1. Introduction

Asphalt pavement has gradually become the main choice for high-grade pavement in recent years due to its advantages such as low noise, high pavement smoothness, low maintenance cost and fast construction [

1,

2,

3]. However, during the service of asphalt pavement, asphalt pavement may suffer from potholes, rutting, cracks and other faults due to the influence of the environment and traffic loads [

4,

5]. Because of the formation of cracks, rainwater and dust can seep into the interior of the pavement structure. From this, more serious faults will occur, which will greatly reduce the service life of the asphalt pavement [

6]. Therefore, it is necessary to carry out continuous maintenance to extend the service life of asphalt pavement, which will consume a lot of energy and economy [

7,

8]. To reduce energy consumption and economic expenditure, scholars have begun to focus on self-healing asphalt and asphalt mixtures. Although asphalt has a certain self-healing ability under natural conditions, it is not sufficient to repair cracks caused by traffic loads or environmental changes in a timely manner. Therefore, it is necessary to improve the self-healing ability of asphalt to prolong the service life of asphalt pavement [

9,

10].

At present, the most common and widely used methods to increase the self-healing property of asphalt include rejuvenator encapsulation, induction heating and microwave heating methods [

11,

12,

13]. The rejuvenator encapsulation method needs to encapsulate the rejuvenator into a microcapsule and then mix the microcapsule with an asphalt mixture. The microcapsules will rupture when a crack appears, and the rejuvenator will be released to fill and repair the crack [

14,

15,

16]. The induction heating method needs to add metal fibers or other conductive materials to asphalt, and then use electromagnetic induction to generate energy inside the asphalt, which will heat the asphalt material and heal the cracks. Through induction heating, the internal temperature of the asphalt mixture can be effectively increased, which will increase the self-healing performance of the asphalt mixture [

17,

18]. What is more, indoor tests have shown that using induction heating technology on asphalt mixtures can increase the service life of asphalt pavements by 30% [

19]. However, it is worth noting that induction heating can only be applied to cracks within a certain width range [

20]. Compared with induction heating, microwave heating has better heating efficiency and a wider range of applications [

21,

22]. Moreover, the microwave heating effect is more significant and the self-healing property of asphalt will be better when a smaller amount of metal materials are added to asphalt. [

23,

24].

Although the above methods can effectively enhance the self-healing ability of asphalt mixtures, there are still shortcomings in practical applications. Microcapsule technology can effectively improve the self-healing ability of asphalt pavement cracks, but the rejuvenator in microcapsules is limited. When cracks occur again in the same location, the self-healing property of asphalt will decrease due to the decrease in microcapsules. Induction heating and microwave heating methods can repair cracks multiple times. However, many microcracks are difficult to detect promptly, so it is easy to miss the best repair opportunity. Based on the shortcomings of current methods, scholars have begun to improve the self-healing property by introducing dynamic covalent bonds into asphalt.

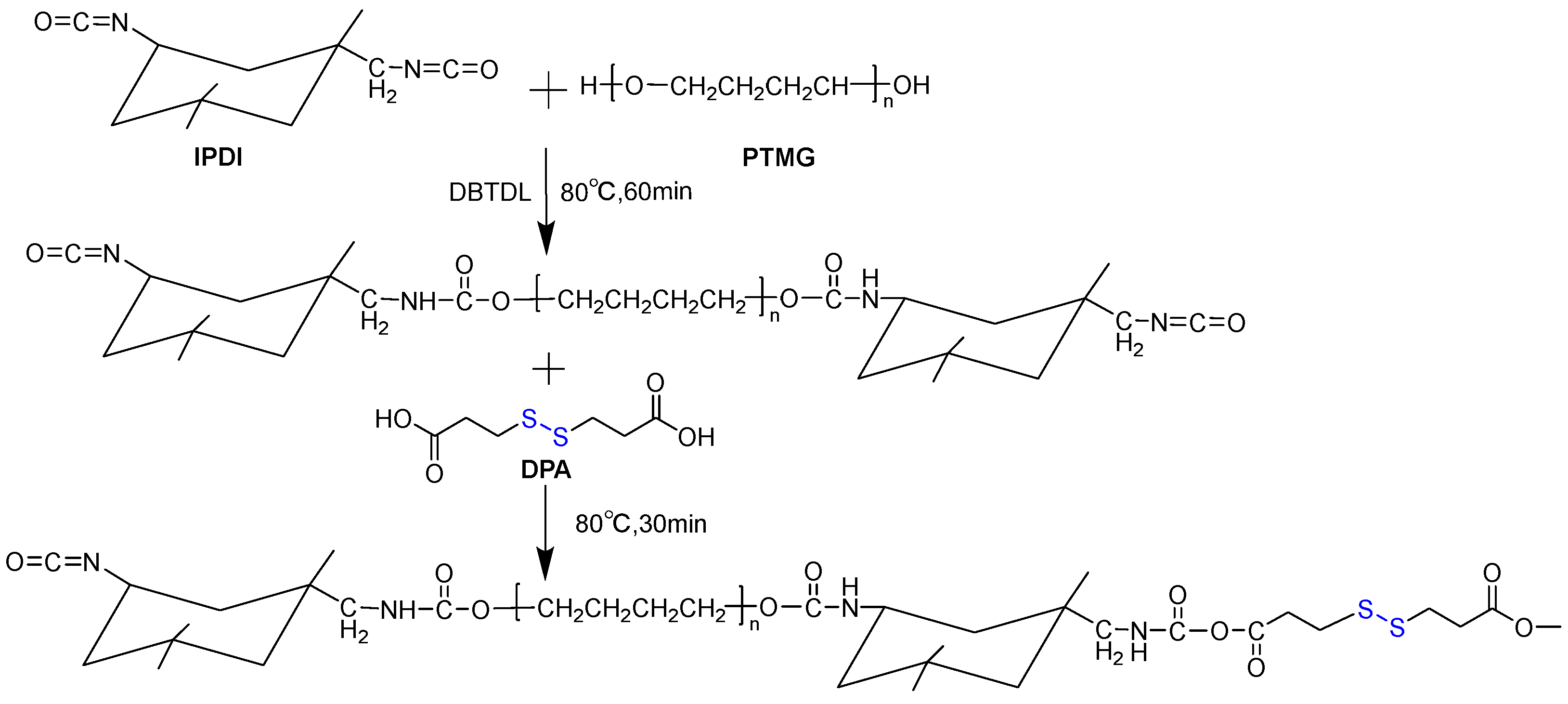

Li et al. [

25,

26] added PU-containing dynamic disulfide bonds to asphalt for modification. The results revealed that the self-healing PU had good compatibility with asphalt. The presence of disulfide bonds provided a foundation for improving the self-healing capability. Researchers also [

27,

28] evaluated the crack healing ability of PU-modified asphalt including dynamic disulfide bonds. The results showed that the presence of dynamic disulfide bonds could effectively increase the self-healing ability of microcracks in asphalt. Zhang [

29] synthesized S-SBS materials with dynamic covalent bonds by introducing disulfide bonds into the SBS structure, and then modified asphalt with S-SBS. The results indicated that the crack resistance and fracture healing ability were improved by introducing disulfide bonds into asphalt. In addition to disulfide bonds, diselenide bonds also have excellent dynamic exchangeability. Lyu et al. [

30] synthesized a kind of PU with dynamic diselenide bonds and applied it to asphalt modification. The results showed that dynamic diselenide bonds endowed asphalt with excellent fracture self-healing abilities. Yang et al. [

31] prepared modified asphalt containing dynamic disulfide and diselenide bonds, respectively, and compared the self-healing properties of these two types of modified asphalt. The results revealed that diselenide bonds had a greater effect on the short-term healing ability of asphalt, while the disulfide bonds had a greater effect on the long-term healing ability.

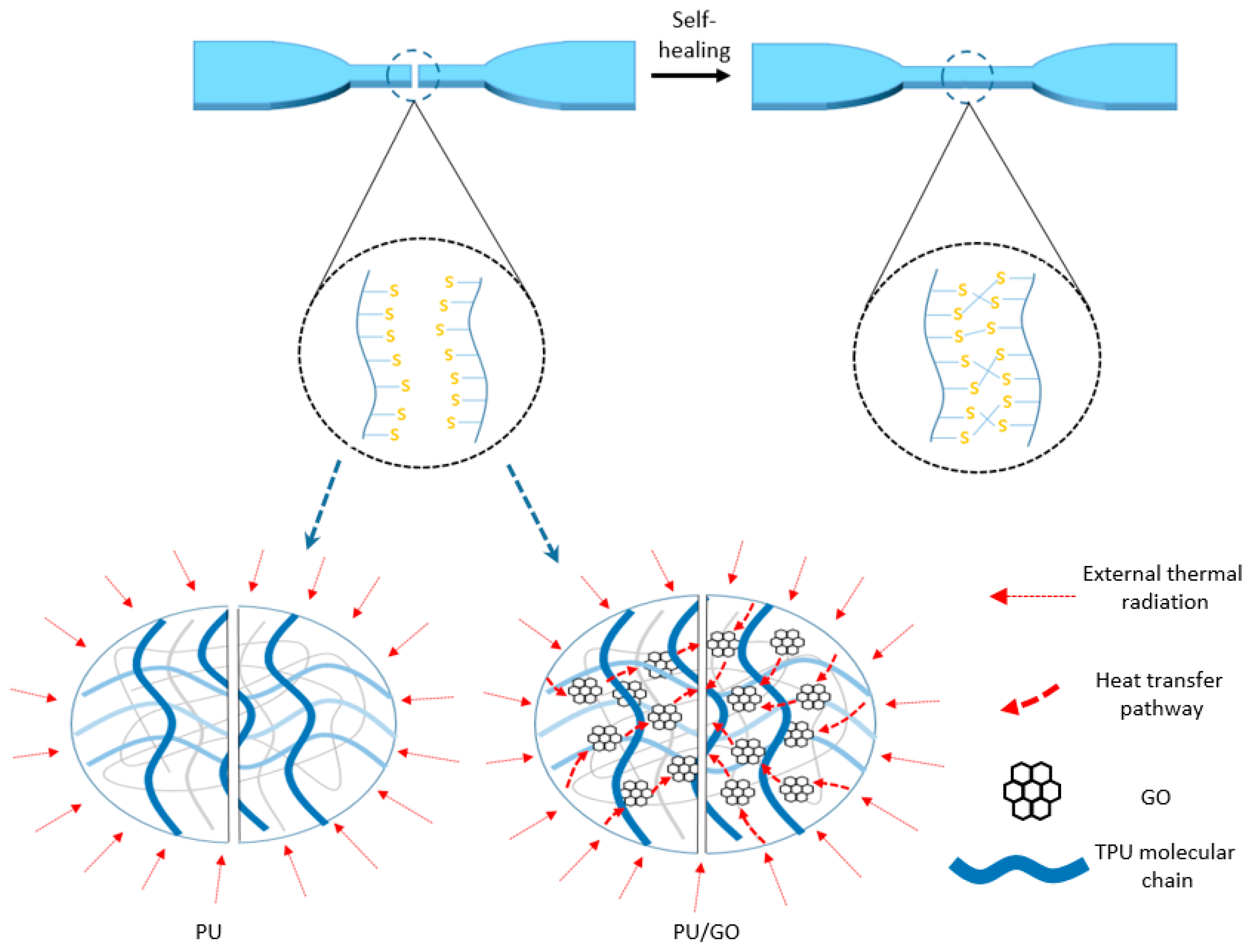

Based on the above research, it has been found that introducing dynamic covalent bonds into asphalt to enhance its self-healing ability is a feasible method. However, the recombination of dynamic covalent bonds is affected by temperature, and the higher the temperature, the higher the recombination efficiency of dynamic covalent bonds [

27,

28,

29,

30,

31]. Researchers have found that graphene has excellent thermal conductivity and infrared absorption ability. Therefore, introducing graphene into PU can improve the heat absorption efficiency of PU. Higher temperatures can enhance the efficiency of covalent bond recombination and improve the self-healing ability of PU [

32,

33]. Xu et al. [

34] even used graphene to modify asphalt mixtures. The results showed that graphene had excellent heat absorption ability, which could increase the surface temperature of asphalt mixtures and enhance the self-healing performance. Compared with graphene, graphene oxide (GO) also has excellent thermal conductivity and infrared absorption ability. At the same time, GO contains a large number of active functional groups, which can react with isocyanate in PU and have better dispersibility in PU. Li et al. [

35] designed and synthesized self-healing PU/GO materials with different GO contents through the Diels Alder (D-A) reaction. The results showed that the material had excellent self-healing function under heating, infrared, and microwave conditions.

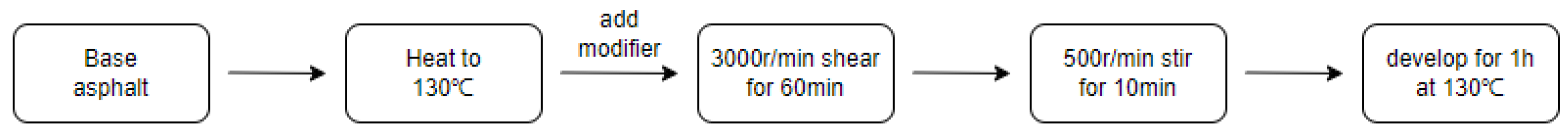

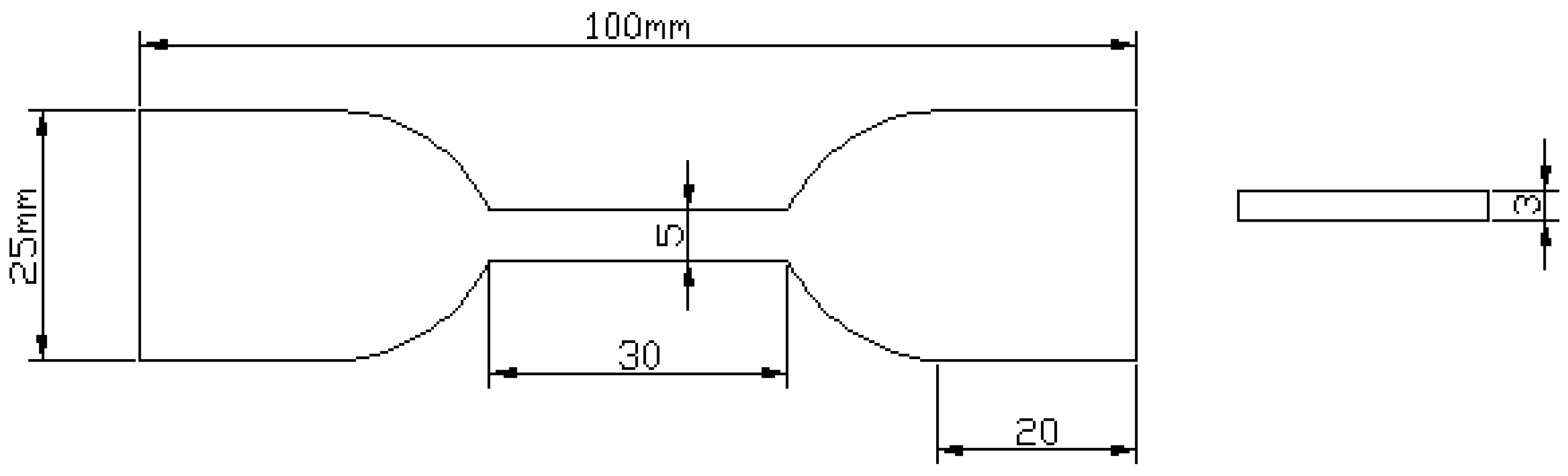

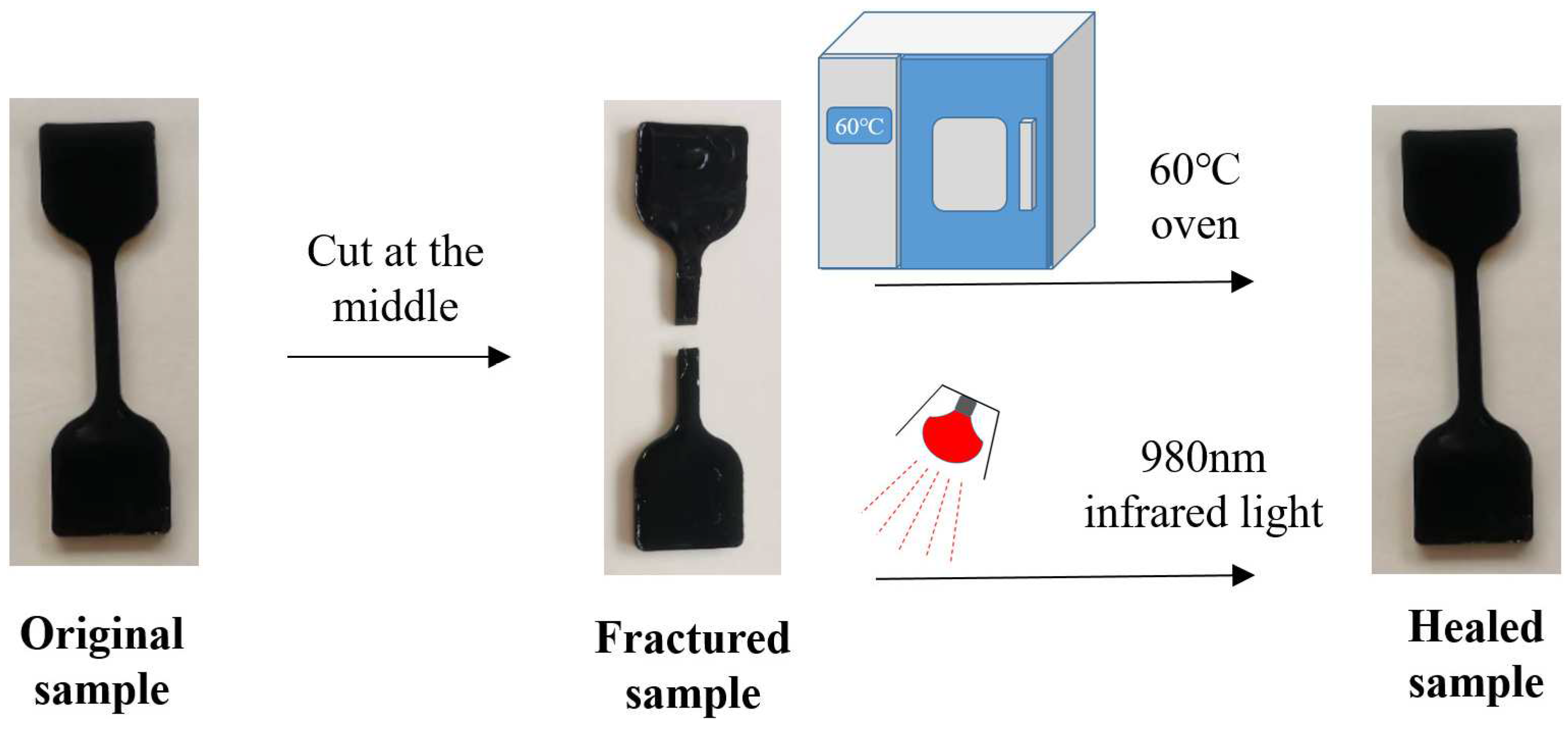

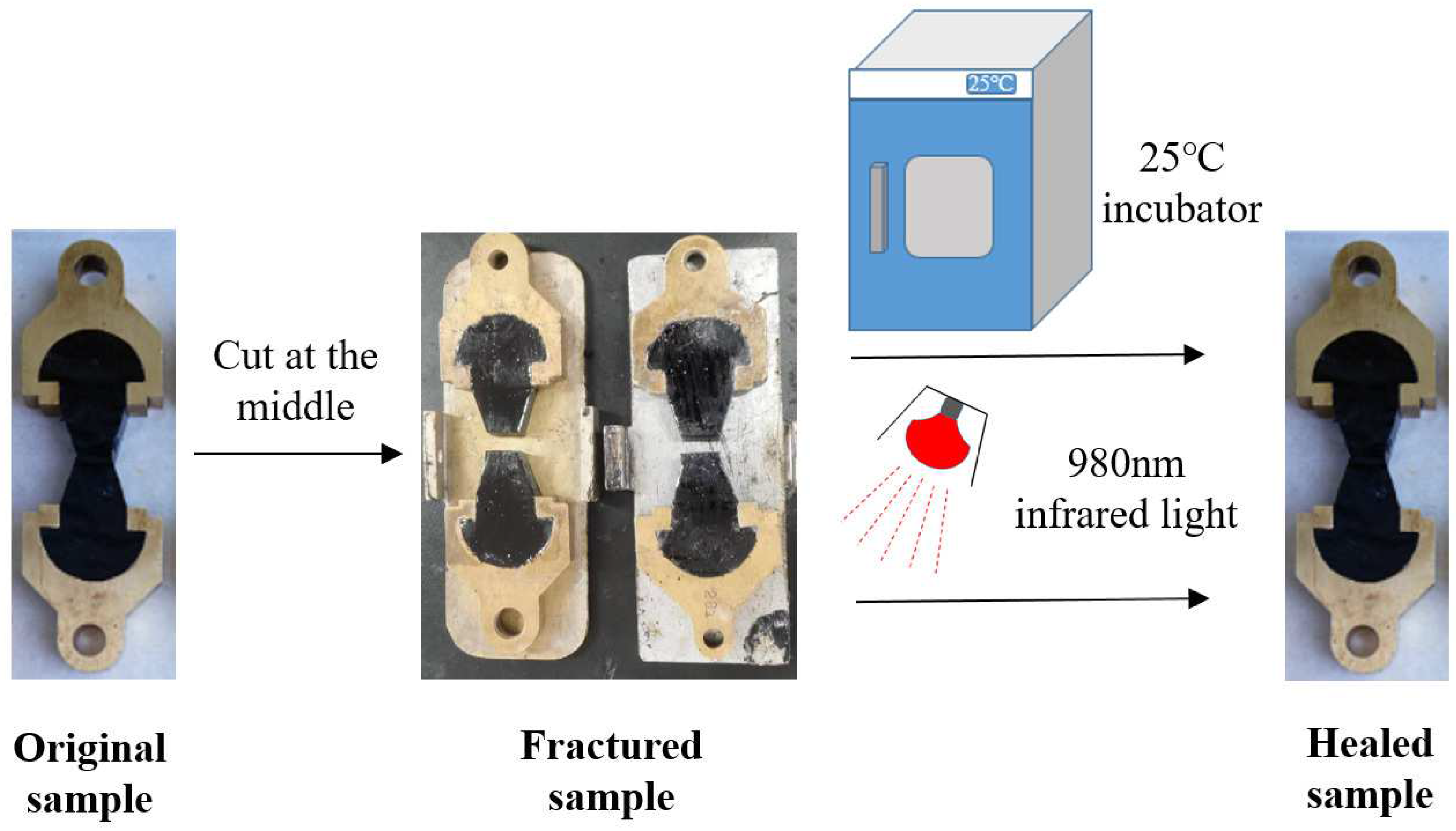

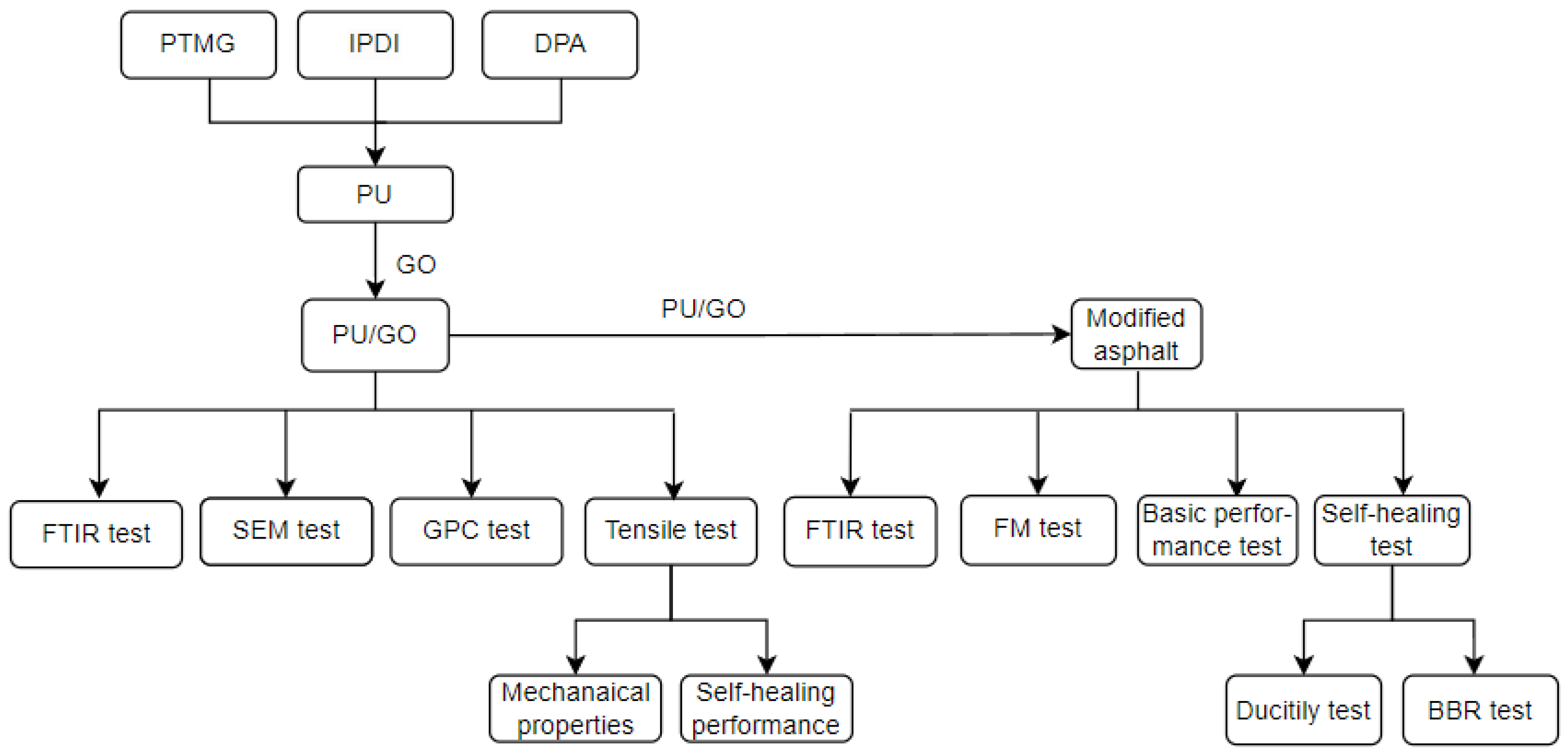

Based on the above discussion, it can be concluded that introducing dynamic covalent bonds into asphalt to improve the self-healing ability is a feasible method. Graphene or GO has excellent thermal conductivity and infrared absorption ability, which can improve the heat absorption efficiency and enhance the self-healing function. However, there is still a lack of research on the synergistic improvement of asphalt self-healing performance by dynamic covalent bonds and GO. Therefore, this study synthesized a kind of thermoplastic polyurethane containing dynamic covalent bonds, and then introduced GO into the PU to synthesize PU/GO composite materials. To explore the influence of GO on the self-healing function of PU under different conditions, two kinds of self-healing conditions were selected: heating condition at 60 °C and infrared light condition. Moreover, the effect of healing time on the self-healing property of PU/GO was also studied. Finally, PU/GO was added to asphalt to prepare modified asphalt with different PU/GO contents. In order to evaluate the self-healing performance of modified asphalt, self-healing tests based on ductility and BBR tests were conducted. Two kinds of self-healing conditions (25 °C room temperature and infrared light condition) were chosen to explore the effect of PU/GO on the self-healing property of asphalt under different conditions. In this study, the utilization of GO to improve the recombination efficiency of dynamic covalent bonds in PU and PU/GO-modified asphalt was investigated, which could provide a reference for the development of self-healing PU and asphalt materials.

4. Conclusions

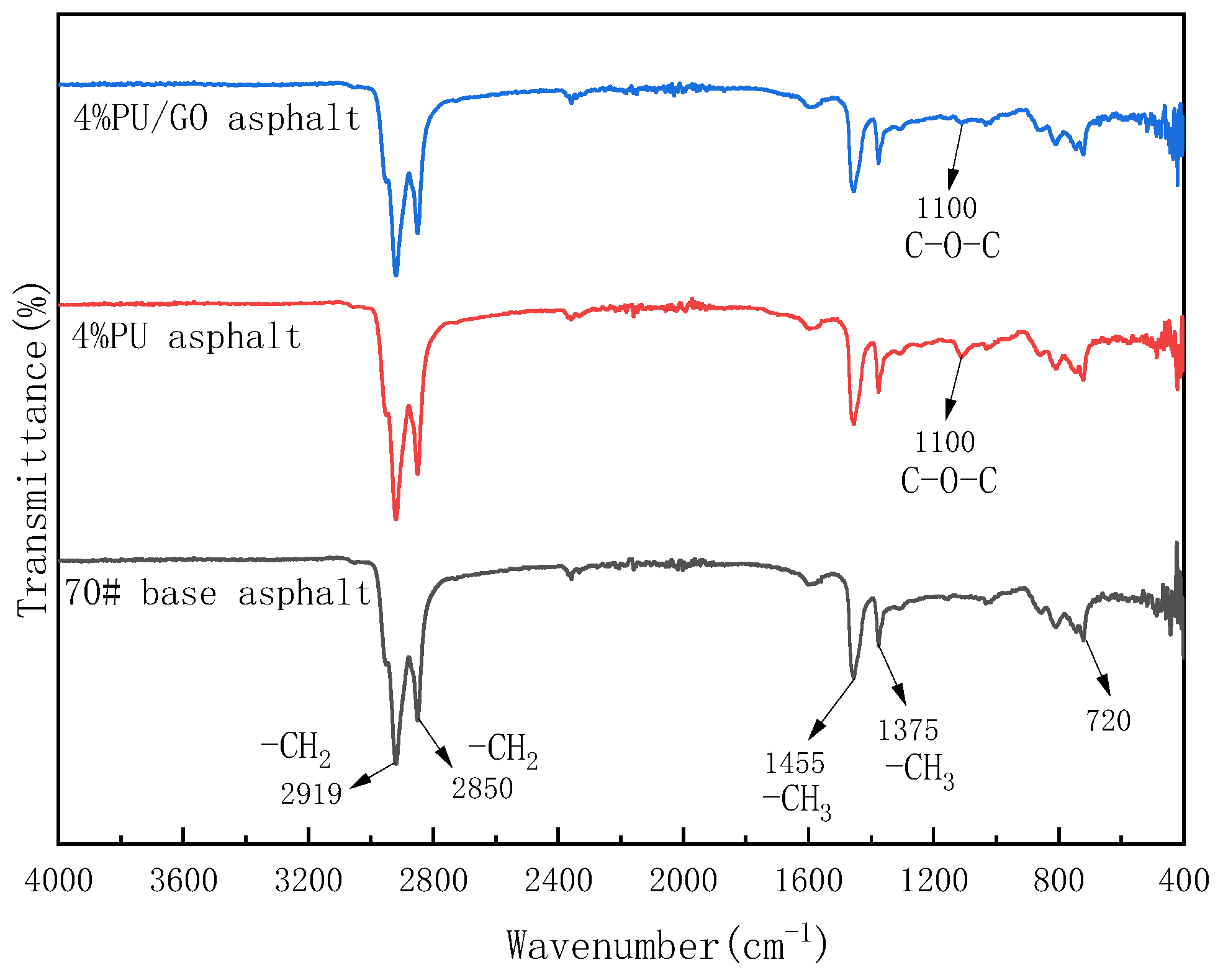

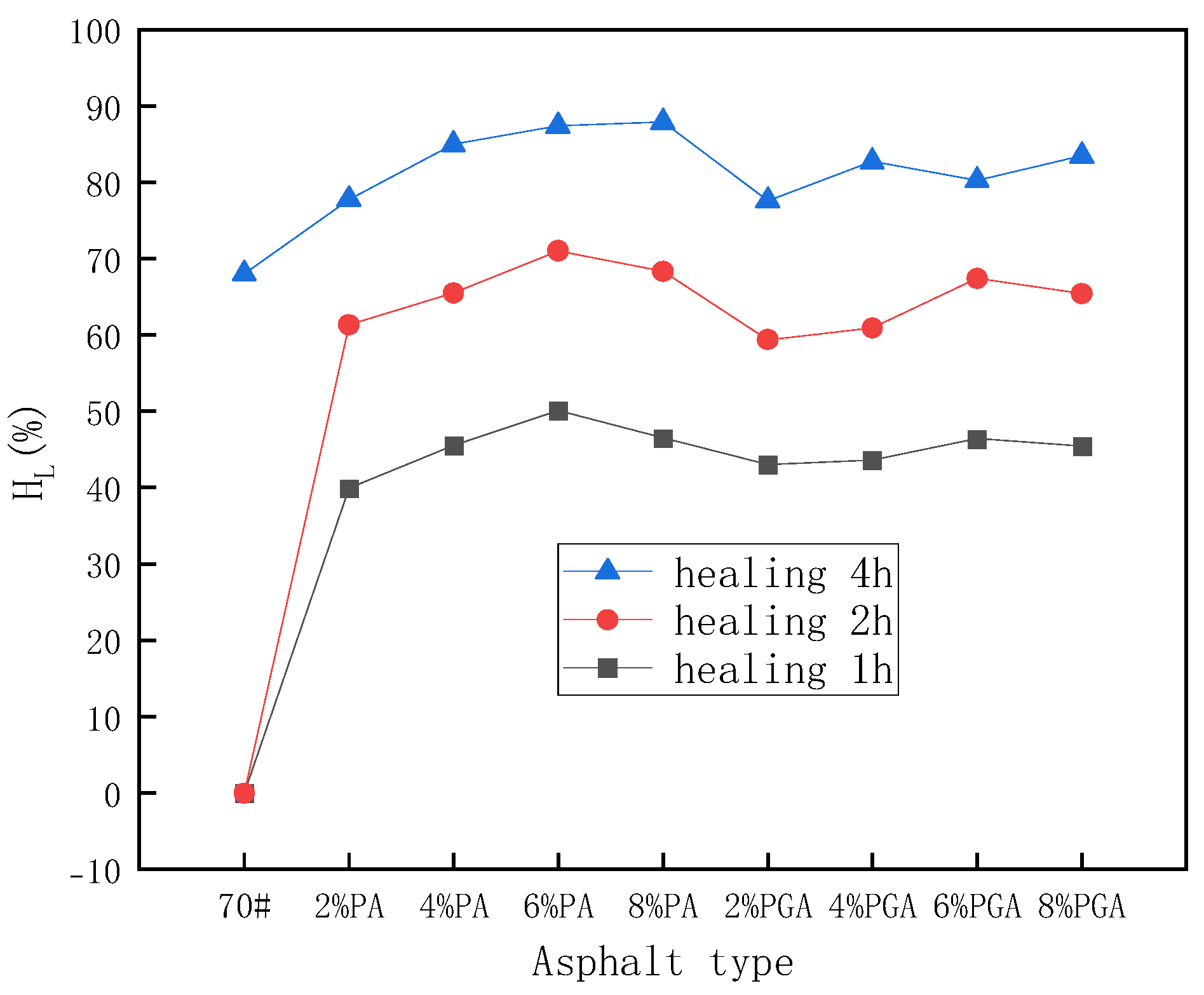

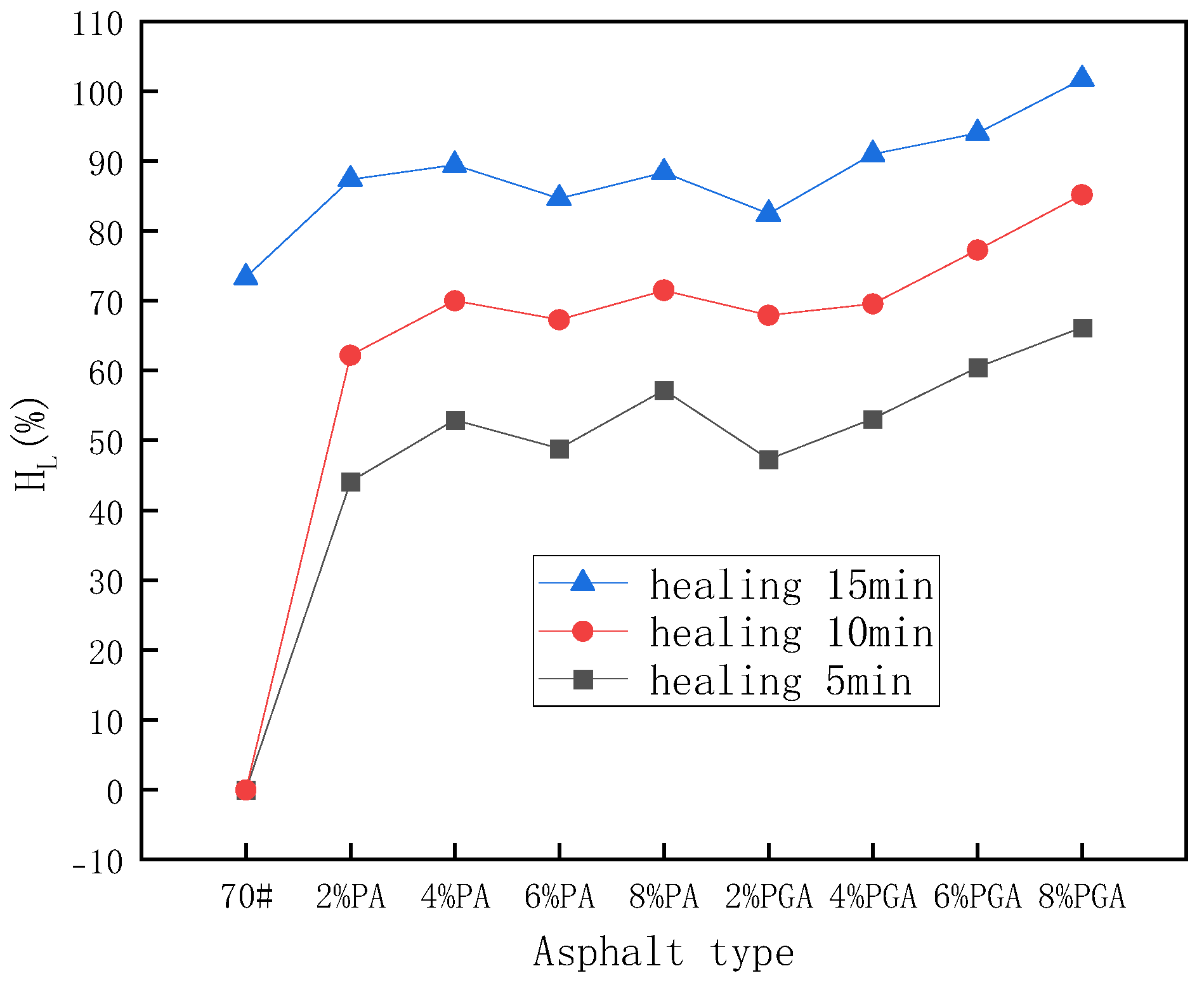

In this study, a composite material, PU/GO, containing dynamic disulfide bonds, was synthesized and used to modify asphalt. The basic and self-healing properties of PU/GO and PU/GO-modified asphalt were explored through FTIR, SEM, GPC, FM and self-healing tests. The key conclusions are as follows:

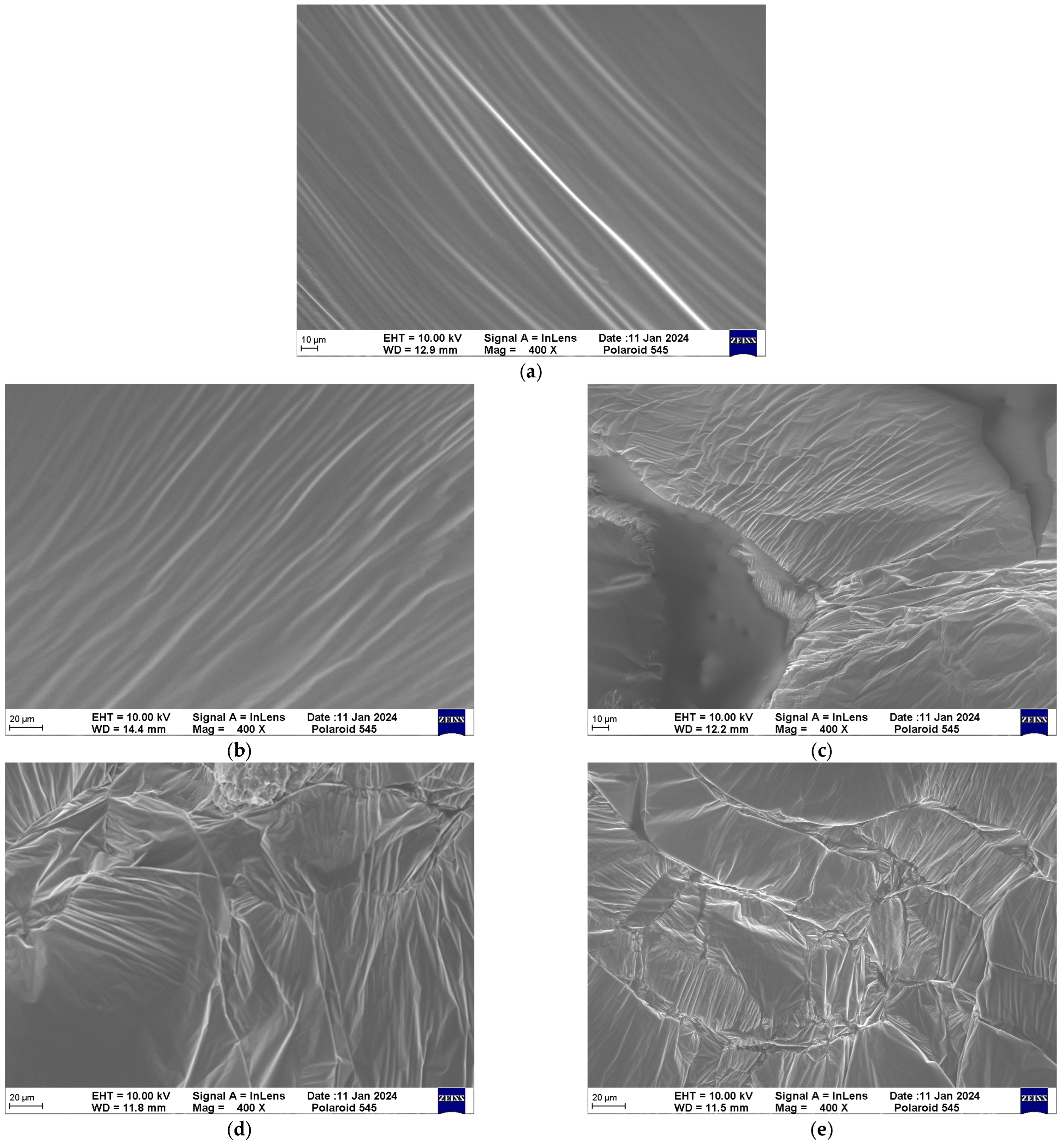

FTIR test results showed that PU/GO was successfully synthesized and the introduction of GO in PU increased the irregularity of PU micromorphology and decreased the molecular weight of PU.

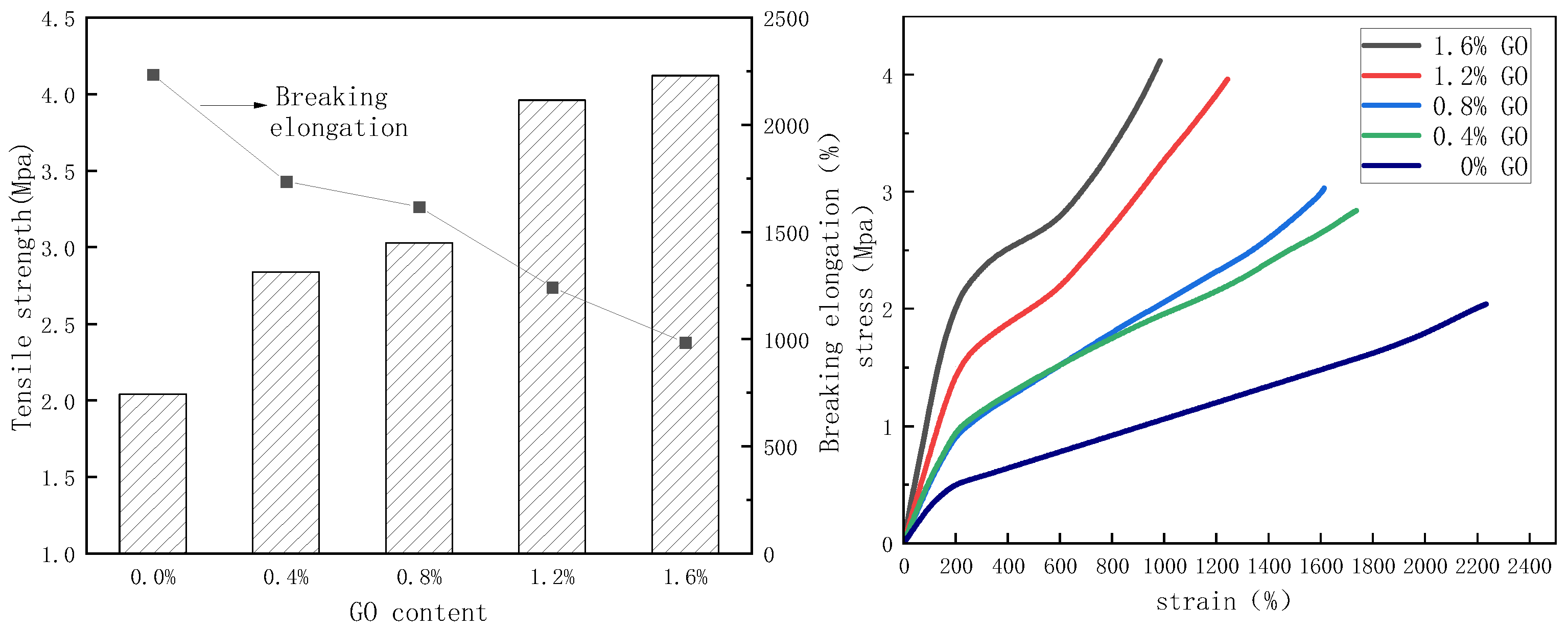

GO could significantly improve the mechanical properties of PU. Due to its excellent thermal conductivity and infrared absorption capability, GO had a positive impact on the early self-healing property of PU under 60 °C conditions and infrared light conditions.

GO had a slight negative impact on the final self-healing results because it hindered the movement of molecular chains to a certain extent.

PU/GO could be well dispersed in asphalt and significantly improve the low-temperature flexibility of base asphalt.

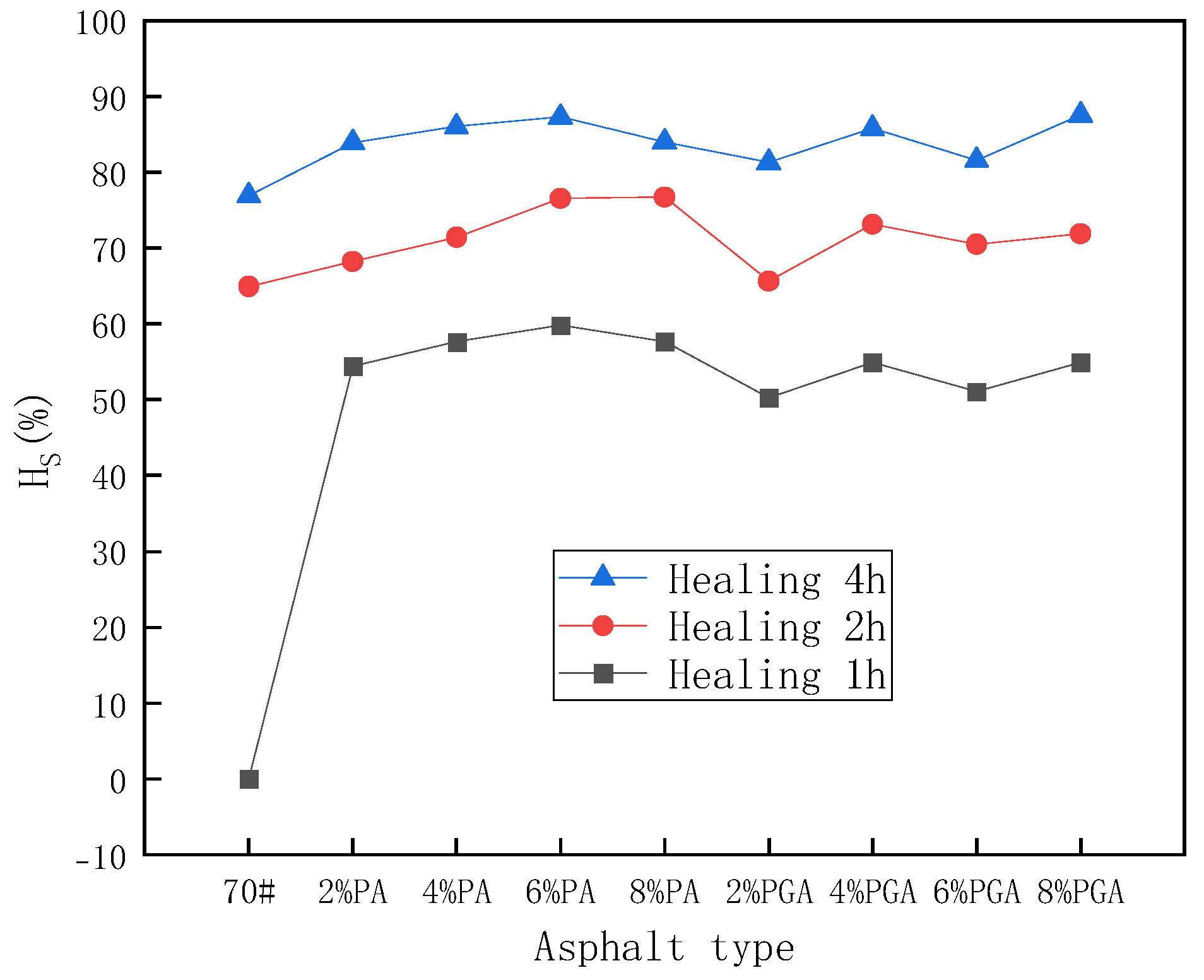

Both ductility and BBR tests showed that PU and PU/GO improved the self-healing properties of asphalt due to the introduction of a disulfide bond. PU had a more obvious influence on the self-healing properties at room temperature because of its excellent flexibility, while PU/GO had a more significant impact under infrared light conditions due to its better thermal conductivity.

This study mainly evaluates the self-healing performance of PU/GO and PU/GO-modified asphalt through macroscopic experiments, which is lacking exploration at the microscopic and molecular levels. In the following research, it is necessary to explore the self-healing mechanism of GO/PU and asphalt at the molecular level.