Effect the Sintering Temperature on the Microstructure and Flexural Strength of ZrO2 Ceramics Produced by NanoParticle Jetting

Abstract

1. Introduction

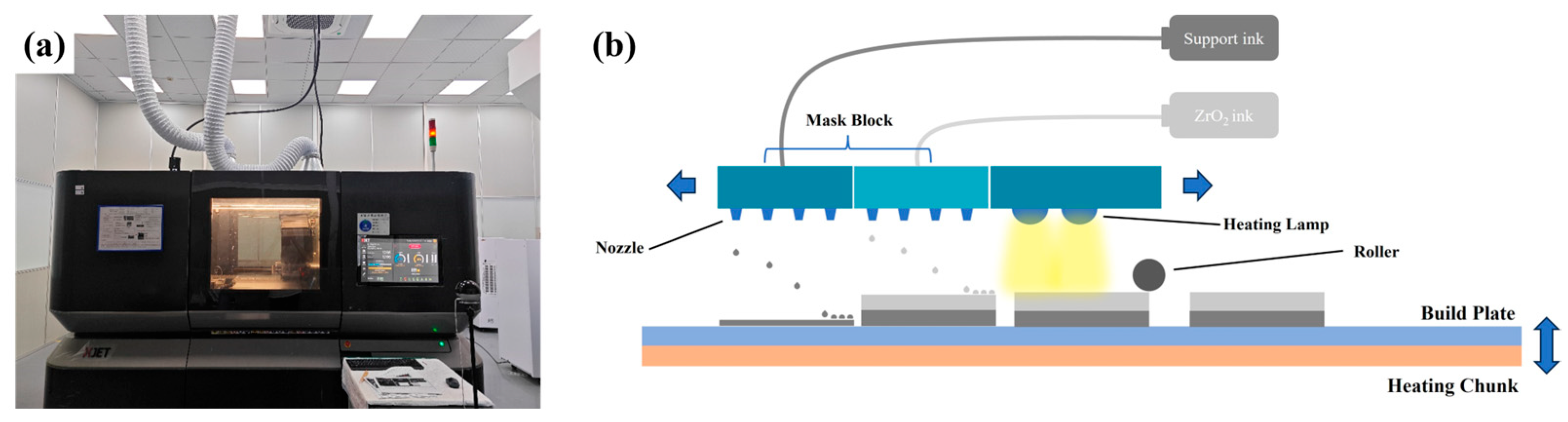

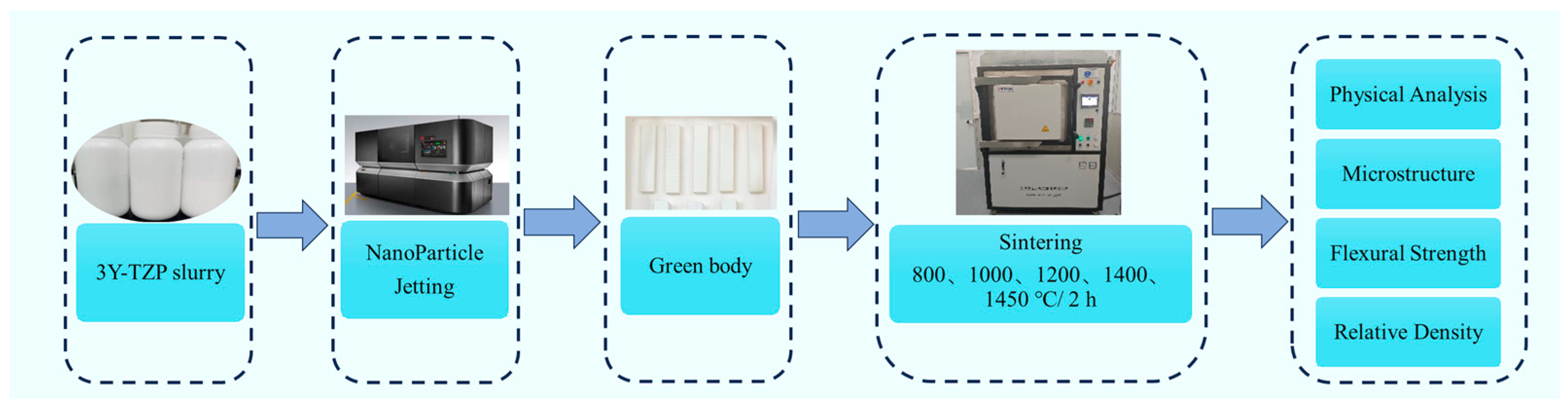

2. Materials and Methods

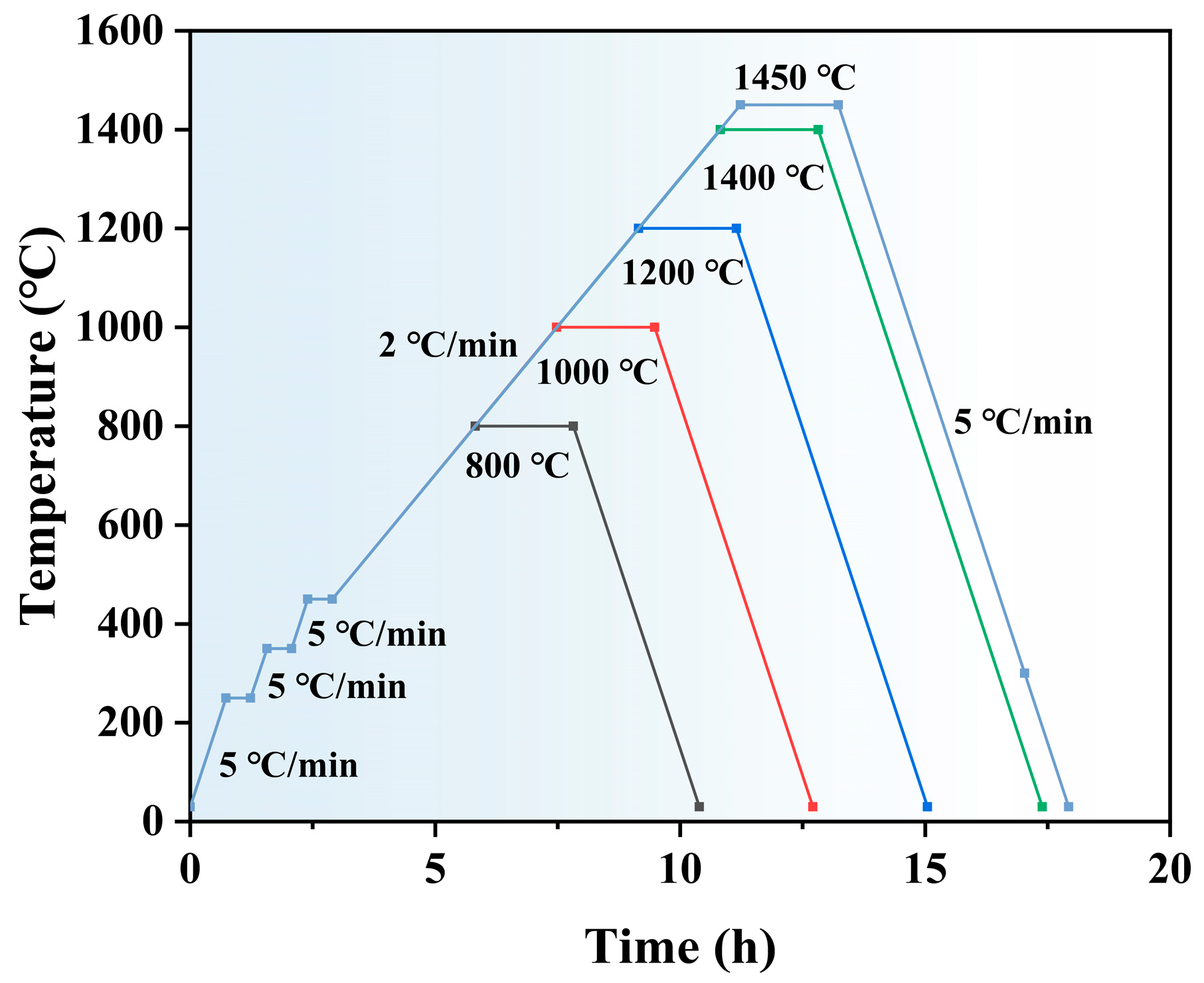

2.1. Green Body Printing and Sintering Process

2.2. Material Property Characterization

3. Results and Discussion

3.1. Density

3.2. Phase Composition Analysis

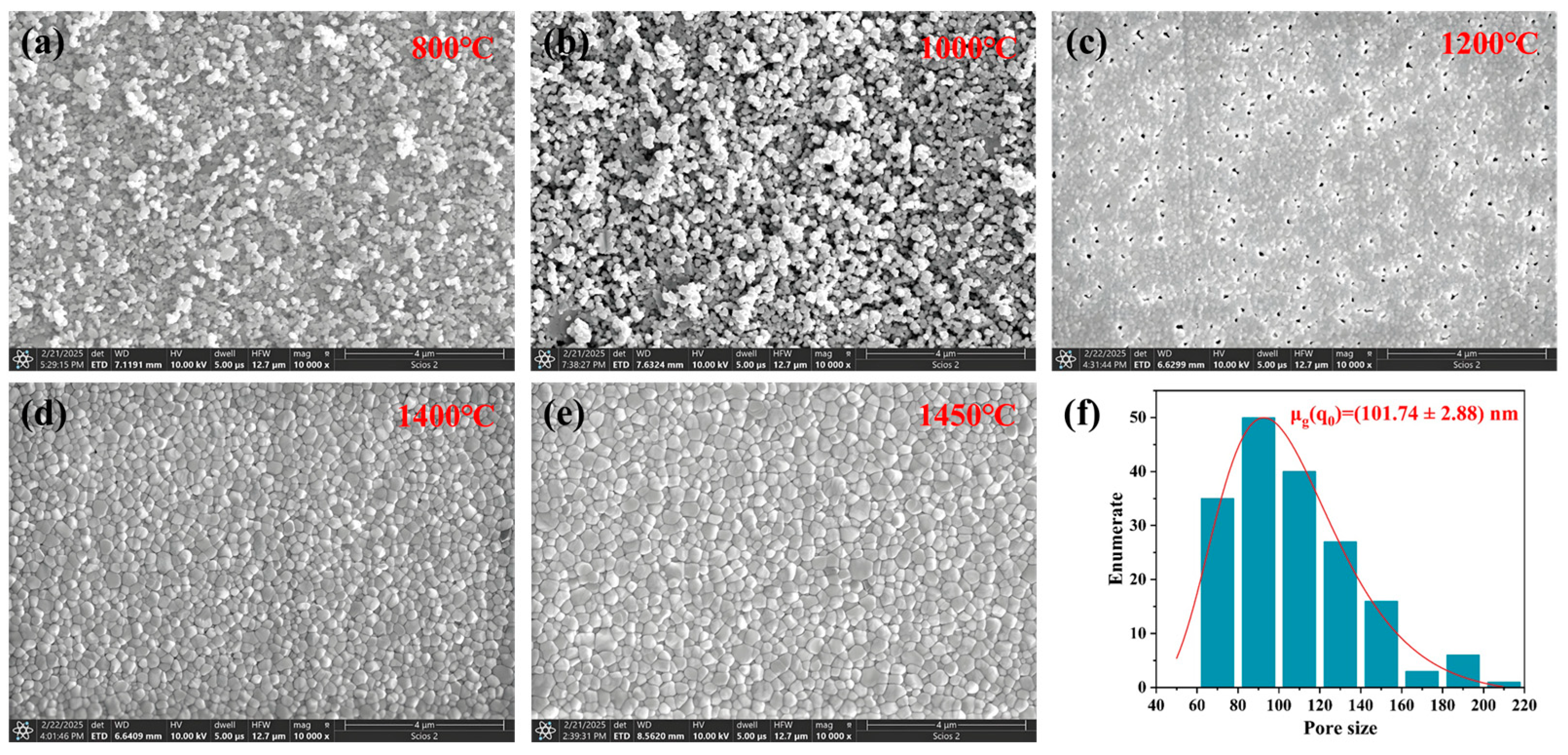

3.3. Microstructure and Flexure Strength

4. Conclusions

- The NPJ green body is composed of m-ZrO2 and t-ZrO2. At a sintering temperature of 1000 °C, m-ZrO2 has completely transformed into t-ZrO2, and only t-ZrO2 is observed in samples sintered at higher temperatures.

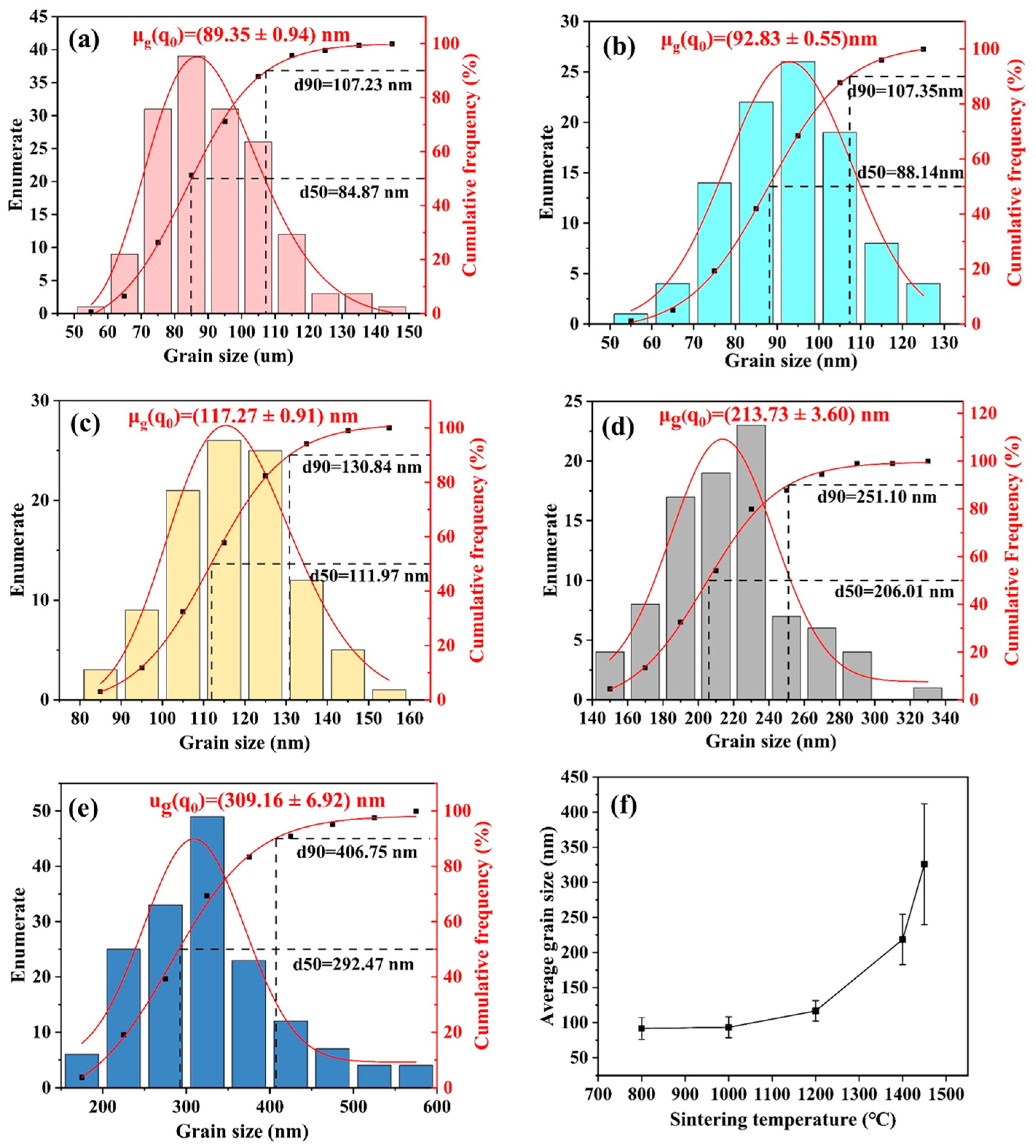

- As the sintering temperature increases from 800 °C to 1450 °C, the average grain size of zirconia increases from 89.35 nm to 309.16 nm, while its relative density rises from 55.0% to 98.3%.

- At sintering temperatures of 800 °C and 1000 °C, the flexural strength of sintered zirconia increases only slightly. When the sintering temperature rises from 1000 °C to 1200 °C, the flexural strength significantly increases from 36.8 MPa to 271.9 MPa, representing 67.8% of the total flexural strength gain. After sintering at 1450 °C, zirconia ceramic achieves a flexural strength of 356.1 MPa. The improvement in zirconia’s flexural strength is primarily attributed to a combination of grain size and porosity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Degidi, M.; Artese, L.; Scarano, A.; Perrotti, V.; Gehrke, P.; Piattelli, A. Inflammatory infiltrate, microvessel density, nitric oxide synthase expression, vascular endothelial growth factor expression, and proliferative activity in peri–implant soft tissues around titanium and zirconium oxide healing caps. J. Periodont. 2006, 77, 77. [Google Scholar] [CrossRef] [PubMed]

- Renuka, L.; Anantharaju, K.S.; Sharma, S.C.; Nagabhushana, H.; Vidya, Y.S.; Nagaswarupa, H.P.; Prashantha, S.C. A comparative study on the structural, optical, electrochemical and photocatalytic properties of ZrO2 nanooxide synthesized by different routes. J. Alloys Compd. 2017, 695, 382–395. [Google Scholar] [CrossRef]

- Piconi, C.; Maccauro, G. Zirconia as a ceramic biomaterial. Biomaterials 1999, 20, 1–25. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.W.; Moussi, J.; Drury, J.L.; Wataha, J.C. Zirconia in biomedical applications. Exp. Rev. Med. Devices 2016, 13, 945–963. [Google Scholar] [CrossRef]

- Zhang, X.P.; Wu, X.; Shi, J. Additive manufacturing of zirconia ceramics: A state-of-the-art review. J. Mater. Res. Technol-JMRT 2020, 9, 9029–9048. [Google Scholar] [CrossRef]

- Miller, R.A. Current status of thermal barrier coatings—An overview. Surf. Coat. Tech. 1987, 30, 1–11. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Duraccio, D.; Mussano, F.; Faga, M.G. Biomaterials for dental implants: Current and future trends. J. Mater. Sci. 2015, 50, 4779–4812. [Google Scholar] [CrossRef]

- Yin, Y.K.; Xu, J.Y.; Ji, M.; Li, L.F.; Chen, M. A critical review on sintering and mechanical processing of 3Y-TZP ceramics. Ceram. Int. 2023, 49, 1549–1571. [Google Scholar] [CrossRef]

- Stefanescu, C.; Ionita, C.; Nechita, V.; Drafta, S.; Oancea, L.; Petre, A. Survival Rates and Complications for Zirconia–Based Fixed Dental Prostheses in a Period up to 10 Years: A Systematic Review. Eur. J. Prosthodont. Restor. Dent. 2018, 26, 54–61. [Google Scholar] [CrossRef] [PubMed]

- Gautam, C.; Joyner, J.; Gautam, A.; Rao, J.; Vajtai, R. Zirconia based dental ceramics: Structure, mechanical properties, biocompatibility and applications. Dalton Trans. 2016, 45, 19194–19215. [Google Scholar] [CrossRef] [PubMed]

- Soon, G.; Murphy, B.P.; Lai, K.W.; Akbar, S.A. Review of zirconia-based bioceramic: Surface modification and cellular response. Ceram. Int. 2016, 42, 12543–12555. [Google Scholar] [CrossRef]

- Camacho, D.D.; Clayton, P.; O’brien, W.J.; Ferron, R.; Juenger, M.; Salamone, S.; Seepersad, C. Applications of additive manufacturing in the construction industry—A forward–looking review. Autom. Constr. 2018, 89, 110–119. [Google Scholar] [CrossRef]

- Prakash, K.S.; Nancharaih, T.; Rao, V.V.S. Additive Manufacturing Techniques in Manufacturing—An Overview. Mater. Today Process. 2018, 5, 3873–3882. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021; Additive Manufacturing–General Principles Fundamentals and Vocabulary. ISO: Geneva, Switzerland, 2021.

- Zhao, X.; Evans, J.R.G.; Edirisinghe, M.J.; Song, J.H. Formulation of a ceramic ink for a wide–array drop-on-demand ink-jet printer. Ceram. Int. 2003, 29, 887–892. [Google Scholar] [CrossRef]

- Ma, J.; Wan, H.B.; Peng, F.; Chen, H.Y.; Chen, C.; Chen, P.Q.; Tufa, H.B.; Chen, H.; Ren, K.; Lyu, B.H. Study on grain removal characteristics and influencing factors of polycrystalline tungsten during polishing process. Precis. Eng. 2024, 91, 499–506. [Google Scholar] [CrossRef]

- Zhao, X.; Evans, J.R.G.; Edirisinghe, M.J.; Song, J.H. Ink-jet printing of ceramic pillar arrays. J. Mater. Sci. 2002, 37, 1987–1992. [Google Scholar] [CrossRef]

- Lian, Q.; Sui, W.Q.; Wu, X.Q.; Yang, F.; Yang, S.P. Additive manufacturing of ZrO2 ceramic dental bridges by stereolithography. Rapid Prototyping J. 2017, 24, 114–119. [Google Scholar] [CrossRef]

- Wang, L.; Wu, M.X.; Chen, H.Y.; Hang, W.; Wang, X.; Han, Y.X.; Chen, H.; Chen, P.Q.; Beri, T.H.; Luo, L.M.; et al. Damage evolution and plastic deformation mechanism of passivation layer during shear rheological polishing of polycrystalline tungsten. J. Mater. Res. Technol. 2024, 28, 1584–1596. [Google Scholar] [CrossRef]

- Bertrand, P.; Bayle, F.; Combe, C.; Goeuriot, P.; Smurov, I. Ceramic components manufacturing by selective laser sintering. Appl. Surf. Sci. 2007, 254, 989–992. [Google Scholar] [CrossRef]

- Wilkes, J.; Hagedorn, Y.-C.; Meiners, W.; Wissenbach, K. Additive manufacturing of ZrO2-Al2O3 ceramic components by selective laser melting. Rapid Prototyping J. 2013, 19, 51–57. [Google Scholar] [CrossRef]

- Wang, L.; Hong, B.B.; Chen, H.Y.; Qi, H.; Zhang, J.G.; Hang, W.; Han, Y.X.; Wang, J.H.; Ren, K.; Lyu, B.H. Enhancing tungsten machinability via laser pretreatment for abrasive particles-based shear rheological polishing. Powder Technol. 2025, 455, 120758. [Google Scholar] [CrossRef]

- Sa, M.-W.; Nguyen, B.-N.B.; Moriarty, R.A.; Kamalitdinov, T.; Fisher, J.P.; Kim, J.Y. Fabrication and evaluation of 3D printed BCP scaffolds reinforced with ZrO2 for bone tissue applications. Biotechnol. Bioeng. 2018, 115, 989–999. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.X.; Bu, Y.Y.; Wang, X.F. Advances in 3D printing of structural and functional ceramics: Technologies, properties, and applications. J. Eur. Ceram. Soc. 2024, 44, 116653. [Google Scholar] [CrossRef]

- Budharaju, H.; Suresh, S.; Sekar, M.P.; Vega, B.D.; Sethuraman, S.; Sundaramurthi, D.; Kalaskar, D.M. Ceramic materials for 3D printing of biomimetic bone scaffolds—Current state-of-the-art & future perspectives. Mater. Des. 2023, 231, 112064. [Google Scholar] [CrossRef]

- Wu, Y.L.; Lu, Y.T.; Zhao, M.; Bosiakov, S.; Li, L. A Critical Review of Additive Manufacturing Techniques and Associated Biomaterials Used in Bone Tissue Engineering. Polymers 2022, 14, 2117. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Pan, Z.X.; Wang, D.; Guo, X.; Li, Y.M.; Zhang, Z.B.; Xu, C.H. High strength and microwave-absorbing polymer-derived SiCN honeycomb ceramic prepared by 3D printing. J. Eur. Ceram. Soc. 2022, 42, 1322–1331. [Google Scholar] [CrossRef]

- Dadkhah, M.; Tulliani, J.-M.; Saboori, A.; Iuliano, L. Additive manufacturing of ceramics: Advances, challenges, and outlook. J. Eur. Ceram. Soc. 2023, 43, 6635–6664. [Google Scholar] [CrossRef]

- Wang, G.Q.; Wang, S.R.; Dong, X.S.; Zhang, Y.J.; Shen, W. Recent progress in additive manufacturing of ceramic dental restorations. J. Mater. Res. Technol–JMRT 2023, 26, 1028–1049. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Shen, M.M.; Wei, M.; Wu, L.W.; Han, Y.X.; Hong, B.B.; Lyu, B.H.; Chen, H.Y.; Hang, W. Dominant parameters and mechanisms influencing the electrochemical shear-thickening polishing of 4H-SiC. Ceram. Int. 2025, 51, 10351–10364. [Google Scholar] [CrossRef]

- Juste, E.; Petit, F.; Lardot, V.; Cambier, F. Shaping of ceramic parts by selective laser melting of powder bed. J. Mater. Res. 2014, 29, 2086–2094. [Google Scholar] [CrossRef]

- Chen, H.Y.; Wang, L.; Peng, F.; Shen, M.M.; Hang, W.; Tufa, H.B.; Zhang, H.B.; Zhao, J.; Han, Y.X.; LYU, B.H. Efficient chemical mechanical polishing of W promoted by Fenton-like reaction between Cu2+ and H2O2. Trans. Nonferrous Met. Soc. China 2025, 35, 257–270. [Google Scholar] [CrossRef]

- Wätjen, A.; Gingter, P.; Kramer, M.; Telle, R. Novel Prospects and Possibilities in Additive Manufacturing of Ceramics by means of Direct Inkjet Printing. Adv. Mech. Eng. 2014, 6, 141346. [Google Scholar] [CrossRef]

- Chen, H.Y.; Wan, H.B.; Hong, B.B.; Hang, W.; Zhu, T.; Zhang, P.; Cao, X.Z.; Xu, Q.; Wang, R.; Han, X.F.; et al. A novel liquid film shearing polishing technique for silicon carbide and its processing damage mechanisms. Appl. Surf. Sci. 2025, 688, 162317. [Google Scholar] [CrossRef]

- Lejeune, M.; Chartier, T.; Dossou-Yovo, C.; Noguera, R. Ink-jet printing of ceramic micro–pillar arrays. J. Eur. Ceram. Soc. 2009, 29, 905–911. [Google Scholar] [CrossRef]

- Willems, E.; Turon-Vinas, M.; Santos, B.C.D.; Van-Hooreweder, B.; Zhang, F.; Meerbeek, B.V.; Vleugels, J. Additive manufacturing of zirconia ceramics by material jetting. J. Eur. Ceram. Soc. 2021, 41, 5292–5306. [Google Scholar] [CrossRef]

- Zhong, S.P.; Shi, Q.M.; Deng, Y.L.; Sun, Y.; Politis, C.; Yang, S.F. High-performance zirconia ceramic additively manufactured via NanoParticle Jetting. Ceram. Int. 2022, 48, 33485–33498. [Google Scholar] [CrossRef]

- Teng, M.H.; Lai, Y.C.; Chen, Y.T. A computer program of master sintering curve model to accurately predict sintering results. West. Pac. Earth. Sci. 2002, 2, 171–180. [Google Scholar]

- Hong, B.B.; Chen, Y.Y.; Chen, H.Y.; Zhu, T.; Zhang, P.; Cao, X.Z.; Zhao, X.Y.; Luo, L.M.; Chen, P.Q.; Li, H.F.; et al. Liquid film shearing polishing for high quality and low damage tungsten surface: Process optimization, removal mechanism, and processing defects. Int. J. Refract. Met. Hard Mat. 2025, 131, 107189. [Google Scholar] [CrossRef]

- Madeira, S.; Pinto, A.M.P.; Rodrigues, L.C.; Carvalho, O.; Miranda, G.; Reis, R.L.; Caramês, J.; Silva, F.S. Effect of sintering pressure on microstructure and mechanical properties of hot-pressed Ti6Al4V-ZrO2 materials. Mater. Des. 2017, 120, 394–403. [Google Scholar] [CrossRef]

- Panthi, D.; Hedayat, N.; Du, Y.H. Densification behavior of yttria–stabilized zirconia powders for solid oxide fuel cell electrolytes. J. Adv. Ceram. 2018, 7, 39–49. [Google Scholar] [CrossRef]

- Shen, M.M.; Wei, M.; Wu, L.W.; Hong, B.B.; Ye, J.H.; Chen, H.Y.; Yuan, J.L.; Lyu, B.H.; Wang, C.S.; Deng, H.; et al. Microwave plasma modification-assisted shear-thickening polishing of single-crystal silicon carbide. Precis. Eng. 2025, 94, 13–25. [Google Scholar] [CrossRef]

- Mazaheri, M.; Simchi, A.; Golestani-Fard, F. Densification and grain growth of nanocrystalline 3Y–TZP during two-step sintering. J. Eur. Ceram. Soc. 2008, 28, 2933–2939. [Google Scholar] [CrossRef]

- Grech, J.; Antunes, E. Optimization of two–step sintering conditions of zirconia blanks for dental restorations. Ceram. Int. 2020, 46, 24792–24798. [Google Scholar] [CrossRef]

- Denry, I.; Holloway, J.A. Ceramics for Dental Applications: A Review. Materials 2010, 3, 351–368. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Özcan, M.; Hallmann, L.; Ender, A.; Mehl, A.; Hämmerlet, C.H.F. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin. Oral Investig. 2013, 17, 269–274. [Google Scholar] [CrossRef]

- Hu, L.F.; Wang, C.-A. Effect of sintering temperature on compressive strength of porous yttria–stabilized zirconia ceramics. Ceram. Int. 2010, 36, 1697–1701. [Google Scholar] [CrossRef]

- Ji, M.; Xu, J.Y.; Yu, D.D.; Chen, M.; Mansori, M.E. Influence of sintering temperatures on material properties and corresponding milling machinability of zirconia ceramics. J. Manuf. Process 2021, 68, 646–656. [Google Scholar] [CrossRef]

- Nonaka, K.; Takeuchi, N.; Morita, T.; Pezzotti, G. Evaluation of the effect of high–speed sintering on the mechanical and crystallographic properties of dental zirconia sintered bodies. J. Eur. Ceram. Soc. 2023, 43, 510–520. [Google Scholar] [CrossRef]

- Oh, Y.; Bharambe, V.; Mummareddy, B.; Martin, J.; McKnight, J.; Abraham, M.A.; Walker, J.M.; Rogers, K.; Conner, B.; Cortes, P.; et al. Microwave dielectric properties of zirconia fabricated using NanoParticle JettingTM. Addit. Manuf. 2019, 27, 586594. [Google Scholar] [CrossRef]

- Chen, Y.A.; Tan, J.L.; Sun, J.X.; Guo, H.S.; Bai, J.M.; Zhou, P.; Zhang, D.Y.; Liu, G. Effect of sintering temperature on the microstructures and mechanical properties of ZrO2 ceramics fabricated by additive manufacturing. Ceram. Int. 2024, 50, 11392–11399. [Google Scholar] [CrossRef]

- Toraya, H.; Yoshimura, M.; Somiya, S. Calibration Curve for Quantitative Analysis of the Monoclinic-Tetragonal ZrO2 System by X-Ray Diffraction. J. Am. Ceram. Soc. 1984, 67, C-119–C-121. [Google Scholar] [CrossRef]

- Malow, T.R.; Koch, C.C. Grain growth in nanocrystalline iron prepared by mechanical attrition. Acta Mater. 1997, 45, 2177–2186. [Google Scholar] [CrossRef]

- Liu, Y.S.; Liu, Y.S.; She, W.T.; Li, W.B.; Cao, Y.J.; Wang, J. Influence of sintering temperature on the thermal conductivity of digital light processing 3D-printed yttria-stabilized zirconia ceramic. Ceram. Int. 2023, 49, 27514–27525. [Google Scholar] [CrossRef]

- Rice, R.W. Limitations of pore-stress concentrations on the mechanical properties of porous materials. J. Mater. Sci. 1997, 32, 4731–4736. [Google Scholar] [CrossRef]

- Rice, R.W. Comparison of physical property-porosity behaviour with minimum solid area models. J. Mater. Sci. 1996, 31, 1509–1528. [Google Scholar] [CrossRef]

| Slurry Type | Ingredient |

|---|---|

| Zirconia ceramic slurry | Zirconia 40–45 wt.%, ethylene glycol 53–58 wt.%, polyvinyl alcohol polymer and other additives is 1.0–3.0 wt.% |

| Support slurry | Sodium carbonate 27–32 wt.%, glycol 65–70 wt.%, other additives such as polyphosphate polymers ≤ 2.0 wt.% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Li, X.; Chen, H.; Ren, K.; Guo, H.; Qi, H. Effect the Sintering Temperature on the Microstructure and Flexural Strength of ZrO2 Ceramics Produced by NanoParticle Jetting. Materials 2025, 18, 2605. https://doi.org/10.3390/ma18112605

Huang Y, Li X, Chen H, Ren K, Guo H, Qi H. Effect the Sintering Temperature on the Microstructure and Flexural Strength of ZrO2 Ceramics Produced by NanoParticle Jetting. Materials. 2025; 18(11):2605. https://doi.org/10.3390/ma18112605

Chicago/Turabian StyleHuang, Youji, Xiaorong Li, Hongyu Chen, Kun Ren, Huijun Guo, and Huan Qi. 2025. "Effect the Sintering Temperature on the Microstructure and Flexural Strength of ZrO2 Ceramics Produced by NanoParticle Jetting" Materials 18, no. 11: 2605. https://doi.org/10.3390/ma18112605

APA StyleHuang, Y., Li, X., Chen, H., Ren, K., Guo, H., & Qi, H. (2025). Effect the Sintering Temperature on the Microstructure and Flexural Strength of ZrO2 Ceramics Produced by NanoParticle Jetting. Materials, 18(11), 2605. https://doi.org/10.3390/ma18112605