Effect of Cr Content on Microstructure and Mechanical Properties of Heat Affected Zone in Supercritical Carbon Dioxide Transport Pipeline Steel

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

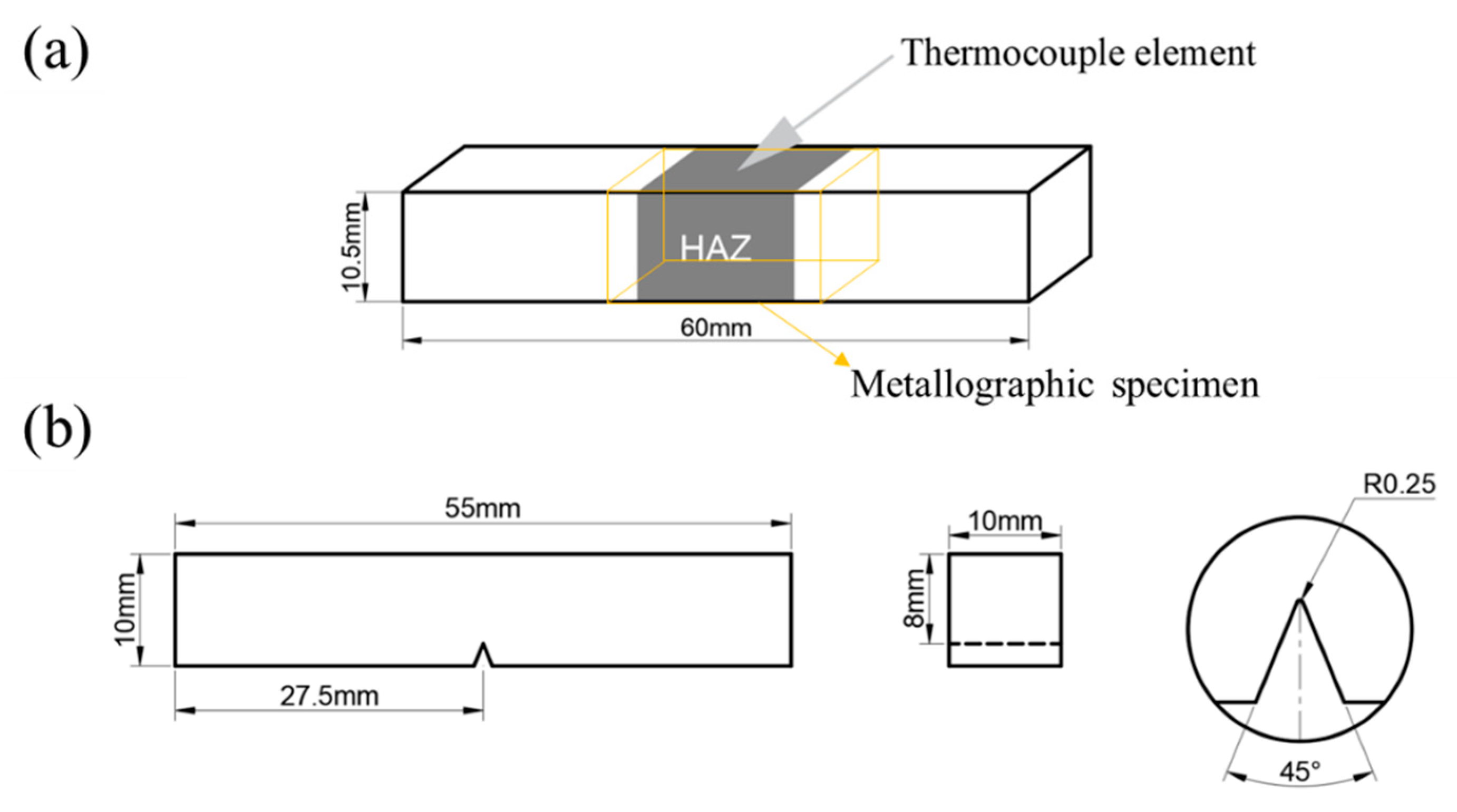

2.2. Welding Thermal Cycle Experiment

2.3. Microstructure and Fracture Surface Observation and Analysis

3. Experimental Results and Analysis

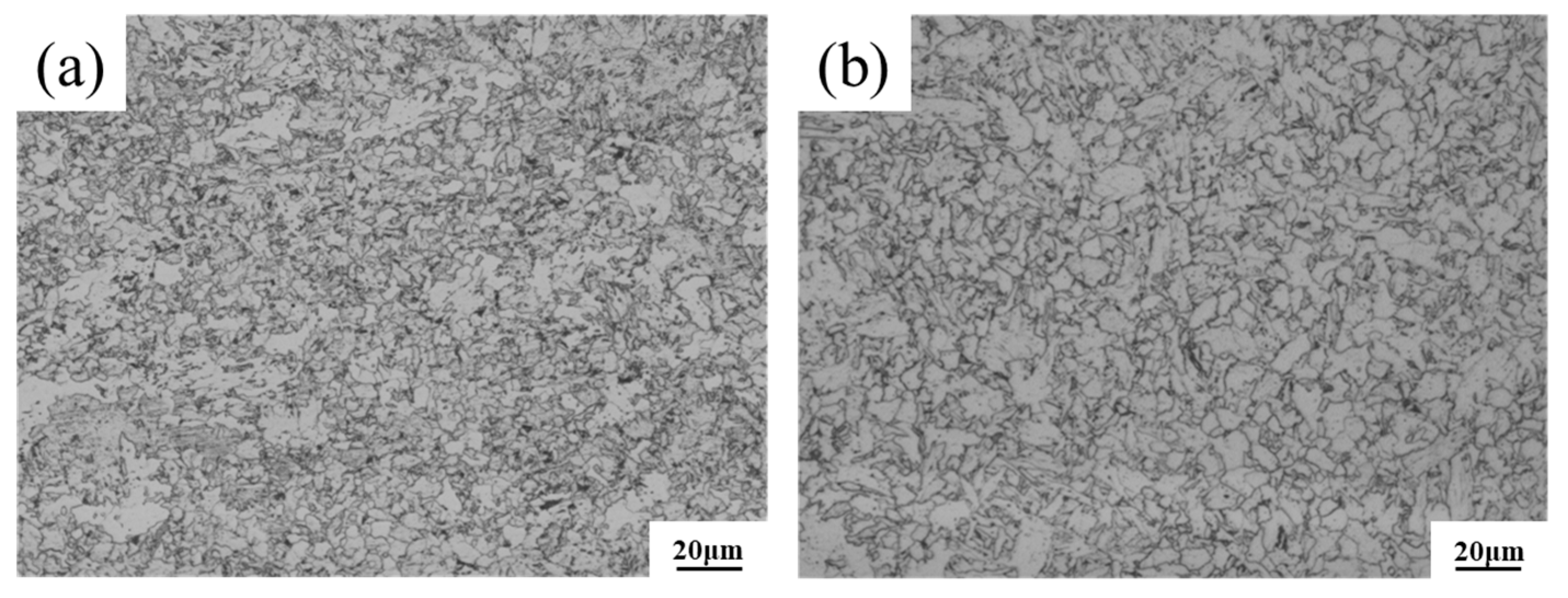

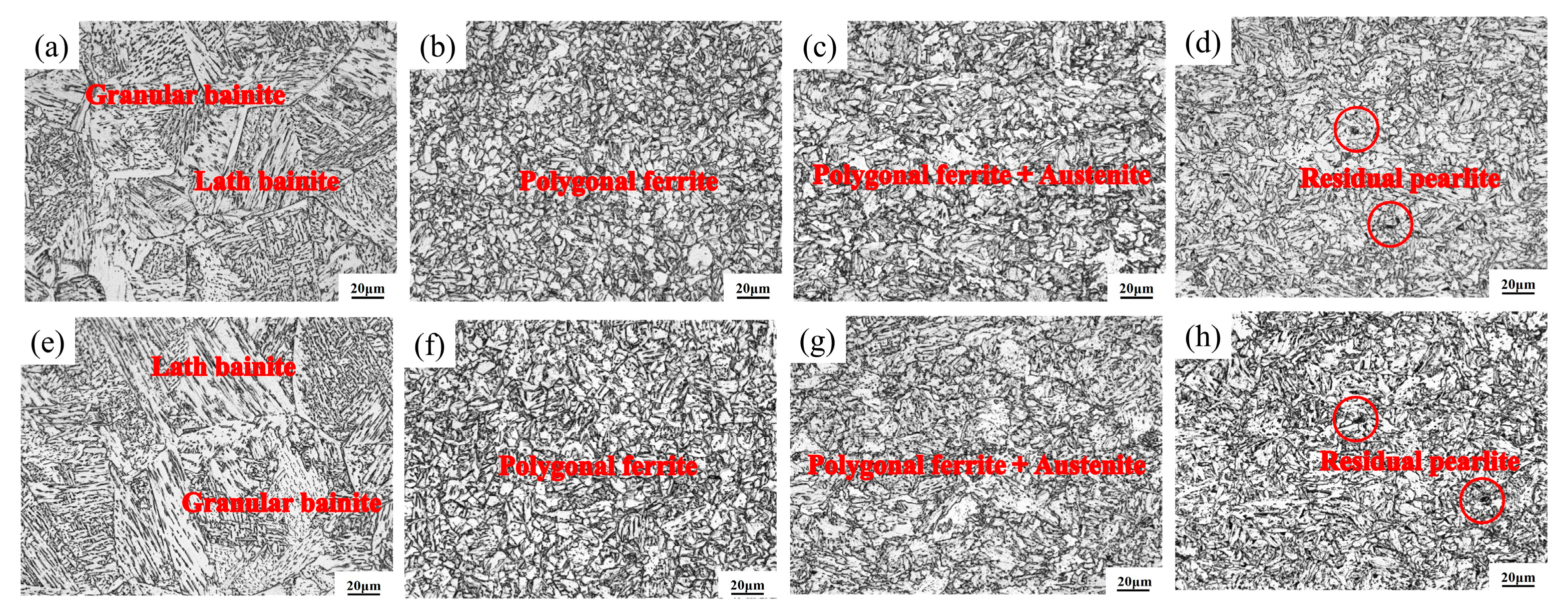

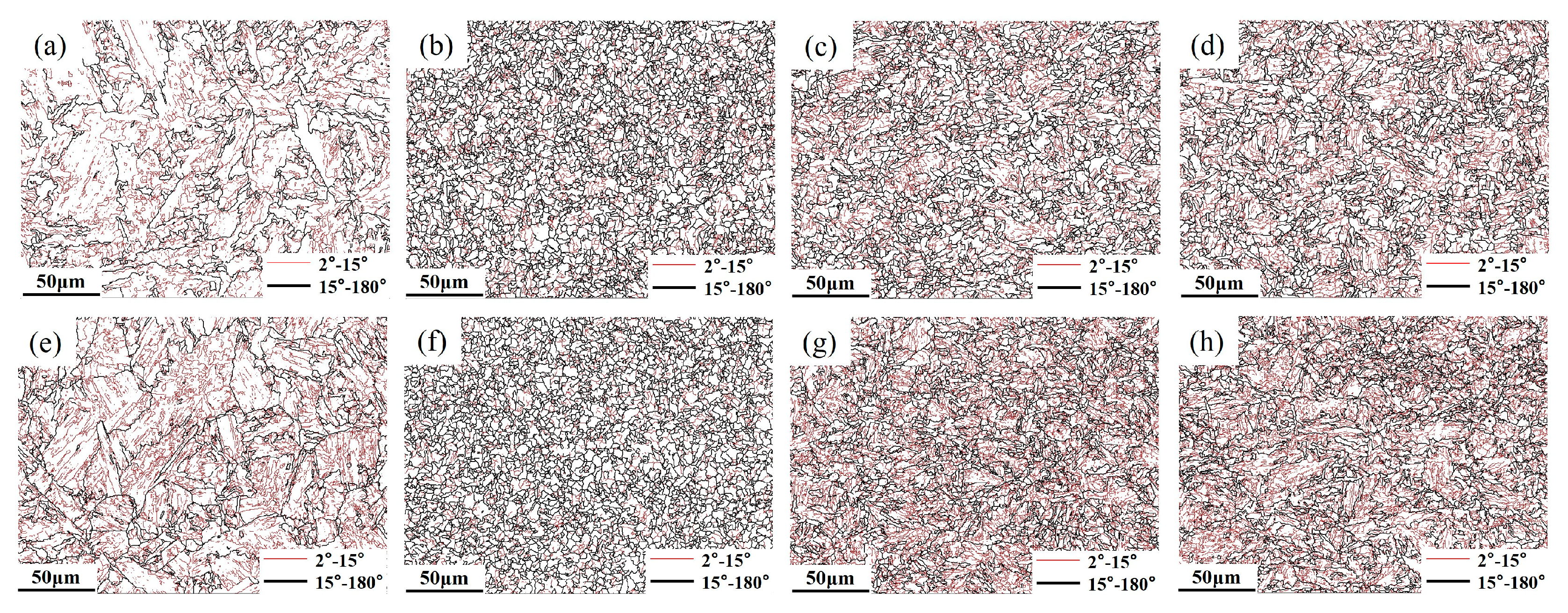

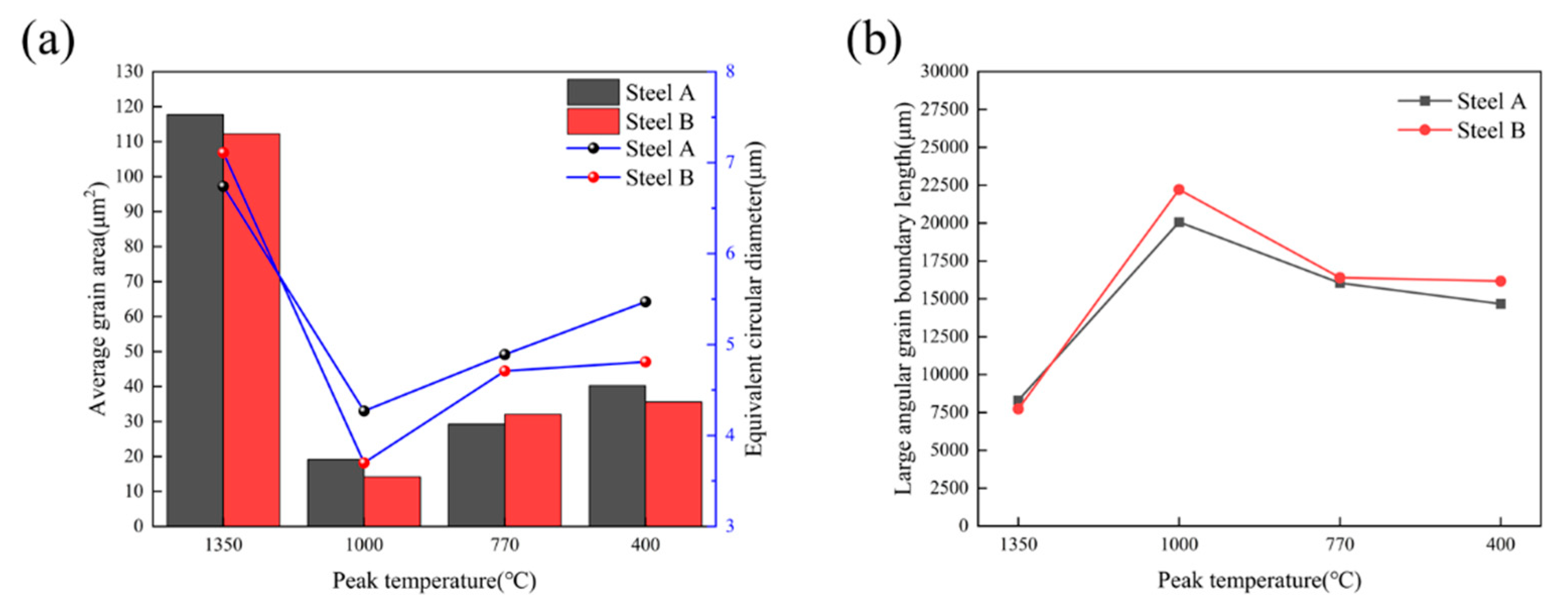

3.1. Microstructure Analysis

3.2. Mechanical Property Analysis

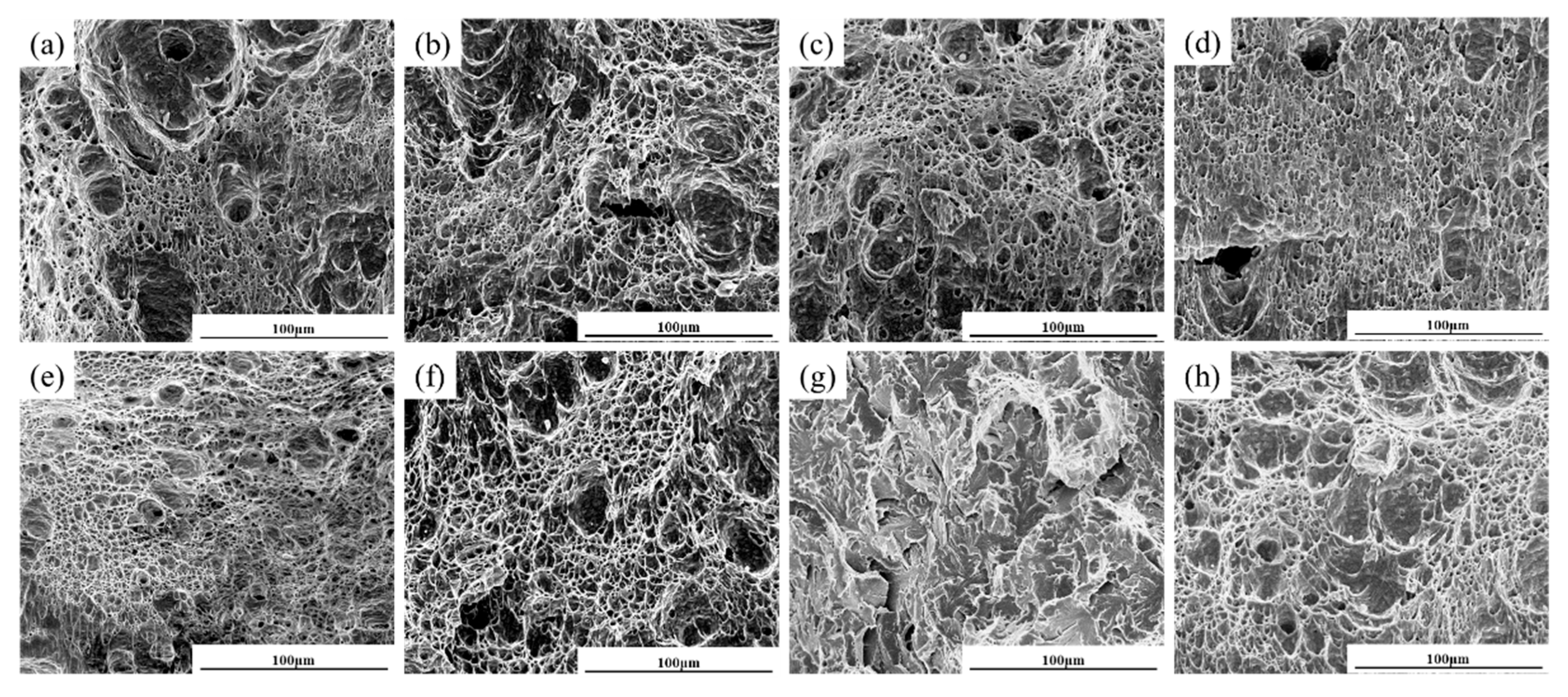

3.3. Analysis of Fracture Surface Morphology

4. Discussion

4.1. Effect of Peak Temperature on HAZ Microstructure

4.2. The Effect of M-A Constituent on Toughness in the ICHAZ

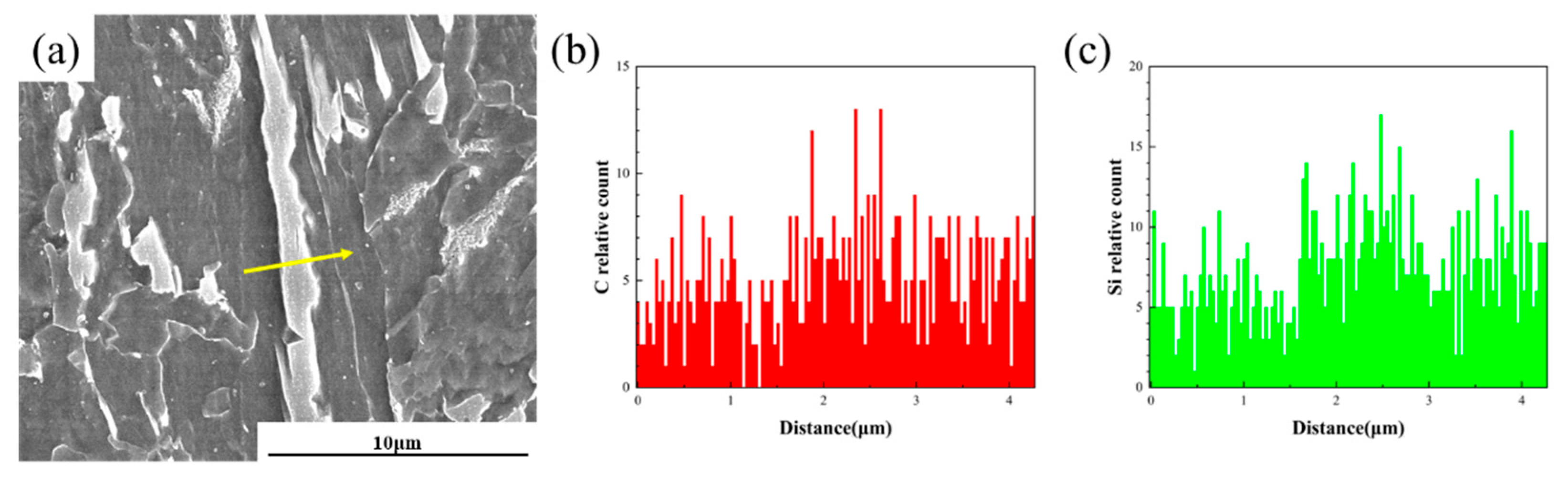

4.3. The Influence of Cr Element on the M-A Component of ICHAZ

5. Conclusions

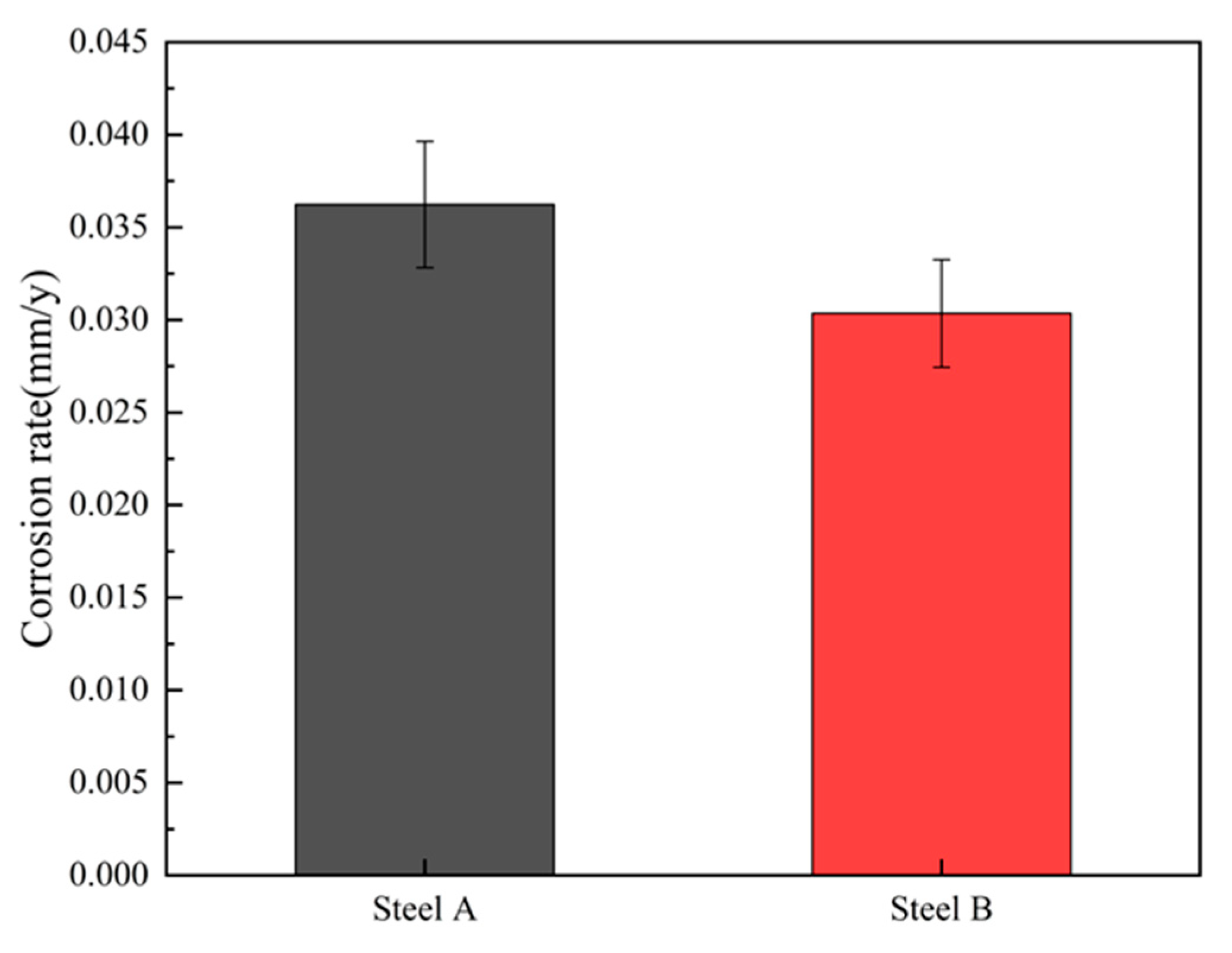

- Addition of 0.5 wt.% Cr to the experimental steel reduced the −10 °C low temperature toughness of the base metal from 277 J to 235 J but improved its corrosion resistance in supercritical CO2 environments.

- With 0.5 wt.% Cr addition to the experimental steel, embrittlement occurred in the ICHAZ subregion of the HAZ, where the low-temperature toughness decreased from 235 J of the base metal to 77 J. A peak in microhardness was also observed in this area, primarily due to partial austenitization during heating and subsequent formation of M-A constituent during rapid cooling.

- As a strong carbide-forming element, Cr significantly reduces the carbon diffusion rate in austenite by forming stable carbides, inducing heterogeneous austenitization and localized carbon-enriched micro-zones in the ICHAZ. During rapid cooling, these carbon-rich regions preferentially transform into core–shell M-A constituent, characterized by retained austenite cores containing micro-twins and high-hardness lath martensite shells. The localized stress concentration arising from this microstructure synergizes with interfacial thermal mismatch stress, triggering microcrack nucleation and ultimately leading to material toughness degradation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Niu, A.J.; Bi, Z.Y.; Wei, F.; Huang, X.J.; Liu, B.; Xi, M.M. Research Progress and Development Trend of Pipes Used in New Energy Transportation in China. Welded Pipe Tube 2024, 47, 16–24. [Google Scholar]

- Bi, Z.Y.; Huang, X.H.; Li, Y.H.; Wei, F.; Qin, J.J.; Wang, L.; Fan, C.Q.; Lu, L. Development of HFW Steel Pipe for Supercritical Carbon Dioxide Transportation. Welded Pipe Tube 2023, 46, 43–48. [Google Scholar]

- Zhao, W.Q.; Chen, W.F.; Yu, C.L.; Wang, Z.; Zhang, J.S. Research Status of Carbon Dioxide Pipeline Transportation Technology. Pet. Chem. Equip. 2023, 26, 40–42. [Google Scholar]

- Tao, Z.; Du, P.; Wang, X.Y.; Hou, S.Y. Bohai Equipment: Seizing the New Heights of CO2 Pipeline Transportation. China Pet. Petrochem. 2025, Z1, 86–87. [Google Scholar]

- Zhao, Y.Y.; Chen, X.W.; Yang, K.; Wang, B.; Wang, X.S. Development of X65 Steel Grade SAWL Pipe for CO2 Transportation. Welded Pipe Tube 2025, 48, 50–54. [Google Scholar]

- Zhao, Y.Y.; Chen, X.W.; Li, Y.P.; Wang, B.; Wang, X.S. Research Progress of CO2 Transmission Pipelines Technology. Welded Pipe Tube 2024, 47, 1–6+16. [Google Scholar]

- Liu, L.S. Study on corrosion characteristics of supercritical carbon dioxide pipeline. Chem. Eng. 2023, 37, 85–88. [Google Scholar]

- Gao, Y.X.; Pan, J.; Li, Y.; Zhang, J.; Li, Y. Research Progress on the Corrosion of the Inner Surface of Pipeline Used for Transporting Supercritical Carbon Dioxide. Mater. Rep. 2024, 38, 184–191. [Google Scholar]

- Li, K.; Zeng, Y.; Luo, J.L. Influence of H2S on the General Corrosion and Sulfide Stress Cracking of Pipelines Steels for Supercritical CO2 Transportation. Corros. Sci. 2021, 190, 109639. [Google Scholar] [CrossRef]

- Li, K.; Zeng, Y. Long-term corrosion and stress corrosion cracking of X65 steel in H2O-saturated supercritical CO2 with SO2 and O2 impurities. Constr. Build. Mater. 2023, 362, 129746. [Google Scholar] [CrossRef]

- Zeng, Y.; Li, K. Influence of SO2 on the Corrosion and Stress Corrosion Cracking Susceptibility of Supercritical CO2 Transportation Pipelines. Corros. Sci. 2019, 165, 108404. [Google Scholar] [CrossRef]

- Li, K.; Zeng, Y. Advancing the mechanistic understanding of corrosion in supercritical CO2 with H2O and O2 impurities. Corros. Sci. 2023, 213, 110981. [Google Scholar] [CrossRef]

- Hu, L.H.; Zhang, L.; Xu, L.N.; Lu, M.X.; Chang, W.; Li, Z.T. Effects of Cr content on microstructure and properties of low alloy corrosion resistant pipeline steel weld joints. Trans. Meter. Heat Treat. 2010, 31, 5. [Google Scholar]

- Li, C. Effect of Carbon Equivalent on the Toughness of Coarse Grained HAZ of Girth Welded Joint of High-Grade Steel Pipeline. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2022. [Google Scholar]

- Tang, H.P. Study on Residual Stress and Microstructure Properties of Heat Affcted Zone During In-Service Welding on X80 Natural Gas Pipeline. Ph.D. Thesis, Southwest Petroleum University, Chengdu, China, 2019. [Google Scholar]

- Wu, Z.W.; Dai, Z.J.; Wang, L.L.; Zhang, P.C.; Wu, H.B. Development of X65 Pipeline for Supercritical CO2 Transport Environment. Steel Pipe 2025, 54, 39–44. [Google Scholar]

- Wang, B. Study of Corrosion and Erosion Mechanism for Cr-Bearing Alloy Steel in CO2-Containing Wet Gas Pipeline. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2019. [Google Scholar]

- Qiao, S.; Yu, J.S.; Wang, H.L.; Zhou, X.G. Research Progress on Corrosion Behavior of Supercritical Carbon Dioxide in Fourth Generation Nuclear Reactors. Mater. Res. Appl. 2022, 16, 460–470. [Google Scholar]

- Wang, C.L.; Guo, H.D.; Fang, J.; Yu, S.X.; Yue, X.Q.; Hu, Q.H.; Liu, C.W.; Zhang, J.W.; Zhang, R.; Xu, X.S.; et al. The role of Cr content on the corrosion resistance of carbon steel and low-Cr steels in the CO2-saturated brine. Pet. Sci. 2023, 20, 1155–1168. [Google Scholar] [CrossRef]

- Lee, H.J.; Lee, H.W. Effect of Cr Content on Microstructure and Mechanical Properties of Low Carbon Steel Welds. Int. J. Electrochem. Sci. 2015, 10, 8028–8040. [Google Scholar] [CrossRef]

- Li, H.C.; Chen, S.Y.; Yue, X.D.; Yang, H.M. Effect of Cr on microstructure and austenite-ferrite transformation temperature of low carton steel. Heat Treat. Met. 2014, 39, 22–25. [Google Scholar]

- Heo, N.H.; Heo, Y.; Kwon, S.K.; Kim, N.J.; Kim, S.J.; Lee, H.C. Extended Hall–Petch Relationships for Yield, Cleavage and Intergranular Fracture Strengths of bcc Steel and Its Deformation and Fracture Behaviors. Met. Mater. Int. 2018, 24, 265–281. [Google Scholar] [CrossRef]

- Hong, R.; Liu, H.C.; Zhu, X.D.; Liu, N.S.; Yin, S.B.; Ma, Q.L.; Jia, S.J. Effect of Cr Element in Gas-Shielded Solid Wire for Oil and Gas Long-Distance Pipeline on Microstructure and Low Temperature Toughness of Weld. Materials 2024, 17, 4704. [Google Scholar] [CrossRef]

- Wang, F.; Fan, Y.R.; Zhang, X.X.; Sun, Q.F. Effect of Cr in Self-shielded Flux-cored Wires on Sharpy Impact Performance and Microstructure of the Weld Metals. Han Guan 2014, 37, 58–61. [Google Scholar]

- Hou, Y. Effect of alloying element on microstructure and properties of girth welded joints of X80 pipeline steel. Metall. Anal. 2023, 43, 24–33. [Google Scholar]

- Wang, Y.F. Effect of Chromium on Rust Layer Structure, Microstructure and Properties of Weathering Bridge Steel. Ph.D. Thesis, Yanshan University, Qinhuangdao, China, 2021. [Google Scholar]

- GB/T 4336-2016; Carbon and Low-Alloy Steel—Determination of Multielement Contents—Spark Discharge Atomic Emission Spectrometric Method (Routine Method). General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2016.

- Li, C. Welding Procedure Study of Corrosin Resistant Steel for Ships. Ph.D. Thesis, Shanghai Jiaotong University, China, 2017. [Google Scholar]

- GB/T 229-2020; Metallic materials—Charpy pendulum impact test method. State Administration for Market Regulation; Standardization Administration of PRC: Beijing, China, 2020.

- Tang, C.J.; An, T.B.; Peng, Y.; Li, C.C.; Ma, C.Y.; Liu, X.M. Effect of heat input on microstructure and mechanical properties of weld metal of 690 MPa grade HSLA steel. Trans. China Weld. Inst. 2024, 45, 110–119. [Google Scholar]

- Zhou, X.Q. Microstructure Evolution and Impact Properties of Low Carbon Bainitic Steels. Ph.D. Thesis, Chongqing University, Chongqing, China, 2023. [Google Scholar]

- Wang, X.Y.; Li, L.; Wu, Q.D.; Wang, C.C.; Liang, X.D.; Yang, P.; Wang, X. Effect of austenitizing temperature on microstructure and mechanical properties of rolled C61 steel. Trans. Mater. Heat Treat. 2021, 42, 72–78. [Google Scholar]

- Di, Y.J.; Ping, L.L.; Tang, X.C.; Zhang, Z.J.; Cheng, G.H. Effect of annealing temperatures on non-magnetic structural steel 20Mn23AlV. J. Iron Steel Res. 2025, 37, 375–385. [Google Scholar]

- Liu, H.; Luo, R.; Qian, X.G.; Sun, X.; Zhao, Q.L.; Cui, L.Y.; Yang, C.; Ding, H.N. Effect of Heat Treatment Process on Properties and Microstructure of UNS N07718 Superalloy for Deep-sea Oil and Gas Development. J. Netshape Form. Eng. 2024, 16, 98–106. [Google Scholar]

- Cao, S.L.; Zhang, Q.J.; Zhang, C.J. Influence of linear energy on microstructure and properties of heat affected zone of EH420 offshore steel. Chian Metall. 2017, 38, 14–17. [Google Scholar]

- Yu, Y.; Gao, Z.Y.; Gong, B.M. Fracture toughness of CGHAZ of X80 pipeline steel in hydrogen sulfide environment. Weld. Join. 2025, 1, 40–45. [Google Scholar]

- Lan, L.; Qiu, C.; Zhao, D.; Gao, X. Microstructural characteristics and toughness of the simulated coarse-grained heat affected zone of high strength low carbon bainitic steel. Mater. Sci. Eng. A 2011, 529, 192–200. [Google Scholar] [CrossRef]

- Matsuda, F.; LI, Z.; Bernazovsky, P.; Ishihara, K.; Okada, H. An investigation on the behaviour of the M/A constituent is simulated HAZ of HSLA steels. Weld World 1991, 29, 307–313. [Google Scholar]

- Duan, H. Study on Microstructure Control and Strengthening & Toughening Mechanism of High Strength Pipeline Steel for Low Temperature Application. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2022. [Google Scholar]

- Huang, K.L.; Zhao, X.; Zuo, X.R.; Wang, H.H. Study on Low Temperature Fracture Behavior of X80 Pipeline Steel with Multiphase Microstructure. Hot Work. Technol. 2020, 49, 35–38. [Google Scholar]

- Li, Y. Effect of Mo on the Toughness of HAZ of Girth Welded Joint of X80 Pipeline Steel. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2023. [Google Scholar]

- Li, B.; Zhou, X.; Jia, S.J.; Chen, X.P.; Fu, S.; Zhao, D.L.; Zhang, H.A.; Guo, J. Study on Fracture Behavior and Toughening Mechanisms of Ultra-High-Strength Pipeline Steel. Metals 2024, 14, 666. [Google Scholar] [CrossRef]

- He, X.M.; Chen, R.W. An Investigation on the Diffusion Coefficient of Carbon in Austenite. Met. Sci. Technol. 1986, 3, 1–12. [Google Scholar]

| Pipeline | C | Si | Mn | Cr | Ni | Mo | Cu | Nb | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Steel A | 0.05 | 0.2 | 1.31 | 0.21 | 0.2 | 0.11 | 0.1 | 0.039 | 0.011 |

| Steel B | 0.05 | 0.2 | 1.32 | 0.50 | 0.2 | 0.10 | 0.1 | 0.038 | 0.012 |

| Experimental Steel Designation | Number of M-A Constituent/0.01 mm2 |

|---|---|

| Steel A | 231 |

| Steel B | 423 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, R.; Zhu, X.; Yin, S.; Liu, N.; Jia, S.; Cao, Y.; Qin, Y.; Ma, Q. Effect of Cr Content on Microstructure and Mechanical Properties of Heat Affected Zone in Supercritical Carbon Dioxide Transport Pipeline Steel. Materials 2025, 18, 2607. https://doi.org/10.3390/ma18112607

Hong R, Zhu X, Yin S, Liu N, Jia S, Cao Y, Qin Y, Ma Q. Effect of Cr Content on Microstructure and Mechanical Properties of Heat Affected Zone in Supercritical Carbon Dioxide Transport Pipeline Steel. Materials. 2025; 18(11):2607. https://doi.org/10.3390/ma18112607

Chicago/Turabian StyleHong, Rui, Xiaodan Zhu, Shubiao Yin, Nengsheng Liu, Shujun Jia, Yuxi Cao, Yuqin Qin, and Qilin Ma. 2025. "Effect of Cr Content on Microstructure and Mechanical Properties of Heat Affected Zone in Supercritical Carbon Dioxide Transport Pipeline Steel" Materials 18, no. 11: 2607. https://doi.org/10.3390/ma18112607

APA StyleHong, R., Zhu, X., Yin, S., Liu, N., Jia, S., Cao, Y., Qin, Y., & Ma, Q. (2025). Effect of Cr Content on Microstructure and Mechanical Properties of Heat Affected Zone in Supercritical Carbon Dioxide Transport Pipeline Steel. Materials, 18(11), 2607. https://doi.org/10.3390/ma18112607