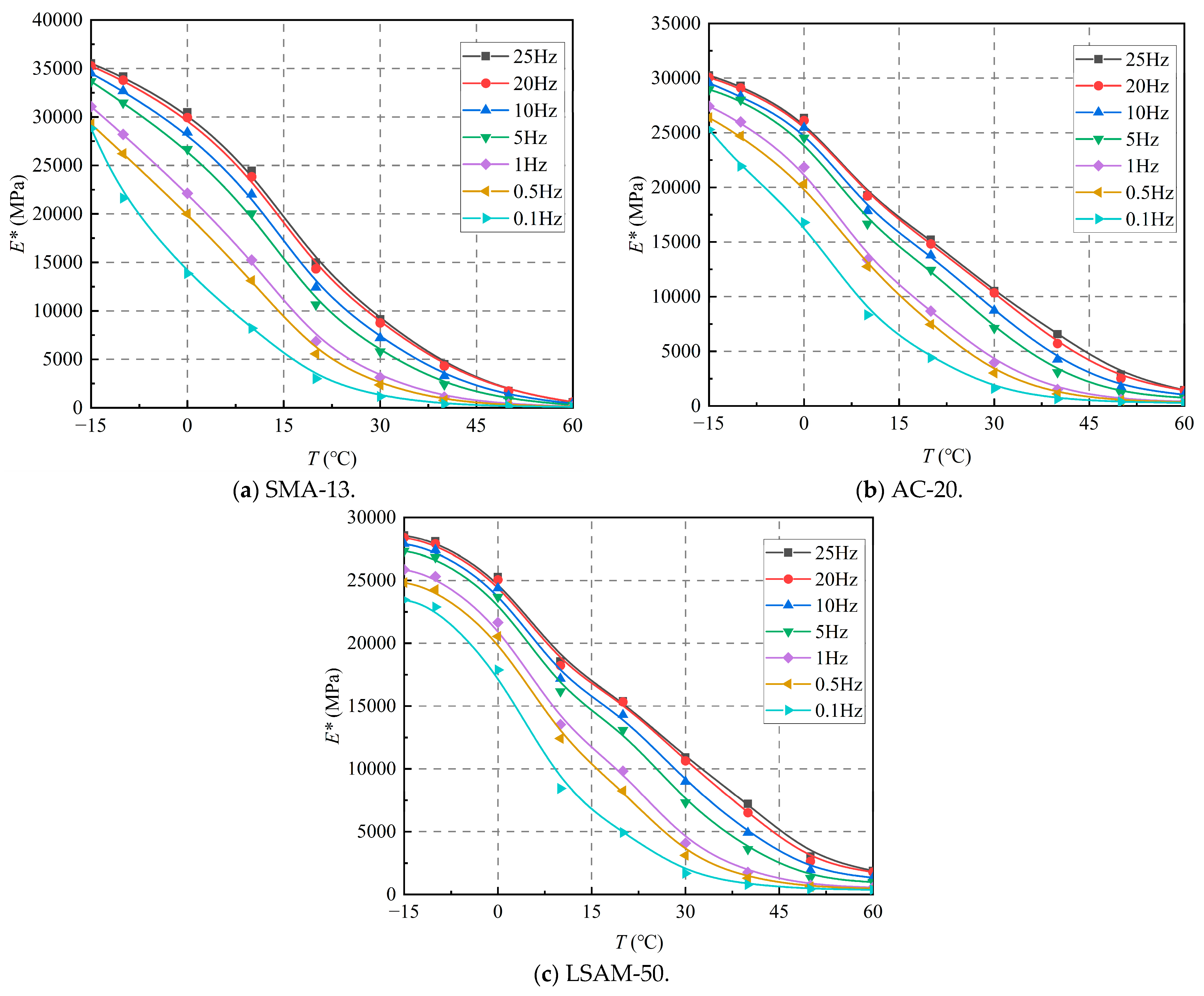

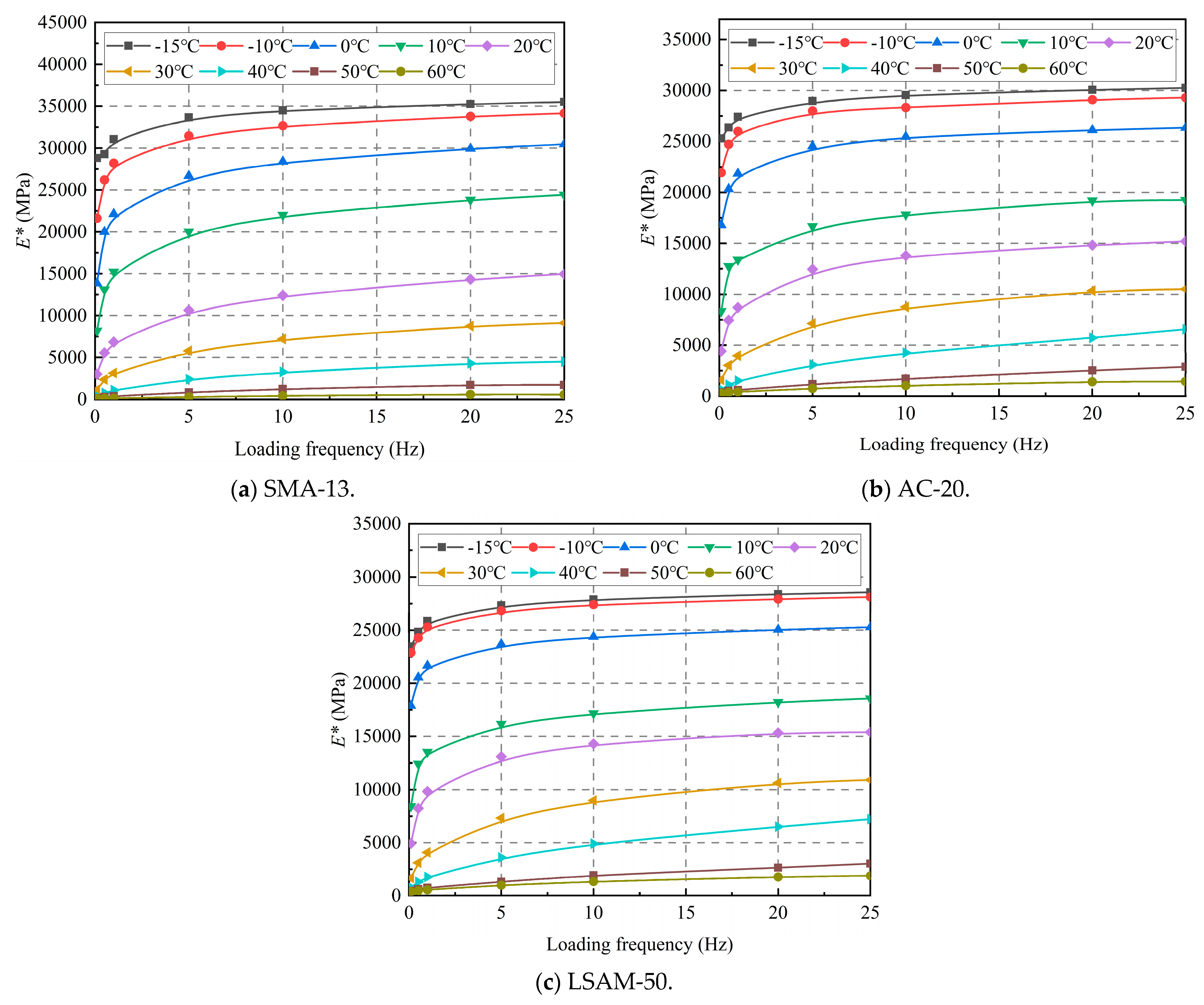

For the resilient modulus test, the test temperatures chosen were −15 °C, −10 °C, −5 °C, 0 °C, 5 °C, 15 °C, 20 °C, 30 °C, 45 °C, 60 °C, and 75 °C. For the dynamic modulus test, the test temperatures chosen were −15 °C, −10 °C, 0 °C, 10 °C, 20 °C, 30 °C, 40 °C, 50 °C, and 60 °C, and the loading frequencies chosen were 25 Hz, 20 Hz, 10 Hz, 5 Hz, 1 Hz, 0.5 Hz, and 0.1 Hz.

2.4. Specimen Sizes and Test Methods

2.4.1. Specimen Sizes

For the resilient modulus test, the SMA-13 and AC-20 specimens had dimensions of φ 100 ± 2 mm × h 100 ± 2 mm, while the LSAM-50 specimens measured φ 200 ± 2 mm × h 160 ± 2 mm. For the dynamic modulus test, the SMA-13, AC-20, and LSAM-50 specimens were φ 102 ± 2 mm × h 150 ± 2.5 mm. The SMA-13 and AC-20 specimens were cored and cut from φ 150 mm × h 170 mm compacted samples, while the LSAM-50 specimens were φ 200 mm × h 160 mm, also obtained from coring and cutting the compacted sample of φ 200 mm × h 160 mm.

2.4.2. Test Methods

- (1)

The resilient modulus test was conducted in accordance with T0713-2000 of the Test Methods for Asphalt and Asphalt Mixtures in Highway Engineering (JTG E20-2011), utilizing a loading rate of 2 mm/min. The testing procedure is shown in

Figure 1. The formula is shown in Equation (1).

where

Ec represents the resilient modulus;

represents the compressive force under a level 5 load (MPa);

h represents the axial height of the specimen (mm); and

. epresents the resilient deformation corrected to the origin at a level 5 load (mm).

- (2)

The dynamic modulus test was conducted in accordance with T0738-2000 of the Test Methods for Asphalt and Asphalt Mixtures in Highway Engineering (JTG E20-2011). The testing procedure is shown in

Figure 2. The specimens were placed in an environmental chamber set to a specified test temperature with an accuracy of ±0.5 °C and maintained at a constant temperature for 4 h to 5 h until the desired test temperature was achieved, as shown in

Figure 2b. During the testing process, the specimens were subjected to axial sine-wave loads at various test temperatures, ranging from a high to low frequency. The determination of each load frequency corresponded to the number of repetitions of the load under axial compressive stress and axial compressive strain, as shown in

Figure 2c. The formula is shown in Equation (2):

where

E* represents the dynamic modulus (MPa),

represents the axial stress amplitude (MPa), and

represents the axial strain amplitude (mm/mm).

The resilient modulus and dynamic modulus tests were conducted at each temperature using four valid specimens. If the measured value deviated from the average value by more than 1.46 times the standard deviation, the measured value was discarded. The average results from four parallel specimens were calculated for each test condition.

5. Correlation Study Between the Resilient Modulus and Dynamic Modulus

This paper examines the temperature dependence of the modulus of LSAM-50 pavement materials. Additionally, it investigates the correlation between these two moduli, facilitating the prediction of the dynamic modulus based on the resilient modulus. The concept of static rotation guides the physical engineering of road design.

By comparing the resilient modulus of SMA-13, AC-20, and LSAM-50 at various temperatures and frequencies during the dynamic modulus test, it is evident that temperature significantly influences both the resilient modulus and dynamic modulus. This observation suggests a correlation between the two properties. Consequently, this section will treat the resilient modulus, temperature, and loading frequency as independent variables, while the dynamic modulus will be considered the dependent variable. A predictive model for the dynamic modulus of LSAM-50 pavement materials will be established based on these variables (17).

where

A,

B,

C, and

D represent the fitting coefficients.

With the assistance of IBM SPSS Statistics 25 software for multiple regression analysis, the regression coefficients of the dynamic modulus prediction model for LSAM-50 pavement materials are shown in

Table 9.

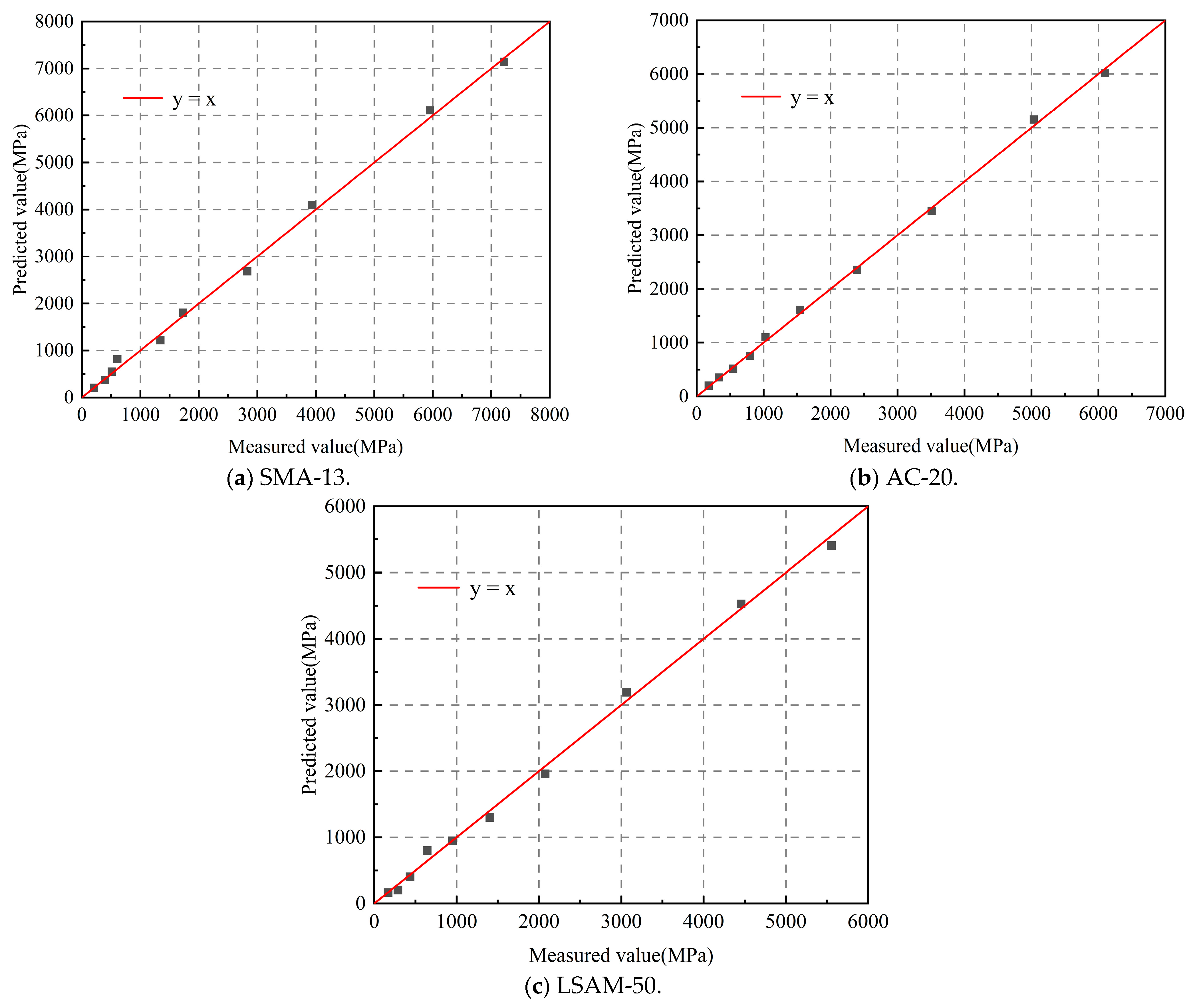

As shown in

Table 9, the goodness of fit (

R2) for SMA-13, AC-20, and LSAM-50 are 0.94, 0.95, and 0.95, respectively. The dynamic modulus of the three LSAM-50 pavement materials can be more accurately predicted using Equation (15).

According to the fitting coefficients of Equation (17) and

Table 9, the dynamic modulus of the LSAM-50 pavement materials at various temperatures and frequencies has been calculated.

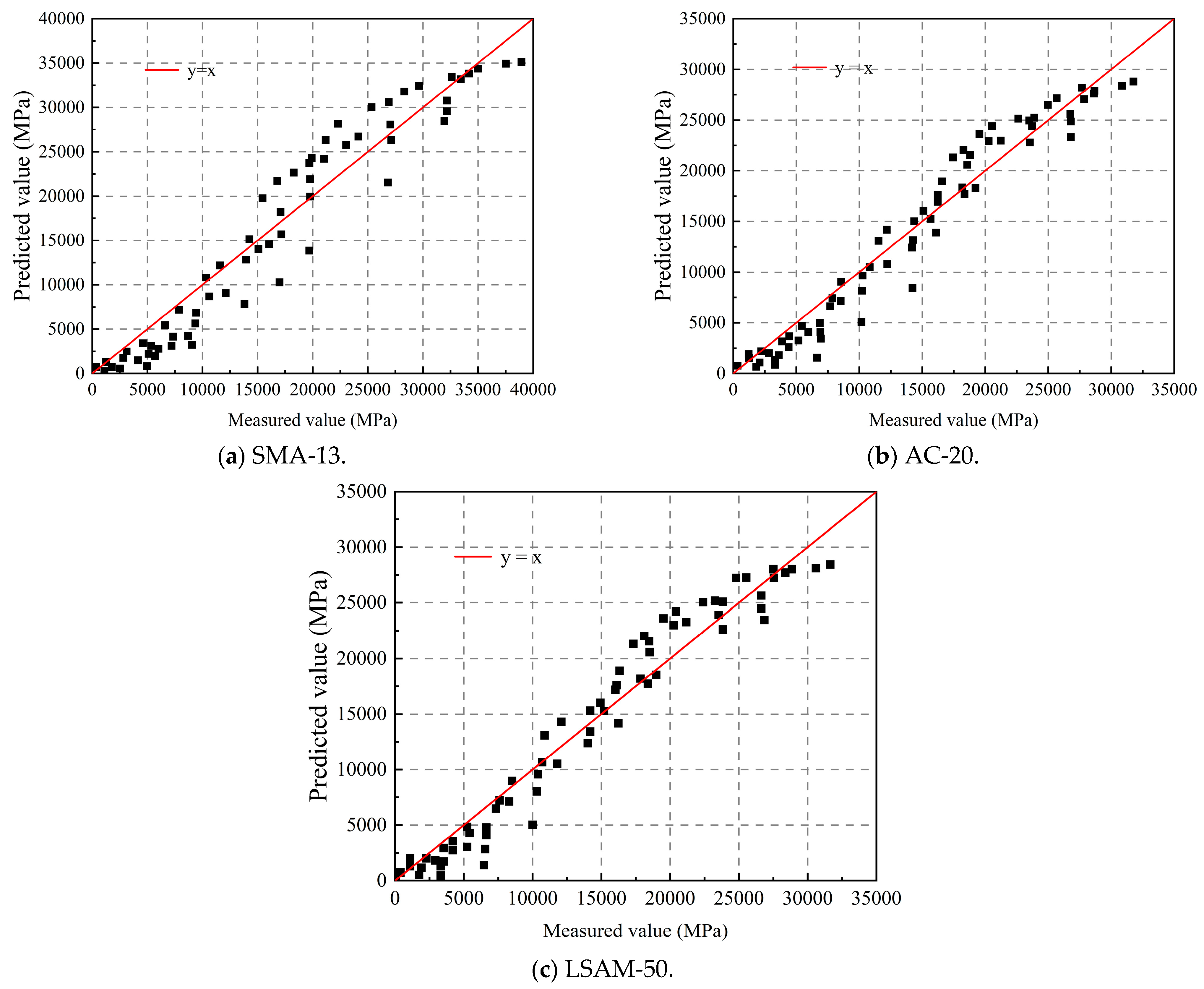

The scatter plot comparing the predicted and measured values of the dynamic modulus for these LSAM-50 pavement materials is presented in

Figure 11.

As shown in

Figure 10, the dynamic modulus predicted values for the three LSAM-50 pavement materials are plotted against the measured values along the line y = x, which can be utilized to calculate the dynamic modulus as described in Equation (17).

6. Conclusions

In this paper, we investigate the modulus temperature dependence of typical structural materials, including SMA-13, AC-20, and LSAM-50, for LSAM-50 pavements. We analyze the factors influencing the modulus, propose a temperature-dependent model for the resilient modulus, and construct the dynamic modulus master curve. Finally, we examine the correlation between the resilient modulus and the dynamic modulus. The main conclusions are as follows:

- (1)

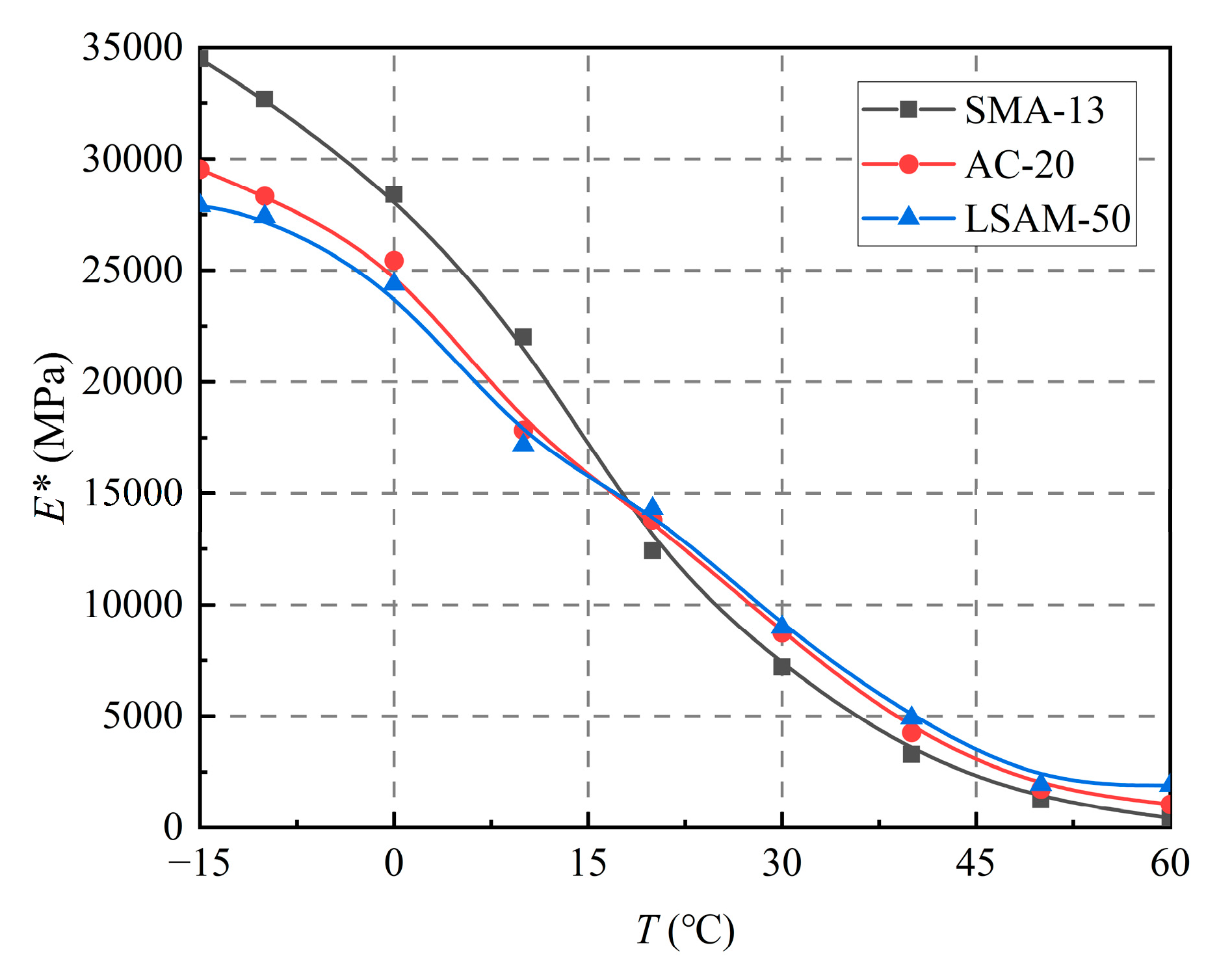

The resilient modulus of the LSAM-50 pavement materials initially decreases sharply with increasing temperature. When the temperature exceeds 20 °C, the rate of decrease in the resilient modulus diminishes, and the curve of the resilient modulus began to plateau. Additionally, a larger nominal maximum particle size corresponds to a higher resilient modulus of the asphalt mixture. At a temperature of 60 °C, the resilient modulus of LSAM-50 is 1.20 times that of AC-20 and 1.37 times that of SMA-13. Temperature-dependent models for the resilient modulus of the three LSAM-50 pavement materials are established, with correlation coefficients (R2) exceeding 0.97.

- (2)

The dynamic modulus of three LSAM-50 pavement materials decreases significantly with increasing temperature, and the rate of decrease diminishes when the temperature exceeds 40 °C. Additionally, the dynamic modulus of three LSAM-50 pavement materials increases with rising loading frequency, and the curve of dynamic modulus changes begins to plateau when the loading frequency exceeds 5 Hz.

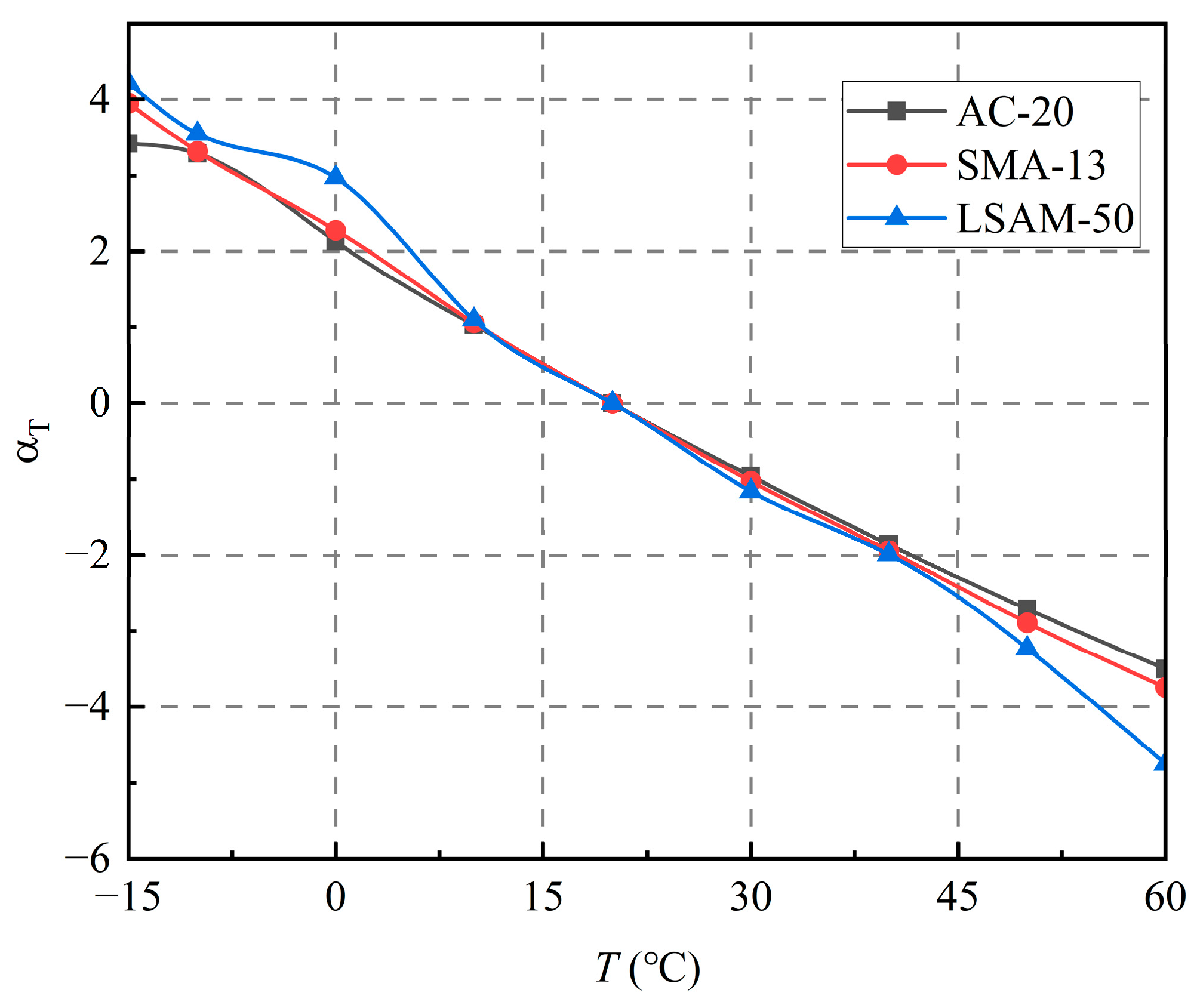

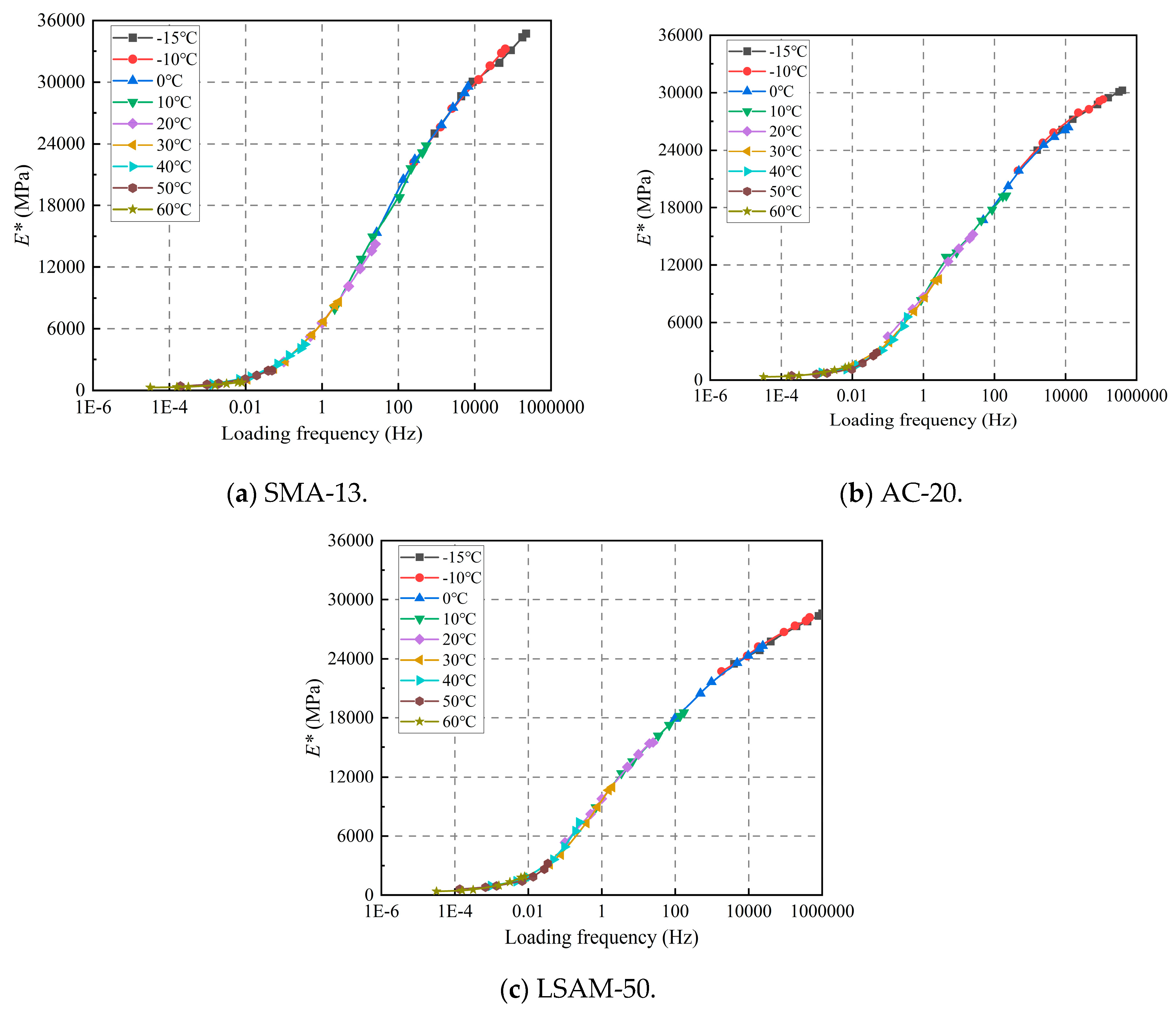

- (3)

The displacement factors of three LSAM-50 pavement materials have been determined. The temperature sensitivities of the three LSAM-50 pavement materials are relatively similar. Additionally, dynamic modulus master curves are constructed for three LSAM-50 pavement materials, extending the dynamic modulus and loading frequency across a broader range and thereby overcoming the limitations of laboratory testing.

- (4)

Multiple linear regression models for the dynamic modulus of three LSAM-50 pavement materials, based on resilient modulus, temperature, and loading frequency, are developed. The goodness of fit (R2) values of SMA-13, AC-20, and LSAM-50 are 0.94, 0.95, and 0.95. The dynamic modulus can be predicted using the resilient modulus, offering critical insights for optimizing pavement design in civil engineering.

These findings reveal the effects of temperature on LSAM-50 pavement materials and provide a theoretical foundation for the design of LSAM-50 pavements. However, it is important to emphasize that these results are based on laboratory tests. Further validation through actual road construction projects is necessary to confirm the reliability of the modulus-temperature dependence model for LSAM-50 pavement materials.